Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

394 results about "Caustic substance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Caustic substances can be found in a variety of household products, from laundry detergent to batteries. Dish washing detergent, laundry soap and drain cleaners all contain sulfuric acid. Even some antibacterial soaps contain this caustic substance.Ingestion of or exposure to caustic substances can lead to severe injuries.

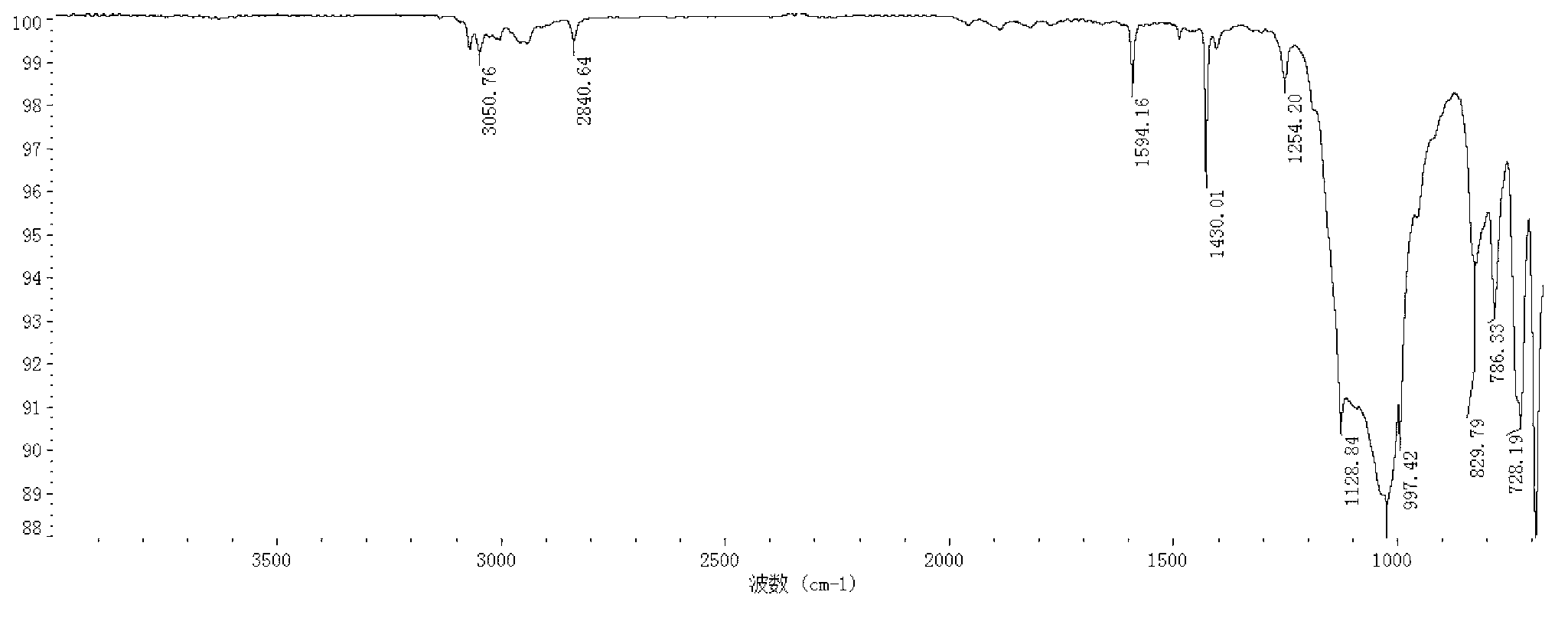

Method for preparing 4-nitrodiphenylamine and 4-nitrosodiphenylamine from carbanilide

InactiveUS6137010AHigh yieldImprove responseOrganic compound preparationAmino preparation by hydrogen substitutionAniline4-aminodiphenylamine

This invention relates to a process for preparing 4-nitrodiphenylamine and 4-nitrosodiphenylamine to be used for 4-aminodiphenylamine as an intermediate of antiozonant, wherein carbanilide is reacted with nitrobenzene in the presence of an appropriate base, while simultaneously adding aniline to the mixture so as to regenerate some amounts of carbanilide as a starting material. According to this invention, 4-nitrodiphenylamine and 4-nitrosodiphenylamine can be prepared in a higher selectivity and conversion rate via a continuous reaction by recycling carbanilide, a starting material, while adding a certain amount of aniline during the process. Further, the amount of waste water can be significantly reduced compared to the conventional method without any corrosive materials harmful to the environment.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

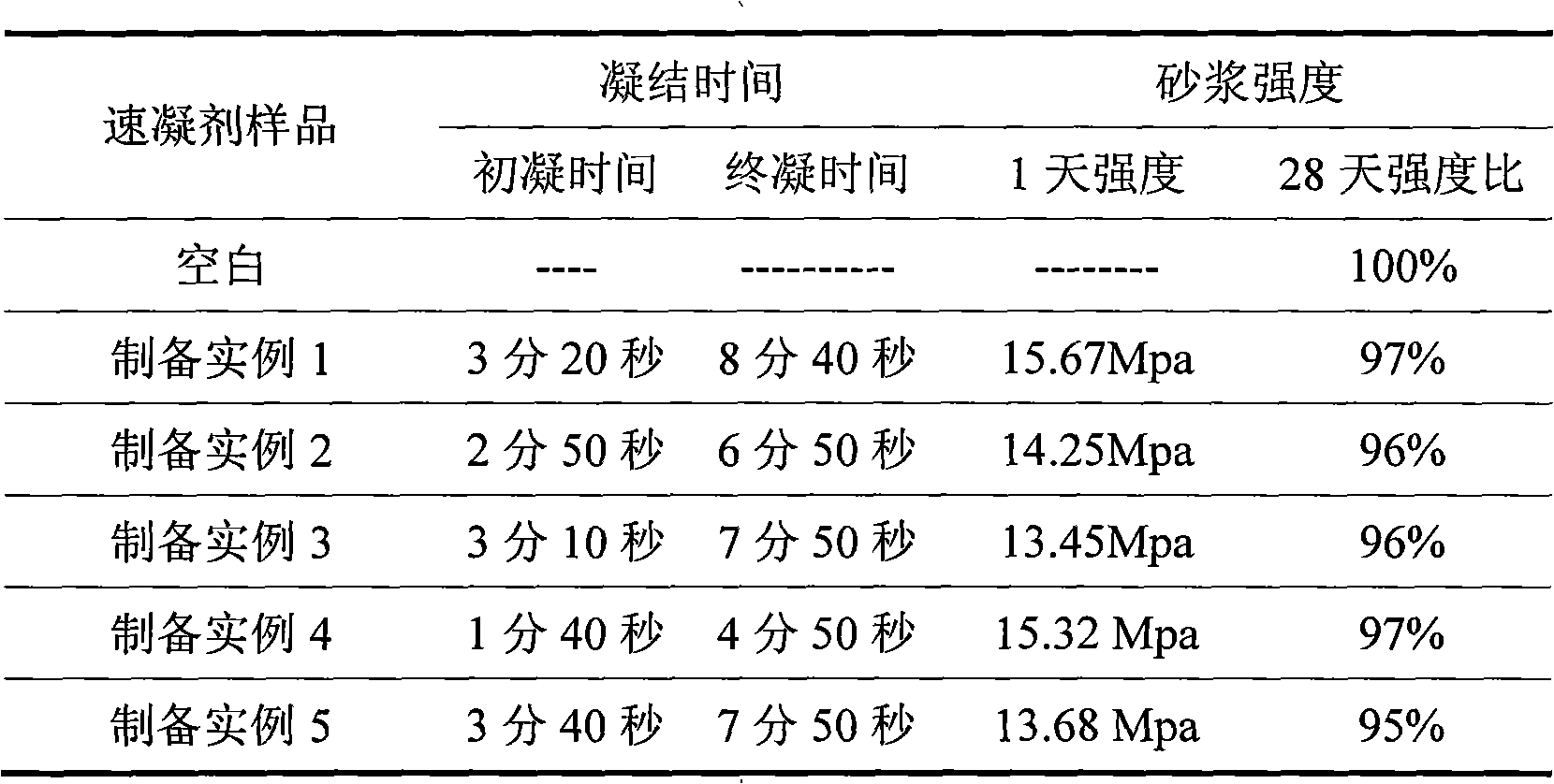

Alkali-free liquid setting accelerator

ActiveCN101648785ANo lossNo irritating smellUnderground chambersBuilding material handlingO-Phosphoric AcidSulfate radicals

The invention discloses an alkali-free liquid setting accelerator which is prepared from the following components by weight percent: 18-40% of hydroxycarboxylic acid, 1-5% of phosphoric acid, 15-30% of aluminium hydroxide, 0-5% of alkylol amine, 0.01-0.2% of defoaming agent and the balance water. The alkali-free liquid setting accelerator of invention does not contain alkali metal ions, sulfate ions and other corrosive materials, is safe to use and has no bad effect on the durability of sprayed concrete, thus being capable to be used in the construction of sprayed concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

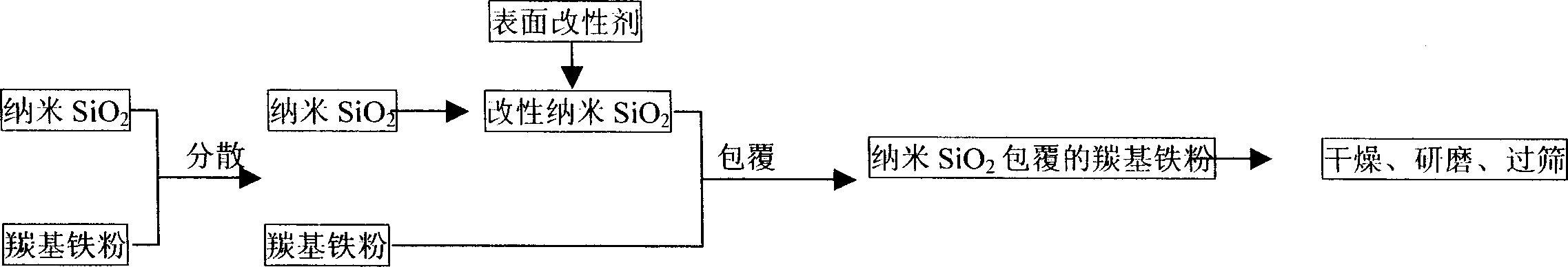

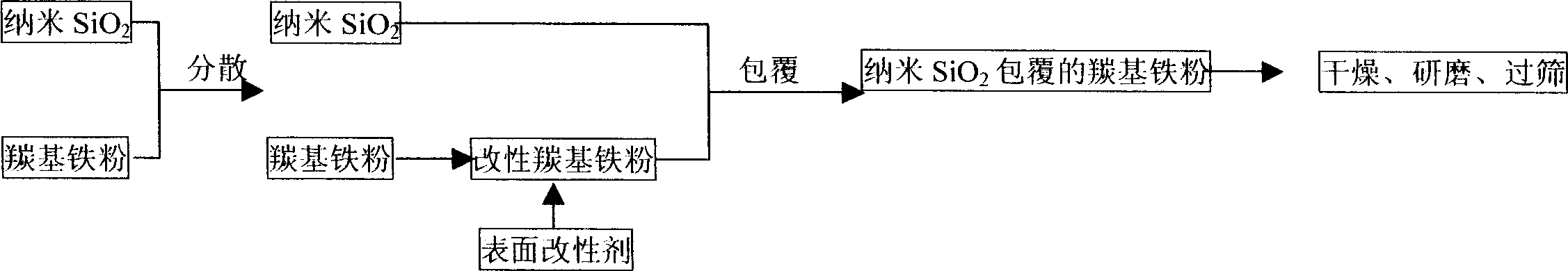

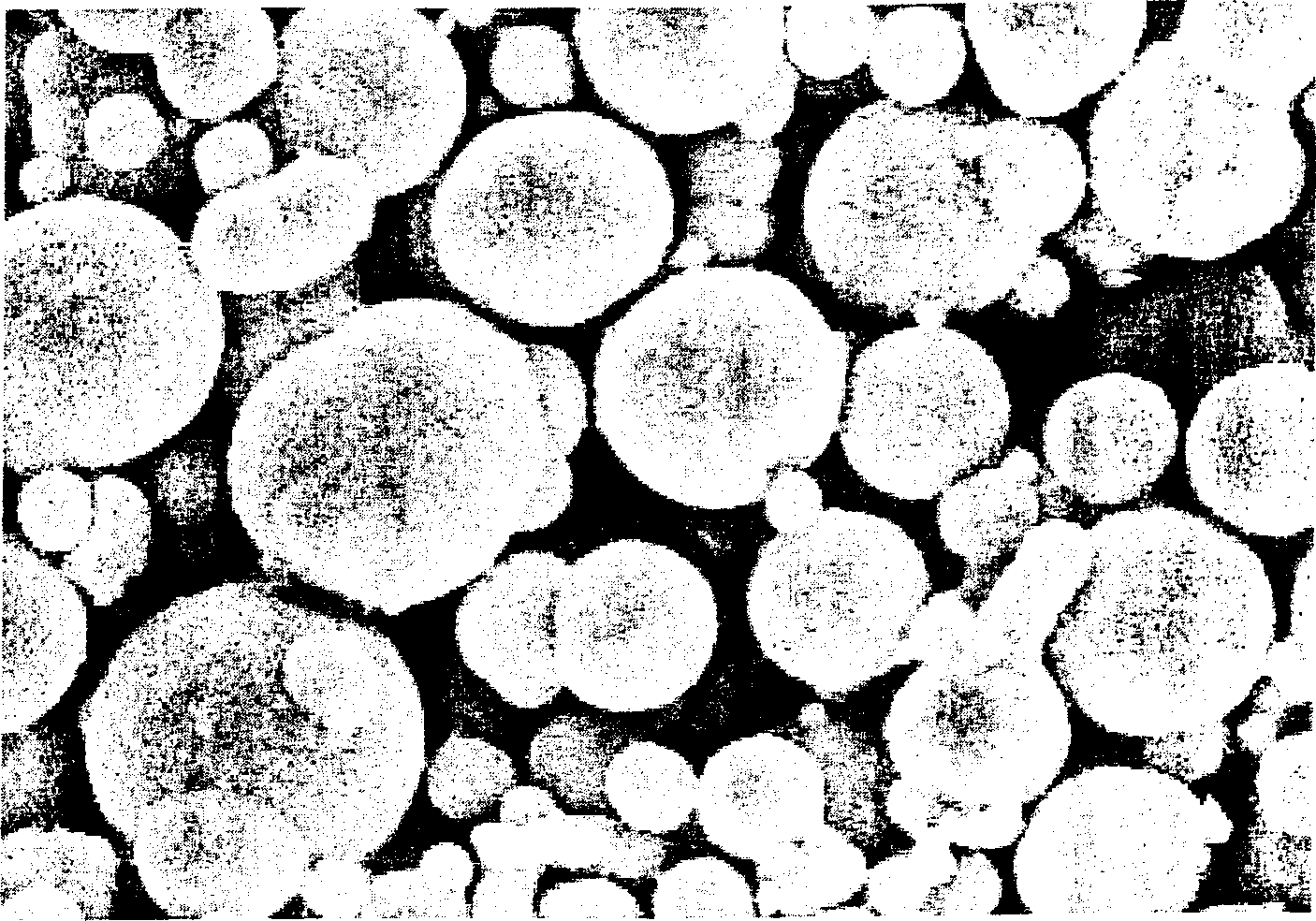

Production of nano-SiO2 for coating carbonyl iron powder

A process for preparing the nano-SiO2 coated carbonyl iron particles includes such steps as dispersing SiO2 nanoparticles and carbonyl iron particles by grinding, modifying the surface polarity of both particles by soluble caustic substance, coating the SiO2 nanoparticles on the surface of each carbonyl iron particle by physical adsorption, backing in vacuum or protective atmosphere, grinding, sieving and packing.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

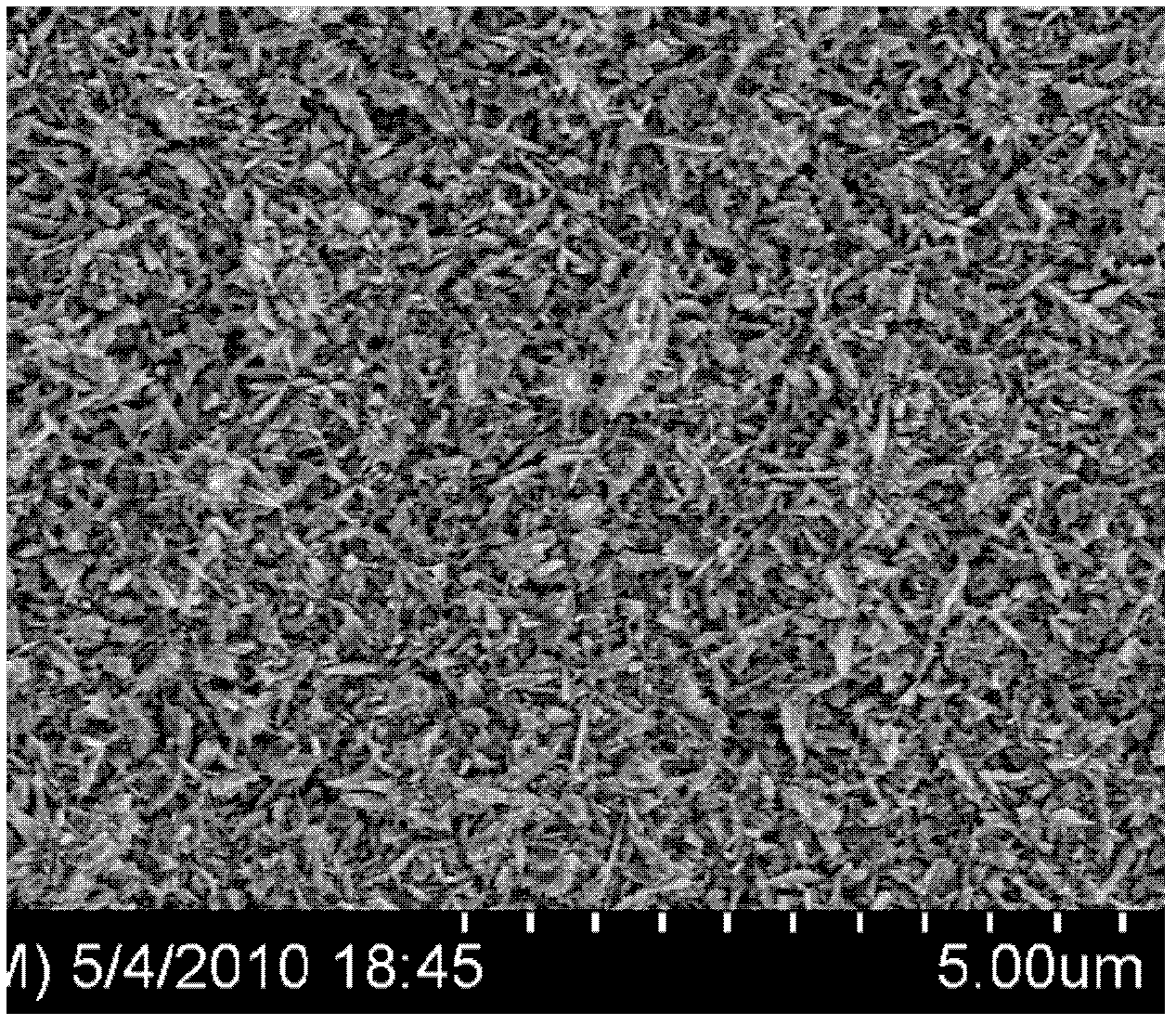

Preparation method of polymer hydrophobic surface

InactiveCN101456016AExcellent superhydrophobic propertiesUniform surface colorPretreated surfacesPolyester coatingsCoated surfacePolymer science

The invention provides a method for preparing a polymer hydrophobic surface and belongs to the technical field of polymer chemical material. The method comprises: preparing a polymer desperation and hydrophobic silica desperation; uniformly mixing the polymer desperation and the hydrophobic silica desperation for preparing a hydrophobic coating; spraying the hydrophobic coating onto a completely cleaned base surface uniformly with a spray gun; and finally, subjecting the sprayed base surface to heat treatment and cooling the base surface to obtain the polymer hydrophobic surface. The surface of a coating processed by the method is obvious in super-hydrophobic performance, uniform in luster and stable in performance, free from damage caused by scrubbing to the super-hydrophobic performance, simple in preparation process, low in preparation process implementation cost and applicable surfaces made from various materials without damaging the original materials by corrosive materials.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for preparing hollow carbon balls

InactiveCN101591016ALow costSuitable for industrial productsPolystyrene microsphereCaustic substance

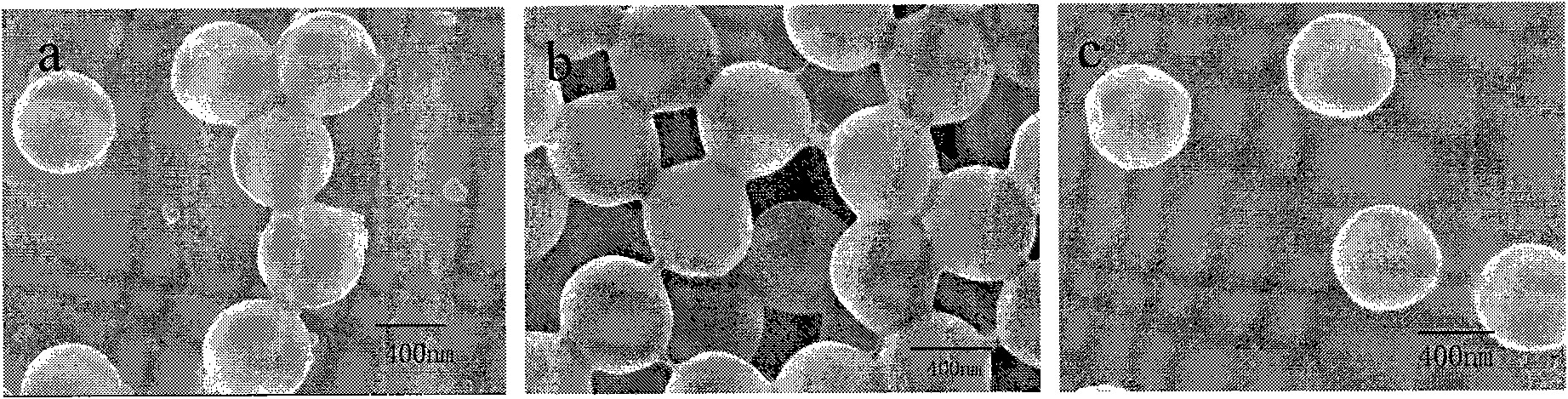

A method for preparing hollow carbon balls belongs to the field of novel carbon material. The existing preparation method for hollow carbon balls has the problems such as use of strongly corrosive substances, high cost and the like. The invention obtains the product hollow carbon balls by 1) preparing polystyrene micro ball template with uniform diameters; 2) adding the polystyrene micro ball template into concentrated sulphuric acid for sulfonation to obtain polystyrene micro ball template with different sulfonation degrees by controlling sulfonation time; 3) using phenolic resin and sulfonated polystyrene micro ball template to prepare polystyrene / phenolic resin composite balls; and 4) carbonizing the composite balls. The method of the invention is simple, convenient and easy to execute, uses no corrosive substances, has low production cost, can be used as electrode material, energy and hydrogen storage material, lubricant, catalyst carrier and the like.

Owner:BEIJING UNIV OF CHEM TECH

Clear coating composition, method of forming multilayer coating film and inmold decoration product

InactiveUS20060014024A1Design value is deterioratedBeautiful designSynthetic resin layered productsPolyurea/polyurethane coatingsClear LayerCorrosion reaction

It is an object of the present invention to provide a clear coating composition which inhibits a corrosion reaction by containing a rust preventive agent in a clear layer on a silver-plating layer and preventing a corrosive substance such as chlorine ion from contacting with the surface of the silver-plating layer, and develops beautiful silver-plating design for a long time, and an inmold decoration product comprising a silver-plating layer. A clear coating composition used in forming a multilayer coating film comprising a silver-plating layer, said multilayer coating film being obtainable by forming a base coating film layer, a silver-plating layer and a clear coating film layer in succession on a plastic substrate, wherein said clear coating composition is a two-package polyurethane coating composition comprising a main material containing acrylic polyol and a curing agent containing a polyisocyanate compound, the equivalence ratio of an NCO group in said polyisocyanate compound to an OH group in said acrylic polyol (NCO / OH) ranges from 0.8 / 1 to 1.2 / 1, and the clear coating composition contains a rust preventive agent in the proportions of 1.0 to 13.0 parts (on a basis of solids weight) with respect to 100 parts by weight of the total of the acrylic polyol and the rust preventive agent.

Owner:HONDA MOTOR CO LTD +1

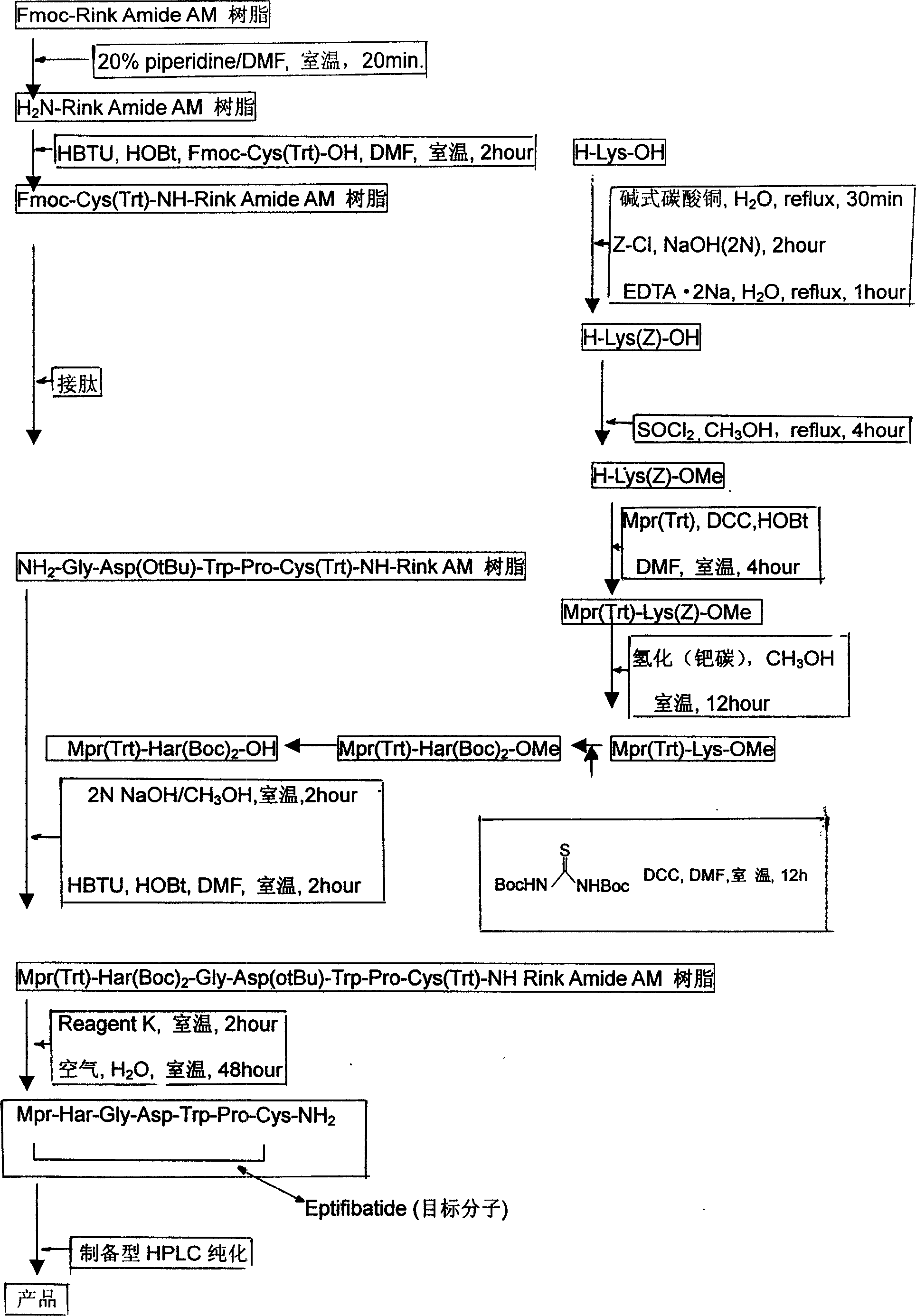

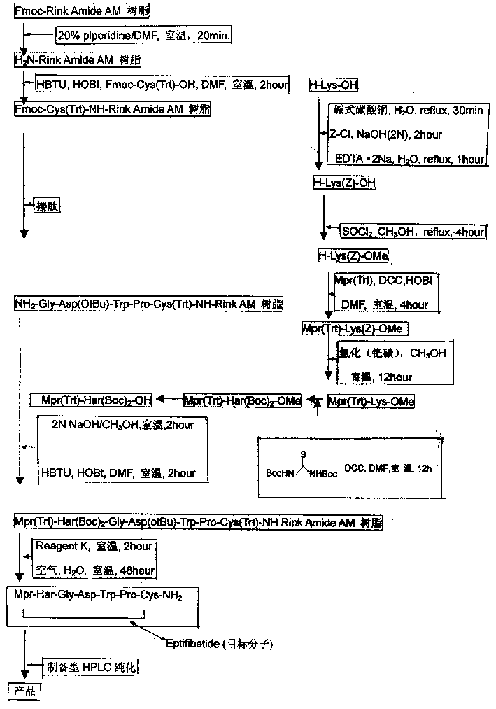

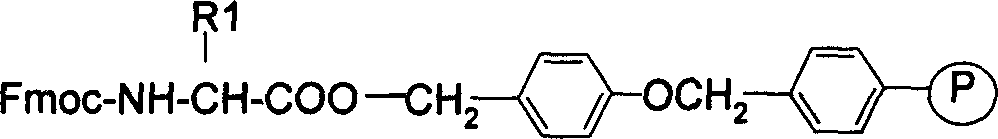

Preparing process for Eptifibatide

InactiveCN1500805AEasy to trackPromote safe productionPeptidesBlood disorderCyclic peptideTert-Butyloxycarbonyl protecting group

The present invention relates to the preparation of cyclic peptide, and is especially new Fmoc-solid phase process of preparing Eptifibatide. The new process is superior to liquid phase process, which has long synthesis period, and BOC solid phase process, which uses virulent and corrosive material. The technological scheme is that the Eptifibatide preparing process includes the following steps: eliminating Fmoc protection of Fmoc-Rink Amide AM resin to obtain H2N-Rink Amide AM resin; connecting various protective amino acids successively to obtain corresponding resin; eliminating Fmoc-protection radical and Kaiser test to detect reaction procedure; preparing S-triphenyl mercapto propionyl-N, N-ditert butyl oxycarbonyl-homoarginine with lysine; grafting S-triphenyl mercapto propionyl-N, N-ditert butyl oxycarbonyl-homoarginine; eliminating side chain protecting radical and resin to reduce into coarse product; and cyclization, oxidation, HPLC tracking purification to obtain pure product.

Owner:GL BIOCHEM SHANGHAI +1

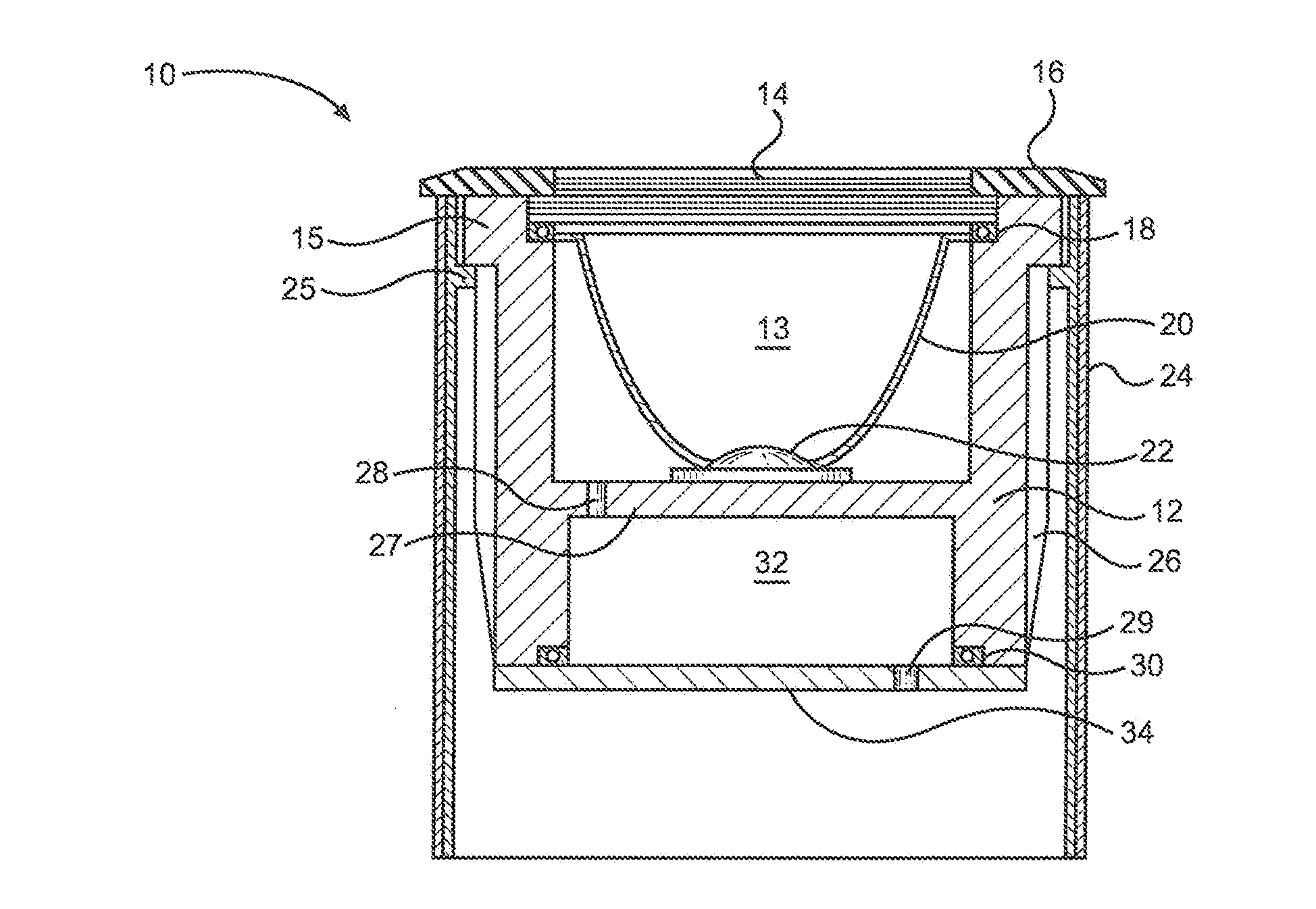

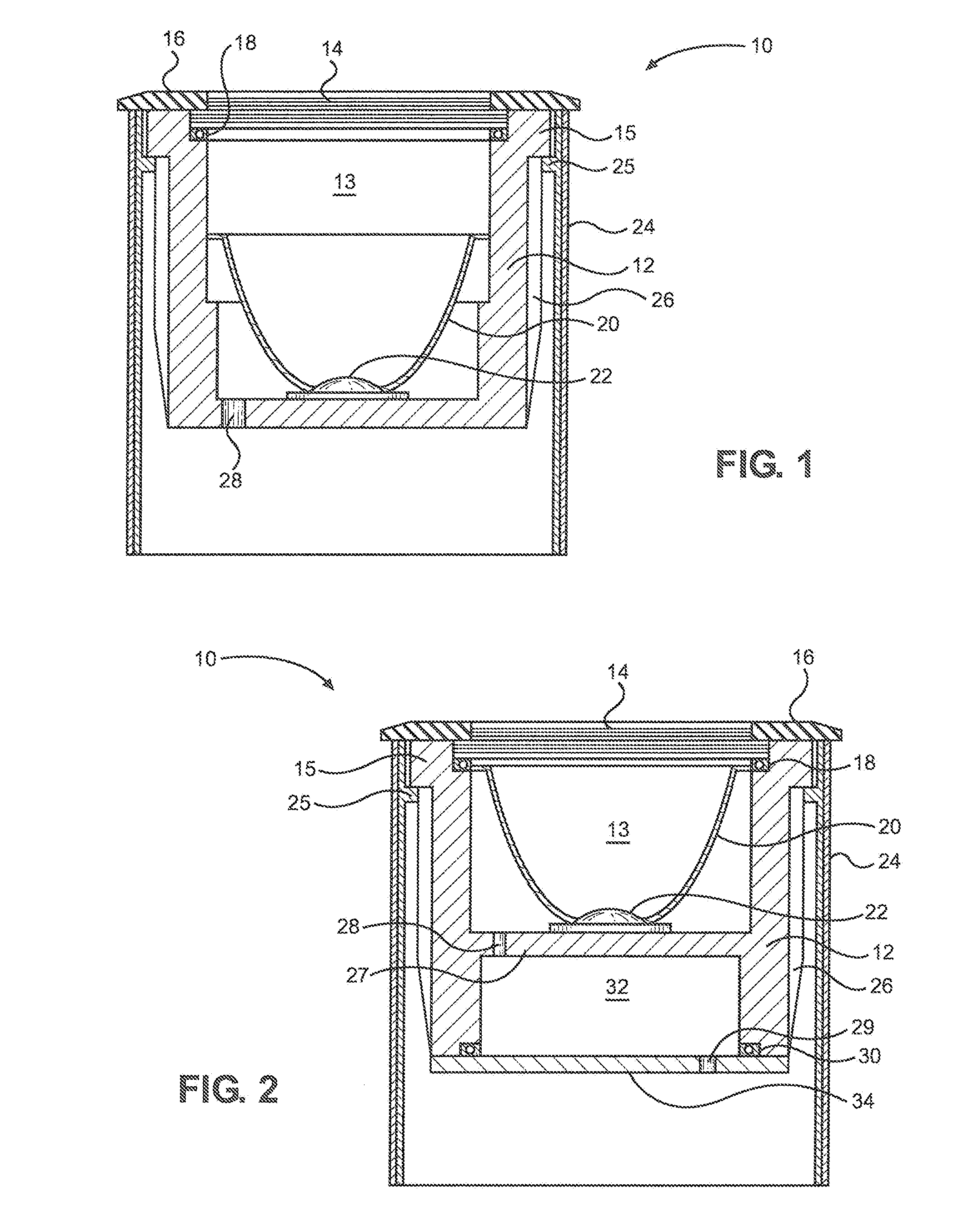

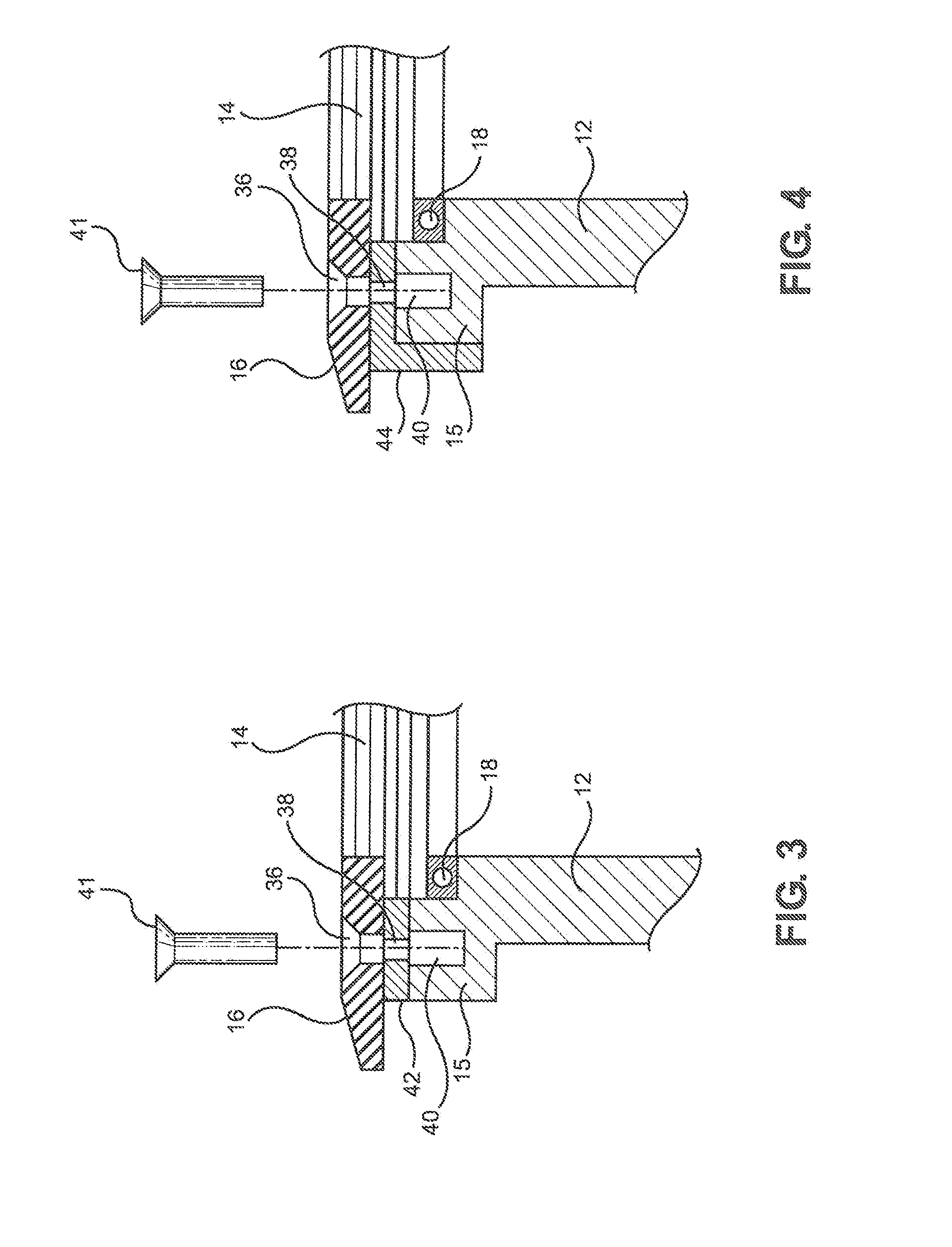

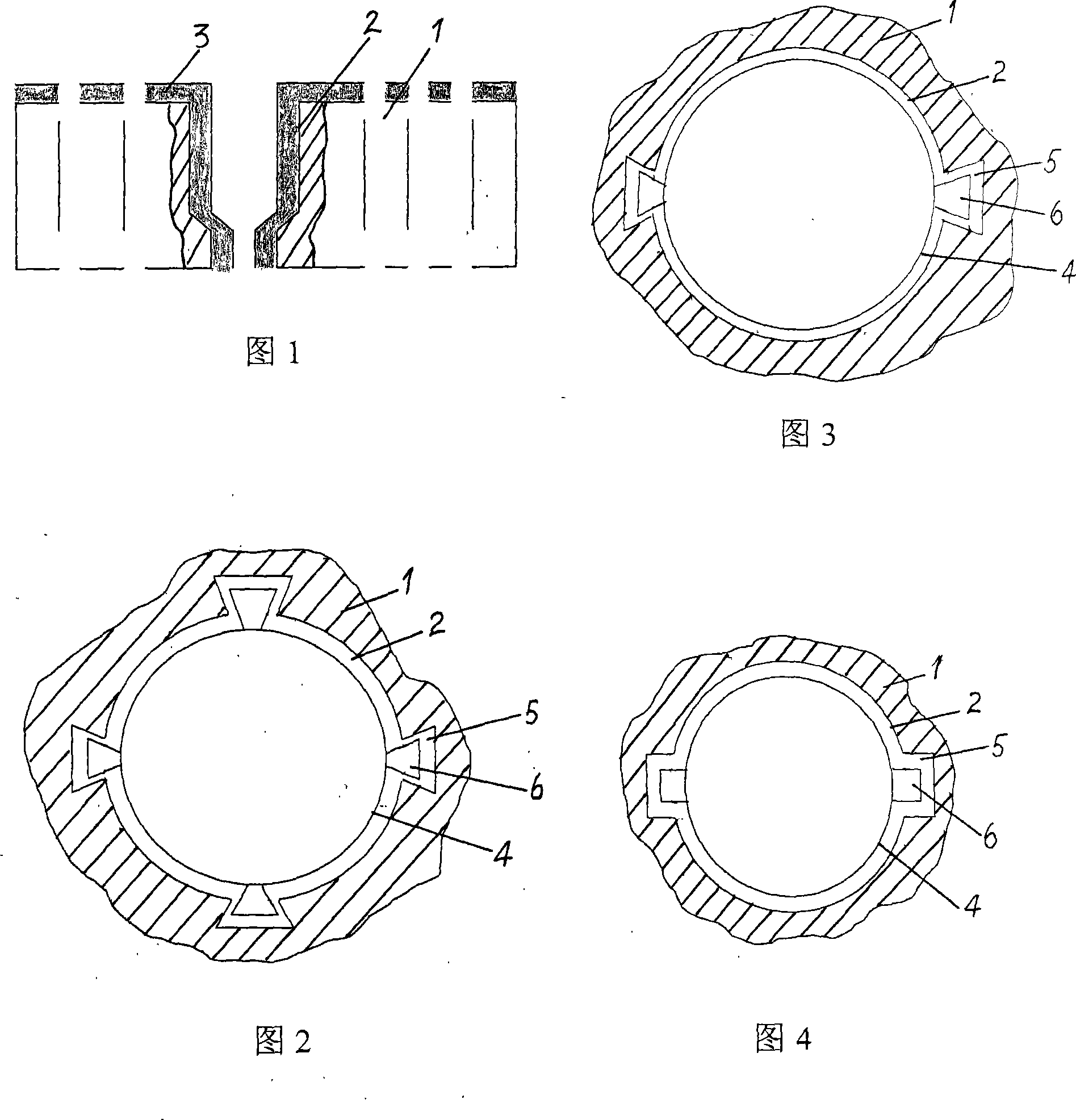

In-Grade and Under-Water Light Fixture Housing Made of Ceramic Material

InactiveUS20150369469A1Improve functionalityIncreased longevityMechanical apparatusPoint-like light sourceElectricityBearing down

A housing, particularly for a Light Emitting Diode (LED) or otherwise lamped in-grade or under-water light fixture, is made of ceramic material, such that the housing is not affected by corrosive substances commonly found in soil, masonry, and water that surrounds the installed fixture. The ceramic housing establishes a good conductor of heat and does not conduct electricity. A lens and lens frame are secured to the housing and provisions are made to assure the integrity of the overall assembly even when the light fixture is employed in damp and wet environments and / or where heavy loads can bear down on the lens, such as when the light fixture is embedded in a paved roadway and subjected to vehicular traffic rolling there over.

Owner:LIEN AI LI +1

Nickel electroplating liquid, and preparation method for super-hydrophobic nickel plating layer using same

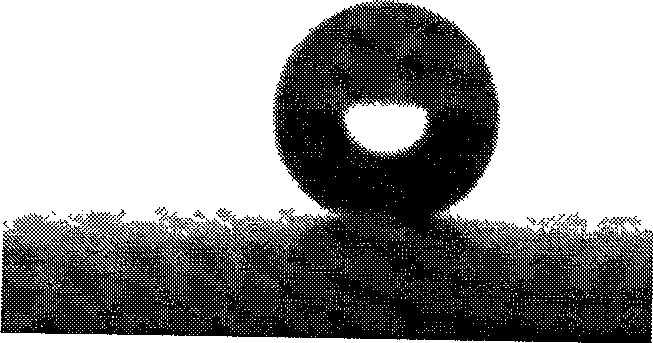

The invention discloses a nickel electroplating liquid, and a preparation method for a super-hydrophobic nickel plating layer using the same. The nickel electroplating liquid is composed of a choline-chloride-based ionic liquid used as a solvent and NiCl2.6H2O or NiCl2 used as a solute, wherein the mol concentration of the solute is 0.1-3 mol / L. The preparation method for the super-hydrophobic nickel plating layer using the nickel electroplating liquid comprises the following step of electroplating in the nickel electroplating liquid with pure nickel as an anode and the workpiece to be electroplated as a cathode at the temperature of the nickel electroplating liquid from room temperature to 200 DEG C and electroplating voltage of 0.2-2 V. The nickel electroplating liquid provided by the invention has simple components, is convenient to prepare and is environmentally-friendly. The preparation method for the super-hydrophobic nickel plating layer using the nickel electroplating liquid has the advantages of simple and controllable process, no corrosive substances and no vapor discharge during the electroplating process, and is beneficial to mass production. More prominent characteristics are that the obtained nickel plating layer has super-hydrophobic property, a contact angle larger than 160 degrees and a sliding angle smaller than 2 degrees.

Owner:ZHEJIANG UNIV

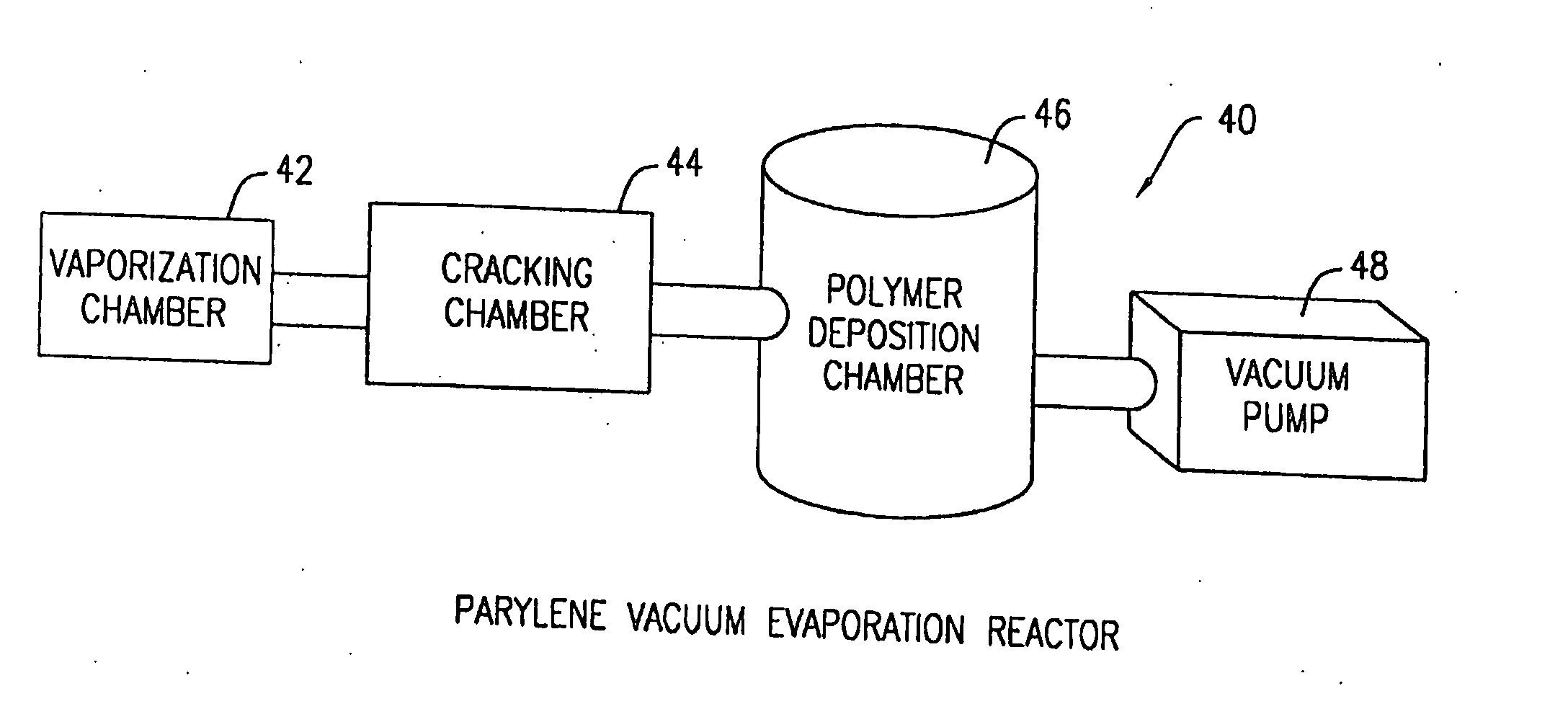

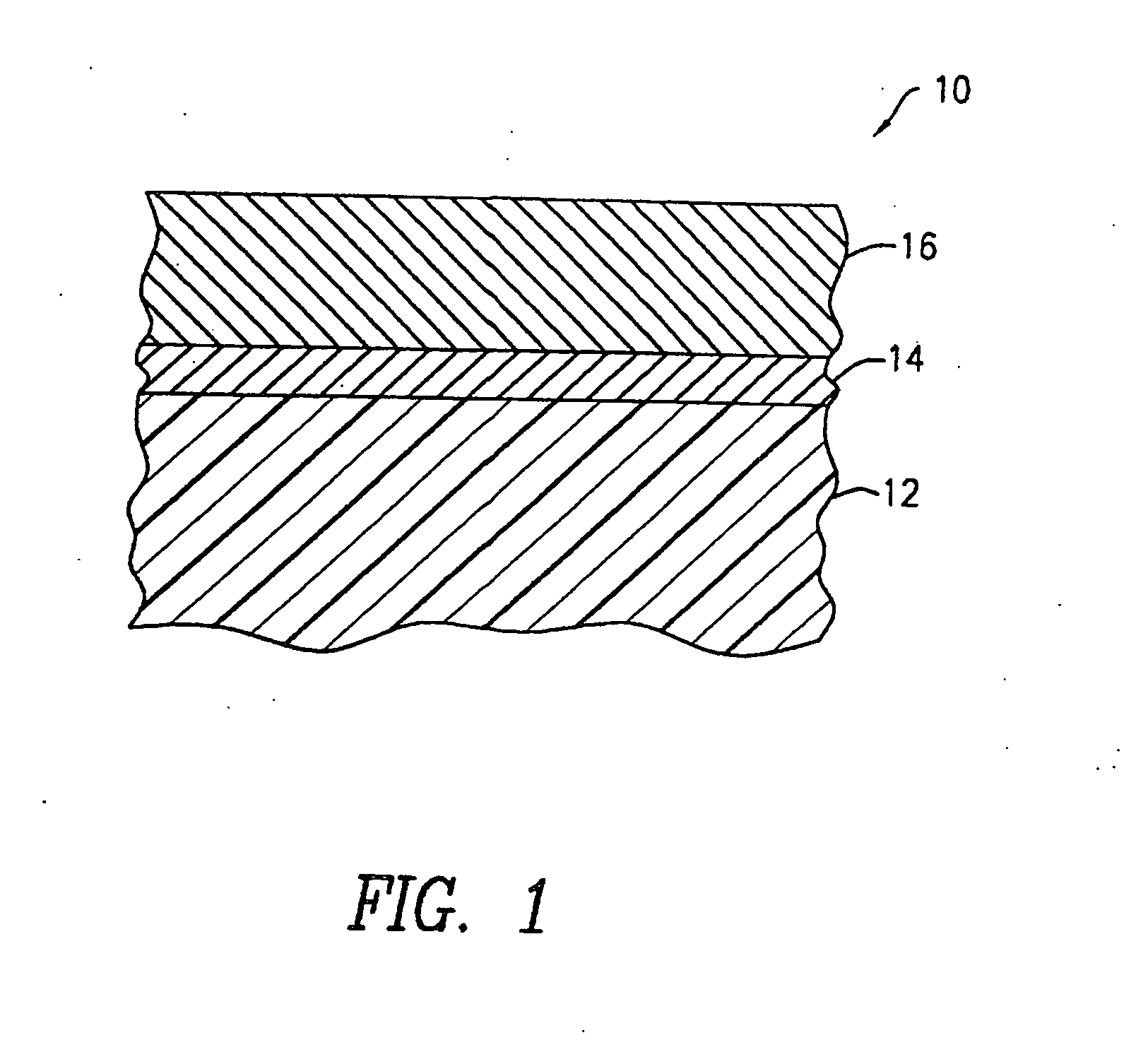

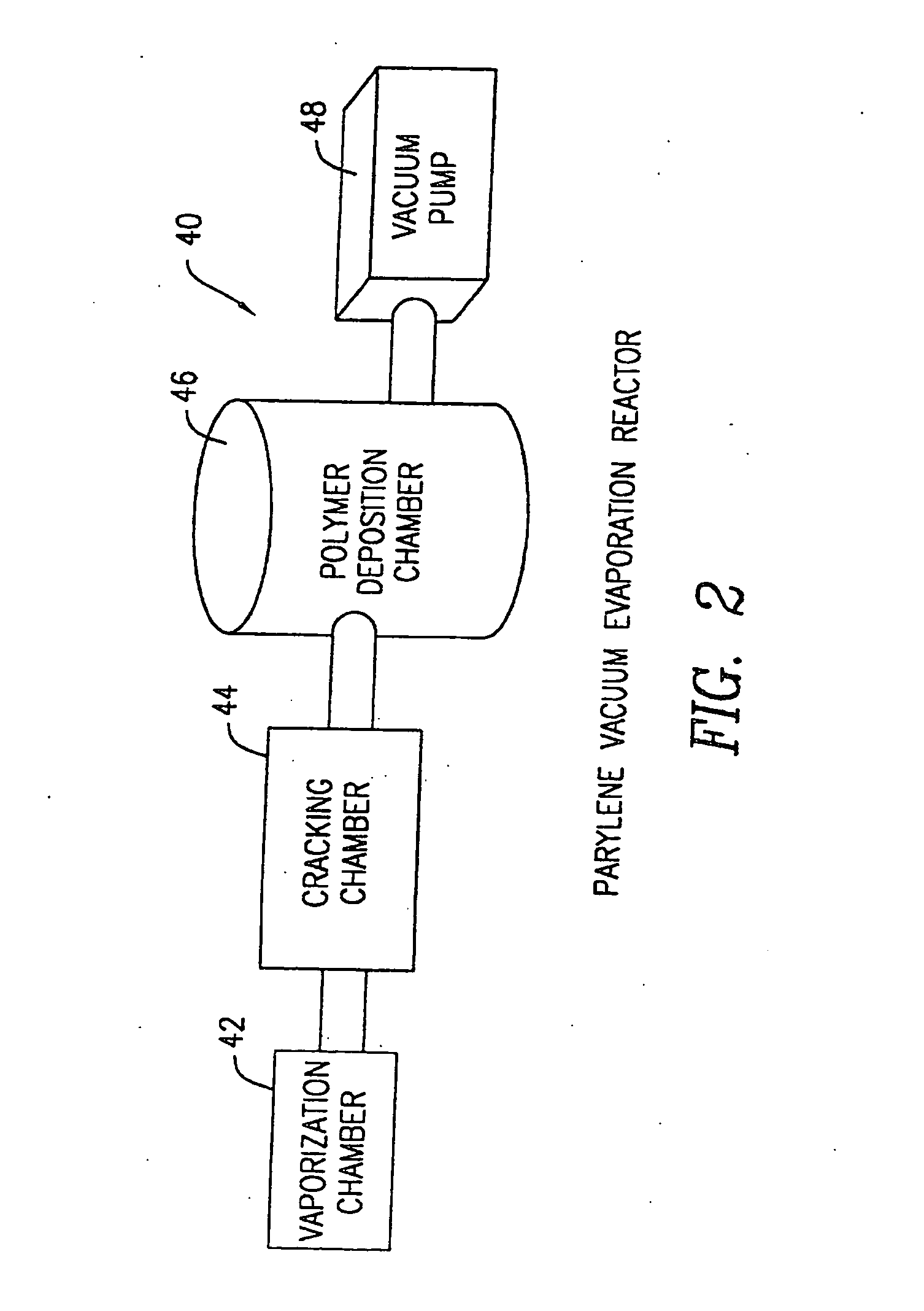

Barrier coating composition for a substrate

InactiveUS20050008848A1Good optical performanceIncreased durabilityGlass optical fibreOptical fibre with multilayer core/claddingPolymer scienceParylene

A barrier layer which protects the surface of a substrate from exposure to ambient conditions, including humidity, salt, corrosive substances, and the like, comprises a composition of a first layer of a parylene polymer over a surface portion of the substrate, a second transition layer of a mixture of the first parylene polymer and a second parylene polymer on the first layer, and a third layer of only the second parylene polymer. The second layer may be a graded layer, and the first and second parylene polymers may be selected from the group of parylene C, D, and N. An adhesion promoting layer may be between the surface of the substrate and the first layer.

Owner:SACCOMANNO ROBERT J +1

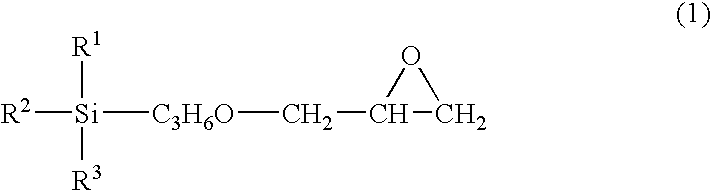

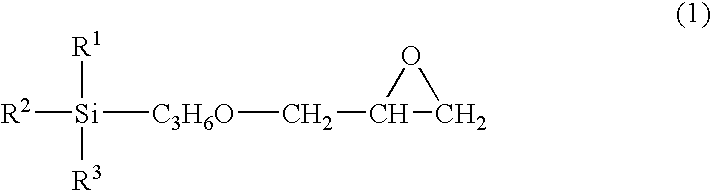

Phenyl MDT silicon resin and preparation method thereof

ActiveCN103232601ANothing producedRaw materials are easy to getOther chemical processesSilanesRefractive index

The invention discloses phenyl MDT silicon resin and a preparation method thereof. The phenyl MDT silicon resin adopts single-group organic silane as a M link, adopts two-group organic silane as a D link and adopts three-group organic silane as a T link, wherein at least one of the D link or the T link is the phenyl silane, and the phenyl silane is collectively hydrolyzed under an acidic catalyst and concentrated under an alkaline catalyst. Raw materials for the phenyl MDT silicon resin are available, no strong corrosive substance is generated in the reaction process, and the requirement on equipment and operation is low. The preparation method comprises the following steps of adding the acidic catalyst in the mixed liquor of the M-link silane, the D-link silane and the T-link silane. The M link, the D link and the T link are unnecessary to drop into a reactor respectively, so that the operation step is simple, the procedure is saved, the production efficiency can be improved, and the industrialized mass production can be realized. The refractive index nD of the prepared phenyl MDT silicon resin is more than 1.53.

Owner:CHENGDU GUIBAO SCI & TECH

Spinneret plate for melt spinning and preparation method thereof

ActiveCN101177793AExtended service lifeReduce stressSpinnerette packsFurnace typesManufacturing cost reductionOrganic solvent

The invention discloses a spinneret plate used for melt spinning. The surface or the inner surface of the spinneret plate is covered by a nano-scaling or hypo-nano scaling oxide film with a thickness of 0.8nm to 28nm or a 0.1mm to 0.25mm metal lamina is embedded in a spinneret orifice in the spinneret plate. The invention also discloses a method for preparing the spinneret plate used for melt spinning. As the surface or the inner surface of the spinneret plate of the invention is covered by the nano-scaling or hypo-nano scaling oxide film or because the metal lamina is embedded in the spinneret orifice , the invention not only can avoid the degradation and degeneration of melten polymer passing through the spinneret plate but also can avoid the damage of corrosive substances and impurities of fused mass to the inner surface of the spinneret orifice, thus prolonging the service life of the spinneret plate and lowering the rejection rate of the fibers. Suspension used in the invention does not use expensive and poisonous organic solvent, thus not only lowering manufacturing cost, but also avoiding environmental pollution.

Owner:德阳科吉高新材料有限责任公司

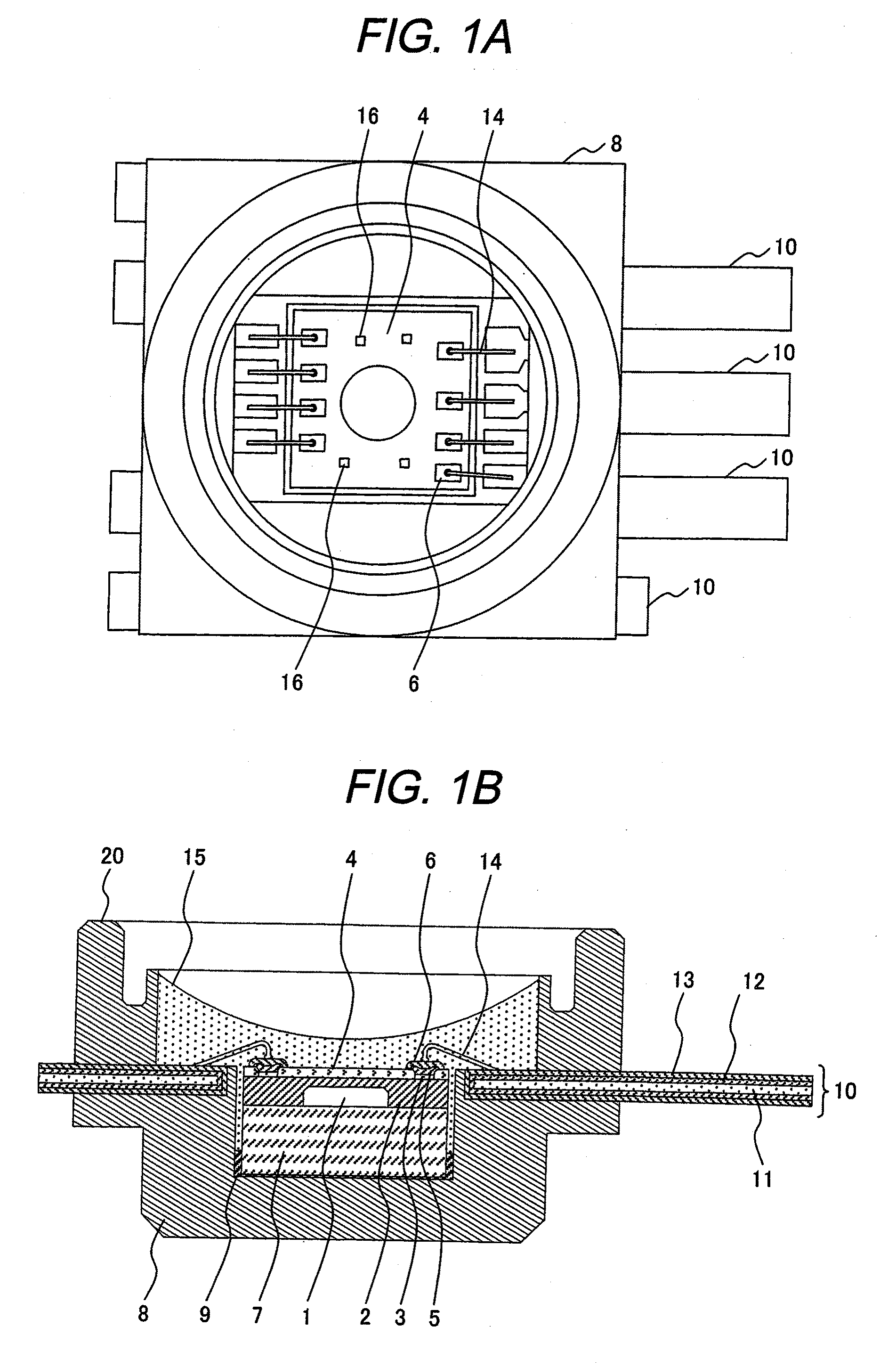

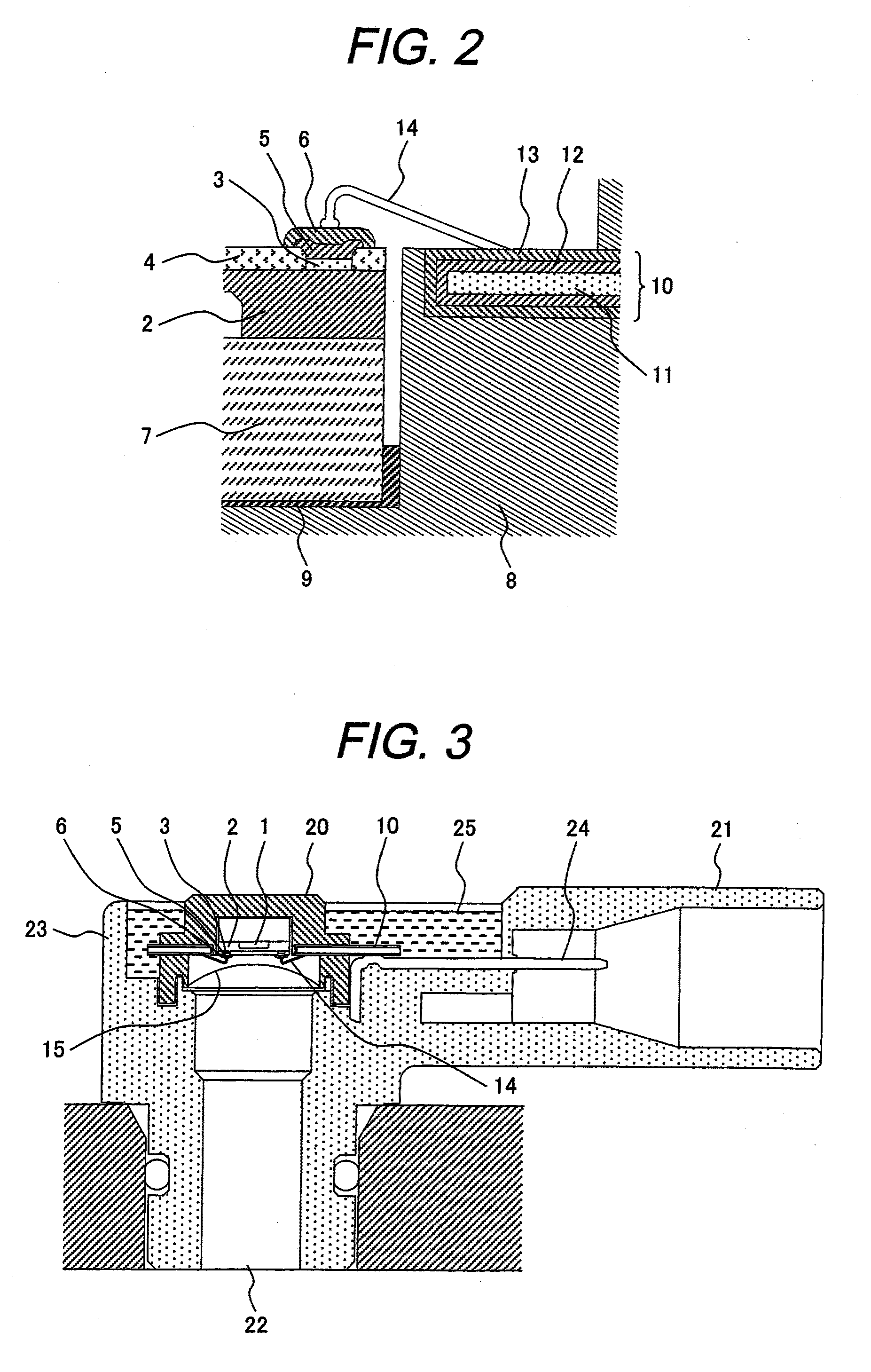

Semiconductor Pressure Sensor

ActiveUS20090218643A1Small ionization tendencyAvoid corrosionAcceleration measurement using interia forcesFluid pressure measurement by electric/magnetic elementsGold layerTitanium

An object of the present invention is to solve problems in that aluminum electrodes, aluminum wires, and I / O terminals are corroded by corrosive gasses when a pressure of a pressure medium containing corrosive matters such as exhaust gas is measured with a semiconductor sensor; and improve not only the corrosion resistance of the sensor chip but also the corrosion resistance of the portion particularly functioning as the pressure receiver.Each of the aluminum electrodes that is likely to be corroded portions is prevented from being corroded by forming a titanium-tungsten layer and gold layer on the aluminum electrode. The connecting wires are prevented from being corroded by corrosive matters by using gold wires. The I / O terminals are also prevented from being corroded by applying gold plating.

Owner:FUJI ELECTRIC CO LTD

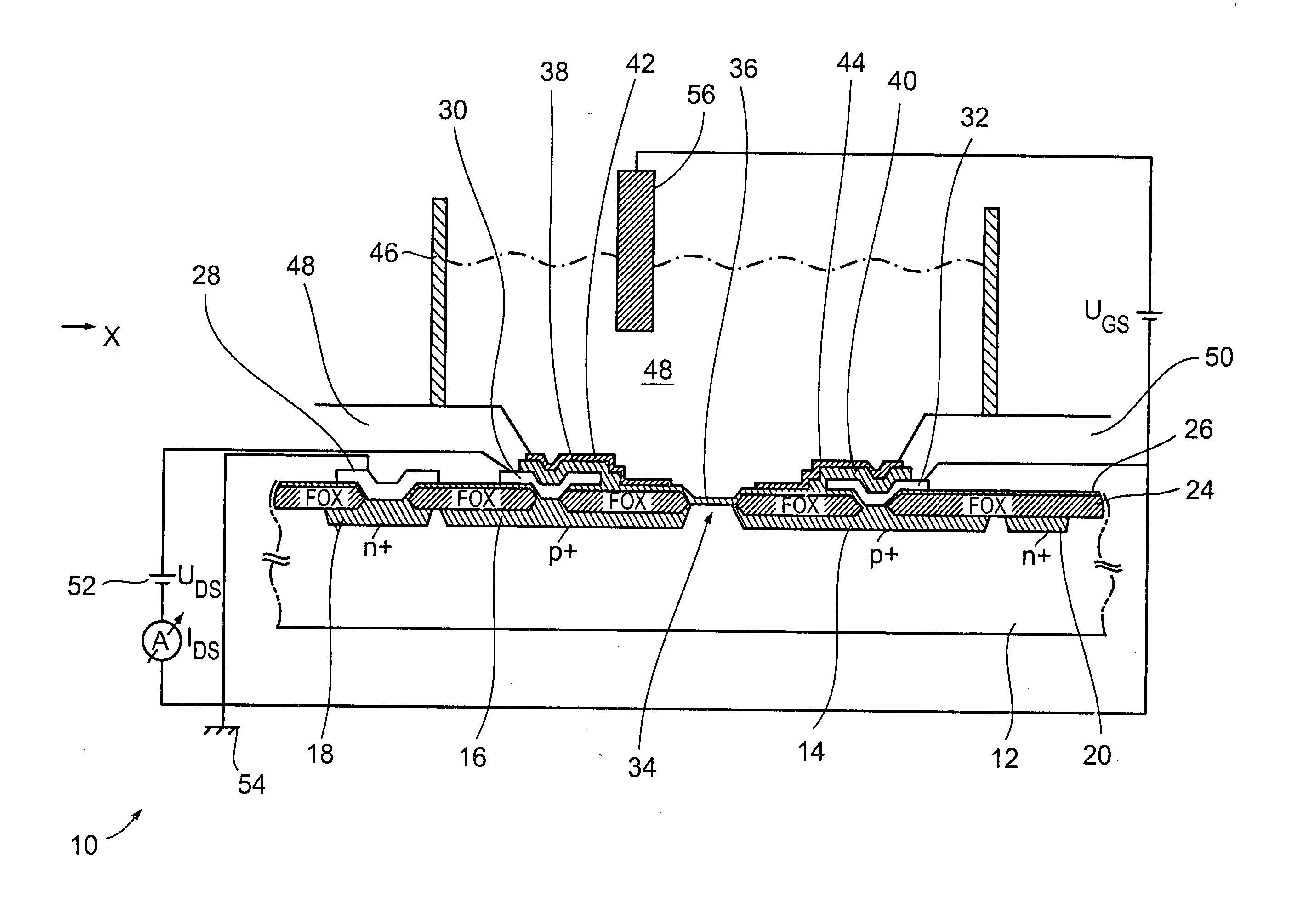

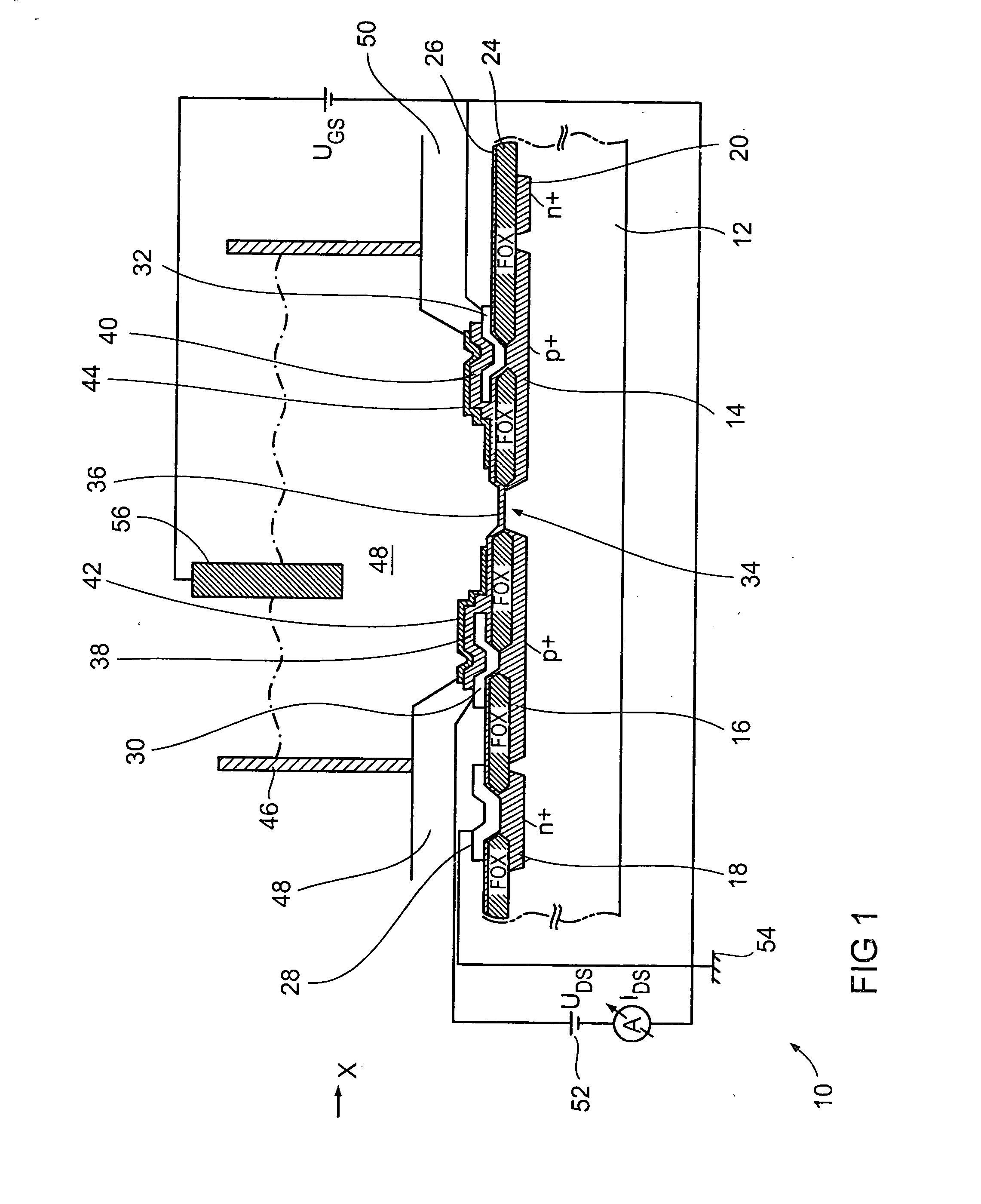

Ion sensitive field effect transistor and method for producing an ion sensitive field effect transistor

InactiveUS20050012115A1Operational safety is highLow production costMaterial analysis by electric/magnetic meansPill deliveryCarbon nitrideCondensed matter physics

The invention relates to an ion-sensitive field effect transistor, comprising a gate (36) consisting of carbon nitride. The carbon nitride gate (36) is highly resistant to aggressive substances to be measured and also exhibits good adhesive properties. In addition, the ion-sensitive field effect transistor has high long-term stability and negligible drift. Said ion-sensitive field effect transistor can be produced in a method that uses CMOS-compatible planar technology.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

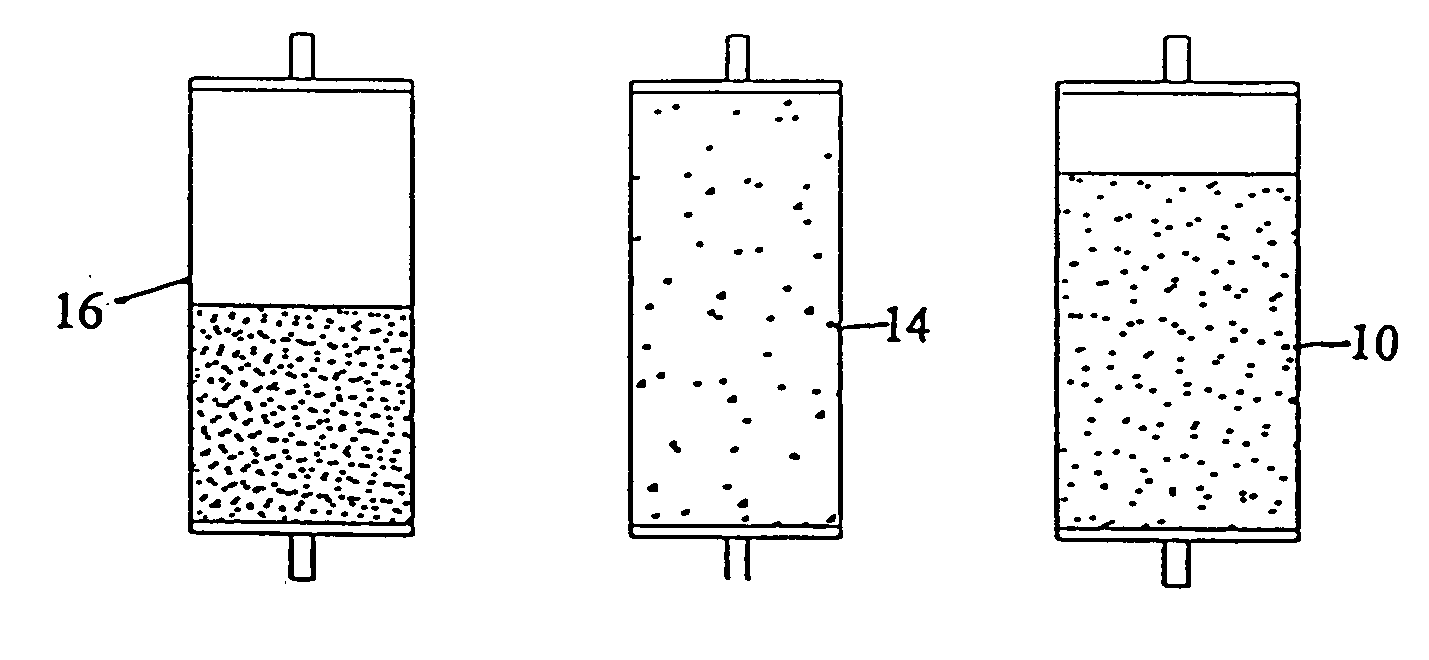

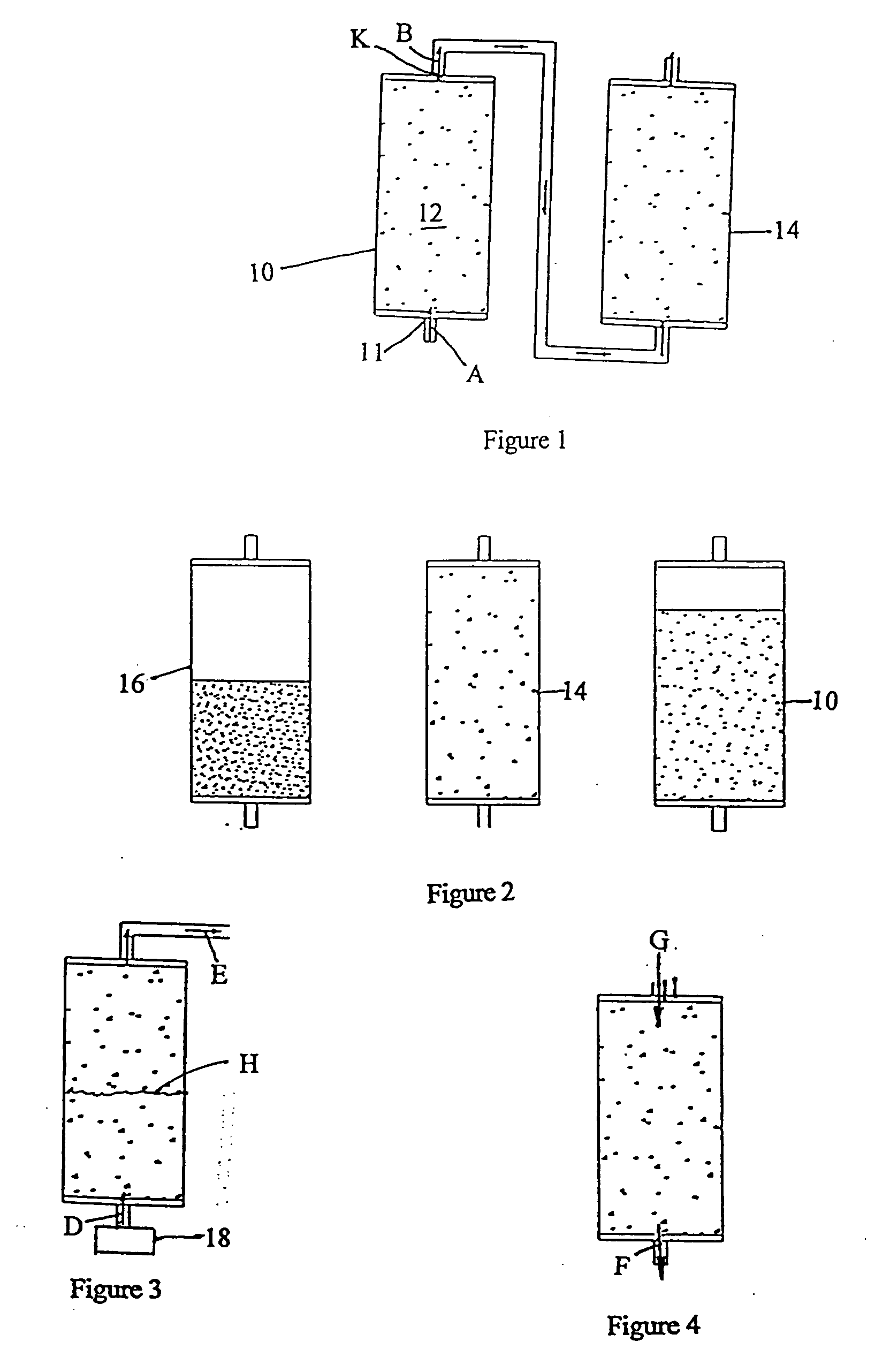

Ion exchange process

InactiveUS20050194319A1Simple and cost-effectiveWater treatment parameter controlSpecific water treatment objectivesSaline waterWastewater

An ion exchange process for treating waste water having caustic materials, uses a bed of cation exchange resin beads to which the waste water is added. Thereafter the bed of beads is allowed to absorb the caustic materials in a brine until the resin is exhausted. The bed having retained organic matter is regenerated by rinsing the bed with water to remove substantially all the organic matter; draining any remaining rinse water; adding water and allowing it to pass through the bed and exit therefrom; mixing the exiting water with acid to form a dilute acid; and adding this dilute acid to the bed until the water exiting the bed has substantially the same pH as the dilute acid entering the bed.

Owner:WEGNER PAUL

Environment-friendly electroplate liquid for copper base plating layer and application method thereof

The invention discloses an environment-friendly electroplate liquid for a copper base plating layer, wherein a choline chloride-based deep eutectic solvent is used as a electroplate liquid solvent; every liter of the electroplate liquid contains 0.1-1 mol of CuCl2.2H2O or CuCl2 and 0-10 g of a composite plating layer additive; the composite plating layer additive is one or a mixture of some of nano carbon tube powder, SiC powder, diamond powder and Al2O3 powder; and the choline chloride-based deep eutectic solvent is the mixed liquid of choline chloride and glycol in the molar ratio of 1: 2, or the mixed liquid of the choline chloride and urea in the molar ratio of 1: 2. The electroplate liquid is featured with simple ingredient, convenience in preparation and environment friendliness. The process in which the electroplate liquid is used for electroplating the copper base plating layer is simple and controllable, and the electroplate liquid contains no corrosive material and has no steam discharging in the electroplating process. The surface of the acquired copper base plating layer is even, and especially in the process of electroplating a copper base composite coating, the electroplate liquid is not needed to be mechanically stirred, which simplifies the composite electroplate technology, and is helpful for the large-scale production.

Owner:ZHEJIANG UNIV

Inkjet ink

An inkjet ink containing a colorant, where an amine compound is added as a pH adjuster. The ink is capable of preventing the pH of the ink from being shifted to the acidity side due to corrosive substances (e.g., acid substances) generated by deterioration of ink, adverse effects due to water absorption and moisture absorption, or degradation of resin (e.g., degradation of vinyl chloride-vinyl acetate copolymer resin), thus preventing erosion of a head nozzle member.

Owner:MIMAKI ENG

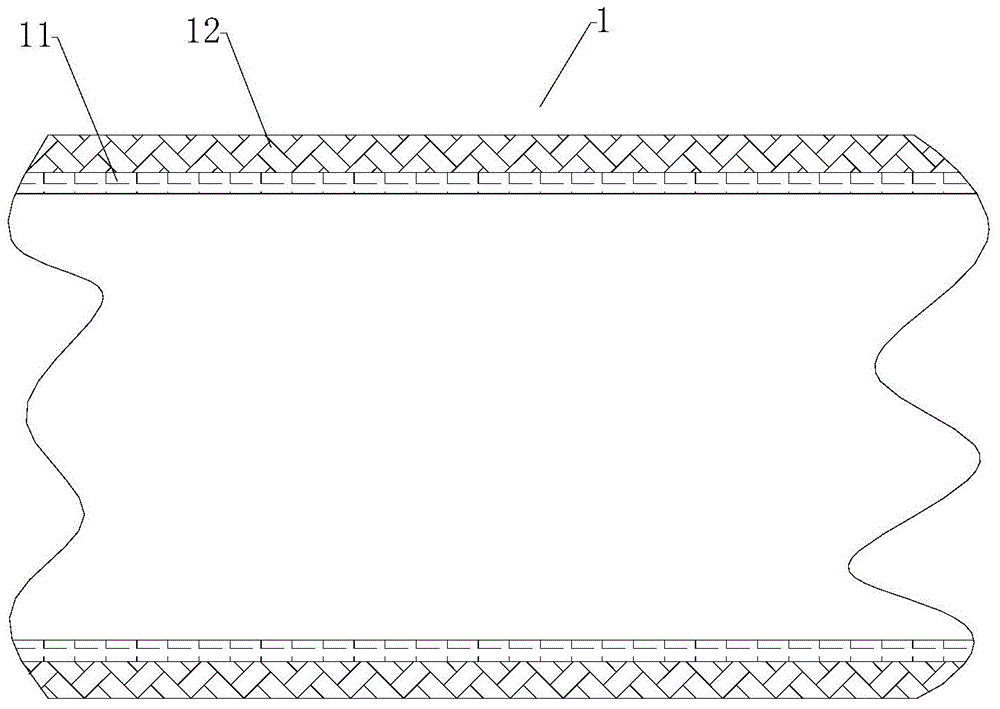

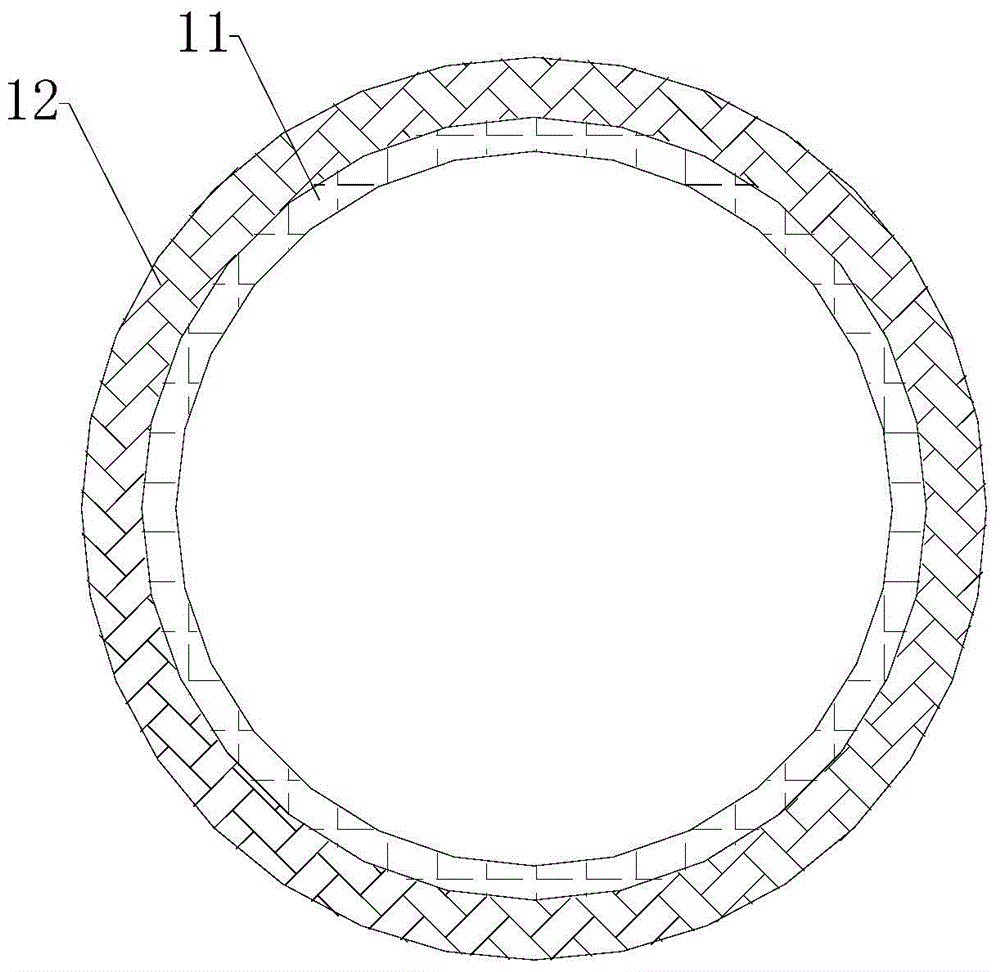

Composite material pipeline

ActiveCN104676141ACorrosion resistanceAvoid corrosionCorrosion preventionPipe protection against corrosion/incrustationFiberElectrochemical corrosion

The invention discloses a composite material pipeline. The composite material pipeline is characterized by comprising a pipeline main body, wherein the pipeline main body comprises a tubular conductive liner; the conductive liner is provided with a pipe cavity; a first fiber enhanced resin layer covers the outer surface of the conductive liner. According to the composite material pipeline, the conductive liner is made of a titanium alloy or thermoplastic resin, has an excellent anti-corrosion performance on corrosive substances in the pipeline, and can be used for resisting corrosion of most of salts, acids and alkalis, and particularly can resist the corrosion of acidic gas including hydrogen sulfide, carbon dioxide and the like. The non-metal first fiber enhanced resin layer covering the outer surface of the conductive liner is a main stress layer, can bear gas pressure or liquid pressure in the pipeline, can resist the corrosion caused by chlorides in seawater outside the pipeline, and can effectively prevent the electrochemical corrosion to the pipeline and the liner; furthermore, the corrosion resistance of the pipeline is improved.

Owner:苏州云逸航空复合材料结构有限公司

Polyurethane reinforced material and preparation method thereof

The invention discloses a polyurethane reinforced material which is characterized by comprising a component A and a component B, wherein the component A comprises the following components in parts by weight: 20-45 parts of polyether polyol A, 25-55 parts of polyether polyol B, 5-10 parts of polyether polyol C, 5-15 parts of a flame retardant A, 5-10 parts of a flame retardant B, 0.2-0.5 parts of an amine catalyst, 0.1-0.5 parts of a tin catalyst and 0.5-1.0 parts of a foam stabilizer, and the component B is polymethylene polyphenyl polyisocyanate. The polyurethane reinforced material further comprises 3-8 parts of a viscosity reducer. Compared with similar materials, the material has better permeability and higher mechanical property, and broken coal and rock masses can be fixedly combined integrally and effectively due to ultrahigh tensile compressive strength and binding performance, so that the top plate and two uppers can bear pressure actively. The material does not contain poisonous volatile and corrosive matters, so that the material satisfies the demand of safety and environment-friendliness of materials under the shaft.

Owner:SHANDONG ANLENG NEW MATERIAL TECH CO LTD

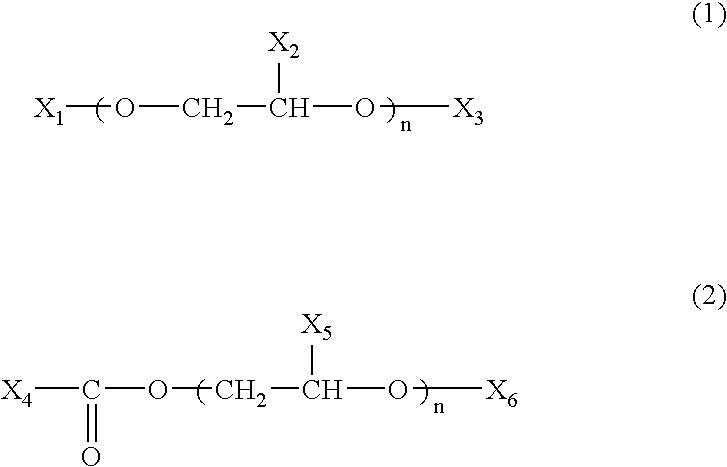

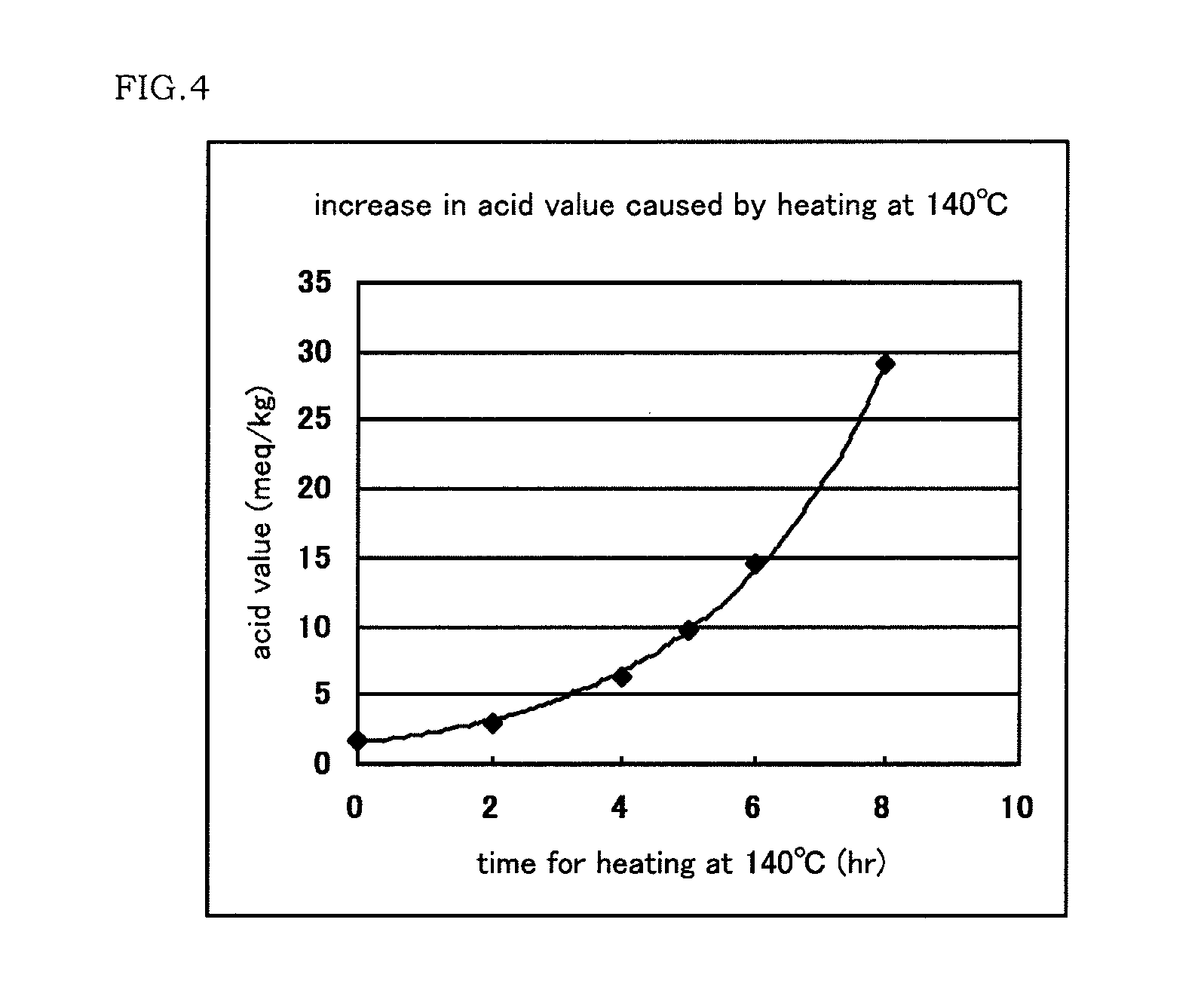

Polyvinyl acetal film and uses thereof

ActiveUS20130074910A1Reduce yellownessGood lookingPV power plantsGlass/slag layered productsPolyvinyl alcoholOxygen

A polyvinyl acetal film as an intermediate film for a laminated glass, can provide a laminated glass that exhibits a low degree of yellowness and excellent surface appearance, and is useful as a sealing material or intermediate film that can prolong the life of a laminated glass provided with a solar cell or functional unit. The content of corrosion-causing substance in the polyvinyl acetal film is low, so that the polyvinyl acetal film permits high-temperature lamination and ensures excellent productivity. A solar cell module and a laminated glass are prepared using the polyvinyl acetal film. A plasticized polyvinyl acetal film which comprises 15 to 60 parts by mass of a plasticizer having a total number of 28 or more of carbon atoms and oxygen atoms constituting a molecule based on 100 parts by mass of a polyvinyl acetal resin, and which has an acid value of 5.0 meq / kg or less.

Owner:KURARAY CO LTD

Waterproof anti-corrosion flame retardant coating for airplane and preparation method thereof

InactiveCN101665657AExtended service lifePrevents delamination and even damageFireproof paintsAnti-corrosive paintsJet aeroplaneDecabromobiphenyl ether

The invention relates to a waterproof anti-corrosion flame retardant coating for an airplane and a preparation method thereof. The coating is prepared from tung oil, ethylene-vinyl acetatecopolymer emulsion, decabromodiphenyl oxide and magnesium hydroxide according to the weight ratio of 60-80:10-30:5-10:5-10. The waterproof anti-corrosion flame retardant coating for the airplane uses the tung oilhaving the characteristics of waterproof property, anticorrosion, high temperature resistance, and the like as the main material, matches the decabromodiphenyl oxide and magnesium hydroxide with theflame retardant function and uses the ethylene-vinyl acetatecopolymer emulsion as the adhesive. Therefore, when applied on the surface of a structural component of the airplane to form an adhesive film with the waterproof, anti-corrosion and flame retardant effects, the waterproof anti-corrosion flame retardant coating can prevent material lamination or even damage caused when the external moisture and corrosive substances enter the inside of the structural component and has flame retardant effect, thereby prolonging the service life of the structural component and ensuring good safety.

Owner:CIVIL AVIATION UNIV OF CHINA

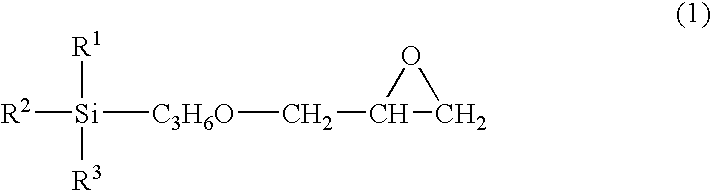

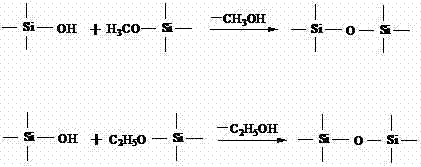

Method for preparing UV (ultraviolet)-curable high-temperature-resistant and corrosion-resistant organic silicon/silica hybrid coating

The invention discloses a method for preparing an UV (ultraviolet)-curable high-temperature-resistant and corrosion-resistant organic silicon / silica hybrid coating. In the method, tetraethoxysilane is taken as an inorganic phase precursor, methyltriethoxysilane and diphenyldimethoxysilane are taken as organic phase precursors, then the mixed liquor of gamma-methacryloxy silane and a free-radical photo-initiator is added, and an UV-curable organic silicon / silica hybrid sol can be prepared by using a sol-gel method; and after a base material is coated, the base material is cured by ultraviolet light for 30-300s so as to obtain an organic silicon / silica hybrid coating, thereby forming hybrid gel space network structure taking Si-O-Si bonds as a skeleton. The method disclosed by the invention has the following technical effects: the hybrid coating subjected to ultraviolet-light curing forms a denser network structure, thereby facilitating the improvement of comprehensive properties, and especially facilitating the improvement of corrosion resistance; and the denser network structure can form a physical 'barrier' better so as to prevent corrosive substances such as water and chemical reagents and the like from contacting a substrate.

Owner:NANCHANG HANGKONG UNIVERSITY

Flame-retardant rubber material capable of protecting high-risk chemicals and method for preparing same

ActiveCN102977478AEffective protectionSolve the problem of large polarity differenceRubber materialDecabromodiphenyl ether

The invention discloses a flame-retardant rubber material capable of protecting high-risk chemicals and a method for preparing the same, belongs to the technical field of rubber and solves the problems of single function and poor quality due to single rubber type, and difficult formation of homogeneous phase while compounding a plurality of types of rubbers of the existing rubber. The flame-retardant rubber material capable of protecting high-risk chemicals is composed of the following components according to parts by weight: 30-80 parts of chlorinated butyl rubber, 30-10 parts of butadiene styrene rubber, 40-10 parts of neoprene, 2.0 parts of sulfur, 0.8-1.2 parts of accelerant TT, 0.8-1.2 parts of accelerant DM, 30 parts of high abrasion proof carbon black, 8-15 parts of decabromodiphenyl ether, 8-20 parts of antimonous oxide, 5-15 parts of chlorcosane, 5.0 parts of zinc oxide, 2.5 parts of stearic acid and 2.0 parts of antiager D. The flame retardant rubber material effectively overcomes the shortcomings of single function and poor quality of single rubber type; the product is capable of effectively protecting high-risk chemicals and highly corrosive materials, and thus can be widely applied to effectively protecting the feet, the head and the skin.

Owner:SHANXI XINHUA CHEM +1

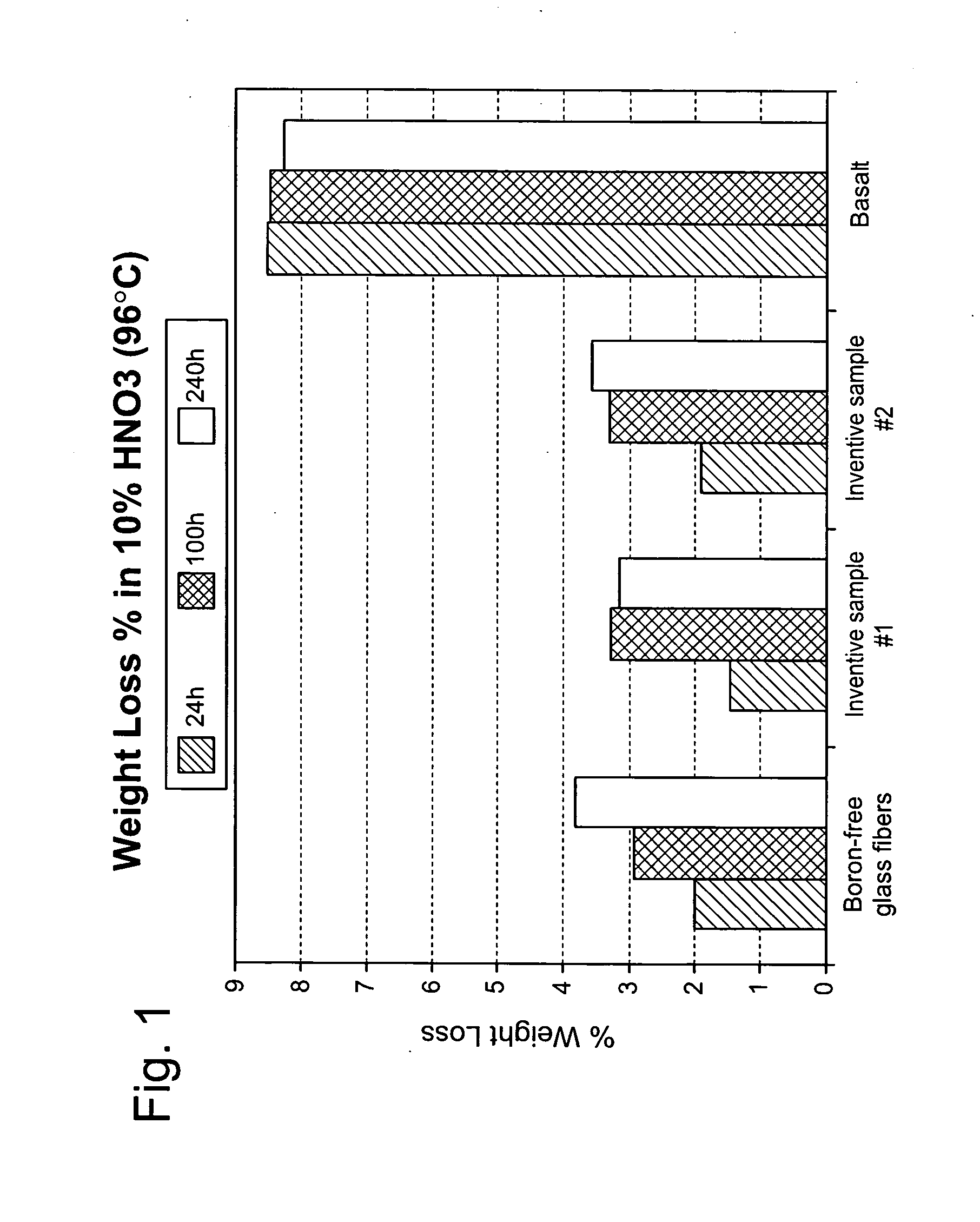

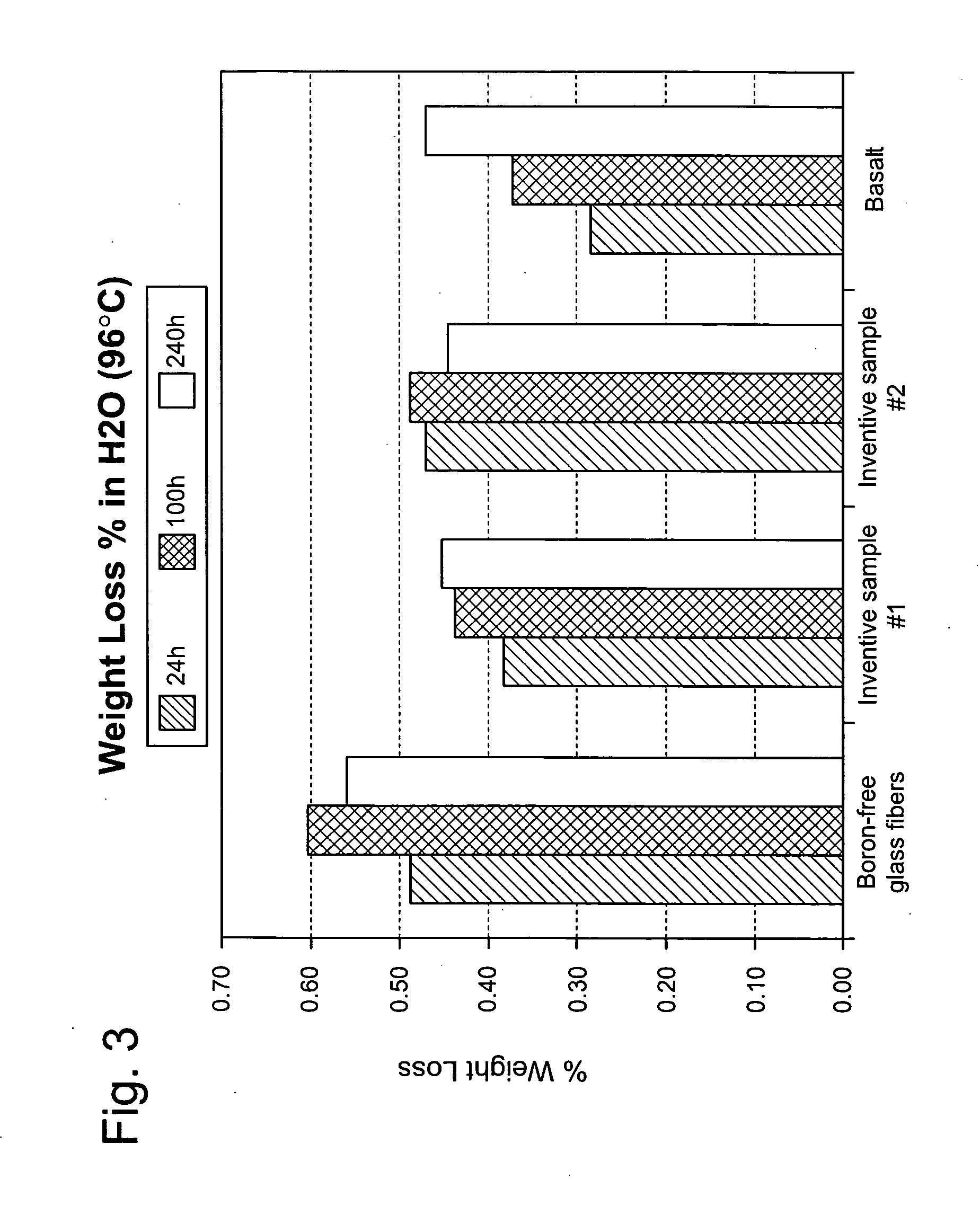

Composition for high performance glass, high performance glass fibers and articles therefrom

Glass batch compositions for the formation of high-modulus, and high-strength glass fibers as well as fibers suitable for use as textile and reinforcements are disclosed. Fibers formed of the composition are especially suitable for use in high-strength, low-weight applications such as windmill blades and high strength and modulus applications where strength and stiffness are required in the composite. The glass composition is up to about 70.5 weight % SiO2, about 24.5 weight % Al2O3, about 22 weight % alkaline earth oxides and may include small amounts of alkali metal oxides and ZrO2. Additionally, glass fibers formed from the inventive composition are non-corrosive or substantially non-corrosive in nature. Due to the non-corrosive nature of the glass fibers, glass fibers made with the inventive composition may be used in applications where the glass fibers or a composite formed from the glass fibers are in contact with a corrosive substance.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Anticorrosive coating used on inner wall of desulfurization and denitrification device and preparation method thereof

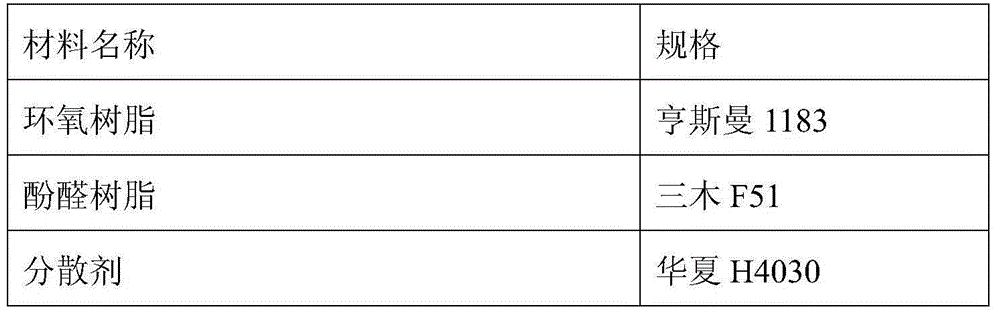

ActiveCN105086772AIncrease crosslink densityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyShock resistance

An anticorrosive coating used on the inner wall of a desulfurization and denitrification device comprises a main paint component A and a curing agent component B. The main paint component A comprises, by weight, epoxy resin, phenolic resin, nano-silicon dioxide, diatomite, ceramic micro-powder, glass powder, carbon black, a dispersing agent, a flatting agent, a defoaming agent, barium sulfate, an antirust agent, a 1# solvent, graphene nano-platelet powder and activated carbon. The curing agent component B comprises, by weight, a modified amine hardener and a 2# solvent. The weight ratio of the component A to the component B is 3.5-4.5:1. The anticorrosive coating is used for corrosion prevention of the inner wall of a dust remover of the desulfurization and denitrification device, is convenient to apply, corrosion of highly corrosive flue gas (such as SO<2>, NO<x>, HF and HCl) to the steel inner wall is effectively prevented, corrosion of highly corrosive liquid (such as H<2>SO<4>, HCl and HF) is effectively prevented, and meanwhile a paint film formed by the anticorrosive coating has very high abrasion resistance, temperature endurance and cold and hot shock resistance.

Owner:江苏云湖新材料科技有限公司

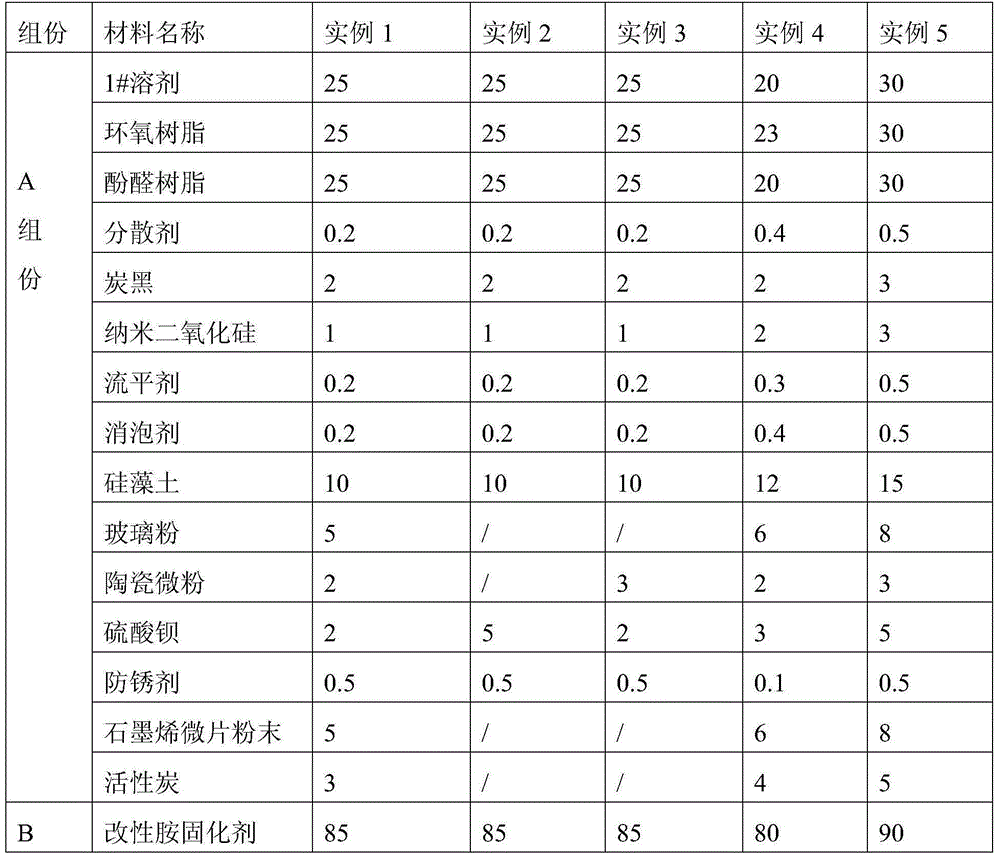

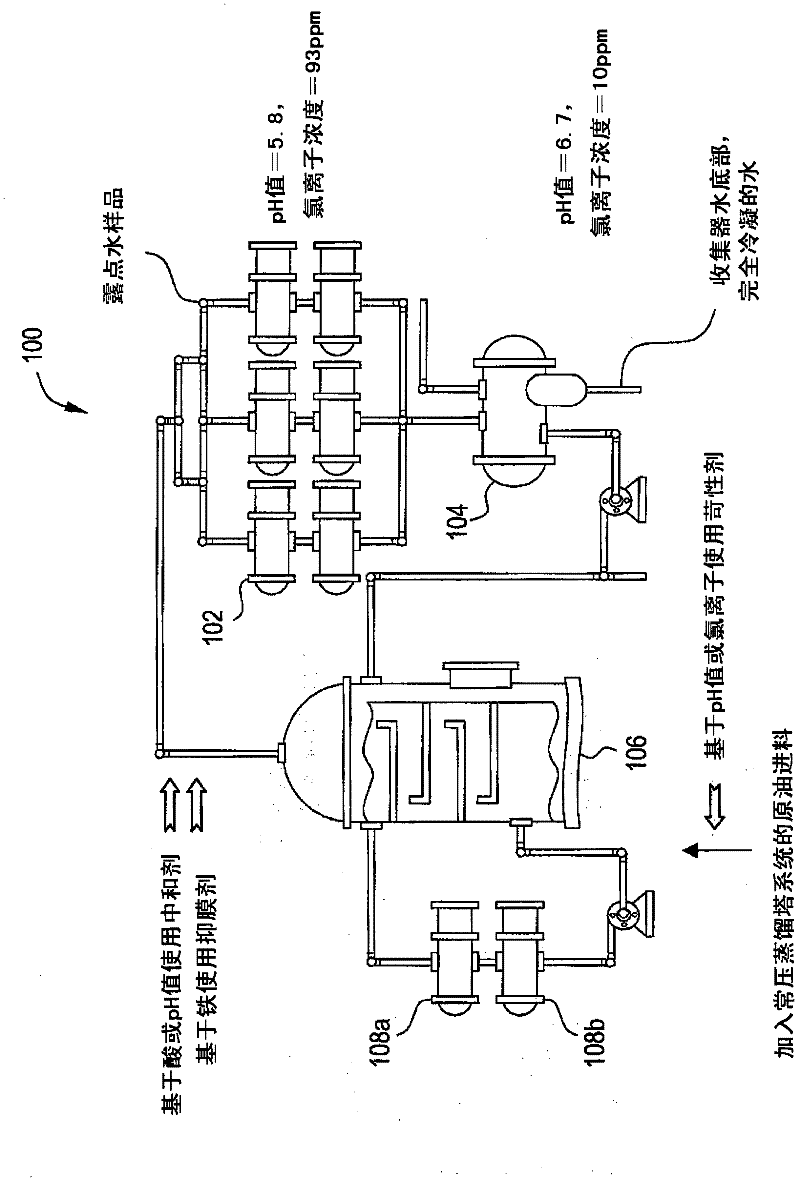

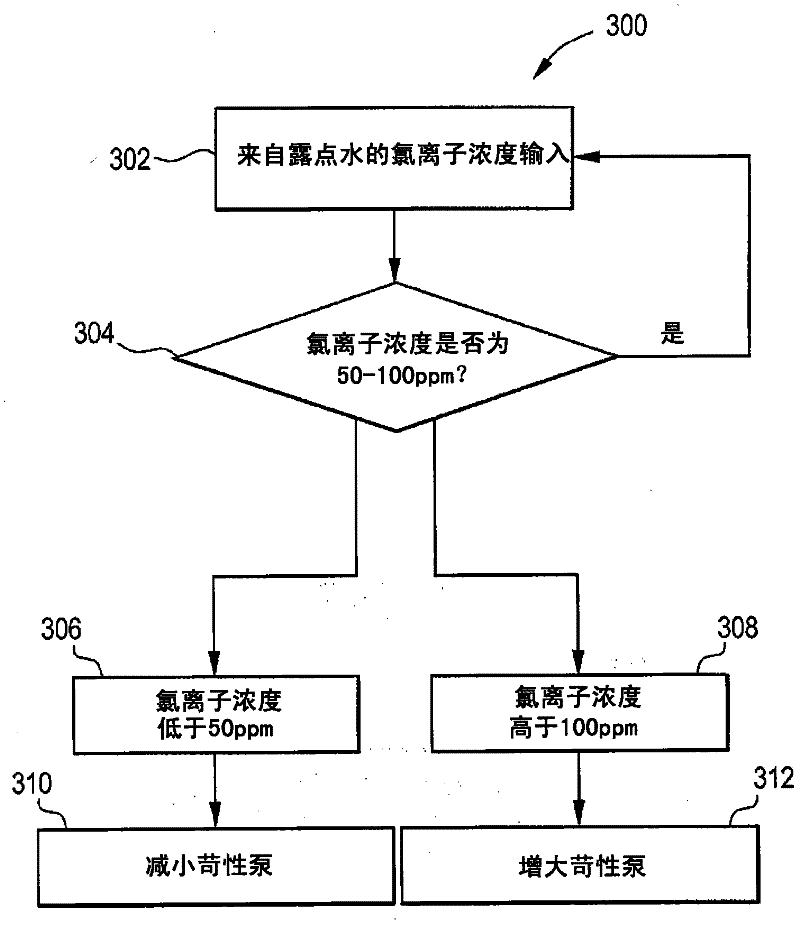

Method of reducing corrosion in a crude unit

ActiveCN102203219AReduce processing stepsReduce corrosionData processing applicationsDistillation corrosion inhibitionProcess engineeringProtection system

A method of optimizing system parameters in a crude unit to reduce corrosion and corrosion byproduct deposition in the crude unit is disclosed and claimed. The method includes measuring or predicting properties associated with the system parameters and using an automated controller to analyze the properties to cause adjustments in the chemical program to optimize the system parameters. Adjusting the system parameters effectively controls corrosion in the crude unit by reducing the corrosiveness of a fluid in the process stream and / or by protecting the system from a potentially corrosive substance. System parameter sensing probes are arranged at one or more locations in the process stream to allow accurate monitoring of the system parameters in the crude unit.

Owner:NALCO CO

Carbon fiber/epoxy resin composite material and preparation method thereof

The invention discloses a carbon fiber / epoxy resin composite material comprising solid epoxy resin, a curing agent, an organic phosphorus fire retardant and carbon fiber, wherein the solid epoxy resin is formed after liquid epoxy resin is crosslinked and cured, and the curing agent is used for crosslinking and curing the liquid epoxy resin. The carbon fiber / epoxy resin composite material takes the organic phosphorus fire retardant as the fire retardant, and a decomposition product of the fire retardant and a combustion product of fire retardant epoxy resin contain fewer corrosive substances and toxic substances, so that secondary pollution to the environment is greatly reduced. The organic phosphorus fire retardant is strong in solubility and easier to disperse in epoxy resin. The organic phosphorus fire retardant as the fire retardant in the carbon fiber / epoxy resin composite material is low in usage and good in fire retardant effect. The carbon fiber / epoxy resin composite material is simple in preparation method and easy for large-scale production.

Owner:CHERY AUTOMOBILE CO LTD

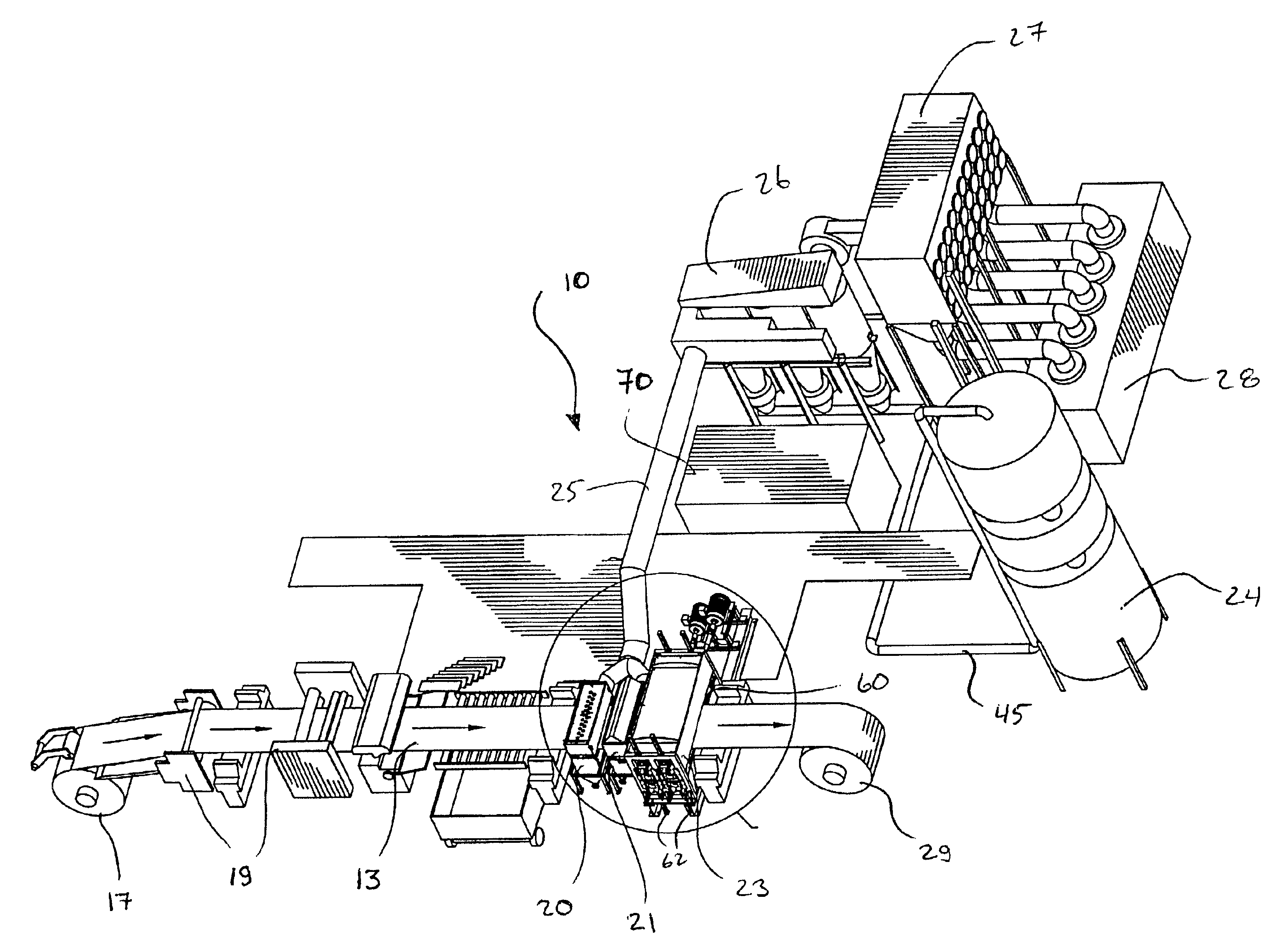

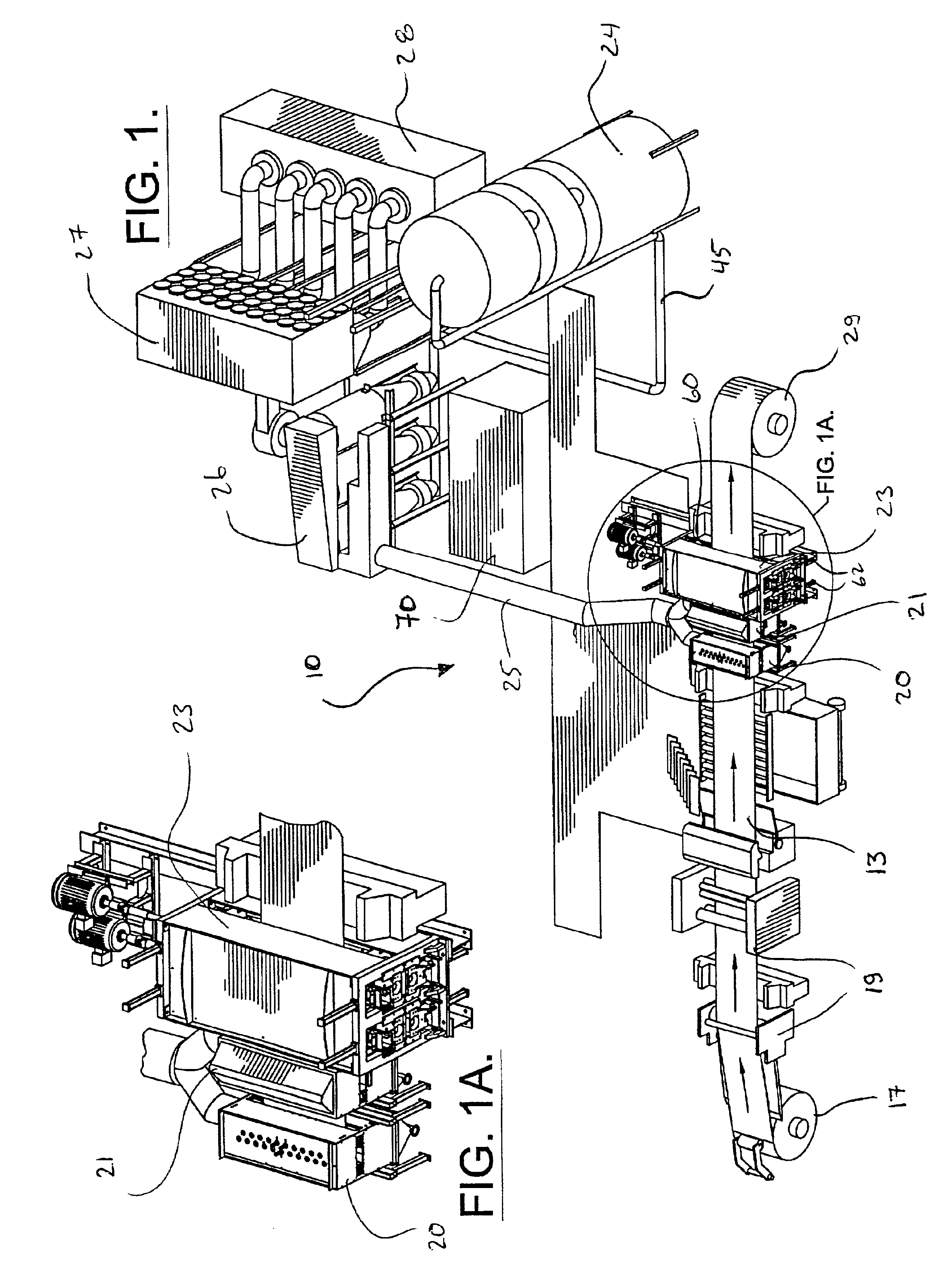

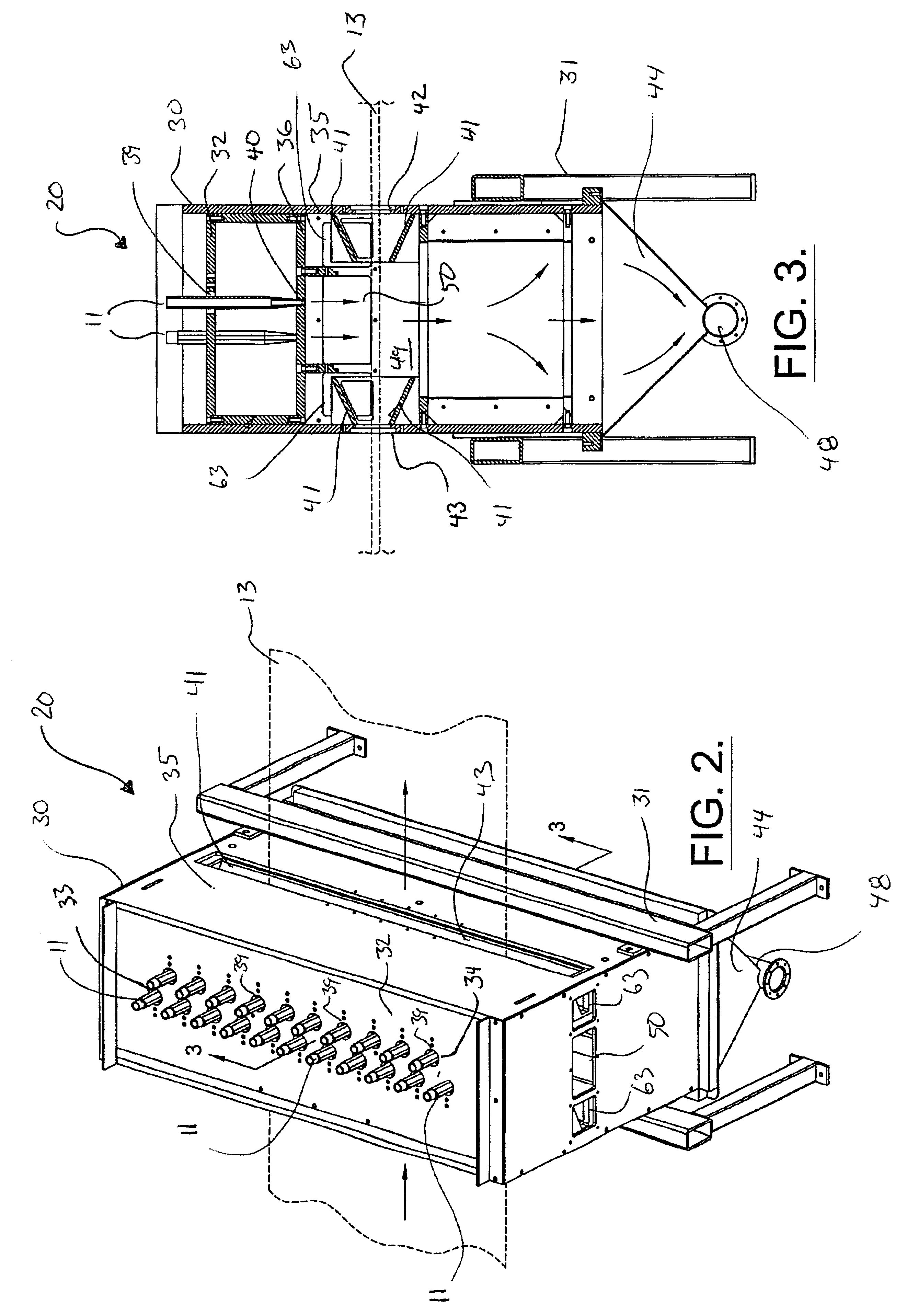

Method for the descaling of metal

InactiveUS6854169B2Corrosion resistanceFaster and robust processWork treatment devicesExtrusion cleaning devicesSheet steelSurface cleaning

A method and apparatus for the descaling of metal surfaces without the use of caustic substances is provided. The apparatus includes a first and second blast heads containing fan shaped nozzles that spray high velocity jets of smooth edged, ceramic media at a scale covered continuous sheet of steel. The continuous sheet of steel is advanced into an abrading station containing a pair of brush assemblies that include stainless steel bristled brushes. The stainless steel brushes engage the surface of the sheet of steel and abrade away the cracked scale, leaving a surface clean of scale. The surface produced is pH neutral and therefore resists additional corrosion and does not require oil coatings, or other protective treatments. The metal surface is produced with a roughness that is less than 2.5 microns Ra without stretching, polishing, cold-rolling or the use of acid pickling. Eliminating these steps makes for a faster, more robust process and saves considerable cost.

Owner:NUCOR CORP

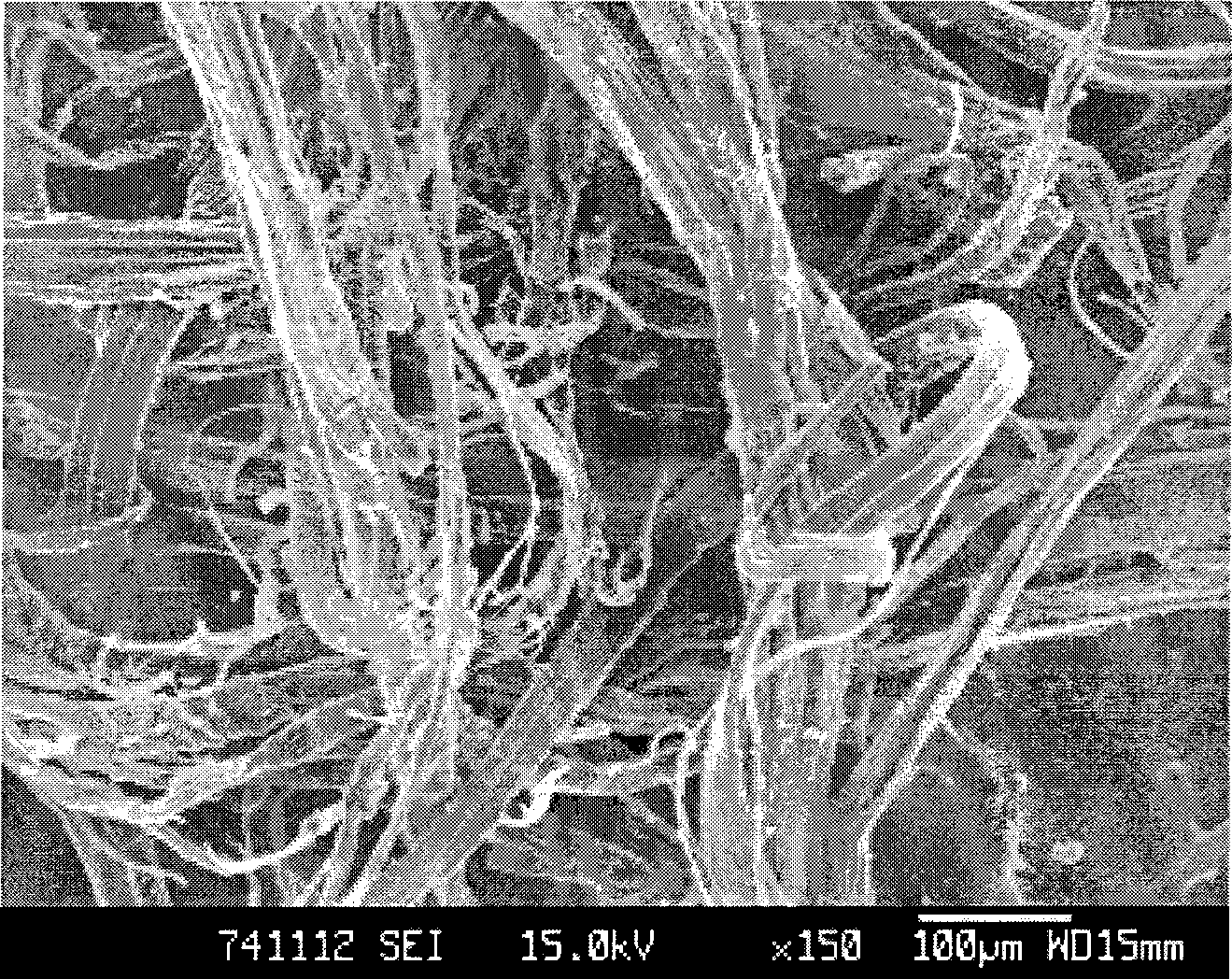

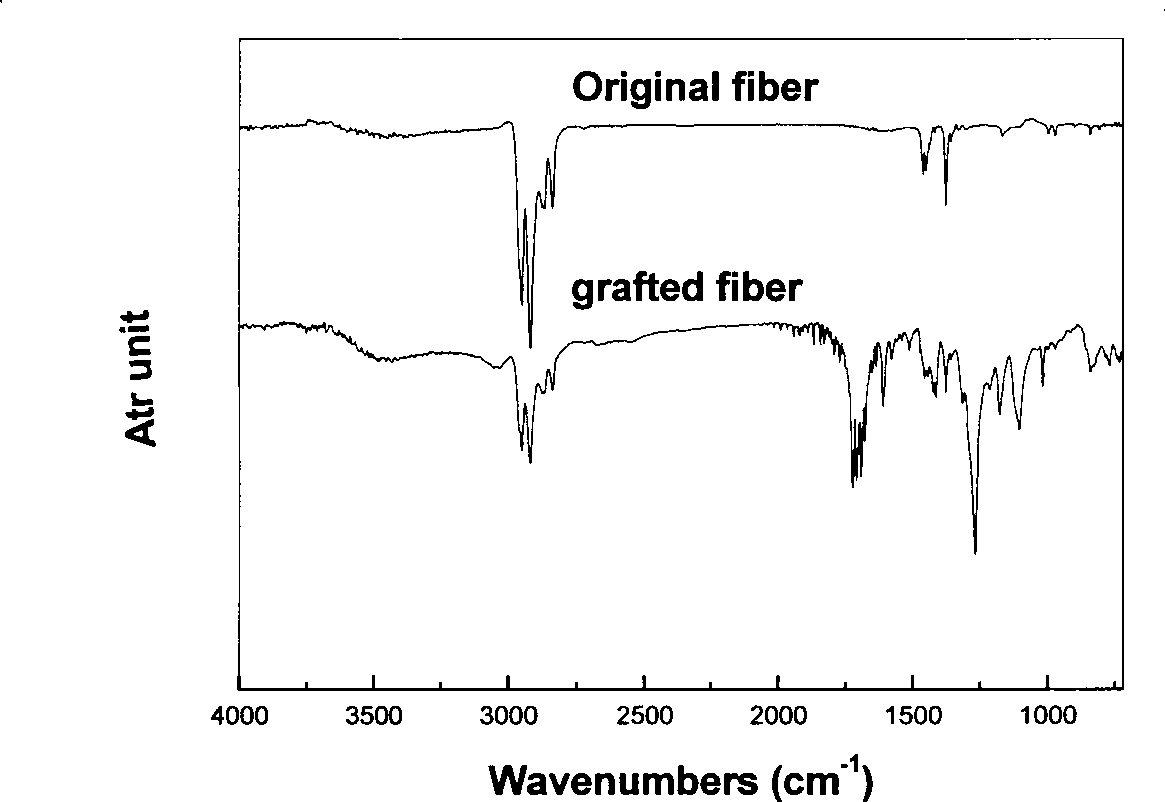

Ion exchange fiber material one-step preparation method

InactiveCN101450330AImprove stabilityImprove integrityIon-exchange process apparatusCation exchanger materialsFiberPre irradiation

The invention relates to a method for preparing ion exchange fiber materials. The method takes fibers such as polytetrafluoroethylene, polypropylene, polyacrylonitrile and polyvinyl alcohol which still have good stability and integrity in an extreme environment as a substrate, prepares the strong-acid and weak-acid bifunctional ion exchange fiber materials by pre-irradiation grafting, and provides products with more superior performance for application (such as purification of strong acid reagent and strong alkali reagent) of the ion exchange fiber materials under harsh conditions. The static adsorption capacity of the products can be controlled to be between 3.0 and 4.98 mmol / g, wherein the static adsorption capacity of strong acid parts is between 1.85 and 2.57 mmol / g. The method has high pre-irradiation grafting efficiency, avoids huge waste of monomers in mutual irradiation, can make the grafting ratio realize controllable operation, avoid utilization of strong corrosive materials such as concentrated sulfuric acid and chlorosulfonic acid for sulfonation reaction, avoid environmental pollution and equipment corrosion, has simple process and easy operation, and provides favorable conditions for industrialization of the ion exchange fiber materials.

Owner:SUN YAT SEN UNIV

Rubber film

The invention discloses a rubber film. The rubber film comprises, by weight, 100 parts of rubber, 15 to 45 parts of a hardening agent, 1 to 3 parts of a yellowing-resistant agent, 1 to 5 parts of a vulcanizing agent, 1 to 5 parts of a vulcanizing accelerating agent, 1 to 3 parts of an aging resistant agent and 1 to 10 parts of an inorganic pigment. The rubber film has high chemical inertness, resists high-corrosivity substances such as acids and alkalis, has certain hardness and deflection, has good luster and an appropriate color, has a low production cost and an appropriate price, can effectively satisfy demands, and is scratched difficultly or has wear resistance.

Owner:LONGMEN DUOTAI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com