Preparation method of foamed boron nitride block material

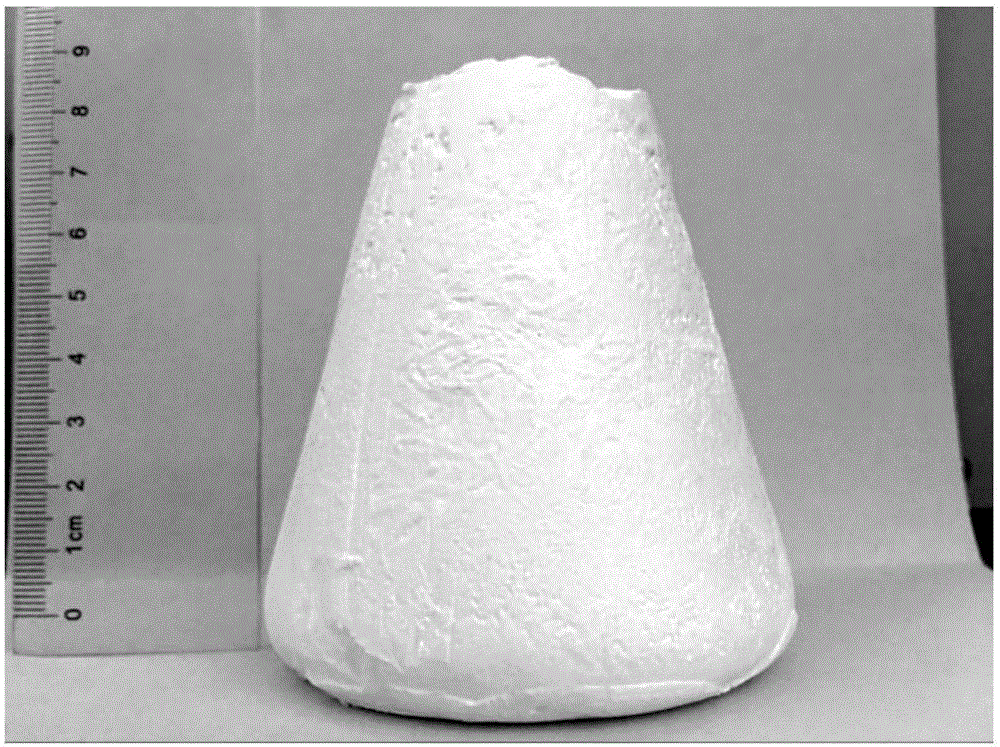

A technology of boron nitride block and bulk materials, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high cost, complicated preparation process, low output, etc., and achieve reduction of production energy consumption and cost, method Non-toxic, uniform product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

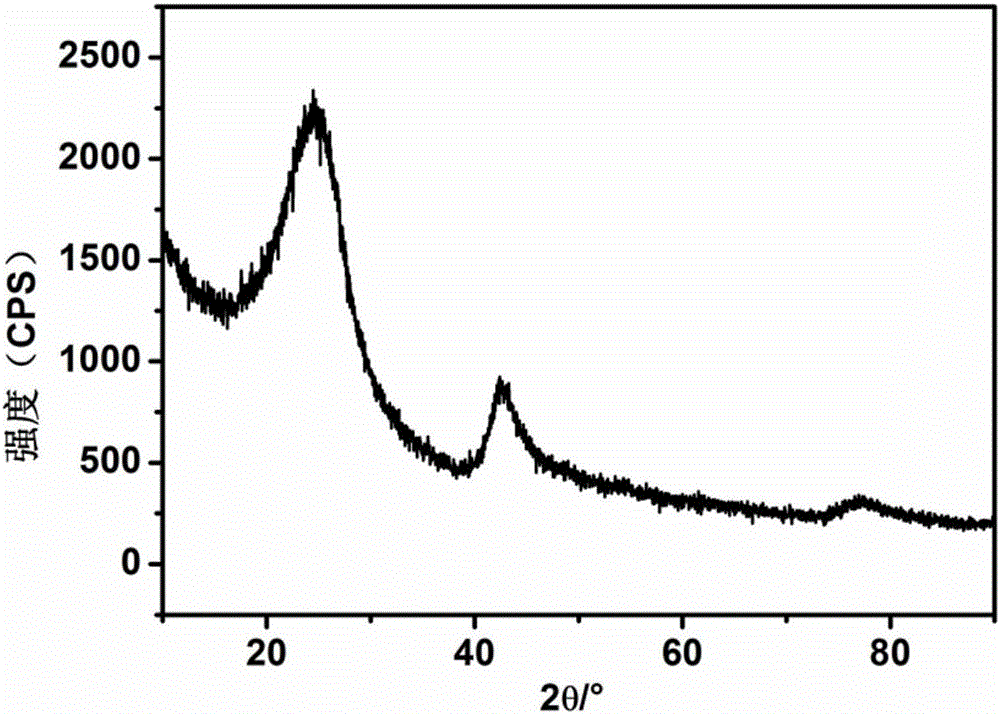

Embodiment 1

[0032] (1) Add 5.0 g of melamine and 7.5 g of boric acid into a glass container filled with 250 ml of water, so that each ml of water contains 0.02 g of melamine and 0.03 g of boric acid. After stirring for 2 hours, put the glass container with a temperature control system In a constant temperature water bath, heat to 95°C to completely dissolve melamine and boric acid and keep it warm for 4 hours;

[0033] (2) Put the stable melamine-boric acid-water mixed solution and its container obtained in step (1) into an ultrasonic instrument with adjustable ultrasonic power and temperature, set the ultrasonic power to 40kHz, and set the temperature to 70°C, keep warm and ultrasonic for 5 hours, white blocks will be precipitated in the solution;

[0034] (3) Place the white block obtained in step (2) together with the solution in a freeze dryer to vacuum freeze and dry (temperature -40°C, pressure 30Pa, drying time 120 hours) to obtain a dry white solid precursor;

[0035] (4) Heat th...

Embodiment 2、 example 3

[0038] Change the concentration of melamine in step (1) in Example 1 to 0.01 gram and 0.05 gram of melamine per milliliter of water respectively. 3 and 65mg / cm 3 , other with embodiment 1.

Embodiment 4、 example 5

[0040] Change the concentration of boric acid in step (1) in Example 1 to 0.01 gram and 0.05 gram of boric acid per milliliter of water respectively. 3 and 43mg / cm 3 , other with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com