Soil remediation agent and preparation method thereof

A technology of soil remediation agent and bentonite, applied in the field of soil pollution remediation, can solve problems such as high cost and decreased soil fertility, and achieve the effects of low cost, reduced heavy metal content, and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

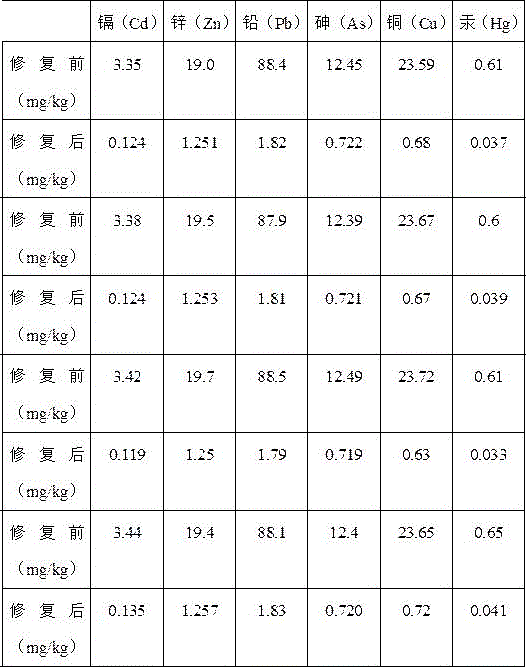

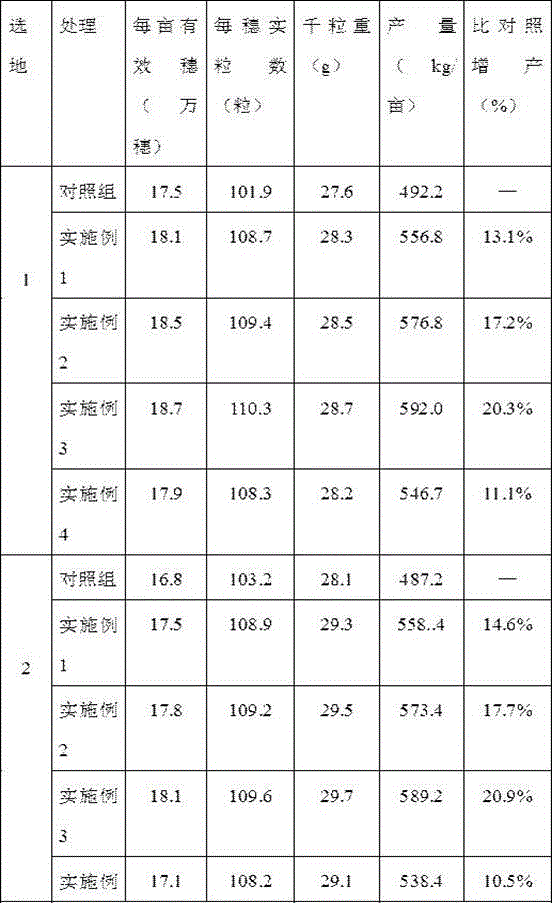

Examples

Embodiment 1

[0020] A soil remediation agent, comprising the following components by weight: 8 parts of slaked lime, 30 parts of limestone, 40 parts of bentonite, 5 parts of sepiolite, 5 parts of biochar, 2 parts of diethyltriaminepentaacetic acid, dimercaptopropane 2 parts of sodium sulfonate, 3 parts of sodium lignosulfonate, 1 part of cysteine, 1 part of potassium sodium tartrate, 1 part of phosphate rock and 0.1 part of sodium sulfide;

[0021] Among them, the biochar is prepared by the following method: put the coconut shell with a water content of 30% in a carbonization furnace, dehydrate and deoxidize it at 250°C for 100 minutes, and then transfer it to carbonization at 650°C for 50 minutes, and then carbonize it after cooling. The product is crushed to a solid powder with a particle size of 0.3-0.8mm;

[0022] Phosphate rock is made of P 2 o 5 Medium and low-grade phosphate rock with a content of less than 25% and a carbonate content of more than 10% and P 2 o 5 It is obtained ...

Embodiment 2

[0028] A soil restoration agent, comprising the following components by weight: 12 parts of slaked lime, 50 parts of limestone, 60 parts of bentonite, 7 parts of sepiolite, 10 parts of biochar, 3 parts of diethyltriaminepentaacetic acid, dimercaptopropane 3 parts of sodium sulfonate, 5 parts of sodium lignosulfonate, 3 parts of cysteine, 1.8 parts of potassium sodium tartrate, 1.5 parts of phosphate rock, 0.5 parts of sodium sulfide;

[0029] Among them, the biochar is prepared by the following method: put the coconut shell with a water content of 10% in a carbonization furnace, dehydrate and discharge oxygen at 220°C for 80 minutes, and then transfer to 600°C for carbonization for 30 minutes, and after cooling, carbonize The product is crushed to a solid powder with a particle size of 0.3-0.8mm;

[0030] Phosphate rock is made of P 2 o 5 Medium and low-grade phosphate rock with a content of less than 25% and a carbonate content of more than 10% and P 2 o 5 It is obtained ...

Embodiment 3

[0036] A soil restoration agent, comprising the following components by weight: 10 parts of slaked lime, 43 parts of limestone, 52 parts of bentonite, 6 parts of sepiolite, 8 parts of biochar, 2 parts of diethyltriaminepentaacetic acid, dimercaptopropane 2 parts of sodium sulfonate, 4 parts of sodium lignosulfonate, 2 parts of cysteine, 1.6 parts of potassium sodium tartrate, 1.2 parts of phosphate rock, 0.2 parts of sodium sulfide;

[0037] Among them, biochar is prepared by the following method: put the coconut shell with a water content of 20% in a carbonization furnace, dehydrate and discharge oxygen at 240°C for 80 minutes, and then transfer to 620°C for carbonization for 40 minutes, and then carbonize it after cooling. The product is crushed to a solid powder with a particle size of 0.3-0.8mm;

[0038] Phosphate rock is made of P 2 o 5 Medium and low-grade phosphate rock with a content of less than 25% and a carbonate content of more than 10% and P 2 o 5 It is obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com