Nickel electroplating liquid, and preparation method for super-hydrophobic nickel plating layer using same

A technology for nickel electroplating solution and mixed solution is applied in the field of nickel electroplating solution and preparation of super-hydrophobic nickel coating, which can solve problems such as injury to environmental operators, and achieve the effects of being environmentally friendly, convenient for preparation, and simple and controllable in process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Choline chloride (purchased from Aladdin Reagent (Shanghai) Co., Ltd.) and ethylene glycol were stirred and mixed at a molar ratio of 1:2 at 75° C. to obtain a choline chloride-based ionic liquid. 5 g NiCl 2 ·6H 2 O was dissolved in 40ml of choline chloride-based ionic liquid to obtain nickel electroplating solution.

[0020] Electrolytic nickel is used as the anode, and the brass sheet is used as the cathode, and electroplating is carried out in the nickel electroplating solution prepared above, the plating voltage is 1V, the temperature of the nickel electroplating solution is 90°C, and the electroplating time is 1 hour. After the electroplating is completed, use methanol Wash the coating with water and dry it in turn.

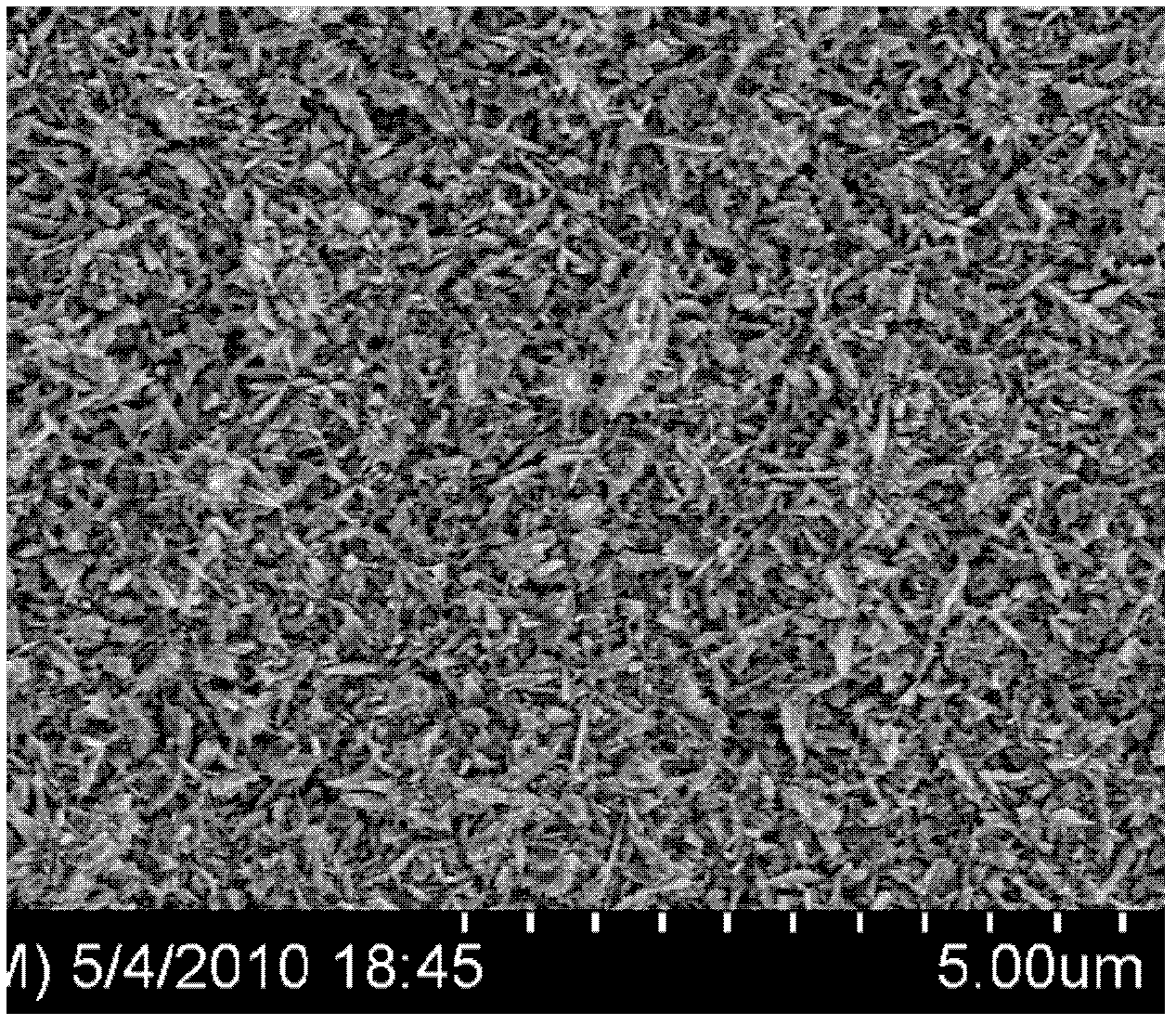

[0021] The thickness of the nickel plating layer prepared above is about 5 μm. The scanning electron micrographs show that the surface of the nickel coating is composed of nanoscale nickel flakes, and the scanning electron micrographs are as follow...

Embodiment 2

[0024] Choline chloride (purchased from Aladdin Reagent (Shanghai) Co., Ltd.) and propylene glycol were stirred and mixed at a molar ratio of 1:2 at 75° C. to obtain a choline chloride-based ionic liquid. 2.0 g NiCl 2 Dissolve in 40ml of choline chloride-based ionic liquid to obtain nickel electroplating solution.

[0025] Electrolytic nickel is used as the anode, and the brass sheet is used as the cathode. Electroplating is carried out in the nickel electroplating solution prepared above, and the electrodeposition is carried out in a pulse deposition mode. The plating voltage is 1V, and the pulse frequency is not required. The temperature of the nickel electroplating solution is 60 ℃, the electroplating time is 1 hour, and after the electroplating is completed, the coating layer is cleaned and dried with methanol and water in sequence.

[0026] The thickness of the nickel plating layer prepared above is about 2 μm. The contact angle and rolling angle of the nickel coating s...

Embodiment 3

[0028] Choline chloride (purchased from Aladdin Reagent (Shanghai) Co., Ltd.) and urea were stirred and mixed at a molar ratio of 1:2 at 75° C. to obtain a choline chloride-based ionic liquid. 13 g NiCl 2 ·6H 2 O was dissolved in 40ml of choline chloride-based ionic liquid to obtain nickel electroplating solution.

[0029] Electrolytic nickel is used as the anode, and the brass sheet is used as the cathode. Electroplating is carried out in the nickel electroplating solution prepared above, and a DC power supply is used for electrodeposition. The plating voltage is 0.5V, and the pulse frequency is not required. The temperature of the nickel electroplating solution is 100 ℃, the electroplating time is 1 hour, and after the electroplating is completed, the coating layer is cleaned and dried with methanol and water in sequence.

[0030] The thickness of the nickel plating layer prepared above is about 12 μm. Measurements of the contact angle and rolling angle on the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com