Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Maintain vividness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital reactive dye printing process for mulberry silk fabric

InactiveCN103451970AHigh color yieldIncrease color depthHeating/cooling textile fabricsDyeing processDigital printingUrea

The invention provides a digital reactive dye printing process for a mulberry silk fabric. The process comprises the following steps: carrying out textile sizing, drying, carrying out jet printing, steaming, washing by cold water, washing by hot water, washing by soap, washing by hot water, washing by cold water, and drying, wherein a sizing agent used in the textile sizing step comprises the following components in percentage by weight: 1%-3% of sodium sulfate powder, 0.5%-1% of sodium alginate, 3%-5% of urea, 0.5%-1.5% of sodium hydrogen carbonate, 1%-2% of modified starch, 5%-7% of electrolyte and the balance being water. By virtue of the process, the digital printing color yield of the mulberry silk fabric is increased, the inkjet printing color depth on a textile is increased, the color difference between a pattern on the textile and an electronic pattern is reduced, and the hand feel of the fabric is good.

Owner:SHIJIAZHUANG HEXI APPL TRADING

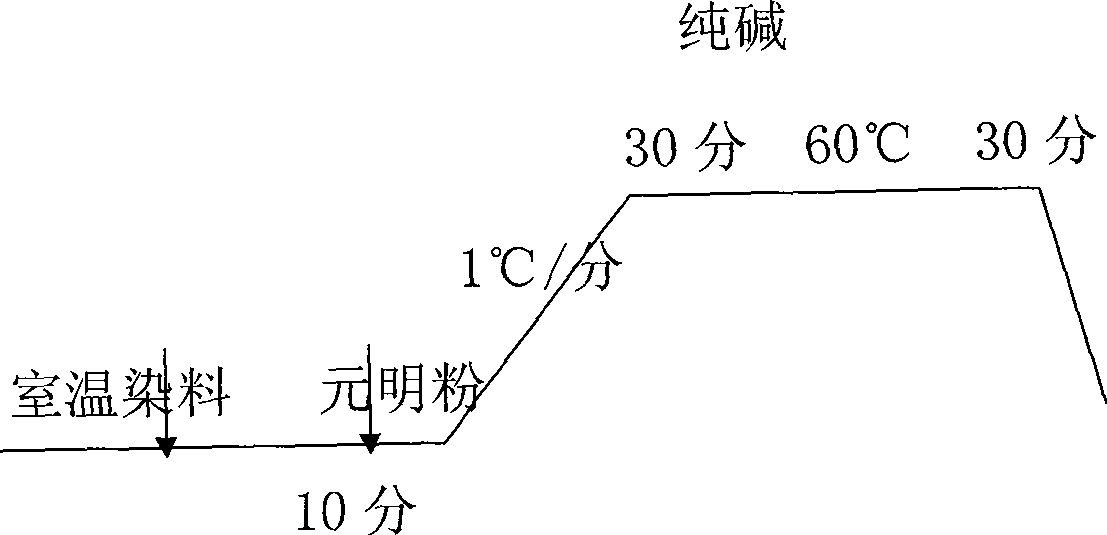

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Dyeing and finishing process for linen and cotton blended fiber fabric

InactiveCN105063998AProcess temperature changeLow processing temperaturePhysical treatmentBiochemical fibre treatmentInorganic saltsManufacturing engineering

The invention discloses a dyeing and finishing process for linen and cotton blended fiber fabric. The dyeing and finishing process comprises preprocessing, pre-sizing, modified processing, dyeing, mordant removing, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Helicase, scouring enzyme and alpha-amylase are used for pretreatment, modification treatment is adopted before dyeing, the performance of linen and cotton blended fabric is modified fundamentally, and the dye-uptake rate is increased; the dyeing procedure does not require a large quantity of alkaline substances and inorganic salt, a leveling agent, substitutive alkali, a migration inhibitor and a dispersing agent are added, the dye uniformity is improved, environment pollution is avoided due to use of natural dye, and requirements for environmental protection are met; self-cleaning processing is added in the after finishing procedure, and the self-cleaning capacity, the crease-resistant performance, the washing resistance and the color fastness of the fabric are improved; crease-resistance finishing is added, and the crease-resistant performance of the fabric is improved; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Preparation method of organic silicon-modified polyurethane copolymer fabric softener

InactiveCN106432670AKeep hydrophilicImprove wearing comfortLight resistant fibresLiquid repellent fibresPolyolPrepolymer

The invention discloses a preparation method of an organic silicon-modified polyurethane copolymer fabric softener. The method comprises the following steps: (a) carrying out a stirring reaction on polyether polyol, a hydroxyl-terminated polysiloxane linear body and diisocyanate for 2-3h at the temperature of 75-85 DEG C under the action of a tin catalyst, so as to obtain an isocyanate-terminated organic silicone-modified polyurethane prepolymer; (b) adding a small molecular amine chain extender into the organic silicone-modified polyurethane prepolymer, and carrying out a stirring reaction for 1-2h at the temperature of 50-60 DEG C, so as to obtain an organic silicon-modified polyurethane copolymer; (c) evenly mixing the organic silicon-modified polyurethane copolymer obtained in the step (b) with an emulsifying agent at the temperature of 50-70 DEG C, and slowly adding deionized water into the mixture for emulsifying, so as to obtain the organic silicon-modified polyurethane copolymer fabric softener. The softener prepared by the method is good in stability, endows fabric with excellent softnesss, smoothness and hydrophilic property, has excellent yellowing resistance, and can maintain the brightness of the light-colored fabrics and the whiteness of the white fabrics.

Owner:ZIBO LURUI FINE CHEM CO LTD

Dyeing and finishing process of polyester and cotton blended fiber fabric

InactiveCN105063997AHigh whitenessAvoid damageSucessive textile treatmentsBiochemical fibre treatmentPolyesterFiber

The invention discloses a dyeing and finishing process of polyester and cotton blended fiber fabric. The process comprises pretreatment, presetting, modification treatment, dyeing, mordant removal, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Snailase and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the polyester and cotton blended fabric is modified fundamentally, and the dye-uptake of the fabric is increased; in the dyeing procedure, fewer alkaline substances and inorganic salt are used, a dye leveler, substitution alkali, a migration inhibitor and a diffusant are added, the dye leveling performance is improved, natural dye is used, environmental pollution is avoided, and the environment-friendly requirement is met; self-cleaning treatment is added during aftertreatment, and the self-cleaning capacity, the crease-resistant performance, the wash durability and color fastness are improved; silk fibroin and sericin are adopted for afterfinish, and the anti-pilling performance and the antistatic performance of the fabric are provided; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Low-temperature dyeing and finishing technology for bamboo fiber fabric

InactiveCN105019250AAvoid damageLower processing temperaturePhysical treatmentBiochemical fibre treatmentAmylaseFiber

The invention discloses a low-temperature dyeing and finishing technology for bamboo fiber fabric. The low-temperature dyeing and finishing technology includes the steps of pretreatment, preshaping, modification treatment, dyeing, mordant removal, soaping, color fixation, after finishing, drying, shaping, calendering and rolling. Helicase, scouring enzyme and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the performance of the bamboo fiber fabric is modified fundamentally, and the dye-uptake rate of the fabric is increased; as in the dyeing working procedure, alkaline substance and inorganic salts are not used in quantity, and a levelling agent is added, the dyeing levelness is improved; environment pollution is avoided by using natural dyestuff, which meets the requirement for environmental protection; as self-cleaning treatment is added in after treatment, the self-cleaning capacity, crease-resistant performance and wash-resisting firmness of the fabric are improved; crease-resistant finishing is added, and therefore the crease-resistant performance of the fabric is improved; the whole technology is environmentally friendly and free from pollution.

Owner:TAICANG TIANLONG CHEM FIBER

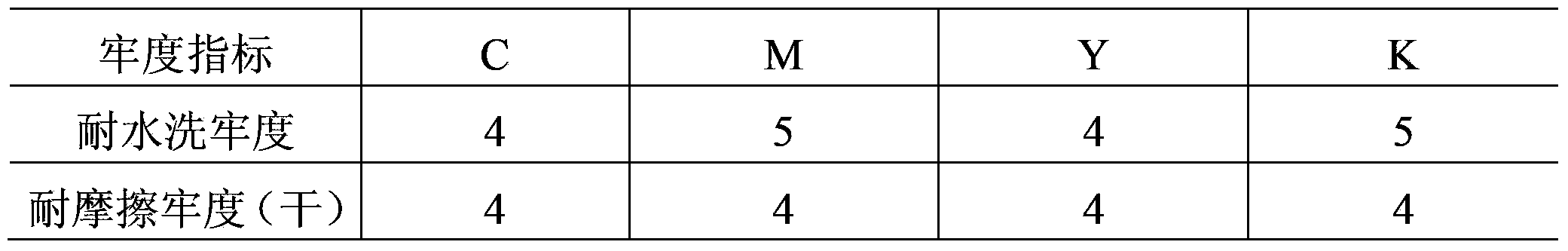

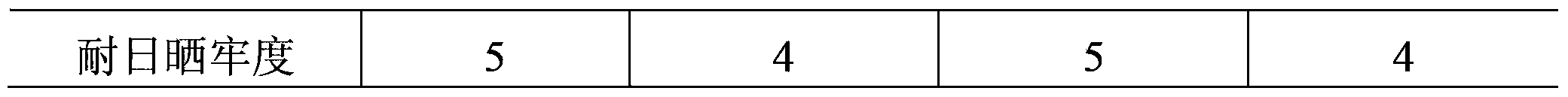

Digital printing process for real silk fabric

InactiveCN106758384AHigh color yieldIncrease color depthUltrasonic/sonic fibre treatmentDyeing processWarm waterEngineering

The invention provides a digital printing process for a real silk fabric. The digital printing process comprises the following procedures: real silk fabric preparation; low-temperature plasma processing; pretreatment liquid padding; drying; inkjet printing; drying; dry heat fixation; cold water flushing; warm temperature washing; soaping; warm water cleaning; and drying, wherein pretreatment liquid in the pretreatment liquid padding contains the following components by contents: 5g / L-10g / L of sodium alginate, 30g / L-50g / L of baking soda, 30g / L-50g / L of urea and 5g / L-15g / L of a defoaming agent. By virtue of the digital printing process, the tinctorial yield of the digital printing of a silkworm silk fabric is increased, the color depth of the digital printing on a textile is increased, and the chromatic aberration with an electronic pattern is reduced; and furthermore, the color fastness is high, and multiple experiments prove that the fabric does not fade or lose color even at relatively hostile experimental environments.

Owner:顾朝晖

Real-wax batik process

InactiveCN104562753AReduce manufacturing costFull of three-dimensional senseDry-cleaning apparatus for textilesDyeing processWaxDyeing

The invention discloses a real-wax batik process. The process flow comprises wax printing by a roller, dyeing, piling and fixation, water washing, dewaxing and printing. Energy saving and consumption reduction measures are taken, so that the production cost is reduced. A wax printing method that the back side is printed and then the front side is printed is adopted, a wax film on the back side extends to some extent under the pressure effect of the front side, the front and back sides are slightly different during batik dyeing of a main pattern, the three-dimensional and vivid main pattern effect is produced after dewaxing, then special processing is performed on the wax film, and the main pattern is more vivid and three-dimensional. Dewaxing is realized in two steps: in the first step, physical dewaxing is performed with a roll compacting rope washing method; in the second step, an alkali and the wax have a saponification reaction, wax remaining in cloth is removed, the white place is not stained, and the dyeing brilliance is guaranteed.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

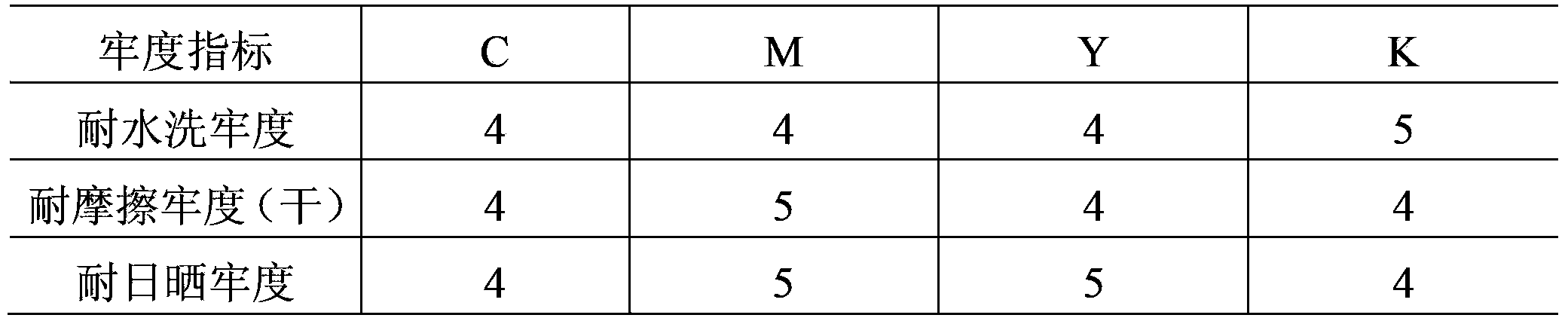

Reactive dye printed fabric color-increasing brightening finishing agent and preparation method

ActiveCN107956168AWill not increase the ammonia nitrogen indexImprove film formationDyeing processHydrogenNitrogen

The invention relates to a reactive dye printed fabric color-increasing brightening finishing agent and a preparation method. The reactive dye printed fabric color-increasing brightening finishing agent is prepared from the following raw materials in parts by weight: 20 to 30 parts of nonionic emulsifier, 50 to 70 parts of methylsilicone oil, 180 to 220 parts of hydroxyl silicone oil, 8 to 12 parts of methyl hydrogen silicone oil, 25 to 30 parts of refined castor oil, 1 to 5 parts of ethyl silicate-40, and 510 to 660 parts of deionized water. The reactive dye printed fabric color-increasing brightening finishing agent is prepared in a liquid crystal emulsification method and contains no ammonium and nitrogen and is soft and smooth in hand feeling and good in washability.

Owner:LIAONING FIXED STAR FINE CHEM

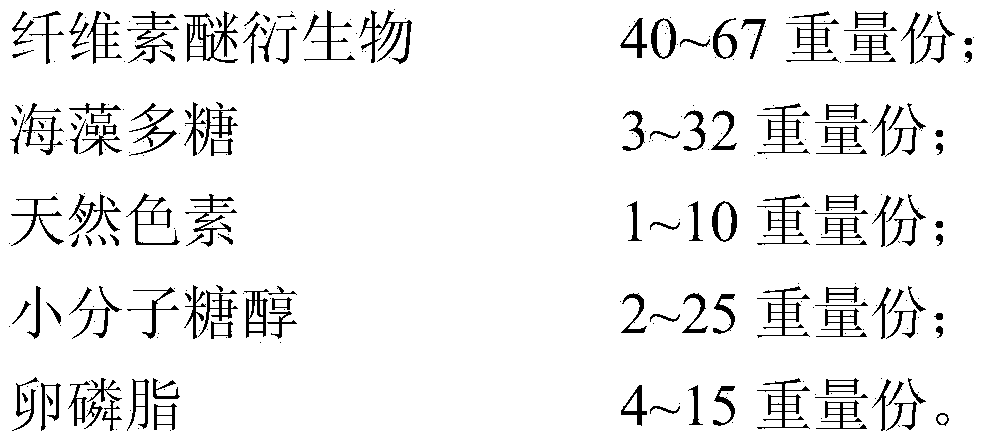

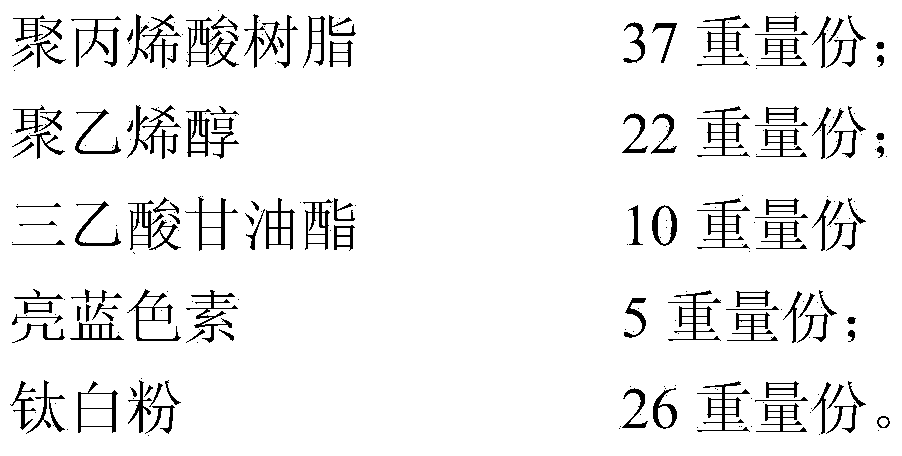

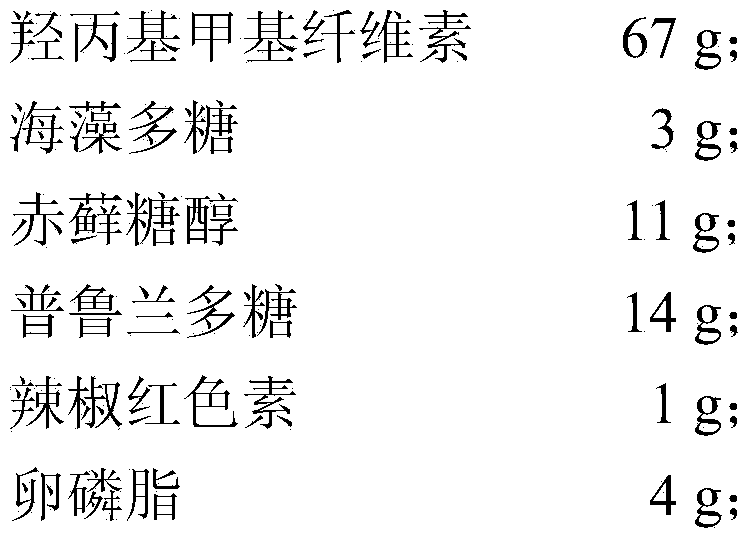

Natural film coating agent applied to food and healthcare products

ActiveCN103583932ADissolve fastGood film formingPharmaceutical non-active ingredientsFood shapingChemical synthesisDirect effects

The invention relates to a natural film coating agent applied to food and healthcare products. The natural film coating agent comprises the following raw materials in parts by weight: 40-67 parts of cellulose ether derivatives, 3-32 parts of seaweed polysaccharides, 1-10 parts of natural pigments, 2-25 parts of micromolecular sugar alcohol and 4-15 parts of lecithin. According to the coating agent, natural plant materials are adopted, pollution of heavy metal lead and arsenic is very low and cannot directly influence the coating agent, and the actually measured heavy metal lead and arsenic content also meets the regulations and standards of food additives; the coating agent does not contain chemical synthesized materials and is free from harmful compounds and monomer residues, so that the requirements of the food and the healthcare products on the safety are fully met; main ingredients in the natural coating agent can be dissolved in water, so that an organic solvent does not need to be used in a coating process and the production cost is greatly saved; a water solution is used for performing a coating process, so that coated drugs do not contain organic solvent residues and the safety of the drugs is improved.

Owner:TIANJIN BOKELIN MEDICINE PACKAGING TECH

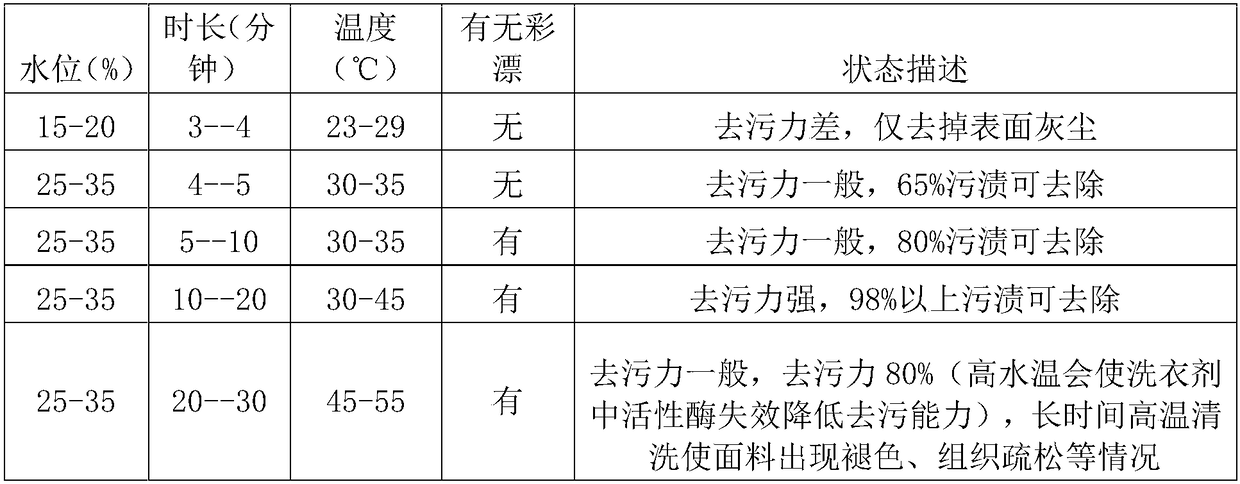

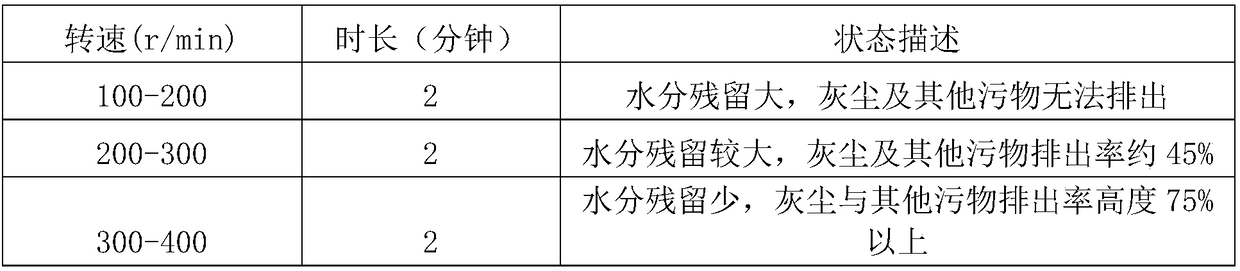

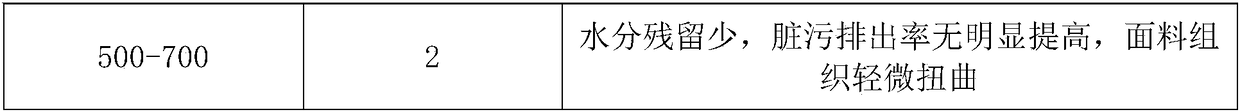

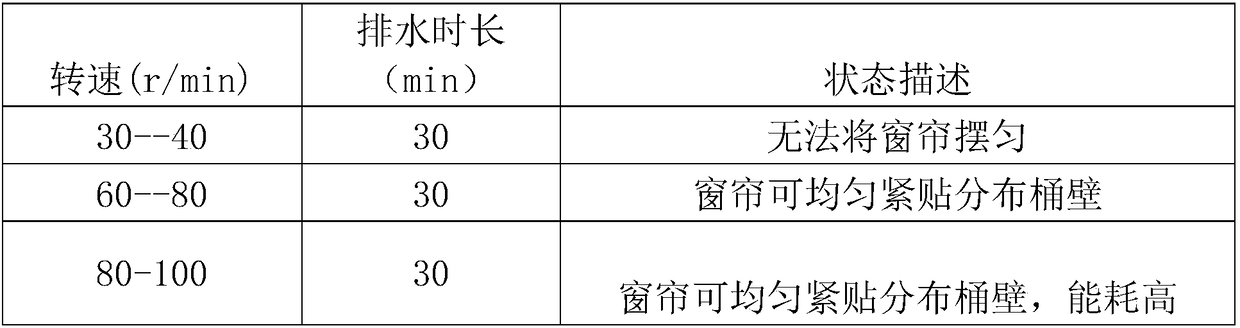

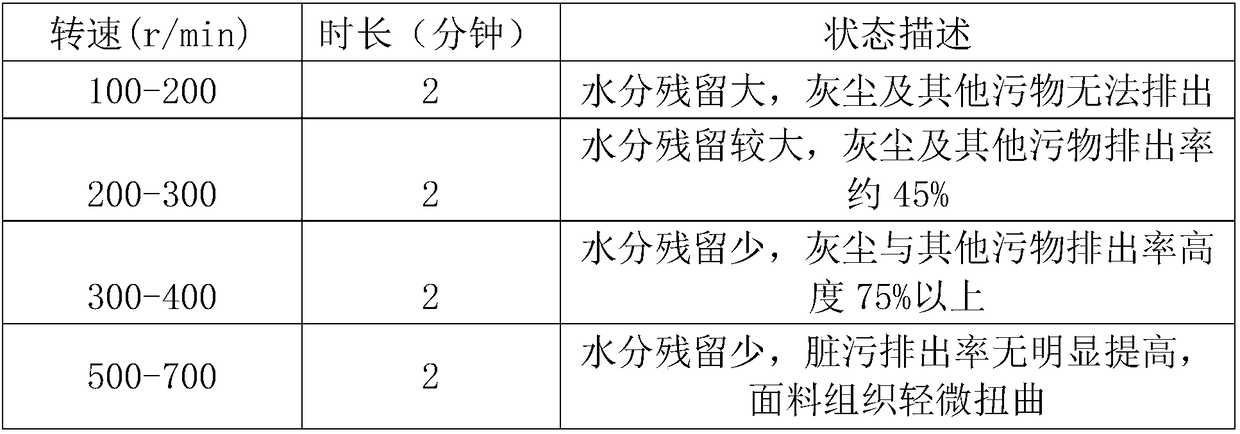

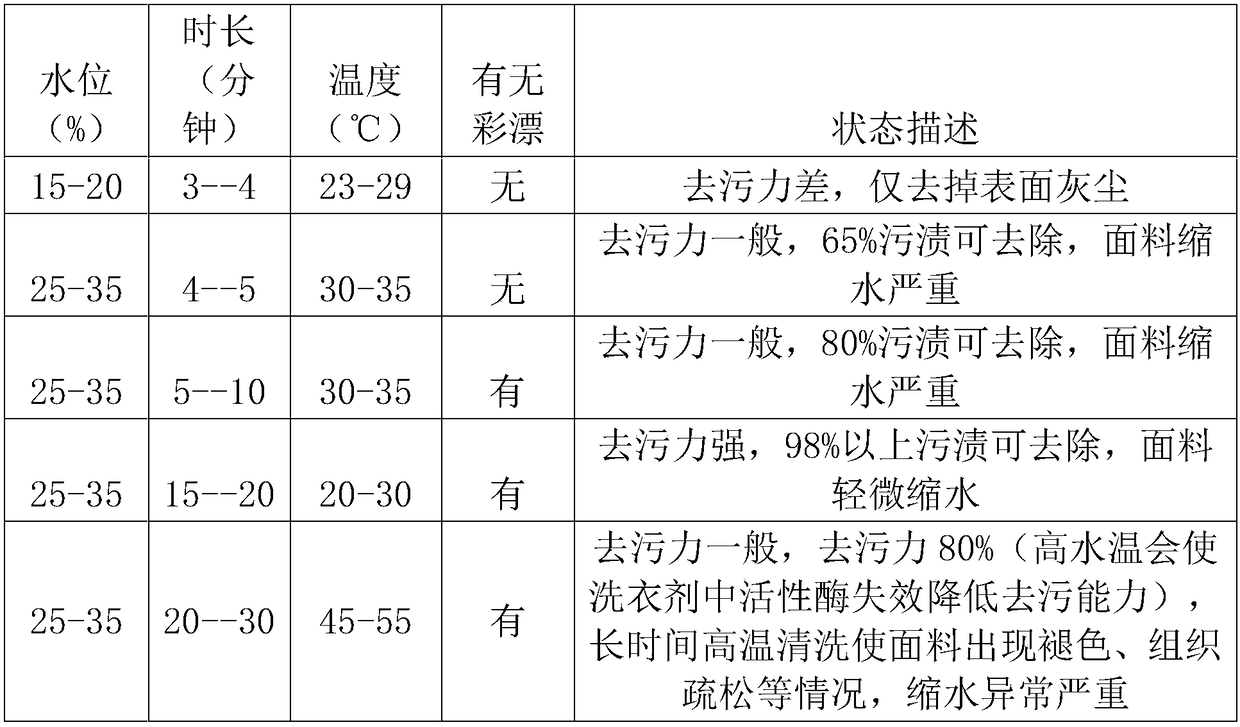

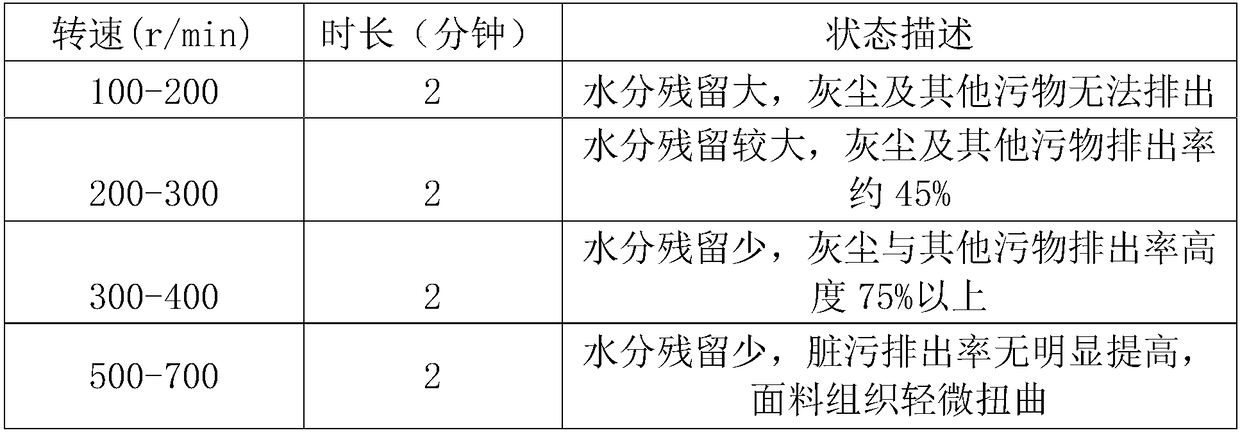

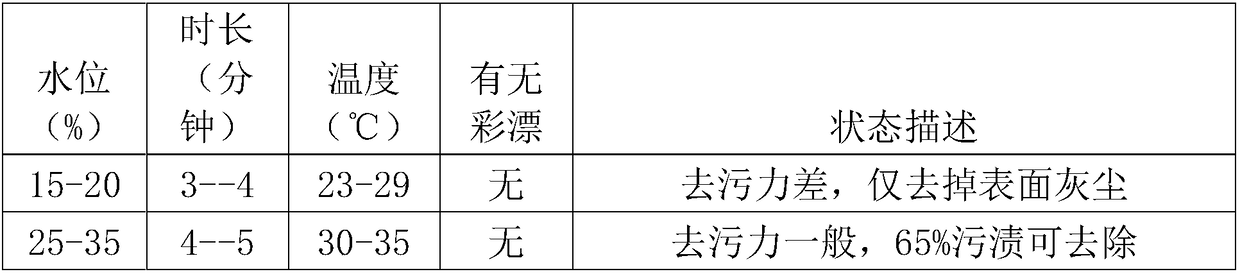

Method for cleaning pure polyester fabric curtain

InactiveCN108301193AMaintain vividnessWon't breakInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPolyesterEngineering

The invention relates to a method for cleaning a curtain. The method for cleaning a pure polyester fabric curtain is characterized in that the drum capacity of a washing machine is 25-60 kg, and the method sequentially comprises the following steps: main washing, primary uniform distribution, primary dehydration, primary rinsing, secondary uniform distribution, secondary dehydration, secondary rinsing, tertiary uniform distribution, dehydration drying and dryer drying; and a laundry detergent and a finishing agent used in the method do not contain phosphorus or fluorescent agents. The method for cleaning the pure polyester fabric curtain has the advantage of good stain removal effect and no damages to the curtain.

Owner:浙江喜创联电子商务有限公司

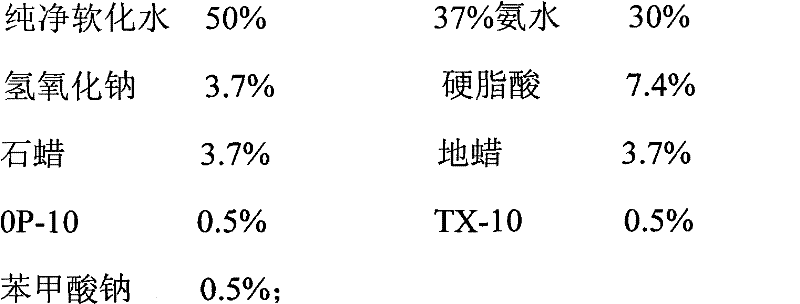

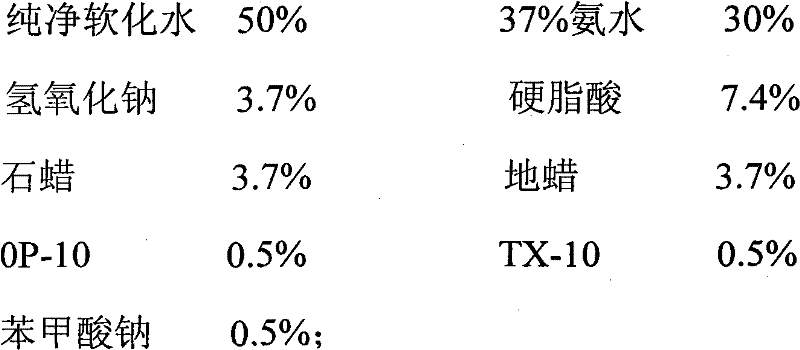

Water-soluble nano bright grease

The invention relates to a water-soluble nano bright grease, belonging to the technical field of preparing auxiliary paintings. The invention is characterized by that: purified softened water is adopted to replace kerosene solvent and organic solvent, ammonia water, sodium hydroxide and stearic acid are used to react with the purified softened water with a certain temperature to generate a sodium amide soap with strong emulsifying ability, paraffin and ozocerite which are solutions in high temperature are emulsified to nano particles, the sodium amide soap reacts with it self to form nano polyamide resin, the temperature drops to normal temperature, so as to obtain the water-soluble nano bright grease. The water-soluble nano bright grease can be used to fill in the nano holes of a high-molecular material to get characteristics of smooth appearance, abrasion resistance, chemical corrosion resistance and good moisture resistance, and prolong the service life of the protective paint, with the advantages of simple productive technology, non-poisonous to smell, safe and reliable usage, wide scope of application and no pollution during the using process. The water-soluble nano bright grease solves the problems that using kerosene solvent and organic solvent in the production of bright grease in prior art is easy on the environment pollution, and the raw materials of the production are so insufficient.

Owner:龚有林 +2

Laundry liquid containing kiwifruit enzyme and plant extract and preparation method of laundry liquid

InactiveCN106675806AHigh affinityAchieve antibacterial and anti-inflammatory effectsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBleachLaundry

The invention discloses a laundry liquid containing kiwifruit enzyme and plant extract and a preparation method of the laundry liquid. The laundry liquid comprises the following components by weight: 8-12% of kiwifruit enzyme, 16-22% of plant extract, 8-10% of alkyl glycoside, 0.5-1% of disodium ethylenediamine tetraacetate, 1-1.5% of hydroxyethyl cellulose, 0.2-0.3% of spice, 2-3% of sodium chloride, 1-2% of ginger juice, 0.5-1% of artemisia vulgaris liquid and the balance of purified water, wherein the plant extract is a mixture composed of sapindus mukorossi extract and gleditsia sinensis extract at a weight ratio of (5-6):(3-5). The laundry liquid containing kiwifruit enzyme and plant extract proposed by the invention is natural and free of phosphorus, fluorescent agent and bleaching agent, and has advantages of being efficient in decontamination, natural and antibacterial, safe, environmentally friendly, promoting skin wound healing, and being mild and non-irritating to skin and the like.

Owner:HEFEI NORMAL UNIV

Green efficient ecological printing and dyeing method

InactiveCN111172786AMaintain vividnessPrinting and dyeing quality is reliableFibre treatmentSingeingEnvironmental engineeringDesizing

The present invention discloses a green efficient ecological printing and dyeing method. The method comprises the following steps of 1) preparing original cloth; 2) (1) performing fabric singeing, (2)performing fabric desizing, (3) performing fabric scouring and (4) performing fabric bleaching; 3) preparing a dye; 4) performing dyeing; 5) performing cleaning; and 6) performing drying. The invention belongs to the technical field of printing and dyeing, and particularly provides the green efficient ecological printing and dyeing method which keeps the color brilliance, does not damage and injure a fabric and the human body, and avoids the environmental pollution and damage by more environment-friendly dye preparation and printing and dyeing methods.

Owner:威海华偲家纺股份有限公司

Quick drying pigment

The invention discloses quick drying pigment to solve the technical problems. The quick drying pigment is characterized by comprising ethyl acetate, butyl acetate, nitrocellulose, modified acetic acid, poly-terephthalate glycol ester, silica, isopropyl alcohol, ethylene glycol, trimethyl pentanediol di-isobutyrate, an acrylic polymer, polyurethane-11 and coloring agents. The quick drying pigment has the benefits that due to the addition of silica, when the quick drying pigment is in contact with paper, moisture in air can be absorbed in advance and retained, so that the coloring agents in the pigment can be distributed more uniformly in a wall due to the moisture; as the moisture can be volatilized fast in a relatively short time, the color of the pigment can be bright.

Owner:TONGLING BAIRUI EQUIP PARTS CO LTD

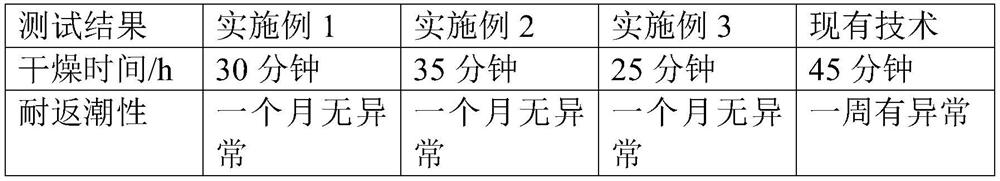

Moisture-regain-resistant drawing pigment and preparation method thereof

InactiveCN112442293AGood water permeabilityImprove water absorptionArtist's paintsPlant GumsMoisture regain

The invention discloses a moisture-regain-resistant drawing pigment in the technical field of pigments. The pigment is prepared from the following raw material components in parts by weight: 50-60 parts of acrylic emulsion, 5-10 parts of diatomite, 5-10 parts of talcum powder, 8-12 parts of toner, 5-10 parts of vegetable gum, 5-8 parts of thickener, 5-8 parts of humectant, 0.3-0.5 part of dispersing agent, 3-8 parts of film-forming agent, 0.03-0.06 part of preservative and 10-15 parts of water. The moisture-regain-resistant drawing pigment of the invention can absorb moisture in the air, so that the moisture regain resistance of the pigment is improved, and the fading time of the pigment is prolonged.

Owner:扬州市创开轩文化用品有限公司

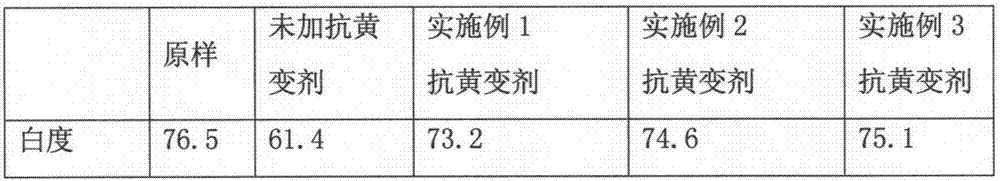

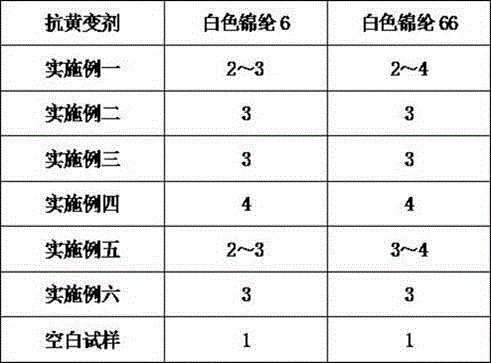

An anti-yellowing agent for nylon

InactiveCN105133313BMaintain whitenessMaintain vividnessFibre typesOrganic solventEnvironmentally friendly

The invention provides an anti-yellowing agent for nylon. The anti-yellowing agent is characterized by comprising, by weight, 10-20% of emulgator, 1-10% of carbohydrazide, 10-15% of an organic solvent and 55-79% of water. The anti-yellowing agent is low in formula cost, good in high-temperature anti-yellowing effect, capable of keeping whiteness and freshness of a fabric, user-friendly, environmentally friendly and wide in market prospect.

Owner:DONGHUA UNIV

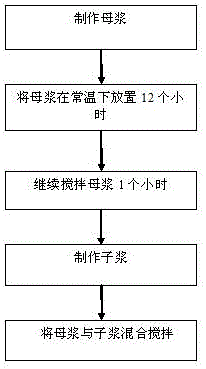

Slurry and preparation method thereof

The invention relates to a slurry and a preparation method thereof. Aiming to overcome the disadvantages that in the prior art, when inkjet printing is carried out after cloth sizing, the color is not bright, and the color fastness of ink does not meet the requirement, the invention provides a slurry. The slurry is composed of the following components by weight: 63 parts of water, 4-10 parts of urea, 1.3-2 parts of sodium bicarbonate, 0.75 part of sodium alginate, 1.8 parts of starch, and 0.5-1 part of a reserve salt. The preparation method of the slurry includes the steps of: A. making a mother slurry, specifically at room temperature, by weight part, mixing 43 parts of water, 0.75 part of sodium alginate, 1.8 parts of starch, and 0.5-1 part of the reserve salt for 30min; B. placing the mother slurry at room temperature for 12h; C. at room temperature, further stirring the mother slurry for 1h; D. making a sub-slurry, specifically at room temperature, by weight part, mixing 20 parts of water, 4-10 parts of urea, and 1.3-2 parts of sodium bicarbonate for 20min; and E. mixing the mother slurry and the sub-slurry at room temperature. The slurry provided by the invention maintains the color brightness, improves color fastness, and is suitable for use during cloth sizing before inkjet printing.

Owner:深圳同益新中控实业有限公司

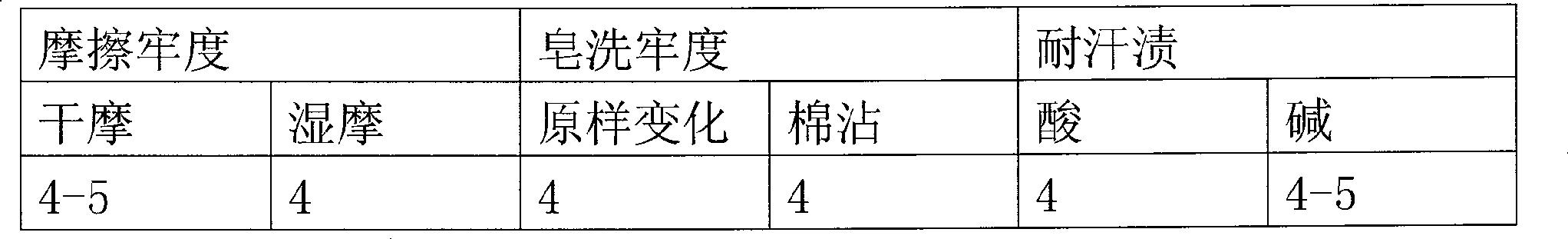

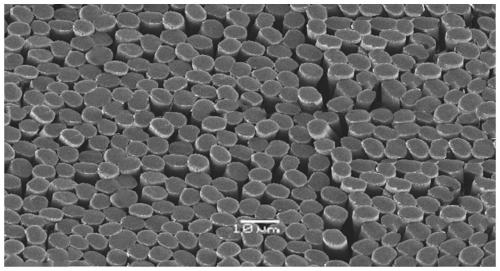

Ecological nano dye and use method thereof

InactiveCN101503576AIncrease profitHigh color fastnessOrganic dyesDyeing processColour fastnessSewage

The invention relates to an ecological nano dye for textile dye printing. The ecological nano dye consists of nano-level ecological paint color paste and liquidized ecological activated dye. The weight ratio of the nano-level ecological paint color paste to the liquidized ecological activated dye is 1:1-9. Before the ecological nano dye is used for dye printing, the textile is modified by cations; and after the dye printing, a wet rubbing fastness reinforcing agent is used to treat the textile. The textile dyed by the ecological nano dye has bright color and greatly improved color yield percentage, does not need high temperature soaping, does not discharge sewage during the dye printing, shortens the technical process, saves the energy source, reduces the production cost and improves the color fastness of the textile.

Owner:吴江桃源染料有限公司

Wool fabric sterilization treating agent

InactiveCN104894858AImprove the bactericidal effectGood decontamination effectAnimal fibresCellulosePolythylene glycol

The invention discloses a wool fabric sterilization treating agent which is prepared from the following raw materials in parts by mass: 8-16 parts of sodium dodecyl benzene sulfonate, 4-7 parts of sodium silicate, 3-5 parts of hydroxymethyl cellulose, 5-7 parts of sodium chloride, 9-15 parts of triethanolamine oleic soap, 1-2 parts of a flourescent brightener, 2-4 parts of sodium formate, 8-17 parts of dihydroxy diphenyl ether, 5-7 parts of sodium sulfate, 8-15 parts of Ethylene glycol monostearate, 12-18 parts of ethyl alcohol, 7-14 parts of lanolin alcohol, 5-12 parts of mineral oil, 6-9 parts of polyacrylamide and 4-6 parts of wool fat. The wool fabric sterilization treating agent is excellent in sterilization and decontamination performances, free of chemical residual, capable of keeping bright color and luster, and not prone to fade.

Owner:QINGDAO DEXITUOCHUANG HIGH TECH CO LTD

Cleaning method for curtain made of adhesive material

InactiveCN108103727AMaintain vividnessAvoid cross-colorInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleaning methodsEngineering

The invention relates to a curtain cleaning method, in particular to a cleaning method for a curtain made of an adhesive material. The drum capacity of a washing machine is 25-60 kilograms. The cleaning method successively comprises the following steps: main washing, primary cloth uniformizing, primary dehydrating, primary rinsing, secondary cloth uniformizing, secondary dewatering, secondary rinsing, ternary cloth uniformizing, dewatering and spin-drying, fabric spreading and air-drying. A laundry detergent and a conditioning agent do not contain phosphorus or a fluorescent agent. The cleaning method for the curtain made of the adhesive material has the advantages of good dirt removal effect and zero damage to the curtain.

Owner:浙江喜创联电子商务有限公司

Washing method of cotton and linen curtain

InactiveCN108589168AMaintain vividnessAvoid cross-colorInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEngineeringLaundry detergent

The invention relates to a washing method of a curtain. According to the washing method of the cotton and linen curtain, the capacity of a drum of a used washing machine is 25-60 kg, and the method sequentially comprises steps as follows: primary washing, first uniform distribution, first dewatering, first blanching, second uniform distribution, second dewatering, second blanching, third uniform distribution, dewatering, spin drying, fabric stretching and airing. A laundry detergent and a care agent do not contain phosphorus and a fluorescent agent. The washing method of the cotton and linen curtain has the advantages that the dirt removal effect is good and the curtain is not damaged.

Owner:浙江喜创联电子商务有限公司

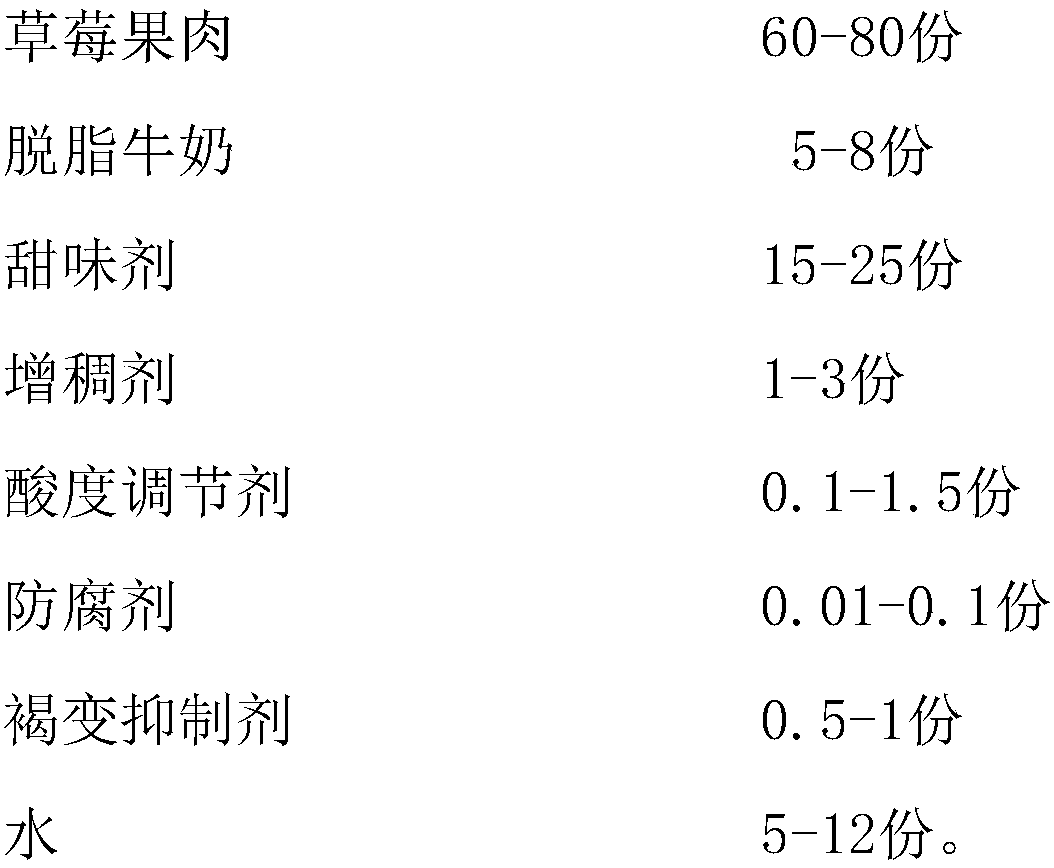

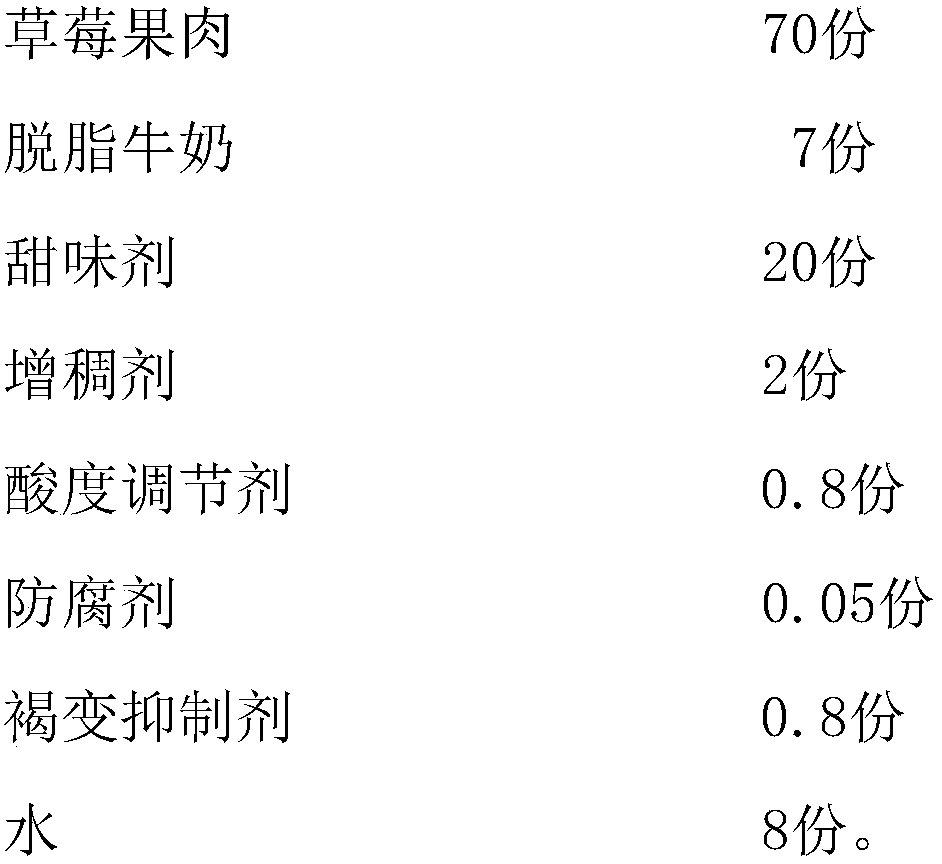

Strawberry fruit paste and preparation method thereof

InactiveCN109287990AReduce liquidityIncrease stickinessSugar food ingredientsFood ingredient as thickening agentFleshLow speed

The invention relates to the technical field of food processing, in particular to strawberry fruit paste and a preparation method thereof. The strawberry fruit paste consists of fruit paste substratesand sesame seed fillings coated in the fruit paste substrates, wherein the weight ratio of the fruit paste substrates to the sesame seed fillings is (10-16) to (1-2), each fruit paste substrate comprises the following raw materials in parts by weight: 60-80 parts of strawberry flesh, 5-8 parts of skim milk, 15-25 parts of a sweetening agent, 1-3 parts of a thickening agent, 0.1-1.5 part of an acidity adjusting agent, 0.01-0.1 part of a preservative, 0.5-1 part of a brown stain inhibitor and 5-12 parts of water. The prepared fruit paste substrates have the characteristics of being low in fluidity, high in viscosity and high in brown stain prevention properties, so that the sesame seed fillings are coated in the fruit paste substrates, the low speed that the sesame seed fillings and the fruit paste substrates are mutually permeated can be guaranteed, various taste of the strawberry fruit paste can be realized, the taste of the fruit paste substrates can be distinguished from the taste of the sesame seed fillings, new fruit paste products are created in the fruit paste market, and the nutrition is richer.

Owner:东莞市宝来食品有限公司

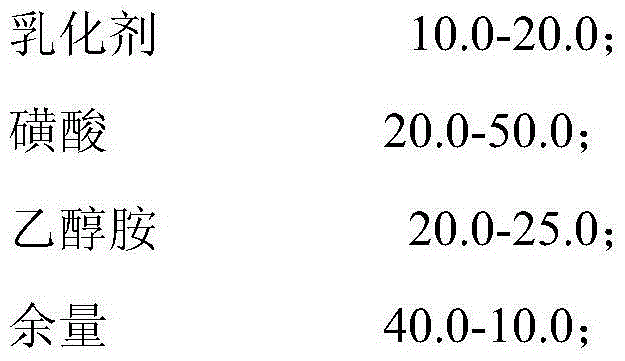

Anti-yellowing agent

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

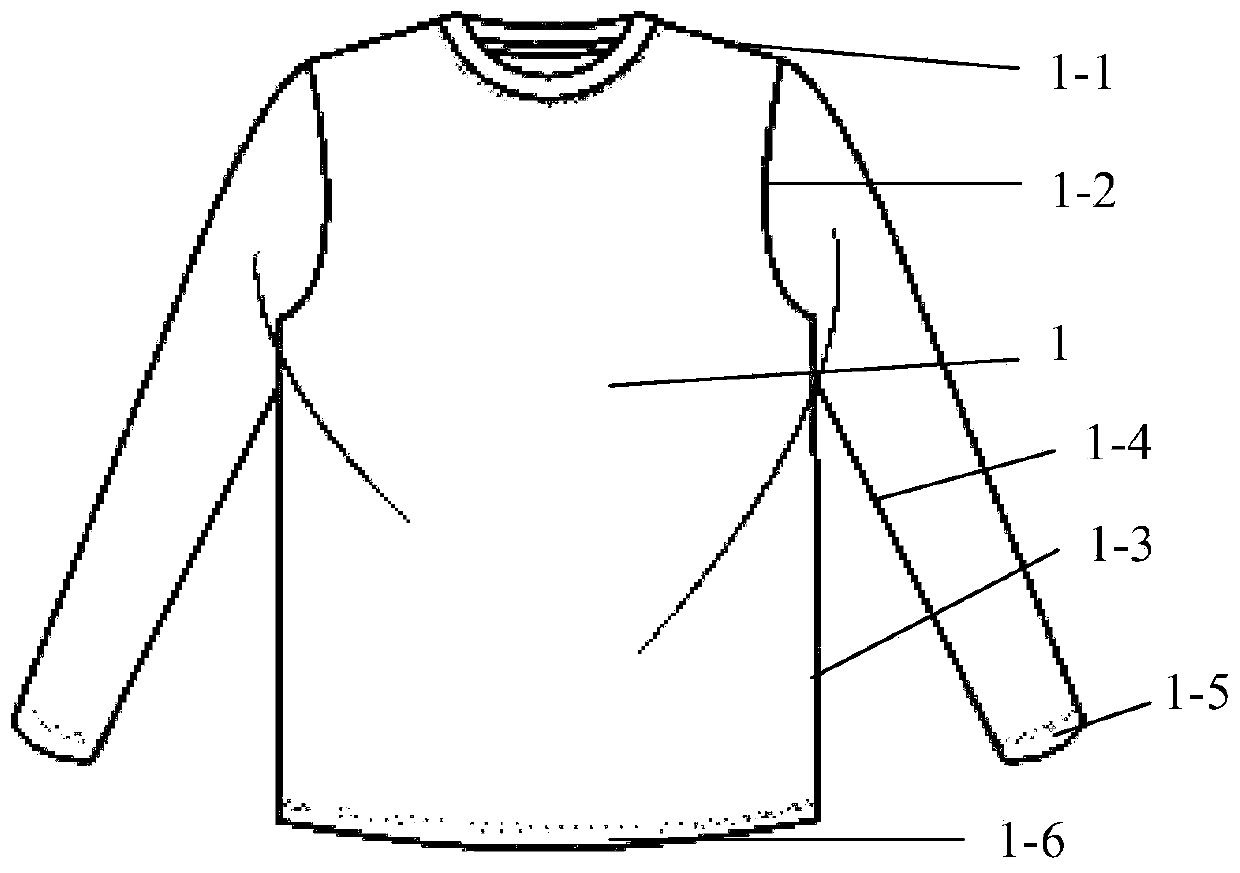

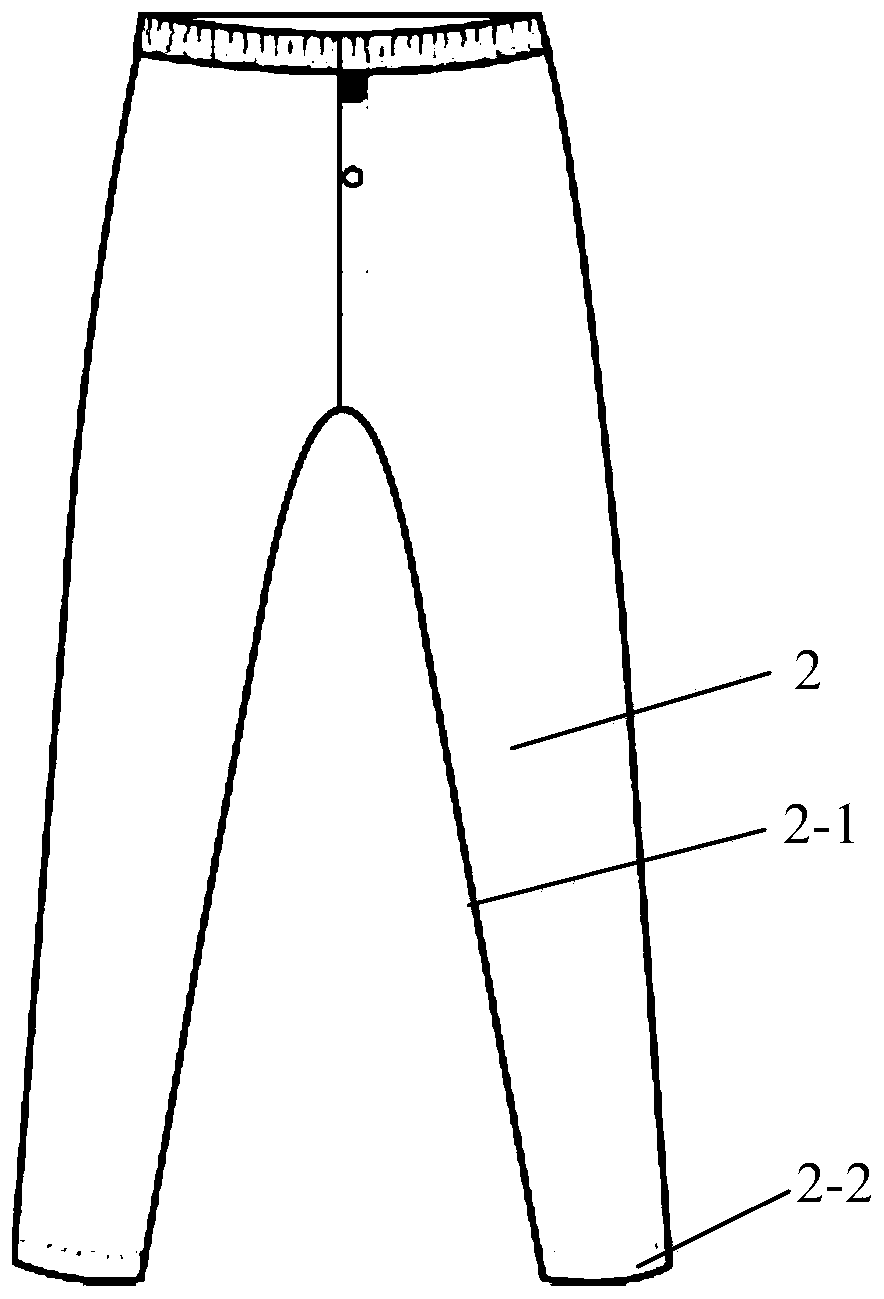

Super-soft heating red-bean-velvet underwear fabric and suit

PendingCN111455538AComfortable to wearWear softFabric breaking/softeningWeft knittingCotton fibreAcrylic fibre

The invention belongs to the technical field of practical functional fabrics, and particularly relates to a super-soft heating red-bean-velvet underwear fabric and suit. The super-soft heating red-bean-velvet underwear fabric is of a single-side weft-knitted structure and is formed by weaving high-count blended yarn and spandex, the gram weight of the fabric is 150-160 g / m<2>, and the blended yarncomprises, by mass, 40%-50% of Lenzing modal, 25%-30% of cotton fibers and 25%-30% of superfine acrylic fibers. The super-soft heating red-bean-velvet underwear fabric is combined with the cotton fibers which are healthy, moisture-absorbing and breathable, the superfine Lenzing modal which is soft and skin-friendly and the superfine soft heating acrylic fibers, and the fabric is softer and skin-friendly; by adding lycra spandex, the fabric has lasting elasticity and restoring force, and underwear is not easy to shrink and deform; and meanwhile, the light and thin single-side fabric is suededthrough a surface layer sueding machine, and the manufactured fabric is softer and more comfortable to wear and does not pill.

Owner:WUXI HODOHOME GARMENT

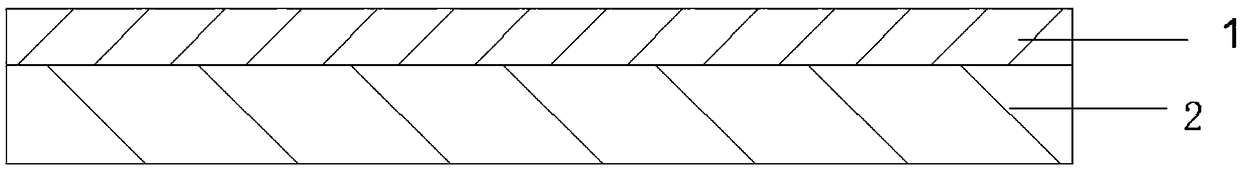

Aluminum plate for thermal transfer printing

The invention relates to an aluminum plate for thermal transfer printing. The aluminum plate comprises a base-layer aluminum plate, wherein a colored pattern layer is coated on the upper surface of the base-layer aluminum plate; the colored pattern layer comprises a bottom layer, a middle layer and a surface layer; and the bottom layer is coated on the base-layer aluminum plate. According to the aluminum plate provided by the invention, the upper surface or two surfaces of the base-layer aluminum plate are coated with the colored pattern layers and each colored pattern layer comprises the bottom layer, the middle layer and the surface layer; and the bottom layer is coated with colored primer and the surface layer is coated with transparent paint, so that the problems caused in a thermal transfer printing process can be completely solved and thermal transfer printing pattern operation is sufficiently carried out; and the image effect and the fullness and brightness of colors are ensuredand the cost is low.

Owner:ZHANGJIAGANG FEITENG ALUMINUM COMPOSITE PANEL

Easy-to-dry paint

InactiveCN105062185AEvenly distributedMaintain vividnessCoatingsChlorinated paraffinsIsopropyl alcohol

The invention discloses an easy-to-dry paint. The paint is characterized by comprising the following ingredients: 40 to 50 parts of common paint ingredients, 30 to 40 parts of mixture of chlorinated paraffin and antimony oxide, 5 to 10 parts of zeolite powder, 5 to 10 parts of isopropyl alcohol, and 20 to 30 parts of silica. The paint has the benefits that (1) due to the addition of isopropyl alcohol, when the paint is in contact with a wall surface, moisture in air can be absorbed first, and can be retained, so that a coloring agent in the paint can be distributed more uniformly in the wall due to the moisture; moreover, the moisture can be volatilized in a relatively short time, so that the color vividness of the paint can be maintained.

Owner:TONGLING BAIRUI EQUIP PARTS CO LTD

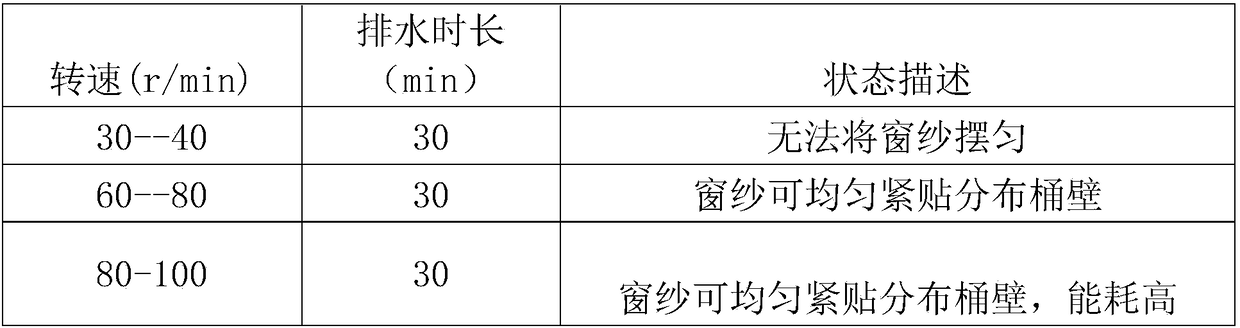

Cleaning method of window screen fabric

InactiveCN108166242AAvoid ectopicAvoid tearing and breakingInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPhosphorCleaning methods

The invention relates to a cleaning method of a window screen fabric. The cleaning method of the window screen fabric is characterized that the drum capacity of the used washing machine is 25 to 60 Kgand comprises the following steps: main washing, first-time fabric flattening, first-time dehydrating, first-time rinsing, second-time fabric flattening, second-time dehydrating, second-time rinsing,third-time fabric flattening, spin dry and drying with a dryer; a laundry detergent and a waste treating agent do not contain phosphor or a fluorescent agent. The cleaning method of the window screenfabric has the advantages of good stain removal effects and no damage to curtains.

Owner:浙江喜创联电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com