Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Reduce the adsorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for novel graphene polyion liquid composite material

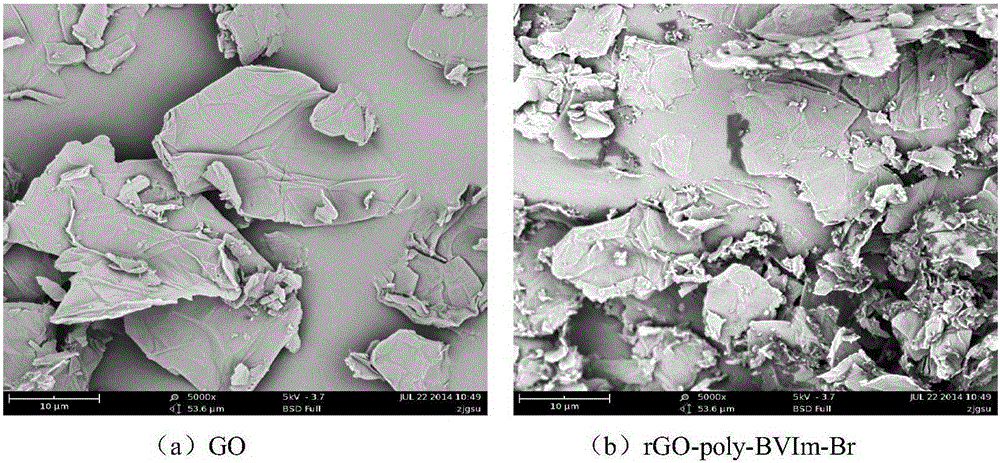

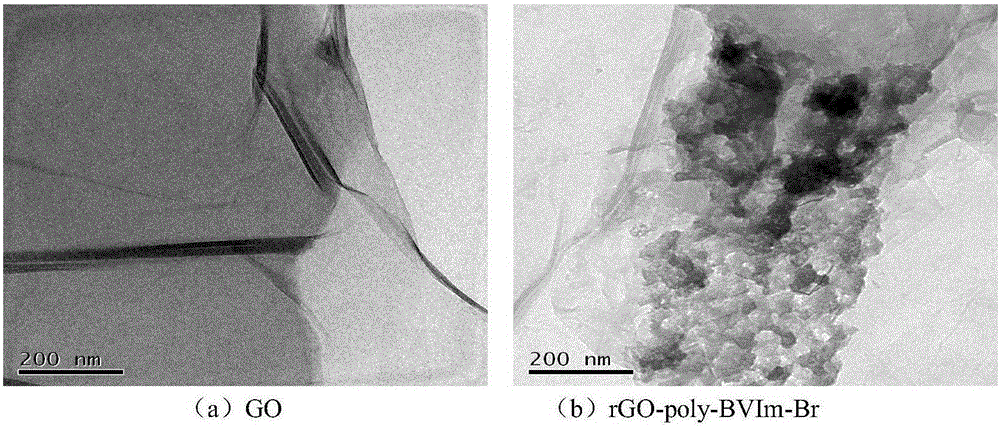

ActiveCN105289503AReduce the adsorption rateHigh adsorption rateOther chemical processes2-methylpropeneSupercapacitor

The invention provides a preparation method for a novel graphene polyion liquid composite material. The method comprises the following steps of 1, preparing graphene oxide; 2, preparing ionic liquid 1-[(2-methylacryloyl)-ethyl-3-(MEBIm-Br); 3, using the 1-[(2-methylacryloyl)-ethyl-3-(MEBIm-Br) as imidazole ionic liquid to obtain the novel graphene polyion liquid composite material (rGO-poly-MEBOm-B and rGO-poly-MEBIm-Br). The obtained novel graphene polyion liquid composite material not only can be applied to the aspects of biological sensors, super-capacitors and the like and but also has the good performance on the aspects of adsorbing and separating pollutants.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Mycotoxin adsorbent and preparation method thereof

InactiveCN104431375AAvoid it happening againMaintain micro-ecological balanceFood preservationAnimal feeding stuffSorbentAntitoxin

The invention belongs to the technical field of agriculture animal husbandry and food antitoxin and detoxication, and relates to mycotoxin adsorbent and a preparation method thereof. The mycotoxin adsorbent is composed of, by weight, 85-90% of montmorillonite, 5-7% of yeast cell walls, 1-3% of chitin, 1-2% of saccharomyces boulardii and 3-5% of natural plant extract in a mixing mode. The natural plant extract comprises tea tree oil, hesperidin, eugenol, citral, cinnamaldehyde and baicalein which are proportionally mixed. The mycotoxin adsorbent can be applied to fodder, aflatoxin B1 in the mycotoxin can be absorbed, other mold toxins such as zearalenone, ochratoxin, deoxynivalenol and fumitremorgin can also be effectively absorbed, the nutrient absorption rate of the fodder is low, meanwhile, breeding and balancing of probiotics in intestinal canals can be promoted, and the immunocompetence of animals is enhanced.

Owner:湖北回盛生物科技有限公司

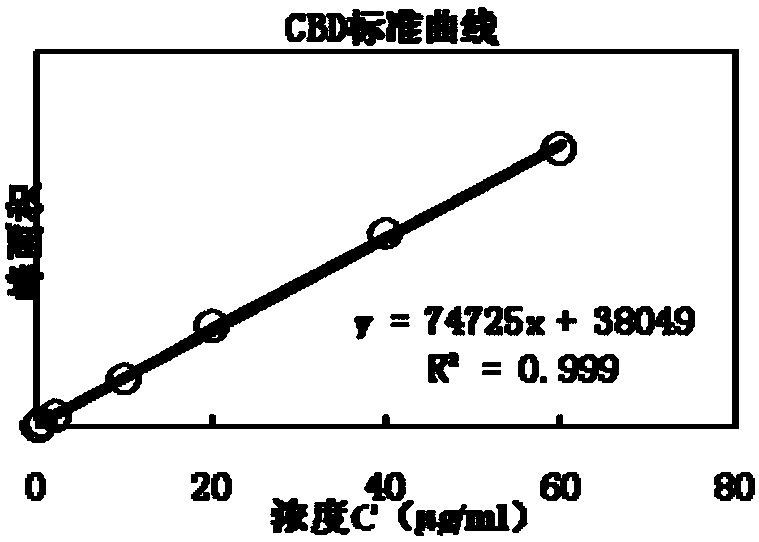

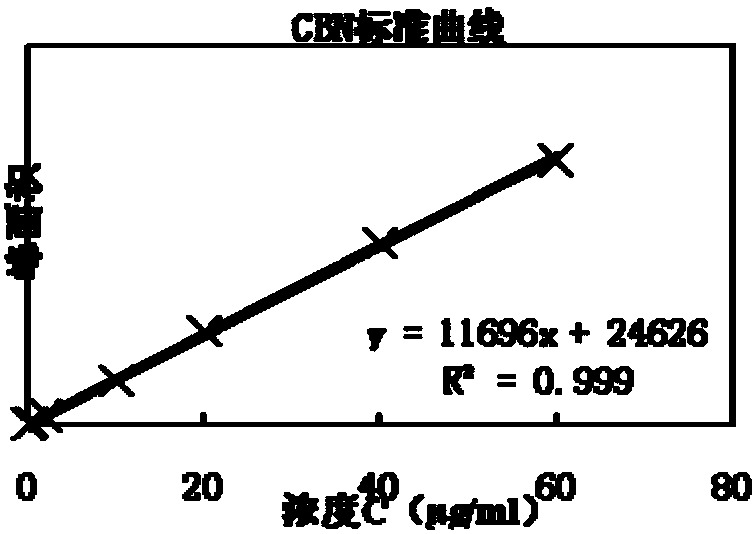

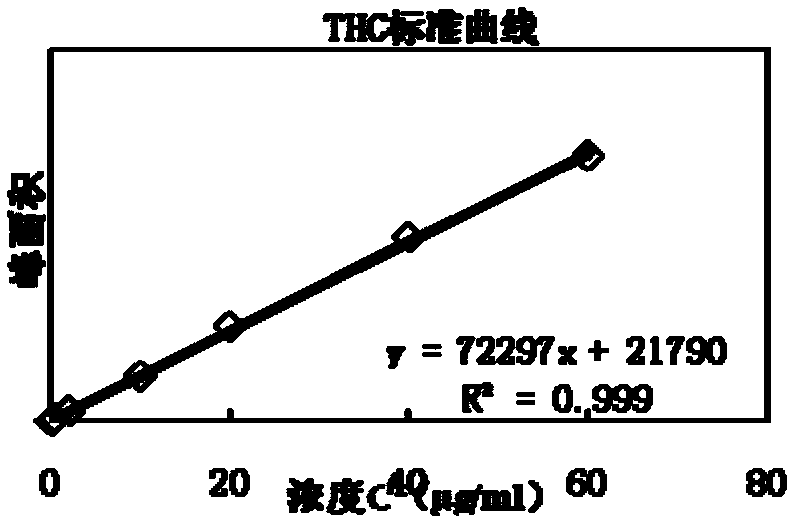

Method for simultaneously detecting three cannabinol compounds in hemp with SPE-HPLC (solid phase extraction-high performance liquid chromatography)

InactiveCN107589203AAccurate judgmentQuick checkComponent separationSolid-phase microextractionLinear regression

The invention belongs to the field of plant ingredient detection and particularly relates to a method for simultaneously detecting three cannabinol compounds in hemp with SPE-HPLC (solid phase extraction-high performance liquid chromatography). The SPE-HPLC is applied to detection of the cannabinol compounds in the hemp and can simultaneously detect the three cannabinol compounds in the hemp and perform qualitative and quantitative analysis on the compounds. According to the method, firstly, the HPLC conditions are determined, and a standard curve of the three cannabinol compounds is drawn anda linear regression equation is determined by detecting a mixed standard solution; a hemp sample is subjected to SPE for impurity removal, finally, high performance liquid detection is performed on the sample, and the content of the three cannabinol compounds in the hemp is obtained through calculation. To-be-detected cannabinol compounds and impurities are separated through SPE, influence of impurities on detection is reduced, and a good basis is provided for liquid detection. The detection method has a good linear relation in a corresponding application range and good precision, repeatability and accuracy.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

High performance agent for removing fluorin, preparation method, and application

InactiveCN101091903ARaise the pHGood defluoridation effectOther chemical processesWater/sewage treatment by sorptionBrickSorbent

The invention relates to a fluorine-removing agent with high efficiency and its preparation method and application. The invention includes the raw material agitation, the formation and the roasting which contains laterite, the aluminum salt, of which the weight dosage of the aluminum salt is 0-30% according to the gross weight of the raw material, the fluorine-removing agent can widely used in the profession of the fluorine sewage treatment, the high fluorine surface water purification. The invention is simple craft, and operation.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

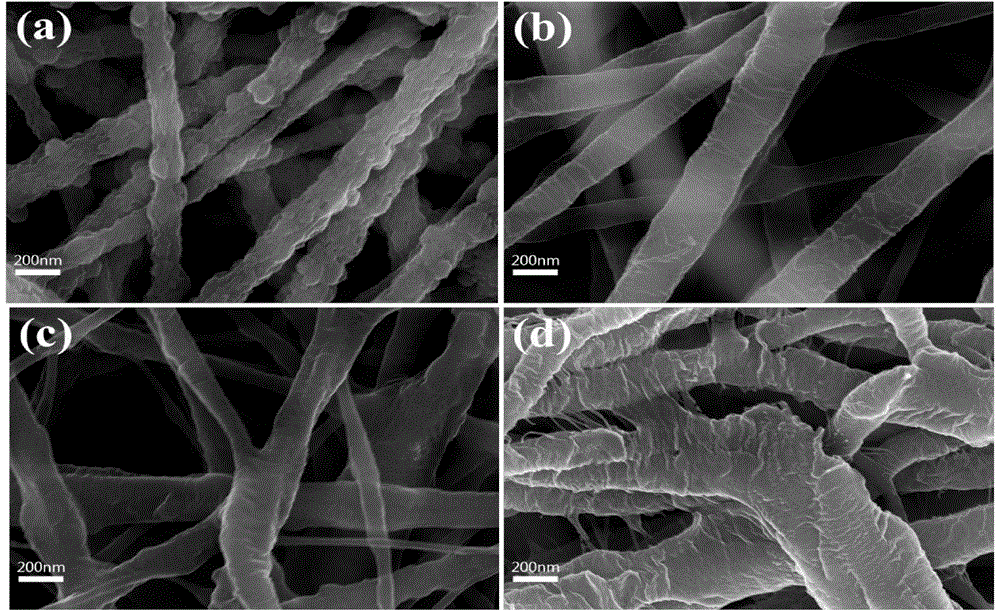

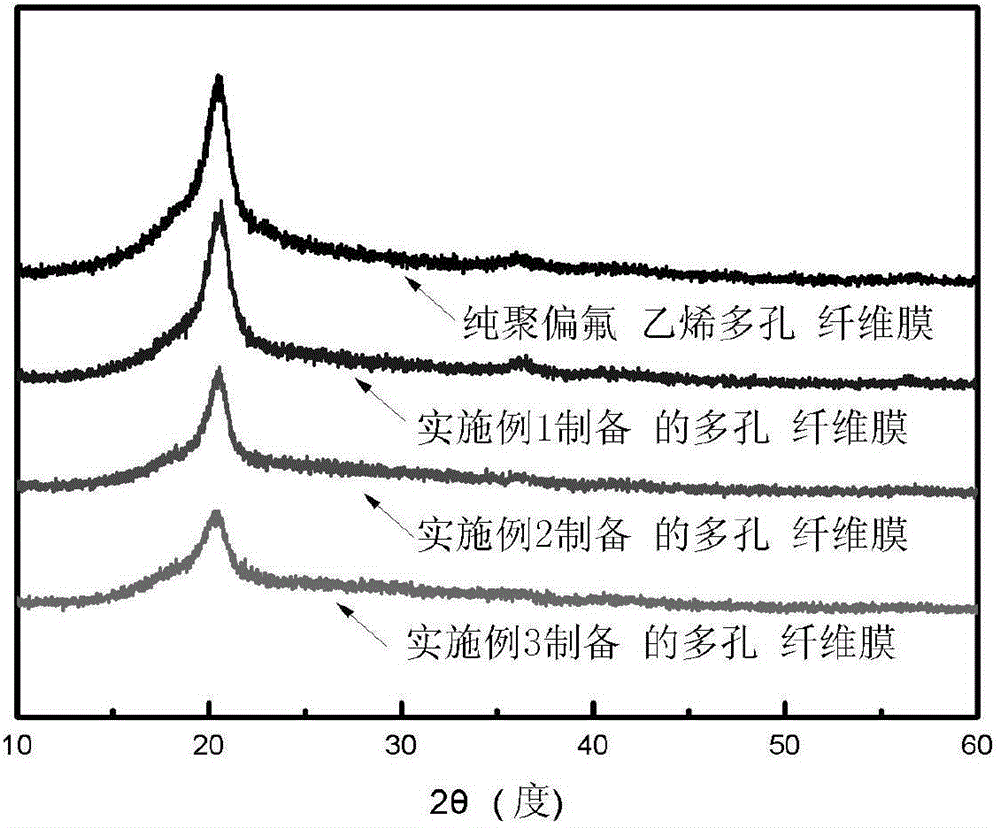

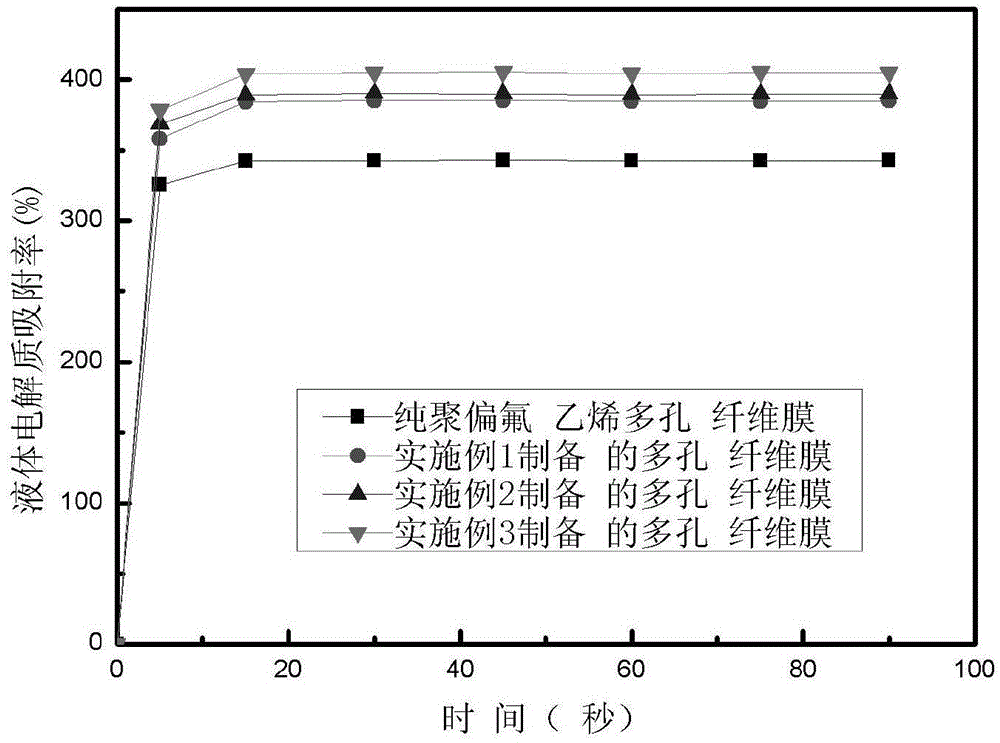

Preparation method of porous fiber gel polymer electrolyte

InactiveCN104900913AOvercoming the low adsorption rateImprove mechanical propertiesSecondary cellsOrganic electrolytesElectrospinningPolyvinylidene fluoride

The invention discloses a preparation method of a porous fiber gel polymer electrolyte. According to the preparation method, firstly, ionic polymer polyurethane polyglycol ester lithium is prepared via condensation polymerization, and then is mixed with polyvinylidene fluoride at a mass ratio of 1:1-1:4; an obtained mixture is dispersed into a N,N-dimethylformamide solution; an obtained mixed material is subjected to electrostatic spinning and drying so as to prepare blended polymer porous fiber membranes; the blended polymer porous fiber membranes are dried, and a liquid electrolyte is absorbed by the blended polymer porous fiber membranes for activation so as to obtain the porous fiber gel polymer electrolyte with a thickness of 50 to 70<mu>m, wherein the mass of the liquid electrolyte absorbed by the blended polymer porous fiber membranes accounts for 200 to 400wt% of that of the blended polymer porous fiber membranes. The optimal ionic conductivity of the porous fiber gel polymer electrolyte is 5.43*10<-3>S / cm, electrochemical stability window is about 5.0V, and application prospect in the field of polymer lithium ion battery is promising.

Owner:JIANGSU UNIV OF SCI & TECH

Preparation method of super-hydrophobic graphene sponge

The invention provides a preparation method of super-hydrophobic graphene sponge. The preparation method comprises the specific steps: (1) cleaning and drying sponge; (2) carrying out plasma processing on the sponge processed in the step (1); (3) soaking the sponge processed in the step (2) into graphene oxide dispersion liquid, and adding hydrazine hydrate; and (4) heating mixed liquid prepared in the step (3) to 85-95 DEG C, maintaining for 0.5-24 hours, taking out the sponge, and drying, so as to obtain the super-hydrophobic graphene sponge.

Owner:SOUTHEAST UNIV

Weak bitter corn oligopeptide with high content of alanine and leucine, and preparation method thereof

The invention belongs to the field of agricultural and sideline product processing and utilization technology with high added value, and discloses a weak bitter corn oligopeptide with high content of alanine and leucine, and a preparation method of the weak bitter corn oligopeptide. The method comprises the steps of: (1) dispersing and hydrating corn gluten meal; (2) carrying out gelatinization and alpha-high temperature amylase enzymolysis, degreasing and removing starch; (3) carrying out enzymolysis; (4) carrying out enzyme deactivation and decoloration; and (5) carrying out rough filtration, ultrafiltration and nanofiltration, and drying to obtain the weak bitter corn oligopeptide. The weak bitter corn oligopeptide contains 85.42-87.63% by mass of protein percent, 92.44-94.21% by mass of peptide with the relative molecular weight being less than 1000Da, 6.75-6.94% by mass of alanine, 14.12-14.66% by mass of leucine and 1.12-1.36% by mass of free amino acid. The weak bitter corn oligopeptide with high content of alanine and leucine can be widely used as raw material of health-care food and common food, and especially can be used in products used for sobering up and protecting the liver.

Owner:广州合诚实业有限公司

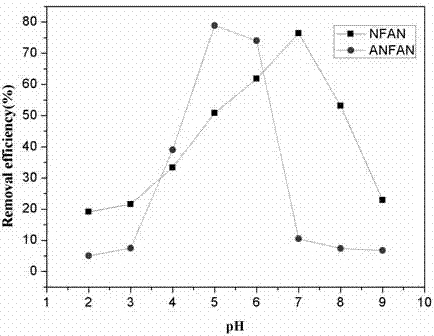

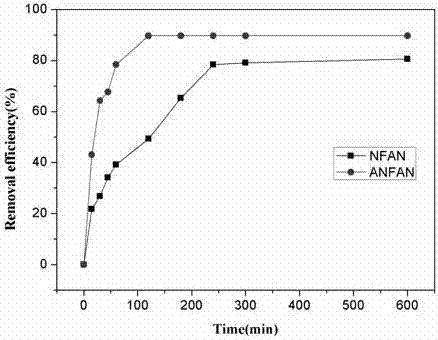

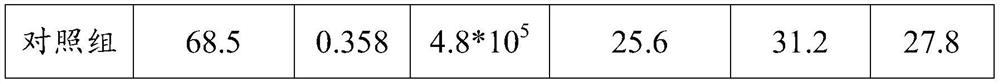

Preparation of amidoxime modified magnetic nano biological adsorbent and method for adsorbing low-concentration uranium by utilizing amidoxime modified magnetic nano biological adsorbent

ActiveCN107537455AHigh adsorption rateThe adsorption rate is stableOther chemical processesAlkali metal oxides/hydroxidesCross-linkSorbent

The invention relates to preparation of an amidoxime modified magnetic nano biological adsorbent and a method for adsorbing low-concentration uranium by utilizing the amidoxime modified magnetic nanobiological adsorbent. The preparation comprises the following steps: modifying magnetic nano Fe3O4 by utilizing amidoxime; grafting the amidoxime modified nano Fe3O4 on aspergillus niger through cross-linking reaction to obtain an amidoxime modified magnetic nano Fe3O4-aspergillus niger biological adsorbent. Lone pair electrons on an electron-donating group of the amidoxime based adsorbent and uranyl ions can form a coordination bond or a stable structure, so that the adsorption speed and the adsorption capacity of the material on the uranyl ions can be effectively improved. The uranium compatible property of the aspergillus niger, the magnetic property of the nano Fe3O4 and the high selectivity and affinity of an amidoxime group on the uranium are combined and the aspergillus niger is a biological material, so that the amidoxime modified magnetic nano biological adsorbent has the advantages of good adsorption property, simplicity in operation, low production cost, low energy consumption, easiness for solid-liquid separation and the like; the product has a good application prospect in the fields of prevention and control of radioactive pollution and uranium cyclic utilization.

Owner:NANHUA UNIV

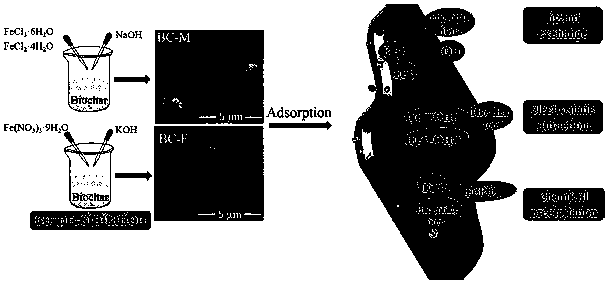

Preparation method and application of biochar/iron oxide composite material

InactiveCN110449125AEasy to usePhosphate works wellOther chemical processesWater contaminantsSorbentPhosphate

The invention relates to a preparation method and application of a biochar / iron oxide composite material. Iron oxide particles are loaded to the surface of biochar by a simple coprecipitation method to form the composite material with good pore structure and large specific surface area, and the composite material is applied to removal of phosphates in aqueous solutions. The synthesis conditions ofbiochar / iron oxide are studied to compare the phosphate removal effect of the synthesized material. By studying the adsorption properties of the biochar / iron oxide composite material on phosphates inwater, optimal adsorbent dosage, adsorption time, adsorption concentration and other values can be obtained. Biochar has a porous structure and large surface area, also has wide sources, and is low in cost. The surface of the iron oxide contains a lot of hydroxyl radicals, which can be converted into positively charged adsorption sites. The biochar / iron oxide composite material prepared by the method has good removal ability on phosphates in water, and also has strong stability and recyclability.

Owner:UNIV OF JINAN

Composite film for flour packaging and manufacturing method thereof

ActiveCN103770411AThe production process is simple and easy to controlReduce the adsorption rateFlexible coversWrappersFunctional monomerPolyurethane adhesive

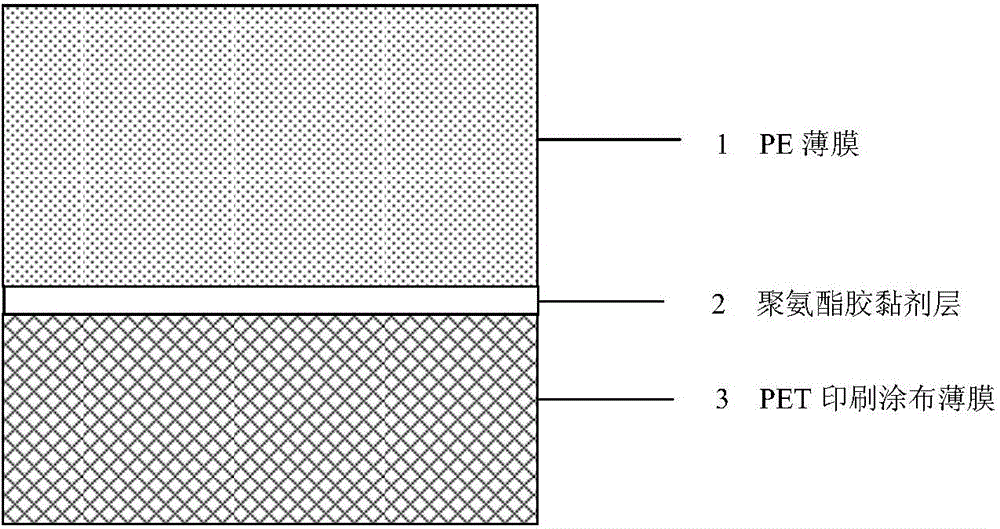

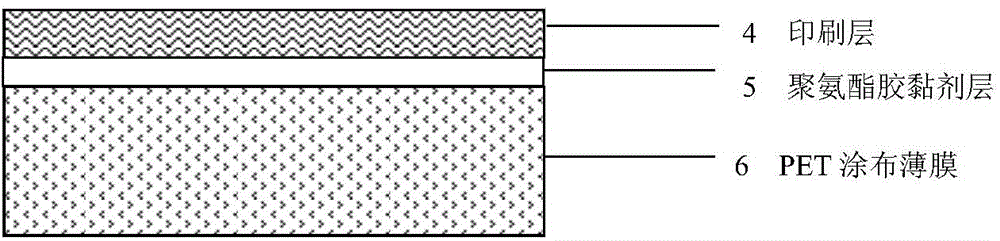

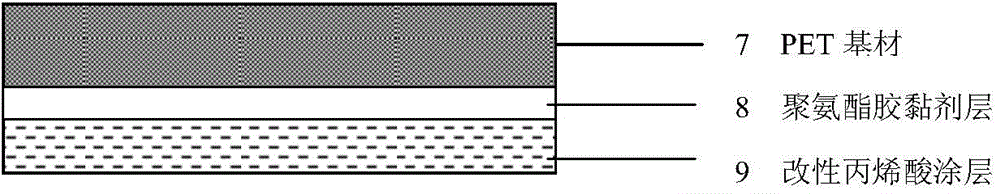

The invention relates to a composite film for flour packaging and a manufacturing method thereof. The composite film comprises three layers (figure. I), namely a PET (polythylene terephthalate) litho-coated thin film, a PE (polyethylene) thin film and a polyurethane adhesive layer arranged between the PET litho-coated thin film and the PET thin film, wherein the PET litho-coated thin film comprises three layers (figure. II), namely a PET coated thin film, a printed layer on the coated thin film and a polyurethane adhesive layer arranged between the PET coated thin film and the printed layer; the PET coated thin film comprises three layers (figure. III), namely a PET base material, a modified crylic acid coating layer on the surface of the base material and a polyurethane adhesive layer arranged between the PET base material and the modified crylic acid coating layer; the modified crylic acid coating layer is obtained by coating the surface of the PET base material with crylic acid emulsion through a coating technology; the modified crylic acid emulsion is prepared from the following raw materials in percentage by weight: 5-10 percent of a functional monomer, 8-12 percent of an adhesive monomer, 6-8 percent of a cohesion monomer, 0.02-0.08 percent of chondroitin sulfate, 0.2-0.5 percent of an emulsifier, 0.05-0.2 percent of a defoaming agent, 0.05-0.1 percent of an initiator, 0.02-0.1 percent of electrolyte, 1-3 percent of ammonia water and 67-75 percent of deionized water. The composite film disclosed by the invention can well achieve the effect of electrostatic dust (powder) absorption during flour packaging and is high in thermal sealing performance.

Owner:HAINAN SHINER IND

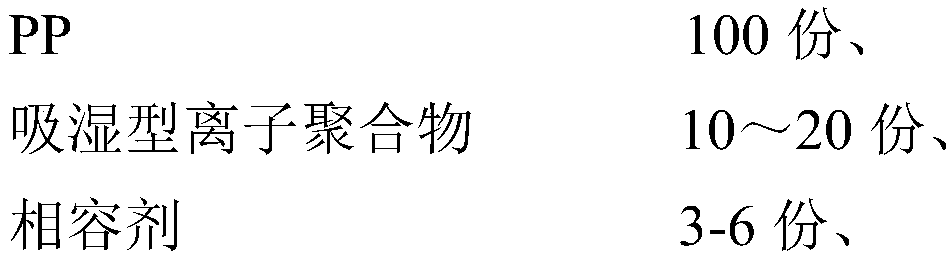

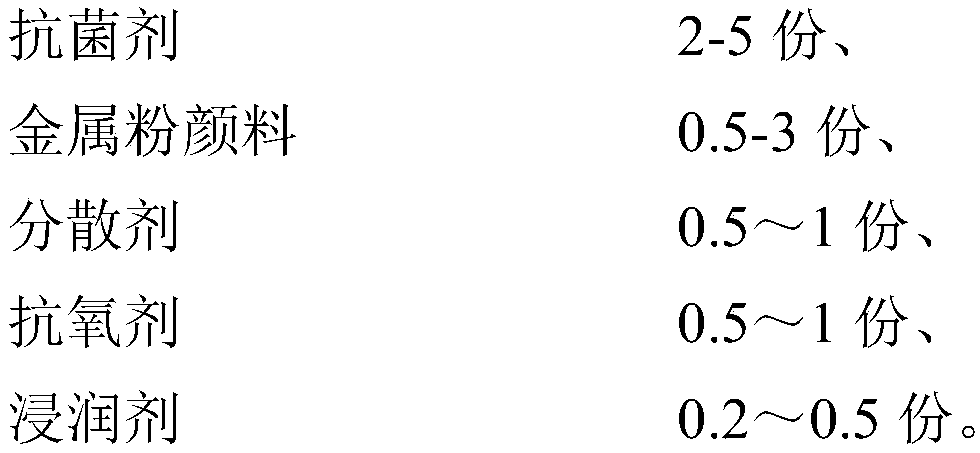

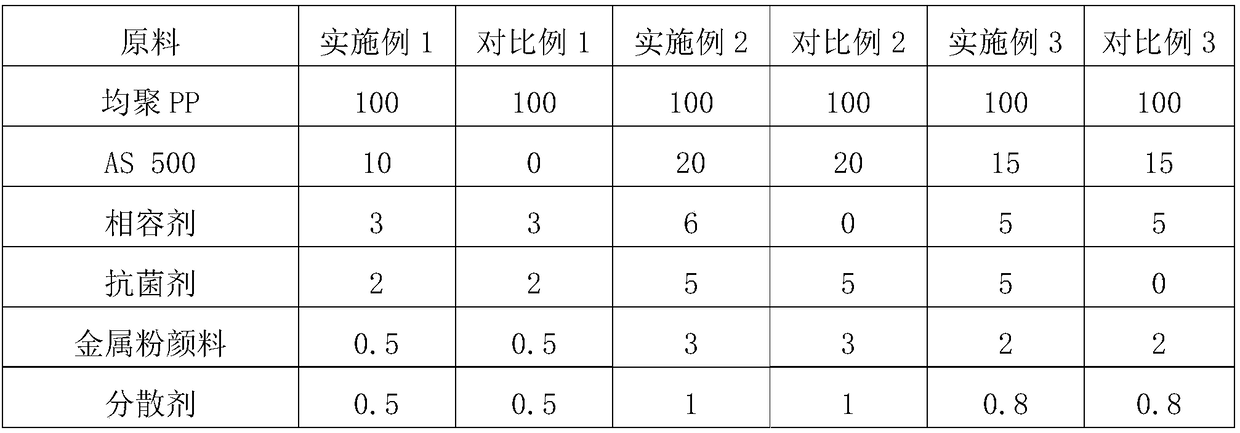

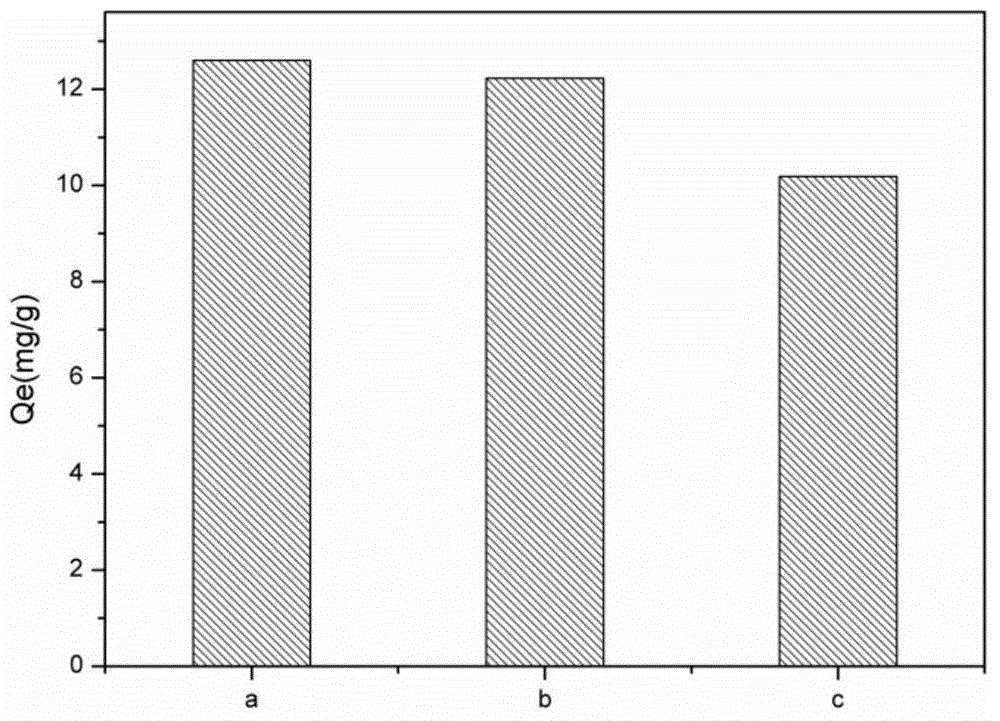

Antibacterial and dust adsorption-free spray-free PP material and preparation method thereof

The invention discloses an antibacterial and dust adsorption-free spray-free PP material and a preparation method thereof. The antibacterial and dust adsorption-free spray-free PP material includes, by weight parts, 100 parts of PP, 10-20 parts of hygroscopic ionic polymer, 3-6 parts of compatibilizer, 2-5 parts of antibacterial agent, 0.5-3 parts of metal powder pigment, 0.5-1 part of dispersingagent, 0.5-1 part of antioxidant and 0.2-0.5 part of infiltrant. The prepared material has the advantages of excellent metal spray-free effect and good dust adsorption resistance and antibacterial property, the problem of flow marks of a conventional metal spray-free effect material can be effectively solved, and the antibacterial and dust adsorption-free spray-free PP material is suitable for occasions where bacteria are bred easily and dust adsorption is high, and the antibacterial and dust adsorption-free spray-free PP material has a wide range of uses in the fields of automobiles, home appliances, and household goods.

Owner:上海日之升科技有限公司

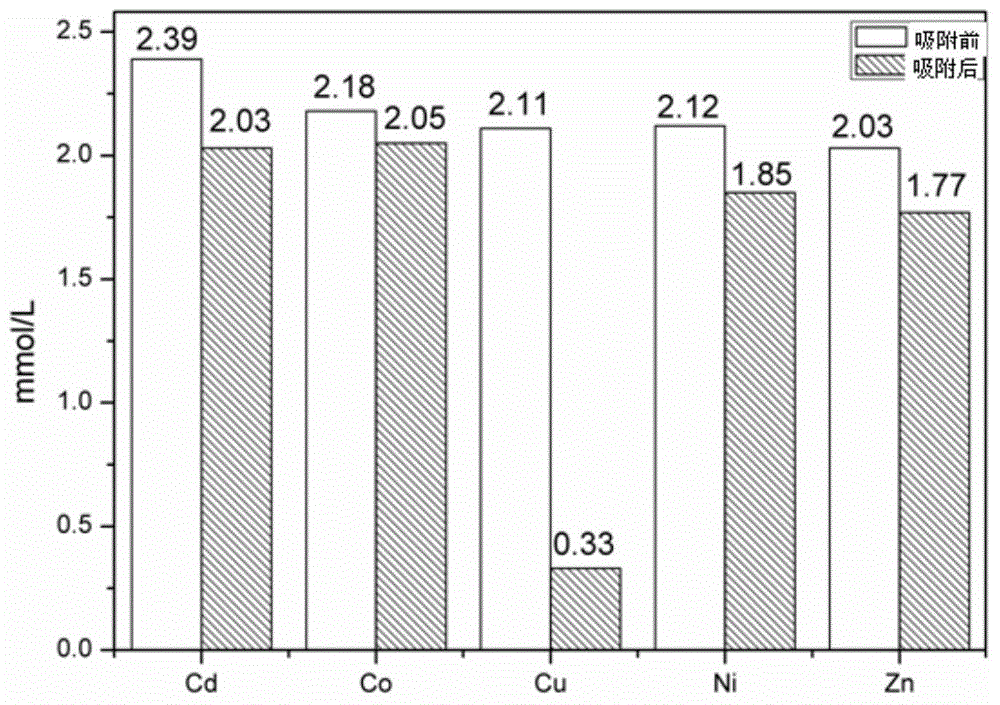

Preparation method of carbon-base adsorbing material capable of selectively adsorbing copper ions

InactiveCN104587969ALow selectivityImprove performanceOther chemical processesWater/sewage treatment by sorptionAlcoholCopper chloride

The invention discloses a preparation method of a carbon-base adsorbing material capable of selectively adsorbing copper ions. The preparation method comprises the following steps: uniformly mixing and stirring tetraethylenepentamine (TEPA), copper chloride and glucose in a mole ratio of 1:1:3-1:1:10; loading the mixture into a reaction kettle and reacting at 180 DEG C for 15 hours to obtain a solid substance; repeatedly soaking and washing the solid substance by 0.01mol / L of EDTA solution; and finally washing by absolute ethyl alcohol to obtain colorless transparent filtered liquid and drying the washed solid substance at 80 DEG C to obtain the carbon-base adsorbing material containing amino. According to the preparation method, maximum adsorption capacity of the material to copper ions is 33.3mg / g and the adsorption rate of the material to copper ions in a water system containing Cu<2+>, Cd<2+>, Co<2+>, Ni<2+> and Zn<2+> is up to 84.4%. The material has an excellent selective adsorption performance to copper ions, so that the copper ions can be effectively extracted or removed from sewage. The preparation method is characterized by simple, fast and efficient processes, and the selected material has excellent selective adsorption capability.

Owner:JILIN UNIV

Synthetic method of pollution-resistant deeply-softened chelating resin

ActiveCN105037601AStrong leakage abilityStrong pollution resistanceOther chemical processesWater/sewage treatment by sorptionDivinylbenzeneDistillation

The invention discloses a synthetic method of pollution-resistant deeply-softened chelating resin. The synthetic method comprises the following steps: preparing an oil phase by adopting a styrene monomer, a divinyl benzene crosslinking agent, a pore-foaming agent and an initiating agent; preparing a water phase by adopting water, a dispersant and NaCl; adding the oil phase into the water phase, lowering the temperature after a temperature rising process, discharging, washing, extracting, drying and screening to obtain polystyrene series styrene-divinylbenzene copolymers of the pollution-resistant deeply-softened chelating resin; then performing chloromethylation reaction, and transforming to obtain polystyrene series chloromethylated beads; performing stirring expansion on the polystyrene series chloromethylated beads by using dichlorethane, adding N-hydroxymethyl phthalimide, dropwise adding a catalyst, heating, preserving the temperature, cooling, pumping out mother liquor, adding water, performing reduced pressure distillation, and cleaning; and adding 25% caustic soda liquid, heating, stabilizing, washing with water, adding a chloroacetic acid solution to perform chelation reaction, heating, preserving the temperature, washing with water, performing acid regulation, washing with water, performing alkali regulation, washing with water until the mixture is neutral, and discharging for package to obtain the pollution-resistant deeply-softened chelating resin.

Owner:TONGJI UNIV +1

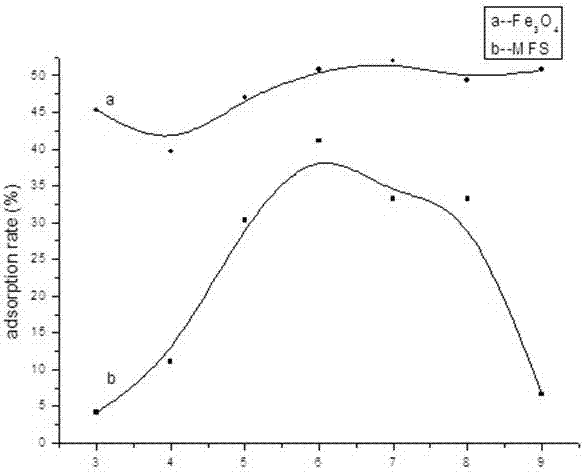

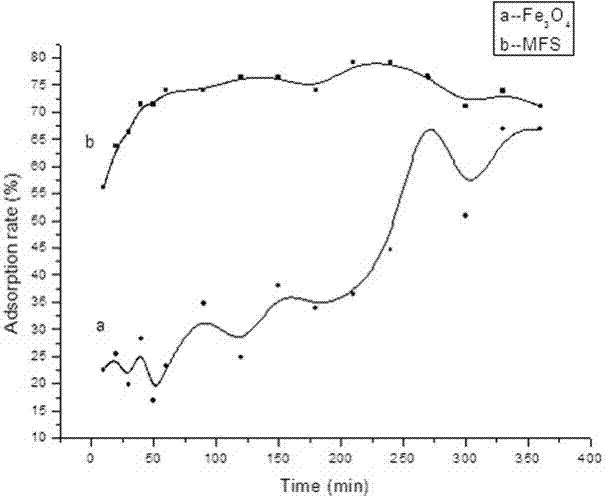

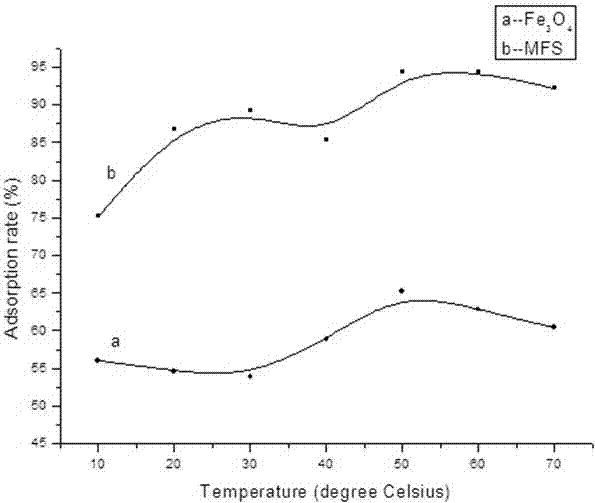

Method for preparing calixarene-modified magnetic nano-adsorbent and adsorbing low-concentration uranium with calixarene-modified magnetic nano-adsorbent

InactiveCN107051394AHigh adsorption rateReduce the adsorption rateOther chemical processesAlkali metal oxides/hydroxidesCalixareneAdsorption effect

The invention relates to a method for preparing an adsorbent 4-sulfocalix[6]arene-modified magnetic nano Fe3O4 and adsorbing low-concentration uranium with the adsorbent. Modification of magnetic nano Fe3O4 with 4-sulfocalix[6]arene is realized as follows: Fe-O bonds are formed through magnetic nano Fe3O4 and phenolic hydroxyl groups on the lower edge of 4-sulfocalix[6]arene to promote grafting of magnetic nano Fe3O4 and 4-sulfocalix[6]arene, and the purpose of modification is achieved. After magnetic nano Fe3O4 is modified with 4-sulfocalix[6]arene, the hydrophilcity of magnetic nano Fe3O4 is increased, the surface area is increased, and magnetic nano Fe3O4 is can be better bonded with UO2<2+> through a complexing reaction, electrostatic bonding and other reactions. The adsorbent has higher adsorption rate and better adsorption effect than the magnetic nano Fe3O4 adsorbent.

Owner:NANHUA UNIV

Preparation method of epicatechin monomer

InactiveCN105219815AAchieve preparationSolve technical problems that are difficult to separateOrganic chemistryFermentationTea catechinGreen teas

The invention relates to a preparation method of an epicatechin monomer. The preparation method comprises the following steps of: (1) adding tannase to a solution containing large-leaf green tea catechin extract, carrying out static enzymolysis at 30-35 DEG C, intermittently stirring, and centrifugally filtering to obtain an enzymolysis solution; (2) introducing the enzymolysis solution into a chromatographic column loaded with adsorptive resin, carrying out gradient elution with ethanol elution agent, collecting eluate, concentrating eluate to 16-18 Baume degree to obtain concentrate, standing the concentrate at 0-4 DEG C for 48-72h, adding a little of epicatechin monomer, crystallizing and recrystallizing, centrifuging and drying to obtain the epicatechinmonomer. According to the method, epicatechin gallate is subjected to enzymolysis by using tannase, so that the method has good transformation effect, high transformation rate and high product quality, short preparation period, and low cost, and is suitable for scaled production.

Owner:HUBEI ZHONGXIN BIOTECH CO LTD

Composite film for flour packaging and manufacturing method thereof

ActiveCN103770411BThe production process is simple and easy to controlReduce the adsorption rateFlexible coversWrappersComposite filmPolyurethane adhesive

Owner:HAINAN SHINER IND

Method for remediating heavy metal contaminated soil through combination of microorganism and plant

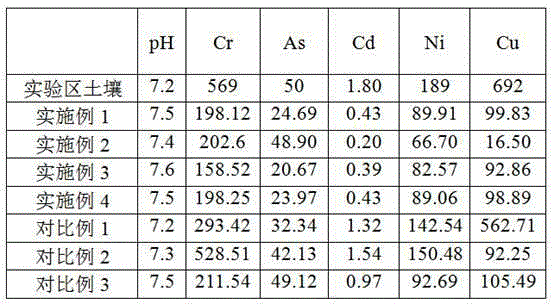

ActiveCN105149332AConducive to survivalImprove adsorption capacityContaminated soil reclamationTherapeutic effectSafety standards

The invention provides a method for remediating heavy metal contaminated soil through combination of a microorganism and a plant. The method comprises the following steps: mixing a magnetotactic bacterium with the heavy metal contaminated soil, irrigating the heavy metal contaminated soil mixed with the magnetotactic bacterium, arranging a magnetic field on the heavy metal contaminated soil, collecting the heavy metal contaminated soil containing the magnetotactic bacterium, washing out the heavy metal contaminated soil, and conducting backfilling on the heavy metal contaminated soil; planting copper weeds in the heavy metal contaminated soil preliminarily remediated by the magnetotactic bacterium, and removing all the copper weeds after 10-12 months; and circularly repeating the steps till the content of heavy metal in soil is up to the safety standard. The method has the advantages that the treatment effect on the heavy metal contaminated soil is good, the operation is simple, the cost is low, heavy metal ions are directly removed, secondary contamination of soil is avoided, and the practicability is strong; moreover, the method is suitable for treating large-area contaminated soil.

Owner:YUNNAN JICHENG LANDSCAPE TECH CO LTD

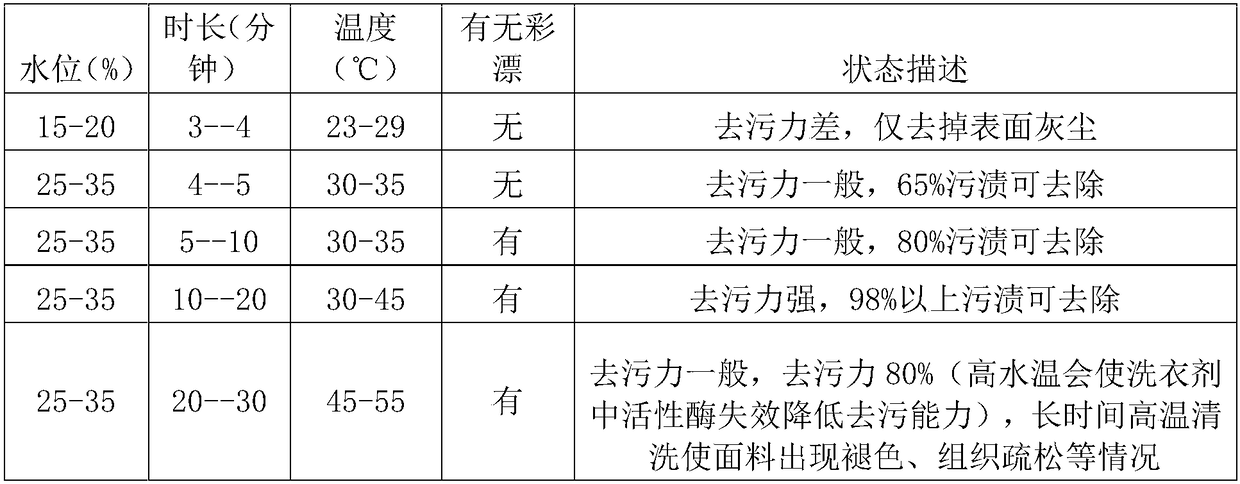

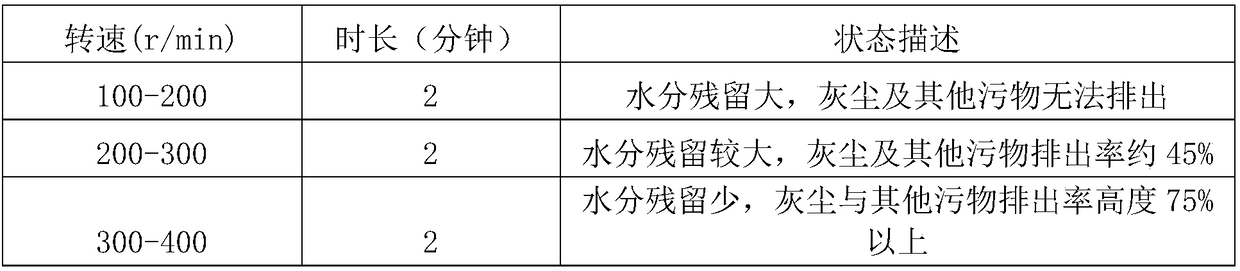

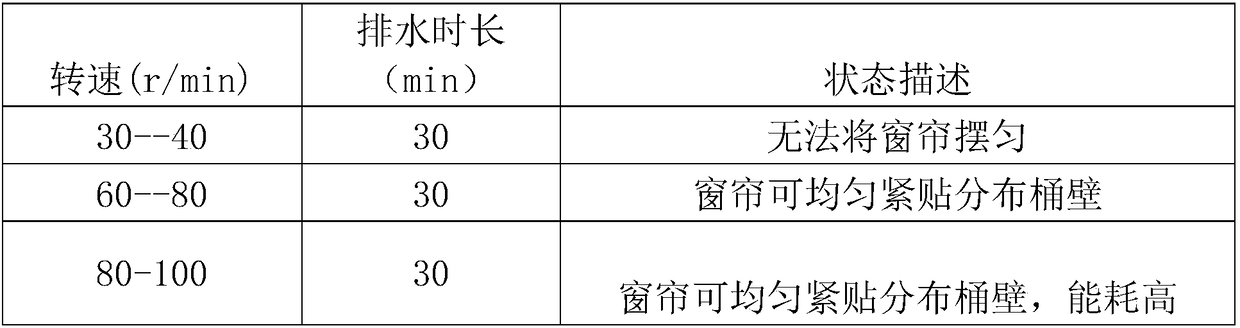

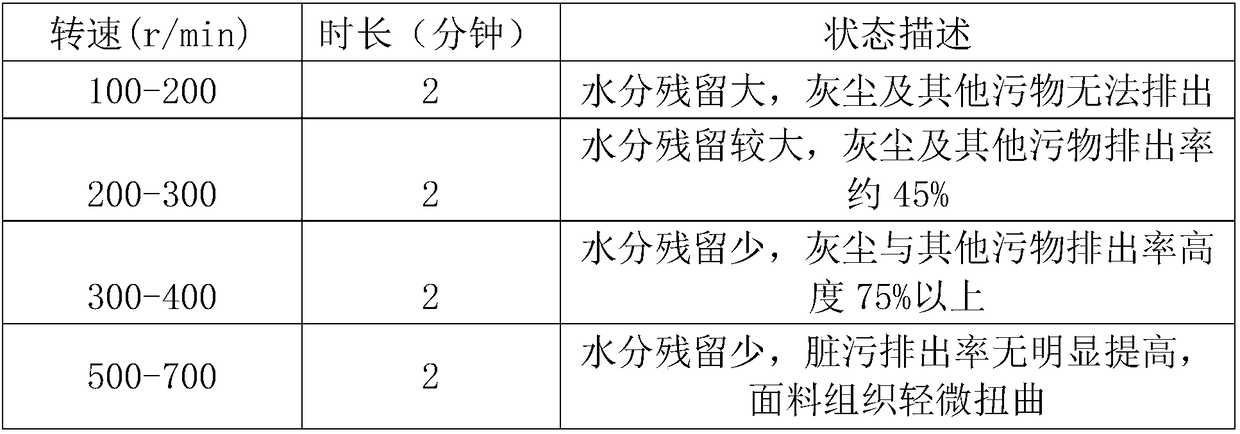

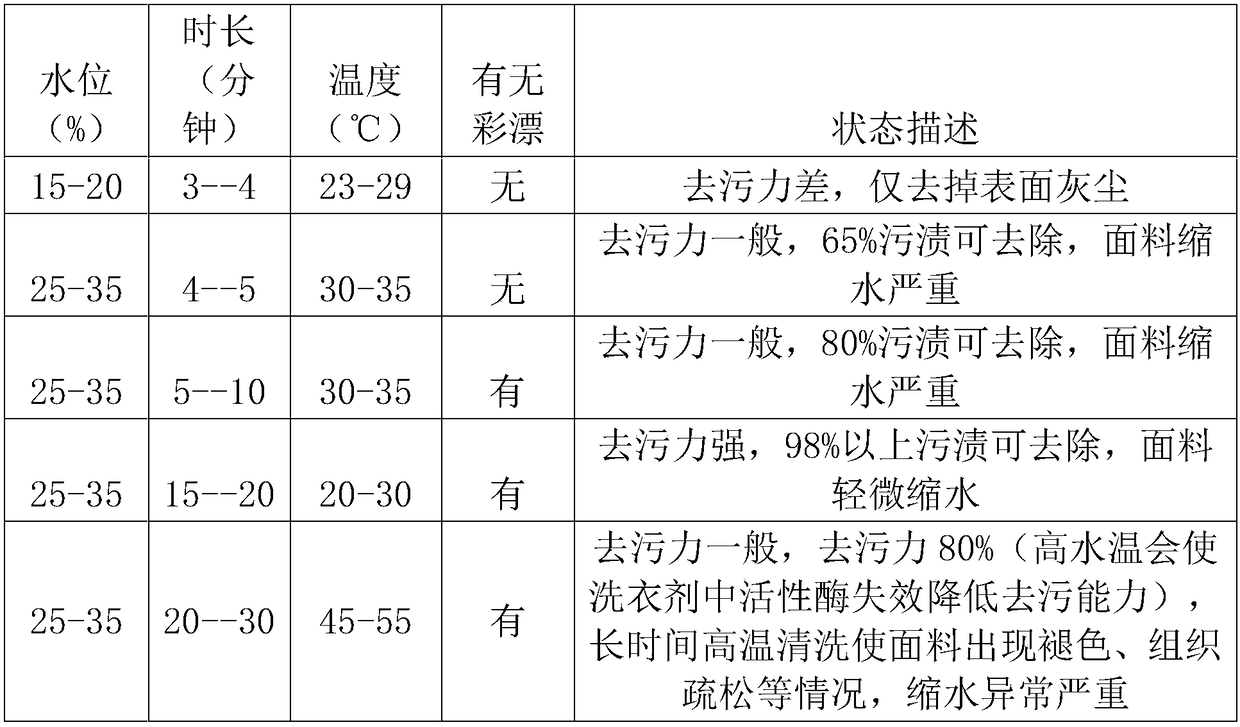

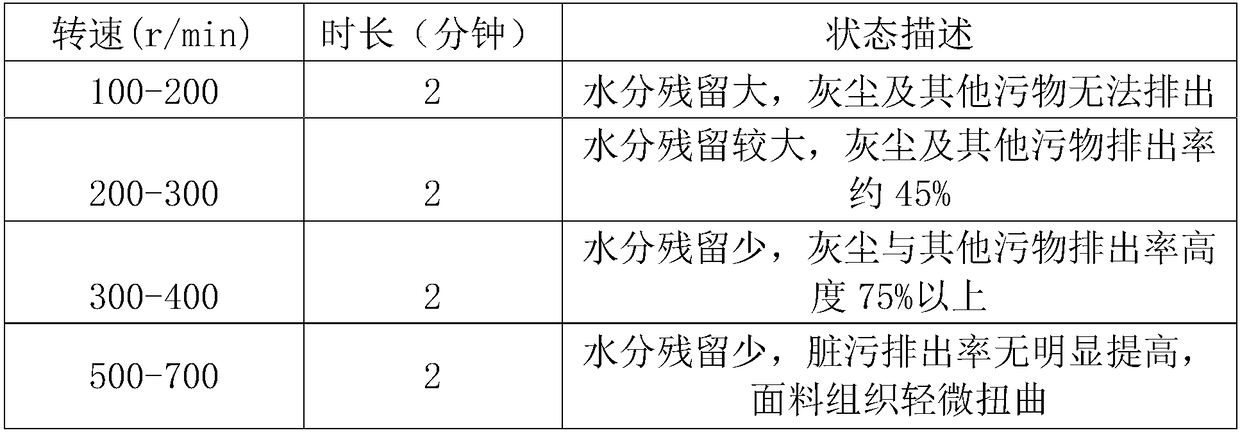

Method for cleaning pure polyester fabric curtain

InactiveCN108301193AMaintain vividnessWon't breakInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPolyesterEngineering

The invention relates to a method for cleaning a curtain. The method for cleaning a pure polyester fabric curtain is characterized in that the drum capacity of a washing machine is 25-60 kg, and the method sequentially comprises the following steps: main washing, primary uniform distribution, primary dehydration, primary rinsing, secondary uniform distribution, secondary dehydration, secondary rinsing, tertiary uniform distribution, dehydration drying and dryer drying; and a laundry detergent and a finishing agent used in the method do not contain phosphorus or fluorescent agents. The method for cleaning the pure polyester fabric curtain has the advantage of good stain removal effect and no damages to the curtain.

Owner:浙江喜创联电子商务有限公司

Ion palladium activating agent

InactiveCN107723689AImprove stabilityIncrease coverageLiquid/solution decomposition chemical coatingGlass fiberCopper plating

The invention belongs to the technical field of activating agents for circuit board through hole chemical copper plating, and particularly relates to an ion palladium activating agent. The ion palladium activating agent aims at achieving the technical effects of being good in stability, good in coverage, free of attack to base materials and free of residue on copper faces. According to the technical scheme provided for achieving the technical effects, the ion palladium activating agent is per liter prepared from 0.15-0.65g of palladium chloride, 4-12 g of aminopyridine, 5-55 g of polyethyleneglycol, 5-25 g of sodium hydroxide and the balance H2O. The ion palladium activating agent has the beneficial effects that solution stability is good, and palladium ions are good in coverage on glassfiber and resin, free of attract to base materials, quite low in adsorption rate on copper faces and free of residue on the copper faces.

Owner:惠州大亚湾金盛科技有限公司

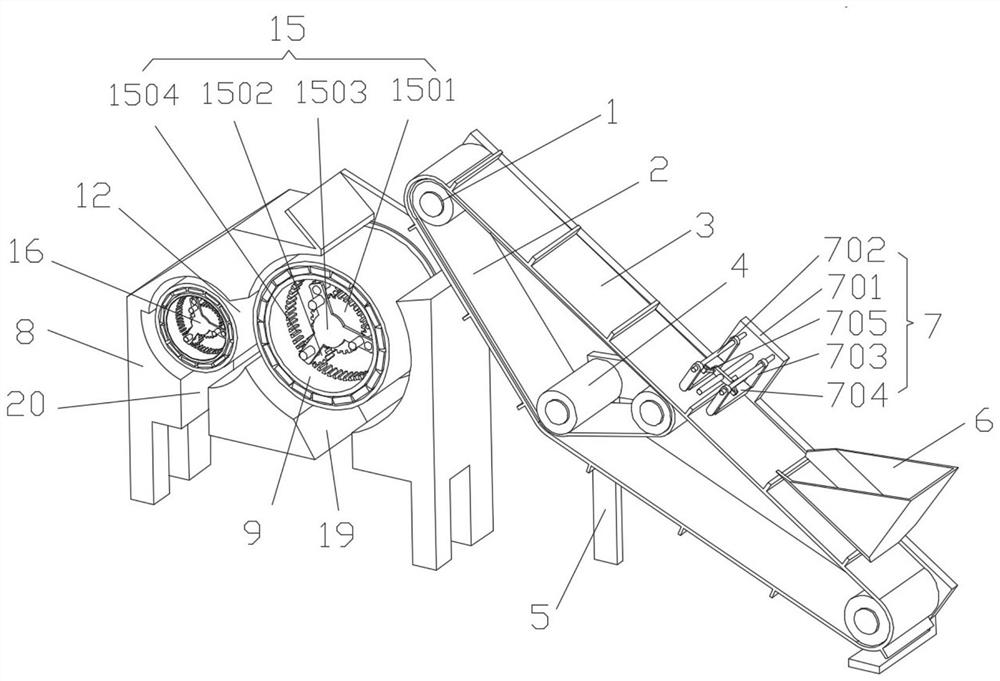

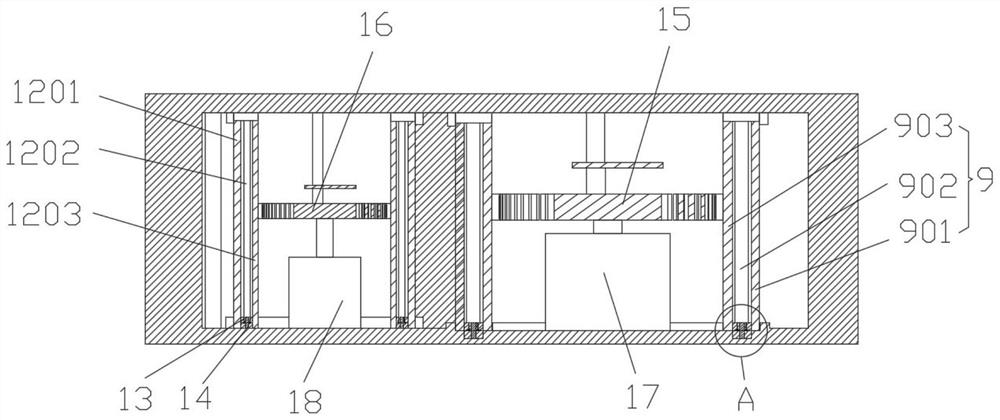

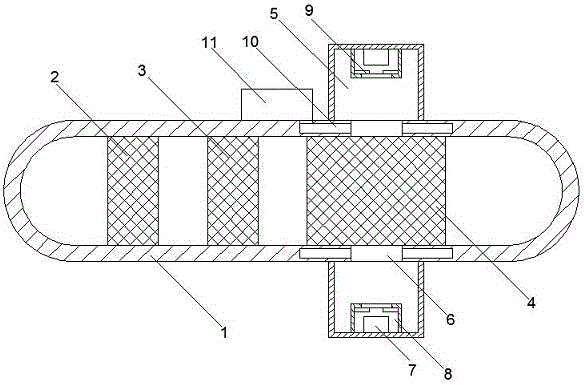

Cement production raw material iron removal device

InactiveCN112604811AEasy to separateReduce the adsorption rateMagnetic separationIron removalEngineering

The invention discloses a cement production raw material iron removal device in the field of cement production equipment, which comprises a driving roller. The outer surface of the driving roller is in transmission connection with a magnetic conveyor belt, the outer surface of the magnetic conveyor belt is in transmission connection with a conveyor belt, and the interior of the conveyor belt is in transmission connection with a driven roller; supports are fixedly connected to the two ends of the driven roller, a hopper is fixedly connected to one end of each support, a refining device is fixedly connected to the middle of each support, and an electromagnetic iron removal box is arranged at the bottom end of the driving roller. In use, the driving roller drives the conveyor belt to enable materials to ascend, and when the materials reach the highest position to be fed into the electromagnetic iron removal box, due to the action of the magnetic conveyor belt in the conveying belt, waste with high iron content is attracted to the conveyor belt to be conveyed downwards; when themagnetic conveyor belt moves upwards, the materials on the conveyor belt fall off without the action of magnetic force, so that the iron-containing waste can be preliminarily screened in the feeding process.

Owner:温州索纽环保科技有限公司

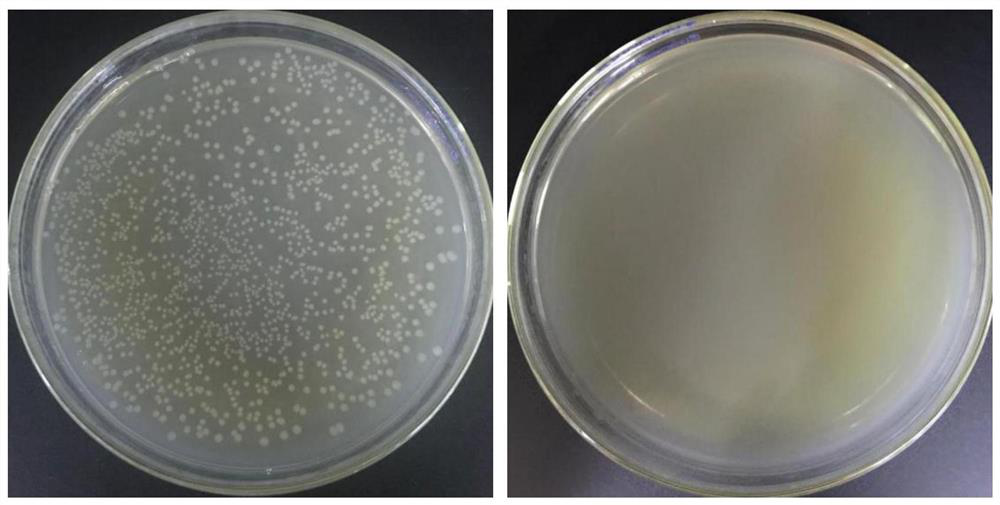

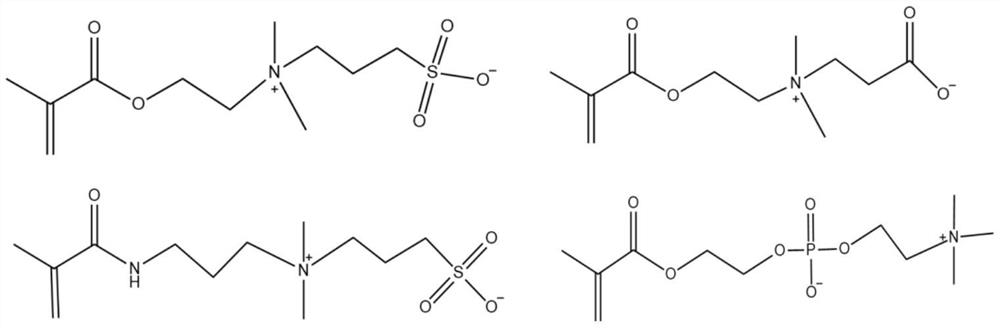

Anti-pollution degerming nanofiber filter membrane and preparation method thereof

ActiveCN112246112AHigh mechanical strengthHigh grafting rateSemi-permeable membranesMembranesFiberPolyvinyl alcohol

The invention provides an anti-pollution degerming nanofiber filter membrane and a preparation method thereof. The preparation method comprises the following steps: preparing polyvinyl alcohol-ethylene copolymer nanofibers with a diameter of 50-300 nm by adopting a melt blending phase separation method; then preparing a suspension, and coating the surface of a non-woven fabric base material to obtain a nanofiber thin layer with a thickness of 2-10 [mu]m and a pore diameter of 90-130 nm; and after a grafted compound is adsorbed on the surface of the nanofiber thin layer, carrying out plasma treatment to form chemical bonding grafting so as to obtain the nanofiber filter membrane with anti-pollution and sterilization functions is obtained. According to the invention, an amphiphilic compoundand / or a compound containing olefin double bonds and at least one of carboxyl and sulfonic acid groups are grafted on the surface of a polyvinyl alcohol-ethylene copolymer nanofiber membrane, so thatbacteria can be efficiently intercepted, and the adsorption of BSA can be reduced so as to inhibit the adsorption growth of bacteria on the surface of the membrane and significantly improve the anti-pollution capability of the membrane.

Owner:WUHAN TEXTILE UNIV

Preparation method of stable type carbon paste electrode

ActiveCN107367536AReduce the surface energy of the materialReduce the adsorption rateMaterial electrochemical variablesIonSurface energy

The invention relates to a preparation method of a stable type carbon paste electrode, belonging to the technical field of electrochemical analysis. The method comprises the following steps: by using fluorite ore powder and a sodium silicate solution as raw materials, preparing crystallized modifying liquid and placing a carbon paste electrode in the modifying liquid, performing high-temperature crystallization, loading nanometer cryolite particles on the surface of a carbon paste electrode material, meanwhile, modifying the surface of the carbon paste electrode to form stable fluoroaluminate ions, and reducing the surface energy of the material, thus reducing the adsorption rate of a tested object on the surface of the material after finishing tests of the material, and improving the stability of the surface physicochemical properties of the carbon paste electrode. By crystallizing the nanometer cryolite particles on the surface of the electrode and adding nano particles on the surface of the electrode, the area of the electrode is effectively increased, meanwhile, as nanometer cryolite has electropositivity, electronegative probe ions are more helped to reach an electrode interface to react, the response effect of the carbon paste electrode to signals is effectively improved, and the carbon paste electrode has excellent sensitivity.

Owner:宁夏蓝伯碳素有限公司

Real-time control-based natural gas liquefied raw gas filtering device

The invention discloses a real-time control-based natural gas liquefied raw gas filtering device. The real-time control-based natural gas liquefied raw gas filtering device comprises a filtering kettle body; a solid particle filtering layer, a dewatering layer and an acid gas filtering layer are arranged in the filtering kettle body; activated carbon is arranged in the solid particle filtering layer; molecular sieves are respectively arranged in the dewatering layer and the acid gas filtering layer; an acid gas collecting chamber is formed in the corresponding position of the acid gas filtering layer in the filtering kettle body, and extends along the side wall of the filtering kettle body; the acid gas collecting chamber is connected with the interior of the filtering kettle body through a collecting pipeline; the acid gas collecting chamber is connected with a plurality of air pumps. According to the real-time control-based natural gas liquefied raw gas filtering device, solid particles, water and the acid gas in raw gas can be effectively collected, meanwhile, the filtering device disclosed by the invention can be kept in a good filtering state by performing real-time precipitation treatment on the acid gas, so that the filtering efficiency and the effect of the filtering device are both improved.

Owner:南京妙策传媒有限公司

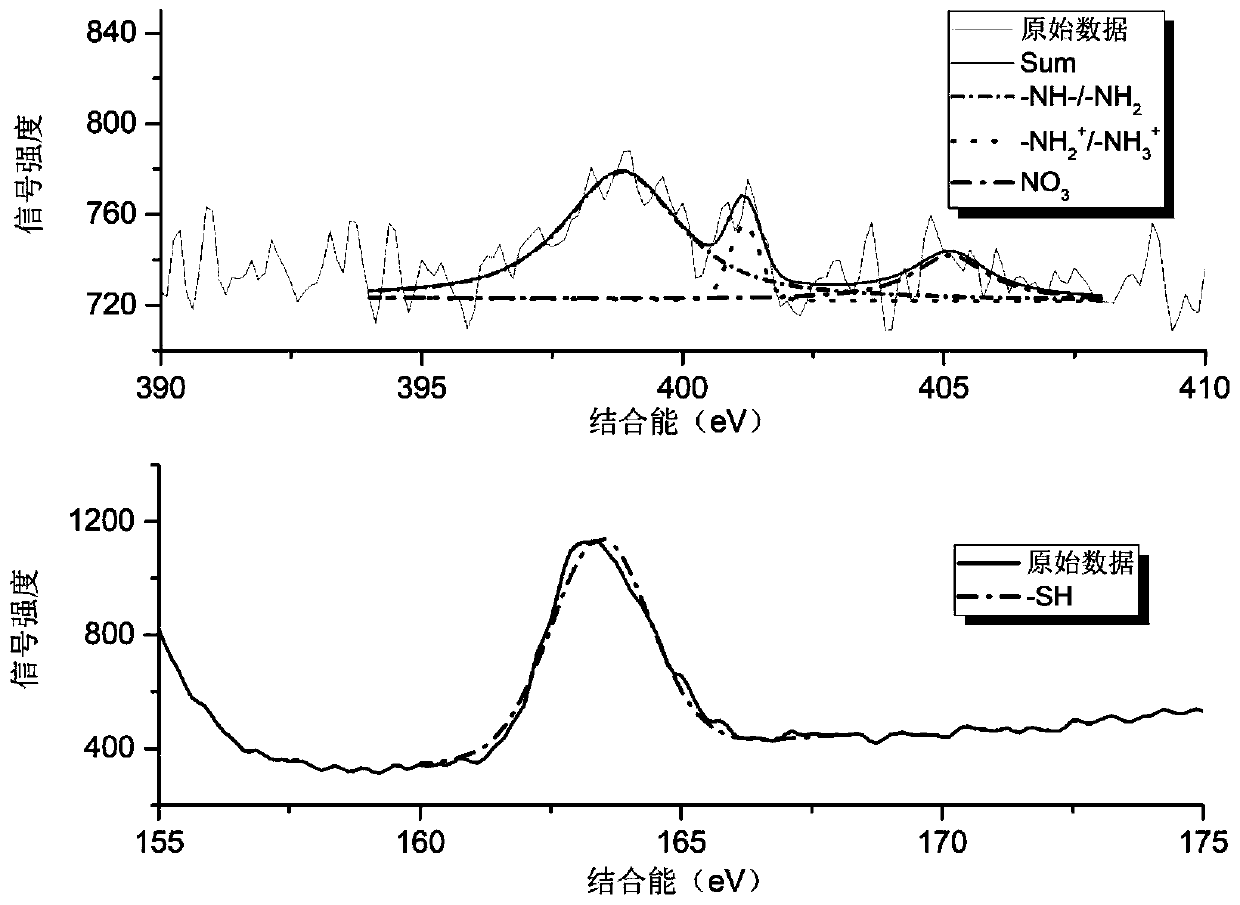

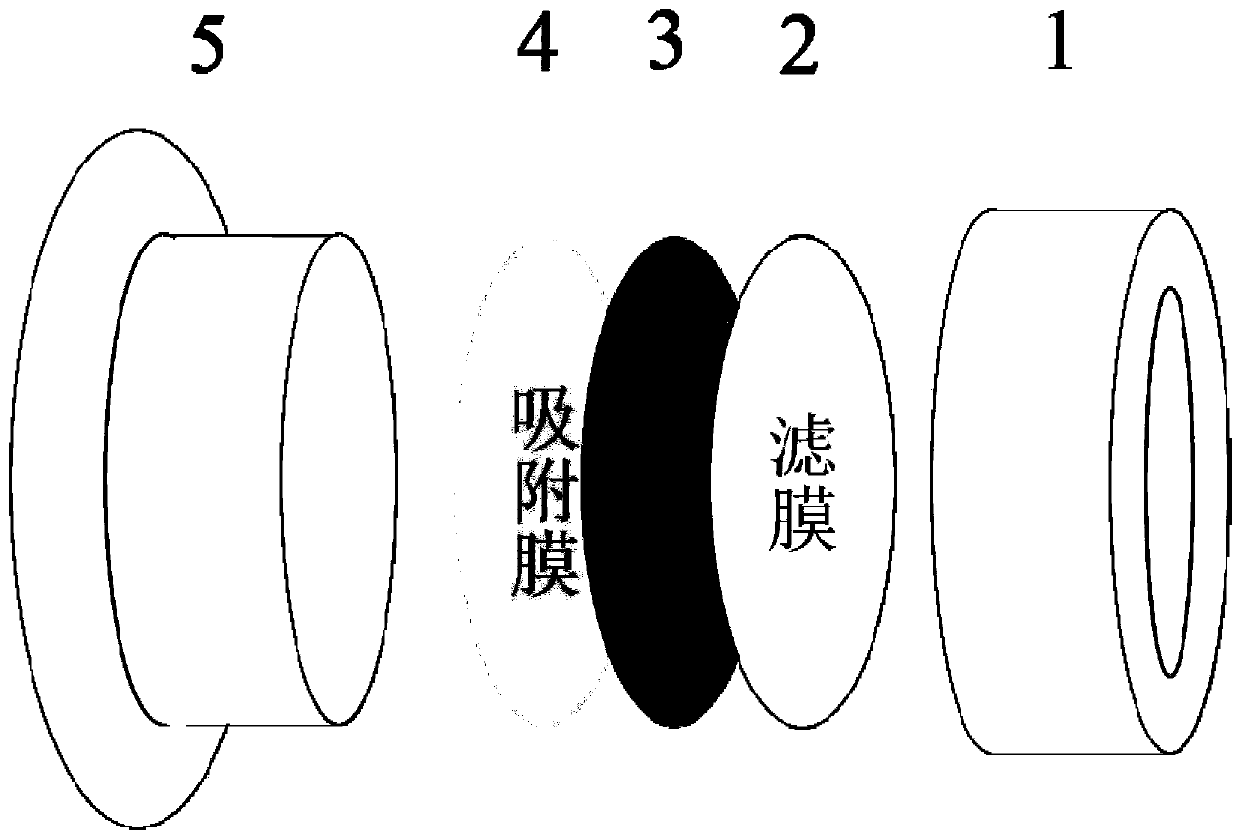

Adsorption film for selectively immobilizing trivalent arsenic, trivalent antimony and tetravalent selenium and preparation method thereof

PendingCN111359597AGuaranteed feasibilityImprove adsorption capacityWater treatment parameter controlOther chemical processesCrystallographyAdsorptive membrane

The invention discloses an adsorption film for selectively immobilizing trivalent arsenic, trivalent antimony and tetravalent selenium and a preparation method of the adsorption film, and belongs to the technical field of gradient diffusion films. The adsorption film is a polyacrylamide hydrogel film, a sulfydryl-amino double-modified SBA-15 type mesoporous silicon material is distributed in the polyacrylamide hydrogel film, and the mole number ratio of sulfydryl to amino is (4-6): 1. The adsorption film disclosed by the invention is simple in preparation process and good in distribution uniformity, and has good selectivity and synchronous fixing capability on trivalent arsenic (As III), trivalent antimony (Sb III) and tetravalent selenium (Se IV).

Owner:NANJING UNIV

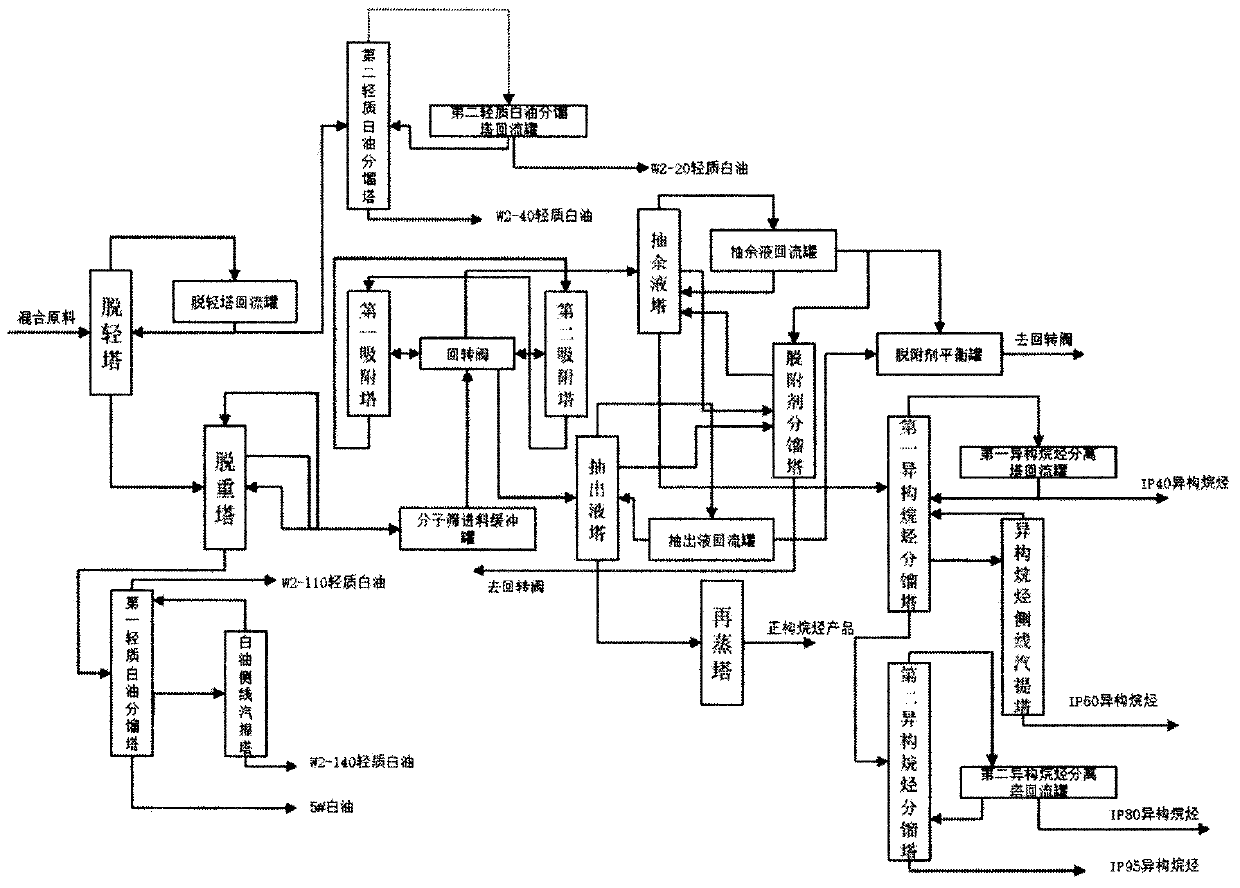

Preparation method of iso-paraffin composition

The invention discloses a preparation method of an iso-paraffin composition. The preparation method specifically comprises the following steps: mixing Fischer-Tropsch crude liquid wax, removing lightcomponents and heavy components, carrying out n-alkane adsorption and separation, and rectifying separated iso-paraffin to obtain an iso-paraffin composition product. The provided preparation method has the advantages of fine process, abundant products, and low energy consumption. The raw materials do not contain sulfur or nitrogen, has an extremely low content of aromatic hydrocarbons, and do notcontain cyclo-paraffin. The obtained iso-paraffin composition is high in purity, free of peculiar smell, narrow in distillation range, non-toxic, colorless, high in chemical stability, low in condensation point, low in conductivity, excellent in wetting and surface diffusion force and high in flash point, and is a high-quality chemical raw material.

Owner:内蒙古伊泰宁能精细化工有限公司

Antibacterial dust-adsorption-resistant composite plastic master batch and preparation method thereof

The invention discloses an antibacterial dust adsorption resistant composite plastic master batch, which is prepared from the following raw materials in parts by weight: 45-50 parts of polypropylene, 25-35 parts of a filler, 5-7 parts of a plasticizer, 4-6 parts of a lubricant, 3-5 parts of a polyhydroxy chemical coupling agent, 3.5-4.5 parts of a performance additive, 1-2 parts of a composite antioxidant, 1-3 parts of a composite antibacterial agent, 1-3 parts of a composite antistatic agent, 1-2 parts of a light stabilizer, 1-2 parts of a flexibilizer, 2-4 parts of hydroxymethyl cellulose, 1-3 parts of an impact modifier, 4-6 parts of a porous ceramic preform, 1-3 parts of a nano flame retardant and 4-6 parts of carbon nanofibers. According to the invention, the defects in the prior art are overcome, the design is reasonable, the process flow is simple, the antibacterial and dust-adsorption-resistant effects are good, and the social use value and the application prospect are relatively high.

Owner:合肥市丽红塑胶材料有限公司

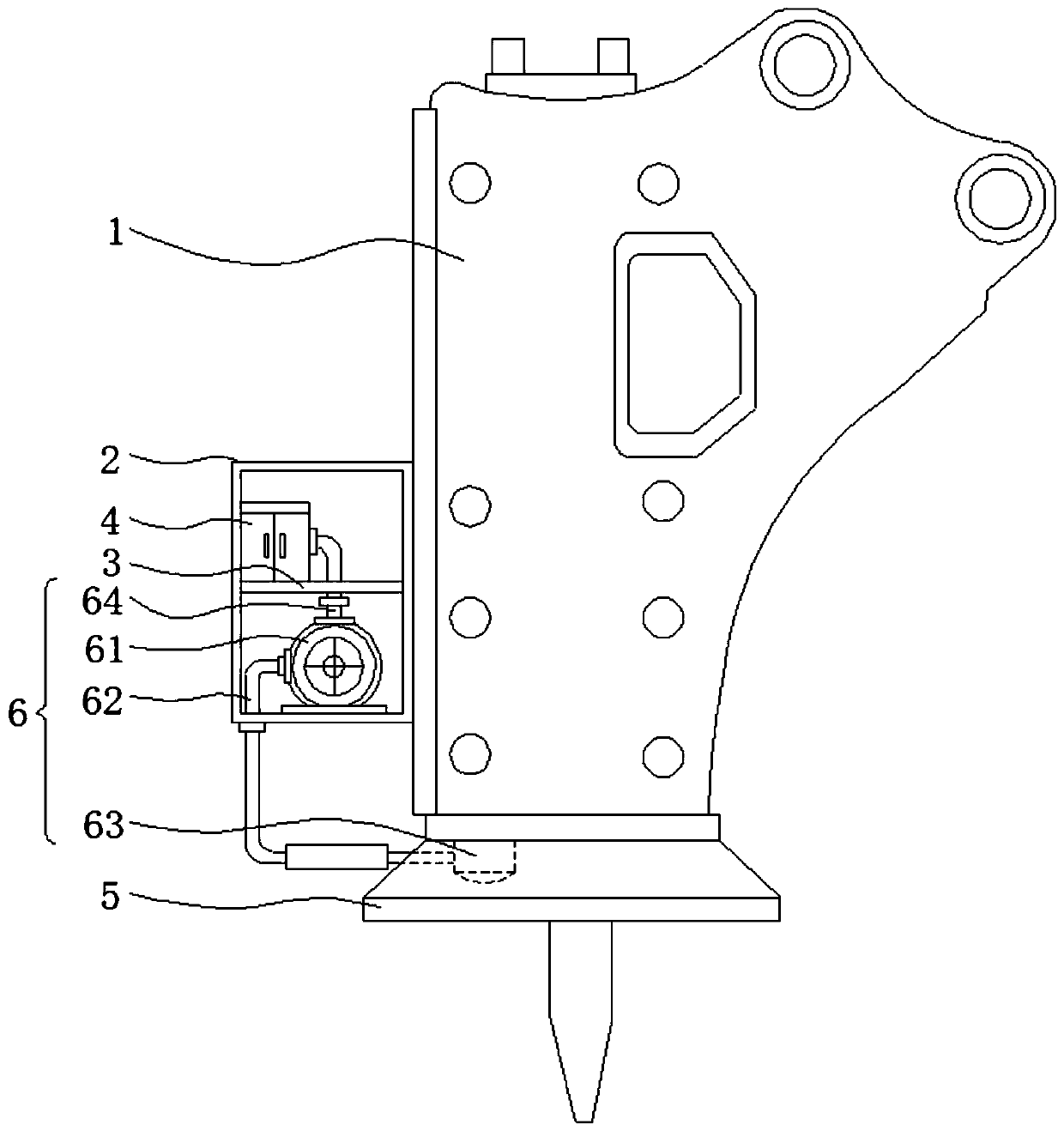

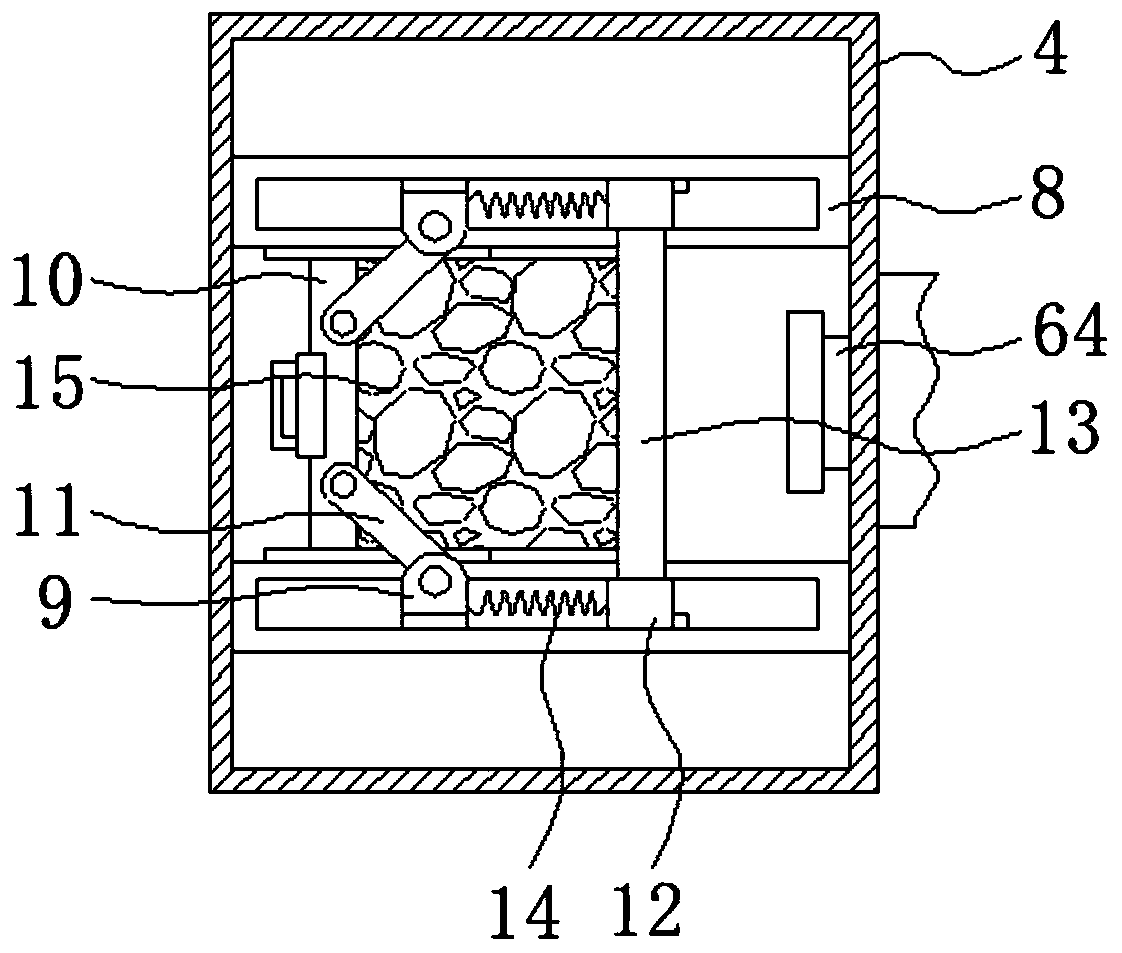

Hydraulic breaking hammer

InactiveCN110984277AThere are security risksAvoid pollutionDispersed particle separationSoil-shifting machines/dredgersActivated carbonDust control

The invention provides a hydraulic breaking hammer. The hydraulic breaking hammer comprises a breaking hammer body, a control box, a protective cover, and a dust removal assembly, wherein one side ofthe control box is fixed to one side of the breaking hammer body, a fixing plate is fixedly connected between the two sides of the inner wall of the control box, a collecting box is fixedly connectedto the top of the fixing plate, the top of the protective cover is arranged at the bottom of the breaking hammer body, and the dust removal assembly is located inside the control box. According to thehydraulic breaking hammer, dust can be well treated, a suction pump is started, a dust suction head on the suction pump can rapidly suck the dust generated in the crushing process, a large amount ofdust is avoided, the environment is prevented from being polluted, and the body health of workers is prevented from being damaged; and an activated carbon plate can be replaced, so that the situationthat the dust suction rate of the activated carbon plate is influenced due to blockage caused by long-time use is avoided, and then the practicability of the hydraulic breaking hammer is further improved.

Owner:HENGYANG CITY LINKEN HYDRAULIC EQUIP

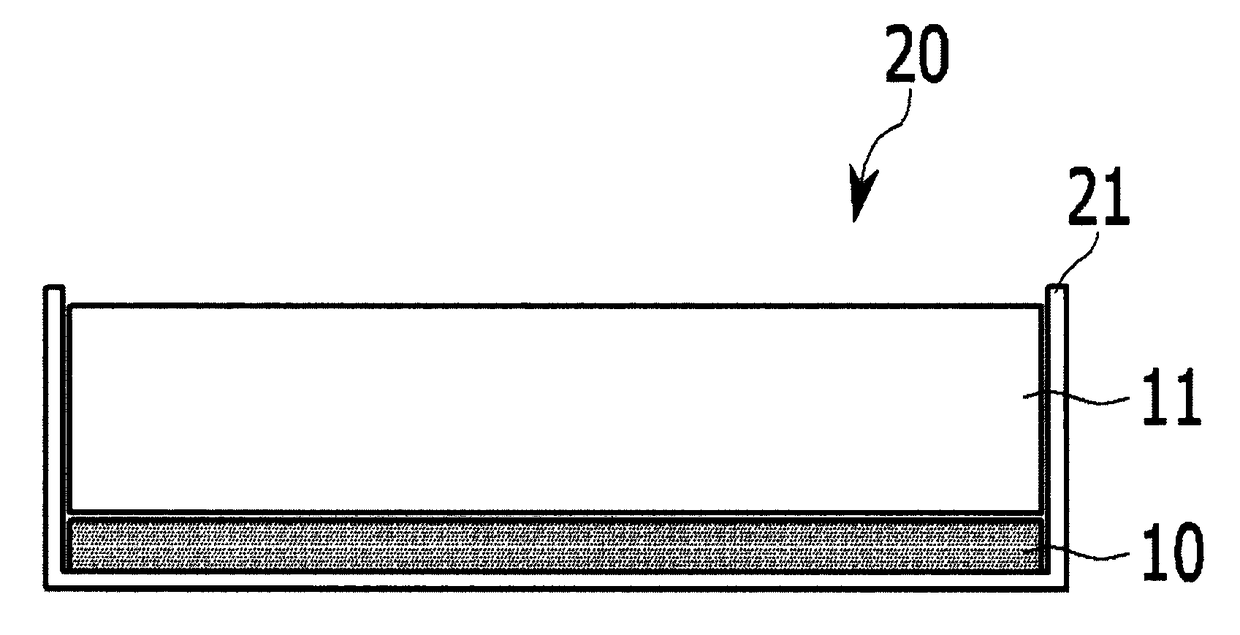

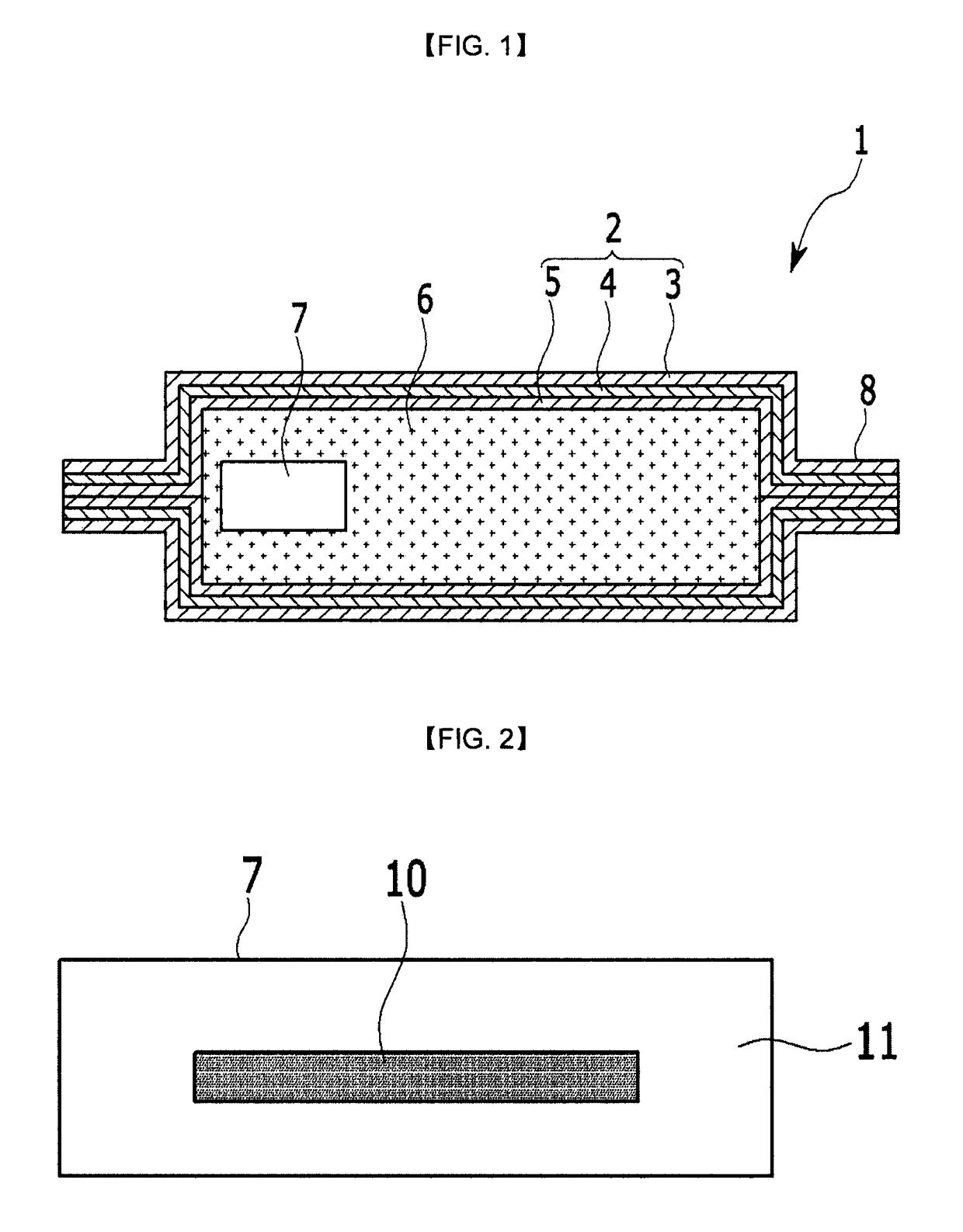

Gas-adsorbing material and vacuum insulation material including the same

ActiveUS9901900B2Reduce the adsorption rateEasy to handleGas treatmentThermal insulationIon exchangeNitrogen

A gas-adsorbing material may increase gas barrier properties for a target gas by reducing a gas-adsorption rate while maintaining gas-adsorption performance. A vacuum insulation material may use the gas-adsorbing material. The gas-adsorbing material may include a gas-adsorbing composition including a copper ion exchanged ZSM-5-type zeolite having a silica to alumina ratio ranging from about 10 to 50 in a framework of zeolite. A ratio of dealuminization of the ZSM-5-type zeolite is at least about 15%, and the gas-adsorbing material is capable of adsorbing at least nitrogen. Furthermore, the gas-adsorbing material may include a calcinated body of a compressed article comprising a gas-adsorbing composition including a copper ion exchanged ZSM-5-type zeolite having a silica to alumina ratio ranging from about 10 to 50 in a framework of zeolite (where a ratio of dealuminization of the ZSM-5-type zeolite is at least about 15%) and a moisture-absorbing material.

Owner:SAMSUNG ELECTRONICS CO LTD

Cleaning method for curtain made of adhesive material

InactiveCN108103727AMaintain vividnessAvoid cross-colorInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleaning methodsEngineering

The invention relates to a curtain cleaning method, in particular to a cleaning method for a curtain made of an adhesive material. The drum capacity of a washing machine is 25-60 kilograms. The cleaning method successively comprises the following steps: main washing, primary cloth uniformizing, primary dehydrating, primary rinsing, secondary cloth uniformizing, secondary dewatering, secondary rinsing, ternary cloth uniformizing, dewatering and spin-drying, fabric spreading and air-drying. A laundry detergent and a conditioning agent do not contain phosphorus or a fluorescent agent. The cleaning method for the curtain made of the adhesive material has the advantages of good dirt removal effect and zero damage to the curtain.

Owner:浙江喜创联电子商务有限公司

Washing method of cotton and linen curtain

InactiveCN108589168AMaintain vividnessAvoid cross-colorInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEngineeringLaundry detergent

The invention relates to a washing method of a curtain. According to the washing method of the cotton and linen curtain, the capacity of a drum of a used washing machine is 25-60 kg, and the method sequentially comprises steps as follows: primary washing, first uniform distribution, first dewatering, first blanching, second uniform distribution, second dewatering, second blanching, third uniform distribution, dewatering, spin drying, fabric stretching and airing. A laundry detergent and a care agent do not contain phosphorus and a fluorescent agent. The washing method of the cotton and linen curtain has the advantages that the dirt removal effect is good and the curtain is not damaged.

Owner:浙江喜创联电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com