Preparation method of polymer hydrophobic surface

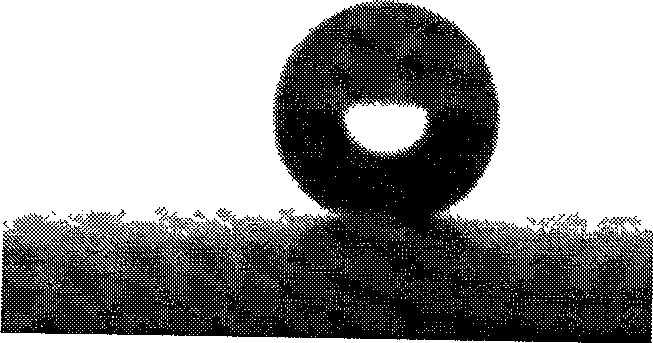

A hydrophobic surface and polymer technology, which is applied in the field of polymer hydrophobic surface preparation, can solve the problems of preparation of hydrophobic surface, multiple assembly, cumbersome steps, etc., and achieve the effect of uniform surface color, stable performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

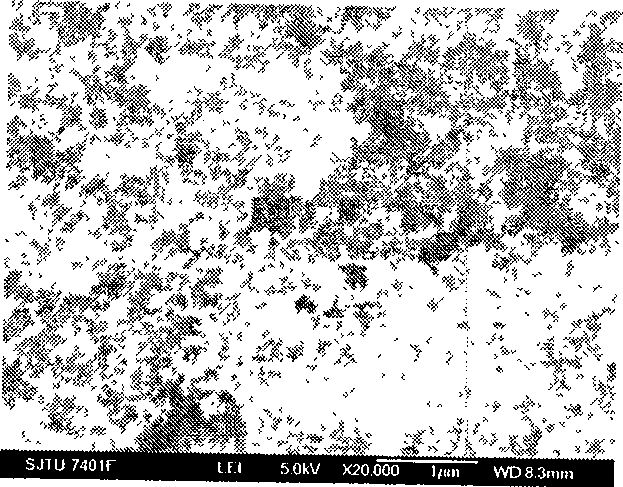

[0024] (1) Weigh 6g of polyphenylene sulfide micropowder, and ultrasonically disperse it in 80mL of a mixed solvent with a volume ratio of water: absolute ethanol: isobutanol = 2:5:1 to make a polymer dispersion;

[0025] (2) Weigh 8 g of polydimethylsiloxane-modified silica hydrophobic micropowder, and ultrasonically disperse it in 120 mL of a mixed solvent with a volume ratio of water: absolute ethanol: isobutanol = 2:5:1, Then add 0.5g of surfactant nonylphenol polyoxyethylene ether, and ultrasonically treat it for 5 minutes to disperse it evenly to make a hydrophobic silica dispersion;

[0026] (3) Mix 80mL of the polymer dispersion and 120mL of the hydrophobic silica dispersion evenly, and then ultrasonically treat them for 5 minutes to disperse them evenly to make a hydrophobic coating;

[0027] (4) Use a spray gun to spray the hydrophobic coating with a pressure of 0.2 MPa onto the tiles that have been washed and dried in advance, then dry the tiles at 80°C for half an ...

Embodiment 2

[0032] (1) Weigh 6g of polyphenylene sulfide micropowder, and ultrasonically disperse it in 60mL of a mixed solvent with a volume ratio of absolute ethanol:isobutanol=1:1 to make a polymer dispersion;

[0033] (2) Weigh 6g of polydimethylsiloxane-modified silicon dioxide hydrophobic micropowder, ultrasonically disperse it in 60mL of a mixed solvent with a volume ratio of absolute ethanol:isobutanol=1:1, and then add 0.5g Surfactant sodium stearate, sonicated for 5 minutes to make it uniformly dispersed to make a hydrophobic silica dispersion;

[0034] (3) Mix 60mL of the polymer dispersion and 60mL of the hydrophobic silica dispersion evenly, and then ultrasonically treat them for 5 minutes to disperse them evenly to make a hydrophobic coating;

[0035] (4) Use a spray gun to spray the hydrophobic coating with a pressure of 0.2 MPa onto the steel sheet that has been cleaned and dried in advance, then dry the steel sheet at 60°C for half an hour and then keep it at 200°C for 1....

Embodiment 3

[0037] (1) Weigh 6g of polyphenylene sulfide micropowder, and ultrasonically disperse it in 60mL of absolute ethanol to make a polymer dispersion;

[0038] (2) Weigh 8g of polydimethylsiloxane-modified silicon dioxide hydrophobic micropowder, ultrasonically disperse it in 120mL of absolute ethanol, then add 0.5g of surfactant cetyltrimethylammonium bromide, Ultrasonic treatment for 5 minutes to make it uniformly dispersed to make a hydrophobic silica dispersion;

[0039] (3) Mix 60mL of the polymer dispersion and 120mL of the hydrophobic silica dispersion evenly, and then ultrasonically treat it for 5 minutes to disperse it evenly to make a hydrophobic coating;

[0040] (4) Use a spray gun to spray the hydrophobic coating with a pressure of 0.2 MPa onto the previously cleaned and dried plastic plate, then dry the plastic plate at 80°C for half an hour and then keep it at 160°C for 1.5 hours. A plastic plate with a superhydrophobic coating, and the thickness of the hydrophobic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com