Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

284results about How to "Short repair time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

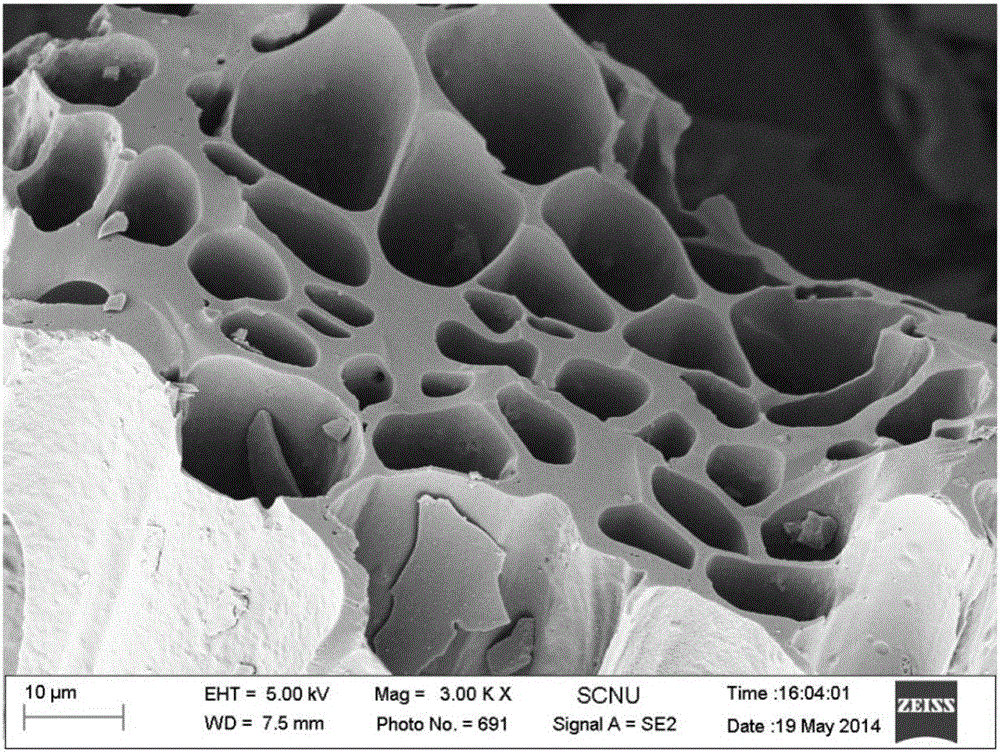

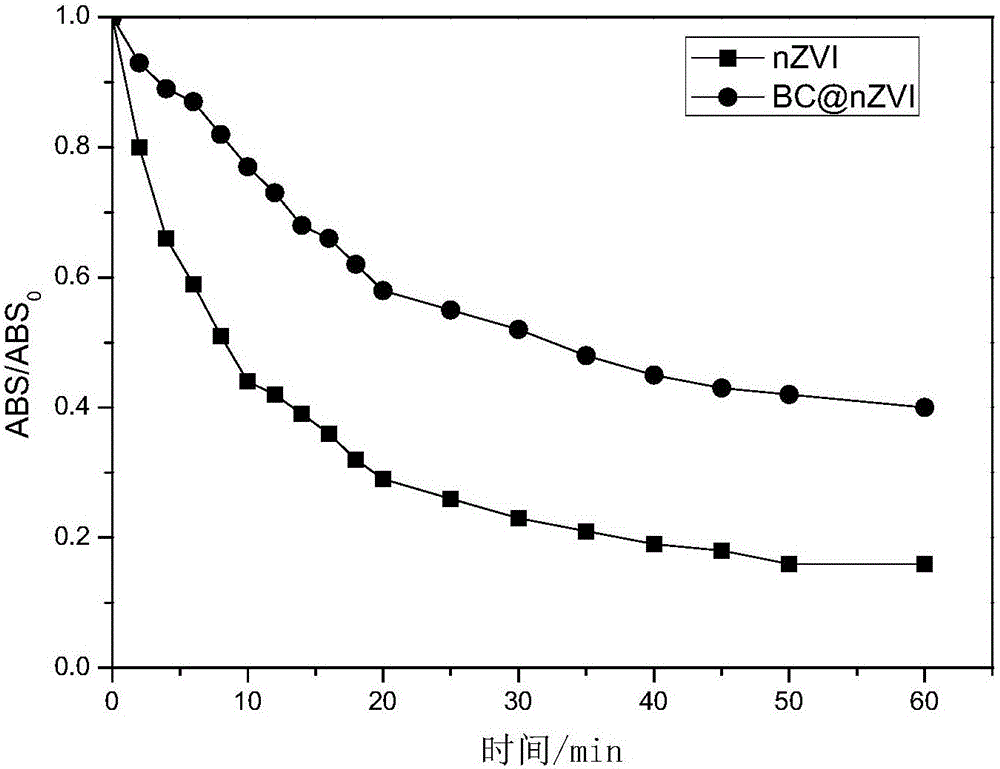

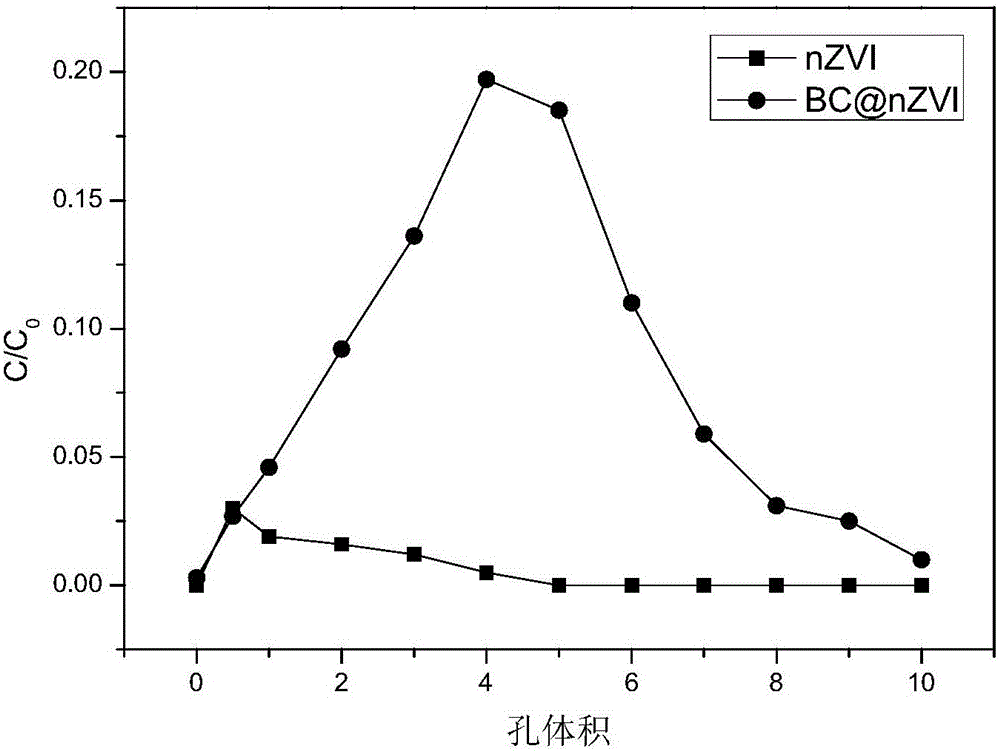

Preparation and application for heavy metal chromium contaminated soil remediation material

ActiveCN105013811AImprove repair efficiencyImprove stabilityContaminated soil reclamationOrganic fertilisersFerrous saltsCarbon particle

The invention discloses preparation and an application for a heavy metal chromium contaminated soil remediation material. Preparation for biological carbon particles comprises the following steps: 1) cleaning, drying and crushing agriculture waste to obtain a substance A; and 2) placing the substance A under a protective atmosphere to deoxidize and carbonize, and grinding and sieving carbonize products to obtain the biological carbon particles. Preparation for supported type nano zero-valent iron particles comprises the following steps: 1) preparing ferrite into a solution; 2) adding biological carbon particles into the solution, and uniformly mixing the biological carbon particles with the solution; and 3) dissolving a reducing agent into a solvent to obtain a mixture, adding the mixture into the system in the last step under the protective atmosphere, stirring the mixture, sufficiently reacting the mixture, separating nano zero-valent iron, washing, drying and grinding the nano zero-valent iron to obtain the supported type nano zero-valent iron particles. The invention further discloses the application of the supported type nano zero-valent iron particles to remediating chromium contaminated soil in situ. The in-situ remediation method for the heavy metal chromium contaminated soil comprises the following steps: adding the supported type nano zero-valent iron particles into soil, uniformly mixing the supported type nano zero-valent iron particles, adding deoxygenated water, and carrying out remediation. The remediation material prepared by the preparation disclosed by the invention is high in efficiency of remediating the chromium contaminated soil, and capable of improving the soil structure and improving the soil fertility.

Owner:师大清远环境修复科技有限公司

Bioremediation method for petroleum-polluted soil

ActiveCN105170644AImprove repair effectShort repair timeContaminated soil reclamationWater contentBioremediation

The invention discloses a bioremediation method for petroleum-polluted soil. The method comprises the steps that 1, biomass containing biomass degrading bacteria is added in the petroleum-polluted soil with the petroleum content higher than 18 wt%, and ploughing is performed to mix the soil with the biomass, the water content of the petroleum-polluted soil is simultaneously kept at 10-30 wt%, and first degrading bacteria are added in the soil in 10-15 days after ploughing is performed to reduce the petroleum content of the soil to 8-18 wt%; 2, second degrading bacteria are added in the soil to reduce the petroleum content of the soil to 5-8 wt%; 3, third degrading bacteria are added in the soil to reduce the petroleum content of the soil to 1-5 wt%; 4, forth degrading bacteria are added in the soil to reduce the petroleum content of the soil below 1 wt%. The method can be applied to both in-situ remediation and ex-situ remediation, the remediation effect is good, the remediation time is short, the method is simple, and the cost is low.

Owner:李磊

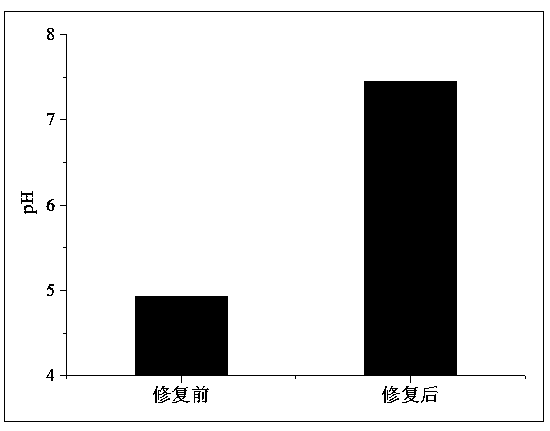

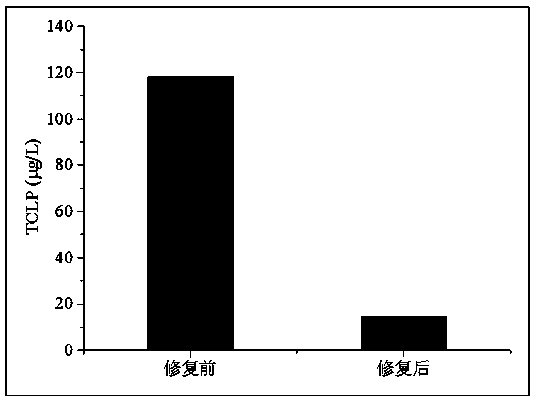

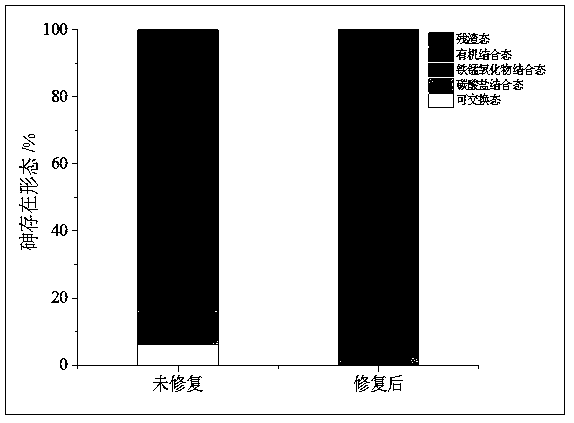

Method for remedying acidified arsenic contaminated soil by biochar-loaded nano-scale zero-valent iron cooperated with bacteria

ActiveCN109570227AReduce dosageAvoid destructionContaminated soil reclamationChemical reactionPseudomonas putida

The invention relates to a method for remedying acidified arsenic contaminated soil by biochar-loaded nano-scale zero-valent iron cooperated with bacteria. The method includes selecting Pseudomonas putida strain MnB1 (ATCC23483); carrying out enrichment culture on the Pseudomonas putida strain in enrichment culture media; inoculating strains in culture media with divalent manganese and carrying out culture on the strains to obtain active metabolites; adding the active metabolites and the green synthetic biochar-loaded nano-scale zero-valent iron into the acidified arsenic contaminated soil anduniformly stirring the active metabolites, the biochar-loaded nano-scale zero-valent iron and the acidified arsenic contaminated soil; carrying out a series of physical-chemical reaction on active manganese oxide, zero-valent iron, biochar and trivalent arsenic or pentavalent arsenic in the soil; converting the arsenic in exchangeable forms into arsenic in residual forms. The method has the advantages that the arsenic in the soil can be effectively immobilized, the pH (potential of hydrogen) of the soil can be increased, and the double purposes of remedying soil acidification and arsenic contamination can be simultaneously achieved; the method is short in remediation time, high in efficiency, wide in treatment range and free of secondary pollution, and stable effects can be realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

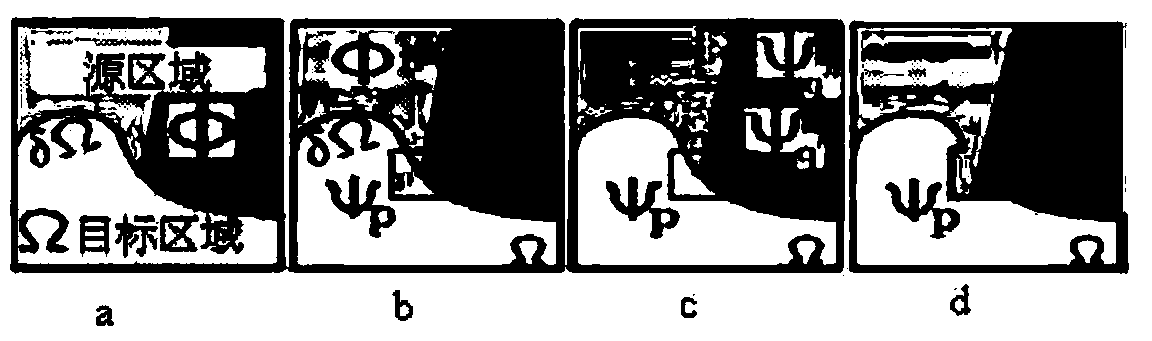

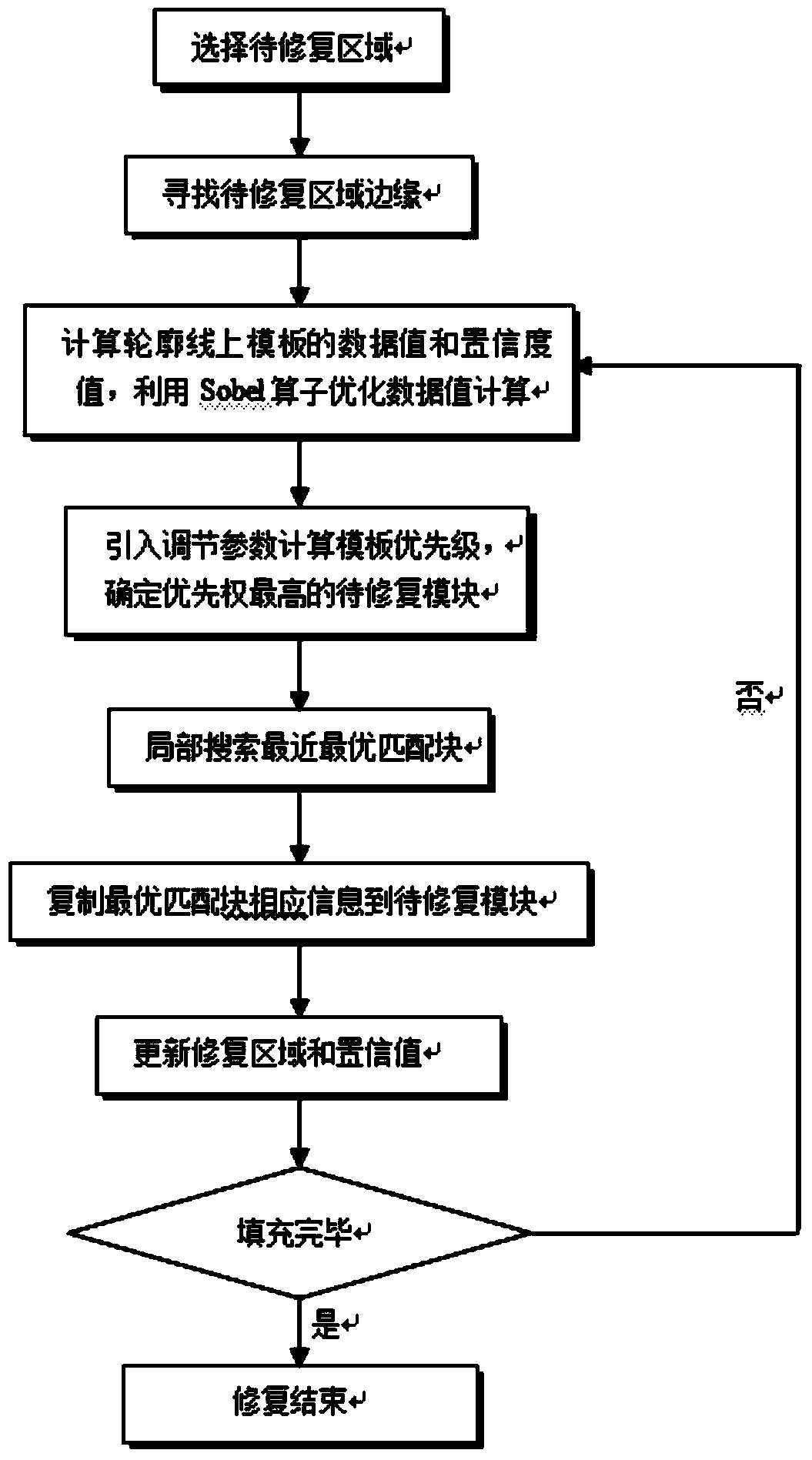

Rapid image repairing method based on sample

ActiveCN104376535ASolve the problem of repair lagEasy to eliminateImage enhancementRepair timeAlgorithm

The invention discloses a rapid image repairing method based on a sample. The rapid image repairing method includes the steps that a to-be-repaired area is determined through marks; a contour line of a boundary of the to-be-repaired area and a known area is selected; a data value and a confidence coefficient value of a template are calculated; adjusting parameters are introduced to determine a to-be-repaired module with the highest priority; in the known area adjacent to the to-be-repaired module, conducting searching from the near to the distant to obtain an optimal matching block according to the distance between the optimal matching block and a center point of the to-be-repaired module; filling the corresponding position of the to-be-repaired module with a pixel point corresponding to the optimal matching block, and meanwhile updating the confidence value of the newly-updated pixel point; repeatedly executing the steps on the to-be-repaired area until the to-be-repaired area is filled completely. The rapid image repairing method is optimized from priority operation, data valve calculation, matching area and optimal matching block searching and confidence value updating, and the repairing effect is more natural; meanwhile, matching only needs to be carried out on a local part during repairing, so that the repairing time is greatly shortened.

Owner:XUZHOU UNIV OF TECH

High performance nano metal/mine ore powder composite self repairing agent and its preparing method

The present invention discloses one kind of high performance nanometer metal / ore powder composite self-repairing agent and its preparation process. The composite self-repairing agent is prepared with nanometer magnesium hydroxyl silicate ore powder 15-25 wt%, nanometer composite metal powder 6-12 wt%, nanometer magnesium hydroxyl silicate ore powder dispersant 0.5-2 wt%, nanometer composite metal powder dispersant 0.5-2 wt%, catalyst 0.2-2 wt%, stabilizer 1-5 wt%, cooperative metal friction additive 0.5-3 wt%, nanometer dispersant 2-5 wt%, auxiliary performance regulator 1-3 wt% and dispersing medium 41-73.3 wt%, and through certain technological process in certain technological conditions. It is used in lubricant oil and lubricant grease for nanometer composite repairing.

Owner:MIYOU GROUP

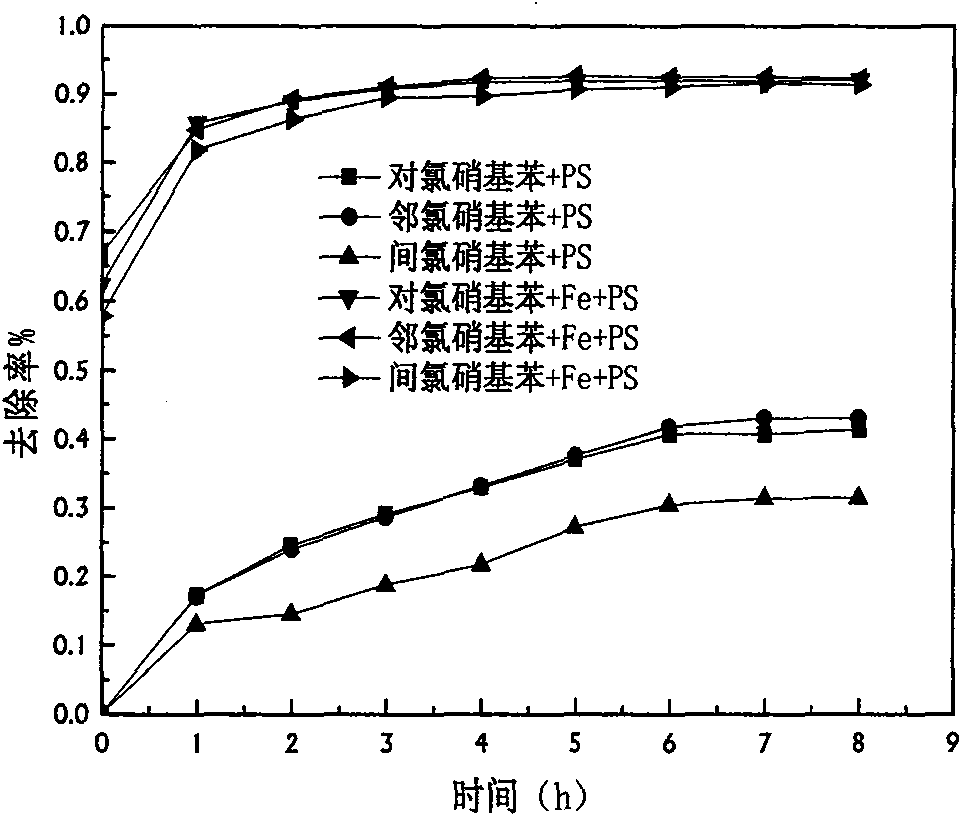

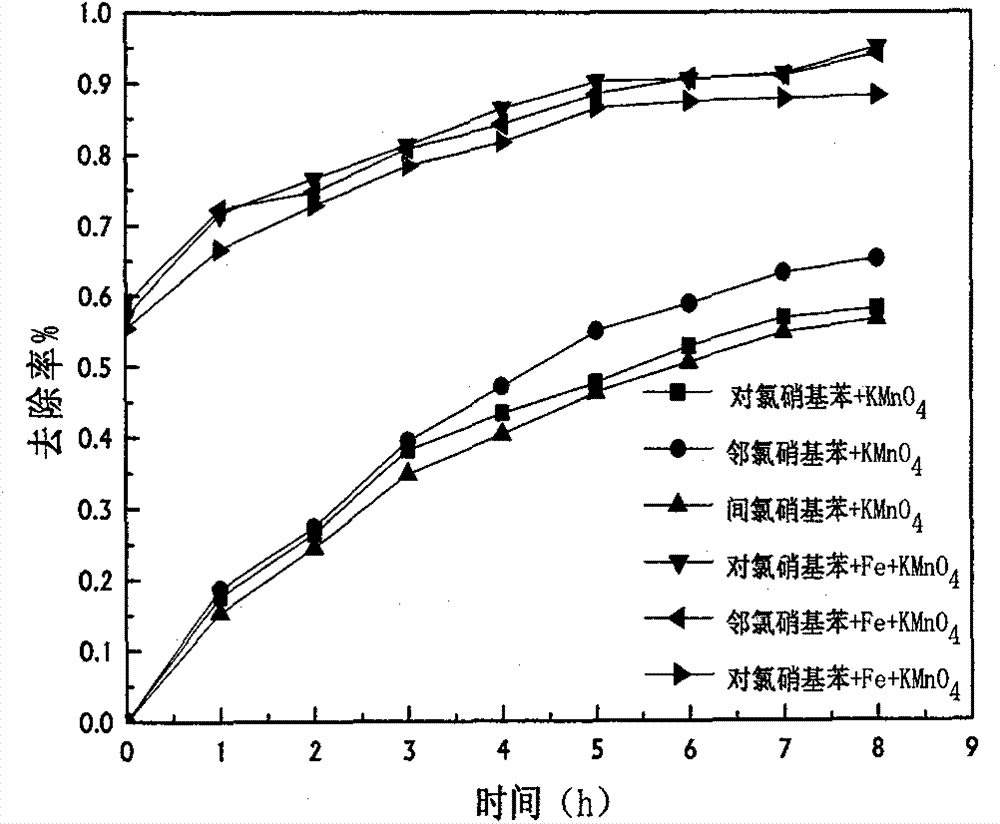

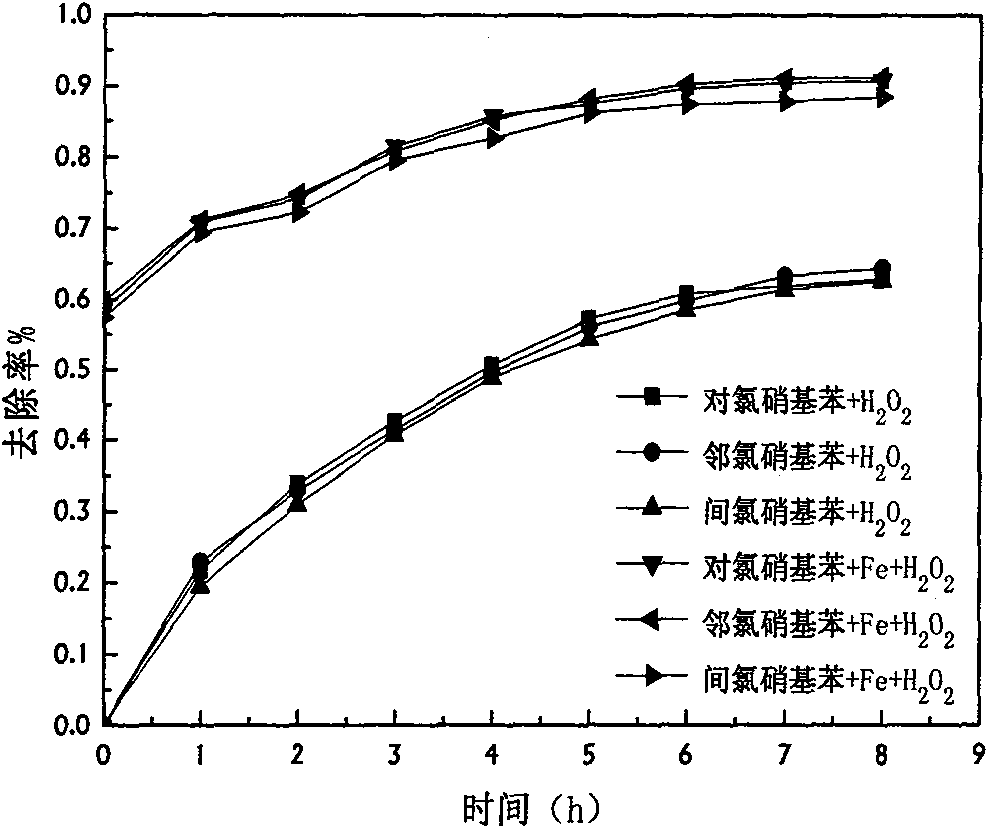

Method for increasing speed of oxidative degradation of organic pollutant in soil

ActiveCN104511476AShort repair timeImprove conversion rateContaminated soil reclamationPotassium persulfateFenton reagent

The invention relates to the technical field of pollution repairing and treatment of organic pollutants in soil, and especially discloses a chemically repairing method used in soil polluted by nitrobenzene, nitrochlorobenzene and the like. By means of the method in which the nitrobenzene, the nitrochlorobenzene and the like are firstly reduced into phenylamine which is easy to oxidatively degrade with zero-valent iron and finally the degraded product is oxidized to generate carbon dioxide and water, the soil, which is polluted by the organic pollutants including the nitrobenzene and the like, is completely repaired and removal efficiency of the organic pollutants is increased. The method can achieve a removal rate of the nitrochlorobenzene being 88.3-95.8%, wherein the nitrochlorobenzene is a difficultly-degraded organic substance. The method can overcome problems of low removal efficiency, high medicine cost and troublesome follow-up treatment during removal of the nitrobenzene-series organic pollutants in the soil with Fenton reagents, potassium persulfate, sodium permanganate and the like which are common in the prior art. By means of an indirectly oxidative degradation in which reduction is carried out firstly and oxidization is carried out after that, usage amount of an oxidizing agent can be reduced and the removal rate of the nitrobenzene-series organic pollutants can be increased. Meanwhile, the method is simple in operation and can avoid secondary pollution to environment by the oxidizing agent. The method can effectively achieve in-situ repairing of polluted soil and is especially suitable for complete repair of the soil severely polluted by the organic pollutants in local factory removal.

Owner:江苏迈克环境工程有限公司

Repairing system and method for heavy metal-organic combined polluted soil and underground water

InactiveCN105312314AImprove removal efficiencyImprove repair effectContaminated soil reclamationGas phaseAlternating current

The invention discloses a repairing system and method for heavy metal-organic combined polluted soil and underground water. The repairing system comprises an electric repairing system, a resistance heating system, a soil gas-phase extraction system, an extracted gas phase treatment system and a system switchover system. The electric repairing system comprises a positive electrode and a negative electrode connected with a direct current power source, and the positive electrode and the negative electrode are arranged in a positive electrode electrolytic cell and a negative electrode electrolytic cell respectively. The resistance heating system comprises a positive electrode and a negative electrode connected with an alternating current power source. The system switchover system comprises a control device which controls the switching-on and off of a first switch and a second switch through a temperature detector probe. According to the repairing system, the electrodes are applied to the resistance heating system and the electric repairing system, effective combination and unification of the electric repairing technology and the heat treatment technology are achieved, equipment of the system is simplified, the repairing effect is enhanced, and the removal efficiency is improved.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Method for ultrasonically repairing heavy metal contaminated soil

InactiveCN104607452AShort repair timeHigh removal rateContaminated soil reclamationContaminated soilsUltrasonic assisted

The invention discloses a method for ultrasonically repairing heavy metal contaminated soil. The method comprises at least following steps: preparation of an extracting agent- citric acid solution; mixing of an extracting agent and polluted soil; mechanical oscillation extraction or ultrasonic-assisted extraction for soil; centrifugal separation and filtration of soil after extraction. According to the method, citric acid is selected as the extracting agent, so that the cost is relatively lower, influence on basic physicochemical property of soil is smaller, secondary pollution cannot be caused, the citric acid is an environment-friendly extracting agent, and four heavy metals including cadmium, copper, lead and zinc in the soil can be effectively removed when the extracting agent and ultrasonic waves are jointly applied to repairing of the heavy metal contaminated soil. The method has the characteristics of good removal effect, small extracting agent dosage and short repairing time.

Owner:ZHEJIANG FORESTRY UNIVERSITY

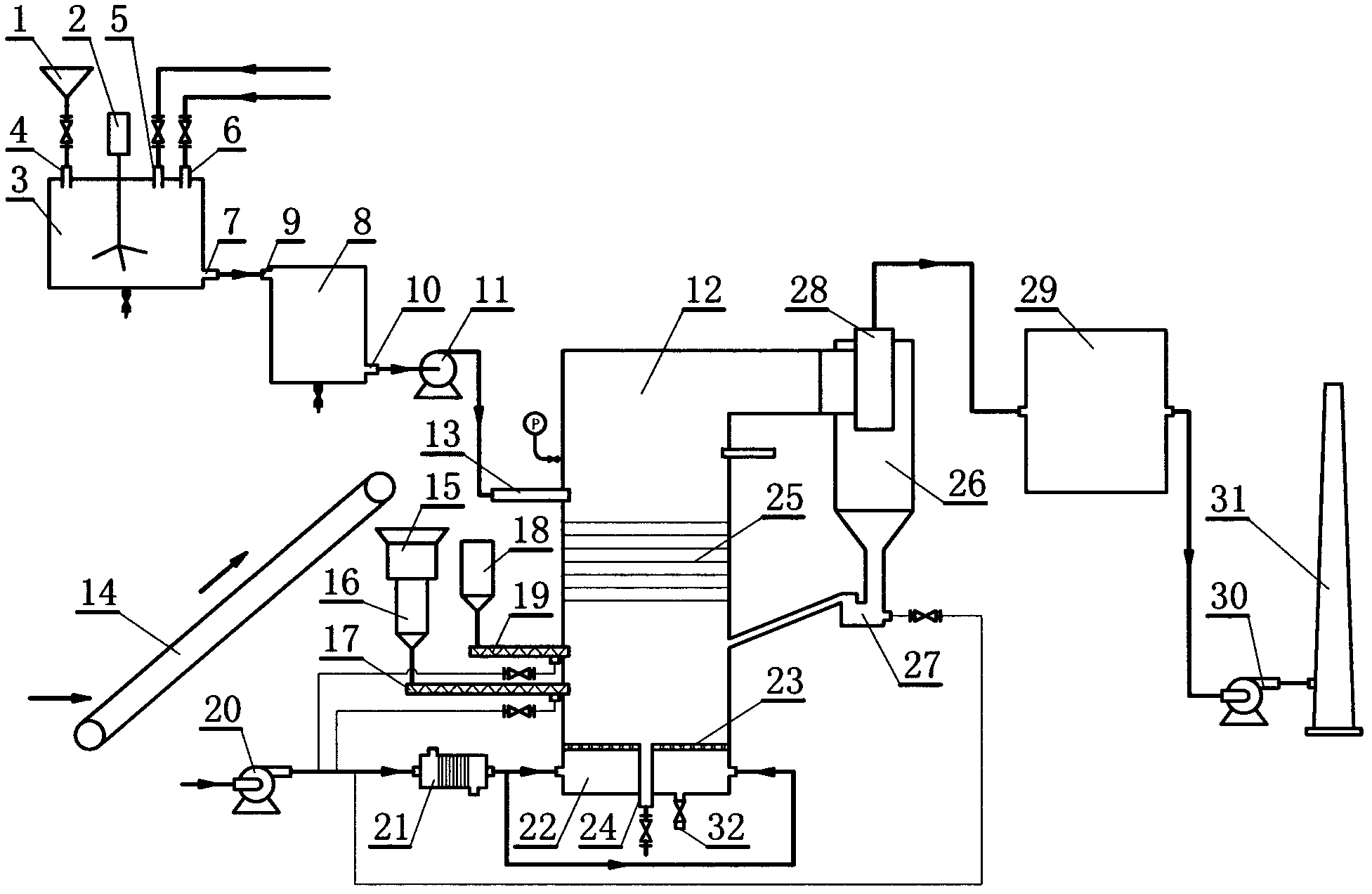

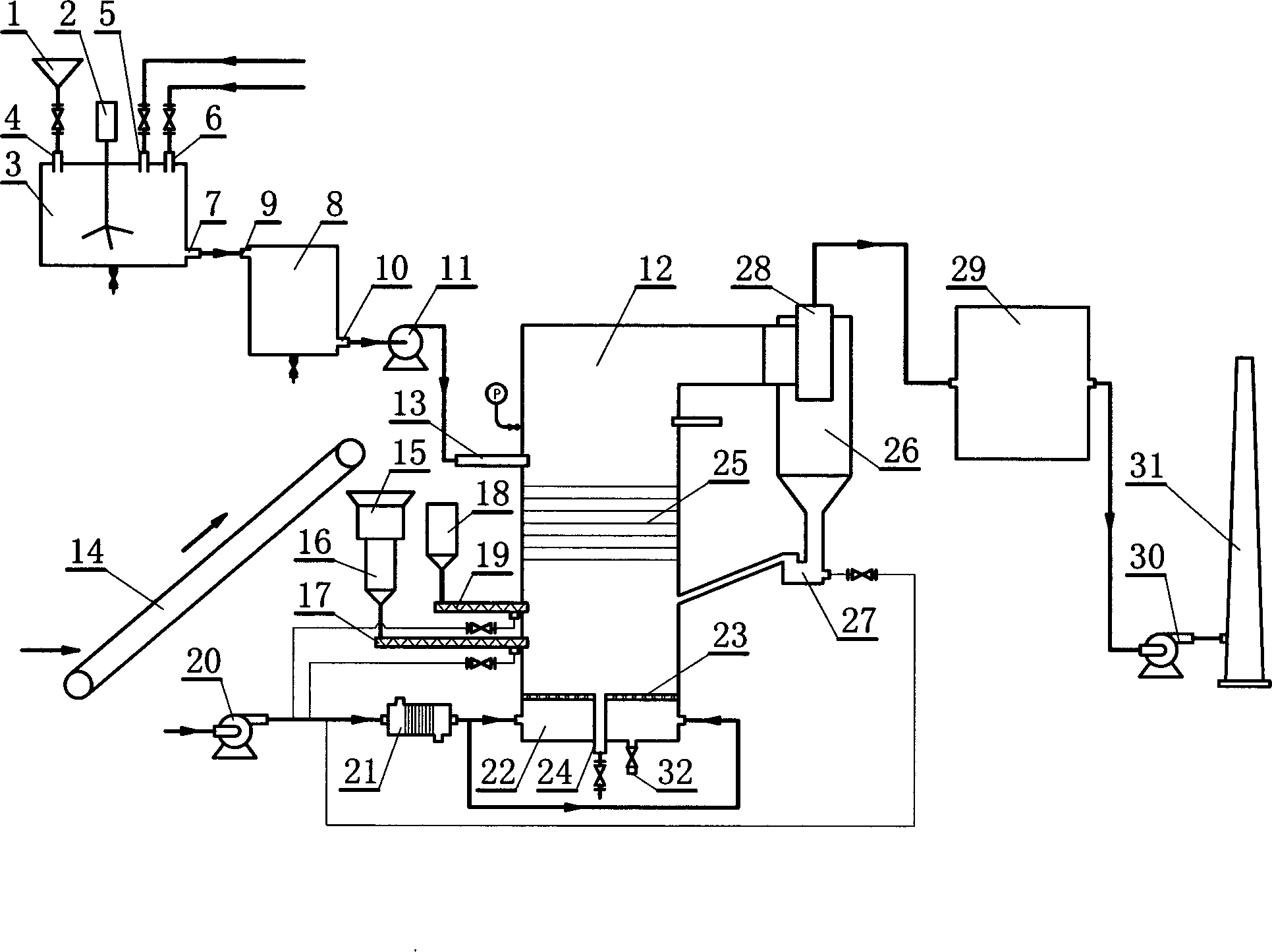

Movable type contaminated soil remediation system adopting recirculating fluidized bed

The invention relates to a movable type contaminated soil remediation system adopting a recirculating fluidized bed, belonging to mechanical equipment. The remediation system takes the recirculating fluidized bed as a reactor; three drug feeding ways of gas state, liquid stage and solid stage, and two heat tracing devices are arranged, so that the contaminated soil can be rapidly remedied by adopting remediation drugs of different states and kinds at different temperatures and pressures according to the characteristics of the contaminated soil, and the movable type contaminated soil remediation system is not only suitable for various soils contaminated by volatile organic compound, semi-volatile organic compound, polycyclic aromatic hydrocarbon, polychlorinated biphenyl, petroleum hydrocarbon, pesticide, heavy metals and the like, but also not limited by types of solid, liquid or gas drugs. The movable type contaminated soil remediation system adopting the recirculating fluidized bed is reasonable in structural layout, convenient in moving, wide in scope of application, high in reaction speed, good in flexibility, and safe and stable in operation, is economically feasible, can be suitable for large-scale centralized processing of the contaminated soil as well as in-situ remediation, thereby having excellent environmental protection benefit and social benefit.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

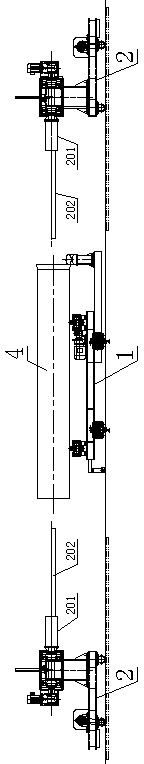

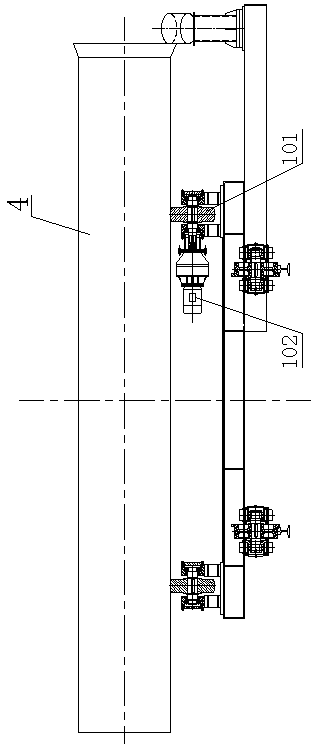

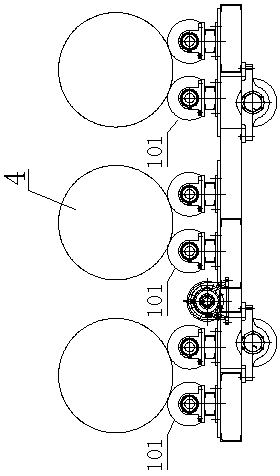

Lining coating technology for spheroidal graphite cast iron tube

ActiveCN103691625AWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

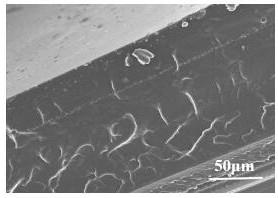

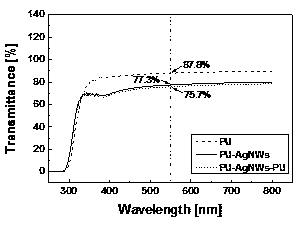

Sunlight self-repairing transparent flexible strain sensing composite material, preparation method and applications thereof

InactiveCN109265643AUniform sizeHigh aspect ratioElectrical/magnetic solid deformation measurementCoatingsCross-linkPolyethylene glycol

The invention relates to a sunlight self-repairing transparent flexible strain sensing composite material, a preparation method and applications thereof, wherein the composite material comprises a polyurethane substrate and metal nano-wires coated on the polyurethane substrate, wherein the polyurethane comprises, by weight, 15-28 parts of a diisocyanate monomer, 10-50 parts of a polyethylene glycol monomer, 5-15 parts of a monomer containing a disulfide bond, and 0.5-2.5 parts of a cross-linking agent. According to the present invention, the sunlight self-repairing transparent flexible strainsensing composite material has excellent light transmittance, is sensitive to tensile strain, and exhibits linear response; when the sunlight self-repairing transparent flexible strain sensing composite material is subjected to scratch or fracture damage, the multiple repairs of mechanical property and the electrical conductivity can be achieved under illumination, wherein the repair time is short, and the repair efficiency is high.

Owner:SUN YAT SEN UNIV

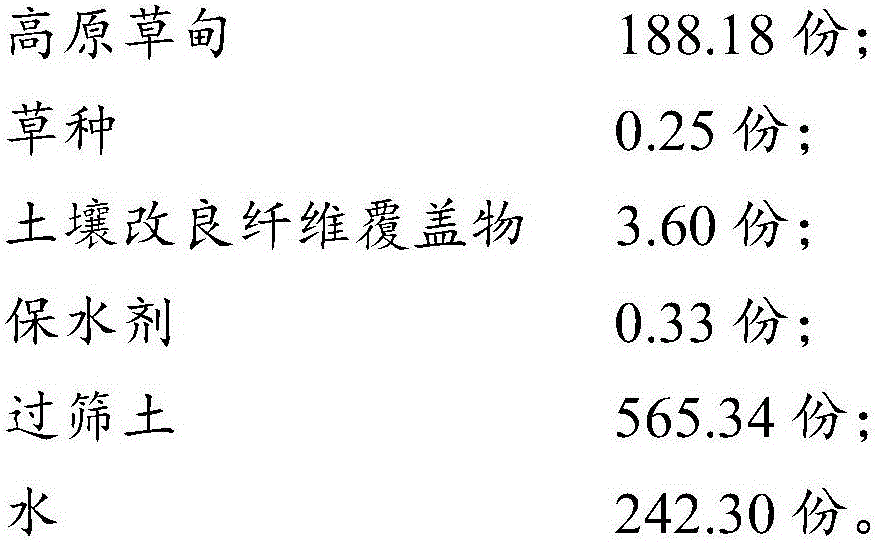

Plateau vegetation restoration composition and vegetation restoration method for plateau regions

ActiveCN107517727AImprove physical and chemical propertiesRatio of improved ingredientsPlant cultivationCultivating equipmentsFiberRevegetation

The invention relates to the field of environment protection and discloses a vegetation restoration method for plateau regions after engineering construction. A plateau vegetation restoration composition comprises plateau meadows, grass seeds, a soil improvement fiber covering, a water retaining agent, sieved soil and water, and the soil improvement fiber covering is prepared from wood fibers, charcoal, humus, mushroom residues, polysaccharides, trehalose, carboxymethyl chitosan, biochemical potassium fulvate, diatomite, shell powder, trichoderma, nitrogen-fixing bacteria and composite bacillus. According to the vegetation restoration method for the plateau regions, large damaged areas can be restored with limited plateau meadows, and severe weather conditions of the plateau regions are overcome to guarantee the survival rate of plants.

Owner:JOFO GREEN CO LTD

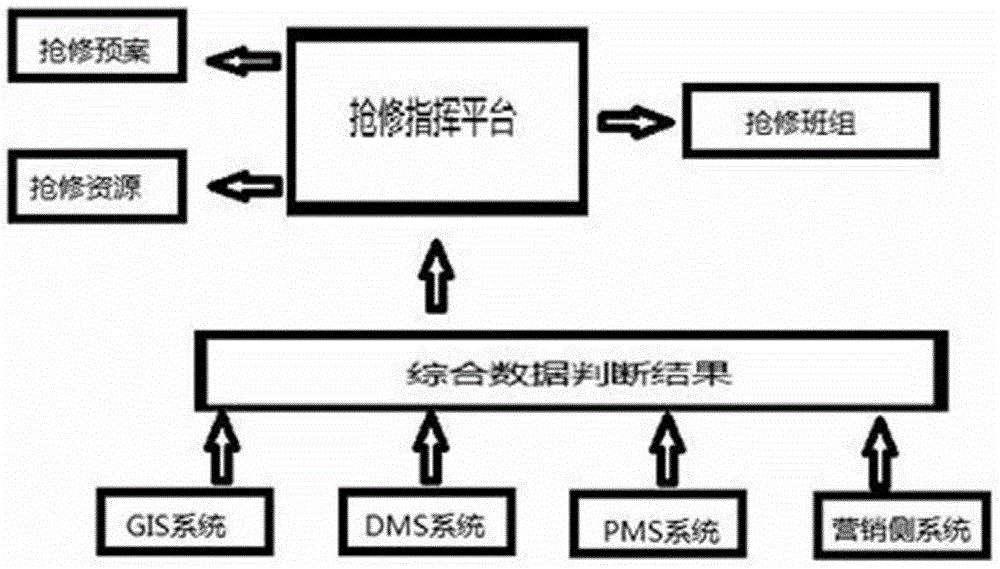

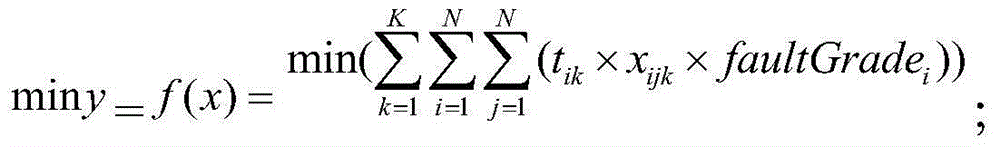

Distribution network resource and information first-aid repair optimization scheduling method

InactiveCN105321014AImprove satisfactionImprove work efficiencyResourcesRepair timeResource utilization

The invention belongs to the technical field of first-aid repair optimization scheduling, and especially relates to a distribution network resource and information first-aid repair optimization scheduling method. The method provided by the invention is high in work efficiency of fault first-aid repair, and is high in resource utilization rate. The method comprises the following steps: 1) setting a variable (shown in the description), wherein tik is the time when a first-aid repair group k arrives at a fault point I, and is not less than tdik; tdik is the maximum time for allowing the first-aid repair group k to arrive at a scene; ekij is a passing time of the first-aid repair group k from the position i to the position j; qk is the first-aid repair capability of the first-aid repair group k; faultTypei is the type of a fault point i; faulGradei is the emergency degree of the fault point i; a target function is shown in the description; the optimization objective is to carry out the first-aid repair of an emergent fault in a preferential manner, and enables the first-aid repair time to be the shortest.

Owner:STATE GRID CORP OF CHINA +1

Hot mending material for spray gun

The invention belongs to the steel smelting field and in particular relates to a hot mending material for a submarine spray gun for carrying out desulfuration pretreatment on molten iron. The mending material is characterized by comprising 8-12% of mullite with granularity being more than 1mm and less than 3mm, 45-55% of mullite with granularity being more than 0.088mm and less than 1mm, 18-22% of mullite with granularity of 0.088mm, 18-22% of refractory cement, 1-2% of aluminium dihydrogen phosphate or sodium silicate and 1-2% of magnesia by weight. The mending material has short mending time, long service life, high bonding strength, high hardening speed and good heat stability and can enhance the plasticity of the refractory mixture, increase the penetration depth of the mending material into the gun lining crack and prolong the life of the submarine spray gun.

Owner:营口东邦环保科技股份有限公司

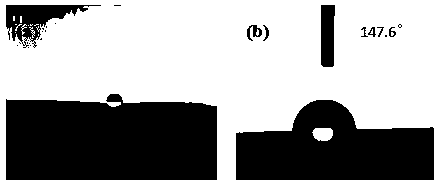

Solvent-free hydrophobic self-repairing polyurethane coating and preparation method thereof

ActiveCN108912371AImprove mechanical propertiesThe method is green and simpleCoatingsFuranPolymer science

The invention belongs to the field of polymer materials, and discloses a preparation method of a thermoreversible self-repairing solvent-free hydrophobic coating; polyisocyanate, polyhydric alcohol, furfuryl amine, bismaleimide and graphene oxide and other raw materials are used to synthesize a bifunctionality polyurethane coating with a coarse structure and a furan-maleimide addition product. Thespecific steps are as follows: (1) preparing a prepolymer having an isocyanate group; (2) preparing a furan-terminated prepolymer; (3) preparing bifunctionality polyurethane containing furan-maleimide; and (4) preparing a low surface energy polyurethane coating. The self-repairing solvent-free hydrophobic coating has simple preparation process, excellent performance, and high tensile strength andelongation at break, a raw material can be repaired from damage in only 4 minutes at the temperature of 120DEG C, material life cycle cost is reduced, and material service life is extended.

Owner:SHAANXI UNIV OF SCI & TECH

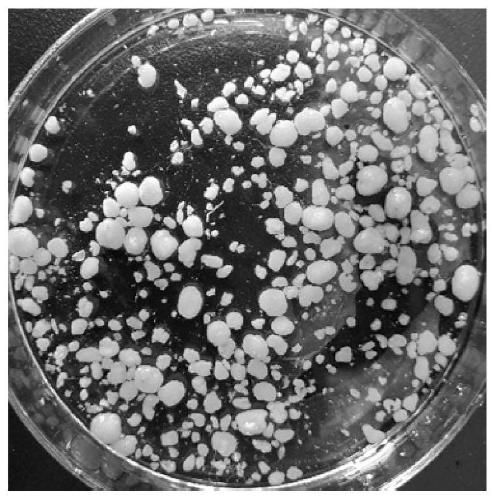

Preparation method of nano Ni/Fe-biochar composite material and application of nano Ni/Fe-biochar composite material in in-situ restoration of polybrominated diphenyl ether polluted soil

ActiveCN105670635AImprove liquidityImprove stabilityAgriculture tools and machinesContaminated soil reclamationDispersityHigh concentration

The invention discloses a preparation method of a nano Ni / Fe-biochar composite material and application of the nano Ni / Fe-biochar composite material in in-situ restoration of polybrominated diphenyl ether polluted soil. The preparation method comprises the following steps: dissolving iron salt or ferrous salt and polyvinylpyrrolidone in an ethanol water solution, uniformly mixing, adding biochar particles, and uniformly mixing to obtain a solution A; adding a reducer-containing ethanol water solution into the solution A, stirring to react completely, separating out the reaction product, washing, and adding into an ethanol water solution to obtain a solution B; and dropwisely adding a nickel-salt-containing ethanol water solution into the solution B, stirring to react completely, separating out the product material, washing, and drying to obtain the nano Ni / Fe-biochar composite material. The nano Ni / Fe bimetal particles are carried on the biochar, thereby further enhancing the flowability of the nanoparticles. The nano Ni / Fe-biochar composite material is beneficial to soil in-situ restoration due to the stability and dispersity. The nano Ni / Fe-biochar composite material can be used for restoring high-concentration PBDEs polluted soil, and has high restoration efficiency.

Owner:师大清远环境修复科技有限公司

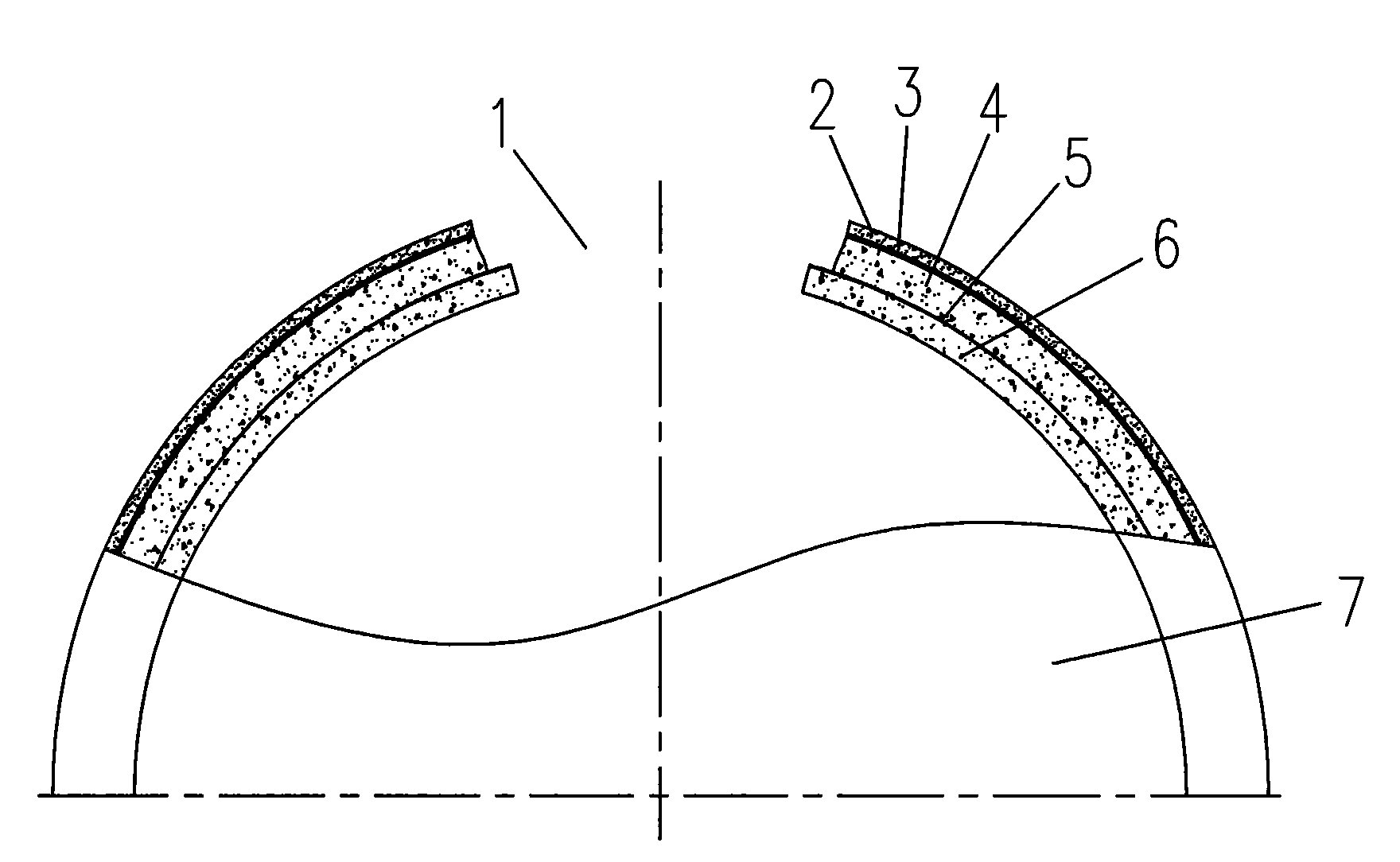

Pipelining emergent repairing method of prestressing steel cylinder concrete pipe

The invention relates to a pipelining emergent repairing method of an underground prestressing steel cylinder concrete pipe (hereinafter referred as to PCCP), in particular to an emergent repairing method for PCCP pipeling damaged by external force. According to the technical solution of the invention, a lining plate is arranged in the inner wall of a pipeline which corresponds to a damaged opening; a screw is arranged on the lining plate; a cover plate which covers the damaged opening is arranged on the external surface of the pipeline which corresponds to an exposed steel cylinder at the damaged opening; a rubber ring is arranged between the cover plate and the steel cylinder; the cover plate and the lining plate are mutually connected; a hollow cavity between the cover plate and the lining plate is filled with concrete; a steel plate which is connected with a sample plate is arranged above the cover plate; and the hollow cavities among the steel plate, the cover plate and a top plate are filled with fine stone concrete. The method can solve the problem that the usual repairing method takes much time, has great waste, high cost, etc.

Owner:无锡华毅管道有限公司

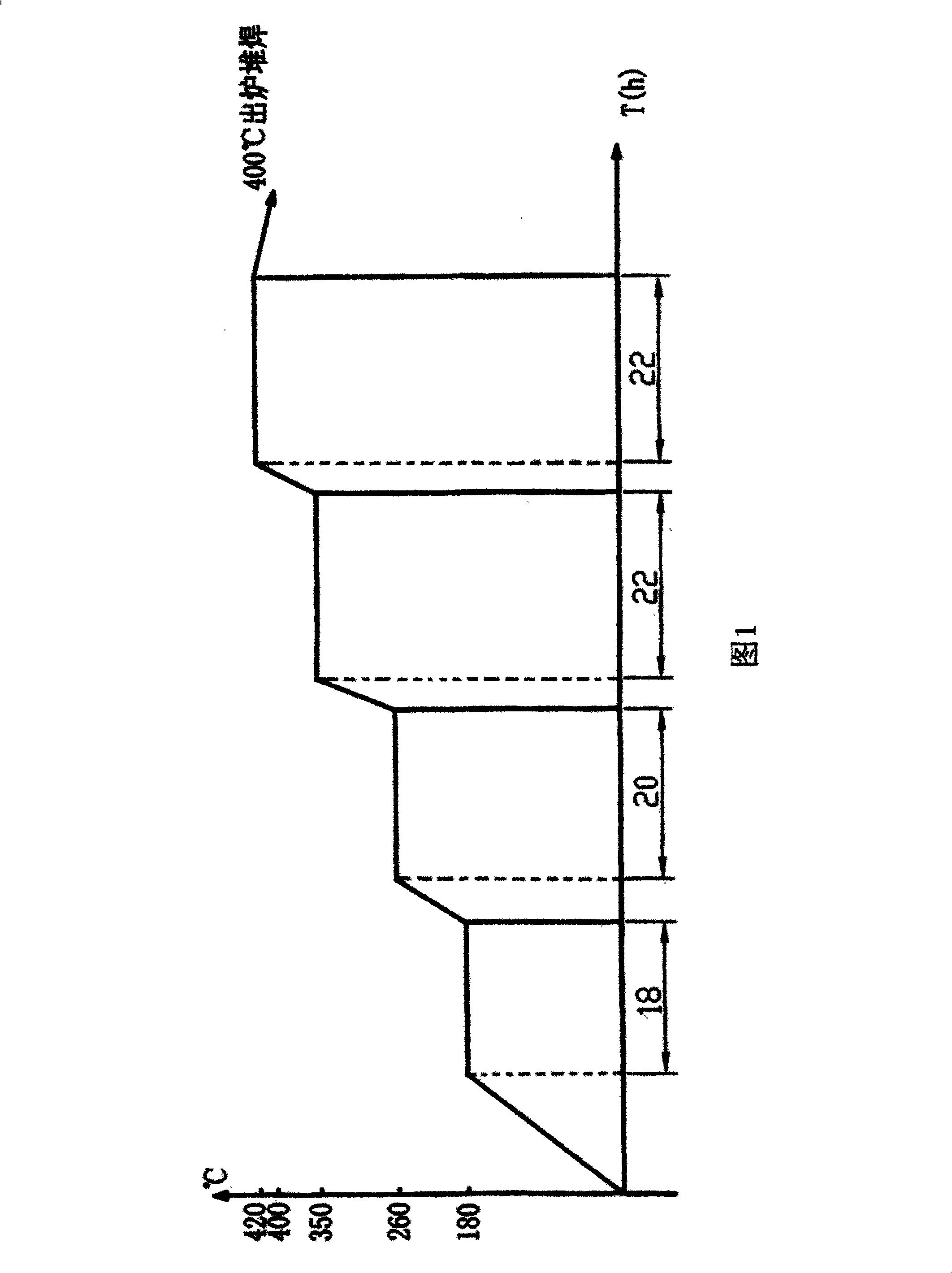

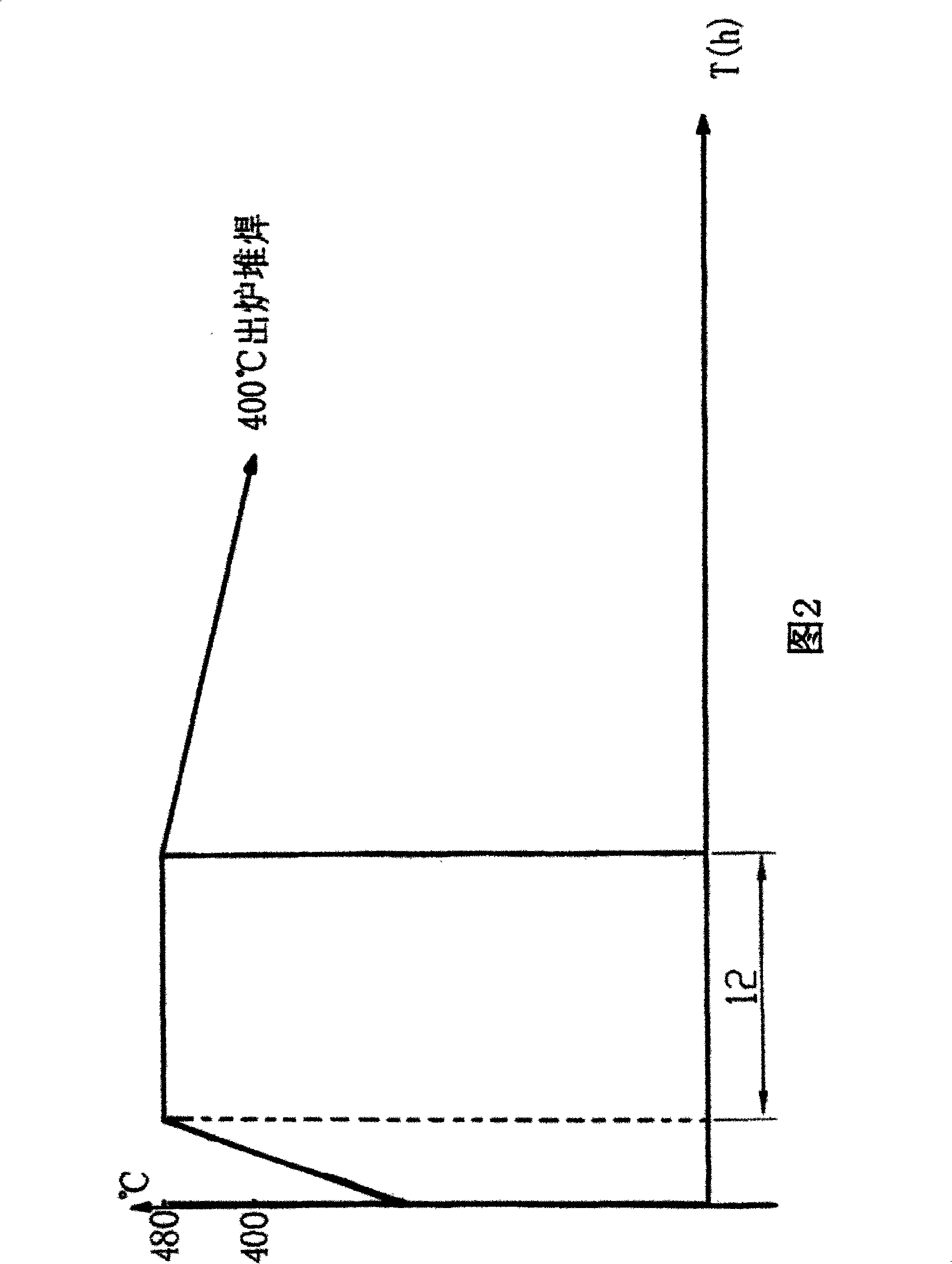

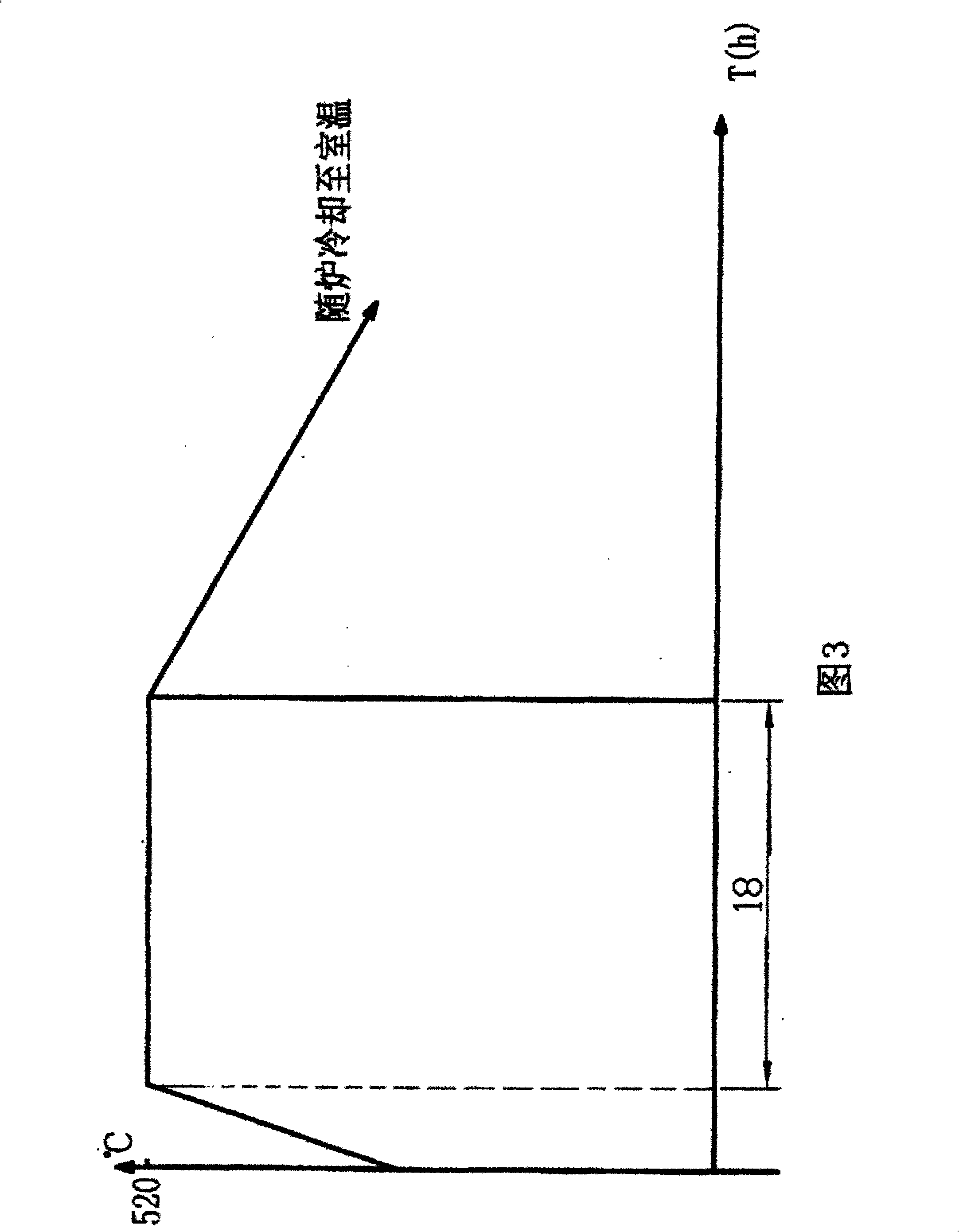

Renovation technique for phi2100í3400mm wrought steel support roll

InactiveCN101293300AEnsure homogeneityPreserve the quality of restorationCounter-pressure devicesArc welding apparatusHeat-affected zoneEngineering

The invention relates to the technical field for repairing an ultra-large type backup roll, in particular to a repair process of a forging steel backup roll with Phi2100* 3400mm. Firstly, welding is carried out on the rib of the backup roll: the roll body of the backup roll which needs to be welded is preheated to 250 DEG C, and the temperature is preserved for 10 hours; then the door of a furnace is opened, rib welding is carried out, zigzag welding is carried out every 100mm, and the length of the weld pass is 50-60mm; oxygen is used on the welded part immediately, and ethyne is used for warming the welded part until the welded part becomes blue. After the rib welding is finished, preheating treatment, temperature preservation treatment and destressing treatment are carried out respectively according to a heat treatment curve when the roll body of the backup roll is overlaid for making a bottom layer, a transition layer and a working layer. Compared with the prior art, in the technology of the invention, the influence on the service performance caused by the temperature circulation and change of a heat influencing region during the overlaying is considered, uniformity and penetration of preheating workpieces and uniformity of temperature between layers are guaranteed in the repair process, the blank in the repair rebirth field of the domestic ultra-large type backup roll is filled in. The time for repair is short, the service life is prolonged, and the cost is saved.

Owner:SHANGHAI SHIWEI WELDING IND

Distribution network resource repair optimal scheduling method based on tabu search algorithm

InactiveCN104156788AAchieving Global ConvergenceImprove utilization efficiencyInternal combustion piston enginesForecastingComputer scienceGlobal optimal

The invention discloses a distribution network resource repair optimal scheduling method based on a tabu search algorithm. According to the distribution network resource repair optimal scheduling method based on the tabu search algorithm, a plurality of factors of repair resource scheduling are comprehensively considered, a repair resource optimal scheduling model is established, and a global optimal engine based on the tabu search algorithm relates to the specific operations of a neighborhood, a tabu list, a tabu length and an amnesty rule. According to the method, the disadvantage that a highly-efficient repair resource optimal scheduling strategy is difficult to make with human experiences caused by the factors of a complex distribution network structure, complex branches and multiple involved repair resources is overcome, the working efficiency of fault repair and the utilization efficiency of the resources are improved, thus the time of fault recovery is shortened, and the customer satisfaction is enhanced.

Owner:STATE GRID CORP OF CHINA +2

Solidification and stabilization method for mercury in mercury contaminants

InactiveCN106391694AReduce dosageReduce the risk of double releaseContaminated soil reclamationUltimate tensile strengthStabilization methods

The invention provides a solidification and stabilization method for mercury in mercury contaminants. The method includes the following steps that (1) mercury contaminant particles with the grain diameter not larger than 5 mm are mixed with soluble sulfide and water, and a first mixture is obtained; (2) the first mixture, cement and water are stirred and mixed, the stirring speed ranges from 20 r / min to 40 r / min, and a second mixture is obtained; and (3), after the second mixture is placed, the treated mercury contaminants are obtained. According to the method, the solidification effect of mercury in the contaminants is enhanced, the cement use amount is reduced on a large scale, the solidification capacity-increase ratio is small, and ready-made construction is rapid; and the leaching concentration of mercury after solidified bodies are stabilized for a long time is low, the mechanical strength of the solidified bodies can meet the requirements of ordinary road paving, and the solidification and stabilization method is suitable for mercury contamination repair projects with the large area, the tight schedule, the simple construction conditions and the low one-time invested cost requirement.

Owner:北京南科大蓝色科技有限公司 +1

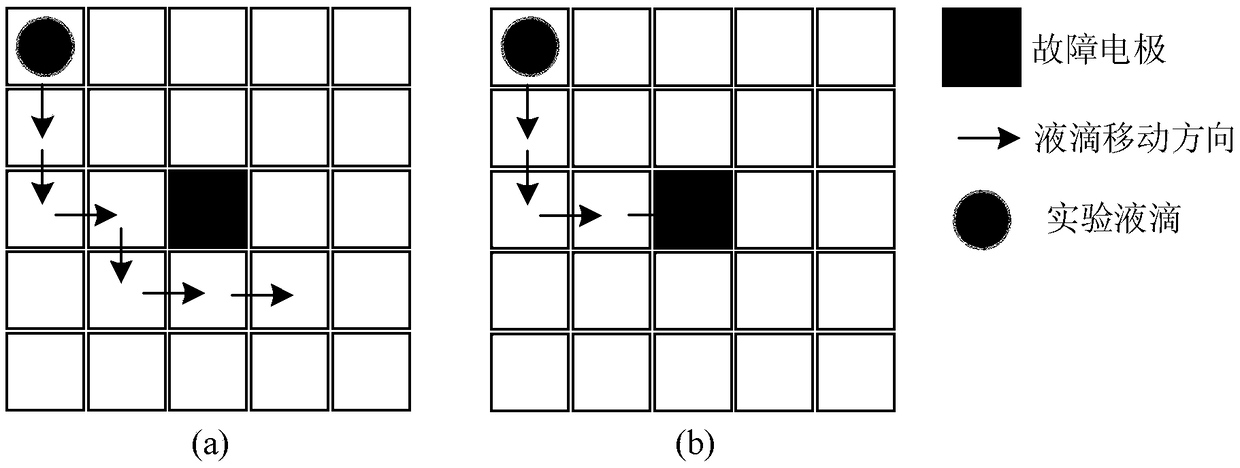

Digital microfluidic chip fault repair method based on combination of improved Dijkstra algorithm and IPSO

ActiveCN109190259AShort repair timeImprove repair efficiencyMulti-objective optimisationSpecial data processing applicationsShortest distanceShort distance

A digital microfluidic chip fault repair method based on the combination of improved Dijkstra algorithm and IPSO relates to the field of digital microfluidic chip fault repair, aiming at solving the problems of time consuming and low efficiency of the existing digital microfluidic chip fault repair methods. The method comprises the following steps: first, calculating the shortest path between twodroplets to be mixed based on the improved Dijkstra algorithm; the improved Dijkstra algorithm introduces a cost function into the existing Dijkstra algorithm. The cost function guides the existing Dijkstra algorithm to search in the direction of the shortest distance to the start point, the shortest distance to the end point and the longest distance to the fault point. Step 2, calculating a moving path based on IPSO, so as to realize the shortest moving distance of droplets and complete fault repair under the condition of ensuring the completion of mixing. The invention is suitable for repairing the faults of the digital microfluidic chip.

Owner:HARBIN INST OF TECH

Adaptive image repairing method

InactiveCN102201111AImprove repair effectImprove repair speedImage enhancementPattern recognitionComputer graphics (images)

The invention provides an adaptive image repairing method. The method is characterized by comprising the following steps: A, reading a damaged image, and setting parameters according to the damaged image; A1, setting the threshold of a curvature adaptive coefficient according to the size of a fracture area of the damaged area of an image; A2, setting a gradient adaptive coefficient according to the edge or details in the image in the damaged area; A3, setting a constant according to the gradient range of the damaged image, required to be protected; and A4, setting iteration frequency and the step length of iterations; B, making a mask image for the damaged image, namely separating the damaged area of the image from the non-damaged area of the image; C, determining the position of the damaged area according to the mask image; D, calculating a semi-point gradient and a magnitude of the semi-point gradient of each point in the damaged area one by one; and E, calculating the semi-point curvature of each point of the damaged area one by one. The method has the advantages of good image repairing effect and short repairing time, and is suitable for automatically repairing all damaged images.

Owner:BEIJING PICOHOOD TECH

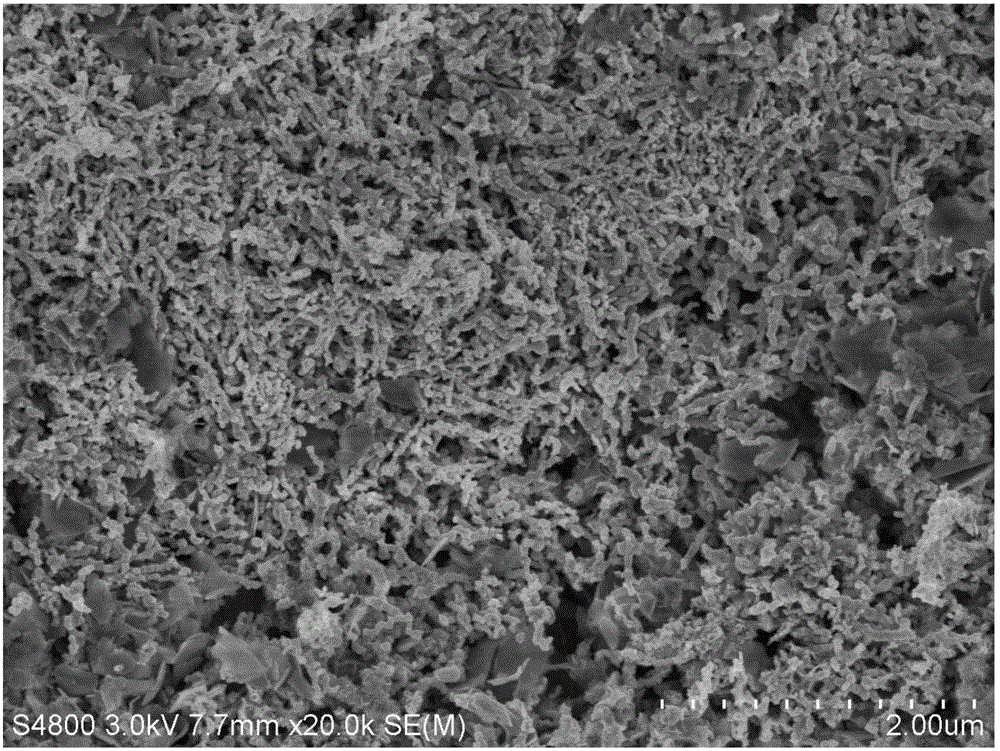

Method for using signal molecules for accelerating repair of disintegrated aerobic granular sludge

PendingCN109987698AImprove hydrophobicityAccelerated structural repairWater treatment parameter controlSustainable biological treatmentSignalling moleculesSludge

The invention relates to a method for using signal molecules for accelerating repair of disintegrated aerobic granular sludge. According to the method for using the signal molecules for accelerating repair of the disintegrated aerobic granular sludge, by adding the exogenous AHLs signal molecules to repair the disintegrated the aerobic granular sludge, in a process of repairing structures of the disintegrated aerobic granular sludge, regranulation of the crushed granular sludge is accelerated, after 20-30 days, the disintegrated aerobic granular sludge is basically and completely repaired, therepaired aerobic granular sludge is smooth in particle surface, regular in shape and compact in structure, and has good settling performance, after adding of the exogenous AHLs is stopped, the granular sludge structures are still intact, and the settling performance and the granule density remain at high levels. According to the method for using the signal molecules for accelerating repair of thedisintegrated aerobic granular sludge, by adding the exogenous AHLs temporarily, an excellent repairing effect on the disintegrated aerobic granular sludge is achieved, the repaired granular sludge is intact in structure and good in settling performance, moreover, operation is simple, and practical application is easy.

Owner:SHANDONG UNIV

Method for rapidly treating heavy metal contaminated soil

InactiveCN105268734ALarge biomassShort repair timeContaminated soil reclamationBiogasContaminated soils

The invention provides a method for rapidly treating heavy metal contaminated soil, belongs to the technical field of soil pollution treatment, and particularly relates to a technology for treating the heavy metal contaminated soil by vegetation measures and biological measures. The method comprises the steps that humate fertilizer is applied to soil which is contaminated by heavy metal of Cd, As, Pb and Zn; then vetiveria zizanioides is planted on the soil, the planting distances between plant clusters range from 18 cm to 22 cm, the line spacing is 47-53 cm, and 6-10 plants are planted per cluster; NPK compound fertilizer is applied three months after the vetiveria zizanioides is planted and survived, and the dosage of the NPK compound fertilizer is 20-30 kg per mu; the stems and leaves of the vetiveria zizanioides are harvested in summer or winter each year; and the stems and leaves are used for fermenting methane or the handicraft industry when it is detected that the total amount of enriched heavy metal exceeds the standard and are used as pasture or fertilizer when it is detected that the total amount of the enriched heavy metal reaches the standard. The adopted vetiveria zizanioides has good heavy metal hyper-accumulation performance, and is resistant to barren, drought, acid and alkali, large in biomass, likely to survive and convenient to manage.

Owner:YUNNAN XIANGCAO BIOTECH ENG CO LTD

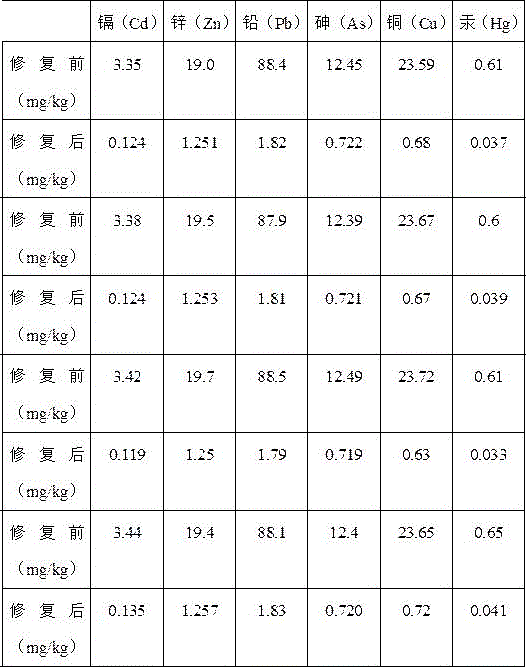

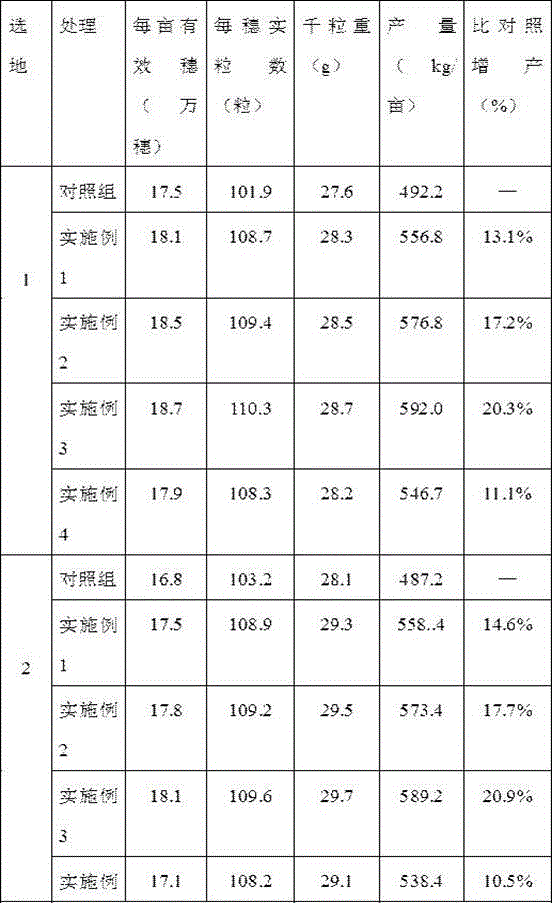

Soil remediation agent and preparation method thereof

InactiveCN106316686AReduce heavy metal contentIncrease productionCalcareous fertilisersAgriculture tools and machinesSodium BentonitePhosphate

The invention discloses a soil remediation agent. The soil remediation agent comprises, by weight, 8-12 parts of hydrated lime, 30-50 parts of limestone, 40-60 parts of bentonite, 5-7 parts of sepiolite, 5-10 parts of biological charcoal, 2-3 parts of diethylenetriamine pentaacetic acid, 2-3 parts of sodium dimercaptosulphonate, 3-5 parts of sodium lignosulfonate, 1-3 parts of cysteine, 1-1.8 parts of sodium potassium tartrate tetrahydrate, 1-1.5 parts of phosphate ore and 0-0.5 part of sodium sulfide. A preparation method of the soil remediation agent includes the steps of firstly, weighing the phosphate ore, the sepiolite and the biological charcoal, and grinding into powder; secondly, adding the cysteine, the sodium potassium tartrate tetrahydrate and the sodium sulfide into the ground powder, and stirring; thirdly, continuously adding the rest of substances, and mixing. The preparation method is simple and low in cost, and the prepared soil remediation agent can lower the heavy metal activity in soil, improve the soil, increase soil fertility and increase crop yield.

Owner:SICHUAN HUAZHI BIOLOGICAL ENG

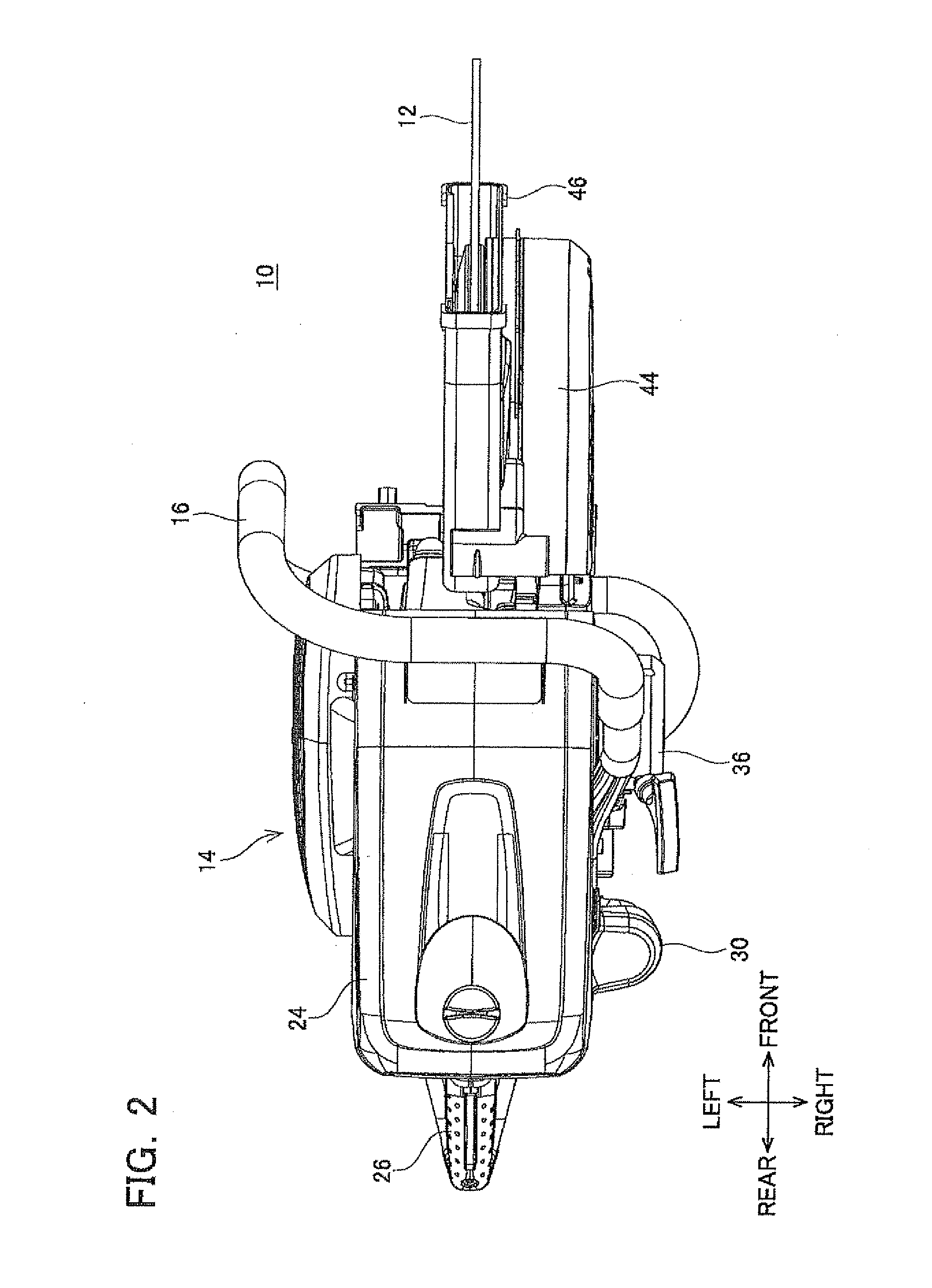

Vibration insulating device for a handheld work machine

InactiveUS20110240324A1Easy to disassembleEasy to assembleMetal sawing devicesSpringsGeneral purposeCoil spring

A vibration insulating device connects two members of a handheld work machine via a coil spring. One end of the coil spring is supported by a first supporting member fixed to one member, and the other end is supported by a second supporting member fixed to another member. At least one of the first and second supporting members includes a threaded groove that engages with the coil spring and a tool engaging portion that configured capable of being engaged with a general-purpose tightening tool.

Owner:MAKITA CORP

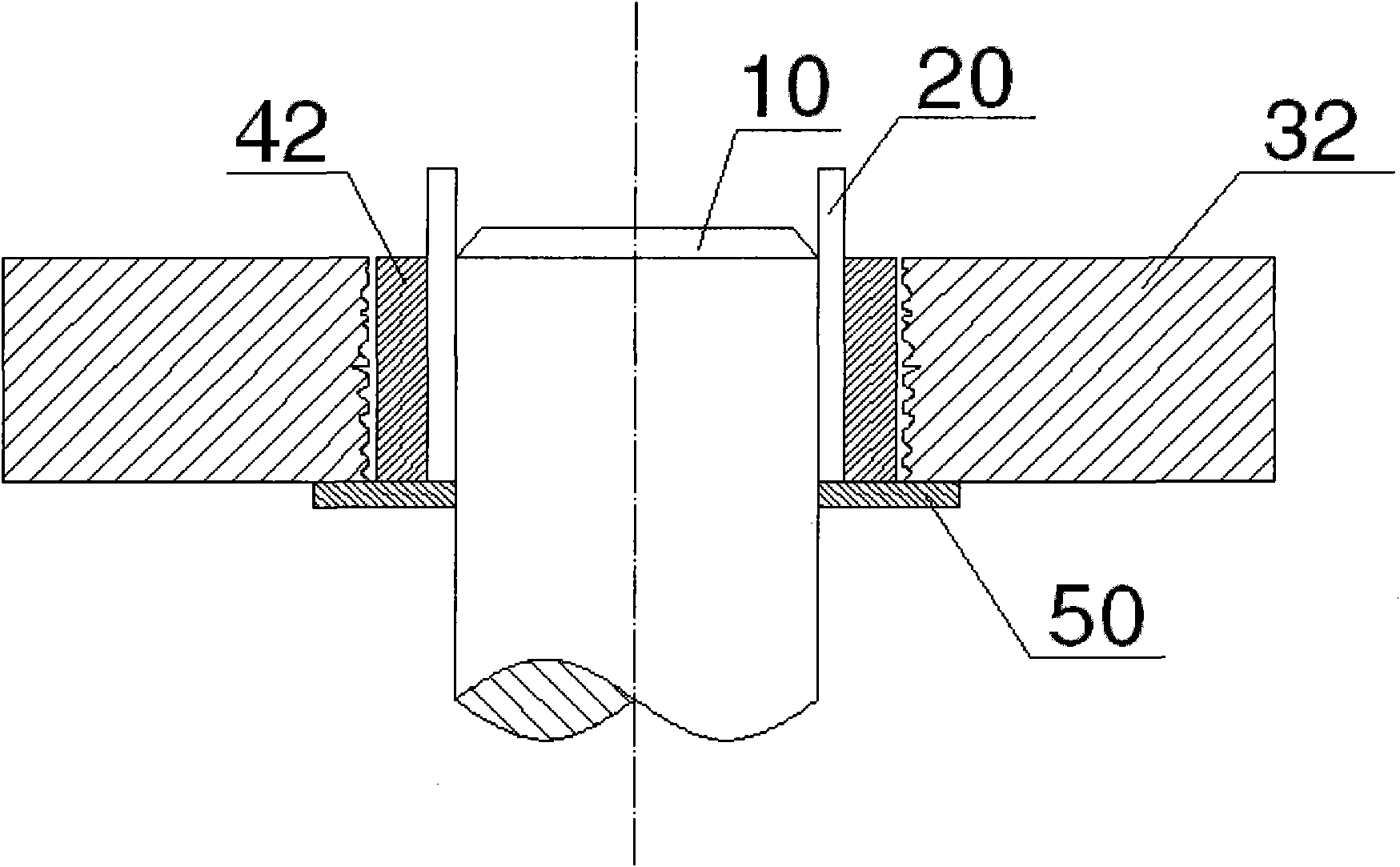

Rapid repairing connection device for off-center adjustable type submarine pipeline

The invention provides a rapid repairing connection device for an off-center adjustable type submarine pipeline, which is applied to repairing connection work for replacement of a submarine pipeline underwater. The connection device is formed by organically combining a plurality of types of sealing technologies including metal, non-metal and the like, so that the sealing between the connection device and the pipeline is guaranteed. An off-center adjusting device realizes off-center adjustment of the submarine pipeline through spherical match of an off-center adjusting body and an off-center adjusting seat and the common effect of all spherical gaskets, and the sealing between the connection device and the newly replaced pipeline is realized by adopting the sealing of an O-shaped sealing ring and the sealing of a metal ring; a propelling body is used for axially propelling and extruding each metal ring and each metal loop of a main sealing device, so that the sealing between the connection device and a prefabricated loop surface of a cutting pipeline, and the sealing between the propelling body and the main sealing device are realized; automatic positioning of the connection device is realized by a positioning device according to a locking mechanism, and an auxiliary sealing box realizes the fixing and sealing between the connection device and an original loop surface of the cutting pipeline by adopting the sealing of packing and the sealing of the O-shaped sealing ring, so that the connection device has the characteristics of short repairing time, low working intensity and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Black and odorous water treatment agent and application thereof

InactiveCN109502769AChange the quality of waterReduce water quality maintenance costsBiological water/sewage treatmentAtmospheric airSorbent

The invention discloses a black and odorous water treatment agent and an application thereof. The treatment agent is prepared from components in parts by mass as follows: 330-500 parts of a flocculating agent, 110-174 parts of an adsorbent, 170-225 parts of a settling agent, 140-190 parts of a water softener, 160-210 parts of an oxidizing agent, 140-165 parts of a purifier, 170-240 parts of an ionexchanger, 90-160 parts of a chelating agent, 8-30 parts of bacillus powder, 5-30 parts of desulphurization bacterium powder and 8000 parts of zeolite particles. The invention provides the application of the black and odorous water treatment agent to treatment and repair of black and odorous water. With the adoption of the treatment agent, quality of the black and odorous water can be changed ina short time and enabled to reach the surface water class-VI standard. When the treatment agent is applied to in-situ treatment of the black and odorous water, the investment is reduced by 60% or morecompared with that of an ex-situ treatment technology for bottom mud, secondary pollution risk of the bottom mud for atmosphere, soil and underground is greatly reduced, and the restoration time is short.

Owner:深圳市固废环保科技有限公司

Intrinsic room-temperature self-repairing crystalline polymer

InactiveCN103073695ASimple structureSynthetic preparation is simpleOrganic chemistryPolyesterPolymer science

The invention relates to an intrinsic room-temperature self-repairing crystalline polymer, which comprises the following components: micromolecule divalent alcohol monomer containing alcoxyl amine group, crystalline polyether or polyester-diol monomer and diisocyanate or triisocyanate monomer. The self-repairing functional material can joint rupture surfaces after being mechanically damaged, and can restore most mechanical properties after being placed at the temperature of 15-25 DEG C for a period time of self-repairing. The repairing mechanism of the intrinsic room-temperature self-repairing crystalline polymer lies in reversible C-ON preferred fracturing, and after re-junction of the fracture surfaces, molecular chains are mutually diffused, and then the carbon free radical and NO free radical at the ends of the molecular chains are combined. The intrinsic self-repairing material presents the characteristics of a rigid solid material, has the characteristics of simplicity in preparation, room-temperature self-repairing performance, high repairing efficiency, short repair time, capability of realizing repeated repair and the like, facilitates prolonging the service life of the polymer material and conforms to the development tendency of global low-carbon economy.

Owner:SUN YAT SEN UNIV

Rudder pintle bearing body repairing process based on metal repairing agent casting

The invention discloses a rudder pintle bearing body repairing process based on metal repairing agent casting, which comprises the following steps that: a corroded rudder pintle bearing body A is sand-blast, and then the sand-blast part of a rudder pintle bearing body is cleaned; the inner hole radius R of the sand-blast rudder pintle bearing body is measured, a new rudder pintle bearing is processed and the excircle radius thereof is R1; a feeler fixes a rudder pintle and a rudder pintle bearing C and puts the same into the rudder pintle bearing body, so that the circle of a rudder pintle bearing body C coincides with the circle of the rudder pintle; and the rudder pintle is fixed, a baffle is arranged below a gap between the rudder pintle bearing C and the rudder pintle bearing body C, metal repairing agent is cast from above the gap, the baffle, the rudder pintle and the feeler are removed after the metal repairing agent is solidified, the rudder pintle bearing C is spliced on the rudder pintle bearing body C, and the repairing of the rudder pintle bearing body A is completed. The rudder pintle bearing body repairing process based on metal repairing agent casting has the advantages of short repairing time, sailing and docking period saving, capability of achieving the same repairing effect with a borehole, no need of boring in repairing, little cost and the like.

Owner:COSCO SHIPPING SHIPYARD (NANGTONG) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com