Simple and convenient cutter setting device for processing keyway and method for milling keyway on high-symmetry degree shaft

A tool setting device and keyway technology, which is applied to feeding devices, metal processing, automatic control devices, etc., can solve the problem of low symmetry of keyway milling, and achieve high keyway symmetry accuracy, convenient operation, and stable processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

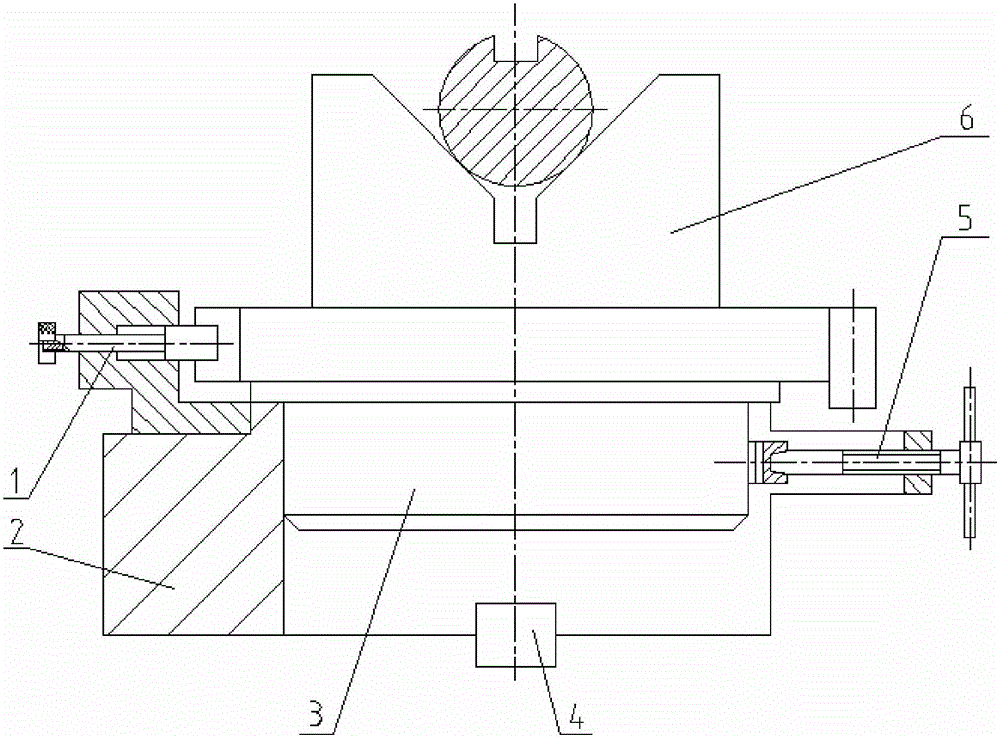

[0025] Such as figure 1 As shown, a simple tool setting device for machining keyways, including:

[0026] It is used to fix the mold base 2 on the workbench of the milling machine. The bottom of the mold base 2 is provided with a positioning key 4. The mold base 2 is installed on the milling machine workbench, and the positioning key 4 is used for positioning, and the mold base 2 is fixed on the milling machine with screws. on stage;

[0027] The indexing gear shaft 3 is rotatably installed on the mold base 2, and can freely rotate 360° along the mold base 2; the indexing gear shaft 3 rotates along the mold base 2, and can process keyways of different shapes;

[0028] The V-shaped frame 6 used to fix the workpiece is fixed on the indexing gear shaft 3 so that the indexing gear shaft 3 drives the V-shaped frame 6 to rotate.

[0029] Preferably, as figure 1 As shown, the indexing gear shaft 3 is also provided with a clamping mechanism 5 for fixing the indexing gear shaft 3. D...

Embodiment 2

[0041] Such as figure 1 As shown, a simple tool setting device for machining keyways, including:

[0042] It is used to fix the mold base 2 on the workbench of the milling machine. The bottom of the mold base 2 is provided with a positioning key 4. The mold base 2 is installed on the milling machine workbench, and the positioning key 4 is used for positioning, and the mold base 2 is fixed on the milling machine with screws. on stage;

[0043] The indexing gear shaft 3 is rotatably installed on the mold base 2, and can freely rotate 360° along the mold base 2; the indexing gear shaft 3 rotates along the mold base 2, and can process keyways of different shapes;

[0044] The V-shaped frame 6 used to fix the workpiece is fixed on the indexing gear shaft 3 so that the indexing gear shaft 3 drives the V-shaped frame 6 to rotate.

[0045] Preferably, as figure 1 As shown, the indexing gear shaft 3 is also provided with a clamping mechanism 5 for fixing the indexing gear shaft 3. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com