Method for preparing modified silicon dioxide aerogel material through normal-pressure drying and by external circulation mode

A silica and aerogel technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of increased cost, high cost of precursor tetraethyl orthosilicate, threats to the environment and operators, etc. , to achieve the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The invention provides a method for preparing a modified silica airgel material, comprising the following steps:

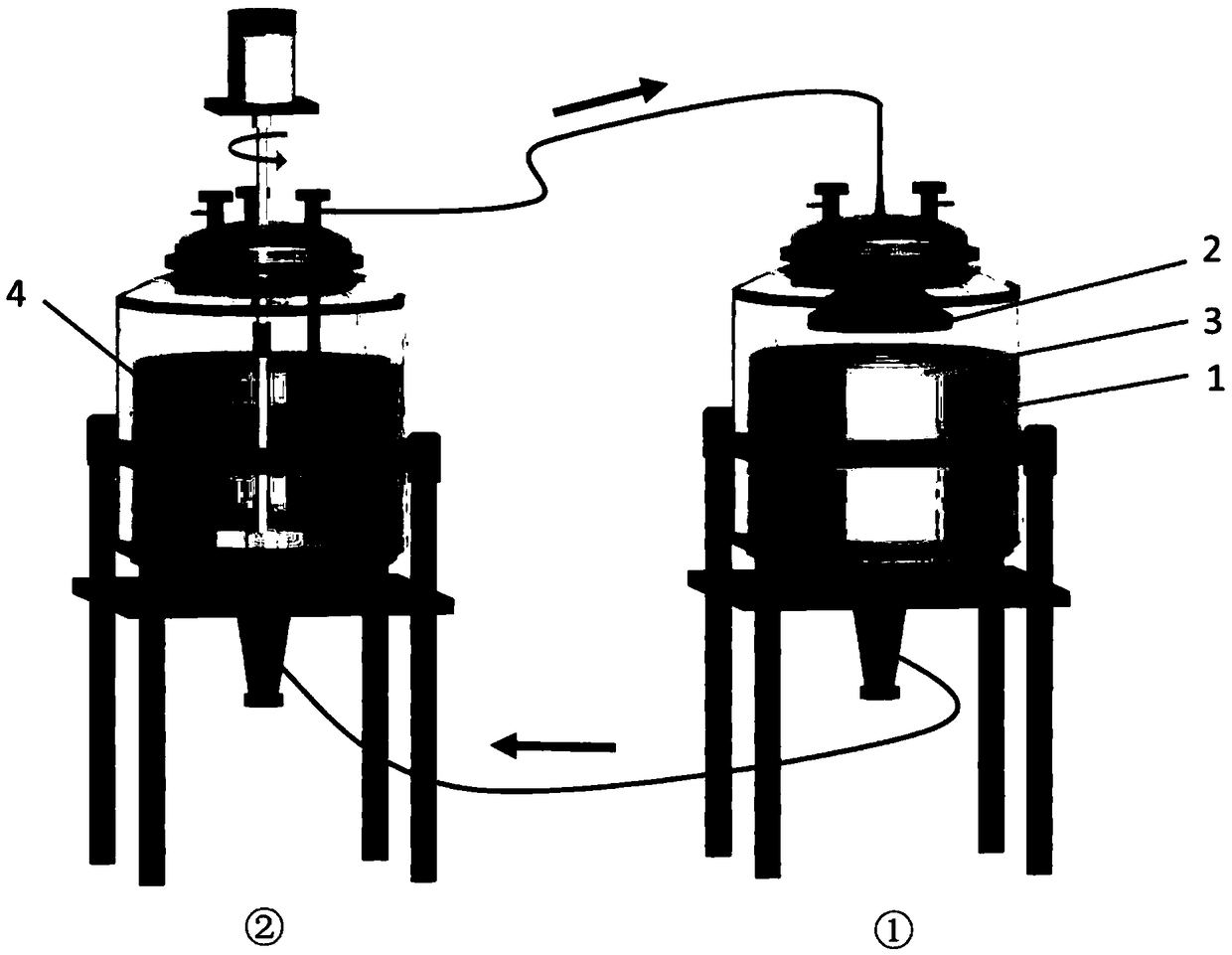

[0075] 1) Put the aged silica wet gel material and the modifier precursor in the reaction container, and at the same time, the modifier precursor is hydrolyzed by the external circulation, and then returned to the reaction container, and after the modification reaction, the improved Reactive silica airgel material;

[0076] The modifier is a modifier that can undergo polymerization reaction with water to generate a modifier precursor.

[0077] The modifying agent in the present invention is a modifying agent that can undergo polymerization reaction with water to generate a modifier precursor. The present invention is not particularly limited to the specific selection of the modifier, and it is sufficient to use conventional modifiers for hydrophobically modified silica aerogels well known to those skilled in the art, and those skilled in the art can accord...

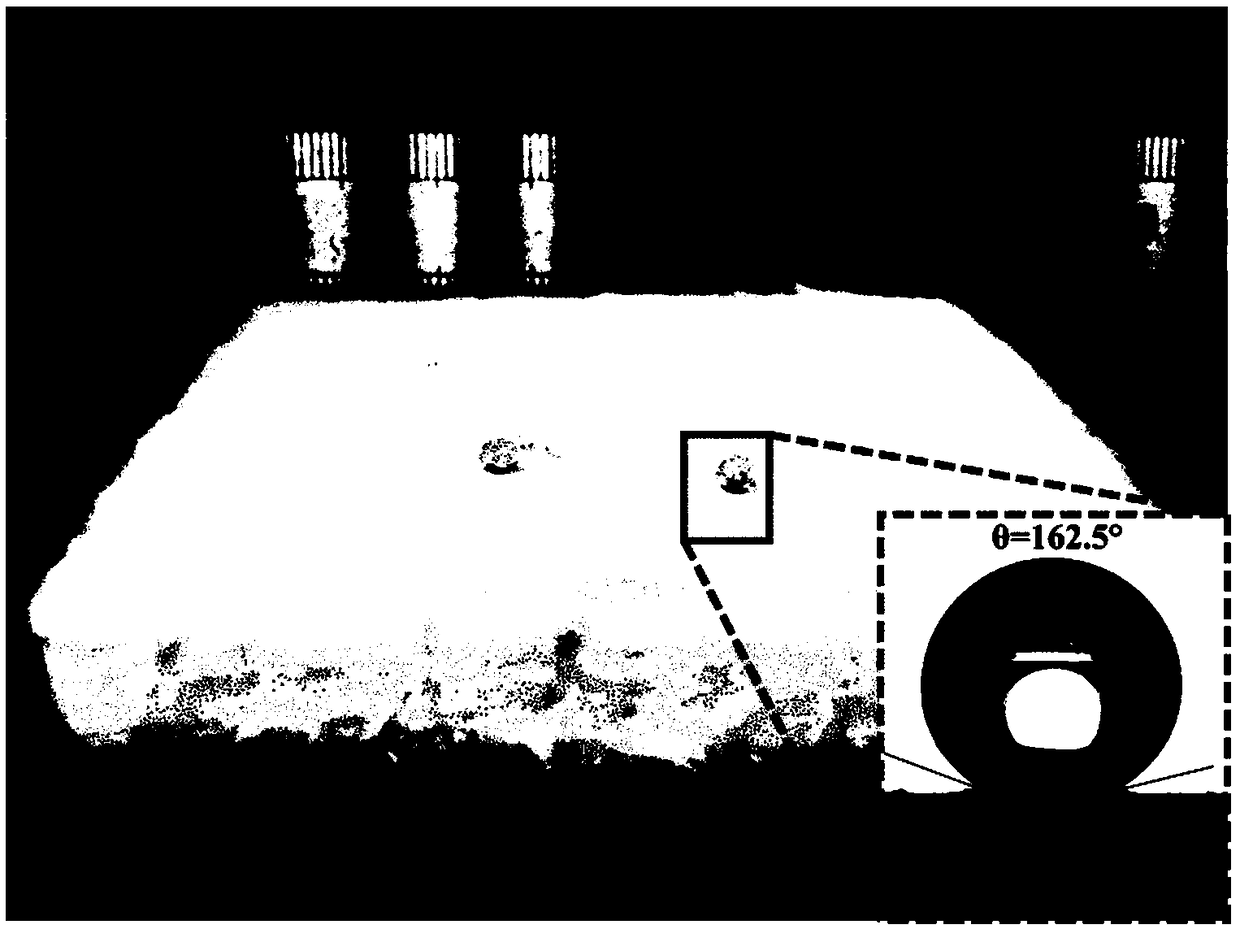

Embodiment 1

[0138] Ⅰ. First dilute the water glass with water, take 1.2L of water glass and 6L of water, mix well and stir evenly to obtain the dilution of water glass. Slowly introduce the diluent of water glass into 244 mL of 10M hydrochloric acid solution to obtain a sol solution.

[0139] II. Adjust the pH of the sol solution obtained in I to 5.0 with 3M aqueous sodium hydroxide solution, and after stirring for several minutes, dip the glass fiber mat into the sol solution. After the sol solution is fully impregnated, the glass fiber mat is taken out, and the gel composite material is obtained by microwave irradiation treatment. The power of microwave irradiation is 0.4KW, and the microwave irradiation treatment time is 150s.

[0140] Ⅲ. Roll up the gel composite material obtained in Ⅱ and put it into the reaction kettle ①, aging at room temperature for 5 hours, then add HMDSO solution into the kettle until the wet gel composite material is just submerged.

[0141] Ⅳ. Then introduce ...

Embodiment 2

[0149] A method for preparing a silica airgel composite material by external circulation modified atmospheric pressure drying, comprising the steps of:

[0150] Ⅰ. First dilute the water glass with water, take 1.2L of water glass and 3.6L of water and fully mix and stir evenly to obtain the dilution of water glass. Slowly introduce the diluent of water glass into 710 mL of 5M hydrochloric acid solution to obtain a sol solution.

[0151] II. Adjust the pH of the sol solution obtained in I to 5.0 with diluted water glass solution, wherein the volume ratio of water glass to water is 3:1. After stirring for several minutes, the glass fiber mat is dipped into the sol solution. After the sol solution is fully impregnated, the glass fiber mat is taken out, and the gel composite material is obtained by microwave irradiation treatment. The power of microwave irradiation is 0.4KW, and the microwave irradiation treatment time is 60s.

[0152] Ⅲ. Roll up the gel composite material obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com