Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Wear soft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Active dot-matrix type flexible electrode paste device

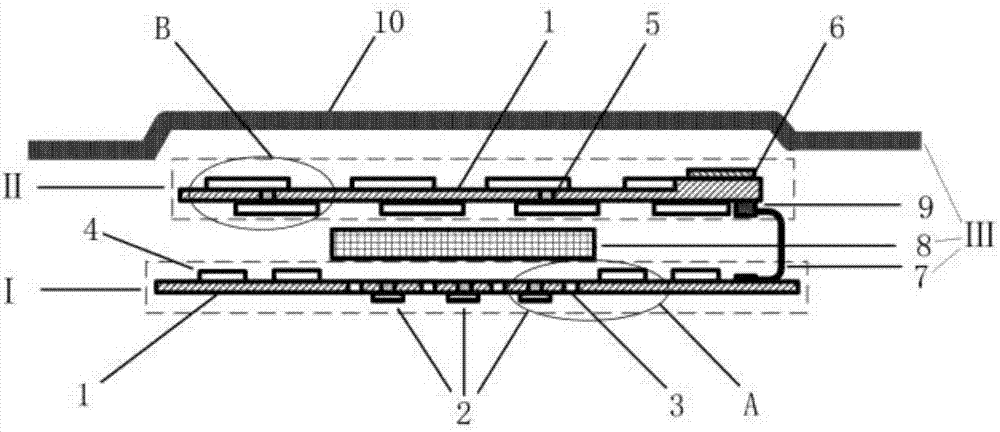

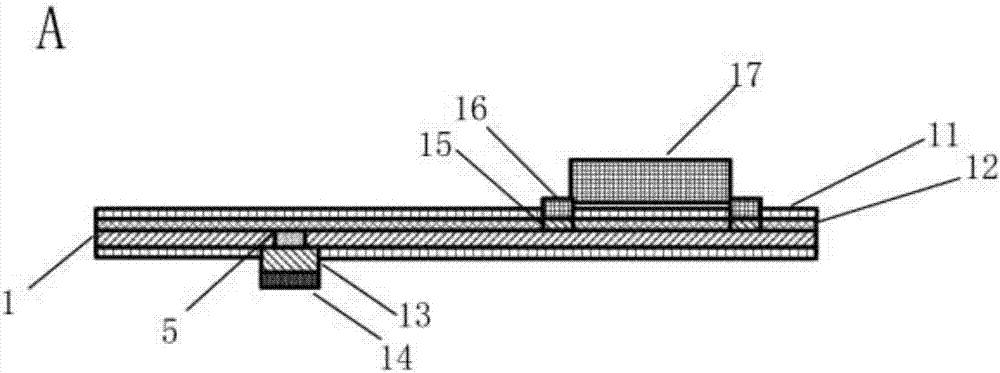

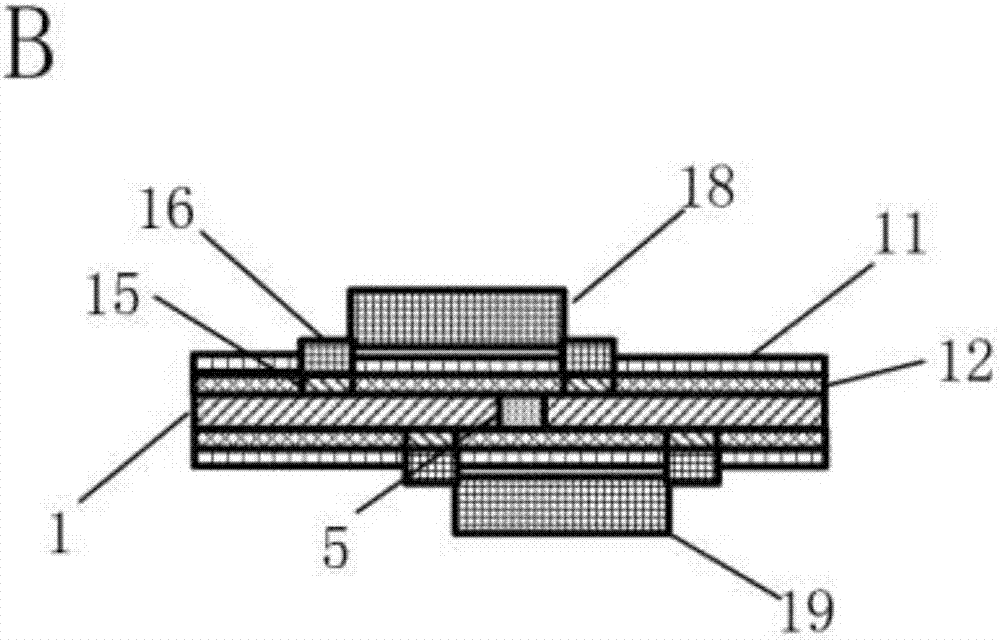

The invention discloses an active dot-matrix type flexible electrode paste device which is applied to the technical field of collecting of human body surface electrophysiological signals in the field of medical treatment and health. According to the active dot-matrix type flexible electrode paste device, a flexible dry electrode module, a signal collecting circuit system and an auxiliary assembly are integrated into a paste piece with viscosity. The flexible dry electrode module directly makes contact with the human body surface to collect human body electrophysiological signals, impedance matching is achieved through a voltage following circuit, the signal collecting circuit system conducts amplification filter and A / D conversion processing on the electrophysiological signals after impedance matching, and finally the electrophysiological signals are transmitted into a client through a wireless communication module. The device has the characteristics of convenient wearing and softness, is suitable for long-term use of 24 hours every day, and meets the requirements such as rehabilitation and diseases of human-computer interaction. A dot-matrix type electrode arrangement mode is adopted, the electrophysiological signals with the irregular muscle fiber trend or the electrophysiological signals of small muscle group parts can be collected, and multidimensional difference calculation can be realized to improve the spatial filtering effect.

Owner:SHANGHAI UNIV

Blended stain color yarn and method for making same

The present invention essentially provides a novel blended fiber segment-color yarn. The technical proposal is that a blended segment-color yarn is composed of colorful fiber and natural fiber, wherein the color fiber is any one or any combination of terylene, acrylon, regenerated cellulose fiber, natural color cotton, artificial dyed cotton and bamboo charcoal fiber; the natural fiber is pure cotton fiber or mixed fiber of cotton fiber and any other fiber; the colorful fiber and the natural fiber are blended and twisted after cotton cleaning, cotton combing and drawing. The yarn has the advantages of rational structure, simple processing, moderate fiber fracture strength, high extensibility, fine spinning and weaving property, etc. With the excellent moisture absorption of natural fiber and the good moisture conductivity of synthesized fiber, clothes made of the yarns feel soft and are gas-permeable.

Owner:浙江云山纺织印染有限公司

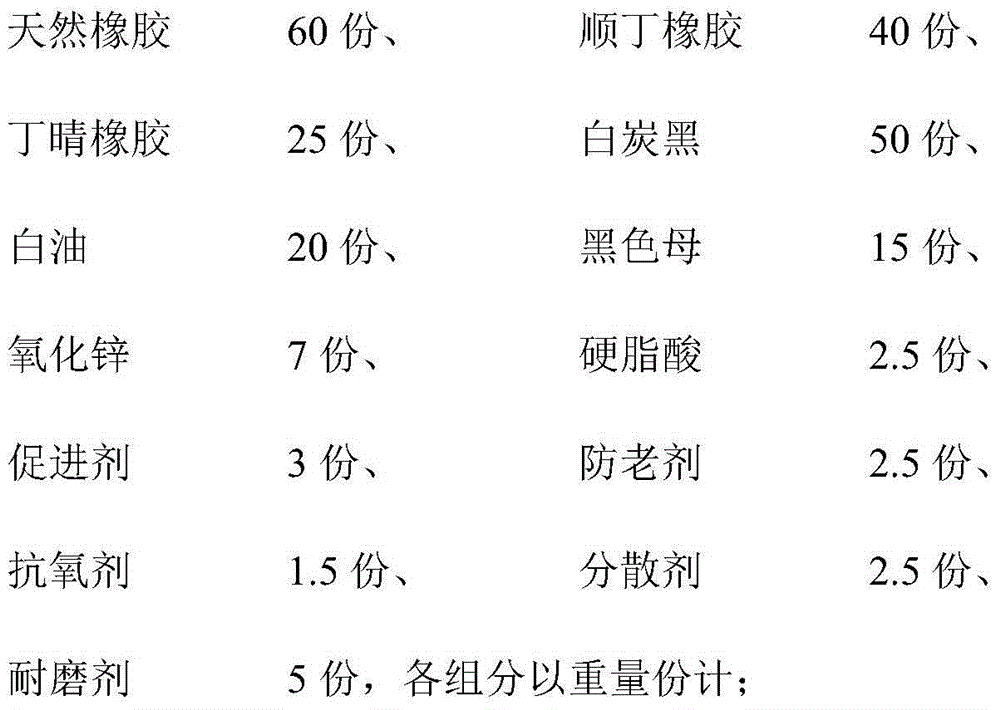

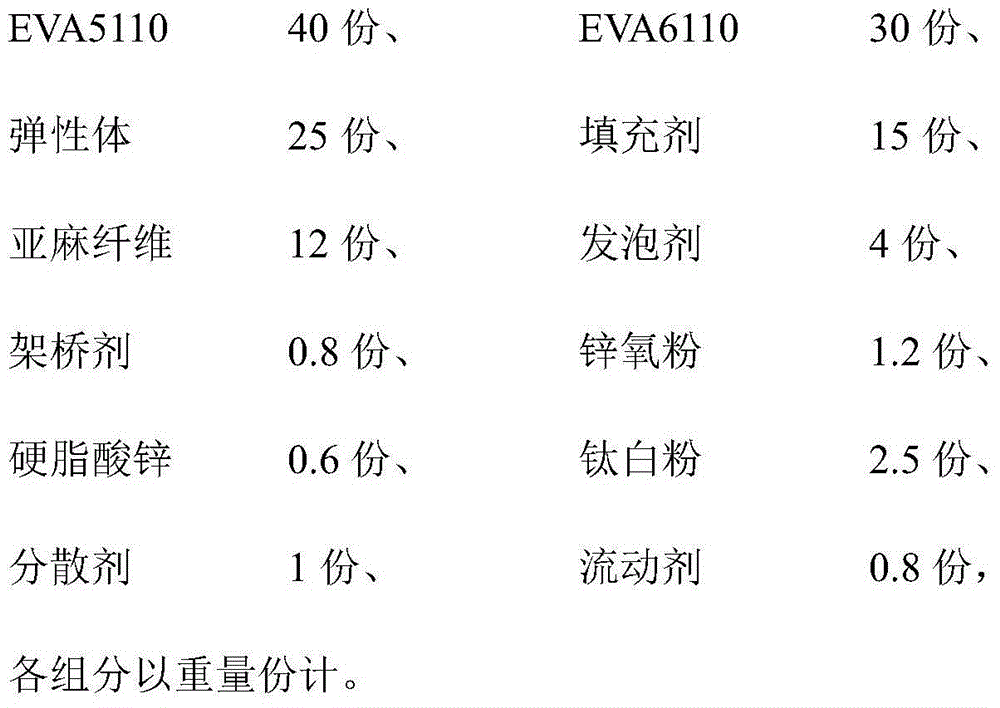

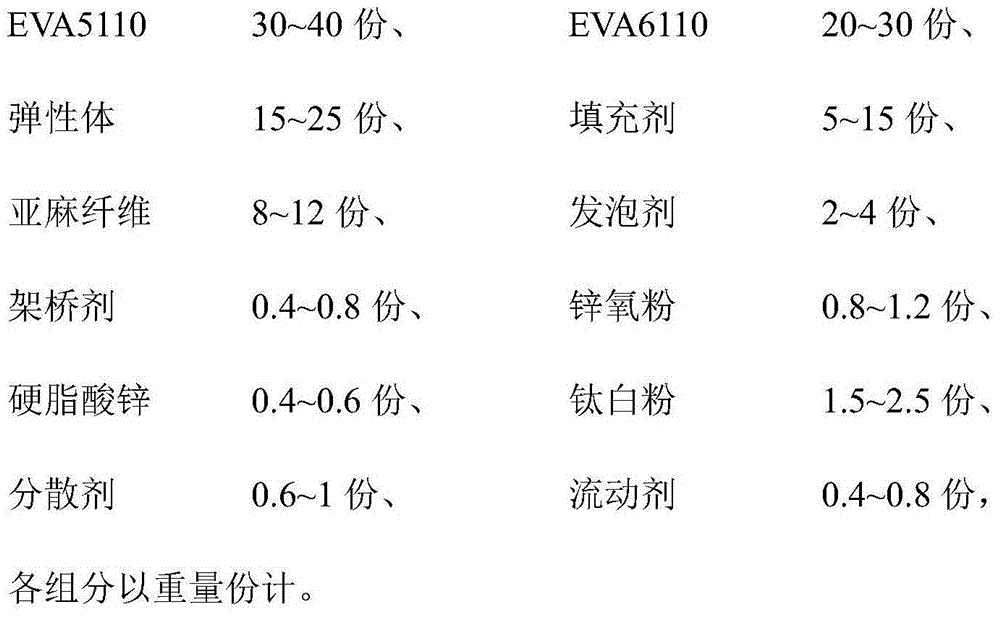

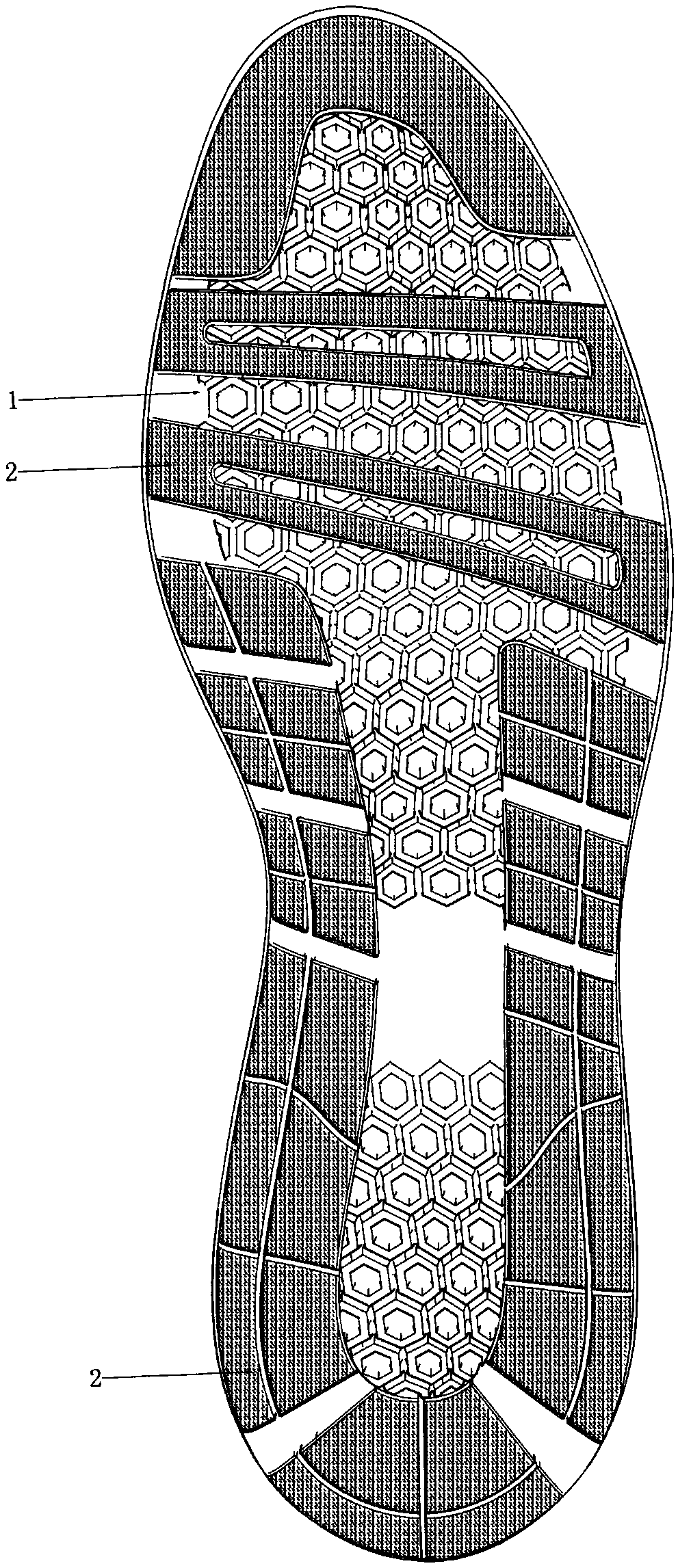

Composite sole combined by natural rubber and EVA and preparation process thereof

ActiveCN104788741AMeet high-intensity training requirementsHigh tear strengthSolesDomestic footwearElastomerAcrylonitrile

The invention discloses a composite sole combined by natural rubber and EVA; a rubber outsole comprises the following components in parts by weight: 50 parts of natural rubber, 30 parts of cis-1,4-polybutadiene rubber, 20 parts of butadiene-acrylonitrile rubber, 45 parts of white carbon black, 15 parts of white oil, 10 parts of a black color masterbatch, 5 parts of zinc oxide, 2 parts of stearic acid, 2.5 parts of an accelerant, 2 parts of an anti-aging agent, 1 part of an antioxidant, 2 parts of a dispersant, and 4 parts of a wear-resisting agent. An EVA midsole comprises the following components in parts by weight: 35 parts of EVA5110, 25 parts of EVA6110, 20 parts of an elastomer, 10 parts of a filler, 10 parts of a flax fiber, 3 parts of a foaming agent, 0.6 part of a bridging agent, 1 part of a zinc-oxide powder, 0.5 part of zinc stearate, 2 parts of titanium dioxide, 0.8 part of a dispersing agent, and 0.6 part of a flowing agent. The sole not only has quite high tearing strength, but also is soft, portable and comfortable and keeps high elasticity when the sloe is worn.

Owner:NANJING DONGYA RUBBER & PLASTICS

Regenerated skin-core structure composite fiber and preparation method thereof

ActiveCN103789873ASolve spinning difficultiesSolve the comfortFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterPolymer science

The invention discloses a regenerated skin-core structure composite fiber and a preparation method thereof. An intermediate, namely, BHET is prepared by performing a chemical depolymerization reaction on recycled polyester by using a chemical regeneration method, and a core-layer structure is constructed by preparing nano-composite regenerated polyester through an in-situ polymerization method. A core-layer anti-ultraviolet agent is dispersed uniformly by being added at a low temperature, and the content is over 3 percent, so that the phenomena of breakage of the fiber and low overhanging factor of a fabric in a preparation process due to over high content of the anti-ultraviolet agent are avoided. Moreover, a skin-core structure interface contains a small amount of polyether produced by excessive ethylene glycol in a depolymerization process, so that a skin-core polymer can be relatively well combined, and the physical property of the skin-core polymer is relatively higher than that of a purely-regenerated full dull fiber. A fabric woven by using the prepared regenerated skin-core composite fiber is soft, comfortable, pendent, stiff, smooth and high in ultraviolet resistance. The regenerated skin-core structure composite fiber is an optimal fiber suitable for high-quality fashionable clothing, health care and sports clothes.

Owner:SHENGHONG GRP CO LTD

Soft and comfortable blended shell fabric

The invention discloses a soft and comfortable blended shell fabric. The soft and comfortable blended shell fabric is formed by blending and weaving high moisture-absorption cotton-like polyester filament yarn fibers, apocynum venetum fibers, kapok fibers and imported long linter fibers. The soft and comfortable blended shell fabric comprises, by weight, 17% to 21% of the high moisture-absorption cotton-like polyester filament yarn fibers, 25% to 29% of the apocynum venetum fibers, 30% to 34% of the kapok fibers and 16% to 28% of the imported long linter fibers. The soft and comfortable blended shell fabric is formed by blending and weaving the high moisture-absorption cotton-like polyester filament yarn fibers, the apocynum venetum fibers, the kapok fibers and the imported long linter fibers, and the woven shell fabric is soft in touch and comfortable to wear, and has the advantages of being capable of absorbing moisture, breathable, cool, thermal, good in drapability and resistant to wear.

Owner:刘喜

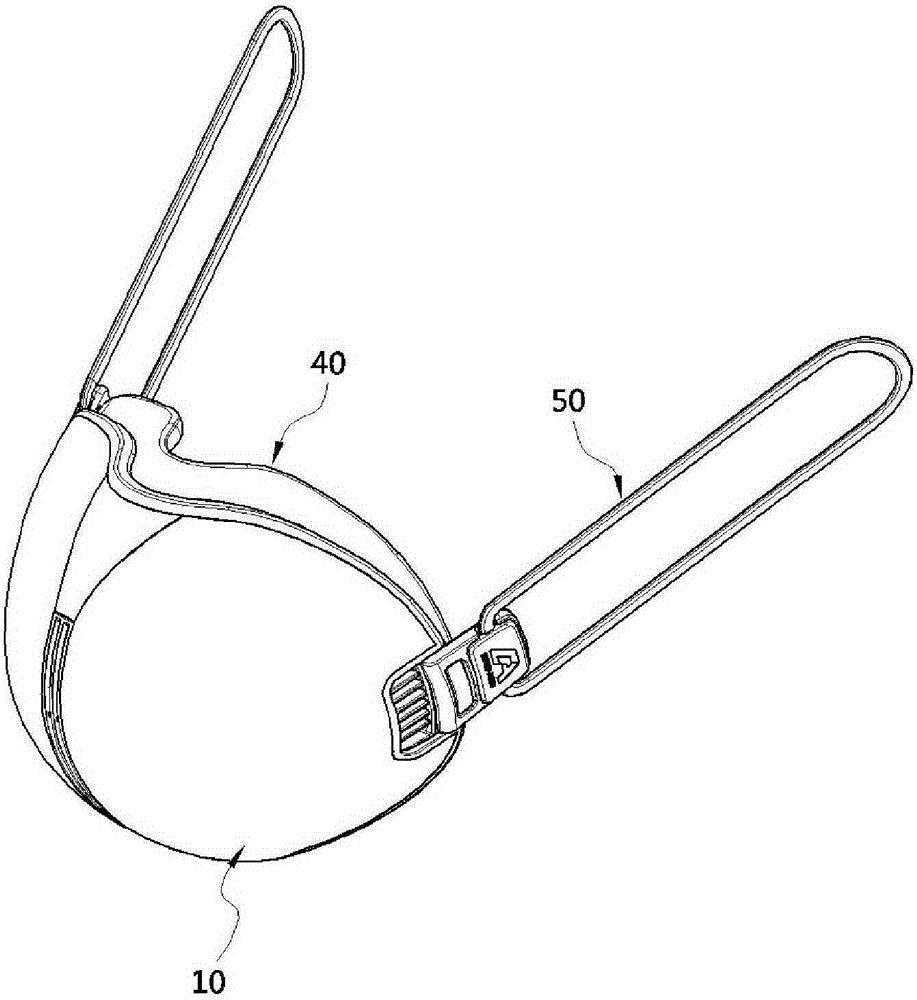

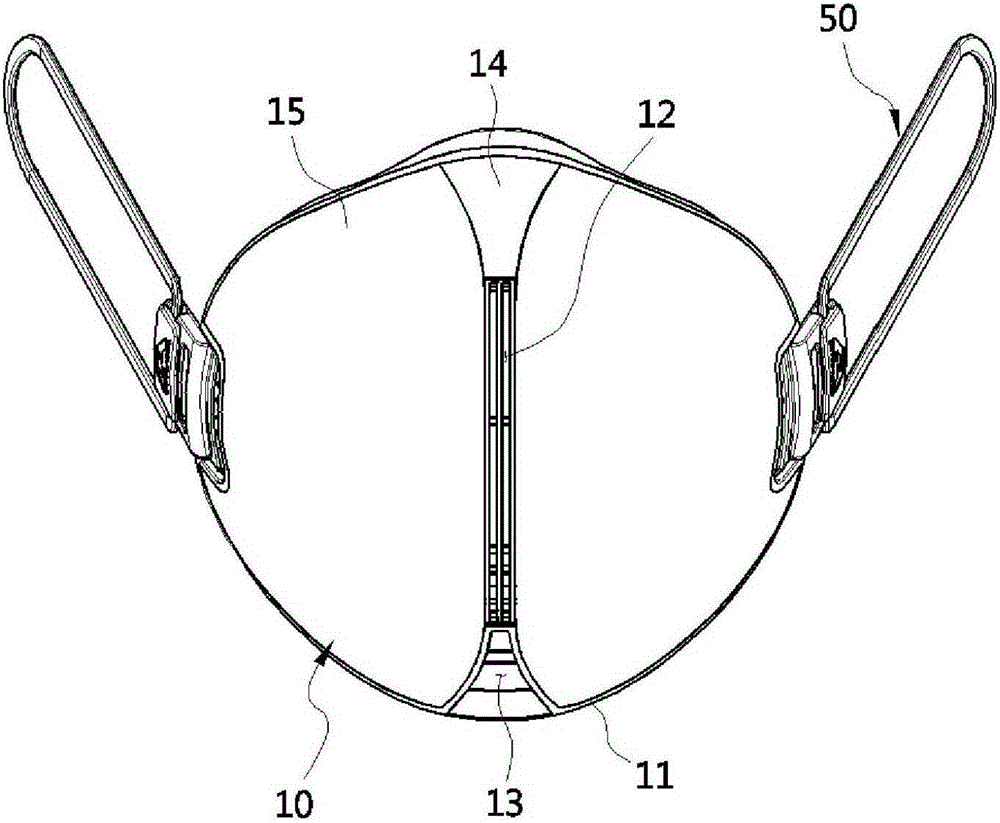

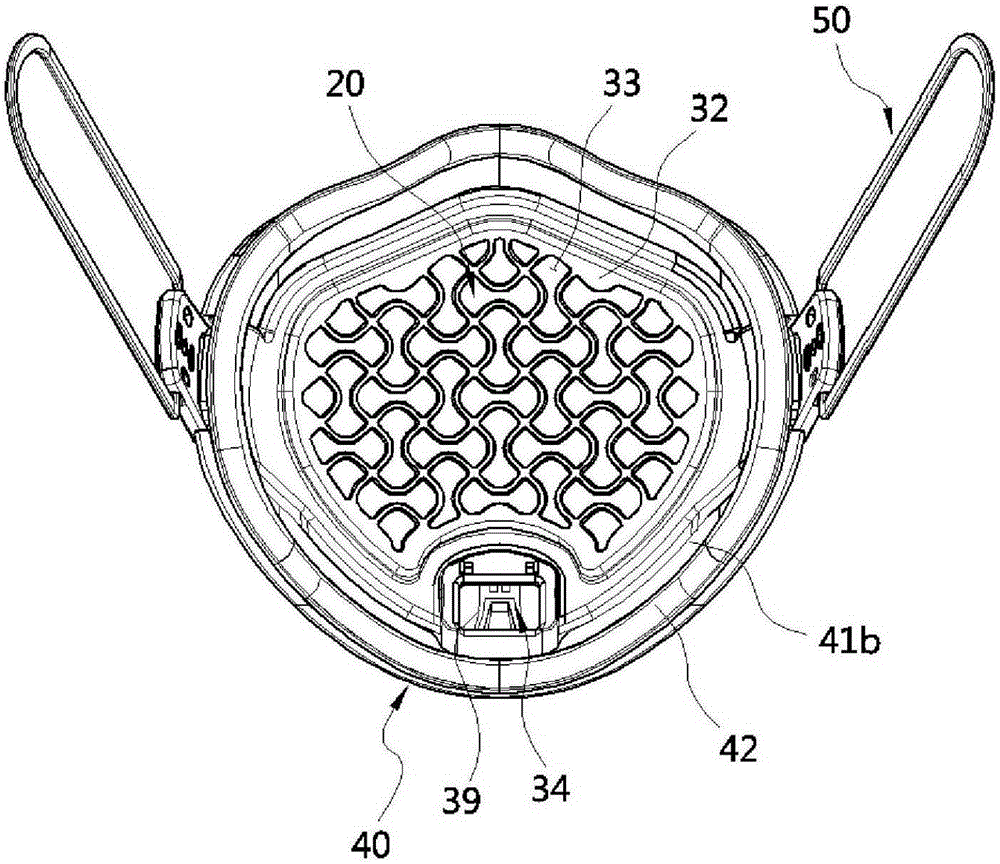

Portable mask

The invention relates to a portable mask and more specifically to a portable mask which make it easy to carry the portable mask, easy to replace a filter, and easy to do outdoor activities, such as exercises or walks, with the portable mask outdoors. The portable mask is characterized by comprising a front mask; a back mask for fixedly installing the front mask; a filter inserted between the front mask and the back mask for filtering foreign matters; a facing portion inserted into the back side of the back mask to cover the nose and the mouth of a wearer; and an ear-hanging portion installed on both sides of the back mask to be hanged over the ears of the wearer.

Owner:CNTUS SUNGJIN

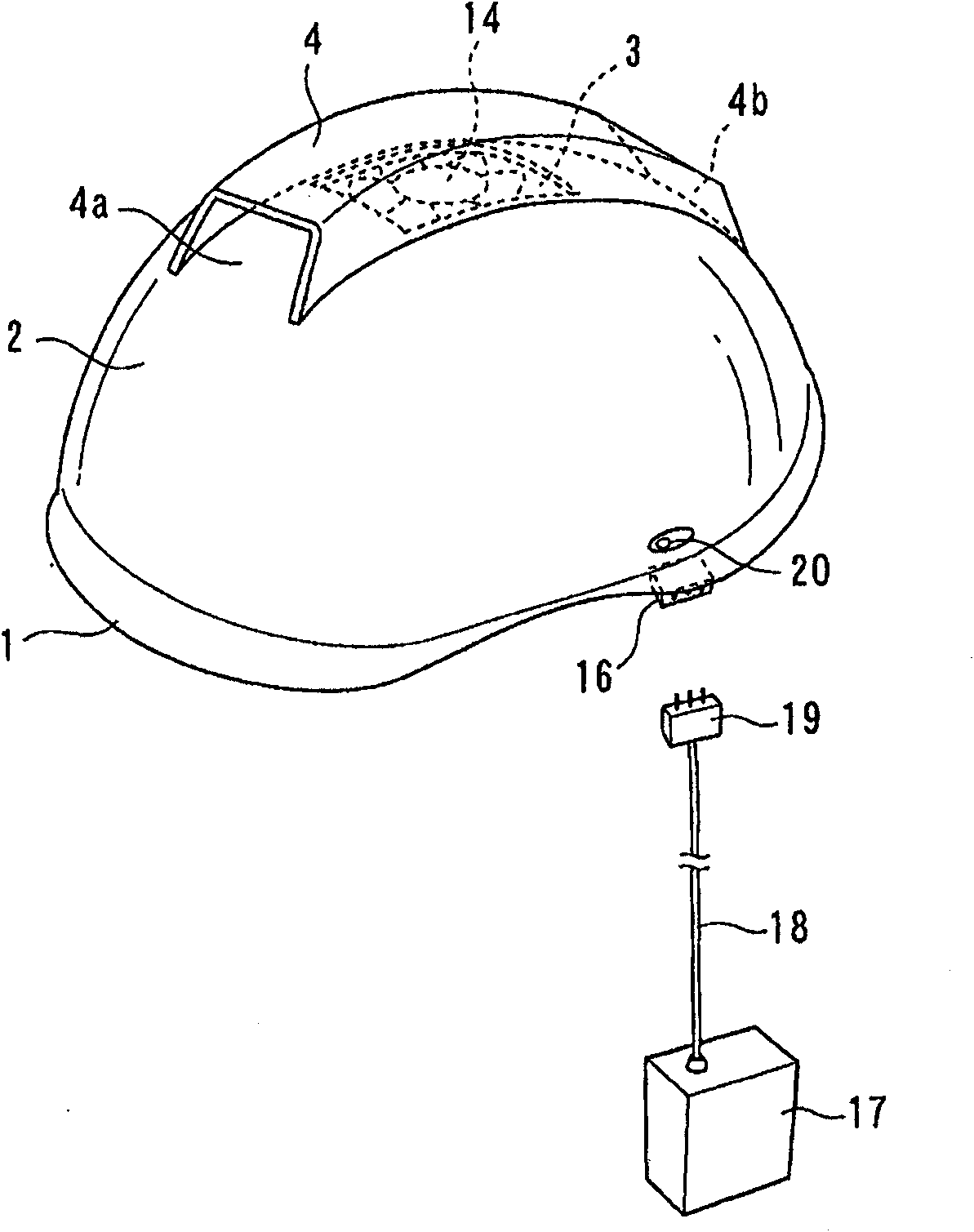

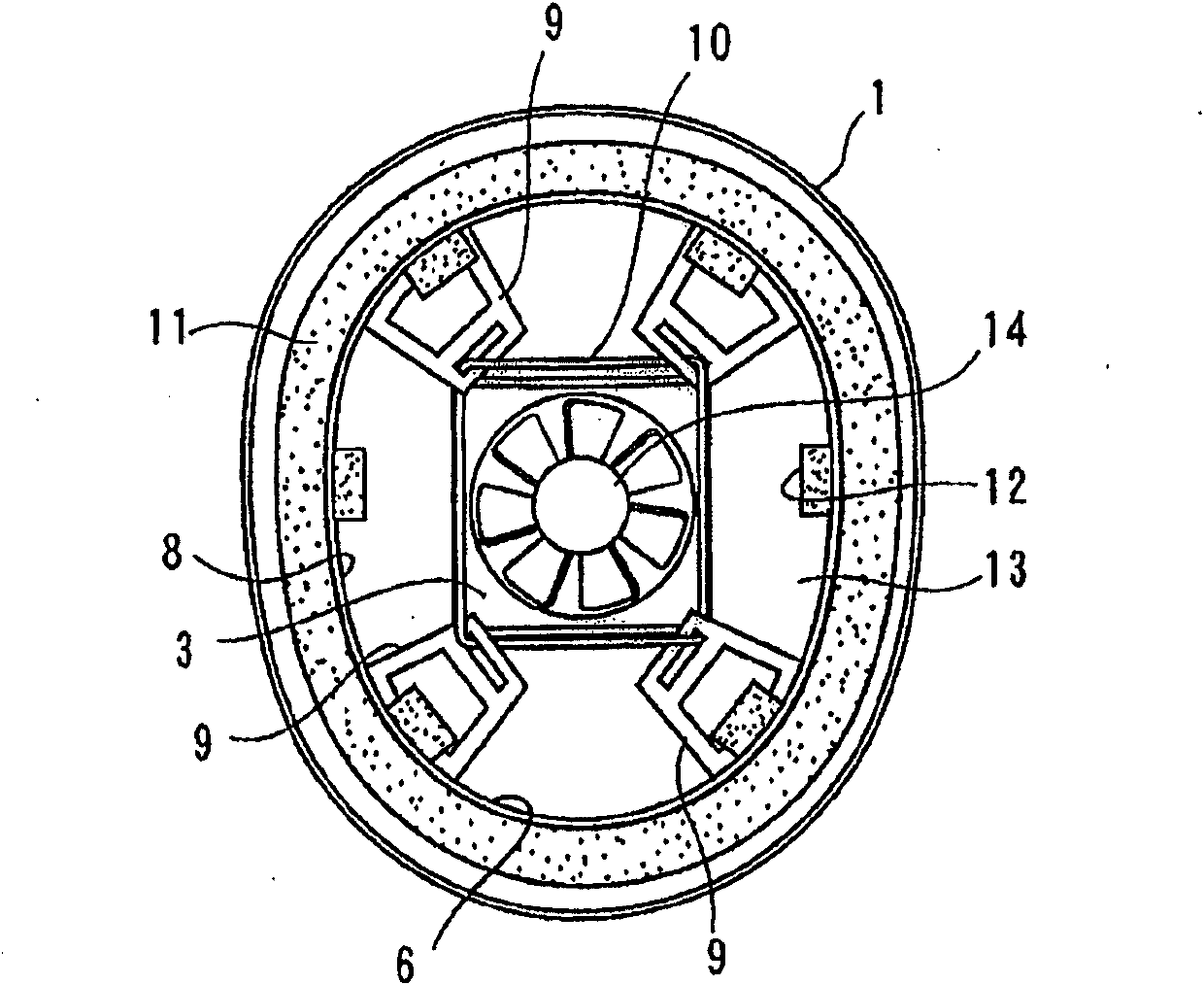

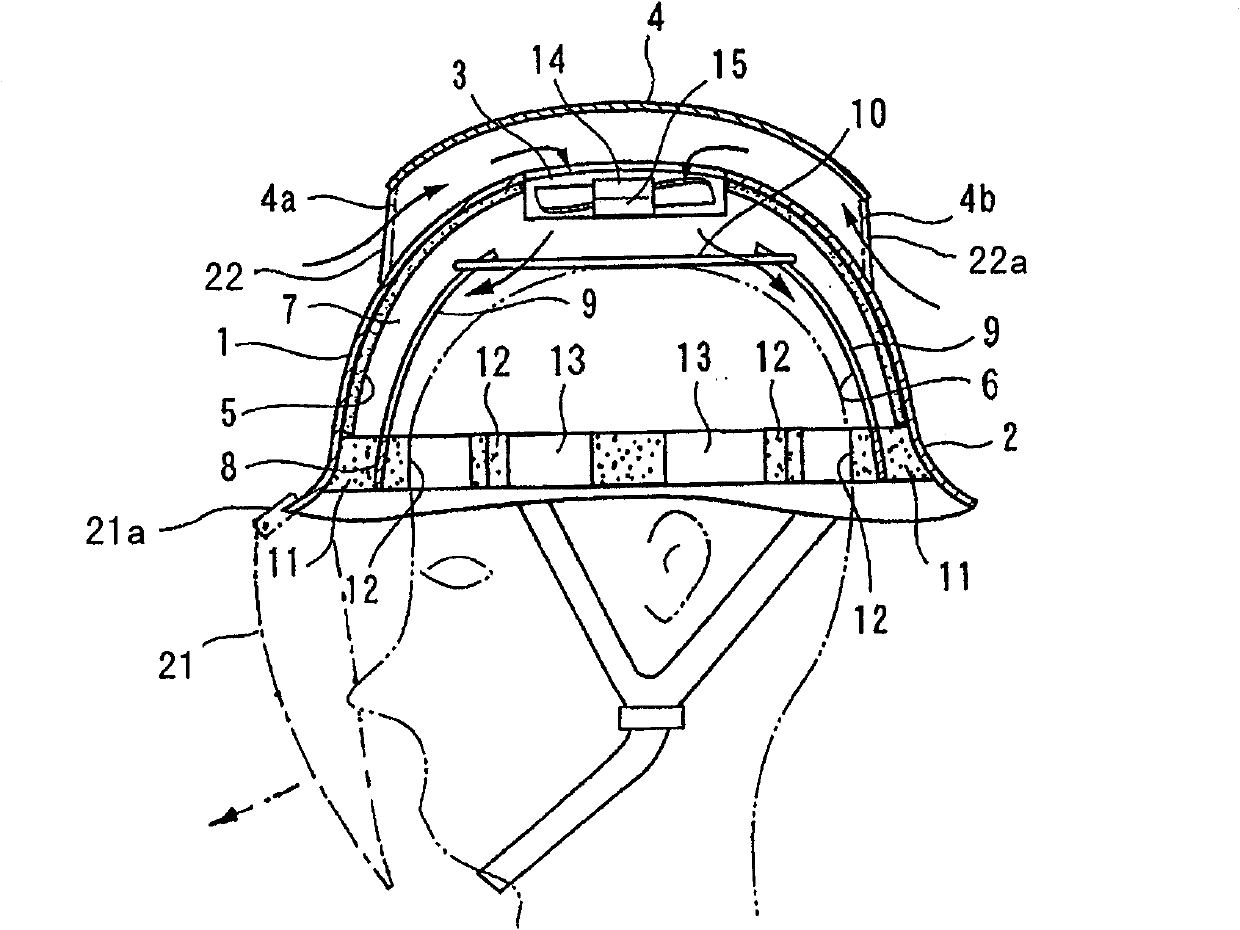

Air-cooled helmet

InactiveCN102197895AAvoid temperature riseOptional air cooling effectHelmetsHelmet coversEngineeringScalp

The invention provides an air-cooled helmet which has the advantages of strong practicability and small noise load. In the invention, an air suction port (3) is arranged on the top part of the helmet body (1); an air supply fan (14) is arranged inside the air suction port (3); an air guide housing (4) is arranged outside the air suction port (3); a sound absorption component (5) is formed on the inner surface of the helmet body (1); a blocking component (11) is filled between a supporting frame (8) and the helmet body (1) so as to separate air flowing out of the position so that the supplied air is concentrated at a scalp side; and then a power terminal (16) of the air supply fan (14) is arranged at one part of the helmet body (1) so that a terminal (19) of a power line (18) which extends from a portable cell (17) is connected with the power terminal (16) for power supply.

Owner:新保 佑幸

Silk blend-fiber fabric

The invention discloses a silk blend-fiber fabric. The silk blend-fiber fabric is woven through mulberry silk fiber, tussah silk fiber, castor silk fiber and cassava silk fiber in a blended manner. The fabric fiber components of the silk blend-fiber fabric include, by weight percentage: 45% to 49% of the mulberry silk fiber, 18% to 22% of the tussah silk fiber, 13% to 17% of the castor silk fiber and 12% to 22% of the cassava silk fiber. The fabric is woven through the mulberry silk fiber, the tussah silk fiber, the castor silk fiber and the cassava silk fiber in the blended manner and has the advantages that the fabric is soft, cool and comfortable to wear, heat insulation is achieved, skin is nourished, human health is promoted, static electricity is resisted, and pests are controlled.

Owner:TAICANG XINTAI KNITTING

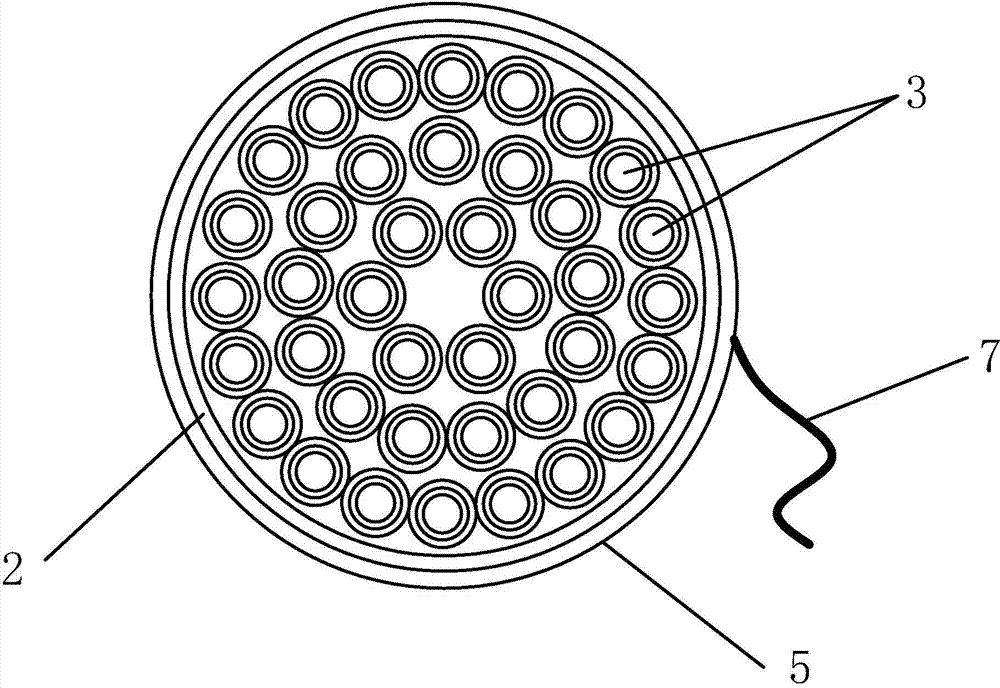

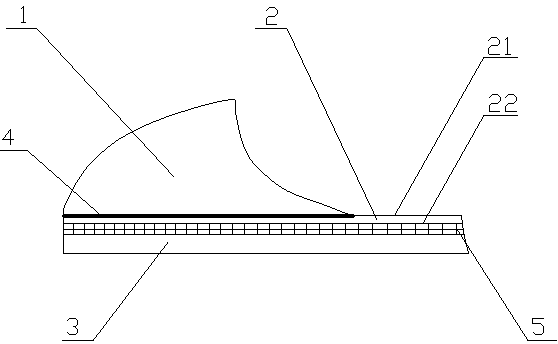

Dry soft electrode based on direct-current magnetron sputtering technology and manufacturing process thereof

ActiveCN103876737ALower impedanceGood chemical stabilityVacuum evaporation coatingSputtering coatingBiochemical engineeringDirect current magnetron sputtering

The invention relates to the field of medical instruments, in particular to a dry soft electrode based on a direct-current magnetron sputtering technology. The dry soft electrode comprises a substrate, the substrate comprises a base and a plurality of needle electrodes arranged on the base, a conducting plate is arranged at the bottom of the base, the conducting plate is provided with a conducting line, the conducting plate and the base of the substrate are closely connected through a die sleeve, and the die sleeve is provided with a hole allowing the conducting line to pass through. The surface of the base is plated with a conducting layer. The invention further provides a manufacturing method of the dry soft electrode based on the direct-current magnetron sputtering technology. The dry soft electrode and the manufacturing method have the advantages that the reliability and sensitivity of brain signal collection are good; the coating of the electrode is high in adhesive force, even in attachment, and controllable in thickness and color; the electrode is soft, and good in comfort; ingenious structural design is achieved.

Owner:BRAIN HOMECARE ELECTRONICS TECH CO LTD

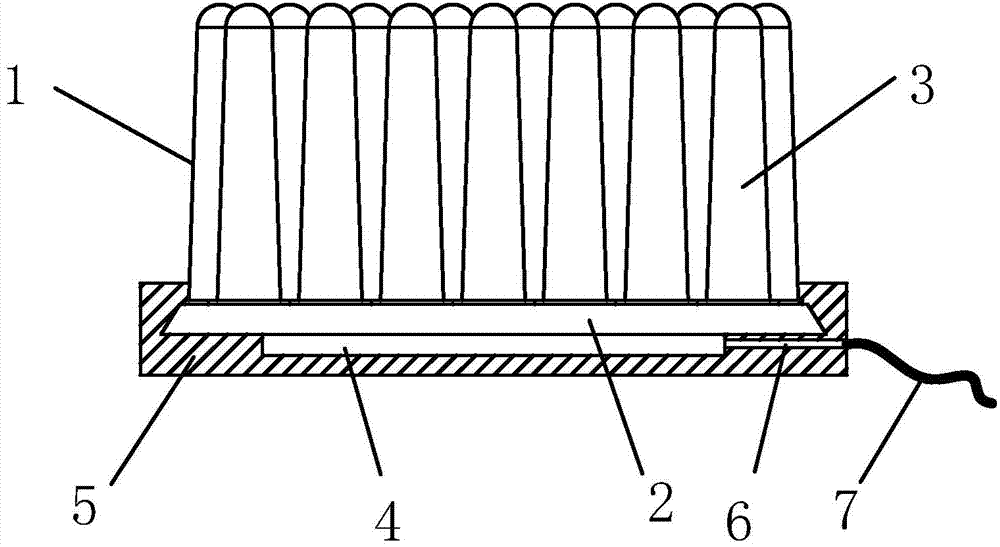

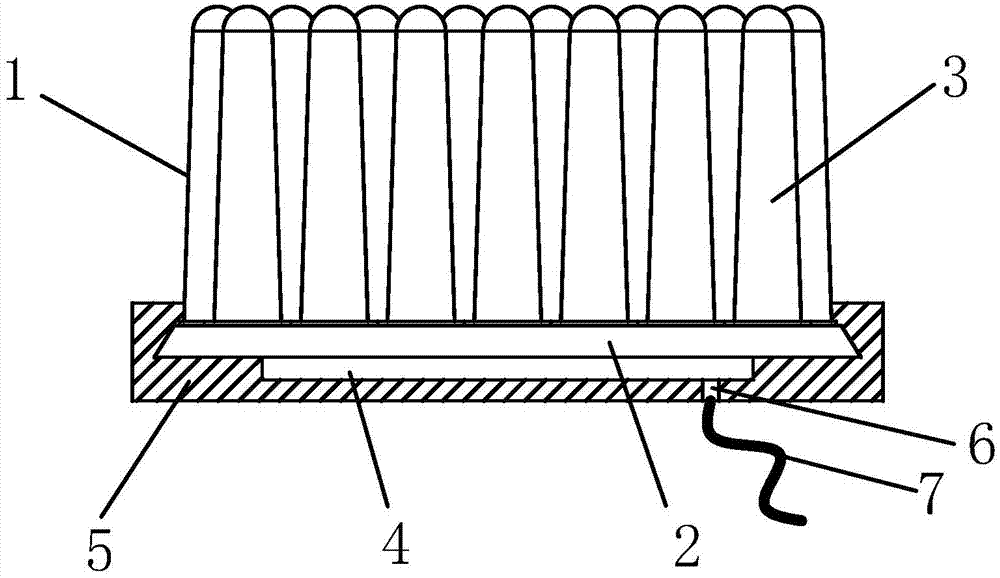

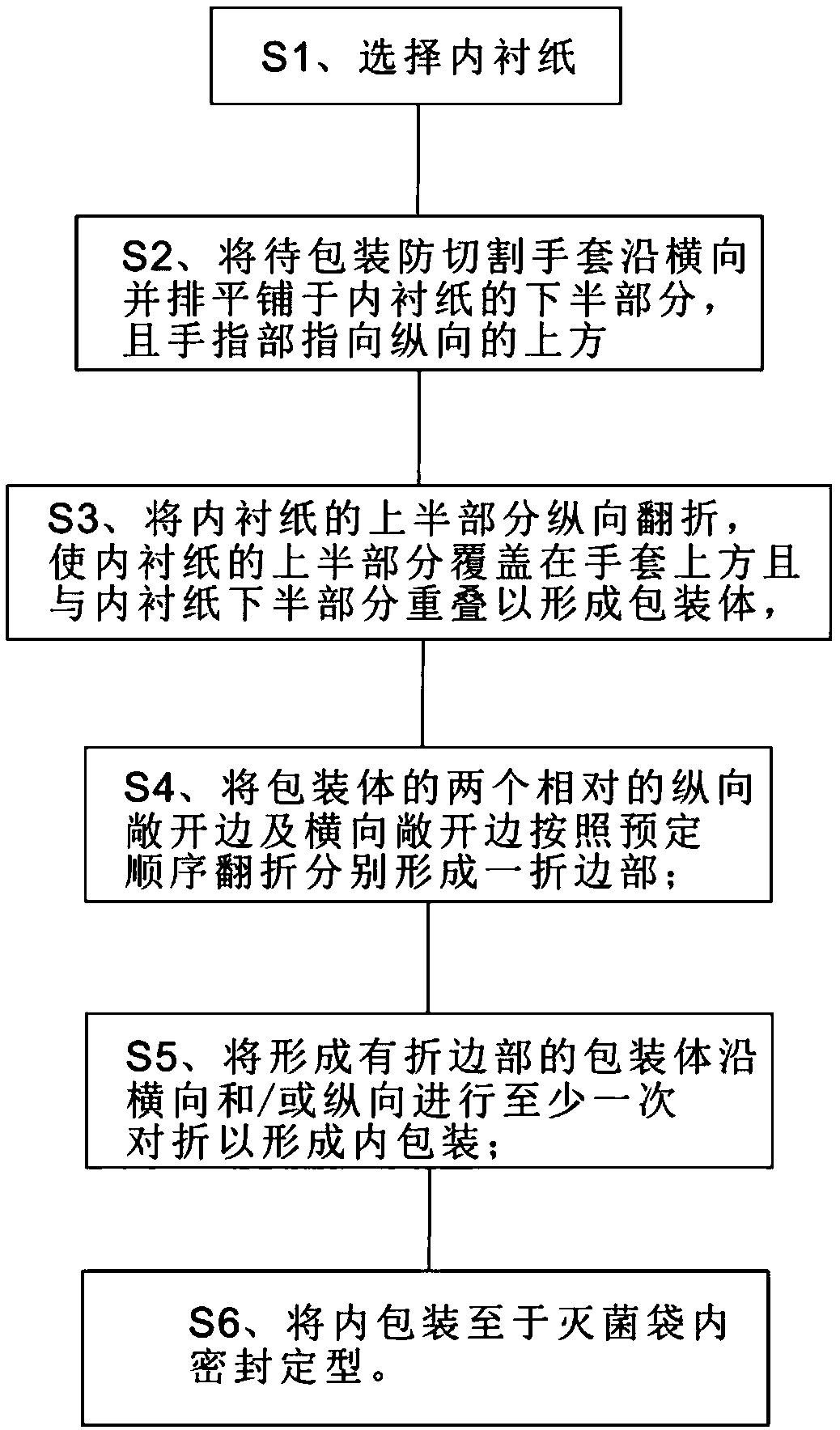

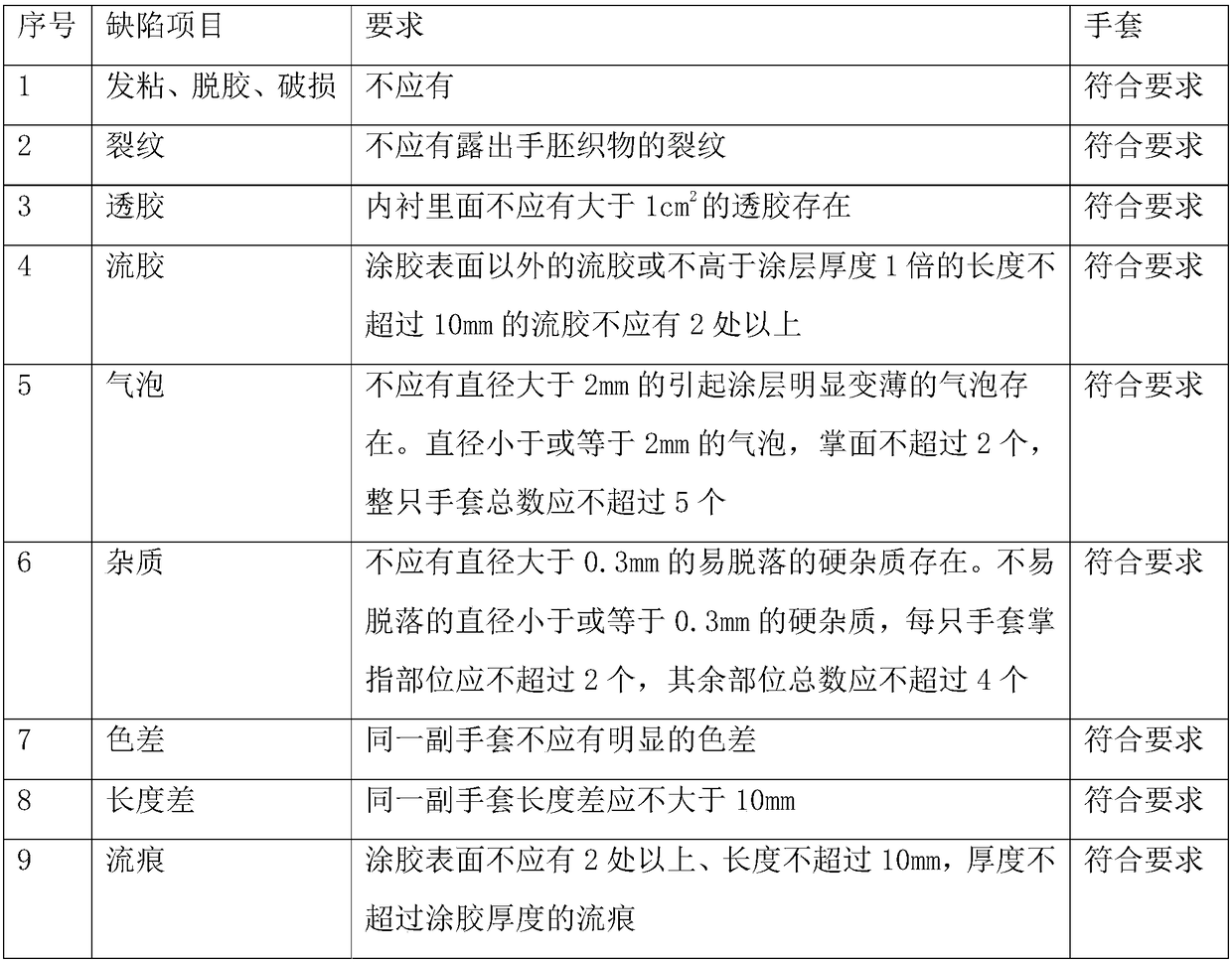

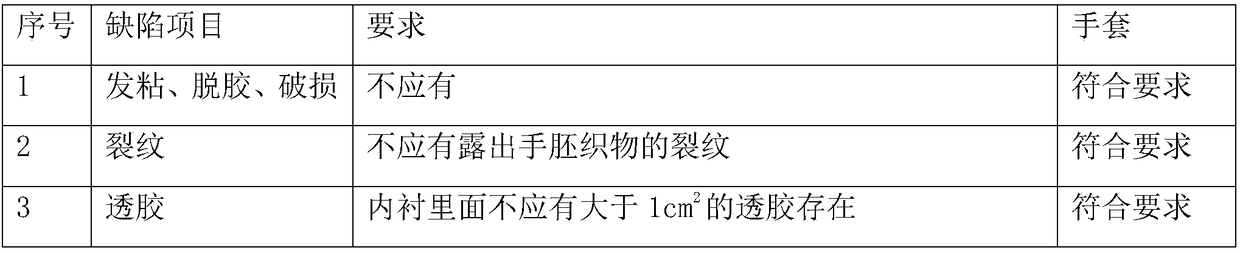

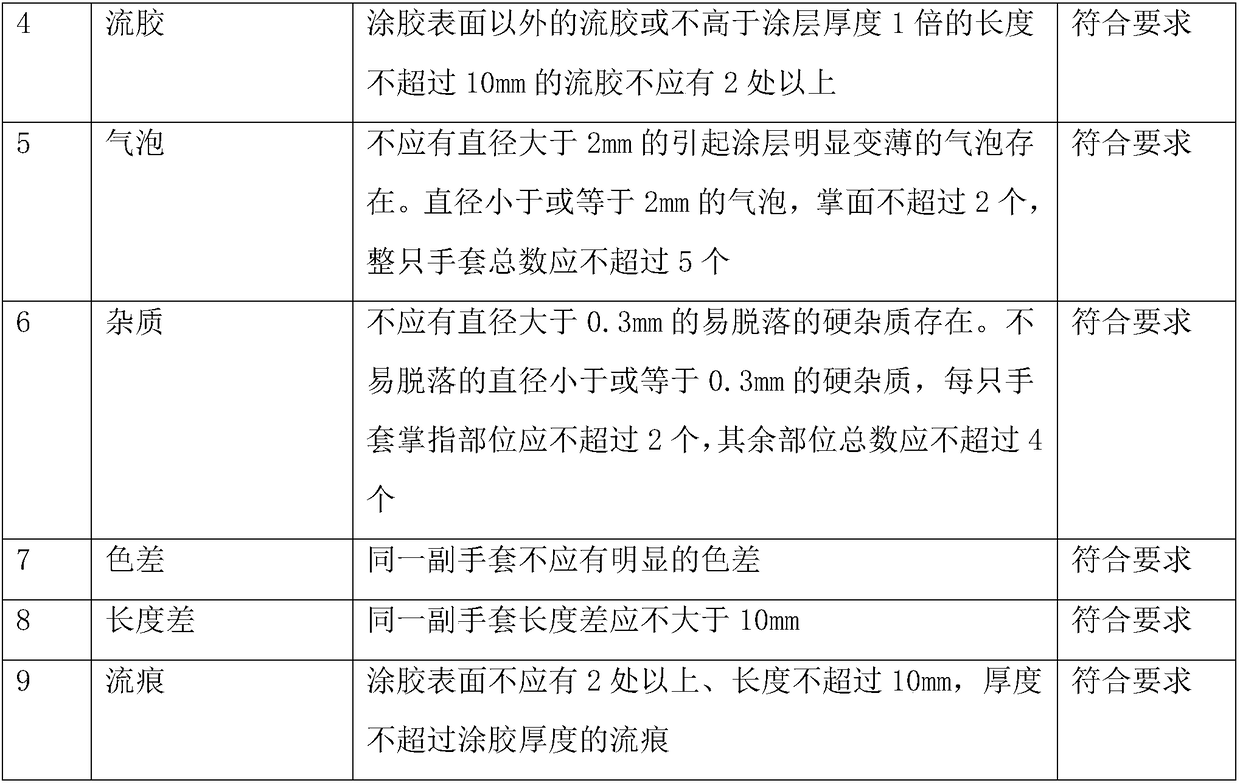

Anti-cutting glove and packaging method thereof

InactiveCN108978013AImprove cut resistanceWon't failWeft knittingWrapper folding/bending apparatusYarnPolyvinyl chloride

The invention discloses an anti-cutting glove and a packaging method thereof and belongs to the technical field of work gloves. The anti-cutting glove is made by knitting yarns which are one or any ofpolyethylene / aramid fiber, polyethylene / aramid fiber / steel wire, PVC-coated (polyvinyl chloride-coated glass fiber spandex yarn, and steel wire; the yarns are knitted into a glove core by an automatic glove knitter; the outside of the glove core is provided with a polymer coating by dipping; the polymer coating is one or a combination of butyronitrile rubber latex, polyurethane and rubber. The anti-cutting glove has excellent cutting protection which is far higher than provisions of national standard of China and European Union standards, has good flame retardance and excellent thermal protection, is light in weight and flexible to wear, and is good in wear resistance, low in production cost and high in batch production efficiency.

Owner:花春丽

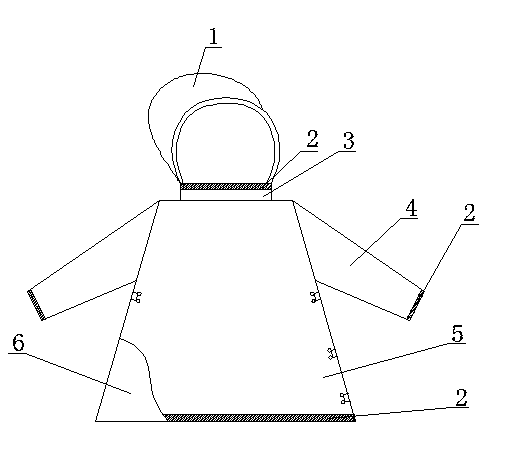

Omni-directional protection type CT (computed tomography) protective garment

InactiveCN103700415AAdjustable widthIncrease widthShieldingRadiation safety meansComputed tomographyTungsten

The invention provides an omni-directional protection type CT (computed tomography) protective garment which comprises a body. The omni-directional protection type CT protective garment is characterized in that the body comprises a front part and a back part which are one-piece, and a length adjusting mechanism is arranged between the front part and the back part; sleeves are detachably connected to two sides of the body, the upper portion of the body is connected with a collar, the upper potion of the collar is detachably connected with a cap, reinforced protective belts are arranged on opening portions of the sleeves and the collar and at the bottom end of the body, and the end portions of the reinforced protective belts are tightened by elastic bands. A user wearing the omni-directional protection type CT protective garment can be protected in omni-directional manner, and X-ray blocking rate reaches 99%; meanwhile, the omni-directional protection type CT protective garment is made of micro lead alloy and multiple elements of tungsten, bismuth and tin, so that weight of the protective garment is reduced, and harm of lead to humans and environment is reduced.

Owner:滨州医学院附属医院

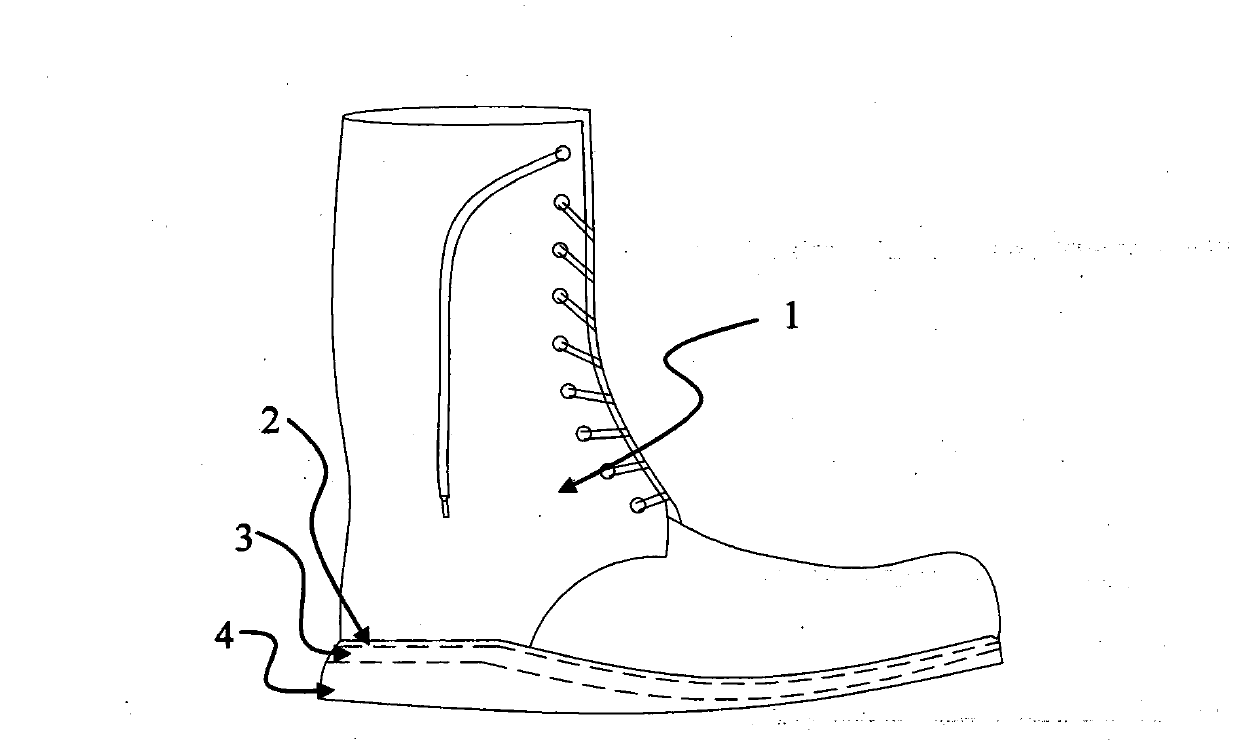

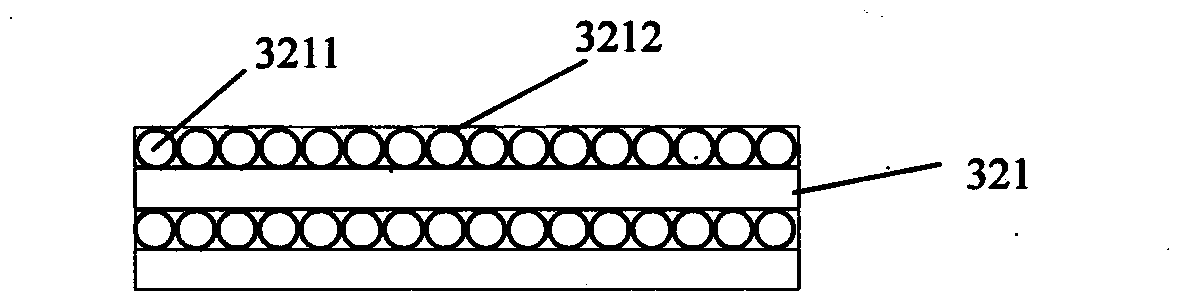

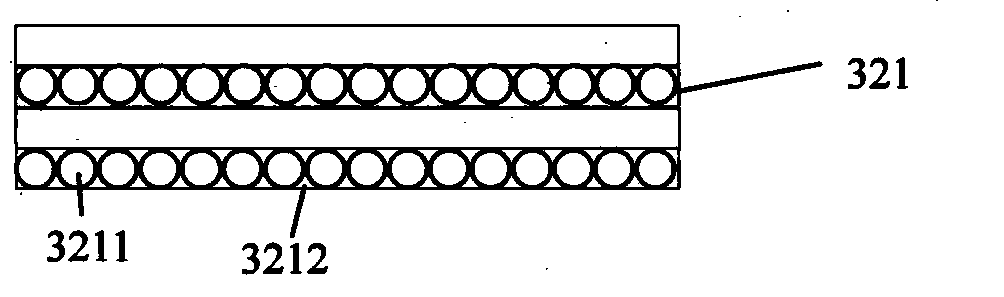

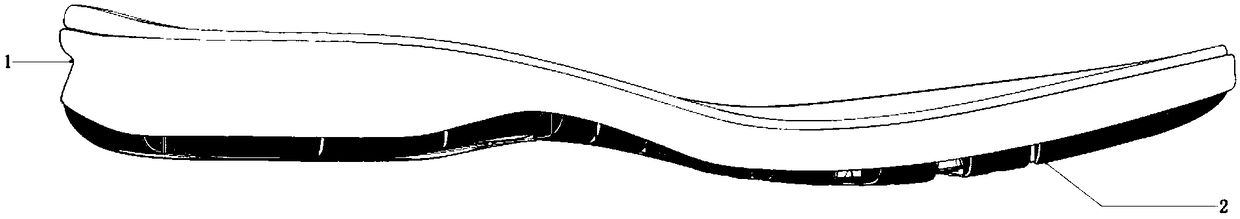

Flexible and high-energy-absorbing stab and cut resistant shoe sole

The invention relates to a flexible and high-energy-absorbing stab and cut resistant shoe sole, comprising an innersole, a stab resistant composite layer and an outer sole, wherein the innersole is made of flexible material capable of being directly dressed to the skin; the stab resistant composite layer is composed of woven fabric layers, non-woven fabric layers and limiting layers; the stable forms of the woven fabric layers and the non-woven fabric layers made of high performance fibers are achieved by the limiting layers made of metal grids; the woven fabric layers and the non-woven fabric layers are in multi-layer stacking in a crossed laying manner, so that the stab resistance of the shoe sole in various directions is improved; the woven fabric layers and the non-woven fabric layers are fixed by sewing threads so as to improve the flexibility; the outer sole is made of high-hardness wear-resisting resin, and is provided with grains on the surface for achieving the non-skid property; the innersole, the stab resistant composite layer and the outer sole are formed through bonding by bond. The flexible and high-energy-absorbing stab and cut resistant shoe sole is simple, convenient and effective to produce, easy to bend and low in cost, has the function of high energy absorbing, and can effectively protect the sole of the foot from stab damage.

Owner:DONGHUA UNIV

Viscose mercerized cloth production process

The invention discloses a viscose mercerized cloth production process. The viscose mercerized cloth production process sequentially includes production procedures of cloth distribution, cloth loosening, pre-setting, double-sided singeing, mercerizing, neutralizing, selvedge sewing, dyeing, dewatering, in-process inspection, scotching, setting and QC (quality control) finish inspection. The viscose mercerized cloth production process is mainly innovative in after-finishing processing, and by means of mercerization for innovation, high fitness, high comfort, pilling resistance and surface glossiness of cloth are realized. Mercerized cloth produced according to the viscose mercerized cloth production process has advantages of high surface glossiness, low hairiness, comfort in touching and wearing, excellent pilling resistance, high moisture absorptivity, softness, excellent draping property, high fitness and the like.

Owner:FOSHAN DONGCHENG LIYI TEXTILE CO LTD

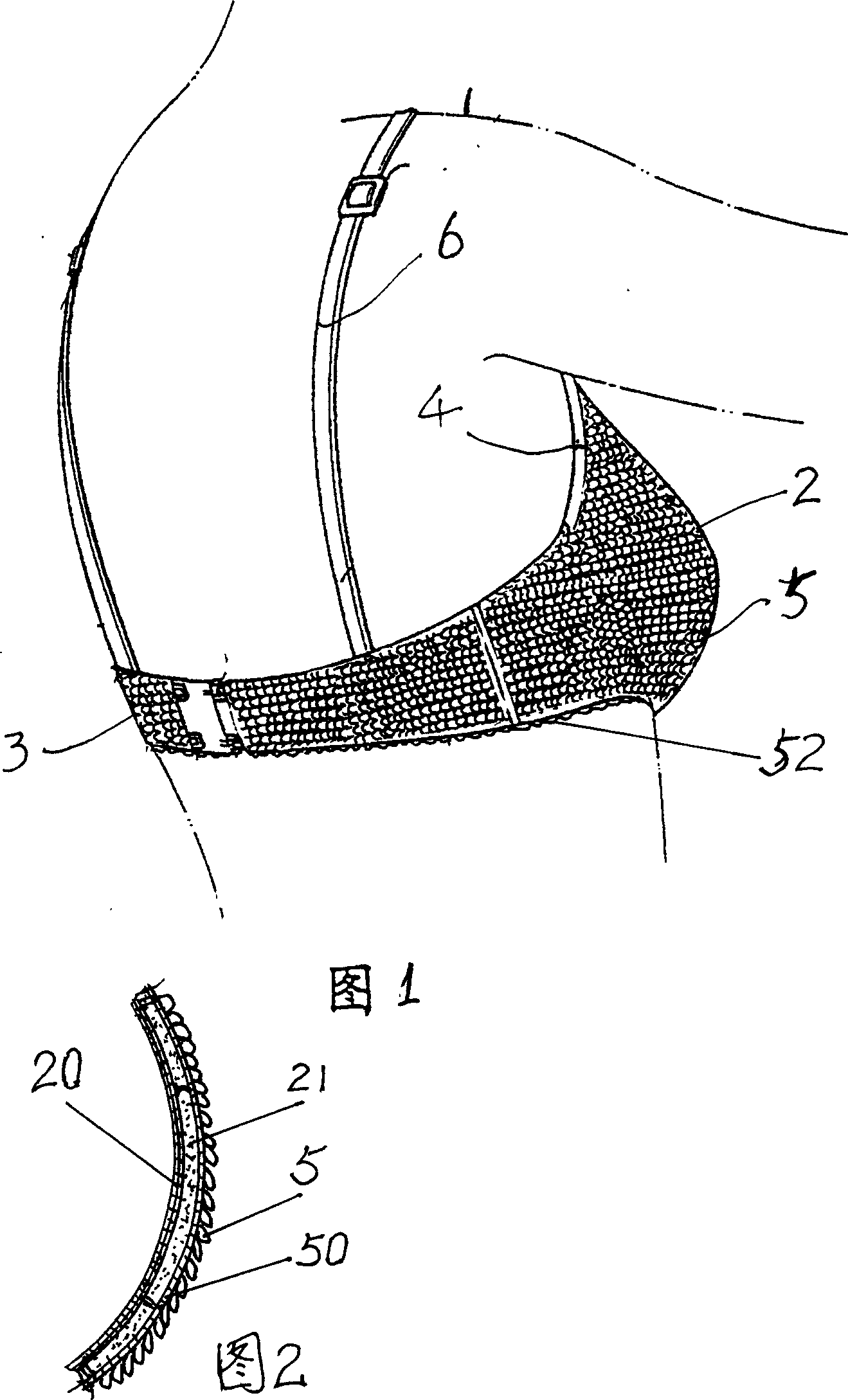

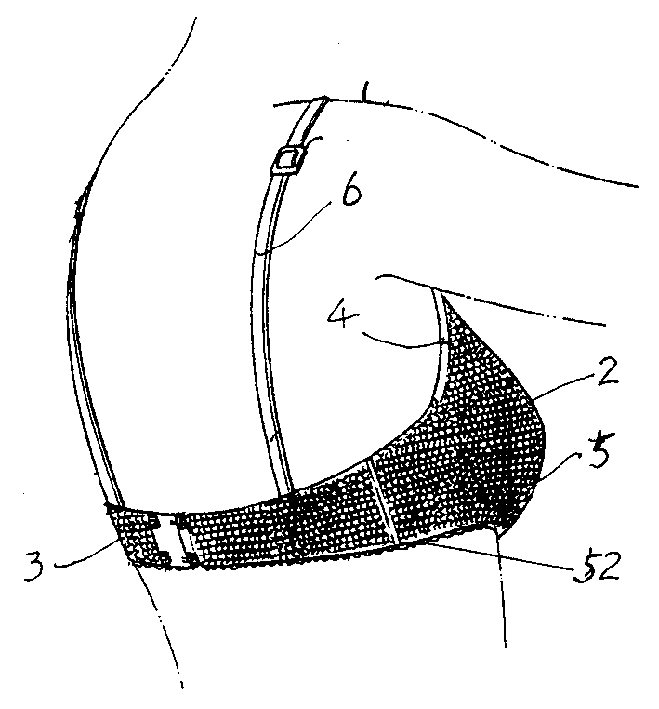

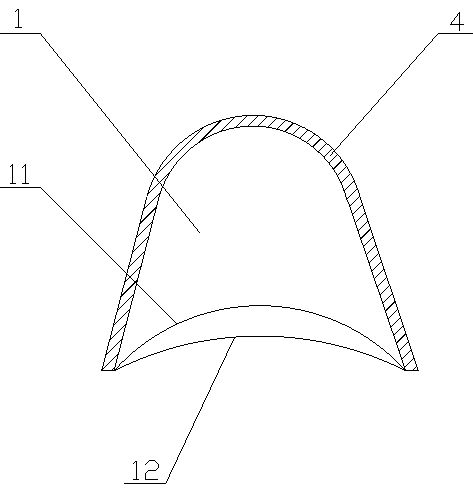

Plush loop bra

InactiveCN1504132ASimple structureReasonable structureBrassieresMedical devicesEngineeringMoisture absorption

The invention relates to a towel brassiere using towel or other fabrics alike which comprises a brassiere cup, a shroud band and a brace, wherein the near sides of the two brassiere cups are connected together, the shroud band is arranged on the outer end, and a tower fabric with at least one surface covered uniformly by curls is applied by the brassiere cup. The advantages of the invention are simple arrangement, low cost of manufacture, comfort in wearing, and good moisture absorption and air permeability property.

Owner:黄文义

Spinning fine spinning blended by milk fibre

The invention relates to a spinning fine count blending with milk fiber. It includes the following steps: cutting off the silk into bulk fiber and the length is 50-60mm, reversion is 18-25%, and oil content is 2-3%, cultivating for 8-24 hours until fully penetrating. The fine combing fiber length is 40-50mm, and spun yarn twist is 850-1600T / M, twist coefficient is 85-130, taking bulk fiber mixing, adding wool cream according to 1:3, and making yarn after taking slivering, forespinning and post spinning processes. The invention has the advantages of natural, green, healthy keeping, low cost, good heat keeping, etc.

Owner:INNER MONGOLIA KINGDEER CASHMERE

Antiskid shoe sole

The invention provides an antiskid shoe sole. The shoe sole is composed of a main body part and an antiskid toothed part. Antiskid toothed part is arranged around the bottom of the main body part; themain body part is formed by soft rubber, wherein the soft rubber is prepared from wearproof rubber, foaming rubber, EPR and MD or EVA; the antiskid toothed part is formed by hard rubber, wherein thehard rubber is composed of composite rubber, short fibers and ceramic particles. The antiskid shoe sole adopts the combination of soft materials and hard materials. The whole shoe is soft and comfortable to wear and has better antiskid performance. Moreover, the situation is avoided that when the whole shoe sole is made of the same group of mixed rubber materials, the antiskid coefficient is low since the content of antiskid materials is low, or since the content of the antiskid materials is high, the low-temperature resistance is poor, bottom materials are easily broken, and the comfort degree is low.

Owner:广州华腾云谷科技有限公司 +2

Technology for manufacturing water absorption soft fabrics

InactiveCN104611818ASoft textureMoisture-absorbing and breathableBiochemical fibre treatmentWoven fabricsDisperse dyeYarn

The invention discloses a technology for manufacturing water absorption soft fabrics. The technology includes steps of manufacturing woven fabrics from selected yarns or threads; carrying out dyeing and finishing processing the manufactured fabrics, to be more specific, desizing the fabrics by the aid of sodium carbonate under the condition that a PH (potential of hydrogen) value is smaller than 10, bleaching the fabrics by the aid of hydrogen peroxide for the bleach wash time of 35min-50min at the water temperatures ranging 60 DEG C to 78 DEG C, performing jig dyeing on the fabrics by the aid of disperse dye at high temperatures under high pressures or dyeing the fabrics by the aid of cationic dye, washing the fabrics under the condition that a PH value is smaller than 10, finishing the fabrics in finishing agents for 25min-60min, ironing the fabrics by the aid of steam at the temperatures ranging from 100 DEG C to 180 DEG C and setting the fabrics to obtain the water absorption soft fabrics. Cotton and polyester fibers which are of hollow structures are blended to form the selected yarns or threads. The technology has the advantages that the water absorption soft fabrics manufactured by the aid of the technology have characteristics of soft textures, moisture absorption, breathability, sweat drainage, warmth keeping and the like and are excellent in elasticity and extensibility, wearers feel comfortable when wearing the water absorption soft fabrics, are free of tightening feel, and can enjoy unprecedented skin comfort, and the body curves of the wearers can be sufficiently embodied.

Owner:NANTONG SIDEFU TEXTILE DECORATION

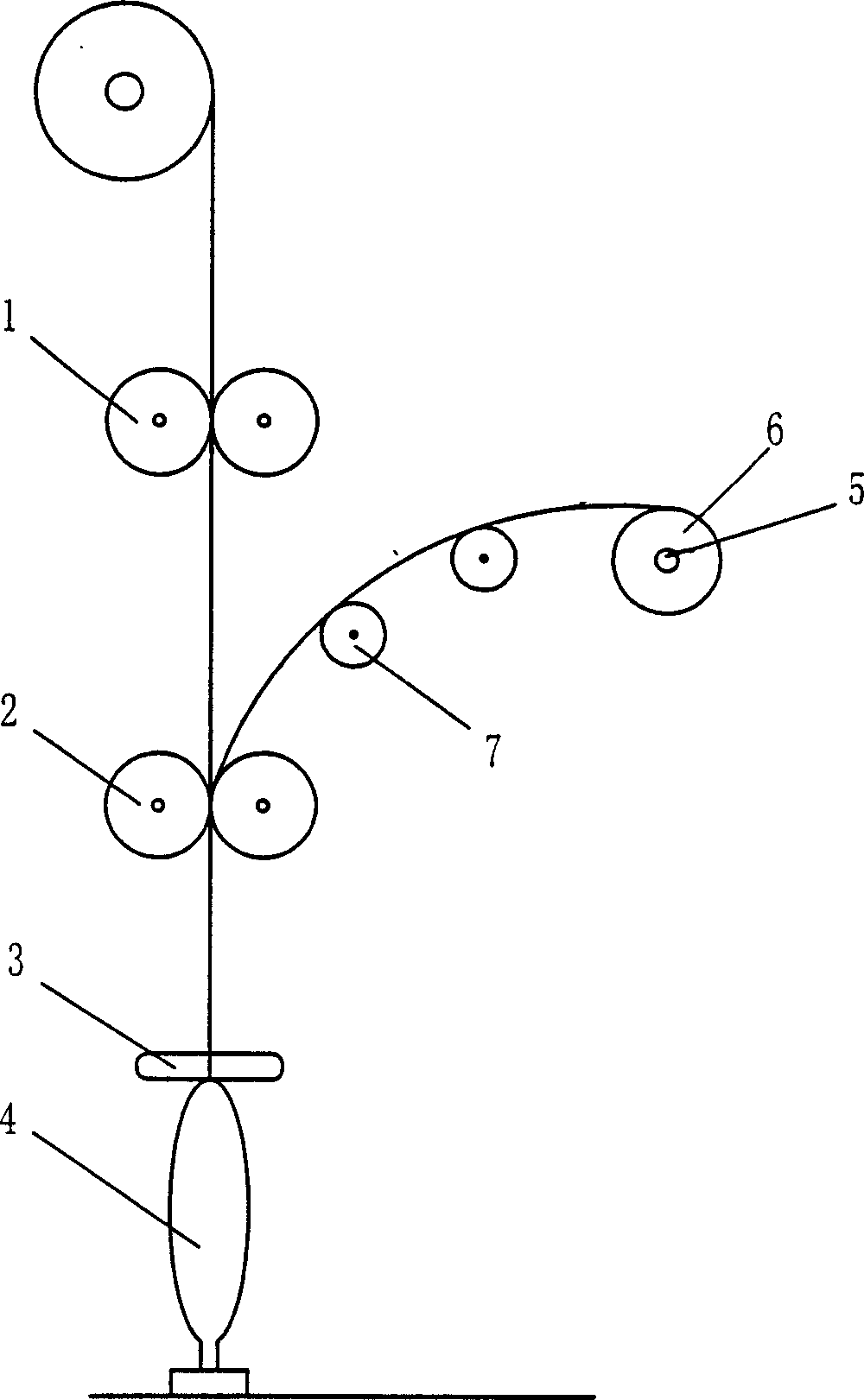

Magnetic therapeutic healthy composite woolen yarn and mfg. equipment thereof

This invention relates to a complex magnet therapeutic health care knitting wool and its production device. It includes the core yarn and the woolen yarn around the core yarn. The core yarn is the magnetic health care fibre, the weight of which is 20-25% taking the weight of magnet therapeutic health care knitting wool as reference standard, the other is woolen yarn. The device includes the drawing part of the wool and the twisting part of the yarn, there is feeding part of the wire between them, and this part has the dead axle on which the metal spinning pipe is fixed besides the drawing part. The sweater and trousers made of this complex knitting wool are felt soft, light and comfortable. The action of the magnetic field is homogeneous and it can massage to stimulate the whole skin which is covered by this material, so the skin can move lightly, stimulate the metabolism activity of the cells, and promote the microcirculation of the body. Its effect is same with the acupuncture, and it also has health care and physiotherapy ability at any time. It specially is suitable to women, wrinkly and older, and it has no minus effect. Its structure is simple and easy to operate.

Owner:王启发

Chef shoe sole and preparation method thereof

The invention relates to a sole and discloses a chef shoe sole and a preparation method thereof. The chef shoe sole comprises the following components: nitrile-butadiene rubber, brominated butyl rubber, nanosilicon dioxide, a plasticizer, an anti-aging agent, a white smoke activator, a silane coupling agent, chlorinated polyethylene, polyethylene wax, magnesium oxide, zinc oxide, sulphur and a vulcanization accelerator. The brominated rubber is used as matrix rubber and is combined with the oil-resistant nitrile-butadiene rubber to obtain the antiskid and comfortable chef shoe sole, the chef shoe adopting the sole can provide a reliable, favorable and safe guarantee for personnel operating in a kitchen environment, and shoe products which are indispensable in work and life are formed.

Owner:MAOTAI FUJIAN SOLES CO LTD

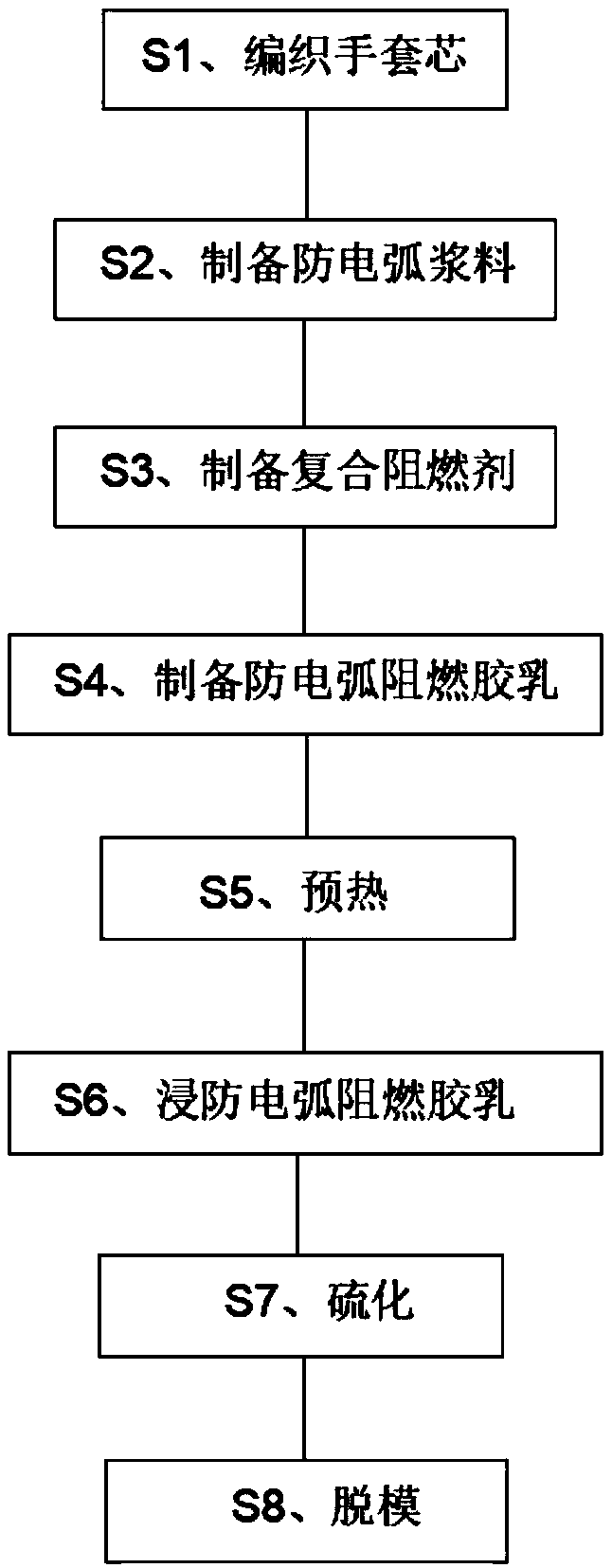

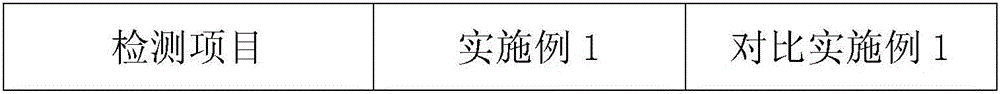

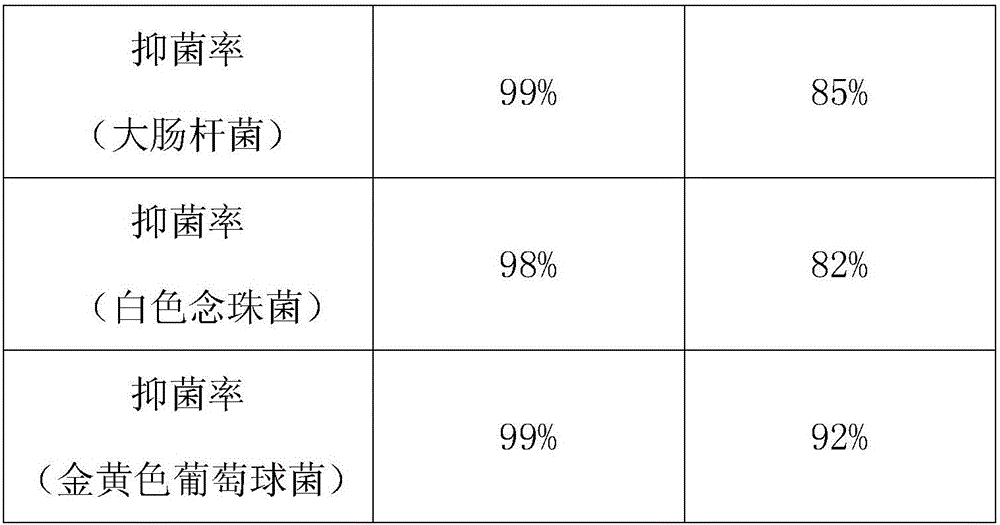

Arc-proof flame-retardant glove and production method thereof

InactiveCN108903094AExcellent arc protection performanceReduced activityGlovesProtective garmentPolymer scienceVulcanization

The invention discloses an arc-proof flame-retardant glove and a production method thereof in the technical field of labor protection gloves. The production method comprises the following steps: the step S1 of weaving a glove core; the step S2 of preparing arc-proof slurry: selecting arc-proof powder and an arc-proof powder solvent, wherein the arc-proof powder is one or more of microcapsule coated red phosphorus, microcapsule coated ammonium polyphosphate, modified aluminum hydroxide and modified magnesium hydroxide; the step S3 of preparing a composite flame retardant: mixing and grinding polydiphosphazene, triethyl phosphate and a flame retardant synergist; the step S4 of preparing arc-proof flame retardant latex; the step S5 of preheating; the step S6 of arc proof flame retardant lateximmersion; the step S7 of vulcanization; the step S8 of demoulding. The glove produced by the method has excellent arc-proof performance that far exceeds the national standard and the EU standard, has superior thermal protection, and is light and flexible to wear, good in wear resistance, low in production cost and high in production efficiency.

Owner:NANTONG JIADELI SAFETY PROD CO LTD

Noble animal fiber blended fabric

InactiveCN104026785AWear softDress elegantlyProtective garmentSpecial outerwear garmentsAnimal fiberFibre composition

The invention discloses a noble animal fiber blended fabric. The noble animal fiber blended fabric comprises animal fibers including, by weight, 25%-29% of fox hair fibers, 14%-18% of mink hair fibers, 16%-20% of sable hair fibers and 33%-45% of otter hair fibers, and the fox hair fibers, the mink hair fibers, the sable hair fibers and the otter hair fibers are blended and woven with one another to form the noble animal fiber blended fabric. The noble animal fiber blended fabric has the advantages that the animal fibers including the fox hair fibers, the mink hair fibers, the sable hair fibers and the otter hair fibers are blended and woven with one another to form the fabric, and accordingly the woven fabric feels soft when a wearer wears the noble animal fiber blended fabric, and can keep the wearer warm; various components of the noble animal fiber blended fabric are the noble animal fibers, accordingly, the wearer looks noble and elegant when wearing the noble animal fiber blended fabric, and the noble animal fiber blended fabric is elegant and is high in grade and low in manufacturing cost.

Owner:TAICANG XINTAI KNITTING

Full-automatic cloth spreading method

InactiveCN108049009AWear softGood hygroscopicityFabric breaking/softeningWeft knittingYarnShrinkage rate

The invention provides a full-automatic cloth spreading method and belongs to the field of cloth preparation. The method comprises the steps of firstly, preparation of premade cloth, wherein S-twistedcolored yarn of cotton, silk and wool, Z-twisted colored yarn of cotton, silk and wool, a full-automatic cloth spreading machine, a double-sided jacquard machine and an inkjet digital printing machine are prepared; secondly, weaving of the raw materials, wherein the double-sided jacquard machine is used for evenly weaving the S-twisted yarn and the Z-twisted yarn at path intervals according to acertain path number; thirdly, secondary treatment of the raw materials, wherein the full-automatic cloth spreading machine is used for spreading the cloth; fourthly, drying, wool grabbing and wool cutting, wherein shaping with clear water and drying are conducted; fifthly, soft cloth treatment, wherein a machine runs at a certain speed, when a front cloth end reaches the front portion of the machine, the machine is stopped, the front and rear cloth ends are sewn into an annular shape, and then the machine is started and stopped to achieve scutching and cloth discharging; sixthly, printing treatment, wherein the treated cloth is placed on the inkjet digital printing machine for printing; seventhly, rubber blanket pre-shrinking and steaming pre-shrinking, wherein the temperature of a rubberblanket is controlled, the processing speed is controlled, and the horizontal and vertical shrinkage rates of fabric and the patterns and effective width of the fabric are processed and adjusted.

Owner:XINMA ANHUI GARMENT CO LTD

Clothing softener

The invention relates to the technical field of daily necessities, and in particular relates to a clothing softener. The clothing softener is prepared from the following components by weight: 5-10 parts of triethanolamine oleic soap, 2-8 parts of fatty alcohol polyoxyethylene ether, 1-3 parts of a penetrating agent, 20-30 parts of a softening agent and the balance of water. All raw materials are mixed, poured into the water, stirred evenly, heated to 60 DEG C, held for heat preservation for 3 hours, and then cooled to room temperature to obtain the clothing softener product. The invention aims to provide the clothing softener with good use effect and low cost.

Owner:谭小毛

Preparation method of children's underwear blended fabric

InactiveCN105908485AEasy to handleCause some damagesPhysical treatmentBiochemical treatment with enzymes/microorganismsFiberIrritation

The invention discloses a children's underwear blended fabric. Being prepared by blending of milk protein fiber, silk and wool, the children's underwear blended fabric has good moisture absorption and moisture retention, is rich in elasticity, is close fitted, soft, smooth and comfortable to wear, is static-free, natural and non-toxic, has good heat retention properties, and no irritation to human body, and also has the functions of bacteriostasis, deodorization, blood circulation promotion and the like. The preparation method does not involve heavy metals, halides or other substances harmful to human body and the environment, and belongs to an environment-friendly fiber treatment process.

Owner:广东婴姿坊婴童用品实业有限公司

Modal mercerized cloth production process

InactiveCN106120224AShinyAnti-pillingShrinkingMercerising of indefinite length fabricsEngineeringMoisture absorption

The invention discloses a modal mercerized cloth production process. The modal mercerized cloth production process sequentially includes production procedures of cloth distribution, cloth loosening, pre-setting, double-face singeing, mercerizing, neutralizing, selvage stitching, dyeing, dewatering, in-process inspection, scotching, shaping and QC (quality control) finish inspection. The modal mercerized cloth production process is mainly innovated in after-finishing processing by mercerization, and cloth surface glossiness, pilling resistance, high comfort and high fitness are realized. The mercerized cloth produced according to the process has advantages of high cloth surface glossiness, low hairiness, comfort in handfeel and wearing, excellent pilling resistance, excellent moisture absorption performance, softness, high drapability, high fitness and the like.

Owner:FOSHAN DONGCHENG LIYI TEXTILE CO LTD

Environment-friendly composite fabric preparation process

InactiveCN104553231ASoft to wearReliable safety performanceLamination ancillary operationsSynthetic resin layered productsTemperature resistanceChemistry

The invention relates to an environment-friendly composite fabric preparation process. The environment-friendly composite fabric preparation process comprises the following steps: (1) soaking a fabric in clean water in a washing tank; (2) scouring the fabric after being washed, and cleaning oxalic acid residue on the fabric; (3) taking out the cleaned fabric; (4) placing polyvinyl chloride resin, calcium carbonate, poly(hexylene glycol), a PVC stabilizing agent, an environment-friendly plasticizer and an organic tin stabilizer into a stirrer; (5) placing a sizing agent for 20 to 90 hours in a normal-temperature room at the temperature of 20 to 60 DEG C; (6) uniformly smearing the sizing agent between an upper layer fabric and a lower layer fabric, rolling at a high temperature, drying, and finally obtaining a finished product. An article for labor protection, produced by the composite fabric, is not only soft and comfortable to wear, but also has the advantages of acid and alkali resistance, high temperature resistance, high strength and reliable safety performance. The production process flow is reasonable in design, the operation is simple and convenient, and the cost is low. The environment-friendly composite fabric preparation process can be applied to other textile fabric markets, is wide in application prospect and is worthy of being popularized and applied.

Owner:QINGDAO XINYIFA IND & TRADE

Dual-purpose slipper

The invention discloses a dual-purpose slipper which comprises an upper, a bottom lining and a sole. The obverse and reverse sides of the upper are provided with a warm shoe side and a sandal side. The bottom lining is composed of a warm layer and a cool layer fixedly connected to each other. Both the edge of the upper and the edge of the bottom lining are provided with raised covered edges. The upper is movably connected with the bottom lining through hook-loop fastener strips at the covered edges. The bottom lining is movably connected with the sole through a zipper arranged at the edges. The dual-purpose slipper is available for warm and cold seasons. When the warm shoe side and the warm layer of the slipper are connected, the dual-purpose slipper warms a foot and is soft to wear. When the sandal side of the slipper is connected with the cool layer, the slipper keeps the foot cool and is comfortable to wear. The value of the slipper is fully utilized. In addition, both the upper and the bottom lining of the slipper are detachable, so that the dual-purpose slipper is convenient to wash and air.

Owner:NANTONG XIYUN TRADE

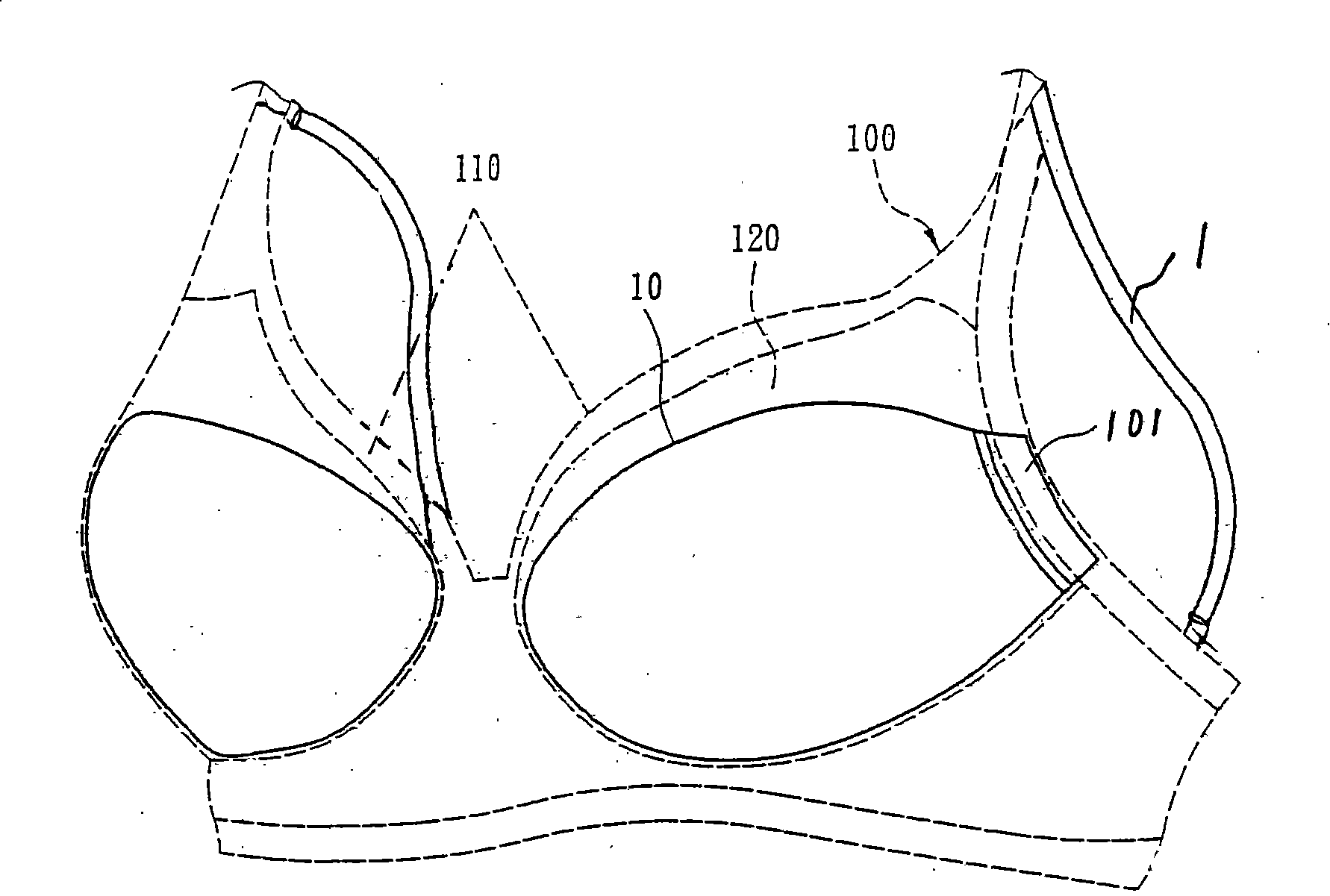

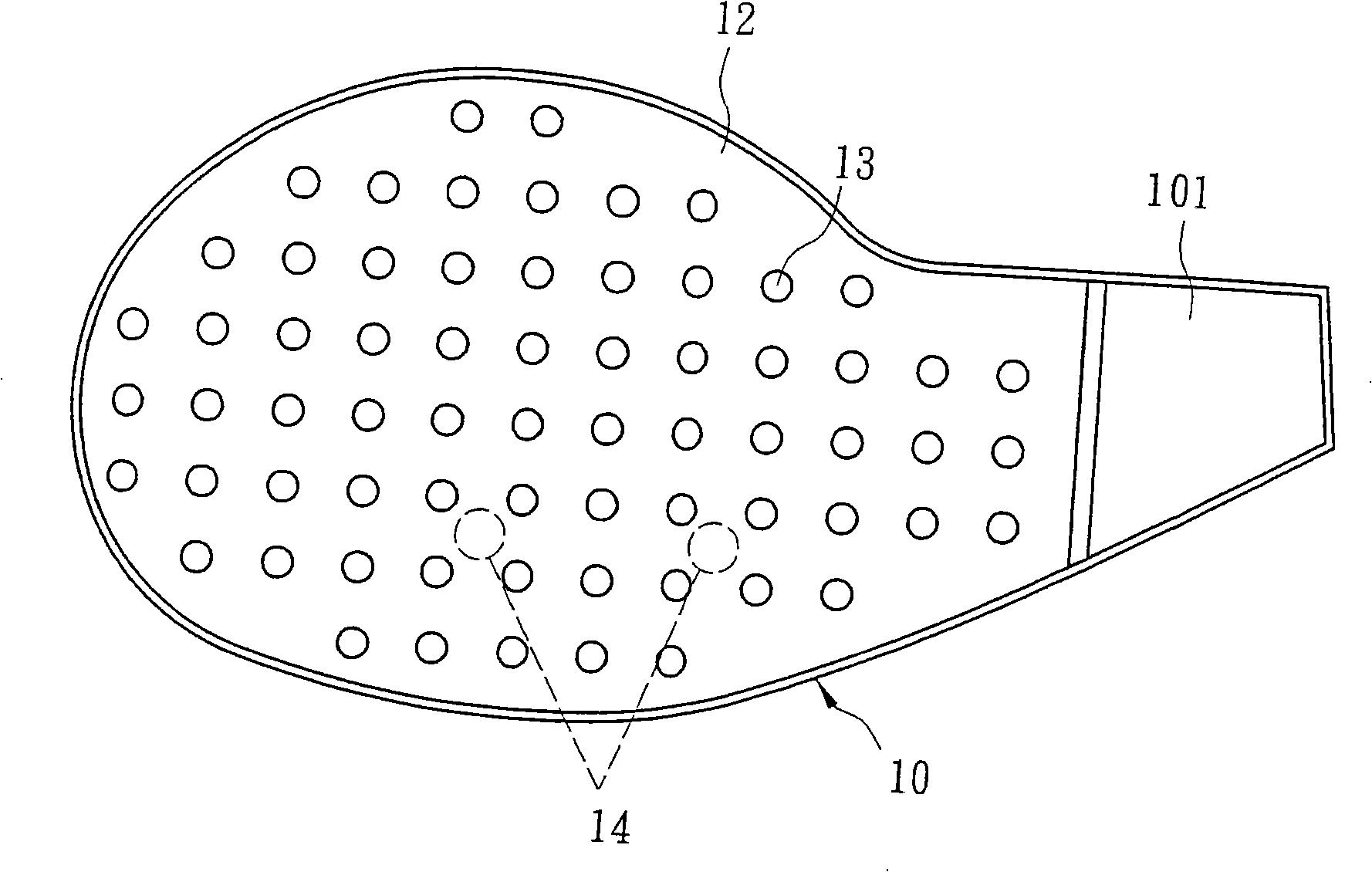

Multifunctional massage, bacteriostasis, and deodorization bra

The invention relates to a multifunctional massage, bacteriostasis, and deodorization bra, which is characterized by comprising a bra lining bag which is a double-layer polyether lining bag of the shape size conforming with the development of human breasts, and the lining bag is provided with scores of particle-shaped projected beads in uniform distribution at the place where the lining bag faces the breasts. The beads are filled with fluidity liquid and solid mixture with specific gravity of 0.35 to 0.4, wherein, the mixture is provided with active magnetic beads and a plurality of active substances. A shoulder tape is air cushion shoulder tape. The lining bag has unique structure and fillings of active substances needed by human beings and light weight and soft tactility similar to adipose, and the bra is a woman bra of stereo cutting and comfortable wear.

Owner:苏扬修

Blended optical fiber fabric

The invention discloses a blended optical fiber fabric. The blended optical fiber fabric comprises a surface optical fiber fabric layer, and an inner heat insulation comfort layer; the surface optical fiber fabric layer is prepared via blended weaving of 73 to 79wt% of high molecular polystyrene optical fiber and 21 to 27wt% of nano silver fiber; the inner heat insulation comfort layer is prepared via blended weaving of 34 to 41wt% of polyimide fiber and 59 to 66wt% of sateen fiber. A double layer structure design is adopted; the surface optical fiber fabric layer is capable of transmitting light, and resisting interference; and the inner heat insulation comfort layer is capable of insulating heat, and is soft and comfort for wearing.

Owner:SUZHOU TANXI TEXTILE TECH CO LTD

Method for making blended stain color yarn

The present invention essentially provides a novel blended fiber segment-color yarn. The technical proposal is that a blended segment-color yarn is composed of colorful fiber and natural fiber, wherein the color fiber is any one or any combination of terylene, acrylon, regenerated cellulose fiber, natural color cotton, artificial dyed cotton and bamboo charcoal fiber; the natural fiber is pure cotton fiber or mixed fiber of cotton fiber and any other fiber; the colorful fiber and the natural fiber are blended and twisted after cotton cleaning, cotton combing and drawing. The yarn has the advantages of rational structure, simple processing, moderate fiber fracture strength, high extensibility, fine spinning and weaving property, etc. With the excellent moisture absorption of natural fiber and the good moisture conductivity of synthesized fiber, clothes made of the yarns feel soft and are gas-permeable.

Owner:浙江云山纺织印染有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com