Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Imidodisulfonic/nitrilotrisulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

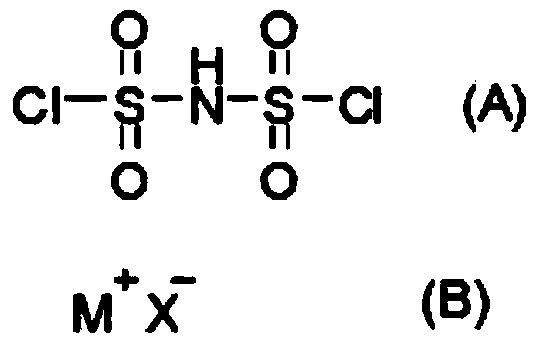

Preparation method for difluorosulfimide lithium salt

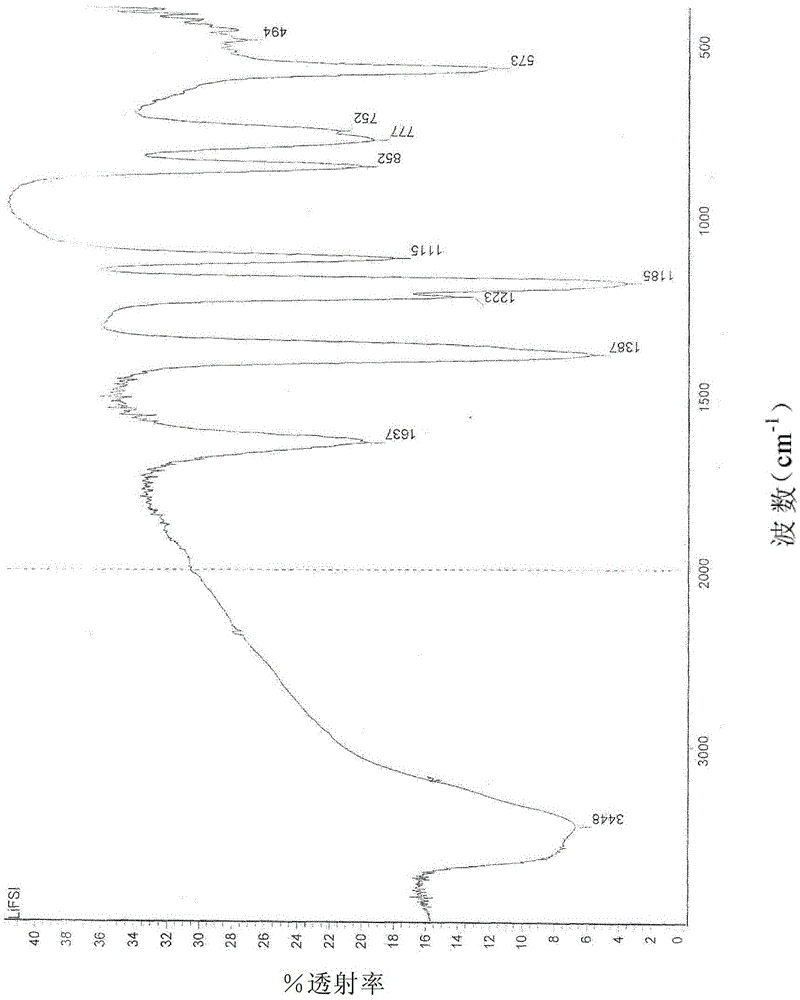

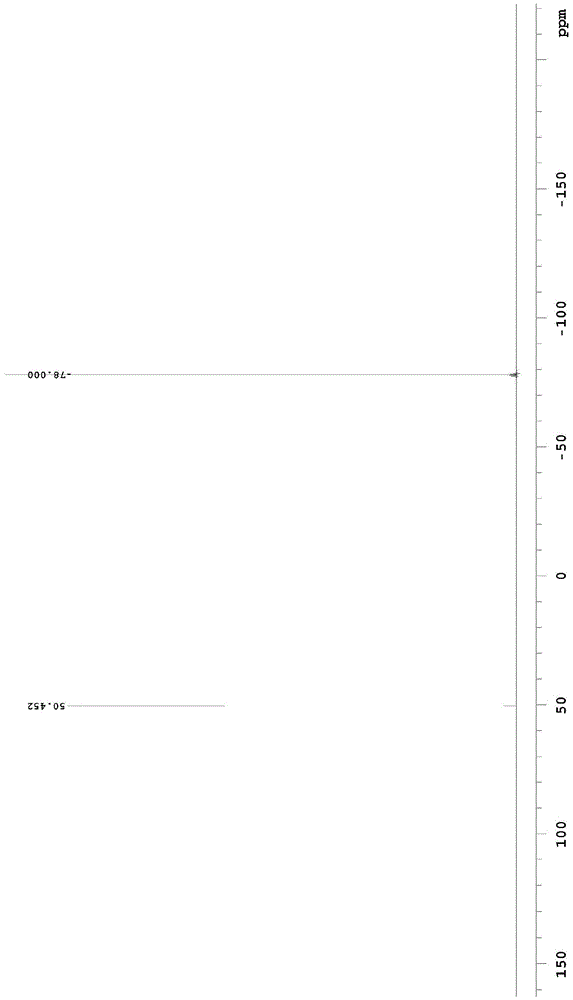

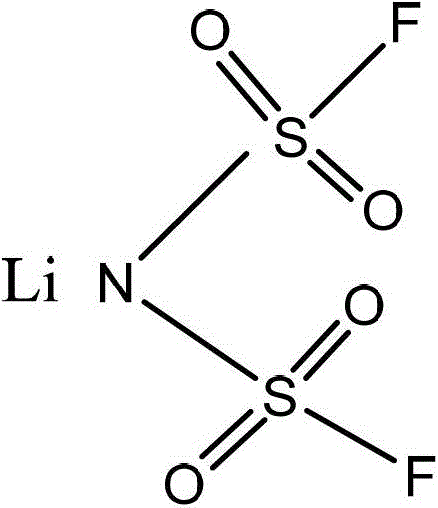

ActiveCN104925765AGuaranteed purityGuaranteed qualityNitrosyl chlorideAmidosulfonic acidHydrogen fluorideLithium-ion battery

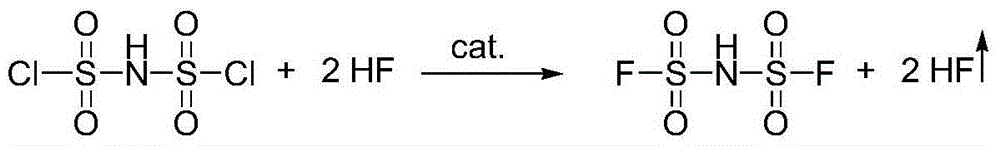

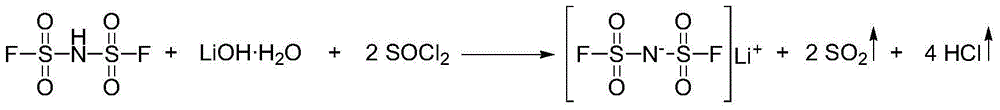

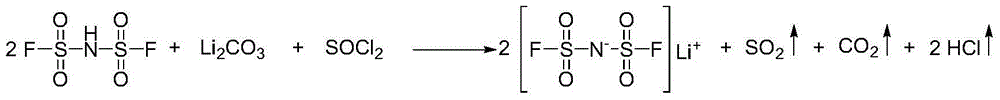

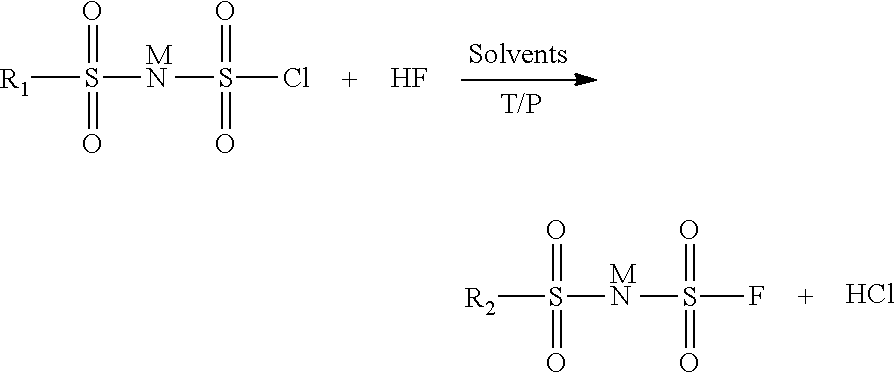

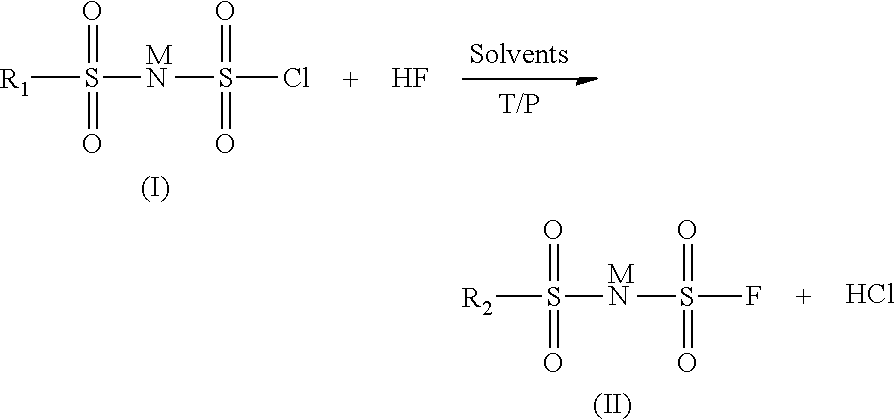

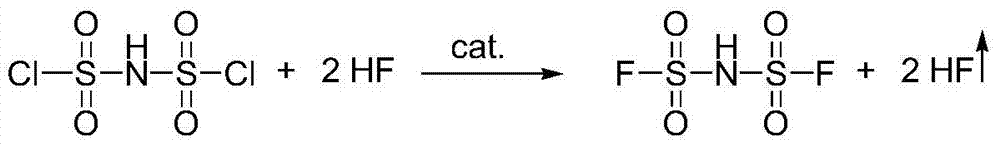

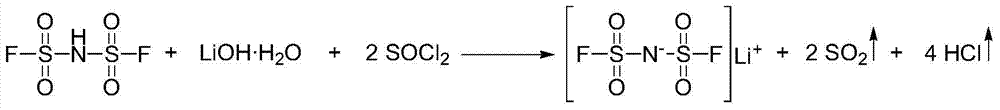

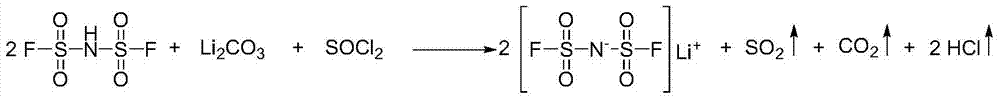

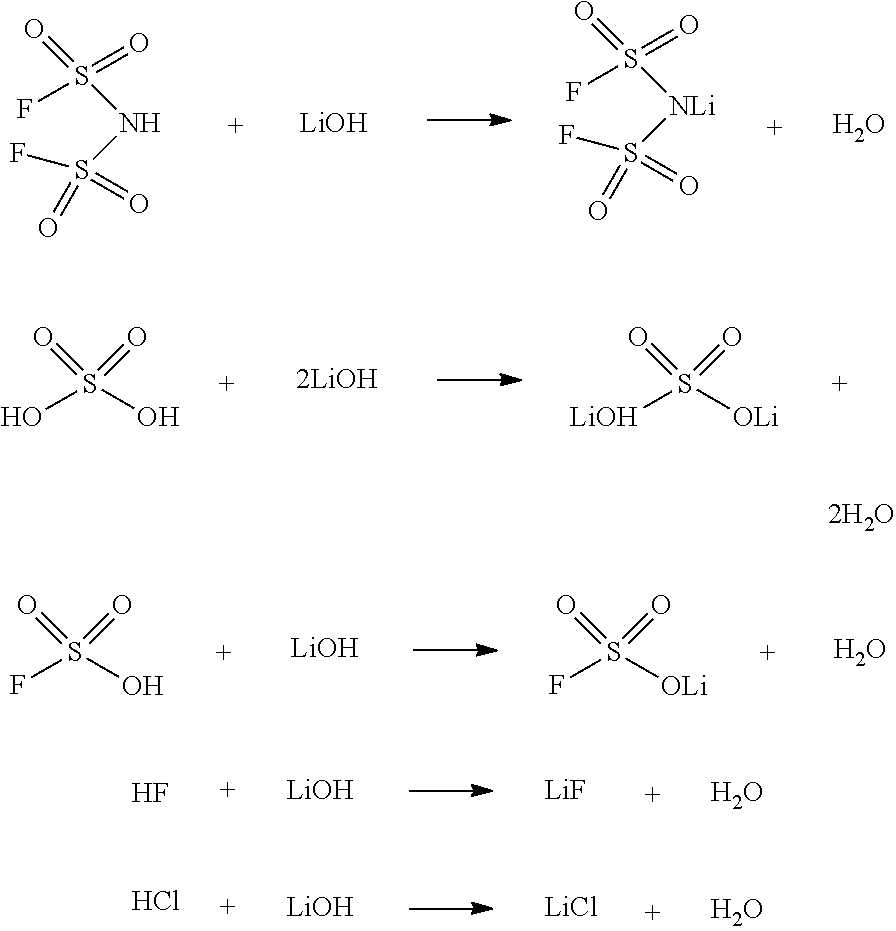

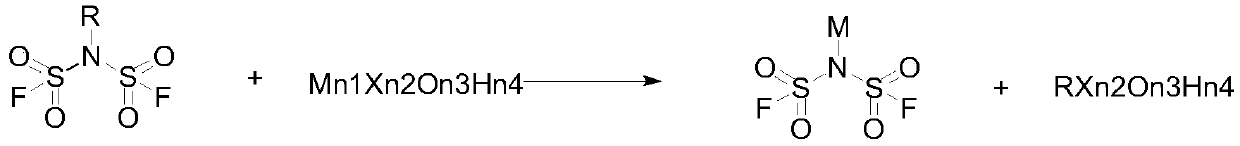

The invention relates to the field of lithium batteries and lithium capacitors, in particular to a preparation method for difluorosulfimide lithium salt and application of the difluorosulfimide lithium salt. The preparation method for the difluorosulfimide lithium salt, provided by the invention, comprises the following steps: (1) performing fluorination reaction: synthetizing midbody difluorosulfimide from dichlorosulfimide and hydrogen fluoride under the action of a catalyst; (2) performing reaction between the difluorosulfimide obtained in the step 1 and alkaline lithium, and performing solid-liquid separation after the reaction to obtain an LiFSI product. The preparation method for the difluorosulfimide lithium salt, provided by the invention, is low in cost, few in by-product and simple in post-treatment, and the quality and the purity of the product are ensured, therefore the preparation method which is capable of obtaining the high-quality and high-purity product and is economic and practical is provided; the preparation method is suitable for industrial production.

Owner:SHANGHAI CHEMSPEC CORP +1

Synthesis of bis(fluorosulfonyl)imide

The present invention provides methods for producing bis(fluorosulfonyl) compounds of the formula:F—S(O)2—Z—S(O)2—F Iby contacting a nonfluorohalide compound of the formula:X—S(O)2—Z—S(O)2—Xwith bismuth trifluoride under conditions sufficient to produce the bis(fluorosulfonyl) compound of Formula I, where Z and X are those defined herein.

Owner:SES HLDG PTE LTD

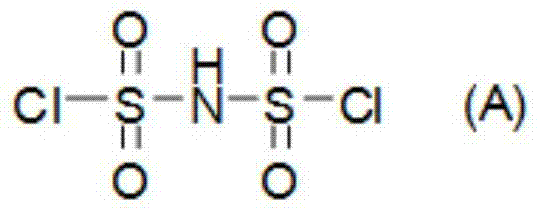

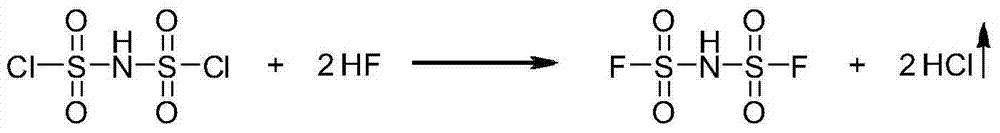

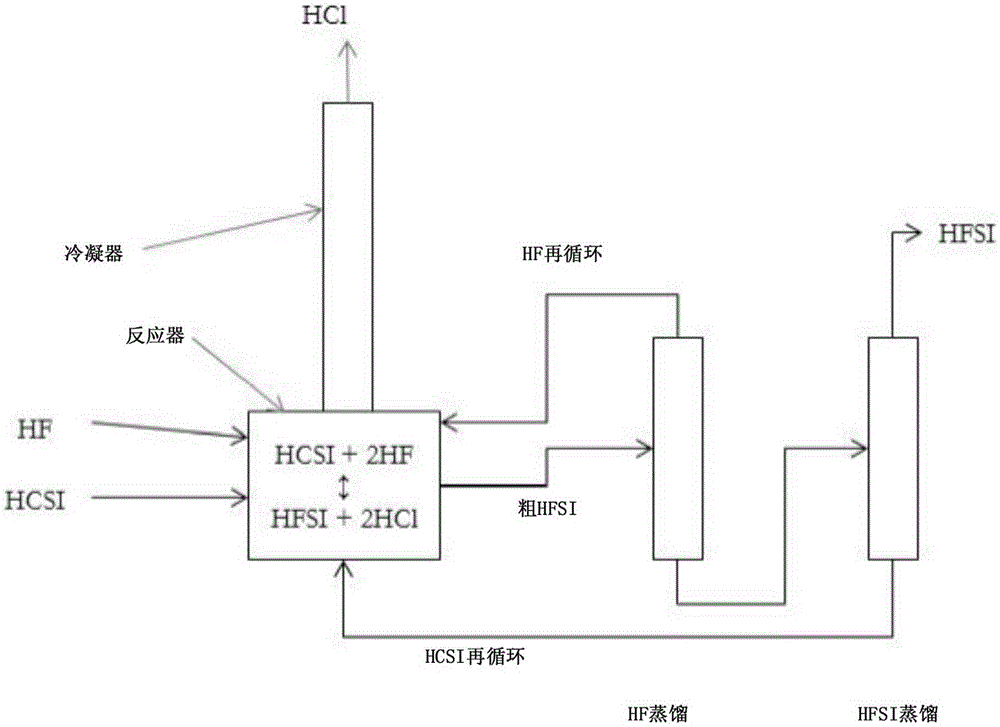

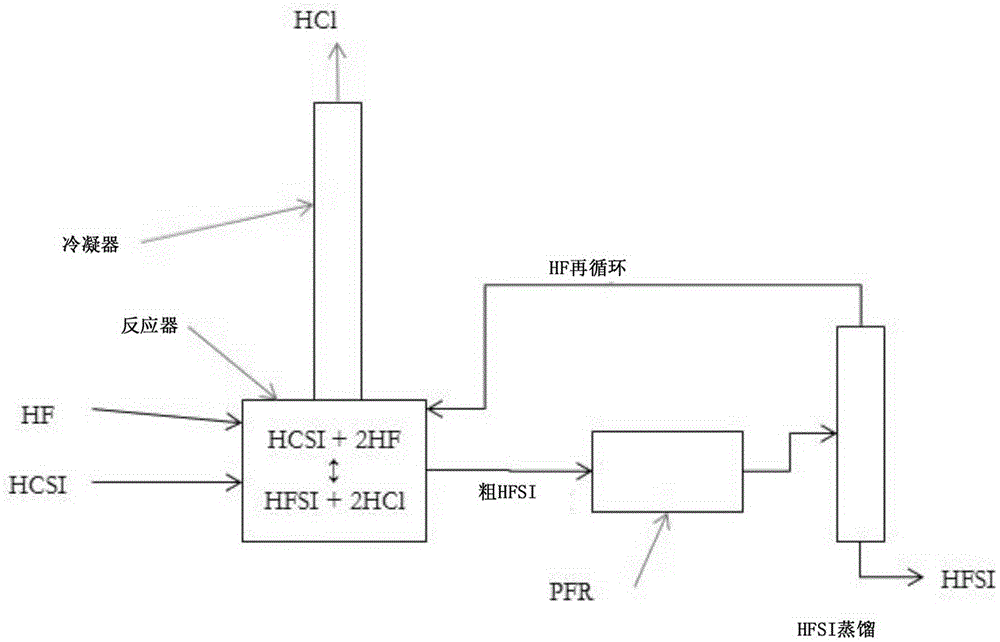

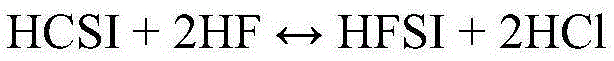

Preparation methods of bis(fluorosulfonyl)imide and alkali metal salts thereof

InactiveCN103935970AEasy to getLow costHybrid capacitor electrolytesAmidosulfonic acidImideHydrogen fluoride

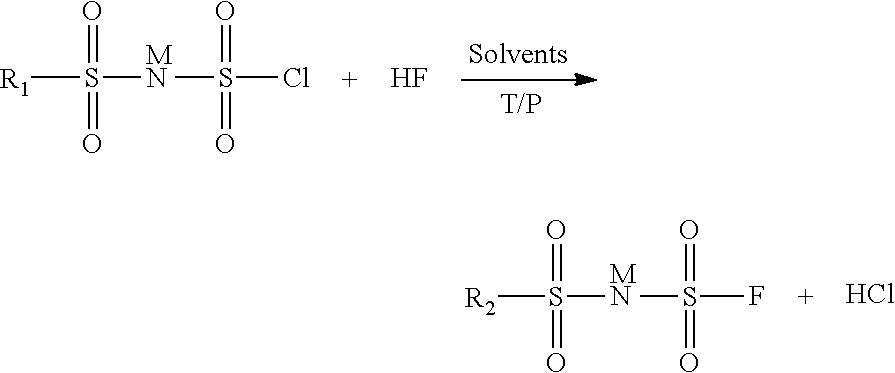

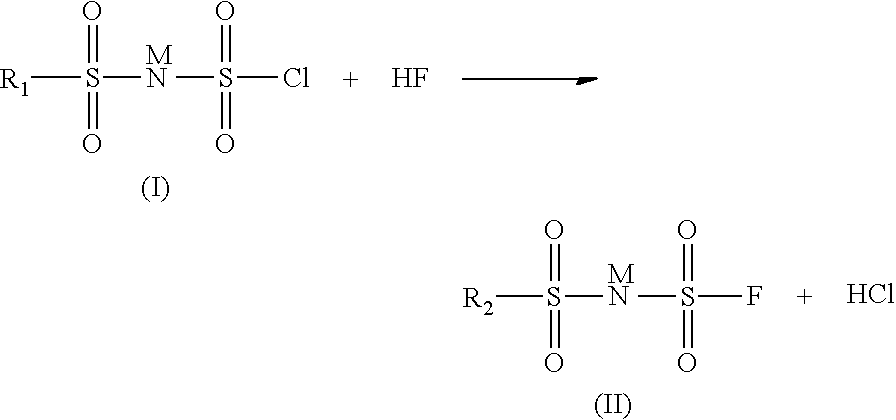

The invention relates to preparation methods of bis(fluorosulfonyl)imide and alkali metal salts thereof. The bis(fluorosulfonyl)imide is prepared by subjecting bis(chlorosulfonyl)imide to react with a fluorinating agent namely hydrogen fluoride. The alkaline metal salts of bis(fluorosulfonyl)imide is prepared by subjecting bis(chlorosulfonyl)imide and alkali metal halides to react with hydrogen fluoride taken as the fluorinating agent and the solvent. The preparation methods can reduce the raw material costs, reduce the material consumption and generation of wastes, improve the raw material utilization rate, product yield, and product purity; moreover, the product purification is easier, the preparation technology process is more concise and more efficient, and the preparation methods provides a very good technical foundation for massive industrial production of bis(fluorosulfonyl)imide and alkali metal salts thereof.

Owner:SHENZHEN CAPCHEM TECH CO LTD

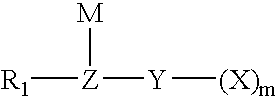

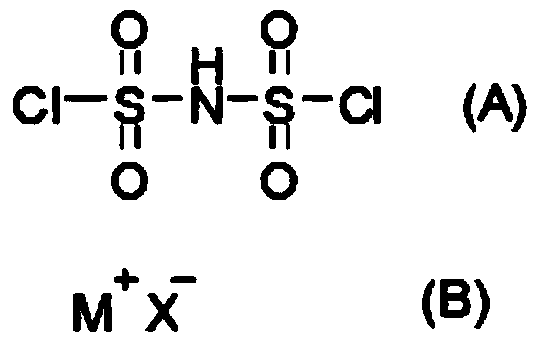

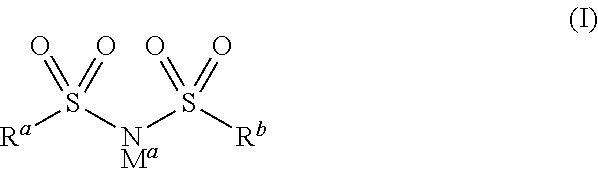

Method for fluorinating a compound comprising a halosulphonyl or dihalophosphonyl group

The invention relates to a fluorination process for producing fluorinated compounds.The process consists in reacting a compound (I) corresponding to the formulawith an ionic fluoride of a monovalent cation. M represents H, an alkali metal, a quaternary phosphonium group or a quaternary ammonium group. Y represents SO2 and m is 1, or else Y is PO and m is 2. Z represents CR2, N or P. R1 represents an electron-withdrawing group which has a Hammet σP parameter of greater than 0.4. R2 represents a carbonaceous and / or electron-withdrawing group. X represents a halogen other than a fluorine.The fluorinated compounds obtained are of use in particular as electrolytes in lithium batteries.

Owner:HYDRO QUEBEC CORP

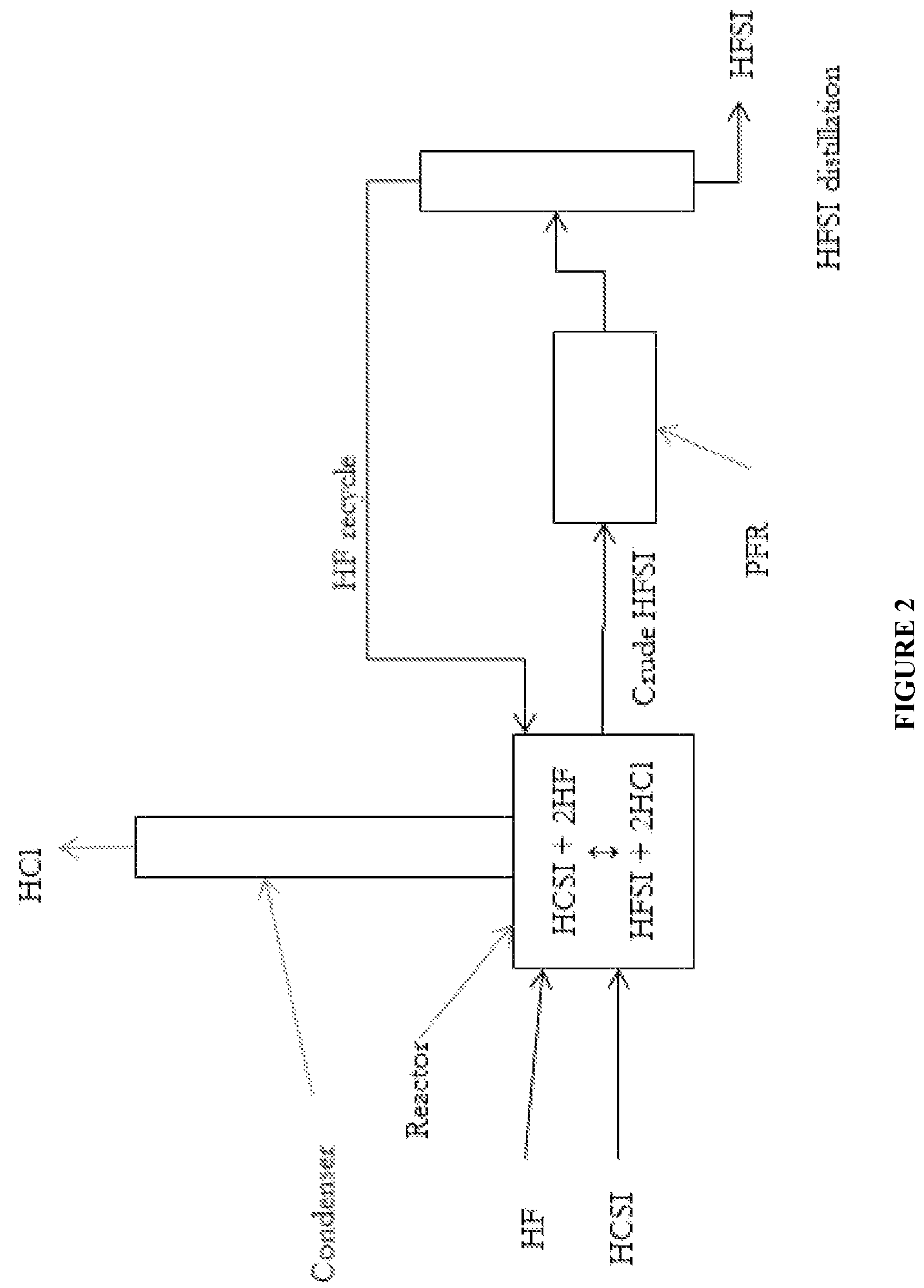

Synthesis of hydrogen bis(fluorosulfonyl)imide

InactiveCN105392736AHybrid capacitor electrolytesImidodisulfonic/nitrilotrisulfonic acidImideHydrogen fluoride

Owner:COORSTEK FLUOROCHEM

Preparation method of bifluorosulfonyl imide onium salt

InactiveCN104230722AEasy to getLow costAmino preparation from aminesImidodisulfonic/nitrilotrisulfonic acidIonSolvent

The invention relates to a preparation method of bifluorosulfonyl imide onium salt. The preparation method comprises the following step: by adopting hydrogen fluoride as a fluorination reagent and a reaction solvent, reacting with dichlorosulfonyl imide and an onium ion halide to obtain bifluorosulfonyl imide onium salt. Therefore, by adopting the preparation method disclosed by the invention, the raw material cost can be reduced, the material consumption and waste generation can be reduced, the raw material utilization rate and the product yield and purity can be improved, products can be more easily purified, a preparation technological process can be simpler and more efficient, and a good technological base for preparing bifluorosulfonyl imide onium salt massively and industrially can be provided.

Owner:SHENZHEN CAPCHEM TECH

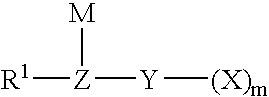

Method for preparing imide salts containing a fluorosulphonyl group

A fluorination process for obtaining fluorinated compounds including at least one fluorosulfonyl group. More particularly, a process for preparing a fluorinated compound of formula (II), including at least one step of reacting a compound of formula (I) with anhydrous hydrofluoric acid in at least one organic solvent, in which R1 is equal to R2 except in the specific case where R1=Cl, then R2=F, and when R1 is equal to R2, R1 and R2 represent an electron-withdrawing group which has a Hammett parameter op of greater than 0, such as F, CF3, CHF2, CH2F, C2HF4, C2H2F3, C2H3F2, C2F5, C3F7, C3H2F5, C3H4F3, C3HF6, C4F9, C4H2F7, C4H4F5, C5F11, C3F5OCF3, C2F4OCF3, C2H2F2OCF3, CF2OCF3, C6F13, C7F15, C8F17 or C9F19, and M represents a hydrogen atom, an alkali metal, an alkaline-earth metal or a quaternary ammonium cation.

Owner:ARKEMA FRANCE SA

Synthesis of bis(fluorosulfonyl)imide

The present invention provides methods for producing bis(fluorosulfonyl) compounds of the formula: F—S(O)2—Z—S(O)2—F I by contacting a nonfluorohalide compound of the formula: X—S(O)2—Z—S(O)2—X with bismuth trifluoride under conditions sufficient to produce the bis(fluorosulfonyl) compound of Formula I, where Z and X are those defined herein.

Owner:BOULDER IONICS

Method for the preparation of bis(fluorosulfonyl)-imide and of its salts

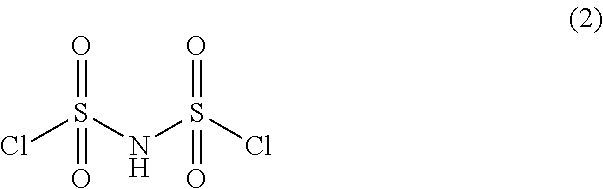

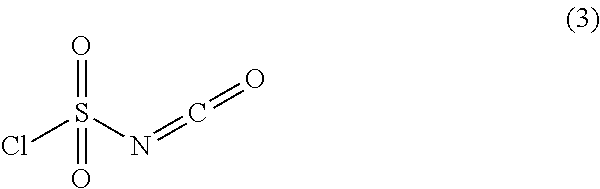

InactiveUS20180362343A1Nitrosyl chlorideImidodisulfonic/nitrilotrisulfonic acidImideChlorosulfonyl isocyanate

The invention relates to a method for the preparation of bis(fluorosulfonyl)-imide, the method starts from bis(chlorosulfonyl)-imide or its respective derivatives, which is reacted with HF in the presence of chlorosulfonyl isocyanate, and uses a certain extraction step for extraction of bis(fluorosulfonyl)-imide from an aqueous solution; the invention is also useful for the preparation of certain salts of bis(fluorosulfonyl)-imide and its derivatives.

Owner:LONZA LTD

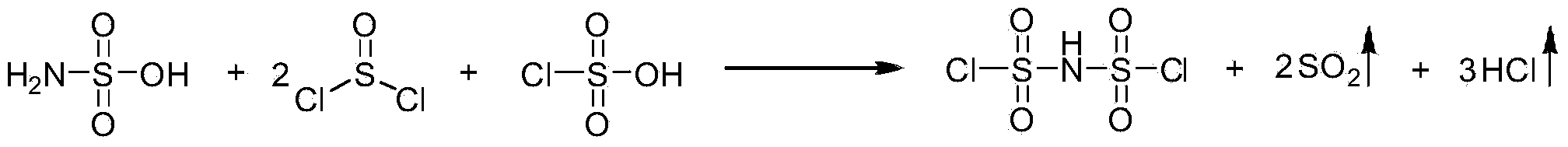

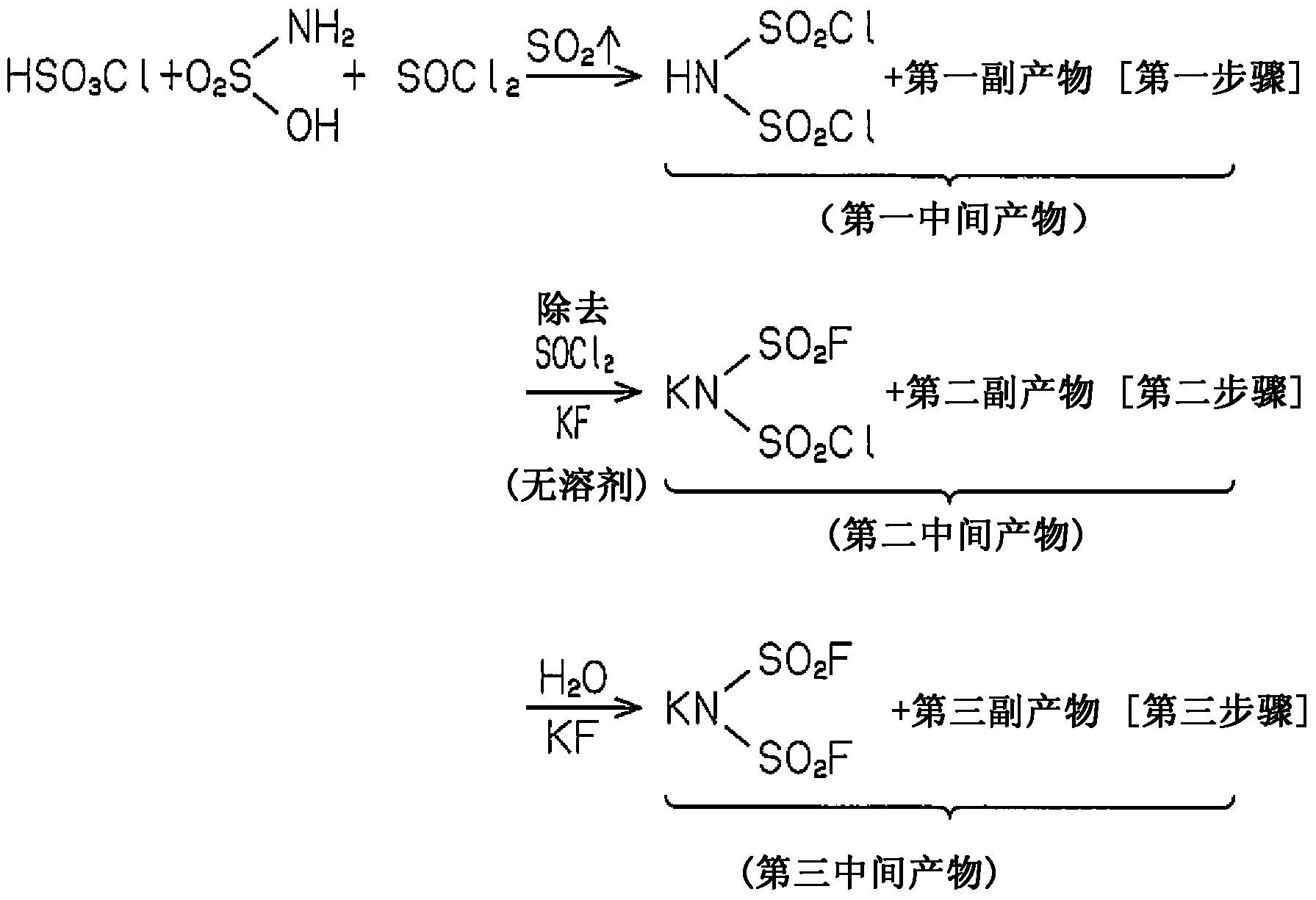

Method for producing imide salt

InactiveCN103889893ALess quantityHigh yieldNitrosyl chlorideImidodisulfonic/nitrilotrisulfonic acidImidePhysical chemistry

A first intermediate product is produced by thermally reacting a mixture of sulfamic acid, a halogenated sulfonic acid, and thionyl chloride. Next, a second intermediate product is produced by reacting the first intermediate product and an alkali metal fluoride (MF). Then, MN(SO2F)2 (M is an alkali metal), which is the target product, is obtained by reacting the second intermediate product and the alkali metal fluoride (MF) in a polar solvent.

Owner:SUMITOMO ELECTRIC IND LTD

A kind of preparation method of bisfluorosulfonimide lithium salt

ActiveCN104925765BGuaranteed purityGuaranteed qualityNitrosyl chlorideAmidosulfonic acidImideHydrogen fluoride

Provided is a preparation method for lithium bis-(fluoro-sulfonyl) imide, comprising the following steps: (1) carrying out fluorination: synthesizing an intermediate bis-(fluoro-sulfonyl) imide by using bis-(chloro-sulfonyl) imide and hydrogen fluoride in presence of a catalyst; and (2) enabling the obtained bis-(fluoro-sulfonyl) imide and alkaline lithium to react, and carrying out solid-liquid separation after the reaction to obtain the lithium bis-(fluoro-sulfonyl) imide. The preparation method is low in cost, fewer in by-products and simple in aftertreatment, and is capable of guaranteeing the quality and purity of products, thereby being suitable for industrial production.

Owner:SHANGHAI CHEMSPEC CORP +1

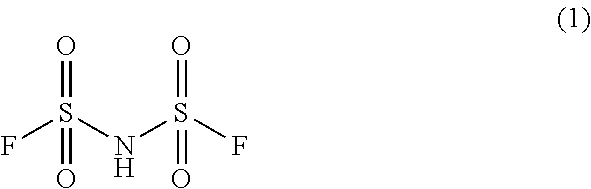

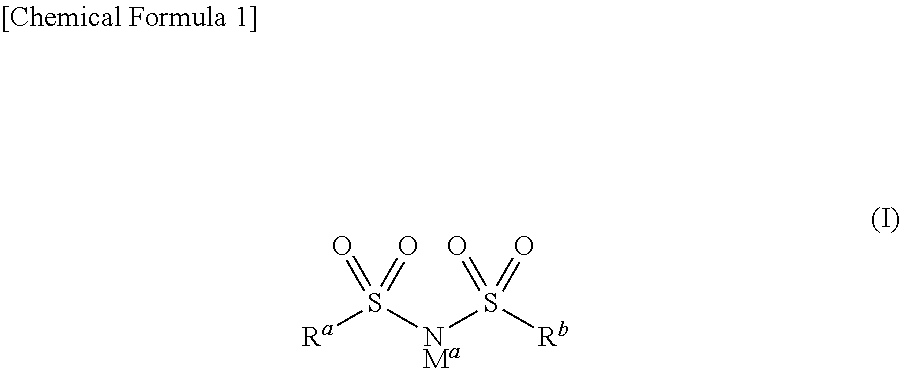

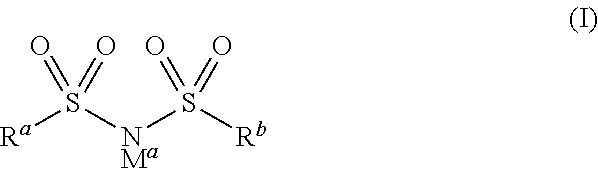

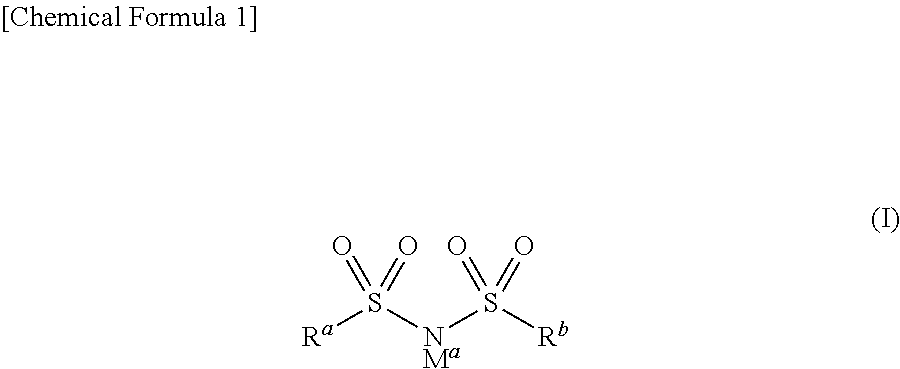

Alkali metal salt of fluorosulfonyl imide, and production method therefor

ActiveUS20170133715A1Improve heat resistanceEasy to removeNitrosyl chlorideElectrolytic capacitorsImidePhysical chemistry

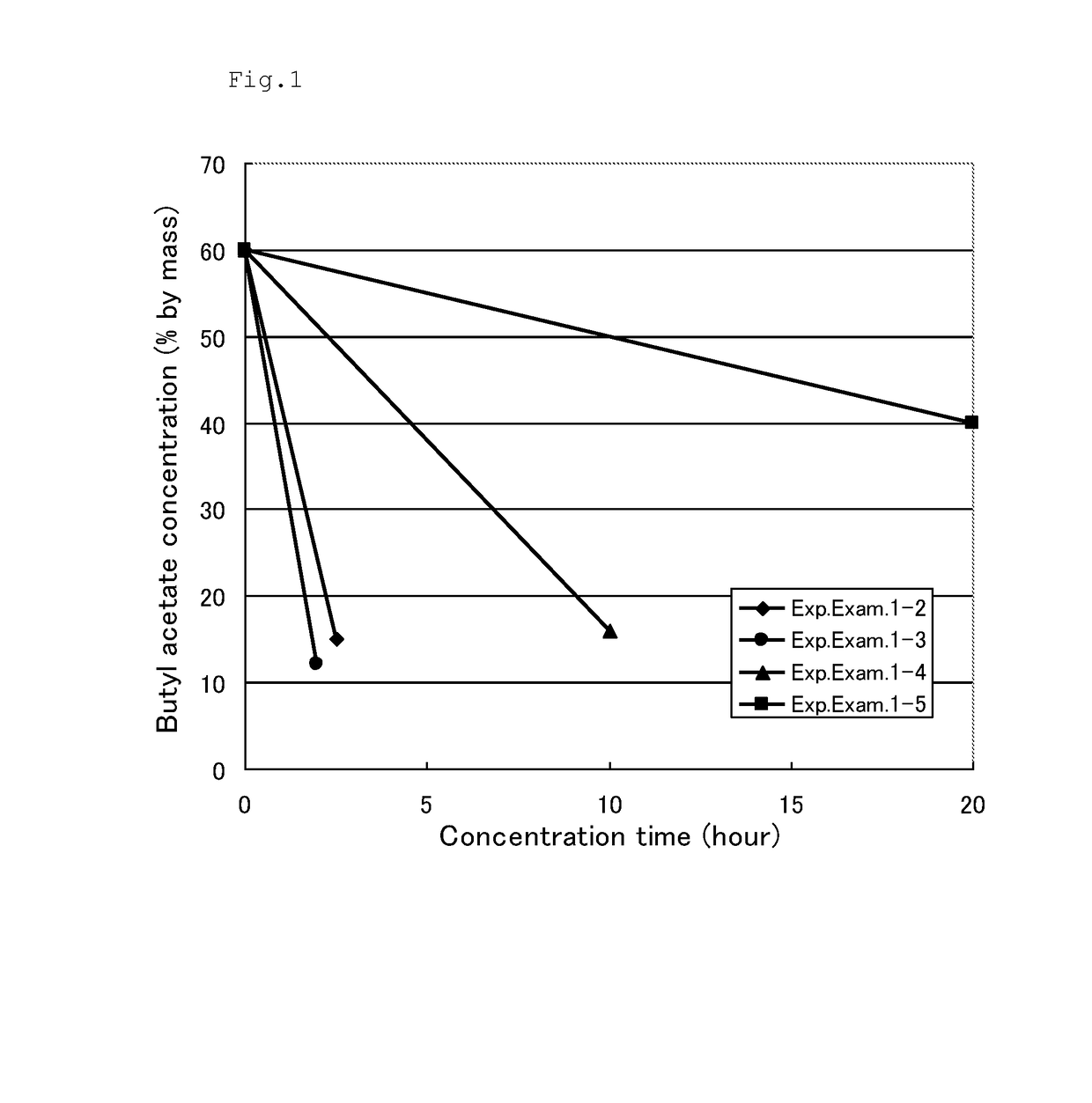

The present invention provides an alkali metal salt of fluorosulfonyl imide having favorable heat resistance and a reduced content of specific impurities and a water content, and provides a method for producing an alkali metal salt of fluorosulfonyl imide, which is capable of easily removing a solvent from a reaction solution. An alkali metal salt of fluorosulfonyl imide of the present invention is represented by the following general formula (I) and has a mass loss rate of 2% or less when the alkali metal salt of fuluorosulufonyl imide is kept at 100° C. for 8 hours under an air current. A method for producing an alkali metal salt of fluorosulfonyl imide of the present invention comprises a step of concentrating a solution of the alkali metal salt of fulorosulfonyl imide by bubbling a gas into a reaction solution containing the alkali metal salt of fulorosulfonyl imide, and / or concentrating a solution of the alkali metal salt of fulorosulfonyl imide by thin layer distillation.

Owner:NIPPON SHOKUBAI CO LTD

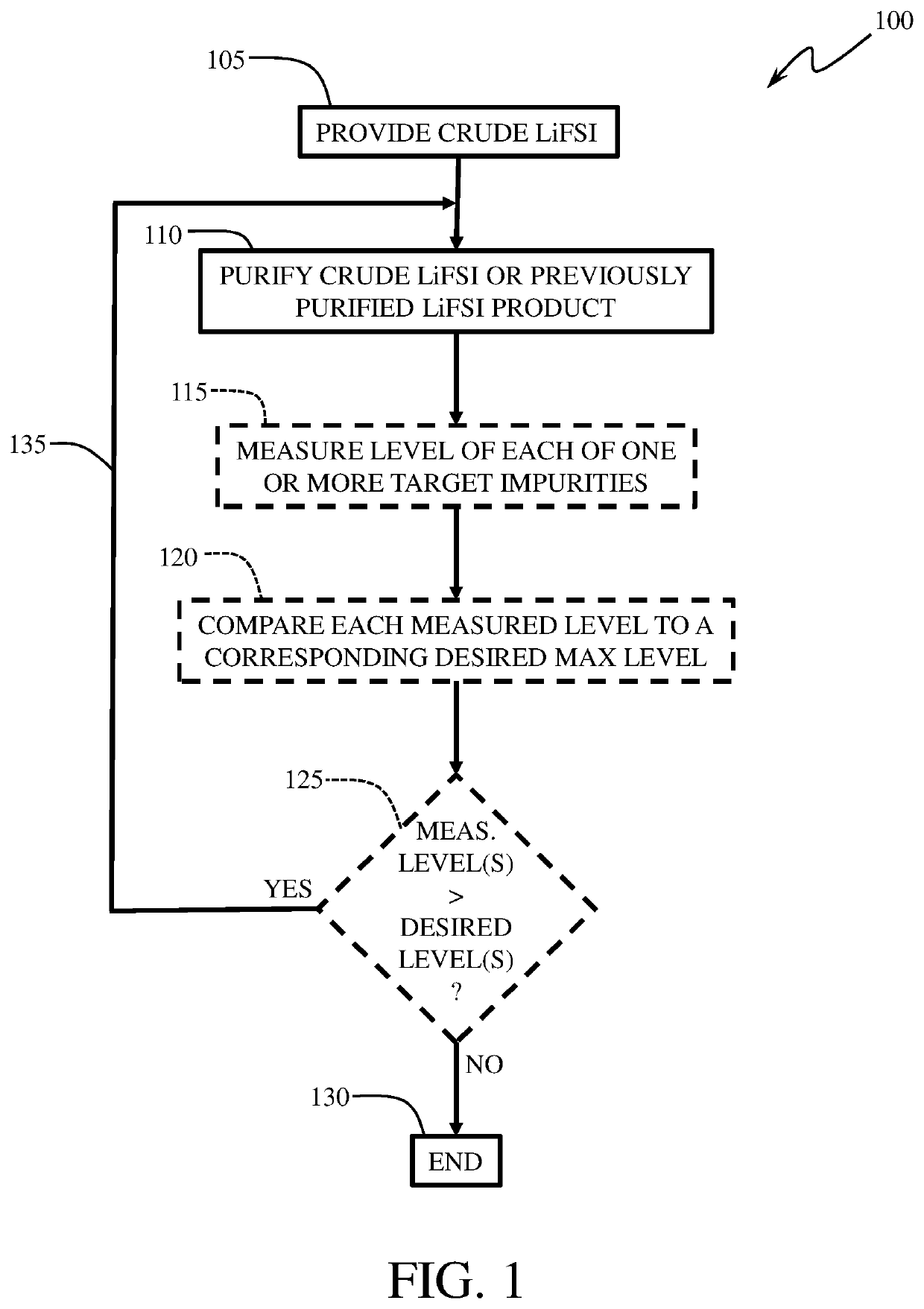

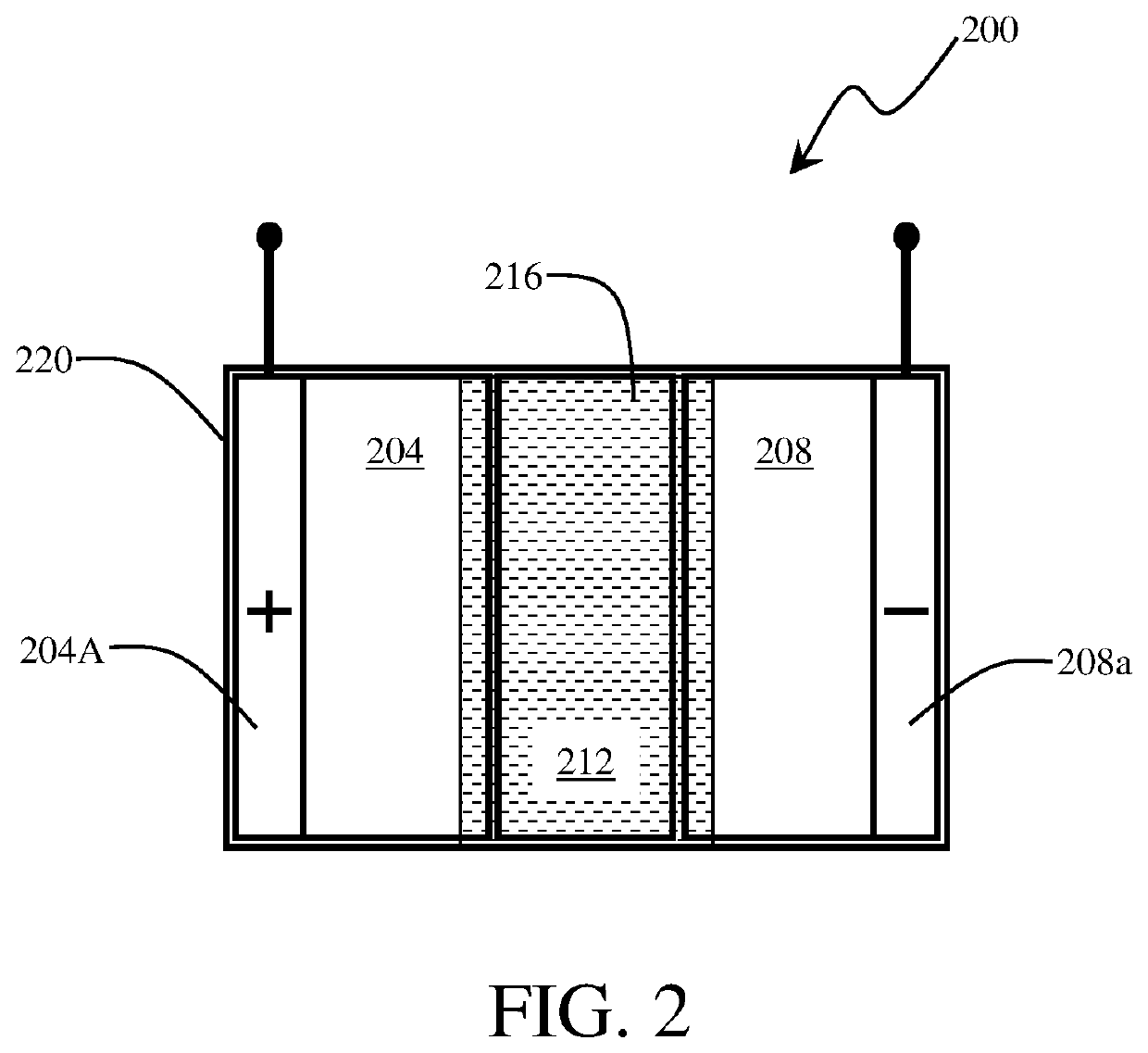

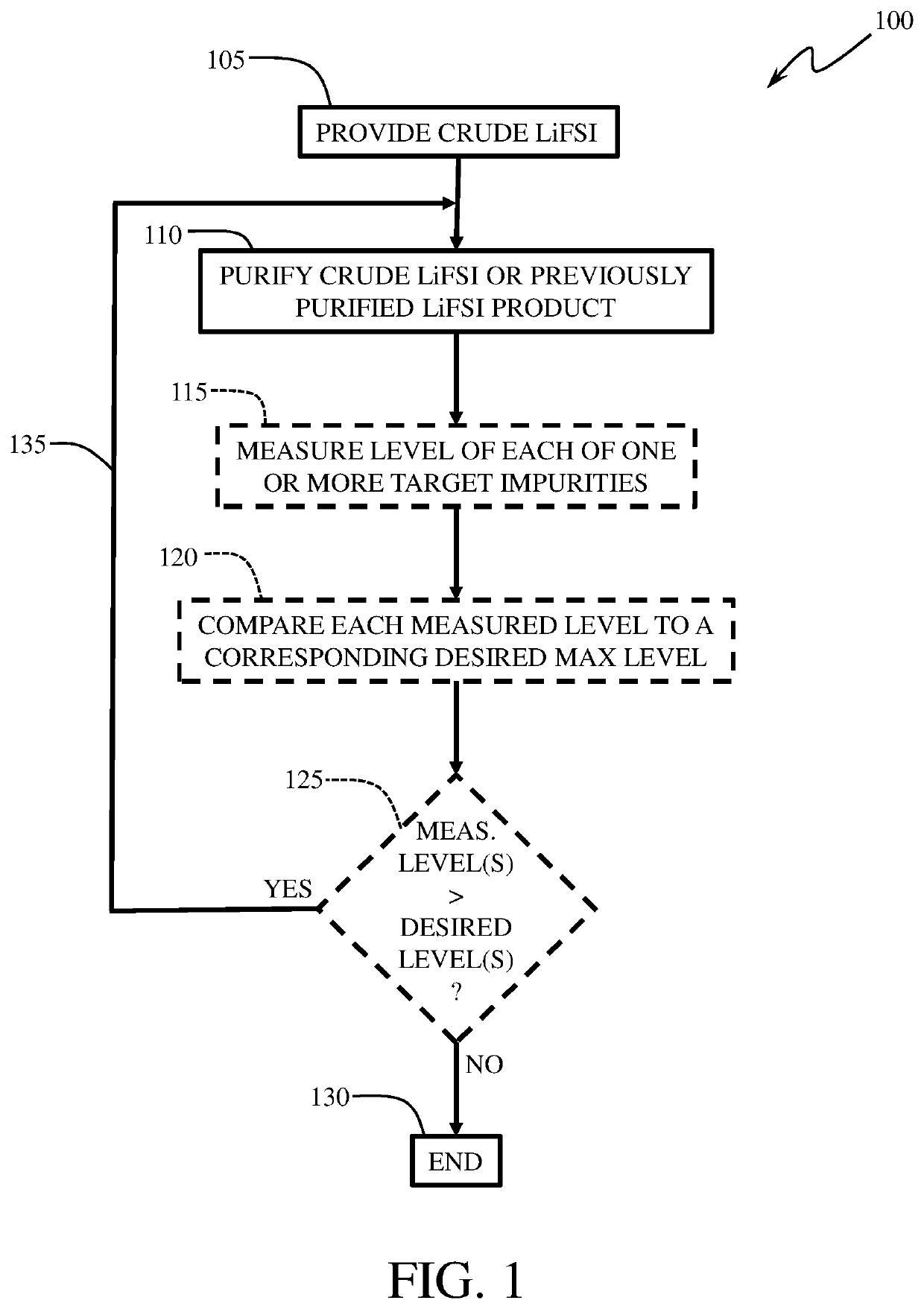

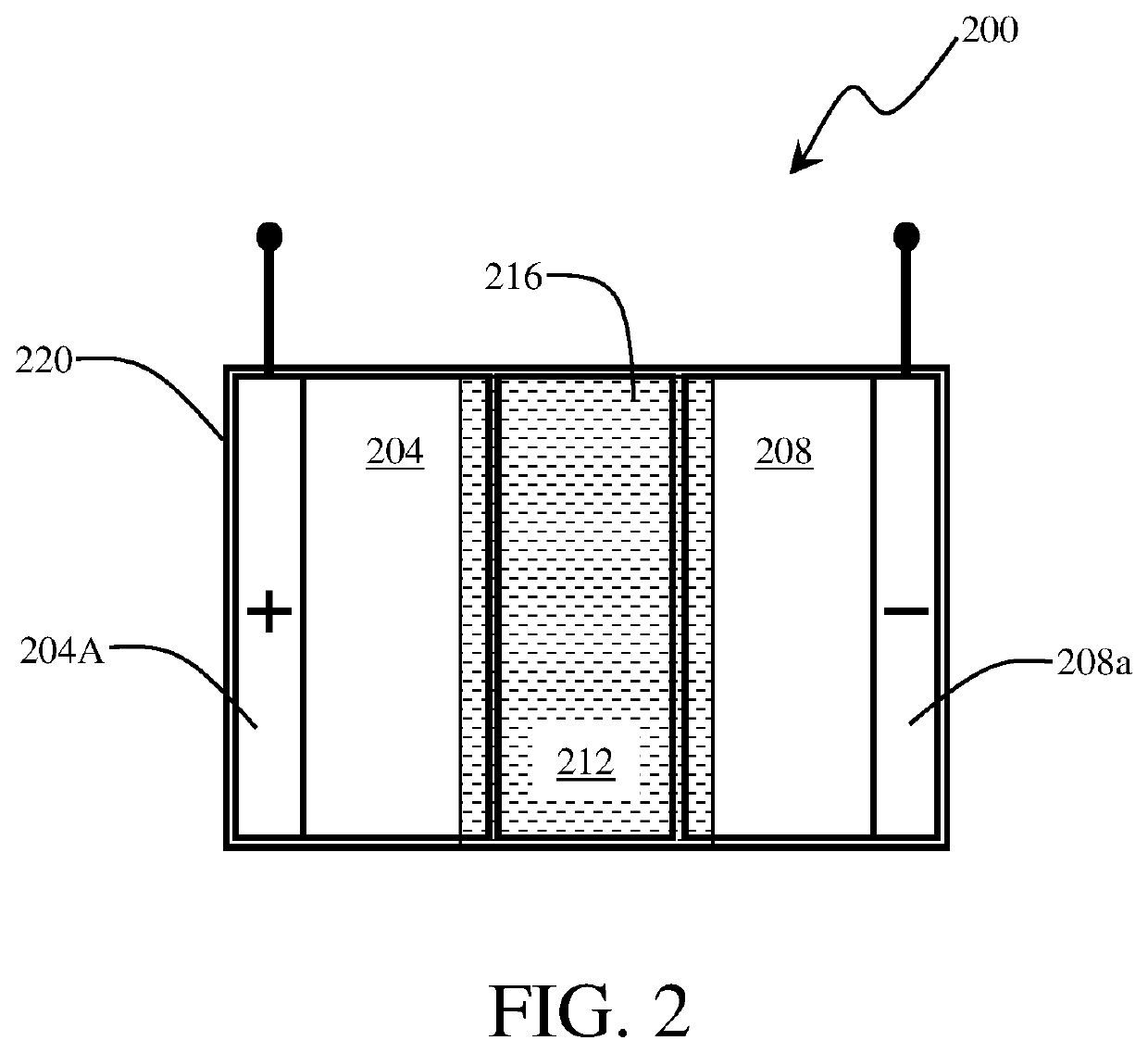

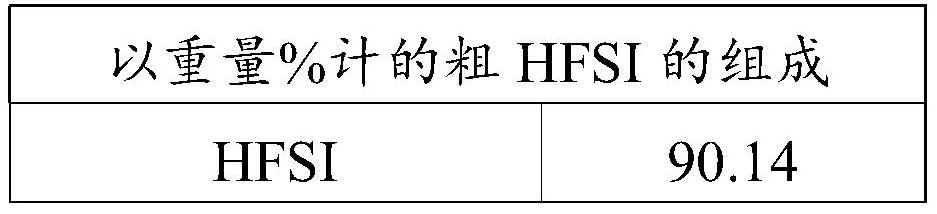

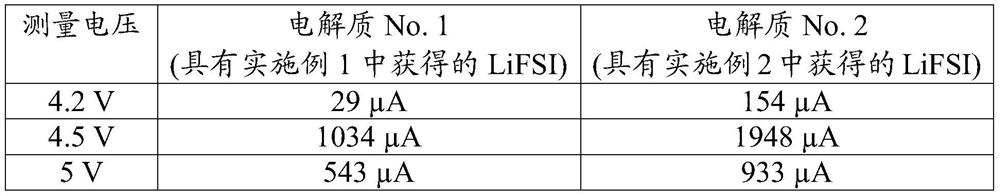

Purified lithium bis(fluorosulfonyl)imide (LiFSI) products, methods of purifying crude LiFSI, and uses of purified LiFSI products

Methods of removing target impurities from a crude lithium bis(fluorosulfonyl)imide (LiFSI) to make a purified LiFSI product. In some embodiments, a purification method includes contacting crude LiFSI with a first anhydrous organic solvent to create a solution containing LiFSI and the target impurity(ies), wherein the LiFSI is soluble and the impurity(ies) is / are substantially insoluble. In some embodiments, a second anhydrous organic solvent is added to the solution to precipitate the target impurity(ies), which is then filtered to obtain a filtrate. In some embodiments, solvent is removed from the filtrate to obtain a solid mass containing LiFSI, which may then be contacted with a third anhydrous organic solvent in which the LiFSI is insoluble. The LiFSI may then be isolated from the third anhydrous organic solvent to obtain the purified LiFSI product. Also disclosed are purified LiFSI products and electrochemical devices utilizing purified LiFSI products, among other things.

Owner:SES HLDG PTE LTD

Method for producing bis(fluorosulfonyl)imide alkali metal salt and method for producing non-aqueous electrolytic solution

ActiveUS20190292054A1Low production costImprove workabilityNitrosyl chlorideOrganic chemistryCyclic etherOxygen

Provided is a method the enables easy production of bis(fluorosulfonyl)imide suitable for a non-aqueous electrolytic solution for a lithium ion secondary battery, etc. The method for producing a bis(fluorosulfonyl)imide alkali metal salt according to the present invention comprises reacting bis(fluorosulfonyl)imide with an alkali metal compound in a reaction solution containing an organic solvent, wherein the organic solvent includes at least one organic solvent (A) selected from the group consisting of carbonate solvents, cyclic ether solvents, linear ether solvents having two or more oxygen atoms in the molecule, cyclic ester solvents, sulfolane solvents, N,N-dimethyl formamide, dimethyl sulfoxide, and N-methyl oxazolidinone.

Owner:NIPPON SHOKUBAI CO LTD

Method for preparing imide salts containing a fluorosulphonyl group

A fluorination process for obtaining fluorinated compounds including at least one fluorosulfonyl group. More particularly, a process for preparing a fluorinated compound of formula (II), including at least one step of reacting a compound of formula (I) with anhydrous hydrofluoric acid in at least one organic solvent, in which R1 is equal to R2 except in the specific case where R1═Cl, then R2═F, and when R1 is equal to R2, R1 and R2 represent an electron-withdrawing group which has a Hammett parameter σp of greater than 0, such as F, CF3, CHF2, CH2F, C2HF4, C2H2F3, C2H3F2, C2F5, C3F7, C3H2F5, C3H4F3, C3HF6, C4F9, C4H2F7, C4H4F5, C5F11, C3F5OCF3, C2F4OCF3, C2H2F2OCF3, CF2OCF3, C6F13, C7F15, C8F17 or C9F19, and M represents a hydrogen atom, an alkali metal, an alkaline-earth metal or a quaternary ammonium cation.

Owner:ARKEMA FRANCE SA

Process for the Synthesis of Fluorinated Conductive Salts for Lithium Ion Batteries

PendingUS20210053913A1Simplify and reduce numberAvoid a lot of timeNitrosyl chlorideCell electrodesImidePhysical chemistry

The invention relates to a new process for the synthesis of fluorinated conductive salts for lithium ion batteries (Li-ion batteries). The said fluorinated conductive lithium ion (Li-ion) battery salts of interest in the framework of the present inventions synthesis process, for example, are Li-ion salts such as LiFSI (lithium bis-(fluoromethanesulfonlyl) imide), LiTFSI (lithium bis-(trifluormethanesulfonlyl) imide), and LiTFSFI (lithium trifluoromethanesulfonylfluorosulfonyl imide), with the formulas as displayed in the Table I herein below. LiFSI, LiTFSI and LiFSTFSI are the most promising conducting salts for Lithium ion batteries and essential for future electromobility.

Owner:FUJIAN YONGJING TECH CO LTD

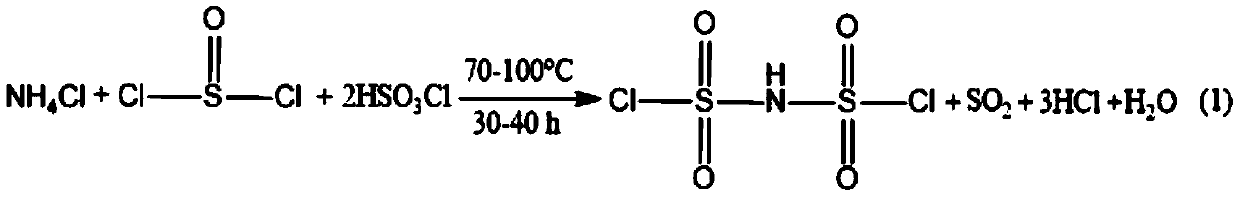

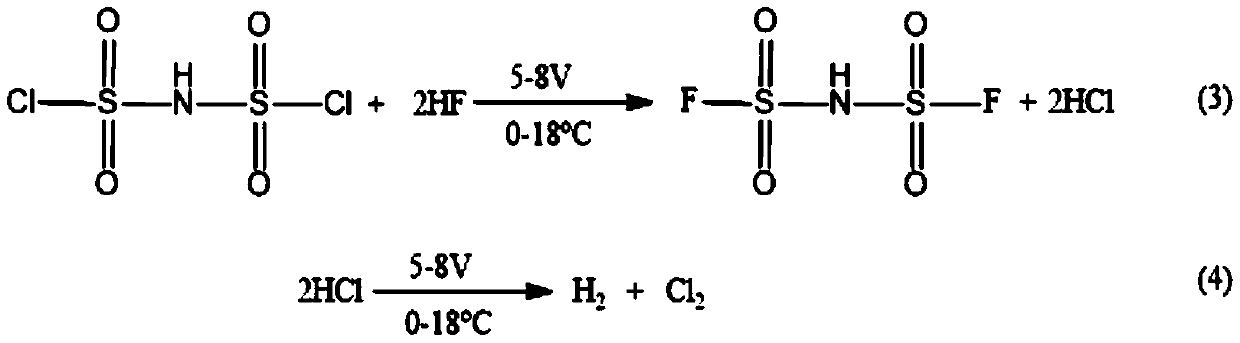

Method for electrochemical synthesis of lithium imidodifluorosulfonate

ActiveCN110745795AHigh purityReduce usageElectrolysis componentsImidodisulfonic/nitrilotrisulfonic acidChemical synthesisPtru catalyst

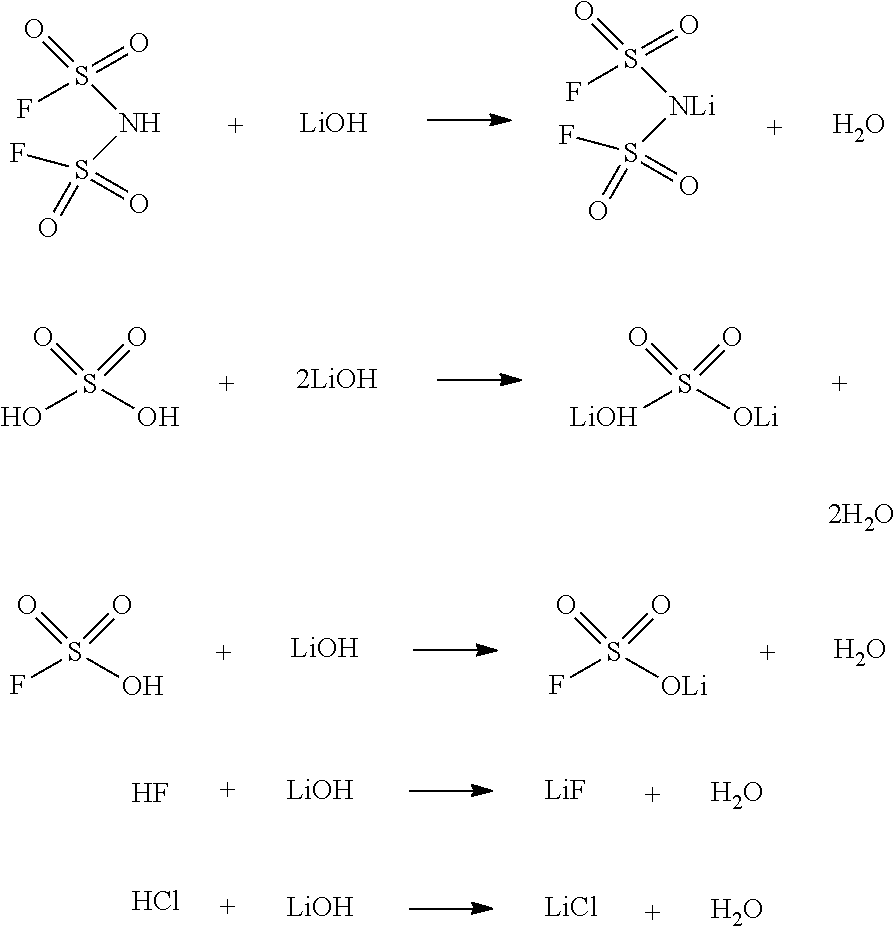

The invention discloses a method for electrochemical synthesis of lithium imidodifluorosulfonate. The preparation method comprises: regulating the temperature of an electrolytic tank to 0-18 DEG C, respectively taking two nickel plates as an anode and a cathode, adding a proper amount of anhydrous hydrofluoric acid into the electrolytic tank, and carrying out electrolysis; after the current in theelectrolytic tank is stabilized, adding a proper amount of imidodichlorosulfonate into the electrolytic tank, and after the imidodichlorosulfonate is dissolved, adjusting the working voltage of the electrolytic tank to 5-8 V; when the current is reduced to below 5 mA, taking out the solution in the electrolytic tank; distilling the solution taken out from the electrolytic tank under normal pressure to separate the imidodifluorosulfonate from the anhydrous hydrofluoric acid, and cooling to obtain the high-purity colorless liquid imidodifluorosulfonate; and reacting with lithium hydroxide, filtering, and re-crystallizing to obtain high-purity lithium imidodifluorosulfonate. According to the invention, water and chlorine ions are electrochemically pre-removed while fluorination is performedthrough electrochemistry without introduction of a metal halide as a catalyst, so that the method is simple in process, low in energy consumption and low in cost, and the prepared LiFSI is high in purity.

Owner:LANZHOU UNIVERSITY

Method for producing a lithium bis(fluorosulfonyl)imide salt

A method for producing a lithium bis(fluorosulfonyl)imide salt F—(SO2)—NLi—(SO2)—F, comprising a step comprising a step of chlorination of sulfamic acid HO—(SO2)—NH2 in order to obtain the bis(chlorosulfonyl)imide Cl—(SO2)—NH—(SO2)—Cl, said step being carried out in a reactor made of a corrosion-resistant material M3, or in a reactor containing a base layer made of a material M1 coated with a surface layer made of a corrosion-resistant material M2.

Owner:ARKEMA FRANCE SA

Purified Lithium Bis(fluorosulfonyl)imide (LiFSI) Products, Methods of Purifying Crude LiFSI, and Uses of Purified LiFSI Products

Methods of removing target impurities from a crude lithium bis(fluorosulfonyl)imide (LiFSI) to make a purified LiFSI product. In some embodiments, a purification method includes contacting crude LiFSI with a first anhydrous organic solvent to create a solution containing LiFSI and the target impurity(ies), wherein the LiFSI is soluble and the impurity(ies) is / are substantially insoluble. In some embodiments, a second anhydrous organic solvent is added to the solution to precipitate the target impurity(ies), which is then filtered to obtain a filtrate. In some embodiments, solvent is removed from the filtrate to obtain a solid mass containing LiFSI, which may then be contacted with a third anhydrous organic solvent in which the LiFSI is insoluble. The LiFSI may then be isolated from the third anhydrous organic solvent to obtain the purified LiFSI product. Also disclosed are purified LiFSI products and electrochemical devices utilizing purified LiFSI products, among other things.

Owner:SES HLDG PTE LTD

Composition of bis(fluorosulfonyl)imide lithium salt

PendingUS20210221685A1Impairs battery performanceImprove performanceNitrosyl chlorideLithium compoundsImideAcetic acid

A composition containing: at least 99.75% by weight of bis(fluorosulfonyl)imide lithium salt; and acetic acid in a content by mass greater than 0 and less than or equal to 400 ppm. A process for preparing the composition, including a) step of preconcentrating a composition C1 including an organic solvent OS1, water and bis(fluorosulfonyl)imide salt, to give a composition C2 including: the lithium salt of bis(fluorosulfonyl)imide in a content ranging from 35% to 50% relative to the total weight of composition C2; water in a mass content of less than or equal to 500 ppm relative to the total mass of composition C2; said preconcentration step being performed at a temperature of less than or equal to 50° C.; b) a step of concentrating composition C2; c) an optional step of crystallizing the composition obtained in step b).

Owner:ARKEMA FRANCE SA

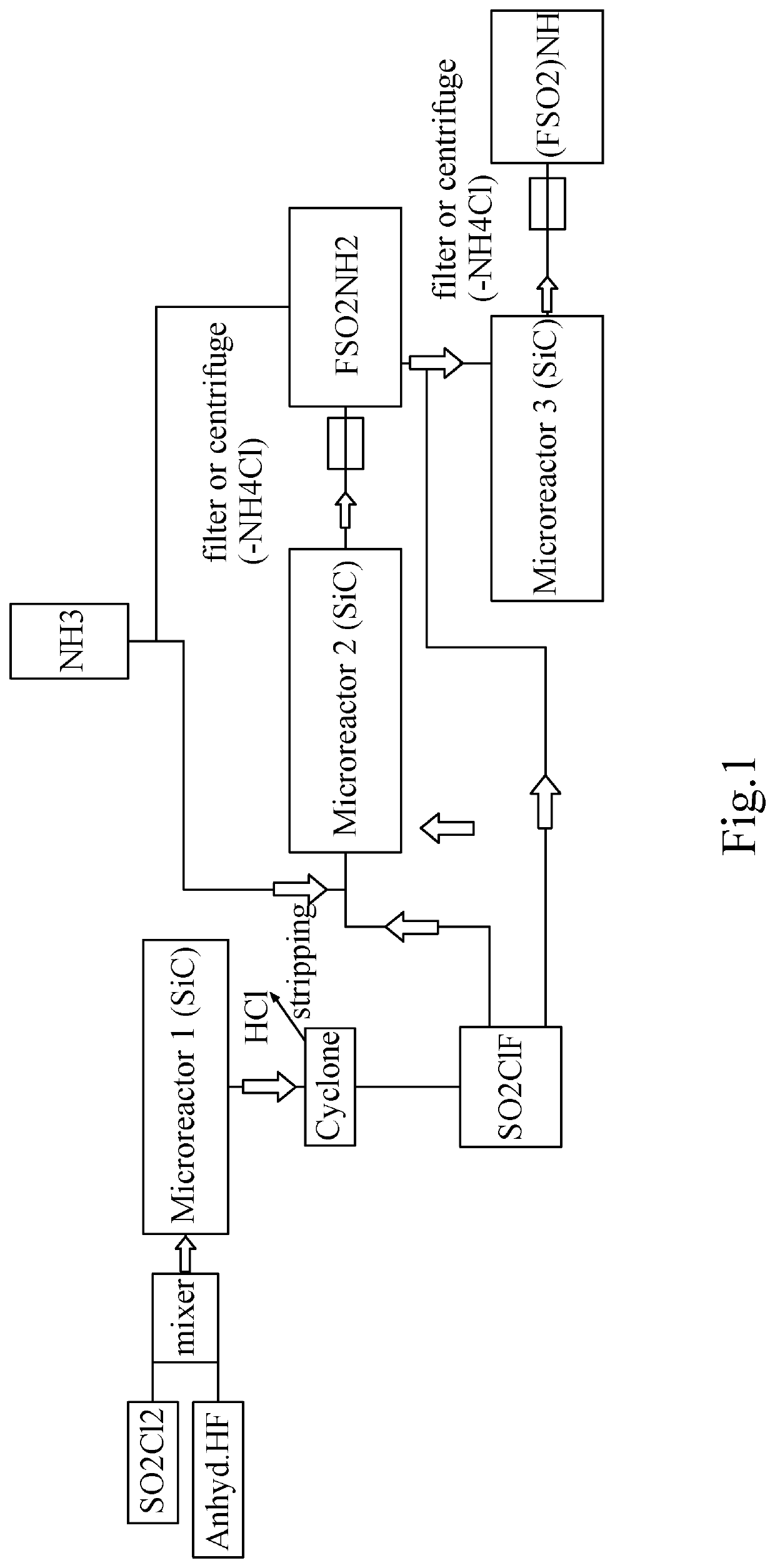

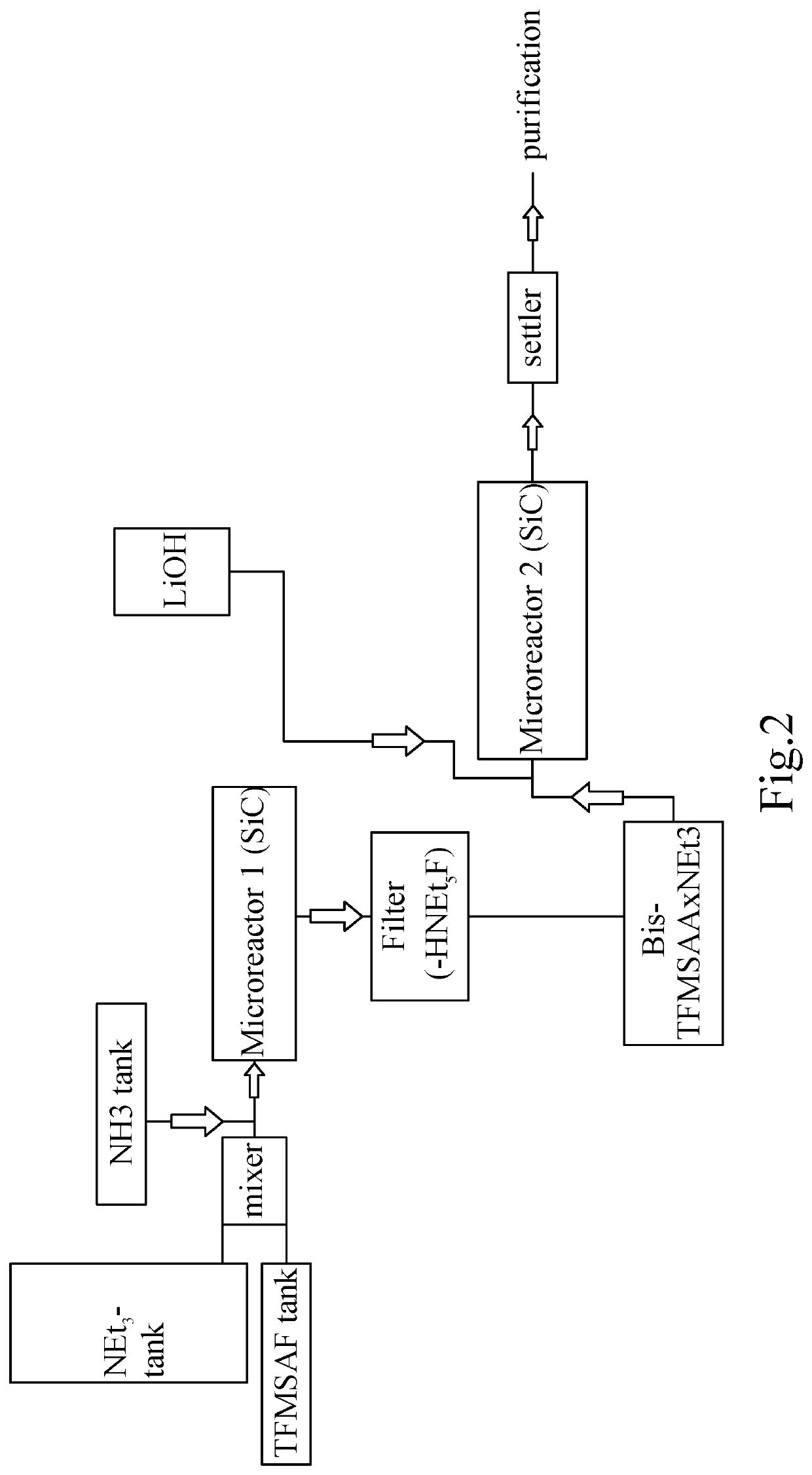

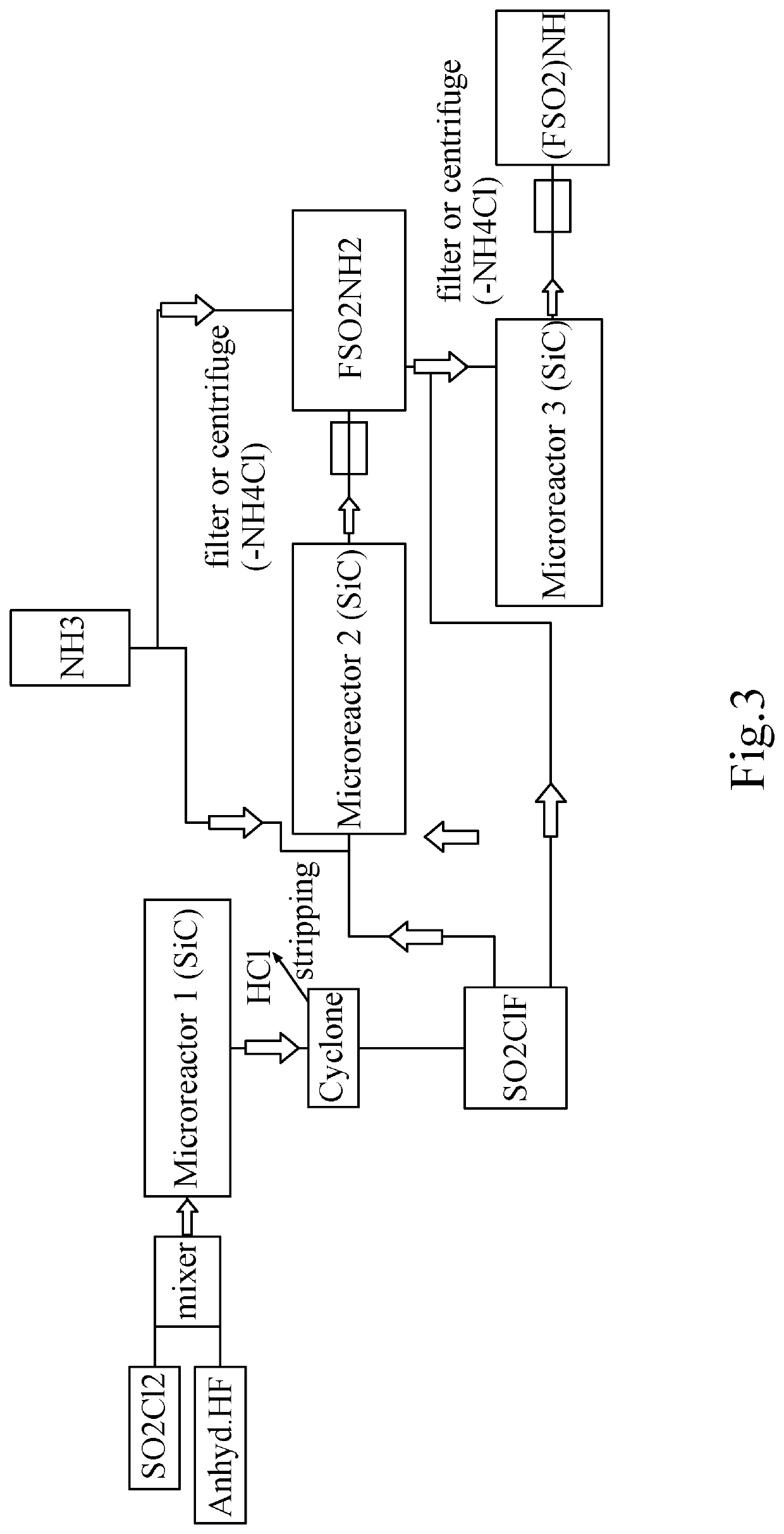

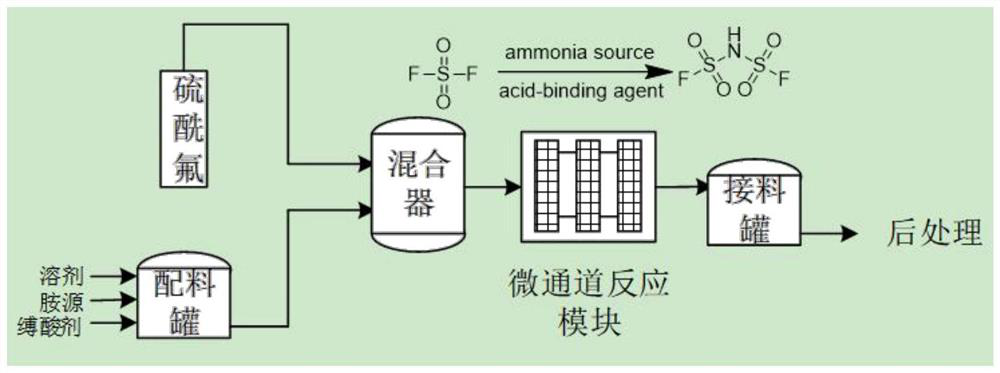

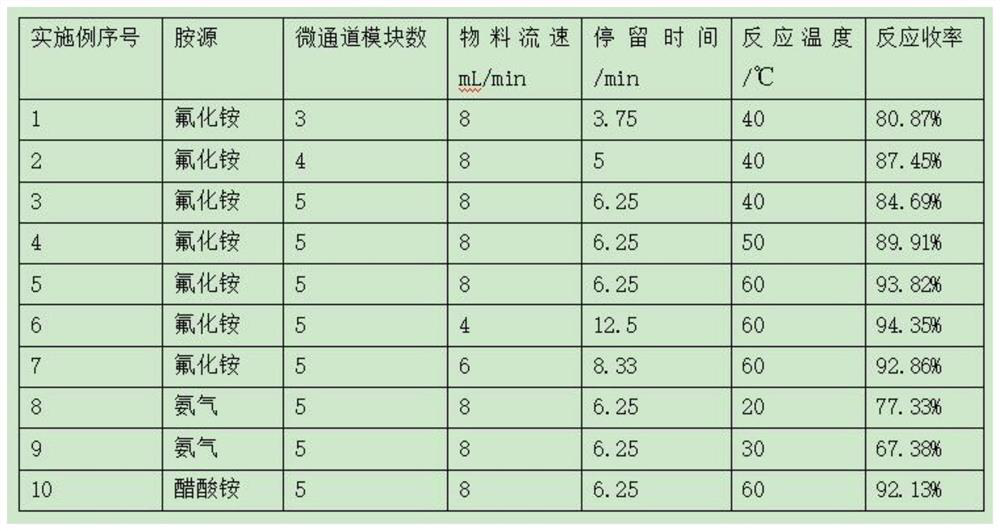

Method for preparing imidodisulfuryl fluoride through micro-channel reactor

PendingCN112897488AEasy to operateSimple structureChemical/physical/physico-chemical microreactorsImidodisulfonic/nitrilotrisulfonic acidCarbide siliconPlunger pump

The invention discloses a method for preparing imidodisulfuryl fluoride through micro-channel reactor. The method comprises the following operation steps: S1, preparation of materials: preparing a certain amount of ammonia gas, an organic solvent, ammonium salt, an organic alkali acid-binding agent, sulfuryl fluoride gas, alkali and acid, and preparing a plunger pump, a gas flowmeter, a micro-mixer, a silicon carbide micro-channel reactor, a rectification device and the like; S2, preparation of a reaction solution: introducing the ammonia gas into the organic solvent or dissolving ammonium salt in the organic solvent, and adding the organic alkali acid-binding agent to prepare a solution; and S3, gas-liquid mixing: adding the solution obtained in the step S2 and sulfuryl fluoride gas into a micro-mixer through the plunger pump and the gas flowmeter respectively. The method for preparing imidodisulfuryl fluoride through the micro-channel reactor is realized through the mature silicon carbide micro-channel reactor, is safe, short in reaction time, stable and reliable in process and simple to operate, does not have the problem of equipment corrosion, and brings better application prospects.

Owner:常州高优纳米新材料有限公司

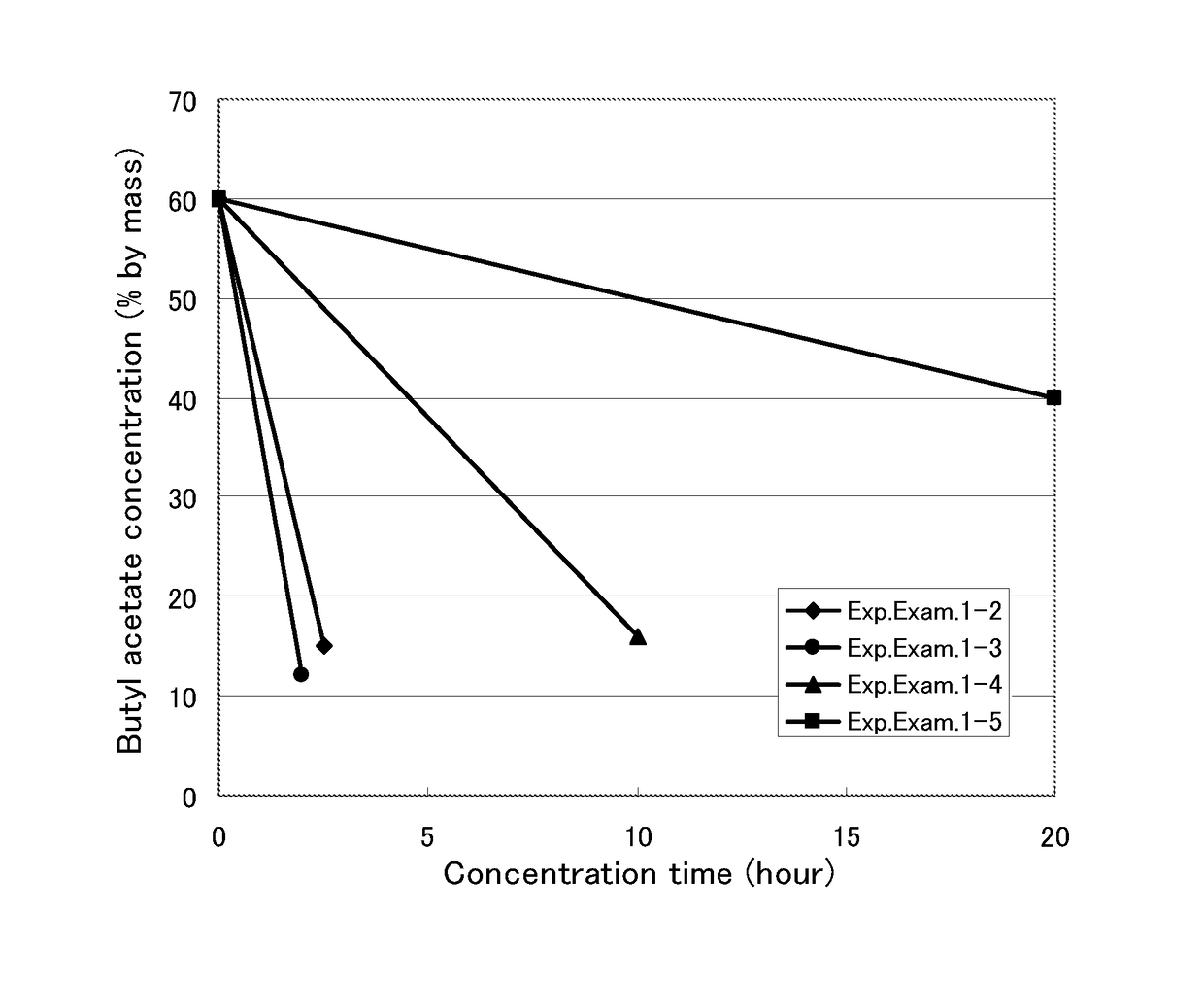

Alkali metal salt of fluorosulfonyl imide, and production method therefor

ActiveUS9985317B2Improve heat resistanceEasy to removeNitrosyl chlorideElectrolytic capacitorsImideDistillation

The present invention provides an alkali metal salt of fluorosulfonyl imide having favorable heat resistance and a reduced content of specific impurities and a water content, and provides a method for producing an alkali metal salt of fluorosulfonyl imide, which is capable of easily removing a solvent from a reaction solution. An alkali metal salt of fluorosulfonyl imide of the present invention is represented by the following general formula (I) and has a mass loss rate of 2% or less when the alkali metal salt of fuluorosulufonyl imide is kept at 100° C. for 8 hours under an air current. A method for producing an alkali metal salt of fluorosulfonyl imide of the present invention comprises a step of concentrating a solution of the alkali metal salt of fulorosulfonyl imide by bubbling a gas into a reaction solution containing the alkali metal salt of fulorosulfonyl imide, and / or concentrating a solution of the alkali metal salt of fulorosulfonyl imide by thin layer distillation.

Owner:NIPPON SHOKUBAI CO LTD

Method for preparing bis(fluorosulfonyl)imide acid and salts thereof

The invention relates to a method for preparing bis(fluorosulfonyl)imide acid. The method includes the reaction of sulphamic acid or one of the salts thereof with a halogenosulfuric acid and at least one fluorinating agent selected from SOF2, F-SO2-F and SF4, and the subsequent recovery of bis(fluorosulfonyl)imide acid. The invention also relates to a method for producing salts of bis(fluorosulfonyl)imide from the bis(fluorosulfonyl)imide acid produced.

Owner:RHODIA OPERATIONS SAS

Method for producing alkali salts of bis(fluorosulfonyl)imide

PendingCN114040888AShort stayHigh purityNitrosyl chlorideImidodisulfonic/nitrilotrisulfonic acidImideAlkali salt

The invention relates to a method for producing an alkali salt of bis(fluorosulfonyl)imide, comprising the step of reacting, within a reaction medium, an ammonium salt of bis(fluorosulfonyl)imide with an alkali agent, to produce alkali salt of bis(fluorosulfonyl)imide and ammonia; and simultaneously contacting the reaction medium with an inert gas stream to strip out ammonia.

Owner:SOLVAY SA

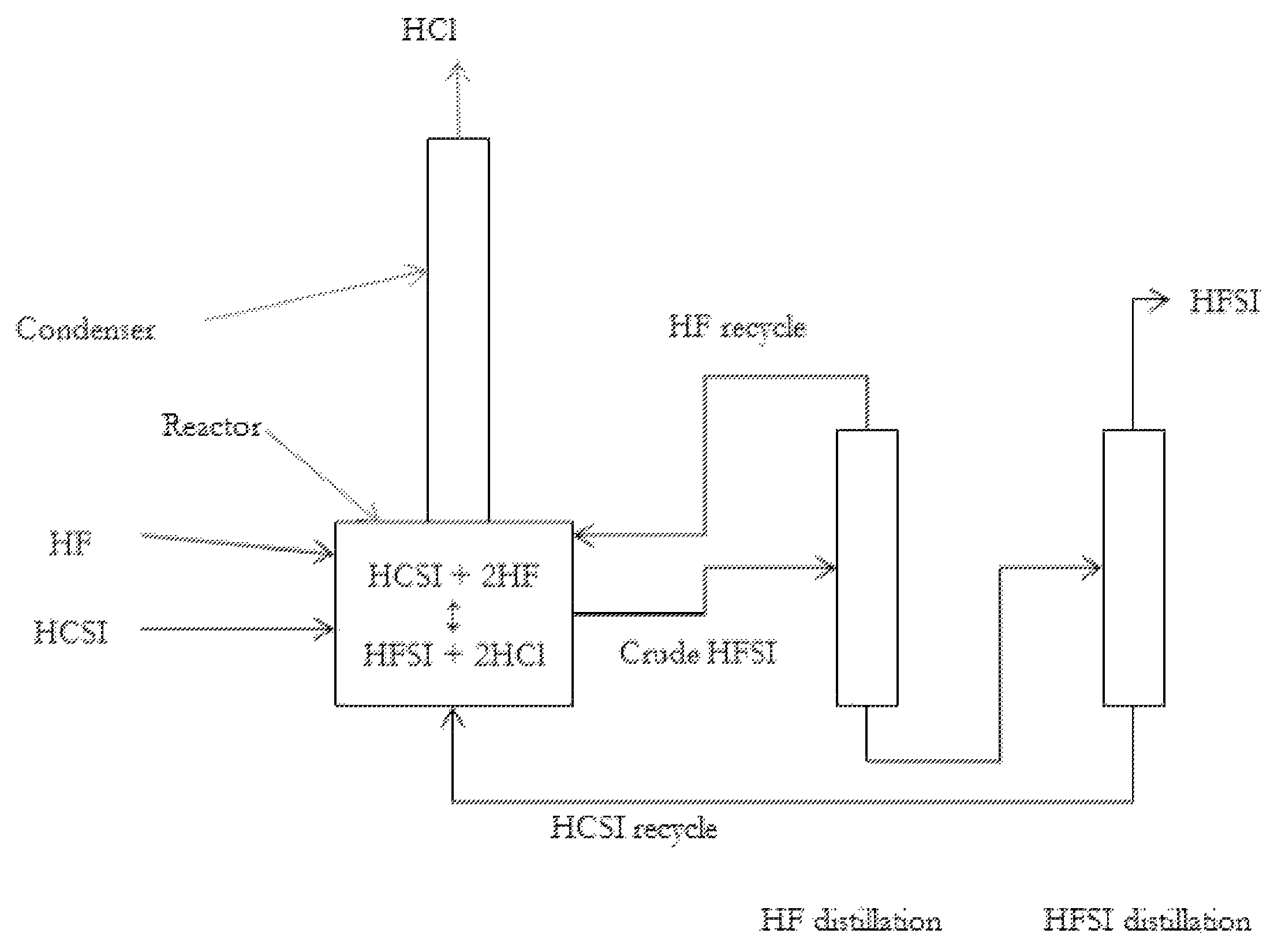

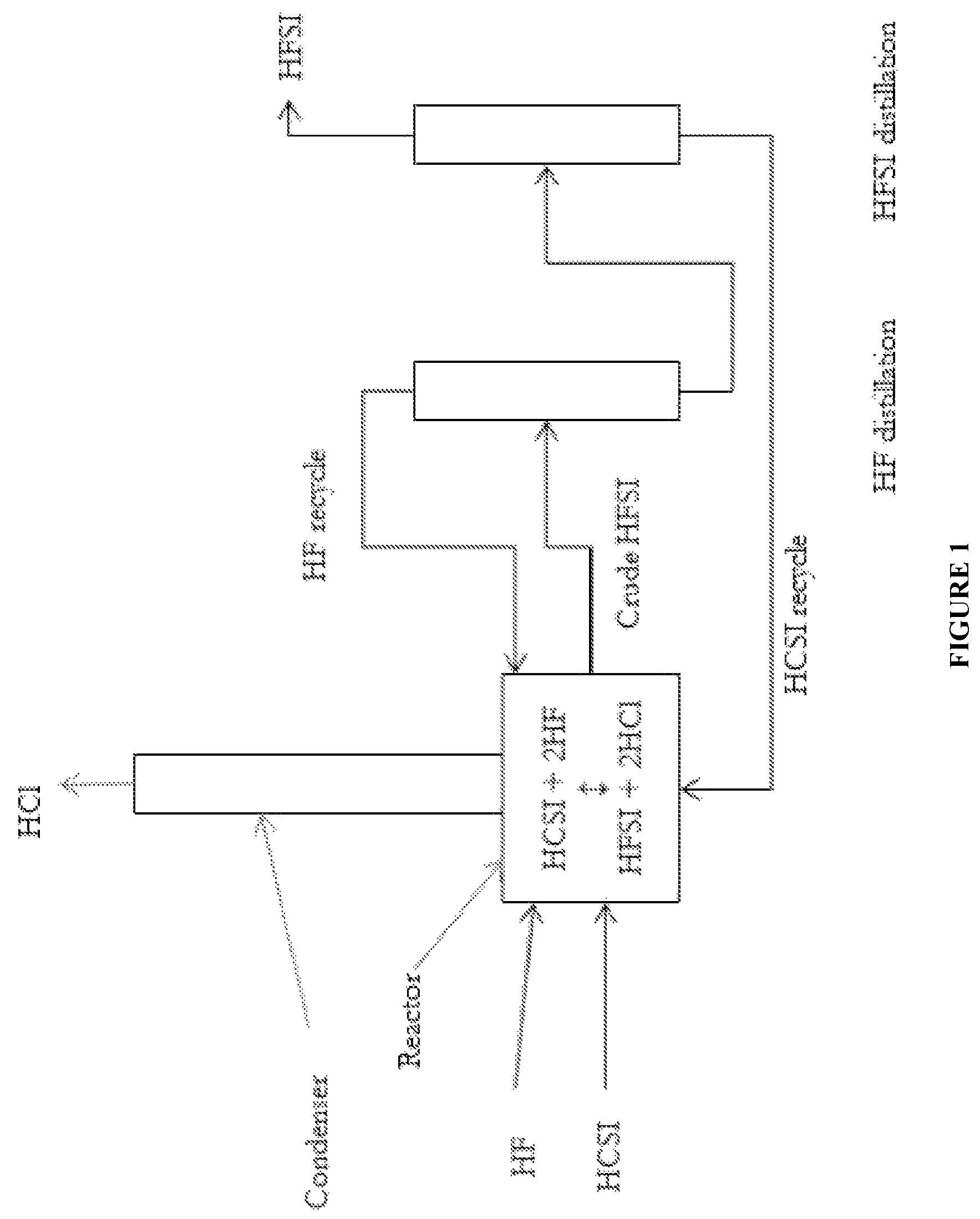

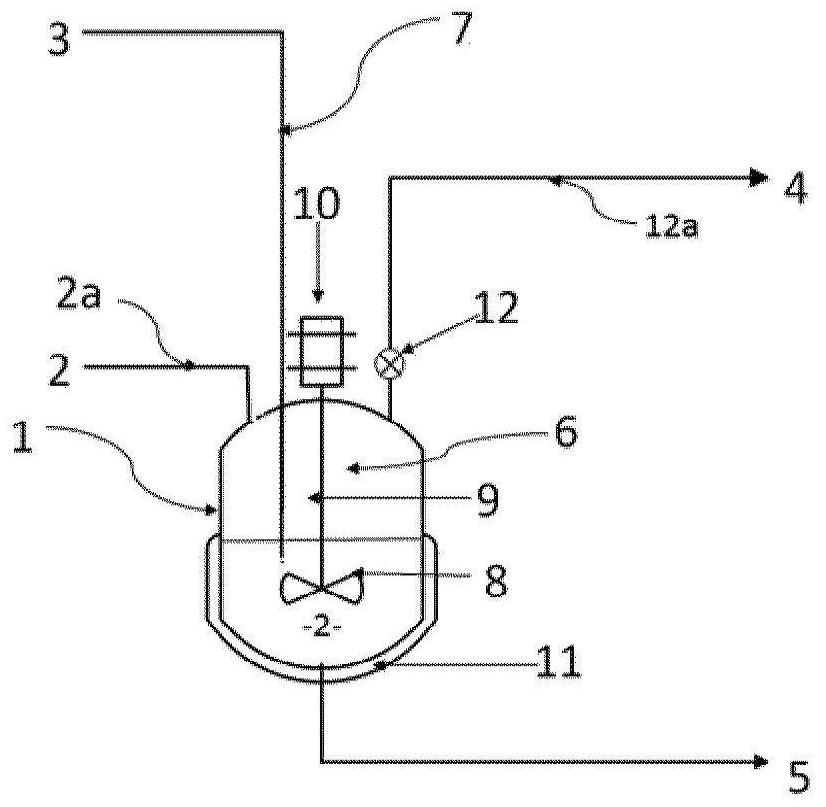

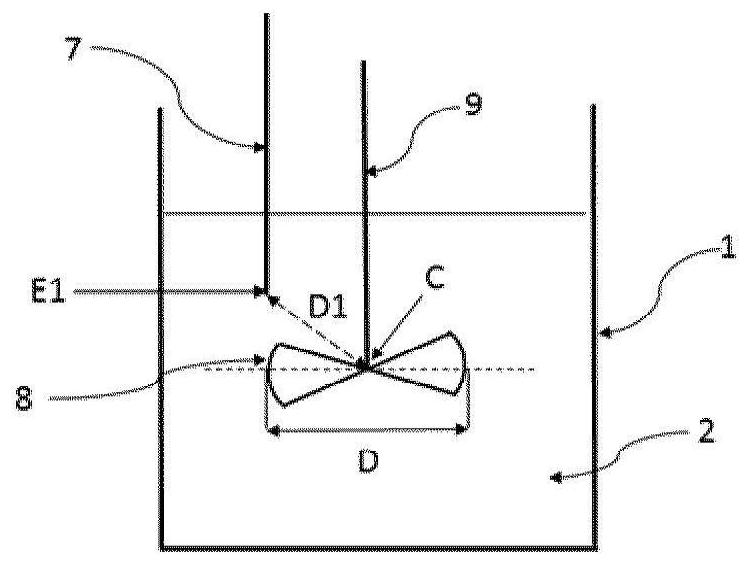

Process for preparing bis(fluorosulfonyl) imide

The invention relates to a process for preparing bis(fluorosulfonyl) imide, comprising the steps of: i) providing a stream A1 containing HF and a reactor containing a liquid phase A2 that contains bis(chlorosulfonyl) imide; ii) in said reactor, bringing said liquid phase A2 into contact with said stream A1 to produce bis(fluorosulfonyl) imide, said process being characterized in that said stream A1 is injected into said liquid phase A2.

Owner:ARKEMA FRANCE SA

Composition of bis(fluorosulfonyl)imide lithium salt

The invention relates to a composition containing: at least 99.75% by weight of bis(fluorosulfonyl)imide lithium salt; and acetic acid in a content by mass strictly greater than 0 and less than or equal to 400 ppm.

Owner:ARKEMA FRANCE SA

Method for producing lithium bis(fluorosulfonyl)imide salt

The present invention relates to a method for producing bis (fluorosulfonyl) imide salt F (SO2) NLi (SO2) F, comprising a step (a) of chlorinating sulfamate HO (SO2) NH2 to obtain bis (chlorosulfonyl)imide Cl (SO2) NH (SO2) Cl. The step (a) is carried out in a reactor made of a corrosion-resistant material M3, or in a reactor comprising a base layer made of a material M1 coated with a surface layer made of a corrosion-resistant material M2.

Owner:ARKEMA FRANCE SA

Preparation method of lithium bisfluorosulfonyl imide

Owner:浙江盛美リ電材料有限公司

A new process for bisfluorosulfonyl imide salt

ActiveCN109721037BStable in natureHigh purityNitrosyl chlorideOrganic chemistryEconomic benefitsCaustic substance

Owner:SHANGHAI ROLECHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com