Protective coating, filter material, matrix, and preparation method for protective coating

A technology of protective coating and filter material, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem of low adsorption force of polytetrafluoroethylene and filter material fibers, limited effect of improving filter material life, and can not be completely protected. Filter fiber and other problems, to achieve the effect of strong binding force, improved coverage and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

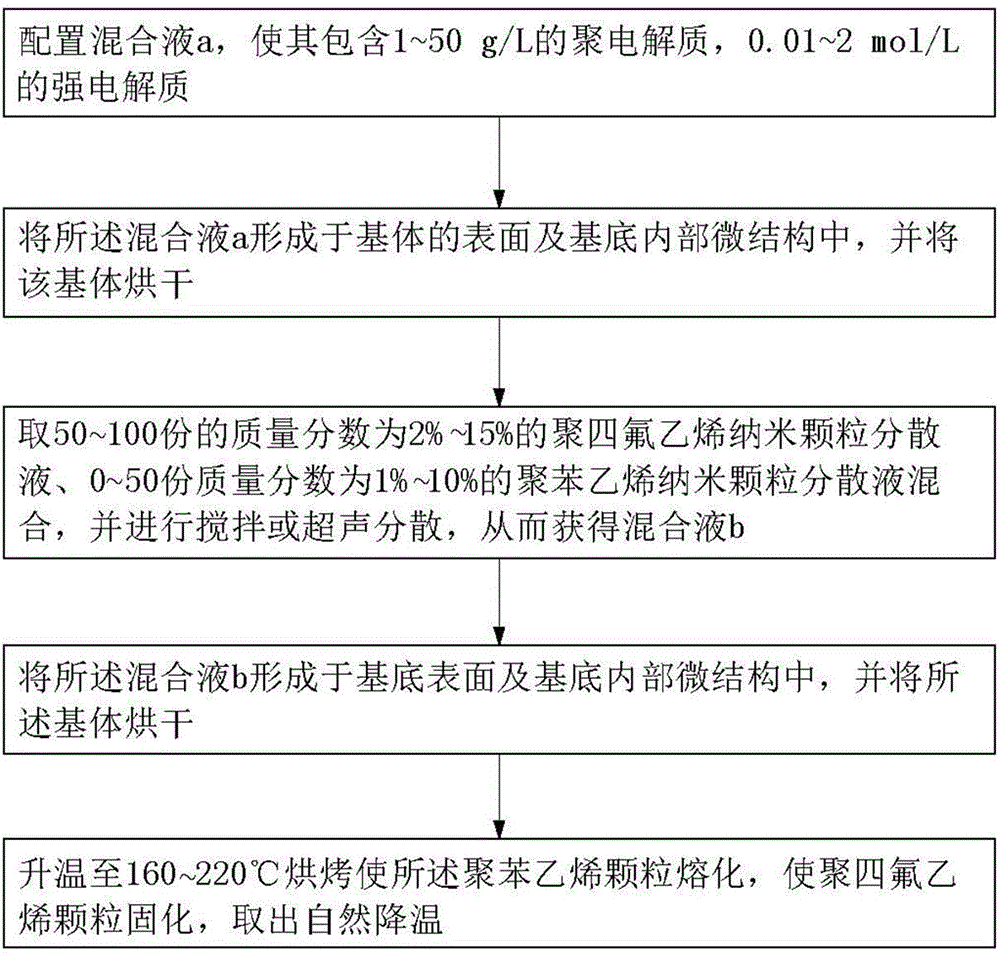

[0019] Please refer to figure 1 , the embodiment of the present invention provides a kind of preparation method of protective coating, it comprises the following steps:

[0020] Step 1: Prepare mixed solution a so that it contains 1-50 g / L polyelectrolyte and 0.01-2 mol / L strong electrolyte;

[0021] Step 2: forming the mixed solution a on the surface of a substrate and the microstructure inside the substrate, and drying the substrate;

[0022] Step 3: Take 50~100 parts of polytetrafluoroethylene nanoparticle dispersion liquid with a mass fraction of 2%~15%, and mix 0~50 parts of polystyrene nanoparticle dispersion liquid with a mass fraction of 1%~10%, and Stirring or ultrasonic dispersion to obtain the mixed liquid b;

[0023] Step 4: forming the mixed liquid b on the surface of the substrate and the microstructure inside the substrate, and drying the substrate;

[0024] Step 5: Bake at 160-220°C to melt the polystyrene particles and solidify the polytetrafluoroethylene p...

Embodiment 1

[0044] Configure mixed solution a so that it contains 10 g / L polyelectrolyte and 0.1 mol / L sodium chloride, the polyelectrolyte is a mixed solution composed of polyallylamine hydrochloride and polyvinylamine in a volume ratio of 3:1; Submerge the polyphenylene sulfide filter cloth completely in the mixture a, deposit for 15 minutes, then take the polyphenylene sulfide filter cloth out of the mixture a, and dry it with hot air at 70°C until it is completely dried; take 80 Parts (volume fraction) mass fraction is 4% polytetrafluoroethylene dispersion liquid, 20 parts mass fraction is the polystyrene dispersion liquid of 2%, is configured as mixed solution b, and described polytetrafluoroethylene nano particle diameter is 200nm , the particle size of the polystyrene nanoparticles is 50nm; the dried polyphenylene sulfide filter cloth is immersed in the mixed liquid b, and after standing for 15 minutes, it is thoroughly dried with hot air at a temperature of 70°C; the dried Put the...

Embodiment 2

[0046] Configure mixed solution a so that it contains 20g / L polyelectrolyte and 0.2 mol / L sodium chloride, the polyelectrolyte is sodium polystyrene sulfonate and polydiallyl dimethyl ammonium chloride in a volume ratio of 1 : a mixed solution composed of 2; completely immerse the polyester filter cloth in the mixed solution a, deposit for 15 minutes, take the polyester filter cloth out of the mixed solution a, and dry it with hot air at a temperature of 70°C until it is completely dried; take 70 Parts (volume fraction) mass fraction is 5% polytetrafluoroethylene dispersion liquid, 30 parts mass fraction is 1% polystyrene dispersion liquid, is configured as mixed solution b, and described polytetrafluoroethylene nano particle diameter is 200nm , the particle size of the polystyrene nanoparticles is 200nm; the dried polyester filter cloth is immersed in the mixed liquid b, and after standing for 15 minutes, it is thoroughly dried with hot air at a temperature of 70°C; the dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com