Renovation technique for phi2100í3400mm wrought steel support roll

A back-up roller and process technology, which is applied in the field of super-large back-up roll repair, can solve the problem that super-large back-up rollers have not been involved in the field of repair and regeneration, and achieve the effects of short repair time, prolonging service life and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below.

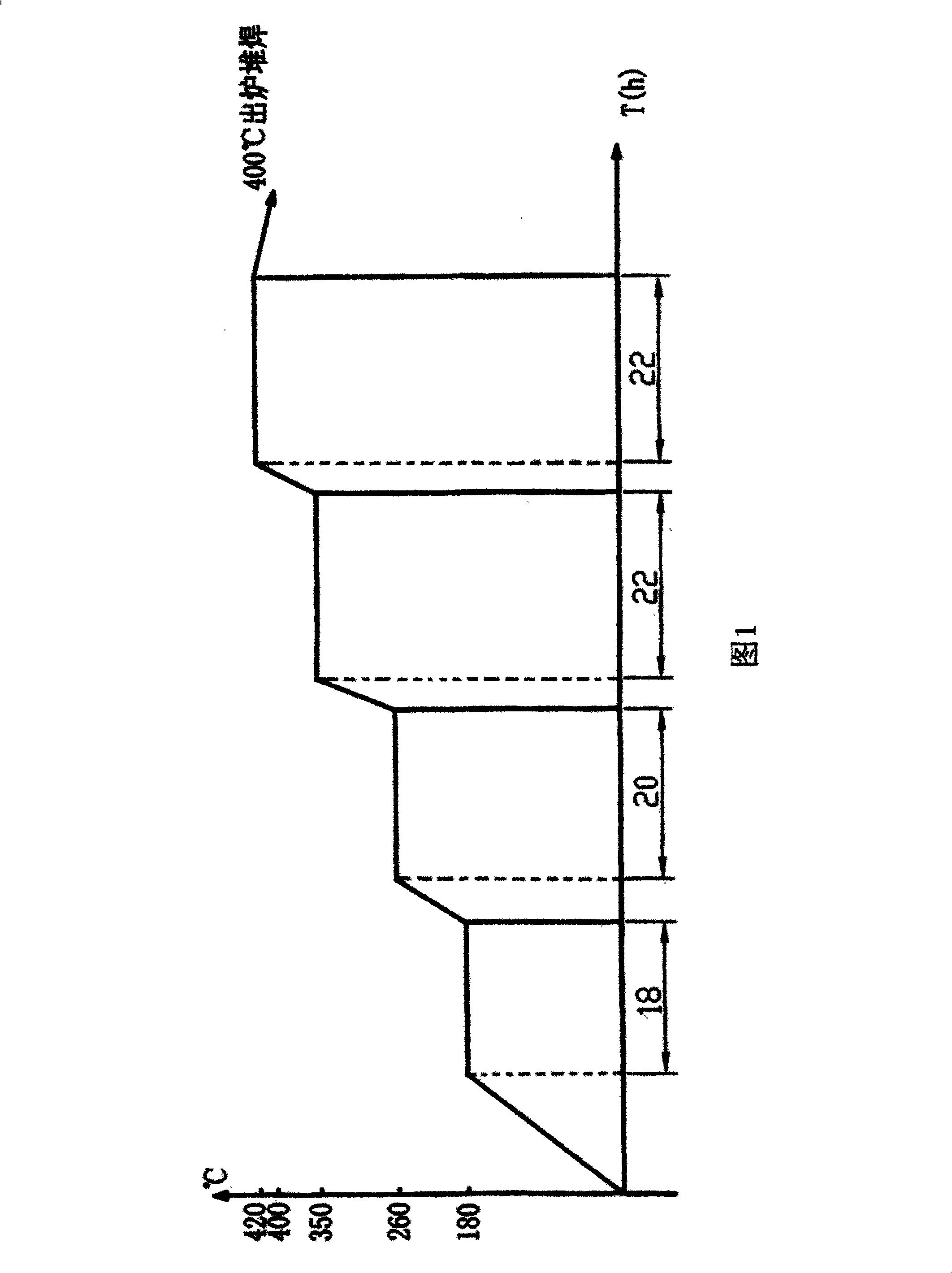

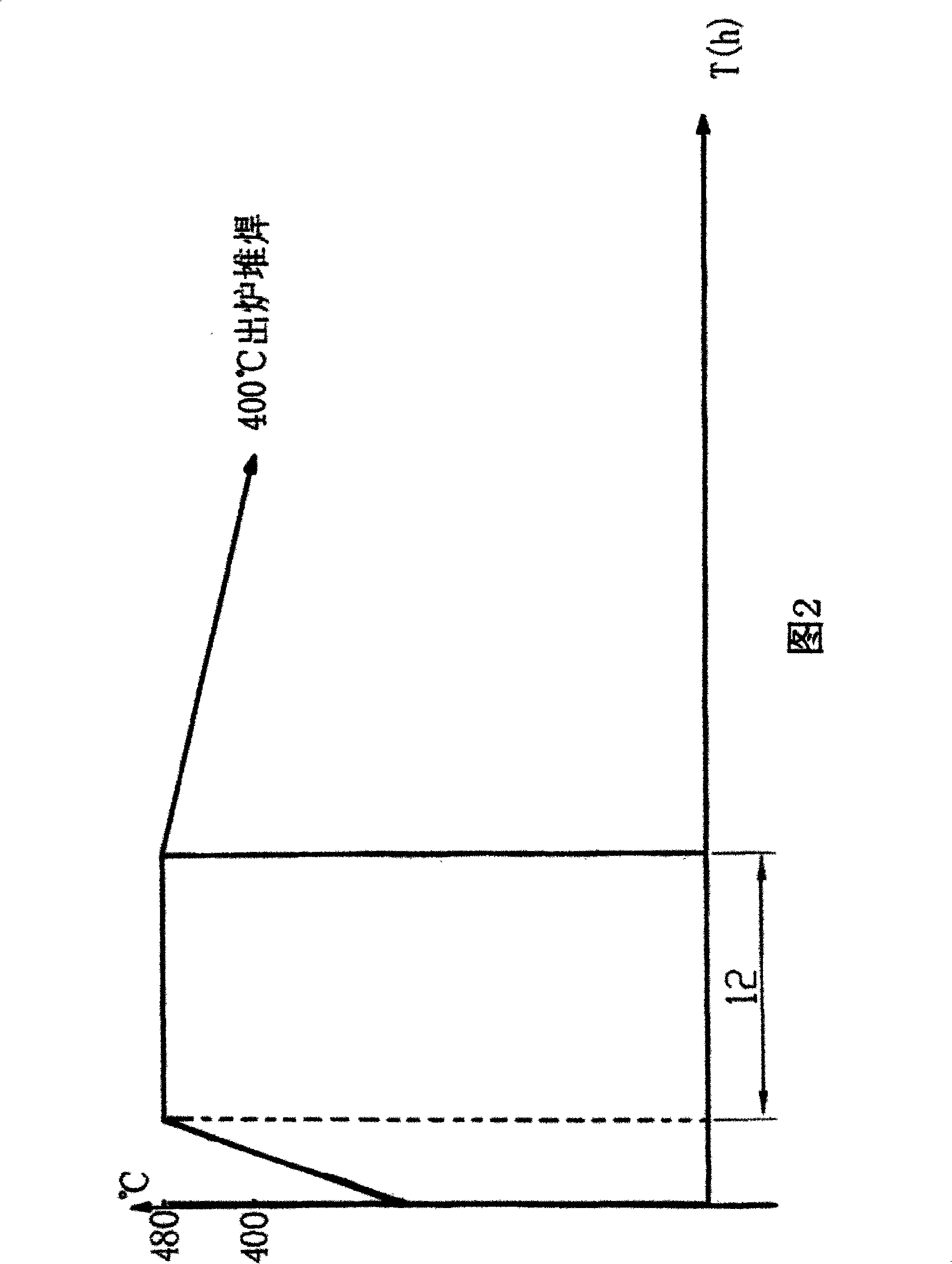

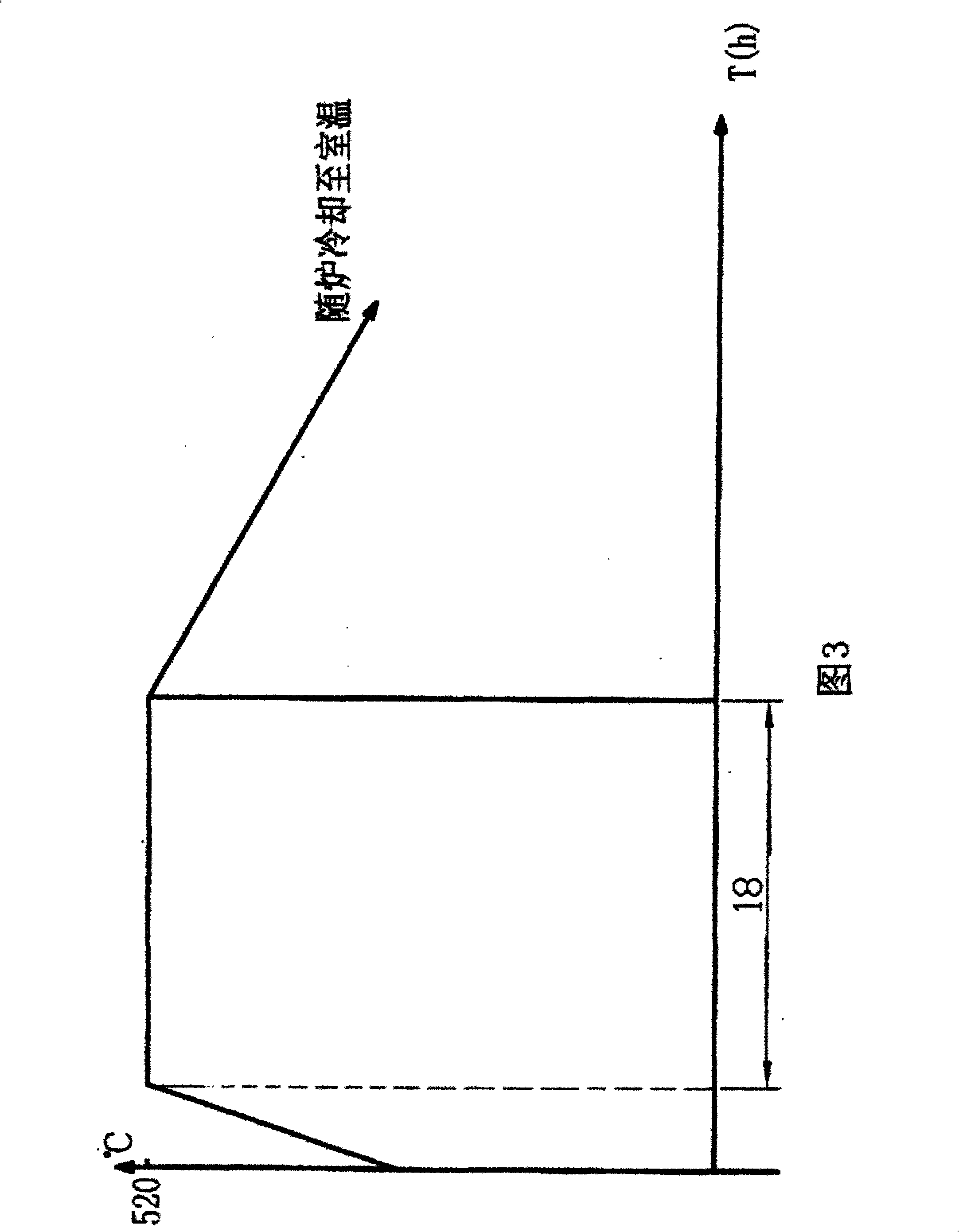

[0014] For the repair of φ2100×3400mm forged steel (3% Cr) back-up roll, firstly, the tubular welding wire should be selected according to the operating conditions, and the heat-affected zone of the welding material and the metallographic state and hardness value of the welding wire should be determined through the sample welding of the test plate. According to the flaw detection results, design a reasonable slope transition, solve the vertical drop size of the roll surface, and adopt unequal heating and heat preservation measures to solve the equilibrium value of the interlayer temperature in the surfacing welding process.

[0015] First of all, carry out back-up roller sidewall welding, using a combination furnace turntable, 80-110A direct current, the used sidewall material is a steel plate with a thickness of 6mm and a width of 50-60mm, and the welding rod is φ3.2E308-16; A102, and the welding rod is passed thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com