Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "Increase color depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

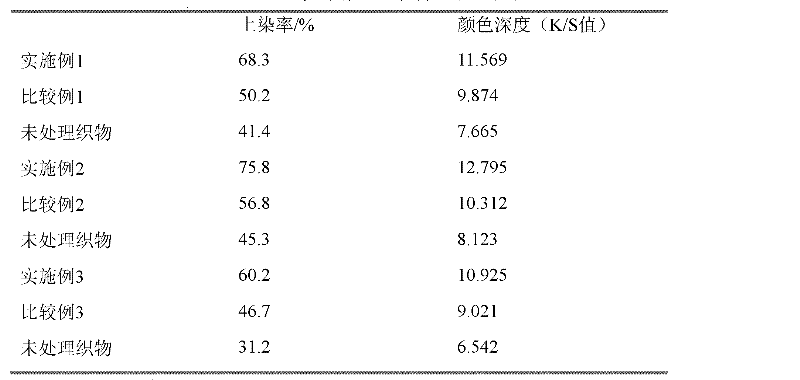

A method for improving the dyeing depth of cellulose fiber fabrics with chitosan

ActiveCN102268823AImprove accessibilityImprove responseDyeing processVegetal fibresEpoxyCooking & baking

The invention relates to a method for improving the dye depth of cellulose fiber fabrics by using chitosan. In the method, a polycarboxylic acid solution is used as a solvent and a cross-linking agent of chitosan and epoxy chloropropane is used as a cross-linking agent, and chitosan is covalently grafted to the surface of the cellulose fiber fabrics through padding, preliminary drying and baking at a high temperature. The combining strength of chitosan and the cellulose fiber fabrics is increased greatly, the electrostatic repulsion between the cellulose fiber fabrics and anionic dyes is reduced, the dye-uptake of dyes and the color depth of the fabrics are improved obviously, and the crease resistance of the cellulose fiber fabrics processed by using the method is improved obviously.

Owner:CHANGZHOU UNIV

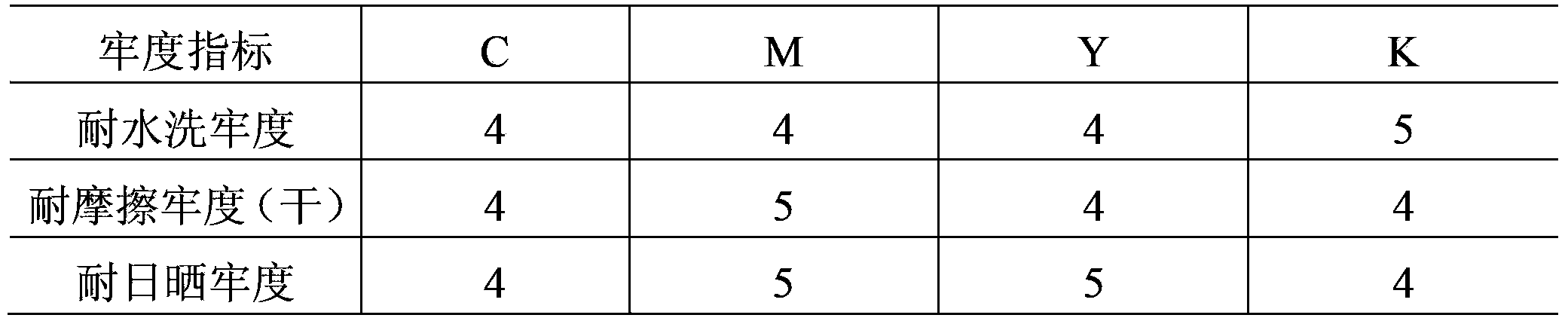

Digital reactive dye printing process for mulberry silk fabric

InactiveCN103451970AHigh color yieldIncrease color depthHeating/cooling textile fabricsDyeing processDigital printingUrea

The invention provides a digital reactive dye printing process for a mulberry silk fabric. The process comprises the following steps: carrying out textile sizing, drying, carrying out jet printing, steaming, washing by cold water, washing by hot water, washing by soap, washing by hot water, washing by cold water, and drying, wherein a sizing agent used in the textile sizing step comprises the following components in percentage by weight: 1%-3% of sodium sulfate powder, 0.5%-1% of sodium alginate, 3%-5% of urea, 0.5%-1.5% of sodium hydrogen carbonate, 1%-2% of modified starch, 5%-7% of electrolyte and the balance being water. By virtue of the process, the digital printing color yield of the mulberry silk fabric is increased, the inkjet printing color depth on a textile is increased, the color difference between a pattern on the textile and an electronic pattern is reduced, and the hand feel of the fabric is good.

Owner:SHIJIAZHUANG HEXI APPL TRADING

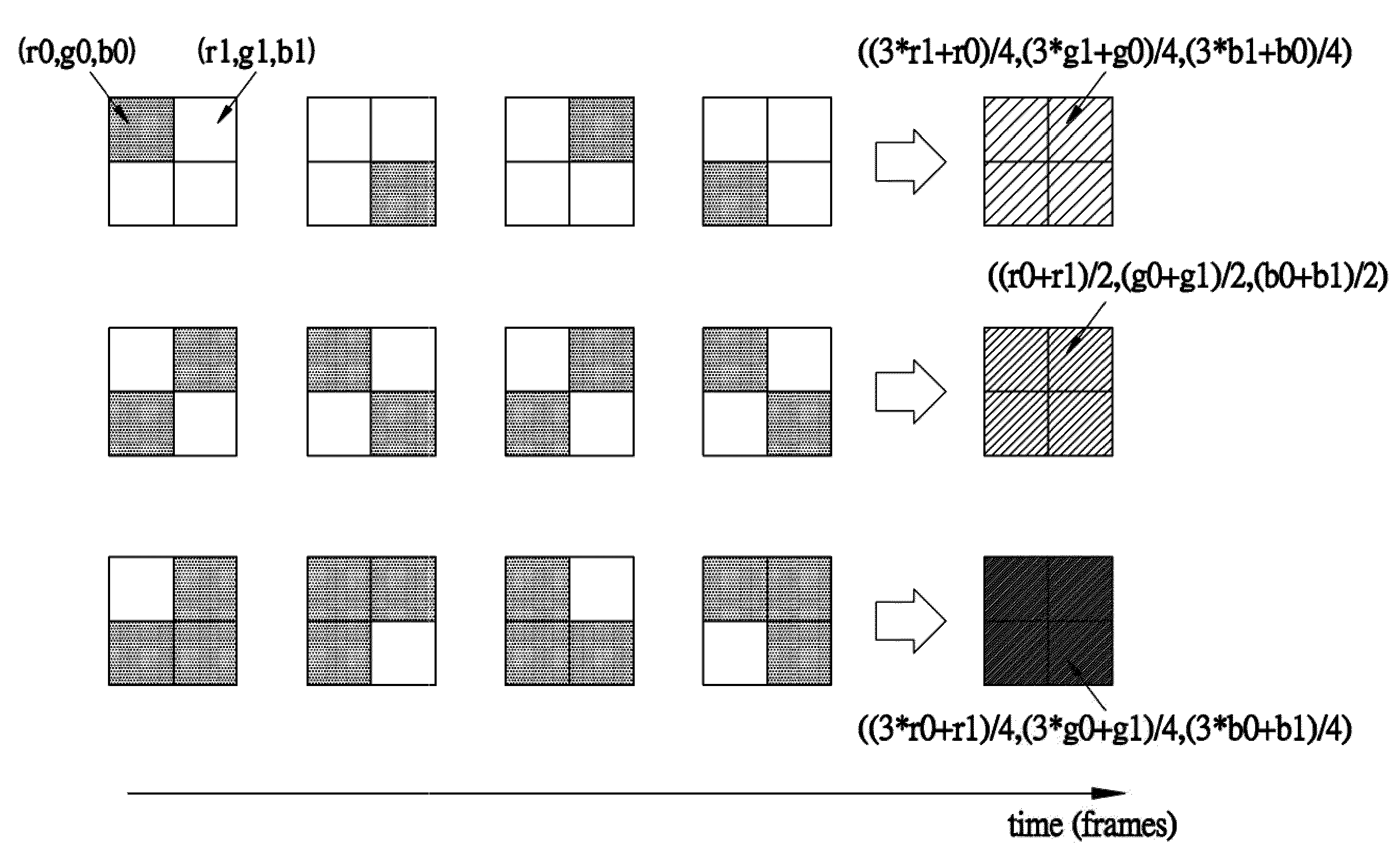

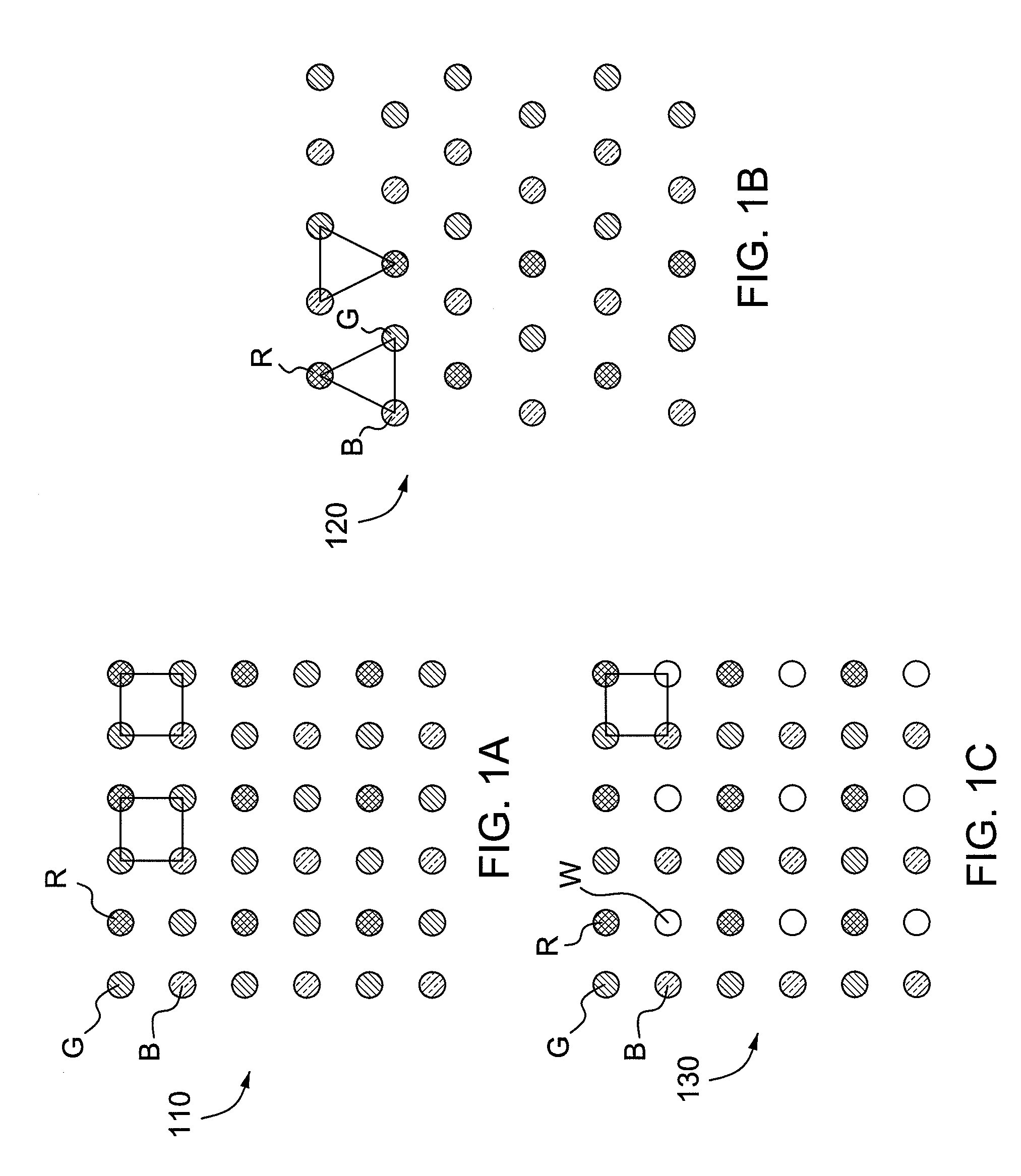

Color sets for low resolution dithering in reflective color displays

ActiveUS20160091770A1Reduce spatial resolutionIncrease color depthStatic indicating devicesNon-linear opticsColor imageImage resolution

The present invention provides for a method of rendering an image on a reflective display wherein each pixel is capable of rendering a limited number of colors, each of which is rendered by predetermined set of waveforms stored in a waveform lookup table. Furthermore, the present invention provides for a method for rendering an image using such colors, having been chosen for optimal color rendition. This invention further provides for rendering a color image formed from a plurality of pixels on a reflective display wherein each pixel has a color selected from the group consisting of at least: red, green, blue, cyan, magenta, yellow, black and white.

Owner:E INK CORPORATION

Method for processing mercerized cotton strip

ActiveCN102493142AGuaranteed alkaline dippingGuaranteed stretchMercerising of sliversLiquid/gas/vapor removalPolymer scienceSpinning

The invention relates to a method for processing a mercerized cotton strip in the weaving field. The method comprises the following production steps: processing a cotton strip, and manufacturing into the required shape; shaking the cotton strip: shaking the processed cotton strip into the twisting shape according to the set circle number and a frame length, tying and fixing; and mercerizing: mercerizing the cotton strip on a hank-mercerizing machine according to the specific technology. According to the method for processing a mercerized cotton strip, which is disclosed by the invention, the industrial problem that the cotton fiber can not be mercerized is mainly solved, a feasible full set of processing method for mercerizing, dyeing and spinning the cotton strip is provided, and cotton silk mercerization, cotton wool mercerization and high-depth color spinning can become true.

Owner:无锡市鳌尊生态科技有限公司

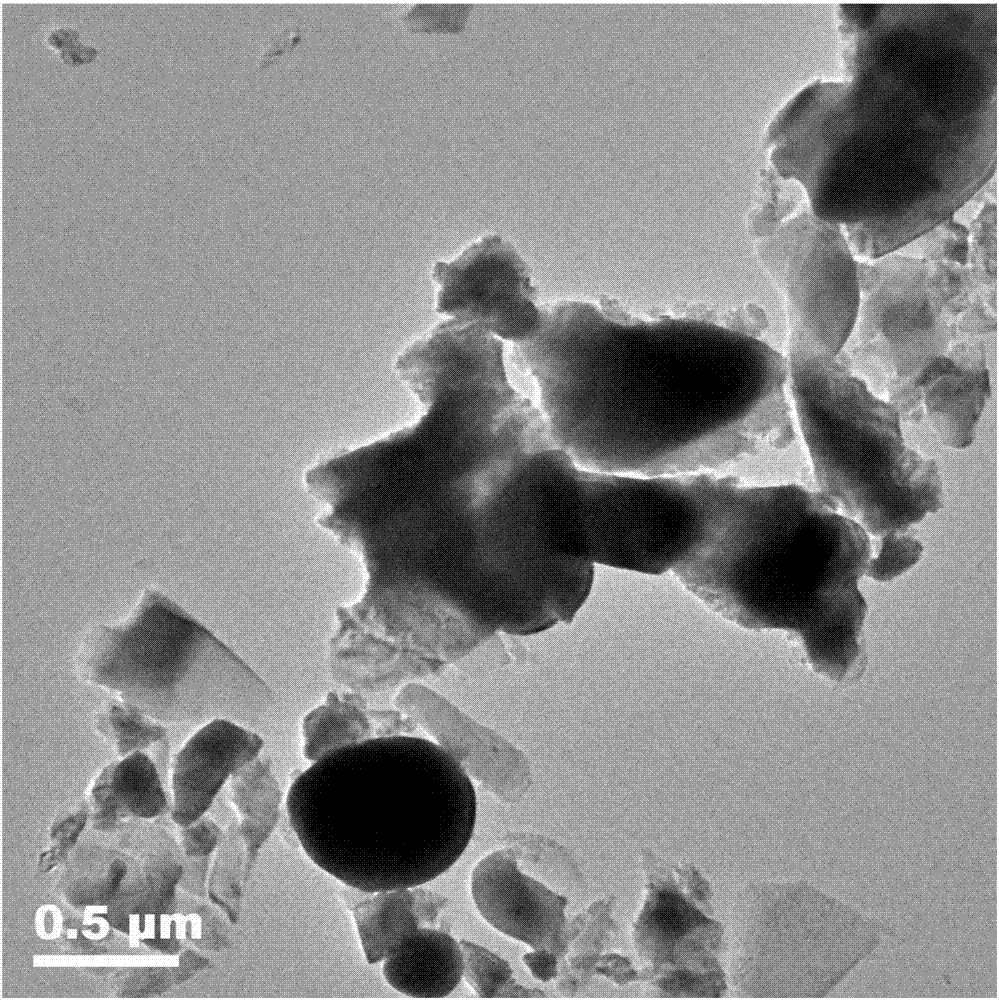

Preparation method of zirconium silicate covered ceramic pigment taking ammonium zirconium carbonate as zirconium source and product prepared by preparation method

ActiveCN106928752AIncrease color depthHigh parcel rateInorganic pigment treatmentHydrogenZirconium(IV) silicate

The invention discloses a preparation method of a zirconium silicate covered ceramic pigment taking ammonium zirconium carbonate as a zirconium source. The preparation method comprises the following steps: firstly, after dispersing powder of a coloring agent, uniformly stirring the coloring agent and an ammonium zirconium carbonate solution to form a stable suspension solution; reacting to form sedimentation on surfaces of coloring agent particles, so as to obtain a zirconium oxide inclusion; adding the zirconium oxide inclusion into a silicon source solution and uniformly mixing; adjusting the pH (Potential of Hydrogen) value to obtain sediment; drying the sediment to obtain a ceramic pigment precursor; calcining the ceramic pigment precursor and removing the uncovered coloring agent so as to obtain the zirconium silicate covered ceramic pigment powder. Furthermore, the invention further discloses a product prepared by the preparation method. By adopting the preparation method disclosed by the invention, damages to the ceramic pigment can be avoided and the covered pigment with high covering ratio and a core-shell structure is formed; the problem that the high covering ratio of the zirconium silicate covered ceramic pigment is incompatible with a low ratio of the coloring agent to the pigment is effectively solved, so that the color-causing depth of the covered pigment is effectively improved and the adding amount in a utilization process is reduced.

Owner:JINGDEZHEN CERAMIC UNIV

Method and related circuit for color depth enhancement of displays

InactiveUS20090251483A1Increase color depthReduce visual discomfortCathode-ray tube indicatorsDisplay deviceComputer vision

Method and related circuit for color depth enhancement of displays is provided. In an embodiment of the invention, when emulating an interpolated color level between a first and a second color levels the display can display, a color channel component of the first color level and another color channel component of the second color level are selected for color dithering and color depth enhancement.

Owner:FARADAY TECH CORP

Cotton sliver mercerizing process and mercerizing device utilizing same

InactiveCN102704225AImprove spinning efficiencyHigh glossMercerising of yarns/threads/filamentsMercerising of sliversComposite materialPolymer chemistry

Disclosed are a cotton sliver mercerizing process and a mercerizing device utilizing the same, which belong to the technical field of textile technology. The cotton sliver mercerizing process includes: a, cotton sliver pretreatment step including dewing cotton slivers and dewatering the same or squeezing water out of the same to form wet cotton slivers with certain liquid content; b, a cotton sliver reeling step including reeling the wet cotton slivers on a reeling machine and fixing the cotton slivers by lay bands; c, a covering step including wrapping the reeled cotton slivers with the wrapping cloth integrally; and d, a mercerizing step realized by concentrated spraying and instant squeezing. The sliver cottons are mercerized effectively by dewing to reinforce and by means of concentrated spraying and instant squeezing, and alkali content of the cotton slivers is controlled all the time, so that the cotton slivers cannot be dissolved due to excessive swelling, and the difficult problem of failure in mercerizing the cotton slivers without twist is solved. In addition, the mercerized cotton slivers are bright, smooth and fluffy, and dye color yield is increased by 20%-30%.

Owner:WUXI NON SIZING TECH

Curcumin-carried pH-response color-changing antibacterial fiber and preparation method thereof

InactiveCN104762684AUniform colorGood level dyeingMonocomponent synthetic polymer artificial filamentDye addition to spinning solutionColor changesSolvent

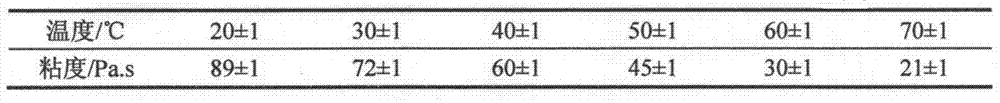

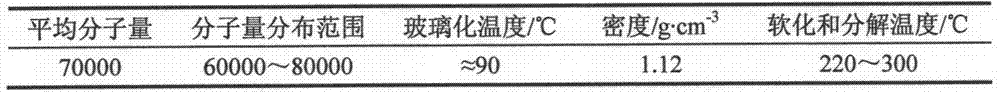

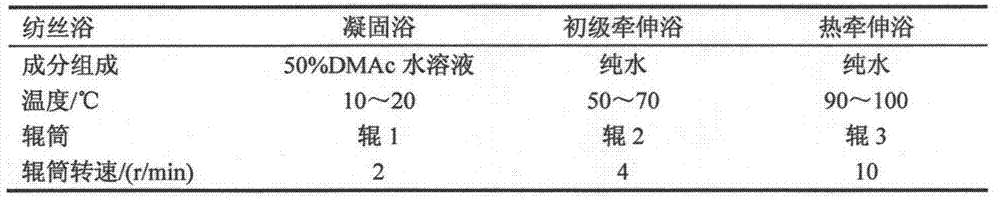

The invention provides a curcumin-carried pH-response color-changing antibacterial fiber and a preparation method thereof. The preparation method comprises the following steps: step 1, drying and dewatering polyacrylonitrile powder, and filtering for separating by utilizing a screen mesh; step 2, mixing curcumin, the polyacrylonitrile powder obtained in the step 1 and a solvent, wherein the mass concentration of the polyacrylonitrile is 18-22%, and the consumption of the curcumin is 0.5-5% of the polyacrylonitrile powder in dry weight; and step 3, stirring a mixed liquid obtained in the step 2 to puff and dissolve polyacrylonitrile to obtain a spinning solution, performing deaeration on the spinning solution, performing wet spinning to obtain a nascent fiber, performing drying densification on the obtained nascent fiber, and performing heat setting treatment, so as to obtain the curcumin-carried pH-response color-changing antibacterial fiber. According to the curcumin-carried pH-response color-changing antibacterial fiber and the preparation method thereof, the fiber is colored uniformly, the color fastness is excellent, and the fiber has the weaving mechanical property and the pH-response color-changing performance; the spinning temperature is low, and the medicine activity of curcumin can be still retained, so that the fiber has the anti-bacterial function.

Owner:DONGHUA UNIV

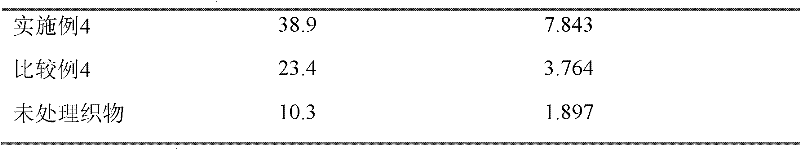

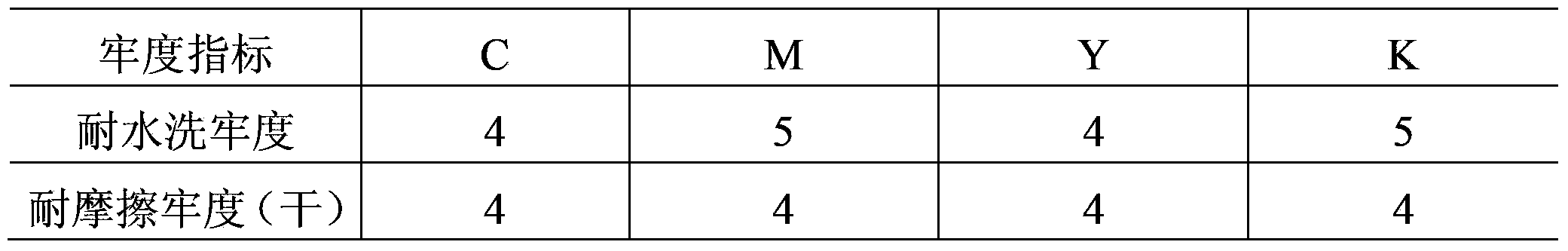

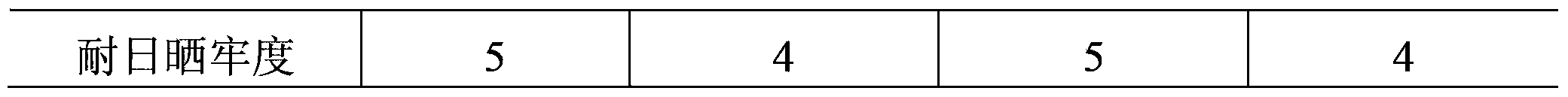

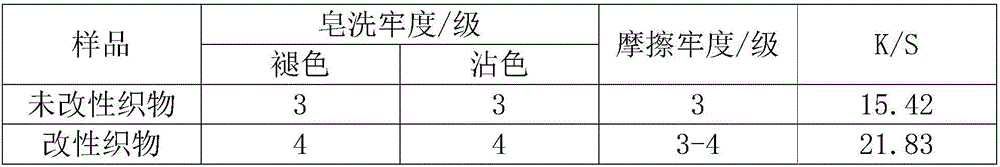

Dyeing method for modified polyimide fabrics

ActiveCN105951435AIncrease color depthHigh color fastnessFibre treatmentDyeing processFiberGraft reaction

The invention relates to the field of fabric dyeing, in particular to a dyeing method for modified polyimide fabrics. The method comprises the following steps that polyimide fabrics are cleaned and dried; low-temperature plasma is adopted for pretreatment; the polyimide fabrics are quickly put in an acrylic acid solution for a grafting reaction, and the modified polyimide fabrics are obtained after washing and drying; dispersed cationic dye is used for dyeing, washing is conducted after dyeing, and then drying is conducted. According to the method, cleaning is conducted firstly to wash away impurities, oil and the like on the surfaces of fibers, the low-temperature plasma is used for roughening the surfaces of the polyimide fibers, total reflection of light is weakened, and diffuse reflection of light is enhanced; besides, a polar group is introduced by initiating the grafting reaction of acrylic acid, cations on dye molecules can be in ionic bond combination with carboxyl, and therefore the problem that the polyimide fibers are hard to dye can be effectively solved. By the adoption of the dyeing method for the modified polyimide fabrics, the process is simple, and the fabrics obtained after dyeing are high in color depth and good in color fastness.

Owner:DONGGUAN SENLIN TEXTILE LTD

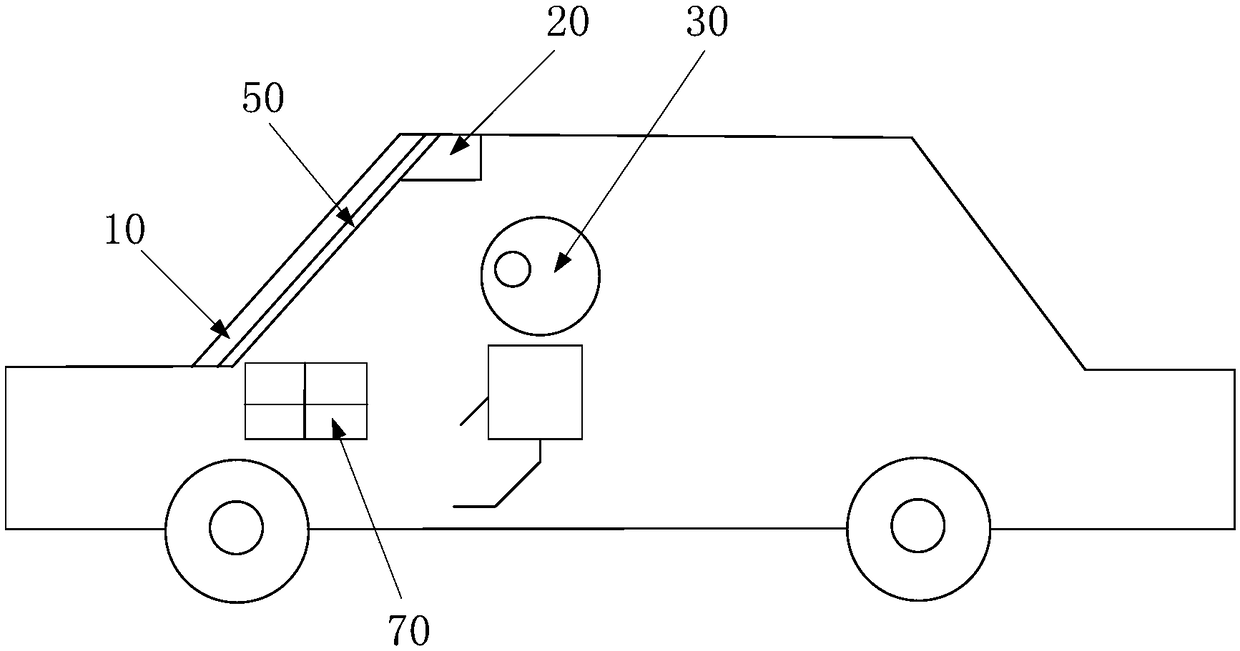

Anti-dazzling system and automobile

PendingCN108819677AIncrease color depthReduce light transmittanceWindowsAntiglare equipmentUltraviolet lightsTransmittance

The invention provides an anti-dazzling system and an automobile, and relates to the technical field of anti-dazzle. The anti-dazzling system comprises a transparent color change film, an optical device, a first light intensity detection device and a control device, wherein the control device is connected with the optical device and the first light intensity detection device respectively by signals. The first light intensity detection device is used for detecting the light intensity on the outside of the automobile and feeding light intensity information back to the control device. Then the control device receives the light intensity feedback information from the first light intensity detection device. When the light intensity information exceeds a first light intensity threshold, the control device controls the optical device to start, and the ultraviolet light emitted by the optical device illuminates the transparent color change film to increase the color depth of the transparent color change film. The anti-dazzling system is applied to automobiles and can adjust the color depth of the transparent color change film according to the light intensity outside the automobiles, thereby changing the light transmittance of the front windshield.

Owner:HASCO VISION TECHNOLOGY CO LTD

Activated dye low-alkaline dyeing method for black regenerated cellulose fiber cheese

ActiveCN104404797ALower dyeing temperatureReduce alkali consumptionDyeing processAcetic acidWater volume

The invention relates to the field of printing and dyeing, particularly to an activated dye low-alkaline dyeing method for a black regenerated cellulose fiber cheese. The method comprises the steps of pretreatment, dyeing, fixing and follow-up treatment; in addition, low alkaline is adopted in the dyeing and fixing processes and the working procedures are reduced. Therefore, the dyeing temperature of the regenerated cellulose fiber is reduced; the alkaline dosage for dyeing the regenerated cellulose fiber is lowered; the method is simple to operate, short in technical duration, and low in alkaline content in the dyeing waste water, can reduce the dosage of glacial acetic acid for neutralization in the follow-up procedure, lowers washing water volume, saves energy and reduces emission, improves the color fastness of the cheese, and lowers the dyeing cost.

Owner:浙江恒生印染有限公司

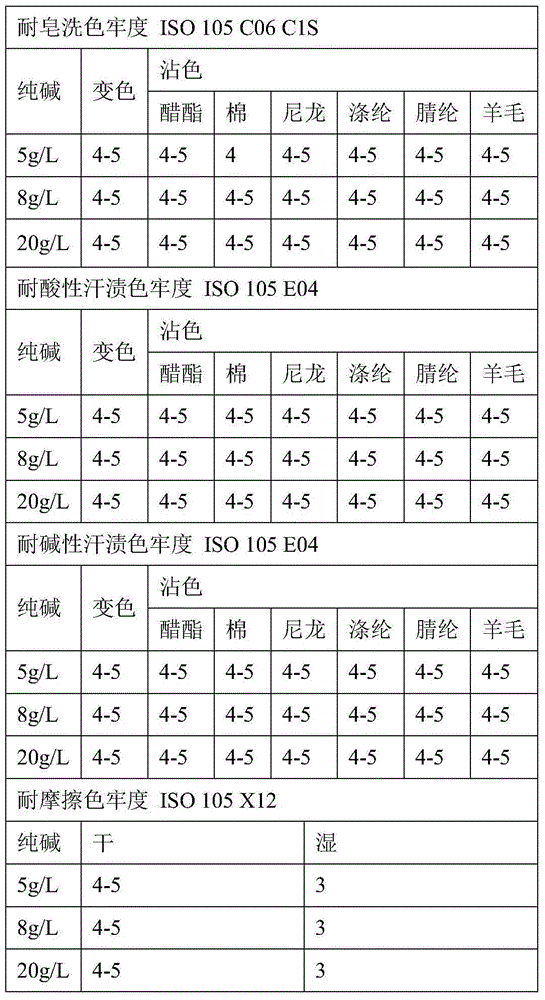

Digital printing process for real silk fabric

InactiveCN106758384AHigh color yieldIncrease color depthUltrasonic/sonic fibre treatmentDyeing processWarm waterEngineering

The invention provides a digital printing process for a real silk fabric. The digital printing process comprises the following procedures: real silk fabric preparation; low-temperature plasma processing; pretreatment liquid padding; drying; inkjet printing; drying; dry heat fixation; cold water flushing; warm temperature washing; soaping; warm water cleaning; and drying, wherein pretreatment liquid in the pretreatment liquid padding contains the following components by contents: 5g / L-10g / L of sodium alginate, 30g / L-50g / L of baking soda, 30g / L-50g / L of urea and 5g / L-15g / L of a defoaming agent. By virtue of the digital printing process, the tinctorial yield of the digital printing of a silkworm silk fabric is increased, the color depth of the digital printing on a textile is increased, and the chromatic aberration with an electronic pattern is reduced; and furthermore, the color fastness is high, and multiple experiments prove that the fabric does not fade or lose color even at relatively hostile experimental environments.

Owner:顾朝晖

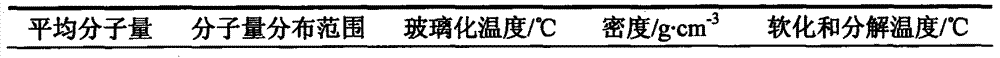

Cationic polymer emulsion for dip dyeing of coating

The invention discloses a cationic polymer emulsion for dip dyeing of a coating. The polymer emulsion is synthesized by adopting an emulsion polymerization method by taking styrene and butyl acrylate as a monomer, hexadecyltrimethyl ammonium chloride as a cationic emulsifier and azobis methylpropion amidine dihydrochloride as a cationic initiator. Emulsion particles in the polymer emulsion have positive charges and can be combined with coating particles and fibers with negative charges, so that the emulsion particles can be fixedly attached on the surfaces of the fibers. According to the cationic polymer emulsion applied to dip dyeing of the coating, the color depth, the fastness and the hand feel are improved.

Owner:QINGDAO UNIV

Flax fibre modifying method

InactiveCN1584183AImprove dyeing effectLoose arrangementPhysical treatmentFlax fibreMaterials science

This invention publishes the method of color flax fibre. A kind of character-change flax fibre: (1.) Put the flax fibre into 50-300g per L carbamide liquid. After endosmosis, put it out. (2) Heat the flax fibre in 300-400w micro-wave oven for 1-4 minutes. (3) Heat the flax fibre in the 600-hange the flax fibre. The color deepness can rise by 6%. (4) The flax fibre after character-change, the face will become coarse, it shows the face of some fibre molecule is cloven, and the face of other fibre molecule appears floss. So the fibre is a little loose, and it is dasy to be 800w imcro-wave oven for 0.5-3 minutes. The availability of the invention is: After character-c colored and character-change, the mechanics capability is not changed.

Owner:HEILONGJIANG UNIV

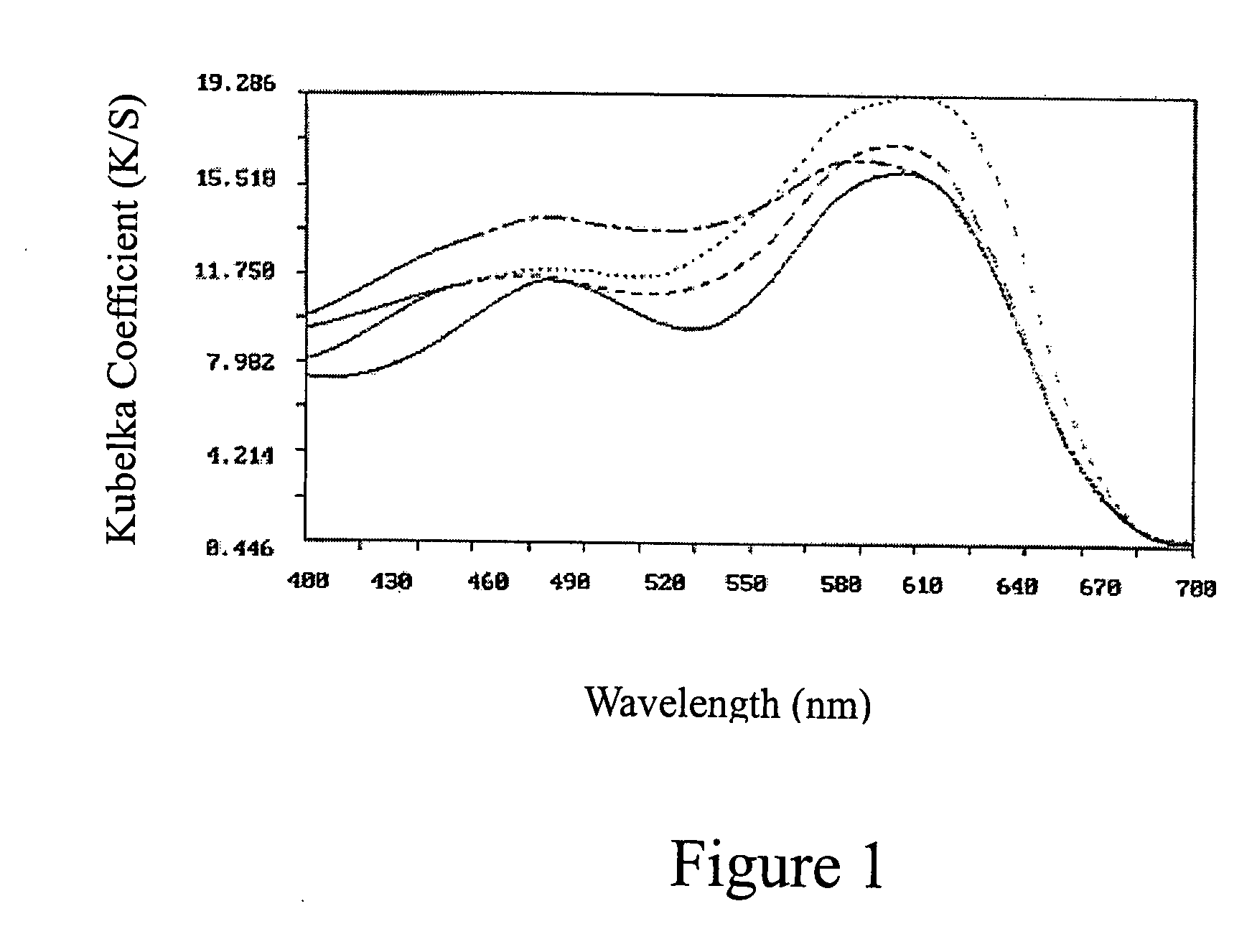

Black dye composition and black ink composition for textile digital printing

ActiveUS20080184912A1Improve accuracyIncrease color depthReactive dyesInksDigital printingColor depth

The present invention relates to a black dye composition, comprising: (a) at least one azo dye of the following formula (I),(b) at least one azo dye of the following formula (II) or (III),wherein R1, R2, and R3 are defined the same as the specification. The present invention also relates to a black ink composition afforded from the aforementioned black dye composition. The black ink composition of the present invention for textile digital printing exhibits the properties of excellent color depth, fixation, stability of storage, stability and accuracy of printing for long time, and improves the issue of nozzle cloggage.

Owner:EVERLIGHT USA INC

Multifunctional fiber with pH discoloration property, antibacterial property and drug-releasing property and preparation method thereof

InactiveCN104762685AUniform colorGood level dyeingMonocomponent synthetic polymer artificial filamentArtifical filament manufactureDrug activityDrug release

The invention provides multifunctional fiber with a pH discoloration property, an antibacterial property and a drug-releasing property and a preparation method thereof. The preparation method is characterized by comprising the following steps: polyacrylonitrile powder is dried and dehydrated, and then is filtered and separated by a filter screen; curcumin, vitamin E, the polyacrylonitrile powder obtained by separation in the step 1 and a solvent are mixed; the obtained mixed liquid is stirred so that polyacrylonitrile is expanded; polyacrylonitrile is heated to be dissolved to obtain a spinning solution; the obtained spinning solution is subjected to de-foaming and wet spinning; and the obtained nascent fiber is subjected to drying densification and heat setting treatment, thus obtaining the multifunctional fiber with pH discoloration property, antibacterial property and drug-releasing property. With the method provided by the invention, the prepared fiber has the advantages of even coloring and excellent color fastness. The fiber has the weaving mechanical property and has the pH response discoloration property. Because of a low spinning temperature, drug activities of curcumin and vitamin E can be maintained, so that the fiber also has antibacterial and drug sustained-release functions.

Owner:DONGHUA UNIV

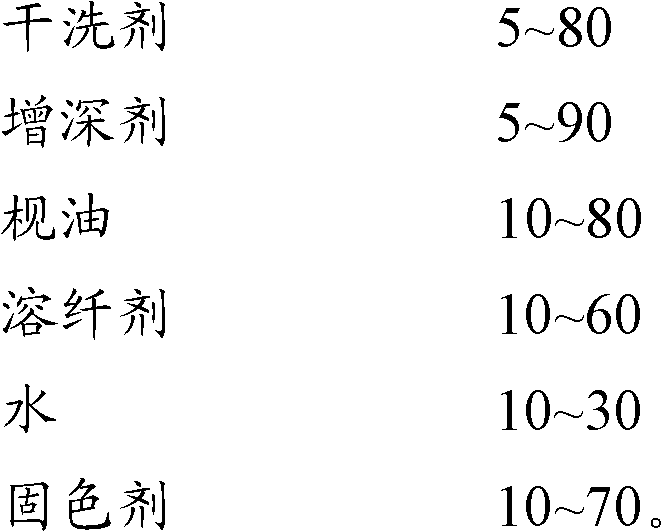

Color-increasing dry cleaning agent composition and preparation method thereof

InactiveCN102618403AIncrease color depthAdd depthDry-cleaning apparatus for textilesNon-surface-active detergent solventsFiberOptical property

The invention discloses a color-increasing dry cleaning agent composition and a preparation method thereof. The color-increasing dry cleaning agent composition consists of dry cleaning agent, deepening agent, detergent agent, cellosolve, water and color fixing agent, wherein the deepening agent has a function of modifying the optical property of fiber surfaces; hydrogel formed by the color fixingagent can adsorb heavy metal ions and pigment, can form a thin film after drying and can take a fixing and protection effect on dyes; and the cellosolve can improve the emulsifying property and can dissolve minerals in the dry cleaning agent. With the dry cleaning of fabrics, firstly the original colors of the fabrics are fixed under the effect of the color fixing agent, then the colors of the cleaned fabrics are deepened under the effect of the deepening agent, the colors of the fabrics are supplemented in time and the goals of effectively fixing the colors of the dry-cleaned fabrics and increasing the depth of the original colors of the fabrics are achieved.

Owner:吉林省亨泰服装洗染科学技术研究所

Flat panel display and driving method thereof

InactiveUS20080150881A1Improve image qualitySave powerStatic indicating devicesDynamic contrastDisplay device

The present invention provides a flat panel display, which is characterized by comprising a display panel; a backlight assembly having a plurality of light-emitting sources arranged in a predetermined pattern; and a driving circuit coupled to the display panel and the backlight assembly. The driving circuit could be operative to receive a first signal and determine a second signal according to the first signal and the predetermined pattern of the plurality of light-emitting sources; to use the second signal to control the light emission of the plurality of light-emitting sources; to determine a third signal according to the light-emitting results of the light-emitting sources controlled by the second signal, and drive the display panel by the third signal. The backlight assembly and flat panel display disclosed in the present invention could achieve the effects of improving quality, power saving, high dynamic contrast, and high color depth.

Owner:HONG KONG APPLIED SCI & TECH RES INST

Method for producing multicolored carpet

InactiveUS20080016625A1Increased durabilityEasy to manufactureOnium based azo dyesDetergent compounding agentsYarnPolyamide

A method of producing a multicolored textured carpet comprises blending a polyamide polymer and a color pigment to form a melt blend, extrusion spinning the melt blend to form pigmented polyamide yarns, tufting (1) the pigmented polyamide yarns and (2) white dyeable polyamide yarns into a carpet, and overdyeing the carpet with an amount of acid dye sufficient to produce the multicolored textured carpet. The color pigment and the acid dye are selected to provide desired multicolored effect in the carpet. The multicolored textured carpet having deeper color and dye light fastness is also disclosed.

Owner:INV PERFORMANCE SURFACES LLC

Heavy metal pollution cultivated soil conditioner and preparing method and application thereof

InactiveCN107892917AReduced effectivenessReduce chemical mobilityAgriculture tools and machinesMagnesium fertilisersApatiteSoil conditioner

The invention discloses a heavy metal pollution cultivated soil conditioner which comprises 10-30 parts of biological charcoal, 30-50 parts of modified apatite and 10-50 parts of bentonite and furthercomprises sylvite. The invention further provides a preparing method and application of the heavy metal pollution cultivated soil conditioner. By applying the conditioner in cultivated soil, throughthe cooperation of all components and proportion, the bioactive state and chemical mobility of various heavy metals in cultivated soil can be collaboratively reduced, the diffusion risk of heavy metals in the cultivated soil is reduced, the absorption and conversion of crops on heavy metals in the soil are reduced, and safe eating of the crops is realized. The conditioner is wide in application range and can be used for paddy fields, dry lands and other cultivated lands.

Owner:湖南新九方科技有限公司

Method for continuously dyeing yarns

The invention provides a method for continuously dyeing yarns. The method comprises the following steps: selecting yarns as a dyeing raw material; selecting an azoic coupling component AS-BO as a prime liquid; dissolving the azoic coupling component; exhausting fluid for the yarns; diazotizing colorradical blue BB which is selected as a color developing agent; dissolving color salt; adding a neutralizer and antalkaline; performing a coupled developing process, controlling the concentration, pH value, temperature, time and other parameters during coupling; rinsing and soaping, and rinsing; and dyeing for the second time, calculating the dosage of a bottoming agent in refill and dosage added into caustic soda, and repeating the process of developing, rinsing, soaping and rinsing to complete continuous dyeing for yarns. According to the method, a dyeing method is improved, a repeated durable dyeing process operation is adopted, the stability for material dyeing is reinforced, the coloring effect is uniform, and defects occurring in single printing and dyeing process is avoided by means of repeated printing and dyeing.

Owner:广州弘雅服装科技有限公司

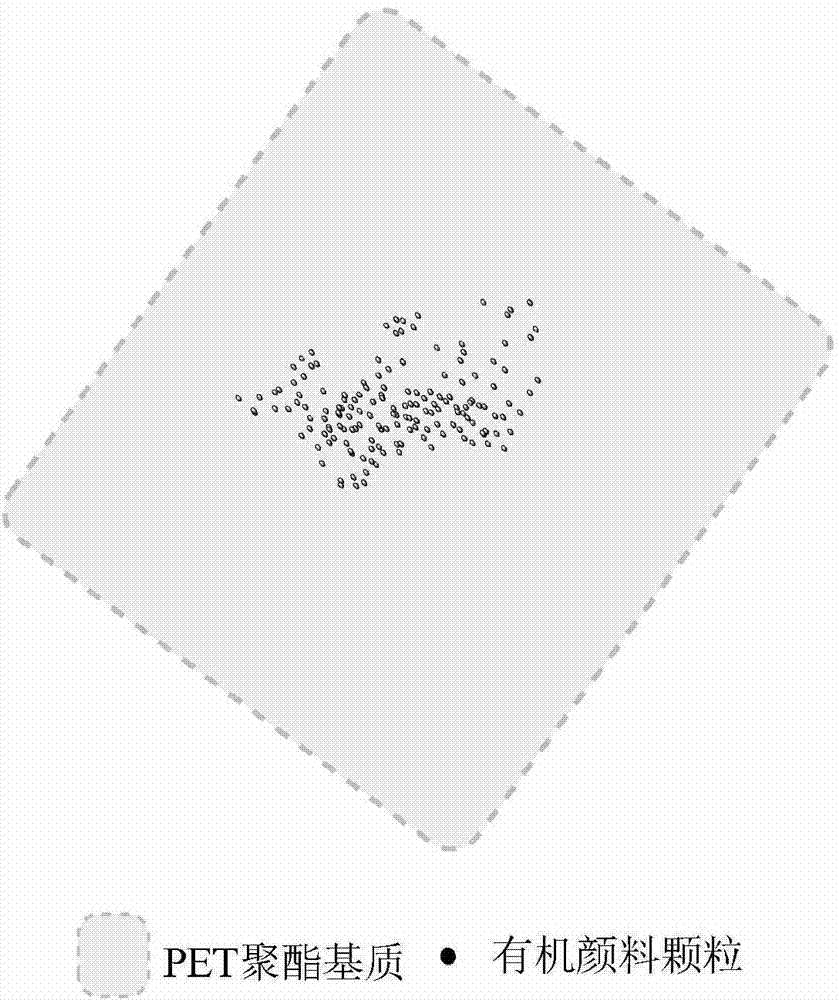

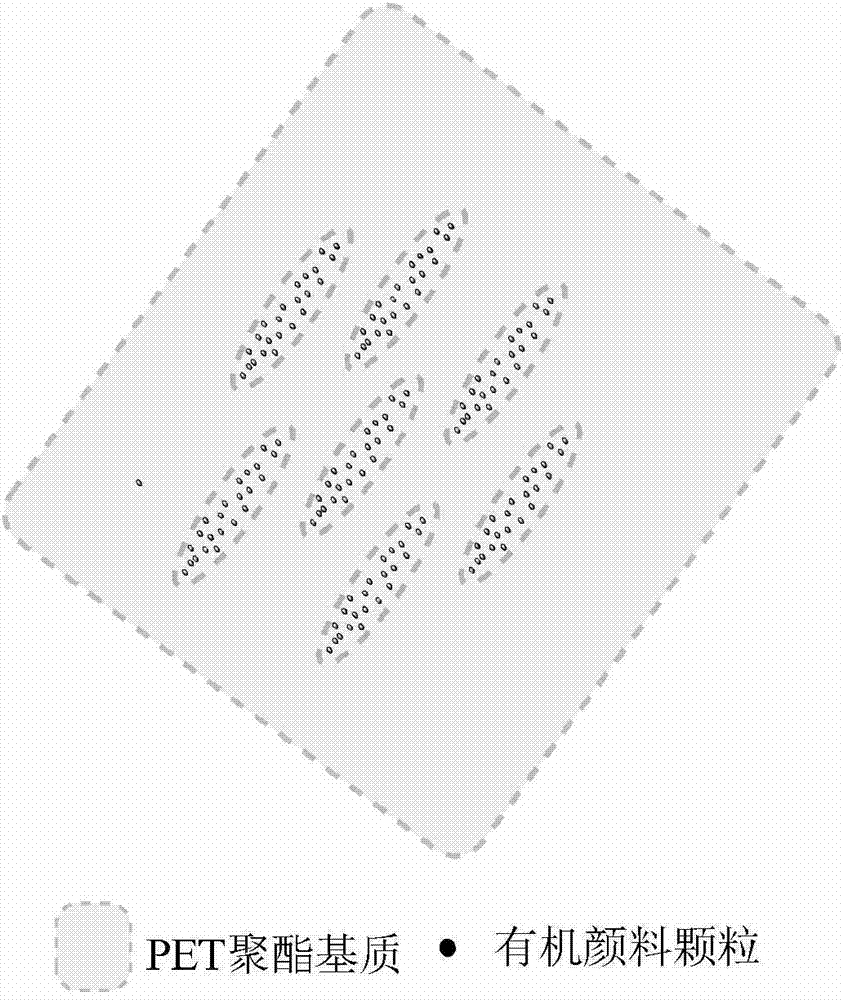

Method for preparing organic pigment microcapsule polyester color yarn

ActiveCN102877154ASimple processEasy to implementMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterYarn

The invention discloses a method for preparing an organic pigment microcapsule polyester color yarn. The method comprises the following steps of: (1) demulsifying organic pigment microcapsule rubber latex, washing by using water, drying, and controlling the mass fraction of the water to be less than 2*10<-6> to obtain solid powder which is used as an organic pigment microcapsule color master batch; and (2) drying polyester chips, controlling the mass fraction of the water in the polyester chips to be less than 2*10<-7>, mixing the polyester chips and the organic pigment microcapsule color master batch obtained in the step (1), adding the mixture into a screw extruder, performing melt blending at the temperature of between 275 and 288 DEG C and the rotating speed of 50 to 60r.min<-1>, spinning at the spinning speed of 3,000 to 3,100m / min, cooling, applying oil, stretching, and winding to obtain the organic pigment microcapsule polyester color yarn. The method is simple in process and easy to implement, and the organic pigment microcapsule polyester color yarn which has a good color developing effect and is high in intensity can be obtained.

Owner:ZHEJIANG SCI-TECH UNIV

Liquid crystal temperature-sensitive anti-counterfeiting printing ink and preparation method thereof

InactiveCN111205701ARaw materials are easy to getLow raw material costLiquid crystal compositionsInksAntifoam agentPrinting ink

The invention provides liquid crystal temperature-sensitive anti-counterfeiting printing ink. The printing ink comprises the following components in parts by weight: 15-25 parts of cholesteric liquidcrystal and a microcapsule thereof, 10-15 parts of a water-soluble glue solution, 50-60 parts of a connecting material, 0.1-1 part of an antifoaming agent, 0.1-1 part of a leveling agent, and 0.1-3 parts of a viscosity regulator, wherein the cholesteric liquid crystal is a mixture of 4-cyano-4'-amyl biphenyl and cholesteric oleyl carbonate; the cholesteric liquid crystal microcapsule is a microsphere capsule prepared from the cholesteric liquid crystal and a water-soluble glue solution; and the water-soluble glue solution is a mixture of gelatin and Arabic gum. The a printing ink has the advantages of easily available raw materials, low raw material cost and simple preparation method, and is suitable for the field of anti-counterfeiting labels, the color of an anti-counterfeiting pattern can change due to the temperature change, defects of slow color change and poor contrast effect of a conventional temperature-sensitive ink are overcome, and thus the printing ink has a great application prospect in the field of anti-counterfeiting package.

Owner:深圳市旺盈彩盒纸品有限公司

Polyamide-cotton mixed fabric catalyzing and printing technology in same sizing agent

InactiveCN104562749AAchieve dyeingStaining does not affectDry-cleaning apparatus for textilesDyeing processPolyamideEngineering

The invention discloses a polyamide-cotton mixed fabric catalyzing and printing technology in the same sizing agent. The technological process comprises the following steps in sequence: printing, drying, steaming, washing with hot water, soaping, washing with water, and drying. The technology of utilizing an activated dye / a neutral dye to be combined with dicyandiamide to catalyze and fix the color can obviously improve the printing color depth, reduces the dosage of an alkaline agent, realizes dyeing of the activated dye to the cotton in the fabric under the alkalescent condition, meanwhile cannot influence the dyeing of the neutral dye to polyamide, so as to achieve a good printing effect; the fastness to wet rubbing of the printed fabric can be up to level 4.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

Dyeing method for anti-cutting fabric

InactiveCN109183463AImprove wettabilityImprove adhesionDyeing processCooking & bakingEnvironmental resistance

The invention discloses a dyeing method for an anti-cutting fabric. The dyeing method comprises the following steps: pre-treating a gray fabric; firstly drying; performing corona treatment; scraping and impressing pigment printing paste; secondarily drying; baking; acquiring the end product. According to the invention, an ultra-high molecular weight polyethylene fabric is subjected to corona treatment so as to generate low temperature plasmas; under the effect of the low temperature plasmas, free radical reaction happens on the surface of the ultra-high molecular weight polyethylene fabric, the polymer is cross-linked, the surface is roughened and the wettability to polar solvents is promoted; the plasmas enter into the surface of the ultra-high molecular weight polyethylene fabric in themanner of electric shock and permeation to damage the molecular structure of the ultra-high molecular weight polyethylene fabric and oxidize and polarize the molecules on the treated surface. According to the invention, ion electric shock is utilized to erode an inert surface of the ultra-high molecular weight polyethylene fabric, so that the adhesive ability of the surface of the ultra-high molecular weight polyethylene fabric is promoted, the adsorptive property of the coating is enhanced, the color depth is increased, the pigment consumption for same color depth is reduced, the cost is lowered and the pigment dyeing is clean and environment-friendly.

Owner:IANGSU COLLEGE OF ENG & TECH

Clothing fabric dyeing and finishing process

ActiveCN113026386AHigh color fastnessImprove permeabilityLiquid/gas/vapor removal by gas jetsDyeing processColour fastnessProcess engineering

The invention belongs to the technical field of clothing dyeing and finishing processing, and particularly relates to a clothing fabric dyeing and finishing process which includes the following steps: S1, pre-treating gray fabric to be treated, and removing dust, impurities, fluff and an oil agent on the gray fabric; S2, on the basis of S1, dyeing the pretreated gray fabric to complete treatment of the gray fabric to obtain semi-finished fabric; and in a dyeing process, atomizing liquid dye on two sides of the gray fabric and then spraying to the gray fabric through spray guns, wherein the spray guns are symmetrically distributed on the two sides of the gray fabric; and S3, feeding the semi-finished fabric into a dryer on the basis of S2, and performing high-temperature drying on the semi-finished fabric to obtain a dried finished fabric. The process is simple and convenient to operate, and the prepared fabric is good in color fastness and color depth; and meanwhile, the fabric is sufficient in liquid absorption and good in shrinkage resistance.

Owner:浙江日升服装有限公司

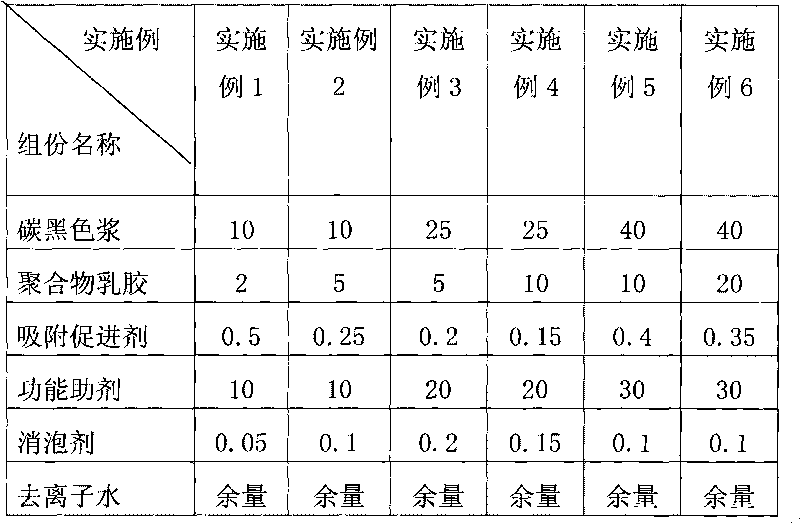

Emulsion absorption black gel ink and preparation method thereof

The invention discloses emulsion absorption black gel ink and a preparation method of the gel ink. The gel ink is composed of carbon black paste, polymer emulsion, absorption accelerator, functional assistant, thickening agent, defoaming agent and deionized water; the raw materials are proportioned according to the total weight percents as follows: 10.0-40.0 percent of the carbon black paste, 2.0-20.0 percent of the polymer emulsion, 0.1-0.5 percent of the absorption accelerator, 10.0-30.0 percent of the functional assistant, 0.5-10.0 percent of the thickening agent, 0.1-0.2 percent of the defoaming agent and the rest percent of the deionized water. The emulsion absorption black gel ink prepared in the invention has the advantages of higher color depth in writing, good hand feel and good glossiness, keeping unchanged writing performance after being stored for 12 months under normal temperature, applying to industrial production, and having significant commercial value.

Owner:SUZHOU SUNMUN TECH CO LTD

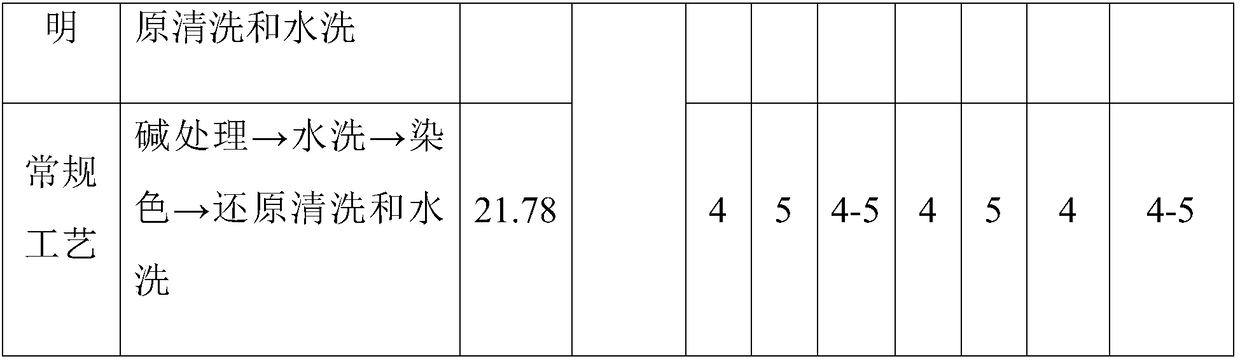

Polyester fabric dyeing technology

ActiveCN108660791AIncrease color depthSave caustic soda consumptionDyeing processEngineeringHigh pressure

The invention relates to the field of textile dyeing and finishing, and concretely relates to a polyester fabric dyeing technology. The polyester fabric dyeing technology comprises the following steps: carrying out high-temperature and high-pressure dyeing on a polyester fabric by a high-alkali resistance disperse dye, then processing the dyed polyester fabric with an alkaline solution, and then carrying out reduction washing and water washing, wherein the pH value of the alkaline solution is 9 or above. The polyester fabric dyeing technology selecting the high-alkali-resistance disperse dye breaks the conventional process flow of alkali lye treatment, water washing, high-temperature and high-pressure dispersion dyeing, reduction cleaning and water washing processing of the polyester fabric, and reconstructs a process flow of high-temperature and high-pressure dispersion dyeing, alkali lye processing, reduction cleaning and water washing, so the color depth of the dyed polyester fabricis significantly improved, the alkali reduction efficiency of the polyester fabric is improved, the waste of water and water pollution in the dyeing technology are reduced, and energy saving and environmental protection are facilitated.

Owner:PENGLAI JIAXIN DYES & CHEM

Binder and coating paint for coating base paper in inkjet paper production

InactiveCN1938160AIncrease color depthReduce color depthCoatings with pigmentsDuplicating/marking methodsLacquerPaper production

The aim of said invention is to obtain a binder for a coating paint used for producing a low-cost and good quality inkjet paper providing with the inkjet colours of relatively high colour densities, thereby substituting in many cases highvalued and expensive qualities of inkjet-photopaper. For this purpose, said invention is characterised in that the inventive binder comprises gelatine in the form of the first component thereof, fractions of at least one type of another binder component selected from vinylalcohol polymers and copolymers, carbohydrates and the derivatives thereof, wherein the gelatine solid content in the binder is greater than the sum of solid content of the other binder component(s).

Owner:GELITA AG

Shell manufacturing method, shell and electronic equipment

ActiveCN112492811AImprove color depthColorfulEdge grinding machinesPolishing machinesManufacturing engineeringHot pressing

The invention discloses a shell manufacturing method, a shell and electronic equipment. The manufacturing method of the shell comprises the steps of carrying out hot pressing on a glass base material,and obtaining a double-curved-surface glass substrate, wherein the double-curved-surface glass substrate is provided with a first surface and a second surface which are opposite in the thickness direction, and the four corners of the double-curved-surface glass substrate are all cambered surfaces; carrying out surface pretreatment on the first surface and the second surface of the double-curved-surface glass substrate to obtain a double-curved-surface glass cover plate, the surface treatment comprising dull polish treatment; and polishing the cambered surfaces of the four corners of the double-curved-surface glass cover plate and the edges of the two opposite long edges of the first surface and the second surface, and forming gradient texture layers of a first preset color on the camberedsurfaces of the four corners and the edges of the two opposite long edges of the first surface and the second surface to obtain the shell. The shell with the edge part having the gradual change effect is formed, and the requirement of a user for the high-quality appearance of the electronic equipment shell can be met.

Owner:VIVO MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com