Preparation method of fiber-based waterproof moisture-permeable film with intelligent unidirectional moisture conductivity

A waterproof and moisture-permeable film, one-way moisture-conducting technology, applied in chemical instruments and methods, lamination, application, etc., can solve problems such as stickiness, lack of one-way moisture-conducting characteristics, etc., and achieve excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

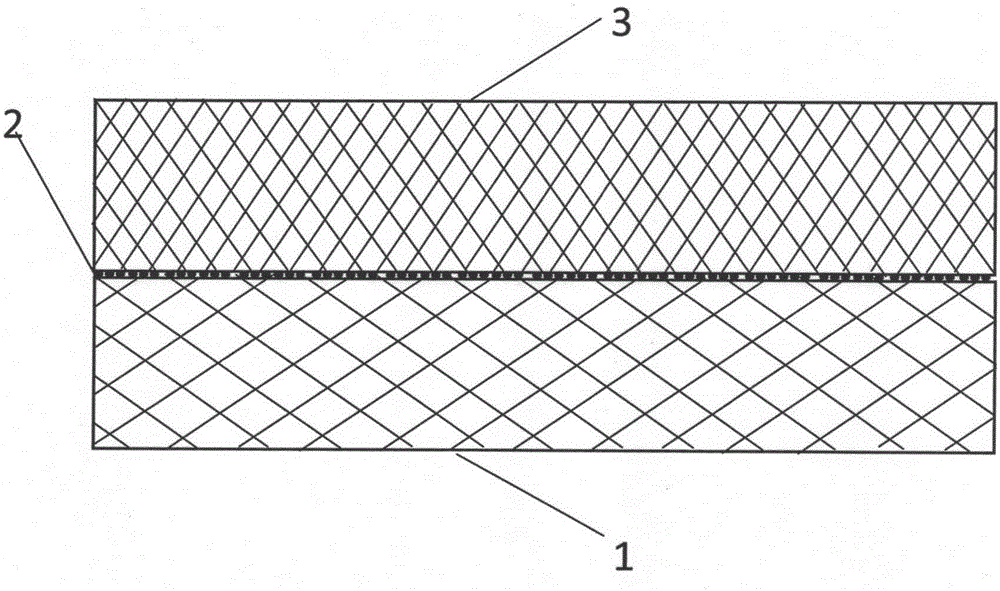

[0034] Such as figure 1 As shown, a fiber-based waterproof and moisture-permeable membrane with intelligent unidirectional moisture-wicking function is composed of a hygroscopic expansion fiber layer 1, an adhesive 2 and a hydrophobic fiber layer 3, and its preparation method is as follows:

[0035] The first step: Sodium polyacrylate (relative molecular mass is 4000) is dissolved in water to prepare a sodium polyacrylate solution with a mass fraction of 20%, and N, N-methylenebisacrylamide is added as a crosslinking agent, N, N - Methylenebisacrylamide accounted for 3% of the mass fraction of sodium polyacrylate, and stirred evenly to obtain a spinning solution; prepared a hydrophilic fiber layer on a copper grid by electrospinning, the spinning voltage was 30kV, and the receiving distance was 20cm , the liquid supply rate of the spinning solution is 5mL / h, and the thickness of the obtained hydrophilic fiber layer is 15 μm;

[0036]Step 2: Spray the phenolic resin adhesive e...

Embodiment 2

[0040] Such as figure 1 As shown, a fiber-based waterproof and moisture-permeable membrane with intelligent unidirectional moisture-wicking function is composed of a hygroscopic expansion fiber layer 1, an adhesive 2 and a hydrophobic fiber layer 3, and its preparation method is as follows:

[0041] The first step: Sodium polyacrylate (relative molecular mass is 4000) is dissolved in water to prepare a sodium polyacrylate solution with a mass fraction of 5%, and N, N-methylenebisacrylamide is added as a crosslinking agent, N, N -Methylenebisacrylamide accounts for 1% of the mass fraction of sodium polyacrylate, and stirs it evenly to obtain a spinning solution; prepares a hydrophilic fiber layer on a copper grid by electrospinning, the spinning voltage is 30kV, and the receiving distance is 20cm , the liquid supply rate of the spinning solution is 5mL / h, and the thickness of the obtained hydrophilic fiber layer is 15 μm;

[0042] Step 2: Spray the phenolic resin adhesive emul...

Embodiment 3

[0046] Such as figure 1 As shown, a fiber-based waterproof and moisture-permeable membrane with intelligent unidirectional moisture-wicking function is composed of a hygroscopic expansion fiber layer 1, an adhesive 2 and a hydrophobic fiber layer 3, and its preparation method is as follows:

[0047] The first step: dissolving sodium polyacrylate (the relative molecular mass is 4000) in water to prepare a sodium polyacrylate solution with a mass fraction of 30%, and adding N, N-methylenebisacrylamide as a crosslinking agent, N, N- Methylenebisacrylamide accounted for 5% of the mass fraction of sodium polyacrylate, and stirred evenly to obtain a spinning solution; prepared a hydrophilic fiber layer on a copper grid by electrospinning, the spinning voltage was 30kV, and the receiving distance was 20cm. The liquid supply rate of the spinning solution is 10mL / h, and the thickness of the obtained hydrophilic fiber layer is 15 μm;

[0048] The second step: Spray the phenolic resin a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com