Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "Has superhydrophobic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

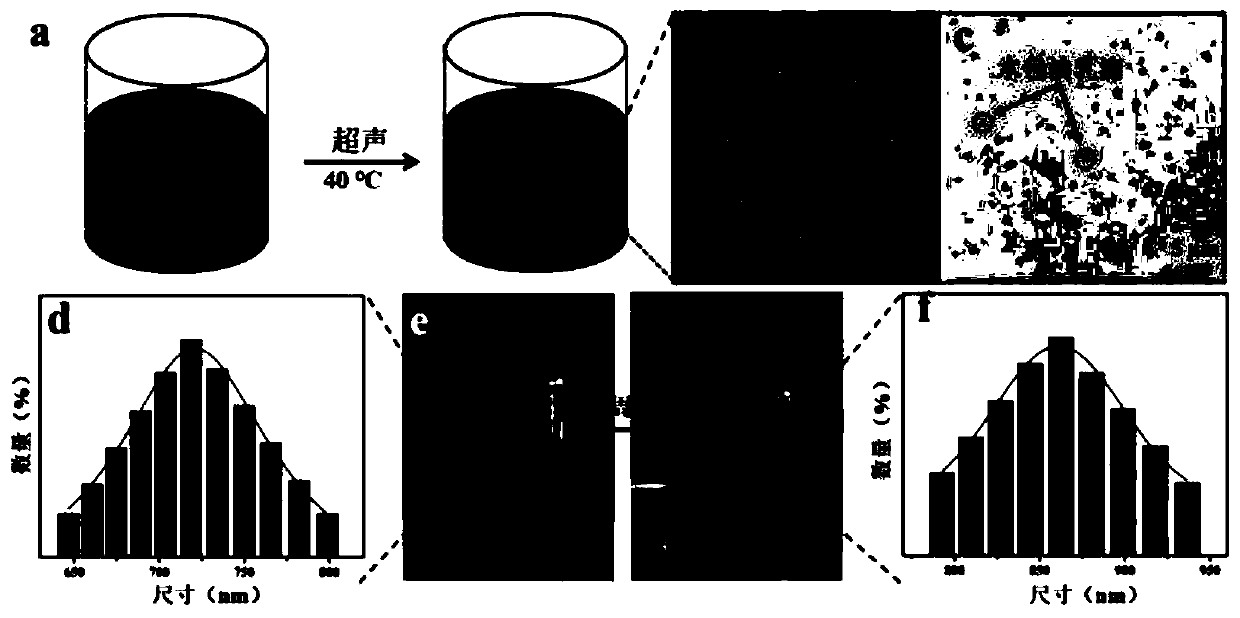

Superhydrophobic paint, superhydrophobic coating and preparation method thereof

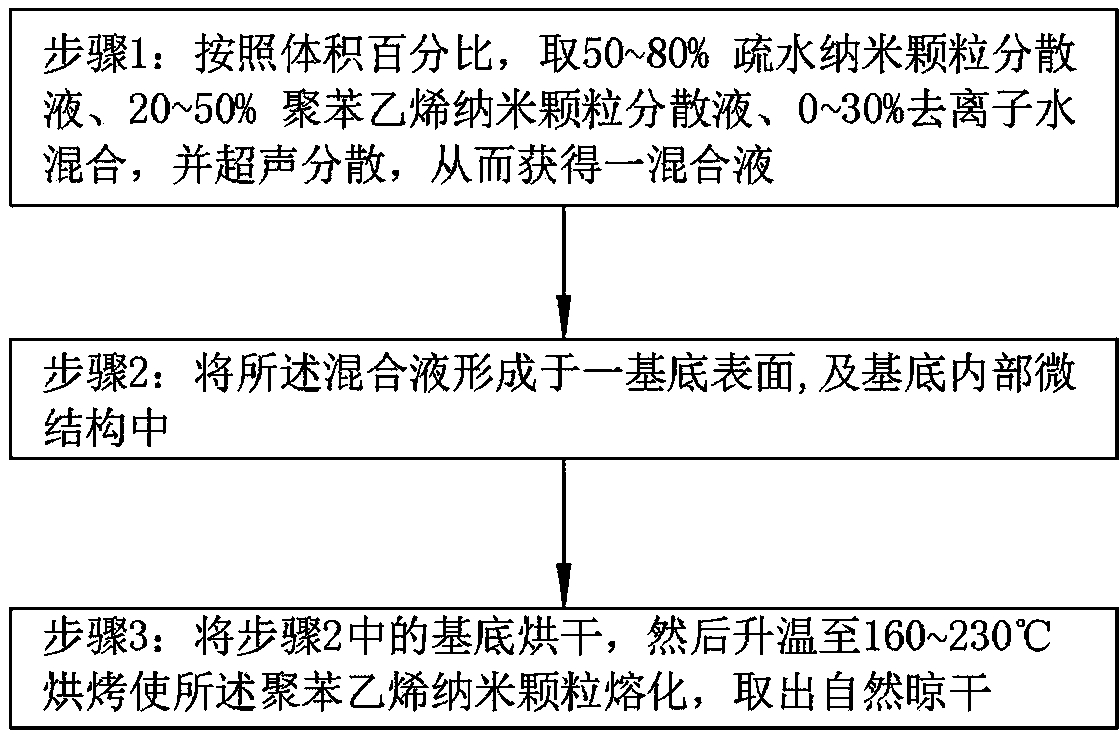

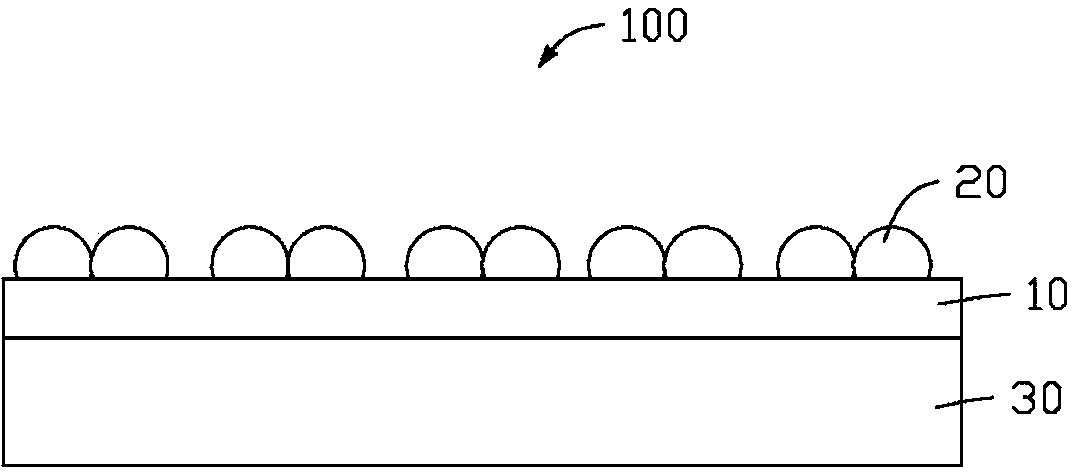

The invention provides a preparation method of a superhydrophobic coating. The preparation method comprises the steps of 1, mixing 50-80 parts of hydrophobic nanoparticle dispersing liquid with the mass percentage of 2-15%, 20-50 parts of polystyrene nanoparticle dispersing liquid with the mass percentage of 1-10% and 0-30 parts of solvent according to the volume part ratio, and ultrasonically dispersing the mixture to obtain a mixed solution; 2, forming the mixed solution on the surface of a substrate and in a microstructure in the substrate; 3, drying the substrate obtained in the step 2, then, raising the temperature to 160-230 DEG C, baking to melt polystyrene nanoparticles, and taking out for naturally airing. The invention also relates to a superhydrophobic paint and the superhydrophobic coating.

Owner:TSINGHUA UNIV

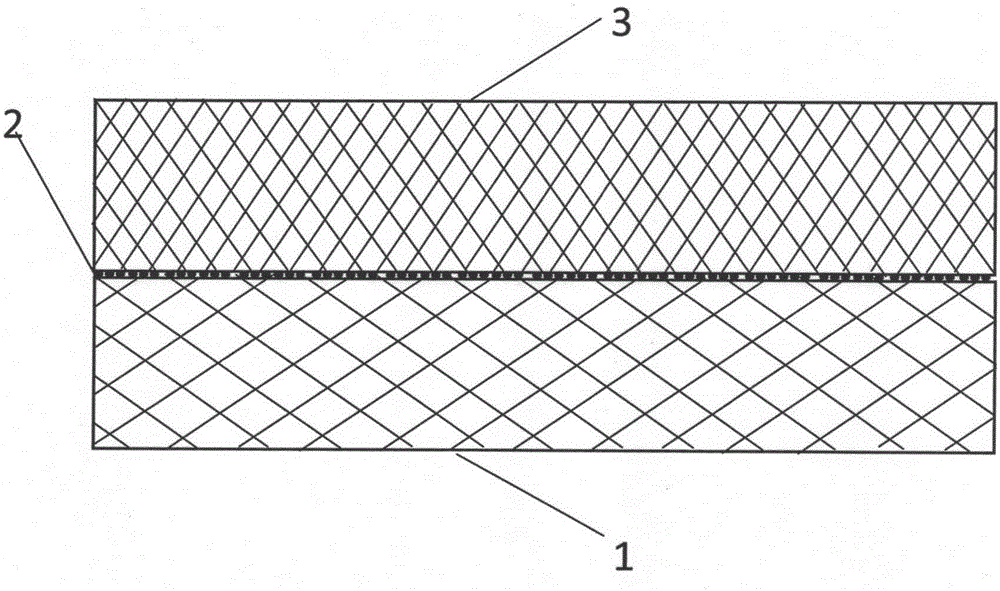

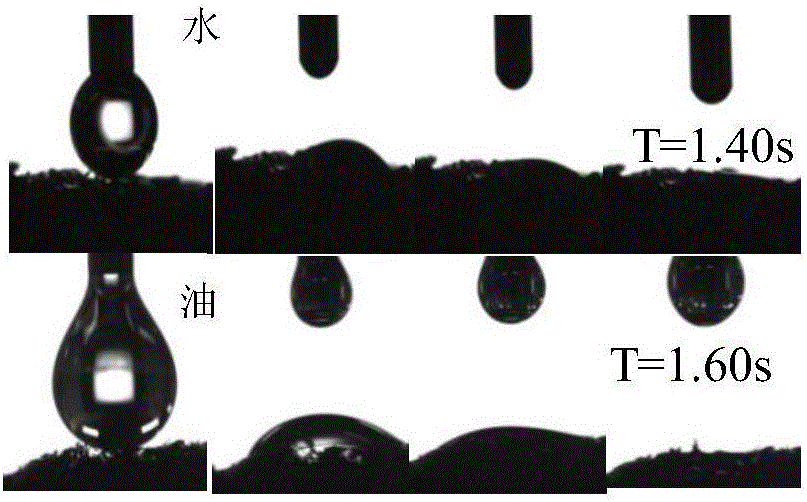

Preparation method of fiber-based waterproof moisture-permeable film with intelligent unidirectional moisture conductivity

ActiveCN105966006AWith hygroscopic expansion propertiesWith one-way moisture transfer functionSynthetic resin layered productsLaminationFiberCross-link

The invention provides a preparation method of a fiber-based waterproof moisture-permeable film with intelligent unidirectional moisture conductivity. The preparation method comprises dissolving a hydrophilic polymer in a solvent A, adding a cross-linking agent into the solution to obtain a spinning solution, preparing a hydrophilic fibrous layer on a reception base through an electrostatic spinning method, spraying glue to the hydrophilic fibrous layer through an electrostatic spraying method to obtain a glue layer, dissolving a hydrophobic polymer in a solvent B to obtain a spinning solution, forming a hydrophobic fibrous layer on the glue layer through the electrostatic spinning method to obtain a fiber film, and carrying out heat treatment on the fiber film so that the polymer in the hydrophilic fibrous layer undergoes a chemical crosslinking reaction to produce a moisture absorption expansion fibrous layer and thus the fiber-based waterproof moisture-permeable film with intelligent unidirectional moisture conductivity is obtained. The fiber-based waterproof moisture-permeable film has intelligent unidirectional moisture conductivity of low moisture opening steam discharge and high moisture closed sweat guide and guarantees human body dryness and comfort in various environments.

Owner:DONGHUA UNIV

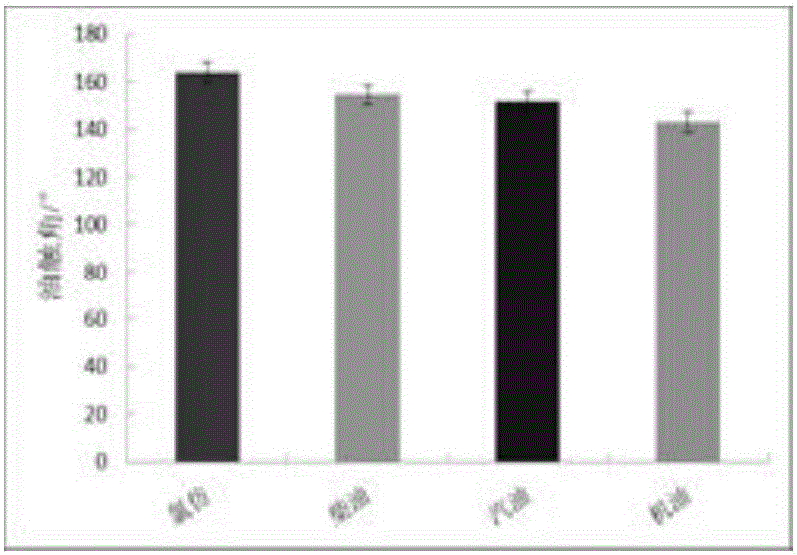

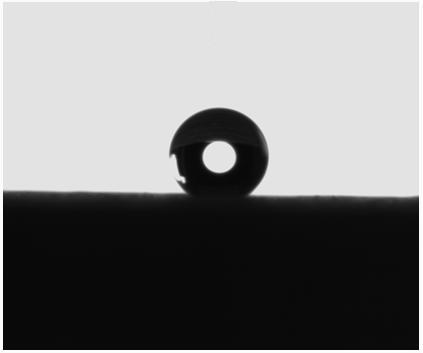

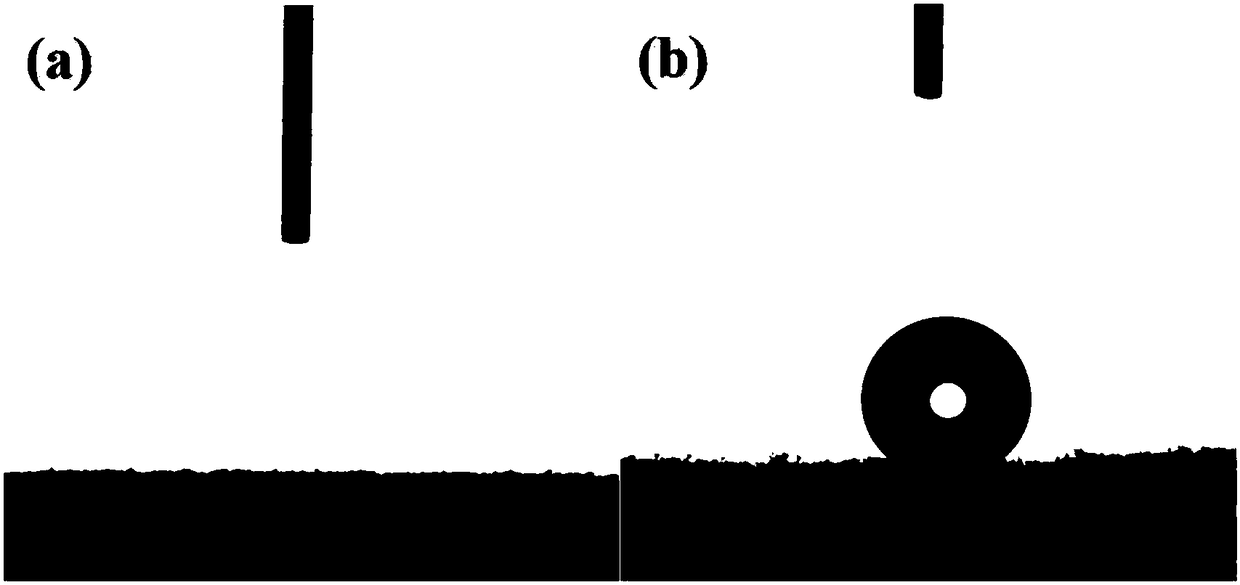

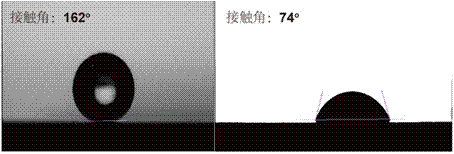

Metal super-hydrophobic surface and preparation method thereof

The invention relates to a metal super-hydrophobic surface and a preparation method thereof. The preparation method comprises following two steps: firstly, electroplating method is adopted, traditional Watts electroplate liquid is taken as a base electroplate liquid, conductive metal base materials such as stainless steel, copper, aluminium alloy, and magnesium aluminum alloy, are taken as a negative electrode, and copper sheets are taken as a positive electrode so as to prepare a nickel coating layer; and secondly, an obtained electroplated surface and an ethanol solution containing fluorosilane are delivered into a heating furnace for heat treatment, and an obtained sample is subjected to washing and blow drying so as to obtain the surface with super-hydrophobicity on metal workpieces. The preparation method of the metal super-hydrophobic surface is simple; cost is low; and the preparation method is convenient for industrialized application. Contact angle of the obtained metal super-hydrophobic surface is more than 155 DEG, and rolling angel is less than 10 DEG; the metal super-hydrophobic surface possesses excellent super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance; the preparation method is suitable for obtaining the metal super-hydrophobic surfaces with super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance on the surfaces of a plurality of metal base materials with complex shapes and large area.

Owner:SOUTH CHINA UNIV OF TECH

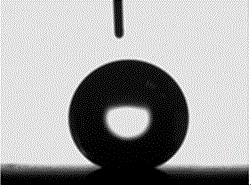

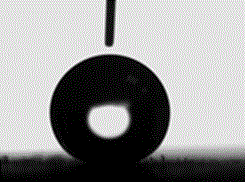

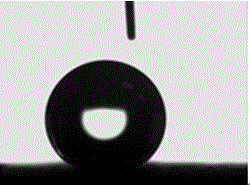

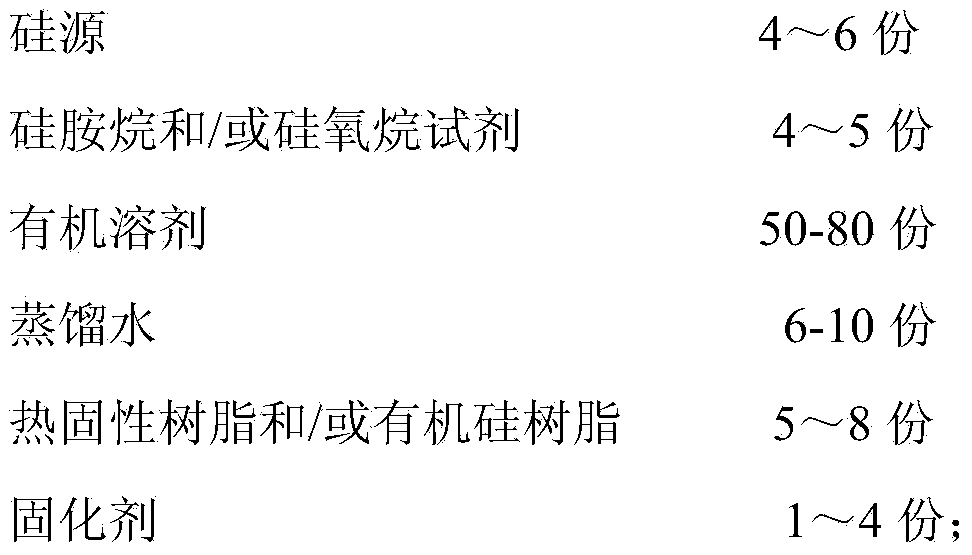

Super-hydrophobic surface with moisture evacuating function and preparation method thereof

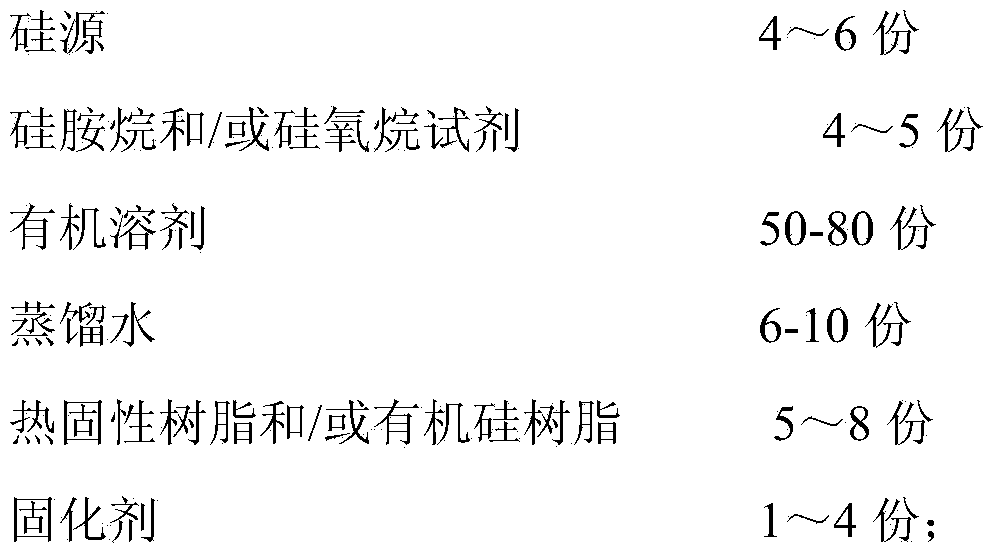

ActiveCN104073031AEasy to makeEasy constructionEpoxy resin coatingsPolyester coatingsOrganic solventDistilled water

The invention discloses a super-hydrophobic surface with a moisture evacuating function and a preparation method thereof, wherein the super-hydrophobic surface is prepared from the following raw materials in parts by weight: 4-6 parts of silicon source, 4-5 parts of silizane and / or siloxane reagent, 50-80 parts of organic solvent, 6-10 parts of distilled water, 5-8 parts of thermosetting resin and / or organic silicon resin and 1-4 parts of curing agent. The preparation method comprises the following steps: adding the silicon source into the organic solvent; adding the distilled water and the silizane and / or siloxane reagent; adding the thermosetting resin and / or organic silicon resin; adding the curing agent; covering the treated substrate surface. The super-hydrophobic surface disclosed by the invention is common and easily available in raw materials and low in cost, and the preparation method is simple in process, simple in process and convenient to construct, and can be applied to various substrate surfaces. The contact angle of the obtained super-hydrophobic surface to water maximally can reach 160 degrees, and the rolling angle minimally can reach 2 degrees. The super-hydrophobic surface maintains a dry state to micro-moisture, and has good mechanical property and durability.

Owner:SOUTH CHINA UNIV OF TECH

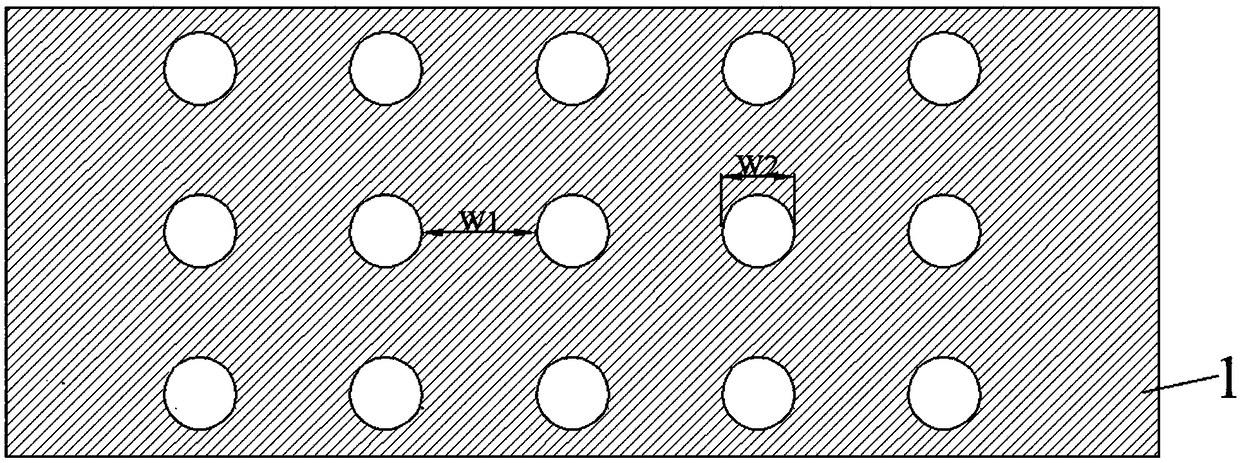

Polymer film, and preparation method and application thereof

InactiveCN107150465AHas superhydrophobic propertiesSuperhydrophobic properties do not affectLamination ancillary operationsLaminationPolymer scienceNanoparticle

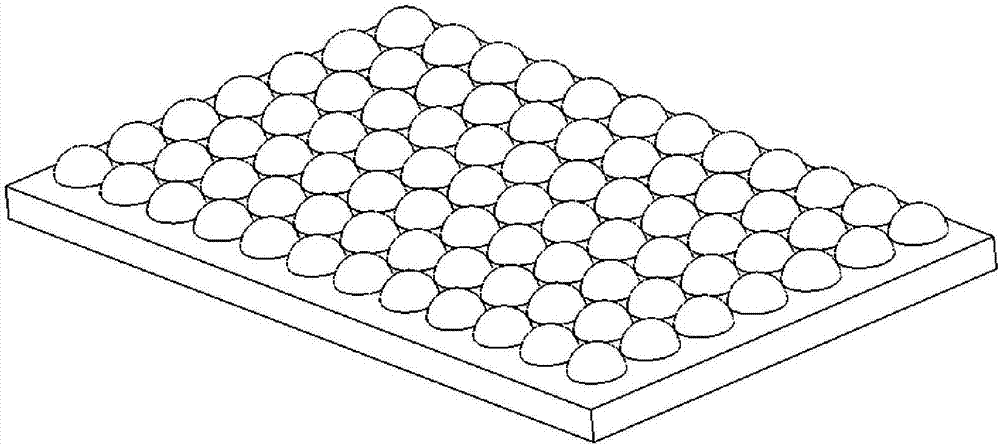

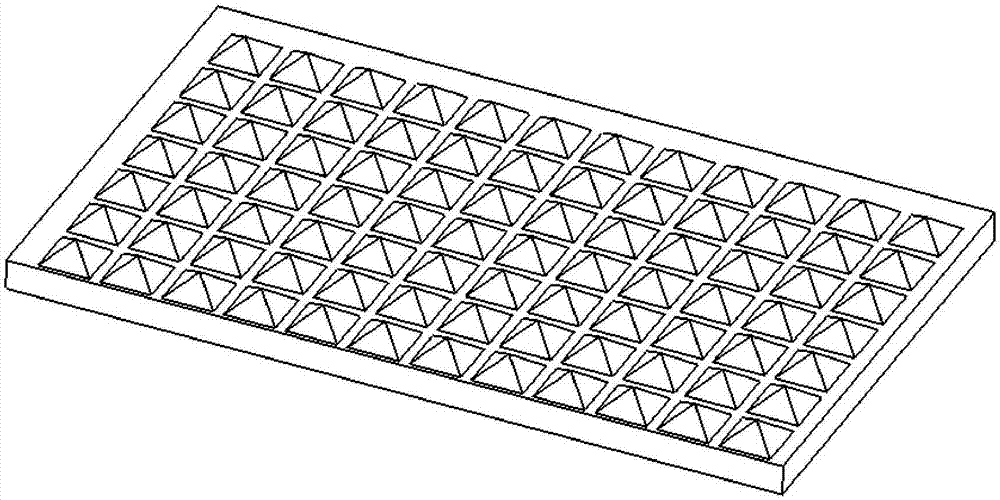

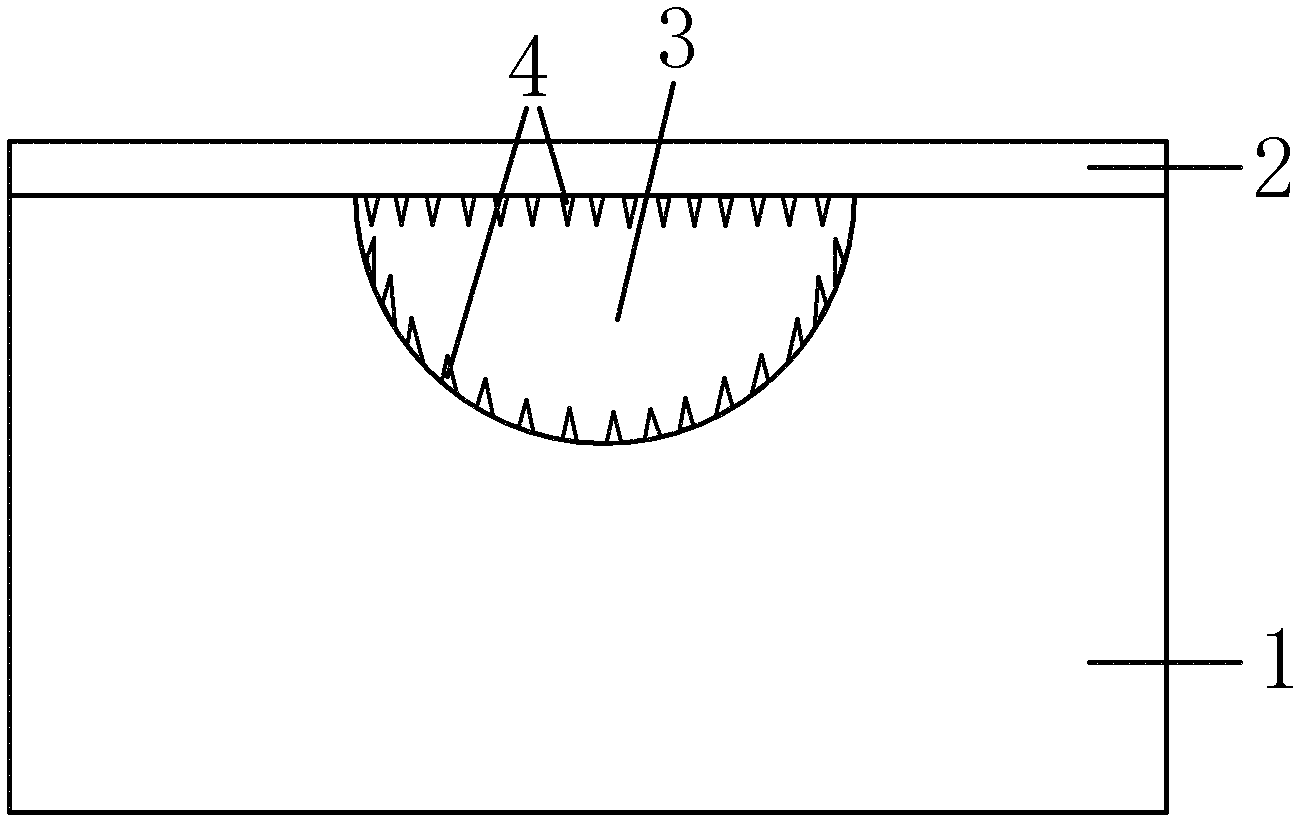

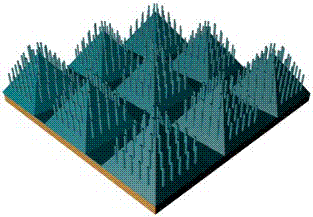

The invention discloses a polymer film, a preparation method and application thereof. The polymer film comprises a substrate layer and a molding resin layer, the molding resin layer is attached to the substrate layer; the side of the molding resin layer away from the substrate layer has several micron-scale protrusions, and the width of the bottom surface of the micron-scale protrusions is 50 μm to 2000 μm , the height of the micron-scale protrusions is 20 μm to 1000 μm, and the distance between two adjacent micron-scale protrusions is 10 μm to 500 μm; the polymer film also includes a nanoparticle layer, and the average particle size of the nanoparticles in the nanoparticle layer is 3 to 150nm ; The nanoparticle layer is attached to the surface of the molding resin layer having micron-scale protrusions. The three-dimensional network structure formed by the nanoparticles of the polymer film between micron-scale protrusions has good stability and fastness. The polymer film has good hydrophobicity, good touch resistance and abrasion resistance, and is heat-sealable. Good features. The preparation method has simple process and low cost.

Owner:SHANGHAI TECHSUN ANTI COUNTERFEITING TECH HLDG

Preparation method of titanium dioxide superhydrophobic film

ActiveCN104176774ARough structure regularGood hydrophobicityTitanium dioxideLaser interferenceMicro pattern

The invention discloses a preparation method of a titanium dioxide superhydrophobic film, which comprises the following steps: constructing a micron-sized dot matrix coarse structure on a titanium dioxide film surface by a photosensitive sol-gel micro-machining technique, and carrying out chemical modification on the titanium dioxide film surface subjected to micro-pattern coarsening by using 1H,1H,2H,2H-perfluorooctyl trichlorosilane to obtain the superhydrophobic titanium dioxide film. By regulating the sol proportioning and dual-beam laser interference fringe width, the size of the micron-sized dot matrix coarse structure on the titanium dioxide film surface can be effectively regulated, thereby preparing the titanium dioxide films with different hydrophobicities. The prepared film surface coarse structure has the advantages of high regularity, excellent hydrophobicity, simple technique and favorable repetitiveness, and is easy to regulate.

Owner:YANGZHOU GUANGTAI CHEM FIBER

Preparation method of graphene composite foam for oil-water separation

ActiveCN106732422AAchieve separationWith underwater super oleophobic propertiesIon-exchange process apparatusFatty/oily/floating substances removal devicesFreeze-dryingAnti bacteria

The invention relates to the field of polymer materials, in particular to a preparation method of graphene composite foam for oil-water separation. The preparation method comprises the steps that reduction and crosslinking are conducted on oxidized graphene by dopamine, a hydrothermal method is used to make the oxidized graphene form a three-dimensional structure in self-assembly mode, chitosan / graphene composite foam is prepared by soaking and freeze-drying with a chitosan solution, and finally the chitosan / graphene composite foam is fluoridized to prepare the fluoridized graphene composite foam. The obtained chitosan / graphene composite foam has super amphipathicity in the air and underwater super lipophobicity, after the fluoridation, the chitosan / graphene composite foam has super hydrophobicity, and chitosan and raphene have the advantages of good flexibility, high selective separation efficiency and long cycle service life; the foam can exist stably in a corrosive medium; water takes use of gravity to go through the chitosan / graphene composite foam and does not need to be driven by external force; non-toxic biological materials such as the dopamine and the chitosan are used, the foam is green and environmentally friendly, an anti-bacteria effect of the chitosan serves as a function of purifying a water body during the oil-water separation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of superhydrophobic self-cleaning material

InactiveCN101982490AHas superhydrophobic propertiesCompliant with self-cleaning material requirementsInorganic pigment treatmentPolymer scienceGlycerol

The invention relates to a preparation method of superhydrophobic self-cleaning material. Firstly silicon rubber and vulcanizer are mixed by weight proportion of 100: (0.5-3), refining is carried out, and pre-mixed glue is prepared; then graphite is fluoridized, polypropylene (100phr), graphite fluoride (1-50phr), pre-mixed glue (1-50phr), antioxidant (0.5-3phr), stearic acid (0.5-3phr) and glycerol (0.5-3phr) are mixed based on weight part, a double screw extrusion machine is used for extrusion, then a pelleting machine is used for pelleting, thus obtaining blended particle; the blended particle is pressed into plates by virtue of a flat high temperature pressing machine, and chips on the surface of plates are removed by adopting 80#-600# sand paper, thus obtaining the required superhydrophobic self-cleaning material. The superhydrophobic self-cleaning material obtained by adopting the method provided by the invention can realize good superhydrophobic and self-cleaning effects, and meanwhile processing method is simple, and application prospect and economic value are good.

Owner:EAST CHINA UNIV OF SCI & TECH

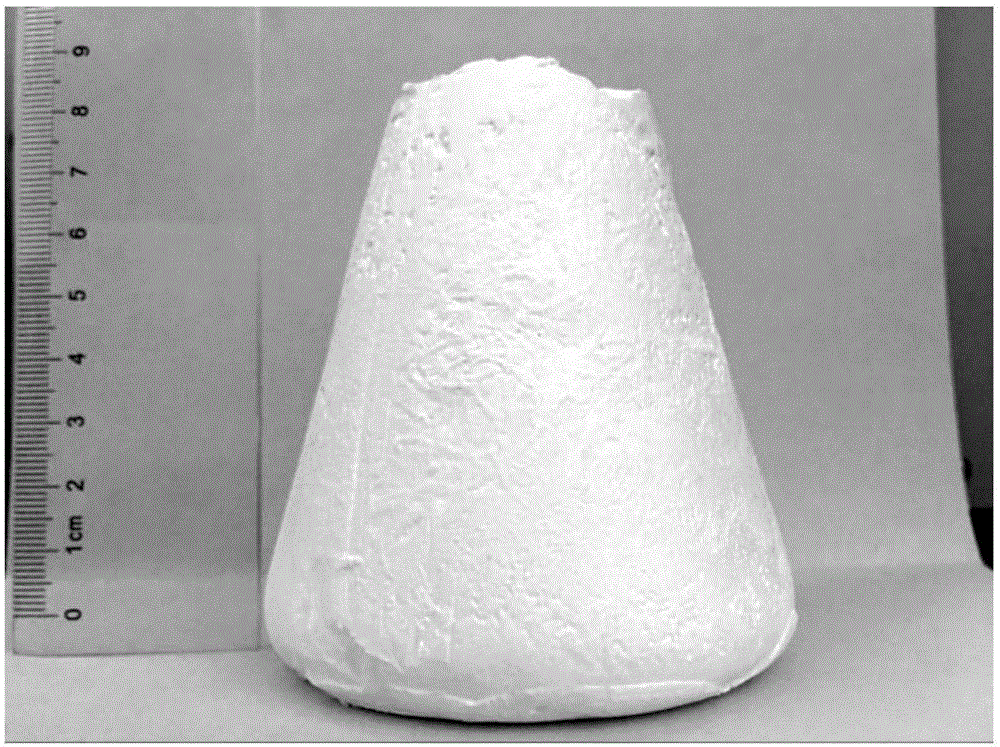

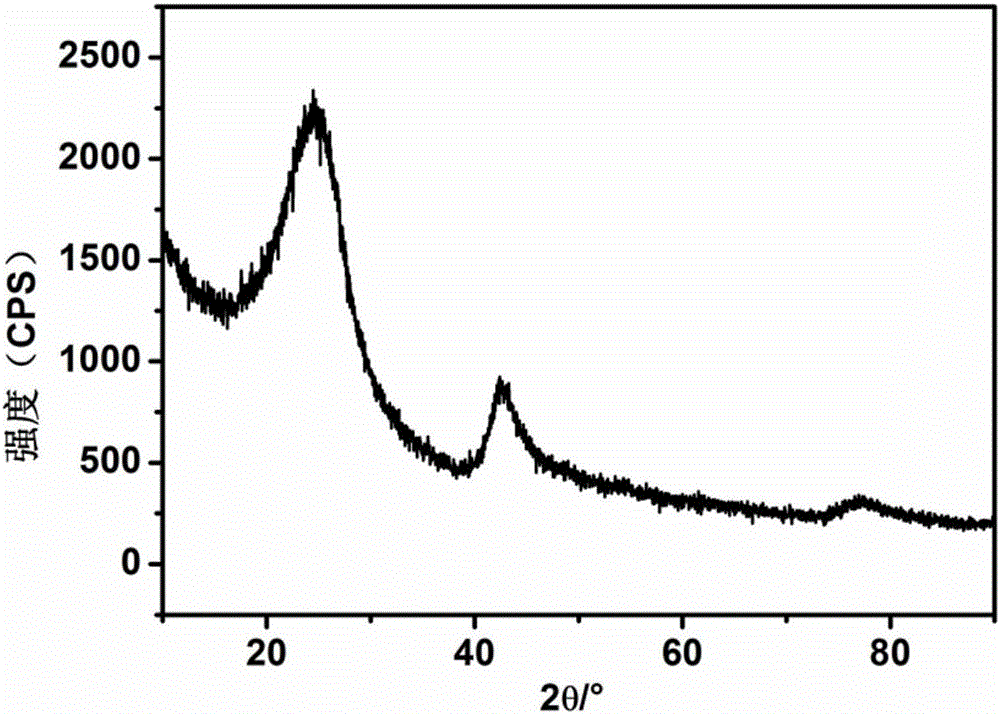

Preparation method of foamed boron nitride block material

ActiveCN106495109AUniform product appearanceReduce production energy consumption and costsNitrogen compoundsMicro nanoDiameter ratio

The invention relates to a preparation method of a foamed boron nitride block material. The preparation method comprises the following steps: (1) preparing a melamine-boric acid-water mixed solution; (2) carrying out ultrasonic treatment for 1h to 24h by an ultrasonic apparatus; separating out a white block body; (3) putting the white block body and a residual solution into a freezing dryer; freezing and pumping in vacuum to obtain a dried white solid precursor; (4) keeping the heat of the white solid precursor at 900 DEG C to 1500 DEG C for 2h to 6h under a protective atmosphere; cooling under the protective atmosphere to room temperature, so as to obtain a white block-shaped solid substance, namely a block-shaped boron nitride foam material. According to the preparation method of the foamed boron nitride block material, the energy consumption and cost of production are reduced; the method has no toxin and has high efficiency, and is applicable to large-scale and industrial synthesis of the foamed boron nitride block material; the prepared foamed boron nitride block material is composed of boron nitride micro-nano fibers with a high length-diameter ratio, and has the characteristics of good connectivity, large specific surface area, super hydrophobicity and the like.

Owner:HEBEI UNIV OF TECH

Method for preparing graphene-based air conditioner filter net by spraying method

ActiveCN104492674AAvoid breedingHas superhydrophobic propertiesFiltration separationSpecial surfacesSilicone ElastomersPulp and paper industry

The invention discloses a method for preparing a graphene-based air conditioner filter net by a spraying method, so that filtering performance of the air conditioner filter net is improved. The method includes the specific steps of firstly, ultrasonically dispersing graphene into a heptane solution; then, adding silicone elastomer bases and corresponding silicone elastomer curing agents into the heptane solution with stirring uniformly, pouring mixed dispersion liquid into a spray bottle, and spraying the mixed dispersion liquid on the air conditioner filter net evenly; finally, heating to enable graphene particles to be better attached to the filter net. The method has the advantages that the air conditioner filter net serves as a carrier and superhigh specific surface and specific electrostatic adsorption capacity of the graphene are utilized, so that smaller particles in air can be blocked off and better purifying effect is achieved; meanwhile, the prepared filter net with super-hydrophobic property is capable of well preventing bacterium breeding.

Owner:SOUTHEAST UNIV

Method for producing super-hydrophobic wood through 3D printing technology

ActiveCN104441091AGood weather resistanceHas superhydrophobic propertiesWood veneer joiningSurface energyWeather resistance

The invention provides a method for producing super-hydrophobic wood through a 3D printing technology. The method includes the following steps that (1) a natural super-hydrophobic surface or a manually built super-hydrophobic surface serves as a template, a scanning electron microscope is adopted to scan the super-hydrophobic surface, and a three-dimensional structural model graph is obtained; (2) inorganic or organic nano particles are dispersed in a solution containing low-surface-energy organic matter for modification treatment, the modified inorganic or organic nano particles are separated centrifugally, recovered and dried to be used as printing raw materials; (3) the surface of a sawn timber is coated with a resin or adhesive film for predrying; (4) the three-dimensional structural model graph is guided into a 3D printing machine, the surfaces of the predried wood are subjected to 3D printing with the modified nano particles as the printing raw materials, the wood obtained after printing is performed is hardened, and then the super-hydrophobic wood is obtained. The produced super-hydrophobic wood has good weather resistance, and the method is simple in process and suitable for large-area industrial production.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

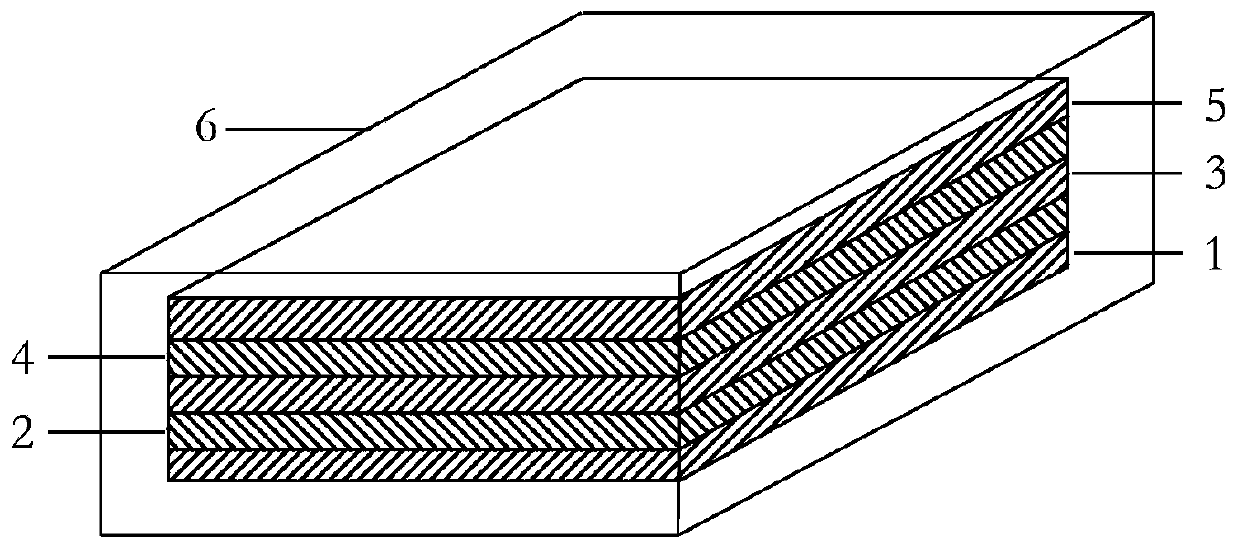

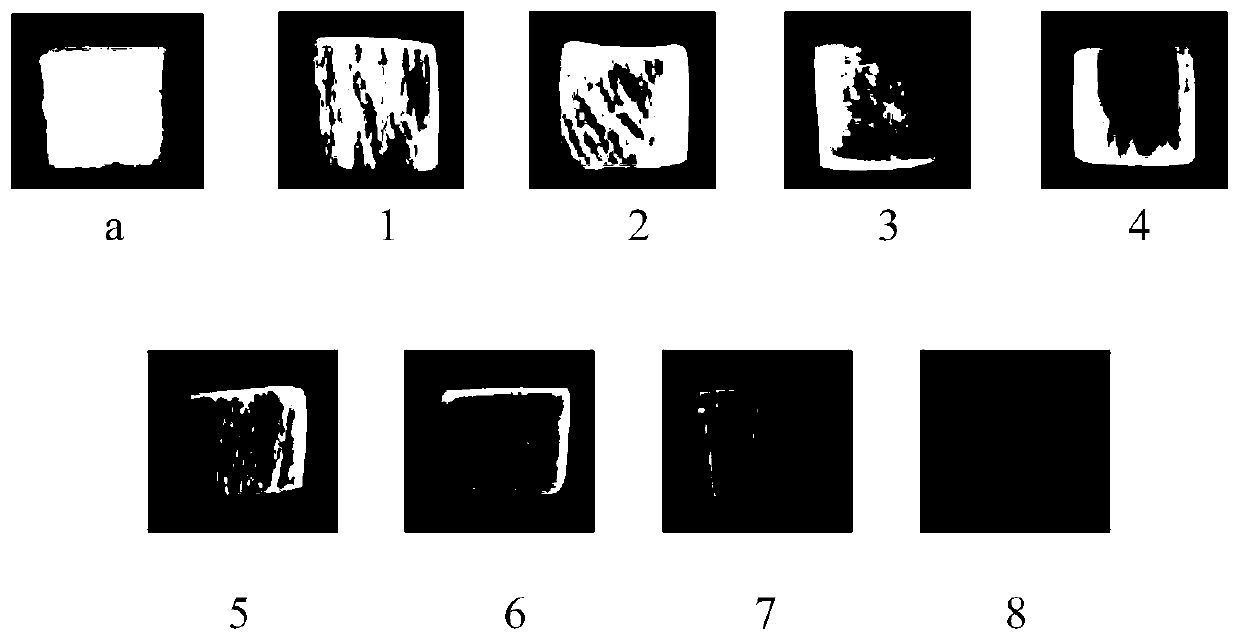

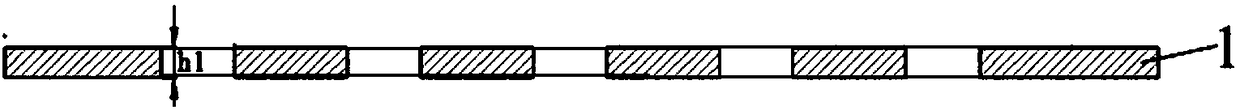

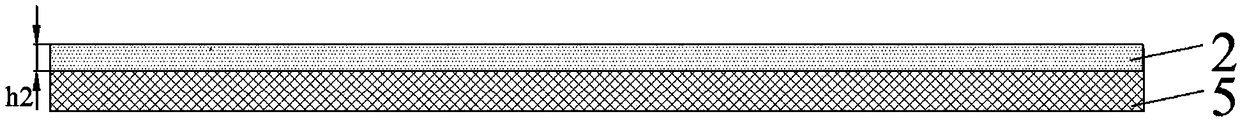

Electrical heating anti-icing assembly with superhydrophobic property and preparation method of electrical heating anti-icing assembly

InactiveCN109794404AHas superhydrophobic propertiesReduced adhesion strengthDe-icing equipmentsLaminationElectricityHeating time

The invention discloses an electrical heating anti-icing assembly with a superhydrophobic property and a preparation method of the electrical heating anti-icing assembly. The anti-icing assembly comprises an insulation heat insulating layer, an electrically heating layer, an insulation heat conduction layer, a heat conduction metal layer, a superhydrophobic coating and waterproof adhesive tape, wherein the insulation heat insulating layer, the electrically heating layer, the insulation heat conduction layer, and the heat conduction metal layer are successively spliced from bottom to top, the superhydrophobic is coated on the surface of the heat conduction metal layer, and the waterproof adhesive tape is sealed around the assembly. The electrical heating anti-icing assembly with the superhydrophobic property has the beneficial effects that the anti-icing assembly has the superhydrophobic property and can remarkably reduce the adhesive strength of a surface ice layer, thus formation of the surface ice layer and removing difficulty of the ice layer can be reduced in a certain level, the ice layer covered on the surface can be removed quickly and completely, heating time is shortened,the removing efficiency of the ice layer is greatly improved, waste of energy is reduced, and great application prospects are provided for equipment such as an airplane in the ice removing field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing super hydrophobic timber

InactiveCN101870130AWith self-cleaning functionHigh mechanical strengthWood impregnation detailsHigh energyPotassium silicate

The invention discloses a method for preparing super hydrophobic timber, which relates to the preparation method for the hydrophobic timber and solves the problems of complex process, high energy consumption and high cost of a preparation method for the exiting super hydrophobic timber. The method comprises the following steps: 1, preparing aqueous solution of methyl potassium silicate; 2, immersing the timber in the aqueous solution of methyl potassium silicate for 5 to 30 hours; 3, adjusting the pH value of the aqueous solution of methyl potassium silicate to be 9 to 13.5 at the temperature of between 10 and 80 DEG C; 4, introducing carbon dioxide gas into the aqueous solution of methyl potassium silicate and stopping the introduction of the carbon dioxide gas when the pH value of the aqueous solution of methyl potassium silicate is between 7 and 8.8; and 5, standing the timber for 0.1 to 30 hours and drying the timber to obtain the super hydrophobic timber. The method has the advantages of simple process, no need of pressure treatment, no need of complex special equipment, low production cost and low energy consumption and is used for preparing the super hydrophobic timber.

Owner:NORTHEAST FORESTRY UNIVERSITY

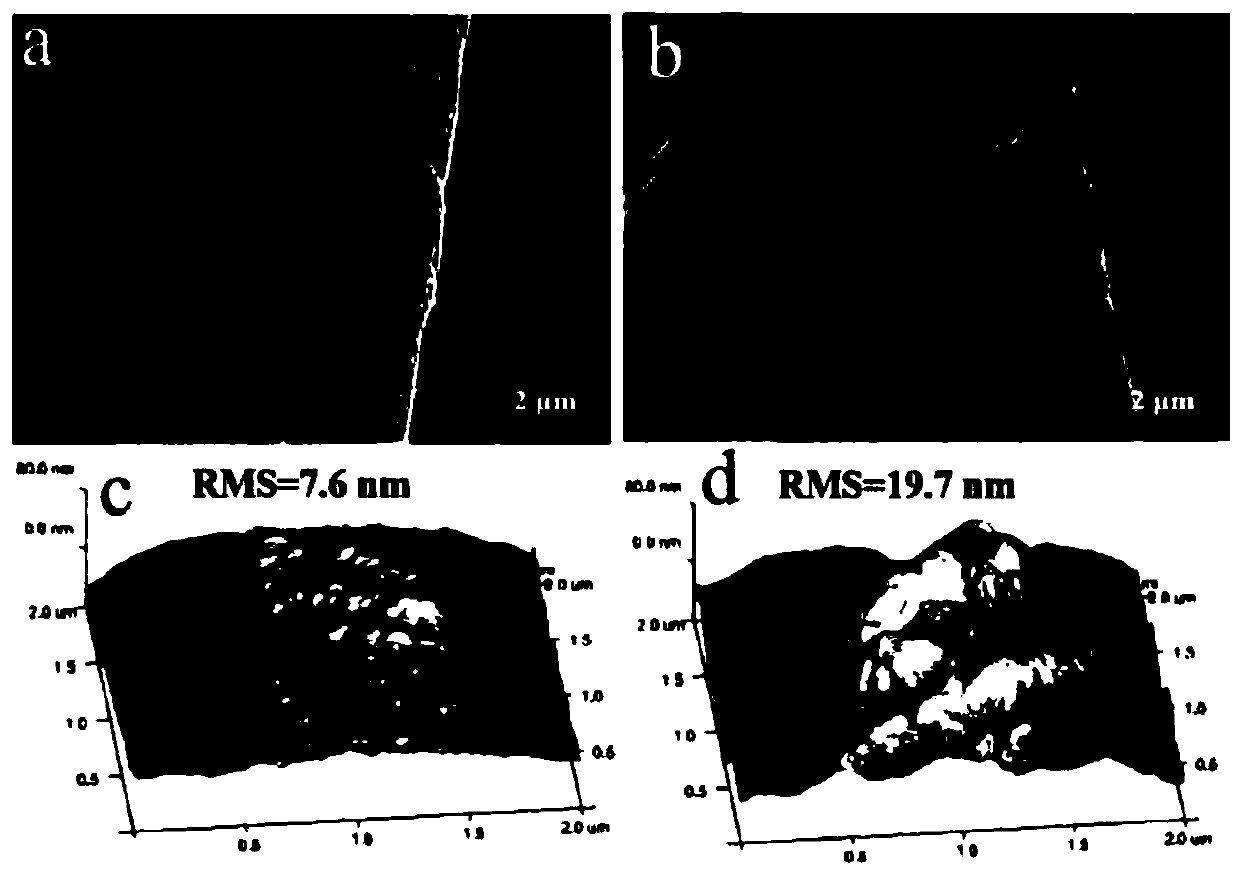

Super-hydrophobic surface coating and preparation method thereof

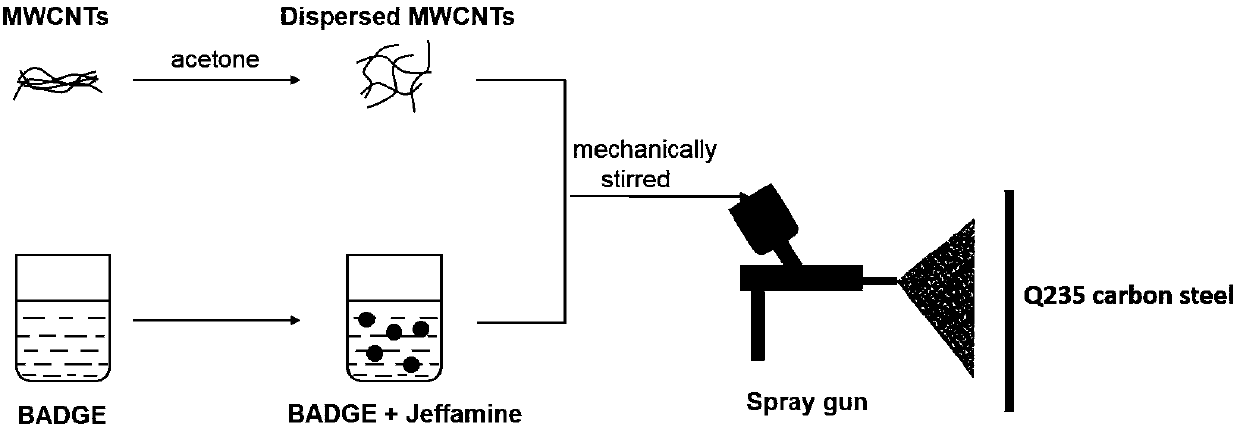

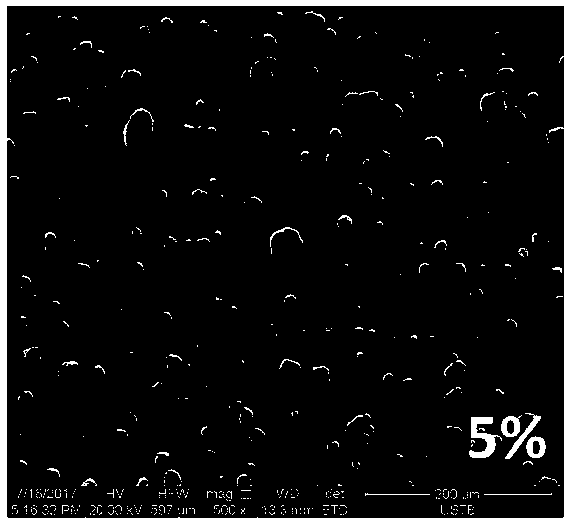

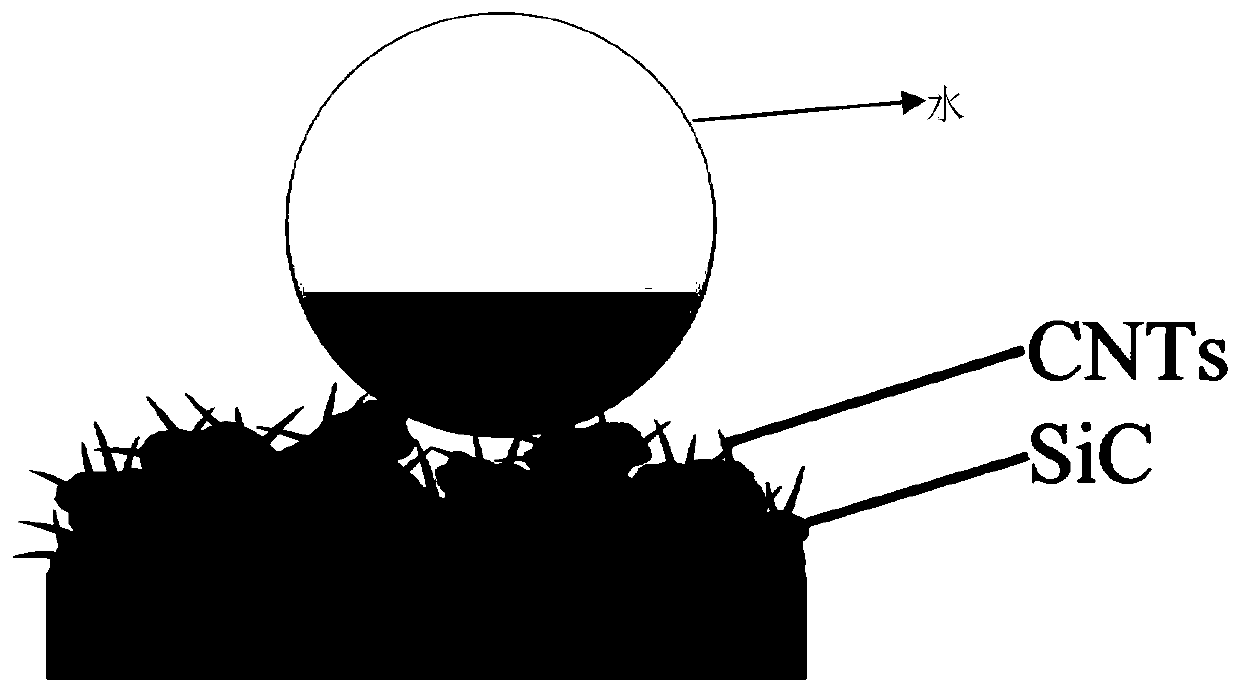

InactiveCN108047884AImprove production efficiencyGood self-cleaningEpoxy resin coatingsElectrically-conductive paintsEpoxyCarbon nanotube

The invention relates to a super-hydrophobic surface coating and a preparation method thereof, and belongs to the field of polymer coating materials. The super-hydrophobic surface coating is obtainedby spraying a super-hydrophobic solution containing epoxy resin, an epoxy curing agent, an epoxy solvent and carbon nanotubes on a substrate material. The super-hydrophobic surface coating has the advantages that materials are easy to obtain, self-cleaning is achieved, and icing is prevented, the preparation technology is simple, and large scale production and application are facilitated.

Owner:UNIV OF SCI & TECH BEIJING

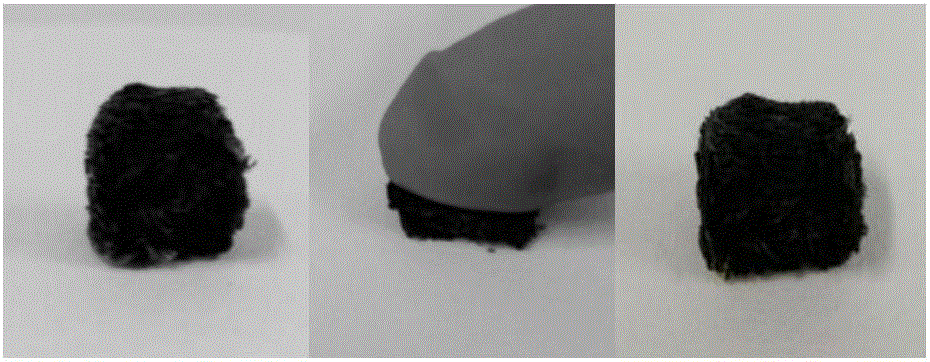

Preparation method of super-hydrophobic graphene sponge

The invention provides a preparation method of super-hydrophobic graphene sponge. The preparation method comprises the specific steps: (1) cleaning and drying sponge; (2) carrying out plasma processing on the sponge processed in the step (1); (3) soaking the sponge processed in the step (2) into graphene oxide dispersion liquid, and adding hydrazine hydrate; and (4) heating mixed liquid prepared in the step (3) to 85-95 DEG C, maintaining for 0.5-24 hours, taking out the sponge, and drying, so as to obtain the super-hydrophobic graphene sponge.

Owner:SOUTHEAST UNIV

Method for preparing multifunctional durable and self-repairing superhydrophobic fabric surface

ActiveCN110644240AImprove microstructureLower surface energyLiquid repellent fibresAbrasion resistant fibresSuperhydrophobeOrganosolv

The invention provides a method for preparing a multifunctional durable and self-repairing superhydrophobic fabric surface, and belongs to the technical field of materials. The technical scheme is provided below. The method for preparing the multifunctional durable and self-repairing superhydrophobic fabric surface is characterized in that after being cleaned and dried, the fabric is put into a polydimethylsiloxane aqueous solution, and after a period of time, the fabric is taken out and dried; the multifunctional durable self-repairing superhydrophobic fabric is subjected to abrasion resistance, water washing and chemical stability test under a harsh environment, and is applied to oil-water separation test. The method has the advantages that plasma treatment is carried out on the PDMS (polydimethylsiloxane), the PDMS is uniformly dispersed in water, the superhydrophobic fabric surface coating is prepared through a one-step impregnation method, no organic solvent and fluorine-containing material are not used, and the coating is environmentally friendly and nontoxic, low in cost, and suitable for industrial production.

Owner:NANTONG UNIVERSITY

Protective coating, filter material, matrix, and preparation method for protective coating

ActiveCN105986480AImprove antioxidant capacityImprove acid and alkali corrosion resistanceFibre typesFiltration separationCooking & bakingPolystyrene nanoparticles

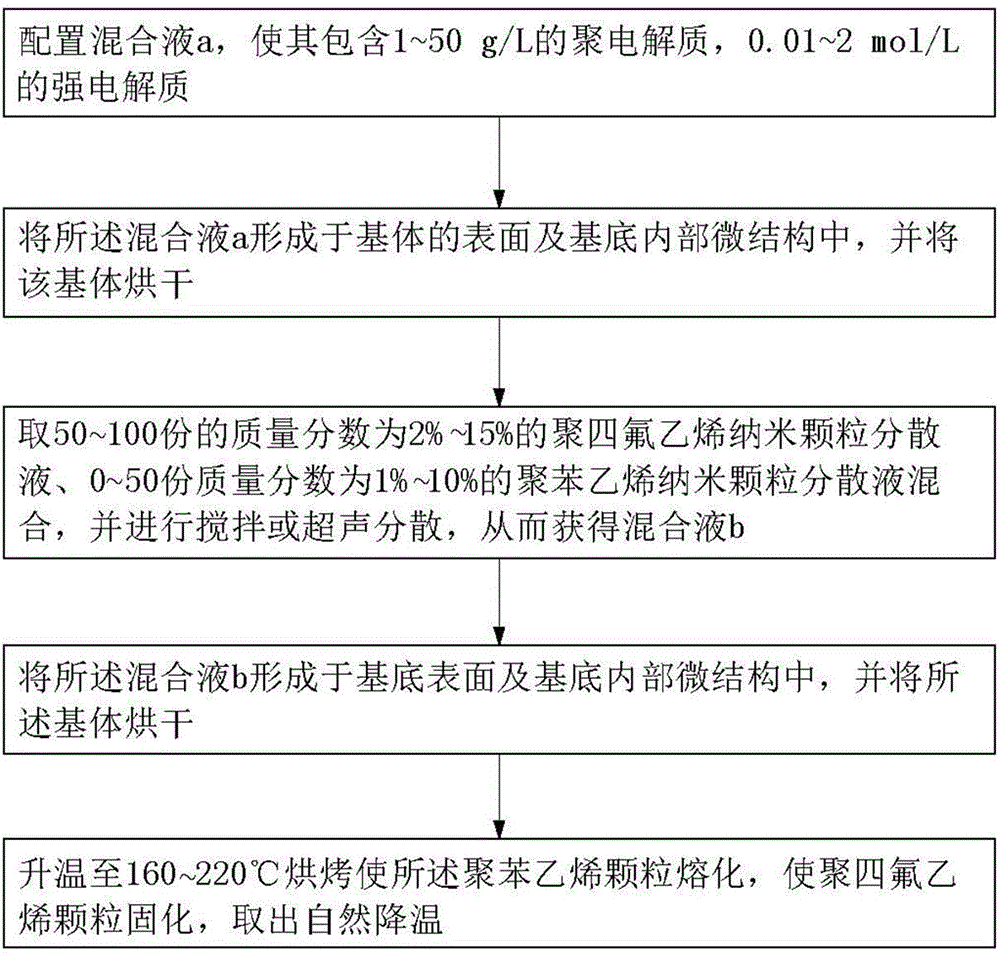

The invention relates to a preparation method for a protective coating. The preparation method comprises the following steps: preparing a mixed solution a containing 1 to 50 g / L of polyelectrolyte and 0.01 to 2 mol / L of strong electrolyte; allowing the mixed solution a to be formed on the surface of the matrix and microstructures in the matrix and drying the matrix; mixing 50 to 100 parts of polytetrafluoroethylene nanoparticle dispersion liquid with a mass fraction of 2 to 15% and 0 to 50 parts of polystyrene nanoparticle dispersion liquid with a mass fraction of 1 to 10% and carrying out stirring or ultrasonic dispersion so as to obtain a mixed solution b; allowing the mixed solution b to be formed on the surface of the matrix and the microstructures in the matrix and drying the matrix; and heating the matrix to 160 to 220 DEG C for baking so as to allow polystyrene particles to be fused and polytetrafluoroethylene particles to be cured, and then taking the matrix out for natural cooling. Moreover, the invention also relates to the protective coating, a filter material and the matrix.

Owner:TSINGHUA UNIV

Preparation method for super-hydrophobic coating

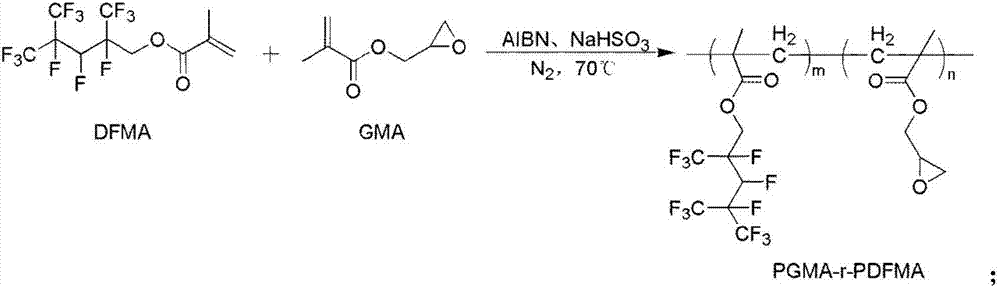

The invention discloses a preparation method for a super-hydrophobic coating. The method comprises the following steps: mixing dodecafluoroheptyl methacrylate, methacrylic acid glycidol, azodiisobutyronitrile and sodium hydrogen sulfite, adding tetrahydrofuran, reacting under a heating state so as to form a reactant, and standing to acquire the super-hydrophobic coating; mixing nanometer silicon dioxide, ethyl alcohol and water and then ultrasonically dispersing, thereby forming a turbid solution; regulating the PH value of the turbid solution to 7, adding a coupling reagent into the turbid solution, condensing and back-flowing under heating and stirring state, thereby acquiring the modified silicon dioxide; performing suction filtration by using an ethyl alcohol solution, thereby acquiring purified amino modified silicon dioxide; drying and grinding, thereby acquiring amino modified nanometer silicon dioxide; dissolving the super-hydrophobic coating by using tetrahydrofuran and then adding triethylamine and amino modified nanometer silicon dioxide in turn, thereby forming a modified solution; soaking the substrate into the modified solution, taking out and then drying. The super-hydrophobic coating prepared according to the preparation method disclosed by the invention has stable and long-lasting super-hydrophobic property and is reusable.

Owner:XIAN UNIV OF TECH

Preparation method of super-hydrophobic sponge adsorbing material

InactiveCN108465460ARich sourcesLow priceOther chemical processesAlkali metal oxides/hydroxidesAlcoholSilicic acid

The invention belongs to the technical field of preparation of environmental functional materials, and specifically relates to a preparation method of a super-hydrophobic sponge adsorbing material. The method specifically comprises the following steps: preparing a dopamine coated sponge base body; dissolving hexadecyltrimethoxysilane, tetraethyl orthosilicate and ammonia water into ethyl alcohol to obtain a mixed solution; adding the opamine coated sponge base body; transferring into a water bath pot; stirring under constant temperature; and oscillating through water bath; washing; and dryingto obtain the super-hydrophobic sponge adsorbing material. The prepared super-hydrophobic sponge adsorbing material is high acid, alkali and salt resistant super-hydrophobic oleophylic material whichis simple, environmentally friendly, low in cost, and small in investment and can realize mass production; and the material is applicable to oil and water separation in a complex industrial environment, and is stable in structure, and high in adsorbing capacity.

Owner:JIANGSU UNIV

Flexible flexional active-deicing super-hydrophobic anti-ice-coating composite material and preparation method and application thereof

The invention belongs to the technical field of anti-ice-coating materials, and discloses a flexible flexional active-deicing super-hydrophobic anti-ice-coating composite material and a preparation method and application thereof. The anti-ice-coating composite material is prepared from a room-temperature vulcanized liquid silicone rubber matrix and a micro-nano material; the room-temperature vulcanized liquid silicone rubber matrix is prepared from room-temperature vulcanized liquid silicone rubber, an organic solvent, a curing agent and a catalyst, and the micro-nano material is composed of an inorganic micro powder, carbon nanotubes, a polar organic solvent and a water repellent agent; the anti-ice-coating composite material is in the organic solvent, the room-temperature vulcanized liquid silicone rubber is semi-cured under the effect of the catalyst and one part of the curing agent, and a semi-cured silicone rubber matrix is obtained; then the micro-nano material is mixed evenly with the remaining curing agent, and the mixture is sprayed on the surface of the semi-cured silicone rubber matrix and dried to obtain the anti-ice-coating composite material. The anti-ice-coating composite material is flexional, photothermal active deicing is combined with superhydrophobic ice coating prevention, the anti-ice-coating effect is significant, and the material is used in the anti-ice-coating field.

Owner:SOUTH CHINA UNIV OF TECH

Super-hydrophobic wood sponge and application thereof

InactiveCN110527132AIntensifies the silanization reactionImprove hydrophobic propertiesIon-exchange process apparatusIon-exchanger regenerationChemistryMethyltrimethoxysilane

Owner:BEIJING FORESTRY UNIVERSITY

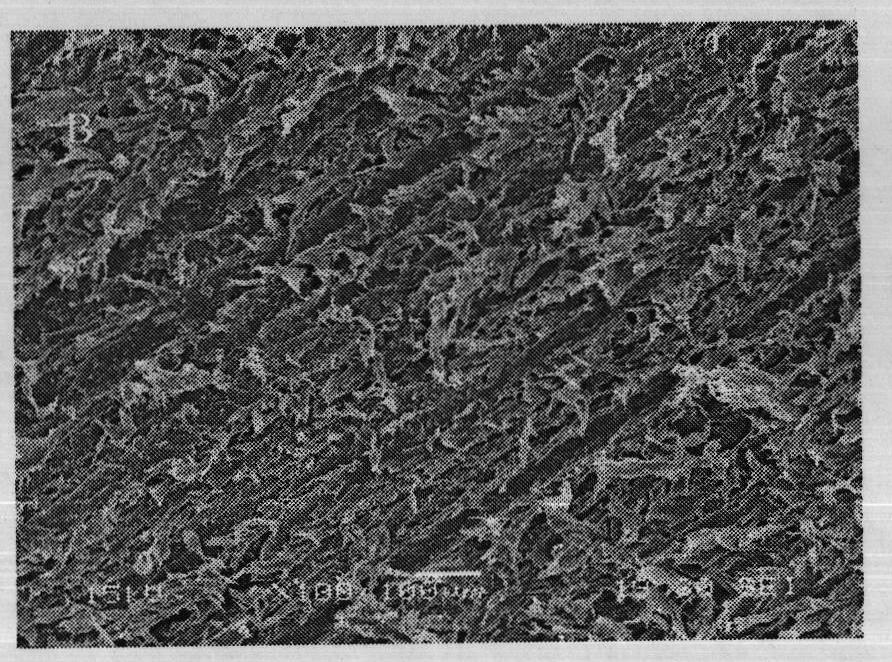

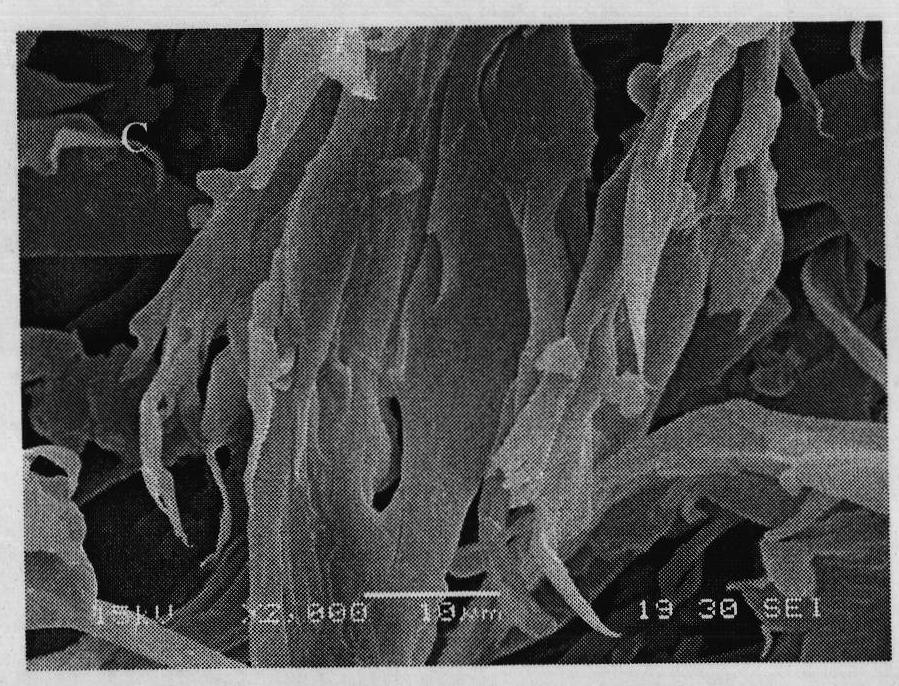

Preparation method of superhydrophobic wood sponge

InactiveCN110497492AUniform particlesLittle difference in hydrophobicityWood treatment detailsThermal wood treatmentAcetic acidWater baths

A preparation method of superhydrophobic wood sponge comprises the following steps: mixing a NaOH solution having a concentration of 2.3-2.6 mol / L with a Na2SO3 solution having a concentration of 0.3-0.5 mol / L according to a volume ratio of 1:1, immersing dried light wood blocks in the obtained mixed solution, and processing the wood under a boiling condition for 18-26 h; then immersing the wood into a sodium chlorite solution having a concentration of 1-2%, performing heating in a water bath at 80-95 DEG C, rinsing the wood, and freeze-drying the rinsed wood; and immersing the wood in a mixedsolution of ethanol, water, glacial acetic acid and methyltrimethoxysilane, processing the wood at 20-40 DEG C for 3-6 h, taking out the wood, carrying out vacuum drying at 30-70 DEG C for 1-2 h, anddrying the obtained wood at 90-130 DEG C. The superhydrophobic wood sponge prepared by the method has the advantages of high hydrophobicity, high porosity and strong adsorption performance, and can be used as an oil spill adsorption material to adsorb and purify polluted water.

Owner:BEIJING FORESTRY UNIVERSITY

Micro-nano integrated processing technology based three-dimensional anti-drag micro-channel structure and preparation method thereof

InactiveCN102627256AAchieve coverageHas superhydrophobic propertiesDecorative surface effectsLaboratory glasswaresMicro nanoNanoscopic scale

The invention discloses a micro-nano integrated processing technology based three-dimensional anti-drag micro-channel structure and a preparation method thereof, relating to the technical field of micromachining. The preparation method comprises the steps of: directly preparing a high density and high aspect ratio nano dimension cone array on each surface of a silicon-based micron dimension groove by utilizing DRIE (Deep Reactive Ion Etching) without mask optimization to increase a superficial area to volume ratio; and depositing a layer of fluoro-based polymer on the surface of the silicon-based micron dimension groove at the same time to reduce a surface energy and realize a surface structure with super-hydrophobic properties, thereby further realizing a true three-dimensional anti-drag micro-channel structure. The micro-nano integrated processing technology based three-dimensional anti-drag micro-channel structure, disclosed by the invention, has the advantages that: the high density and high aspect ratio nano dimension cone array can be produced without damaging the original micron dimension structure; 100% coverage of a nano forest for the micron dimension groove can be realized and a true three-dimensional anti-drag micro-channel is thereby realized. The micro-nano integrated processing technology based three-dimensional anti-drag micro-channel structure can improve the area to volume ratio thereof extremely and reduce the surface energy to enable the surface of the micro-channel to have the super-hydrophobic properties, thereby realizing an excellent anti-drag effect. The micro-nano integrated processing technology based three-dimensional anti-drag micro-channel structure has simple technology, low cost and easy industrialization.

Owner:PEKING UNIV

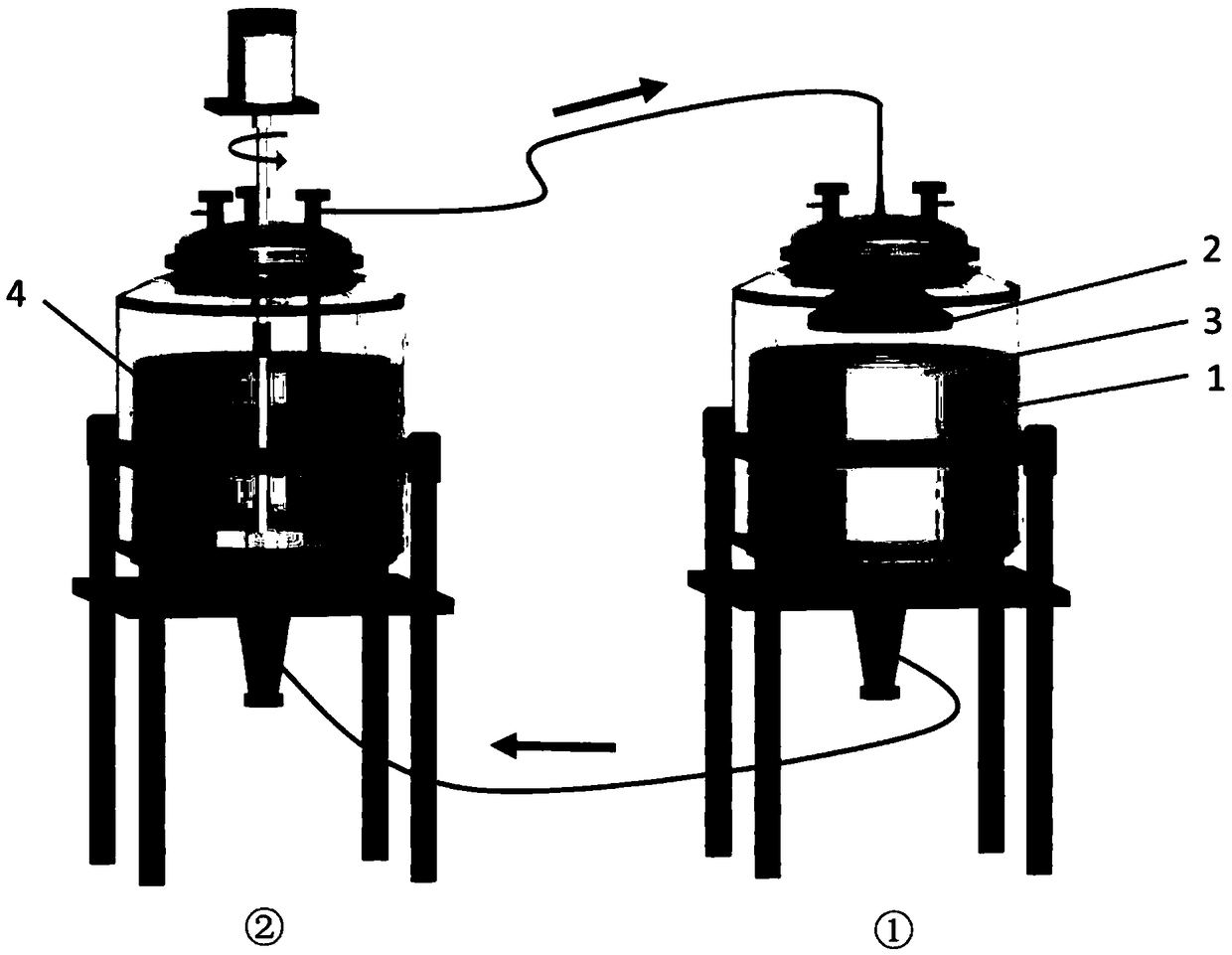

Method for preparing modified silicon dioxide aerogel material through normal-pressure drying and by external circulation mode

The invention provides a preparation method of a modified silicon dioxide aerogel material. The preparation method comprises the following steps: placing an aged silicon dioxide wet gel and a modifierprecursor into a reaction container, performing external circulation hydrolysis on the modifier precursor, and returning to a reaction container and performing modified reaction to obtain the modified silicon dioxide aerogel material, wherein the modifier can encounter water to generate polymerization reaction to generate the modifier precursor. The traditional organic solvent exchange process link is abandoned, an external circulation one-step modification mode is adopted, the consumption quantity of the organic solvent is small, the cost is low, the environmental hazard is small, use and waste of the organic solvent in the link are avoided, a large amount of silane modifiers are saved for the subsequent surface modification process, the surface modification efficiency is improved, the cost is reduced and the environmental hazard is avoided; furthermore, the preparation method is short in preparation cycle, high in efficiency, simple and convenient to operate, mild in reaction condition and suitable for industrialized continuous production.

Owner:UNIV OF SCI & TECH OF CHINA

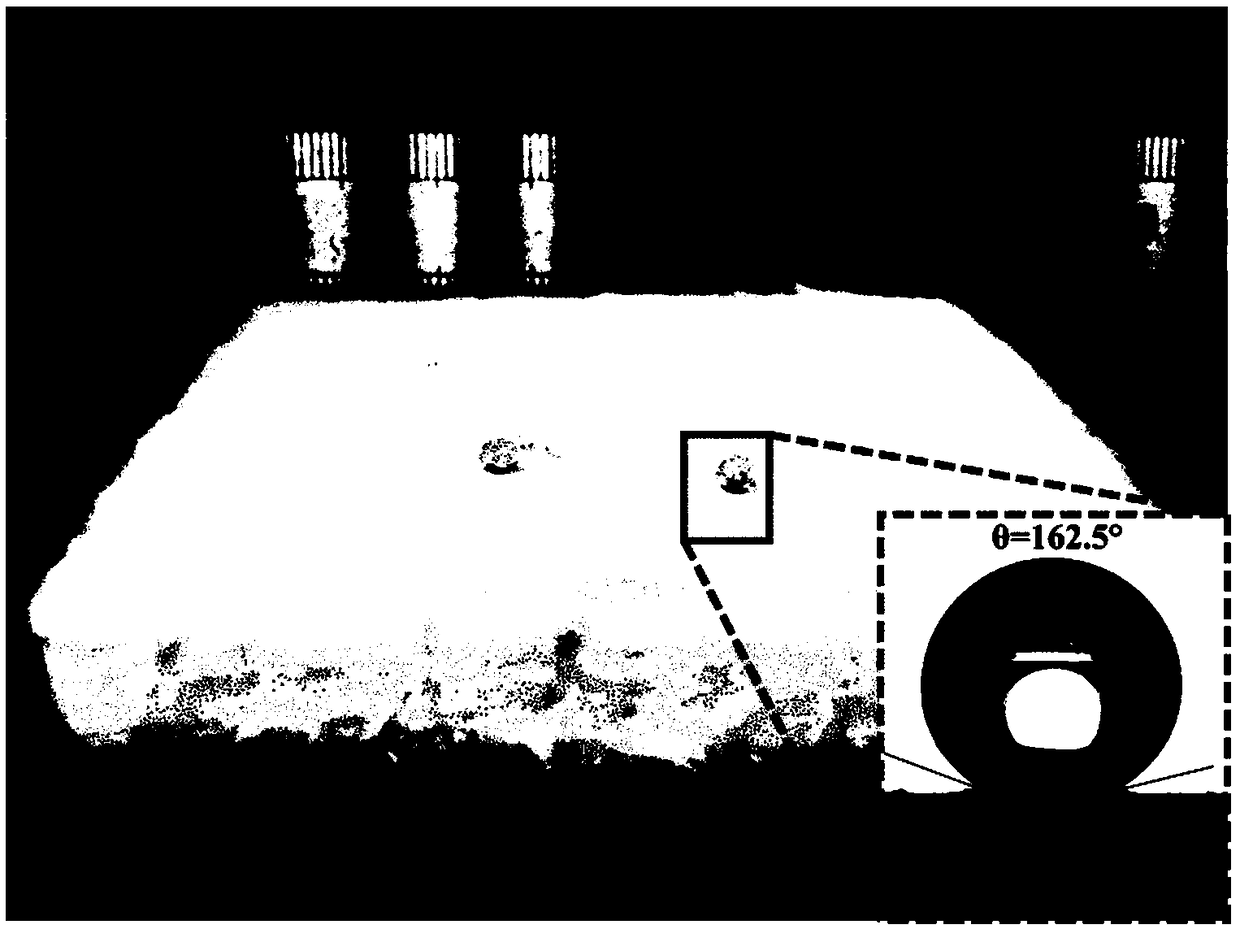

Preparation method of heat exchanger with efficient heat exchange and corrosion resistance and provided with graphene protective membrane

InactiveCN106802106AGuaranteed thermal conductivityEnhanced heat transferSingle layer grapheneChemical industryCvd grapheneBatch production

The invention discloses a preparation method of a heat exchanger with efficient heat exchange and corrosion resistance and provided with a graphene protective membrane. The preparation method is characterized by comprising the following steps: (1) firstly cleaning a copper pipe; (2) growing graphene on the surface of the copper pipe: setting the growth temperature at 800 to 1,200 DEG C, feeding protective gas into a reaction chamber, quickly heating the reaction chamber to the growth temperature of the graphene, then feeding methane gas, keeping feeding the methane gas for 8 to 15 minutes, then quickly cooling the reaction chamber, and cutting the feeding of all types of gas, wherein the growth time of the graphene is equal to the methane feeding time; and (3) controlling the pressure of the reaction chamber at 8 to 15 mbar in a graphene preparation process, thus the high-quality graphene protective membrane is prepared on the surface of the copper pipe, and covers copper to prevent corrosion. The preparation method disclosed by the invention is proper in cost, suitable for large-batch production and relatively high in membrane forming quality.

Owner:GUANGDONG MACRO GAS APPLIANCE

Antibacterial coating masterbatch, antibacterial coating woven bag and production method of antibacterial coating masterbatch

ActiveCN105199490AStable antibacterial persistenceExcellent barrier functionFibre treatmentCoatingsAnti bacterialPolymer chemistry

The invention relates to antibacterial coating masterbatch which comprises 60+ / -4 parts of coating-grade polyethylene aggregates, 30+ / -3 parts of a nano antibacterial agent, 4+ / -1 parts of oxidized polyethlene wax and 6+ / 1 parts of an auxiliary. The production method comprises the following steps: mixing the various raw materials in a material mixing machine at a high speed for 5 minutes; introducing a raw material mixture into a double-screw granulator through vacuum suction; performing melt extrusion, water cooling, air drying, cutting and screening under the temperature of 210 to 270 DEG C, thus obtaining a finished product. The antibacterial rate is up to 99.07-99.62 percent; after the antibacterial coating masterbatch is soaked by one month, the antibacterial rate to various germs is still kept at 94.93 to 98.45 percent; the oxygen penetration amount (cm<3> / m<2>.d.0.1MPa) reaches 825 to 1,090; the contact angle is larger than 150 degrees.

Owner:山东寿光健元春化工有限公司

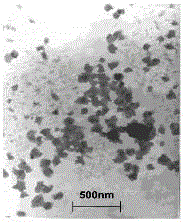

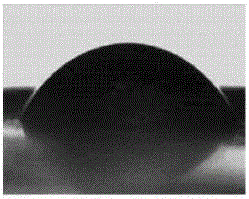

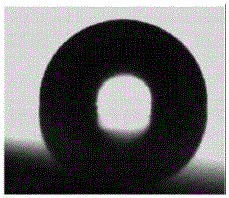

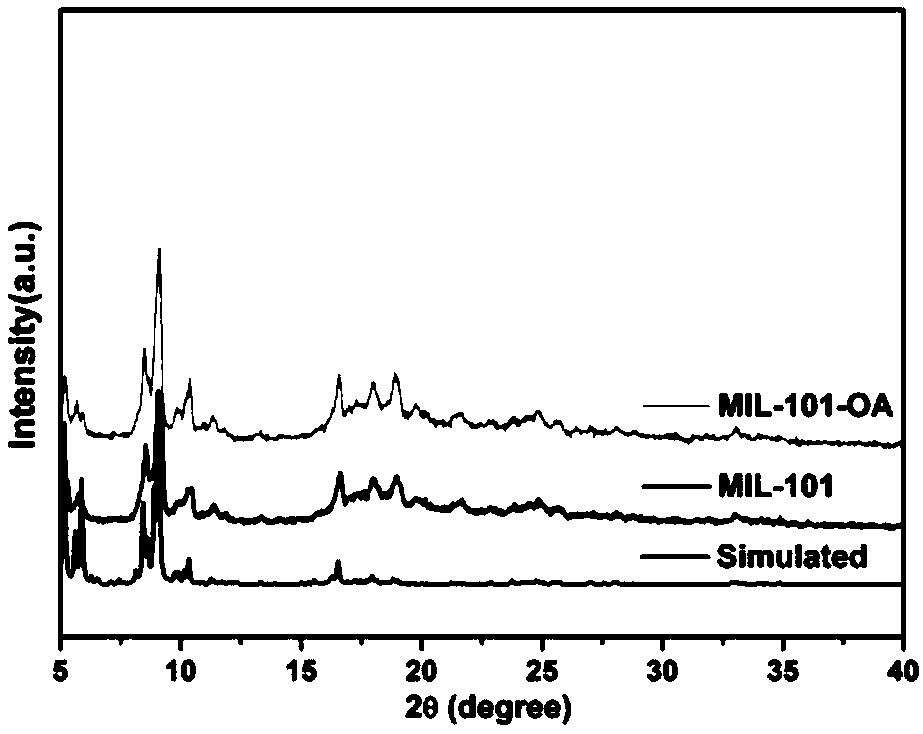

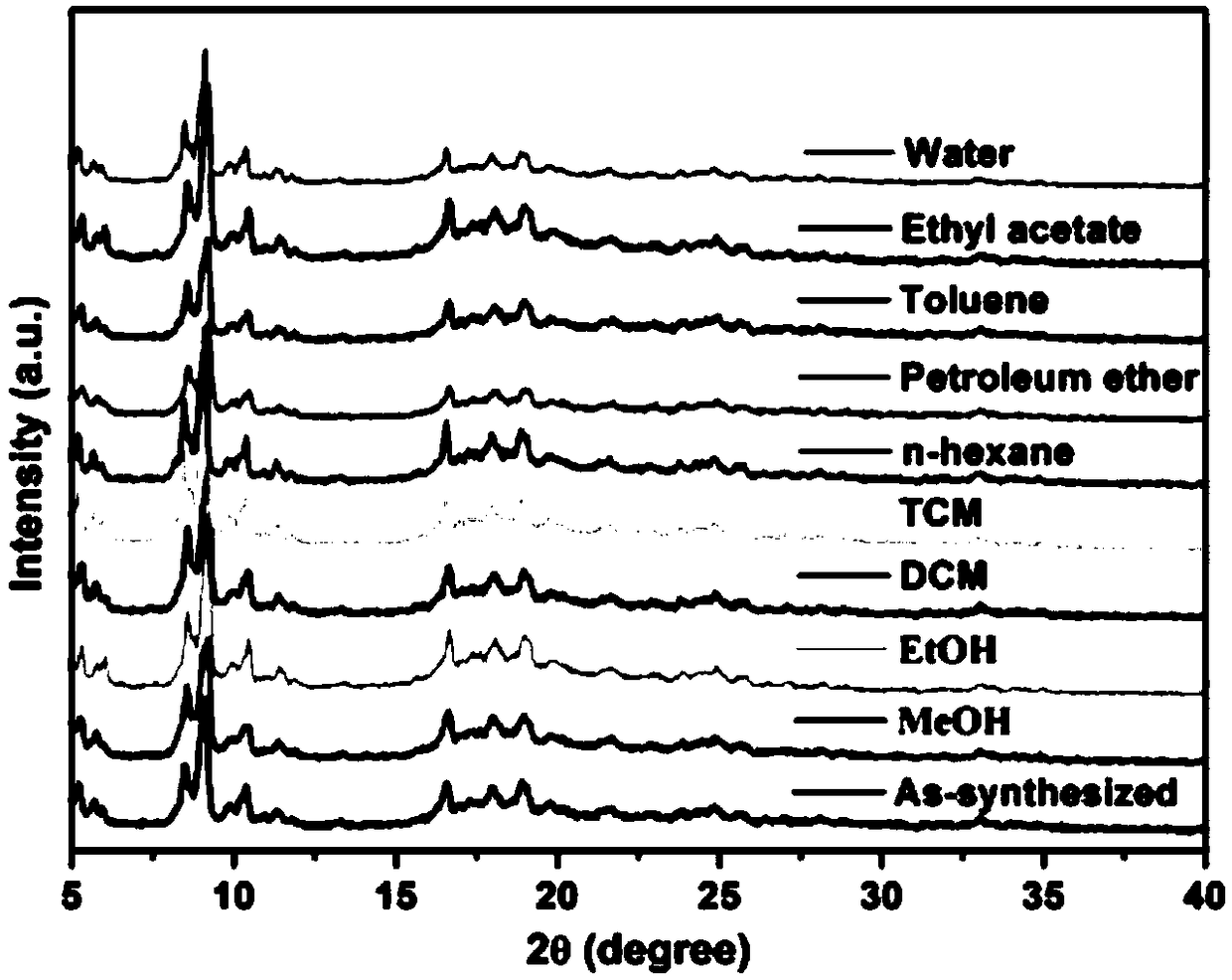

Superhydrophobic metal-organic framework composite material, and preparation method and application thereof

ActiveCN109174011AImprove hydrophobicityGood chemical stabilityFatty/oily/floating substances removal devicesOther chemical processesNitrogen atmosphereMetal-organic framework

The invention relates to a superhydrophobic metal-organic framework composite material, and a preparation method and an application thereof. The preparation method comprises the following steps: carrying out vacuum activation on a metal-organic framework material at 120-150 DEG C for 24 h, wherein the metal-organic framework material is MIL-101 (Cr) nanocrystals; adding a toluene solution of octadecylamine to the activated metal-organic framework material MIL-101 (Cr) nanocrystals, and carrying out a reaction at 333-393 K in nitrogen atmosphere for 12-24 h; and slowly cooling the obtained solution to room temperature, centrifuging the cooled solution, washing the collected solid with toluene, centrifuging the washed solid, and drying the centrifuged solid to obtain the target product. Thesuperhydrophobic metal-organic framework composite material prepared in the invention can be applied to the field of oil-water separation, and can efficiently separate multiple oil and water mixtures.

Owner:LIAONING UNIVERSITY

Super-hydrophobic film with singular microstructure, and preparation method thereof

ActiveCN108545694AEasy to prepareIncrease roughnessDecorative surface effectsChemical vapor deposition coatingHigh pressureDimethyl siloxane

The invention discloses a super-hydrophobic film with a singular microstructure, and a preparation method thereof. The preparation method comprises the following steps: processing a through hole microarray pattern structure on a metal plate; spin coating a layer of thermosetting polymer polydimethylsiloxane on a lower electrode plate; placing a metal through hole template above the polymer coatingand forming a micro-contact; forming a pair of planar electrodes by using an upper electrode plate and the lower electrode plate, reserving a preset air gap between the upper electrode plate and themetal through hole template, and filling and maintaining a high-voltage power supply into the upper electrode plate and the lower electrode plate, so that the electric field force applied to the polymer is greater than the own surface tension until the polymer forming is ended; and curing the formed polymer to obtain the super-hydrophobic film with the singular microstructure. The preparation method provided by the invention is a preparation method based on electric field induction, thus requiring no expensive low surface energy material, and having simple process and relatively low cost; andno toxic benzene series is used in the preparation process, which is beneficial to large-scale application in engineering.

Owner:陕西竞宇智能装备发展有限公司

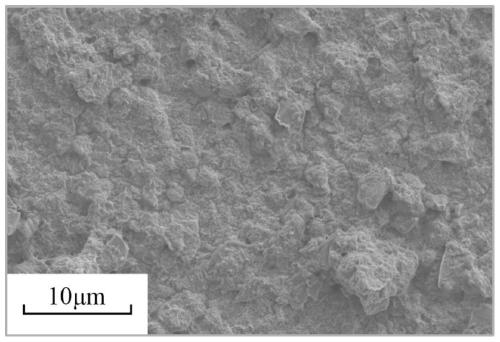

Preparation method for thermal formation of protective composite coating on ultrahigh-strength steel

ActiveCN109055890ANot easy to fall offHigh bonding strengthSolid state diffusion coatingMicro nanoSilicon alloy

The invention belongs to the technical field of metal surface treatment, and in particular, relates to a preparation method for thermal formation of a protective composite coating on ultrahigh-strength steel. The preparation method comprises surface pretreatment of a steel plate, preparation of a penetrating agent, coating of the penetrating agent, high-temperature permeation of zinc and aluminum,double-glow plasma permeation of an aluminum silicon alloy and plasma oxidation. The preparation method can form a protective coating of a four-layer structure on the surface of the ultrahigh-strength steel; the protective coating consists of a Fe-Zn and Fe-Al intermetallic compound diffusion layer, a Zn-enriched layer, an aluminum silicon alloy layer and a micro-nano oxide layer in sequence frominside to outside; the composite coating is simple in preparation process and stable in quality, and solves the difficulty of giving consideration to both high-temperature oxidation and incision corrosion resistance; and as the surface of the coating has the super-hydrophobic characteristic, the industrial production is easily realized.

Owner:NANJING XINGQIAO Y TEC AUTOMOBILE PARTS CO LTD

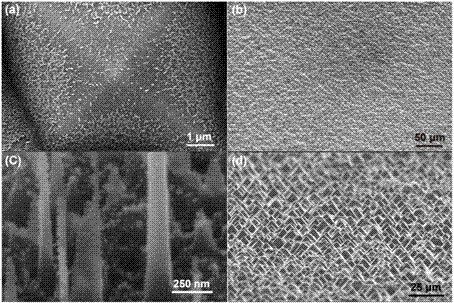

Super-hydrophobic surface reinforced Raman substrate prepared from silicon nanometer dielectric material and preparation method thereof

ActiveCN107064107AImprove performanceChange capture abilityMaterial nanotechnologyRaman scatteringDielectricWater baths

The invention relates to a super-hydrophobic surface reinforced Raman substrate prepared from a silicon nanometer dielectric material and a preparation method thereof. The substrate is formed by a silicon micron cone integrated with metal nanoparticles and a cascade structure formed by nanowires. The preparation method of the structure comprises the following steps that S1, a silicon wafer is put into a micromolecule alcohol and strong base mixed solution; the silicon micron cone structure is built through water bath heating; S2, the silicon micron cone structure is put into mixed corrosion liquid of silver salt solution and HF solution; etching is performed to obtain a silicon micron / nanometer cascade structure; S3, the silicon micron / nanometer cascade structure obtained in the S2 is soaked by acid solution so as to remove silver nanoparticles remained at the surface; then, the silicon micron / nanometer cascade structure is subjected to gold nanoparticle wrapping covering; S4, low-surface-energy substances are used for performing surface covering modification on the gold-silicon composite structure obtained in the S3, i.e., the super-hydrophobic surface reinforced Raman substrate is obtained. The super-hydrophobic surface reinforced Raman substrate provided by the invention has super-hydrophobic property; the static contact angle with water is 160 to 162 degrees.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com