Phenyl MDT silicon resin and preparation method thereof

A silicone resin and phenyl technology, applied in the field of polymer chemistry, to achieve the effect of simple operation steps, saving procedures, and low equipment and operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

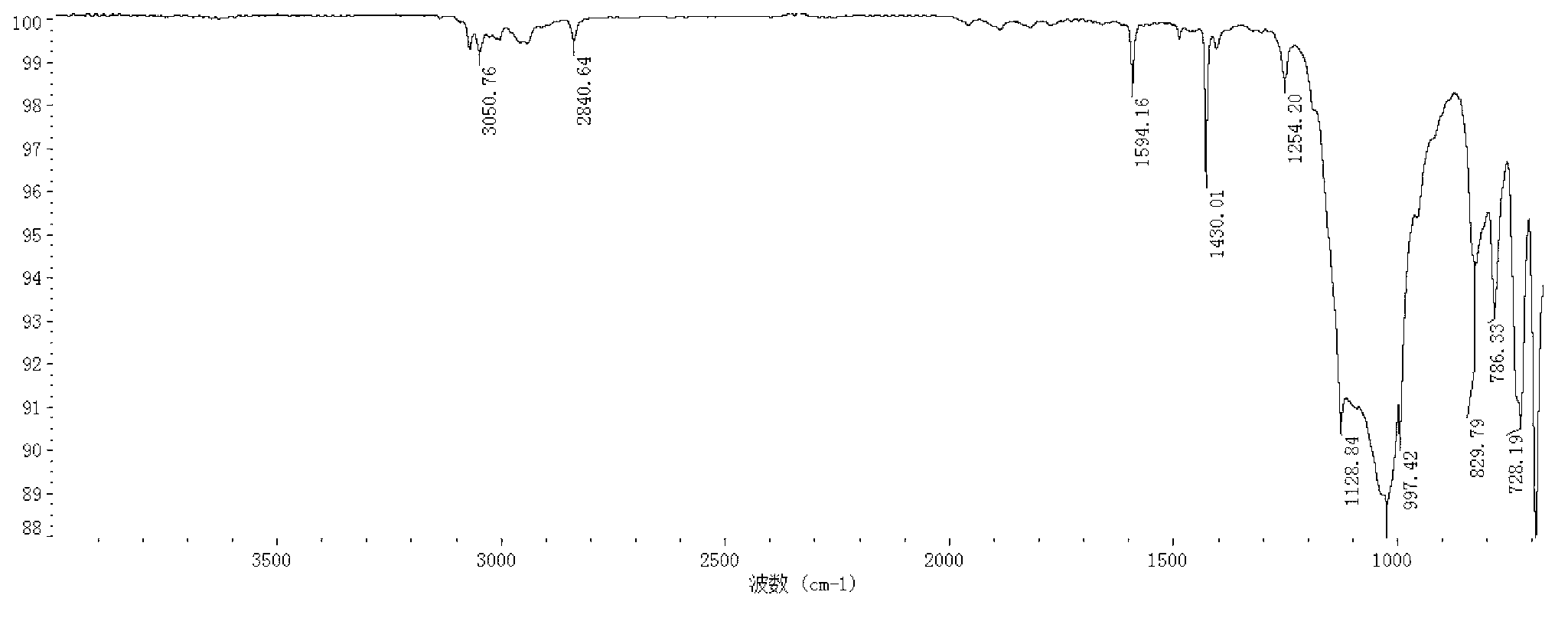

Image

Examples

Embodiment 1

[0024] Add the source of T chain link into the three-necked bottle: 100 parts of phenyltrimethoxysilane; the source of D chain link: 25 parts of diphenyldimethoxysilane, 50 parts of dimethyldiethoxysilane; the source of M chain link: 10 parts of vinyldimethylethoxysilane, 20 parts of hexamethyldisiloxane; 55 parts of hydrochloric acid with a mass fraction of 1% was added dropwise at room temperature, and the drop was completed in 30 minutes. After completion, the temperature was raised to 50°C for 1 hour, and then the temperature was raised Reaction at 70°C for 5h. The reaction solution was left to stand for stratification, the organic layer was washed to neutrality, dried with 5 parts of calcium chloride, and the filtrate was collected by filtration. The filtrate was equilibrated with tetramethylammonium hydroxide at 110°C for 5 hours and heated to 180°C. The catalyst was decomposed and removed, and the low-molecular substances were removed under the negative pressure conditi...

Embodiment 2

[0026] Add T chain link: 121 parts of phenyltriethoxysilane into the three-necked bottle; D chain link: 28 parts of diphenyldiethoxysilane, 40 parts of dimethyldimethoxysilane; M chain link: vinyl 10 parts of dimethylmethoxysilane, 20 parts of hexamethyldisiloxane; 50 parts of 0.5% sulfuric acid aqueous solution was added dropwise at room temperature, and the dripping was completed in 30 minutes. After completion, the temperature was raised to 50°C for 1 hour, and then the temperature was raised to 70°C Reaction 5h. The reaction solution was left to stand for stratification, the organic layer was washed to neutrality, dried with 5 parts of calcium chloride and filtered to collect the filtrate, the filtrate was reacted at 120°C for 5h with 0.03% of the weight of the filtrate, and the temperature was raised to 180°C for decomposition The catalyst was removed, and low-molecular substances were removed under negative pressure conditions of -0.096MPa to obtain a colorless and trans...

Embodiment 3

[0027] Add T chain link: 100 parts of phenyltrimethoxysilane into the three-necked bottle; D chain link: 50 parts of diphenyldimethoxysilane; M link: 16 parts of vinyldimethylmethoxysilane, hexamethoxy 20 parts of base disiloxane; 8 parts of macroporous strongly acidic cation exchange resin, 50 parts of deionized water; the temperature was raised to 80° C., and the reaction was carried out at this temperature for 8 hours. The reaction solution was filtered, the filtrate was allowed to stand and separated, the water layer was removed, the organic layer was dried with 5 parts of calcium chloride and filtered, and the filtrate was reacted with 0.5 parts of 1% KOH at 140°C for 6 hours, and CO 2 Filter the reaction solution until the reaction solution is neutral, and remove low-molecular substances from the filtrate under negative pressure conditions of 180°C / -0.096MPa to obtain a colorless and transparent oily product. Product refractive index n D =1.5421, the vinyl content is 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com