Hot rolling roller-containing bearing seat liner symmetry detection method and device

A detection method and bearing seat technology, which are applied to measuring devices, optical devices, instruments, etc., can solve the problems of low symmetry detection accuracy, and achieve the requirements of fast-paced requirements, high roller system symmetry accuracy, and improved detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] First of all, it should be noted that the specific structure, characteristics and advantages of the method and device for detecting the symmetry of the chock liner of the hot strip roll according to the present invention will be described in detail below, but all descriptions are only for carrying out illustrative, but should not be construed as forming any limitation on the present invention. In addition, any single technical feature described or implied in each embodiment mentioned herein, or any single technical feature shown or implied in each drawing, can still be described in these technical features (or their equivalents) ) to continue any combination or deletion, so as to obtain more other embodiments of the present invention that may not be directly mentioned herein.

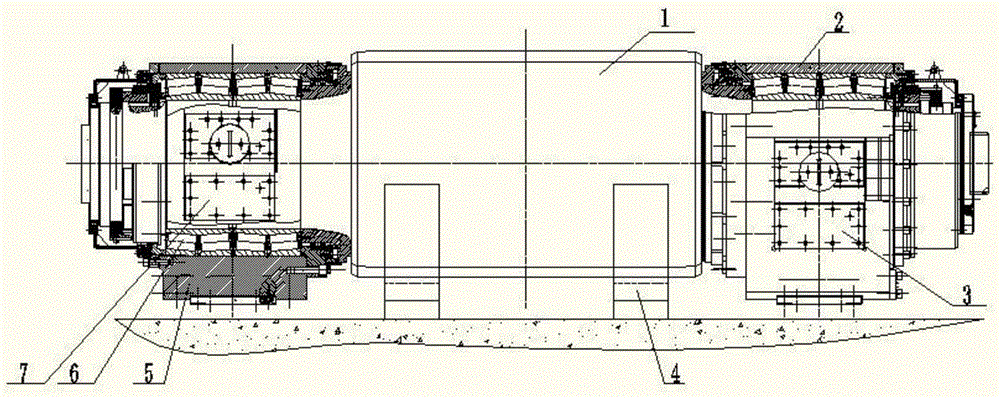

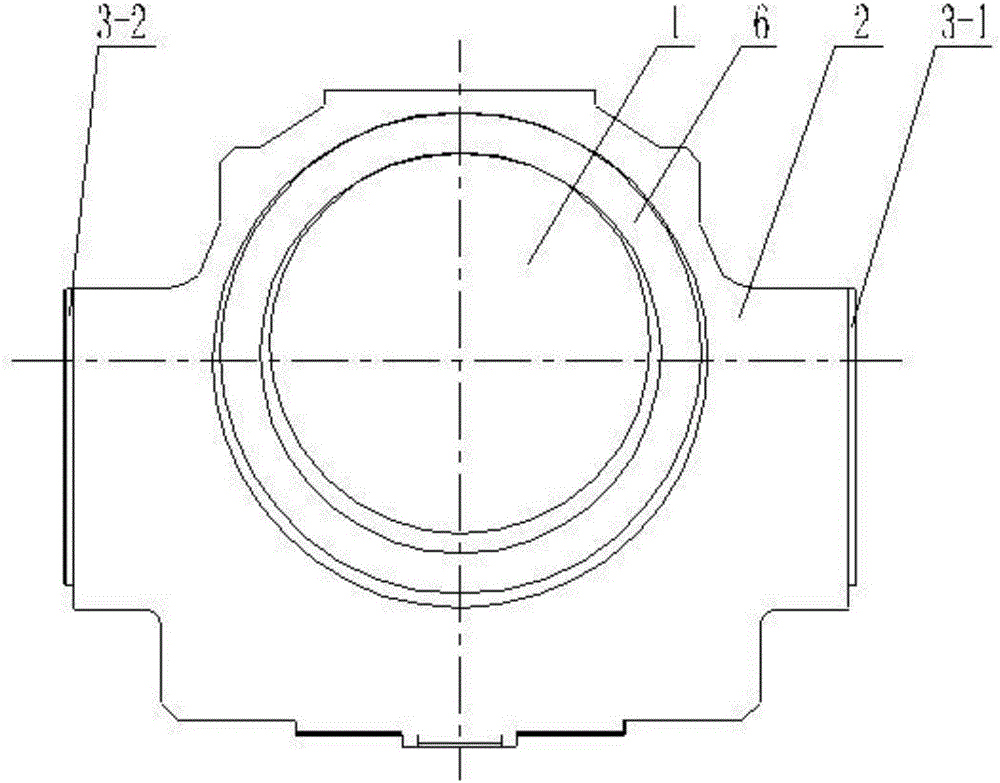

[0034] Please refer to Figure 1 to Figure 4 , the method and device for detecting the symmetry of the chock liner of a hot strip roll according to the present invention will be exemplarily desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com