Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Anti-pilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing modified cation polyester filament and product thereof

ActiveCN102094256ABionic features are obviousLow boiling water shrinkageMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterPolymer science

The invention belongs to the field of manufacture of chemical fibers, in particular to a method for producing a modified cation polyester filament imitating a cellulose fiber. The method comprises the following steps of: preparing modified cation polyester; carrying out melting spinning by aiming at the characteristics of the modified cation polyester to obtain an orientated filament; and carrying out false twisting on the orientated filament under the condition of a special elasticizing process. The invention also provides a modified cation polyester filament prepared with the production method. The cation polyester filament disclosed by the invention has favorable fuzzing and pilling resistance, can be dyed at normal pressure without high-temperature and high-pressure conditions, saves the dyeing cost and has bright color after being dyed and high skin intimacy, and the hygroscopicity is better than that of common cation terylene filament.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Copolyester section or fiber and preparation method thereof

InactiveCN101357981ASoft touchSoft lusterMonocomponent copolyesters artificial filamentMelt spinning methodsFiberAlcohol

The invention relates to copolyester sheets or a copolyester fiber, which comprises terephthalic acid, m-phthalic acid, glycol and 2-methyl-1, 3-propanediol; the mol ratio of dibasic acids to diatomic alcohols is 1 to 1.7-2.4. The preparation method of the copolyester sheet or fiber comprises the following steps: (1) the terephthalic acid, the m-phthalic acid, the glycol and the 2-methyl-1,3-propanediol are mixed for esterification for 1 to 5 hours together with a catalyzer and a heat stabilizer at 220 to 275 DEG C under the pressure of zero to 0.5MPa; (2) pre-polycondensation follows; the pressure is reduced and the temperature is raised to complete polycondensation, thus getting the copolyester sheets; the copolyester sheets are dried in vacuum, thus getting dry copolyester sheets capable of spinning; and the dry copolyester sheets are spun to get the copolyester fiber. The dyeing behaviour of the copolyester fiber is improved; and the copolyester fiber has the characteristics of resisting roughing and pilling and high contractibility. The preparation method is designed rationally and can be industrialized easily, which is safe for the environment.

Owner:DONGHUA UNIV

Fluorescent inflaming-retarding multifunctional double-layer fabric and preparing method thereof

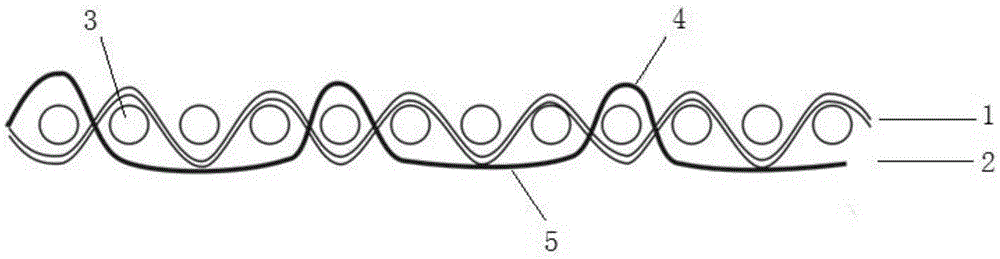

ActiveCN105483898AFlame retardant hasHigh temperature resistantFibre typesMulti-ply fabricsYarnSurface layer

The invention discloses a fluorescent inflaming-retarding multifunctional double-layer fabric. The surface layer of the fabric is woven from inflaming-retarding yarn capable of being dyed with fluorescence color, and the inner layer of the fabric is woven from non-melting inflaming-retarding yarn incapable of being dyed with fluorescence color. The warps of the inner layer are lifted to be interwoven with the wefts of the surface layer to form a binding texture so that the two layers can be connected. The fabric is prepared in the way that the warps of the inner layer are lifted to be interwoven with the wefts of the surface layer to form the binding texture so that the two layers can be connected, and then dyeing treatment is conducted to generate the fluorescent inflaming-retarding multifunctional double-layer fabric. Specifically, the two layers of the fabric are connected in the way that when surface wefts are put in for surface layer weaving, all inner warps must sink to the space below a shed and can not be interwoven with surface wefts; when inner wefts are put in for inner layer weaving, all surface warps must be lifted and can not be interwoven with inner wefts. The double-layer fabric can have different spaces and can be used for making protection garments in a plurality of fields.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

Blended yarn containing 11 different fibers and production method

The invention discloses a blended yarn containing 11 different fibers, belongs to the technical field of textile, and specifically relates to a technological method for producing the blended yarn. The weight percentage composition of the blended yarn comprises: 32 to 36% of Tencel Sun, 5 to 8% of silver ion antibacterial glue, 6 to 9% of aloe fiber, 2 to 6% of rose fiber, 2 to 6% of modal, 2 to 4% of viscose fiber, 2 to 6% of cotton fiber, 2 to 6% of Tencell A100, 5 to 8% of copper ammonia fiber, 8 to 11% of ramie fiber, and 8 to 11% of bamboo fiber. The textile technology used by the blended yarn containing 11 different fibers is capable of adequately blending the different fibers, achieving the adequate blending between cell fibers, and solving the problem of inadequate blending of the blended yarn containing multiple compositions; and using the half-free end handing spinning technology of the air-jet vortex spinning, and wrapping and twisting the outer fibers under the reaction of the high-speed vortex in a nozzle chamber through the air twisting. The yarn is smoother and cleaner, straight, and rigid, and has the advantages of fluff and pilling resistance, absorption, quick dry and the like.

Owner:DEZHOU HUANYUAN ECOLOGICAL TECH

Production method of flax blended knitting yarns

The invention discloses a production method of flax blended knitting yarns. In the method, flax and modal fibers are blended according to a ratio of 15:85 to 85:15. The method comprises a spinning process and a rotor spinning process. The modal fibers selected in the invention are the most ideal material for light and thin knitted fabrics for their sweat-absorbing, thermal-insulation and cooling properties and integration of the comfortableness of cotton, the drapability of adhesive, the strength of terylene and the handfeel of real silk. The flax-modal blended knitting yarns exploit development space for high-quality flax light and thin knitted fabrics. Although the flax and modal fibers are susceptible to generating hairiness, the rotor spinning used in the invention is one-step bobbin forming and therefore reduces the hairiness of finished fibers and ensures the knitted fabrics are clear and full in appearance. The rotor spun yarns also have the advantages of few yarn faults, high elasticity, pilling resistance, wear resistance and the like. The method has the advantages that: the process flow is short; the cost is low; high grade flax knitting yarns with high balance of various performance indexes such as high fineness, little hairiness, yarn levelness and soft handfeel; and the application value in textile processing field is high.

Owner:QIQIHAR UNIVERSITY

Polyester fabric production method

InactiveCN103590166ADisadvantages of changing high temperature dyeingImprove color absorption performanceDyeing processWoven fabricsFiberDye absorption

The invention discloses a polyester fabric production method. The method includes the following steps: (1), selecting raw materials, namely selecting 30D / 36F semi-gloss polyester filaments as warp and selecting 50D / 72F polyester filaments as weft; (2) inspecting the raw materials; (3), performing doubling, reeling, two-for-one twisting, natural shaping and drafting on qualified warp, and performing reeling, two-for-one twisting, shaping and rewinding on qualified weft; (4), weaving; (5), inspecting fabric; (6), bleaching and scouring; (7), dyeing; (8), rinsing and drying. The polyester fabric production method is simple; dispersible cationic dye is adopted for dyeing, so that the defect of high-temperature dyeing of common polyester fabric is overcome, and dyeing can be performed at normal temperature; dye absorption performance of fibers is greatly improved, crystallinity is lowered, dye molecules are enabled to be prone to permeation, the fibers are enabled to easy to dye, and dye absorption rate is increased.

Owner:钜诚纺织(苏州)有限公司 +1

Long-acting antibacterial fabric containing copper ion fibers

InactiveCN109532142AImprove structural strengthImprove antibacterial propertiesSynthetic resin layered productsClothingsCompound aCopper

The invention relates to the technical field of textile fabrics, and specifically relates to long-acting antibacterial fabric containing copper ion fibers. The long-acting antibacterial fabric is prepared by compounding a natural fiber net and an antibacterial fiber net, wherein the natural fiber net is prepared from the following raw material components: wood pulp fibers and jute fibers; the antibacterial fiber net is prepared from the following raw material components: bamboo fibers and the copper ion fibers; in percent by mass, the wood pulp fibers account for 45%-55% of the long-acting antibacterial fabric, the jute fibers account for 15%-18% of the long-acting antibacterial fabric, the bamboo fibers account for 15%-20% of the long-acting antibacterial fabric, and the copper ion fibersaccount for 7%-13% of the long-acting antibacterial fabric; and a polyurethane antibacterial film is laminated between the natural fiber net and the antibacterial fiber net. According to the invention, by optimizing the raw material components and ratio of the natural fiber net and the antibacterial fiber net, the obtained fabric has excellent structural strength and antibacterial performance, and the problems that the long-lasting antibacterial fabric on the existing market is poor in antibacterial performance and weak in antibacterial durability are solved.

Owner:泉州维林森体育用品有限公司

Yarn spinning technology for multi-fiber semi-worsted melange yarn and yarn

InactiveCN104878490AImprove insulation effectIncrease elasticityWool fibre washing/scouringAnimal materialCardingWorsted

The invention relates to a yarn spinning technology for multi-fiber semi-worsted melange yarn and the yarn prepared with the technology. The technological steps of the yarn mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise mercerized wool fiber, nylon fiber, viscose fiber and cashmere wool fiber. The problems of high probability of water shrinkage and pilling of wool are solved with a more environment-friendly method, meanwhile, nylon, cashmere wool and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are increased; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

Intelligent temperature-adjustment comfortable knitting fabric and weaving method thereof

Owner:QINGDAO XUEDA GRP

Moisture-transfer and fast-drying wool knitted fabric and its making method

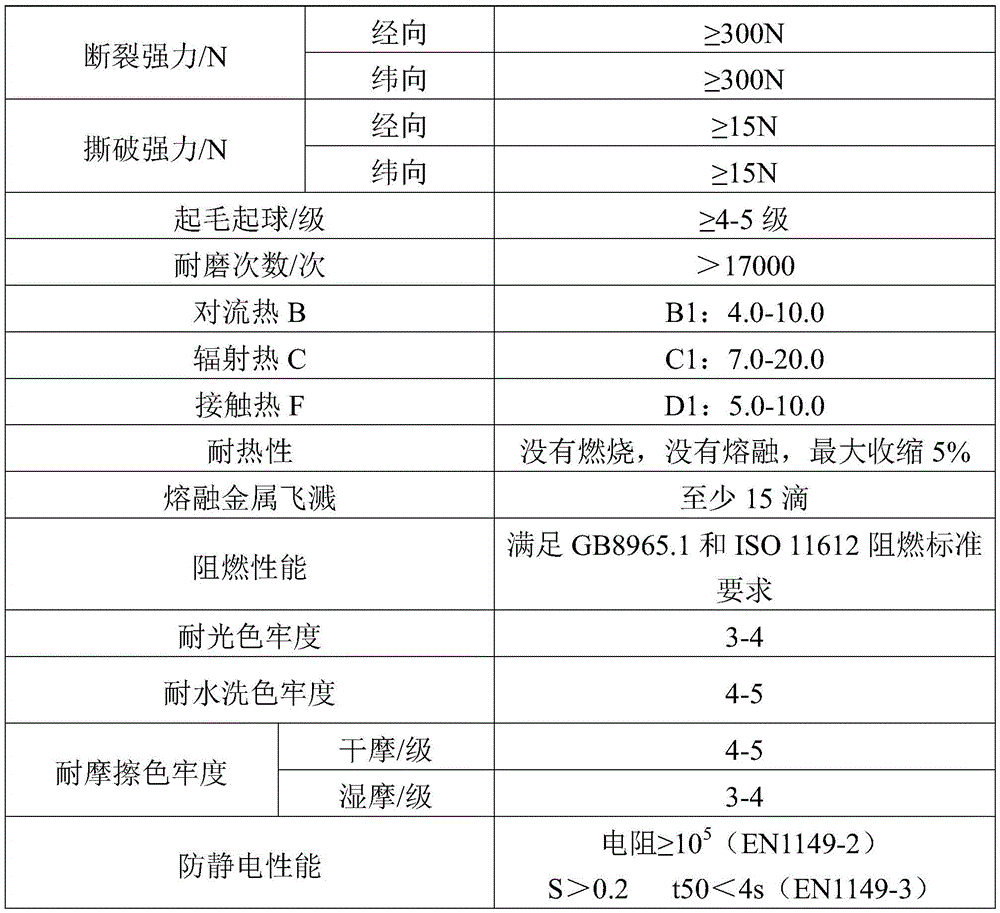

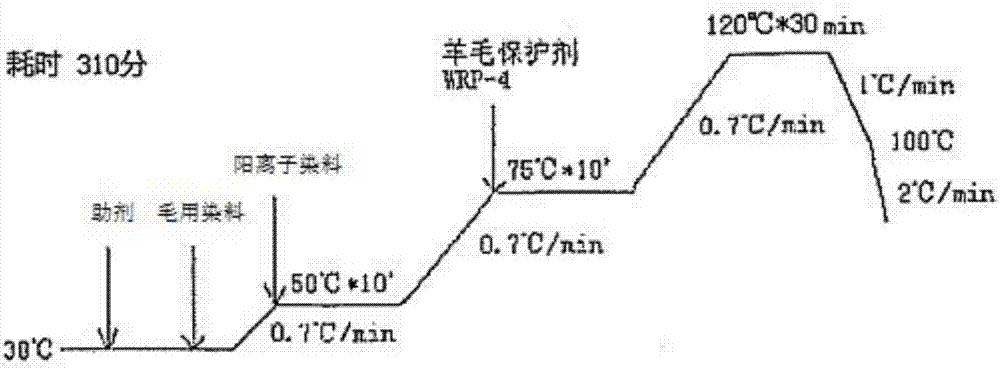

InactiveCN107574544ALarge specific surface areaHelp exportWeft knittingHeating/cooling textile fabricsYarnFiber

The invention relates to a moisture-transfer and fast-drying wool knitted fabric and its making method. The fabric is a double-side knitted fabric and includes a next-to-the-skin surface and a front surface; yarn used by the next-to-the-skin surface is fine-denier cation modified polyester fibers, and yarn used by the front surface is high-count wool and cation modified polyester fibers. The yarnis woven to obtain the fabric; water is injected in a dye vat, the fabric is soaked in water with the bath ratio of 1:20, an auxiliary agent and dye used for wool are then added, after the temperatureis kept for 10 min, the temperature is increased to 50 DEG C, cationic dye is added, the temperature is kept for 5-10 min and then increased to 75 DEG C, after a wool protection agent is added, the temperature is kept for 5-10 min and then increased to 120 DEG C, after the temperature is kept at 120 DEG C for 20-30 min, cooling is conducted, finally, a hydrophilic finishing agent is added, the temperature is increased to 40 DEG C for 10-20 min, and a dyed fabric is obtained; the dyed fabric is subjected to setting to obtain the moisture-transfer and fast-drying wool knitted fabric. The fabricis thin, delicate, smooth in hand feeling and comfortable to wear and has the moisture-transfer and fast-drying functions.

Owner:SHANGHAI CHALLENGE TEXTILE

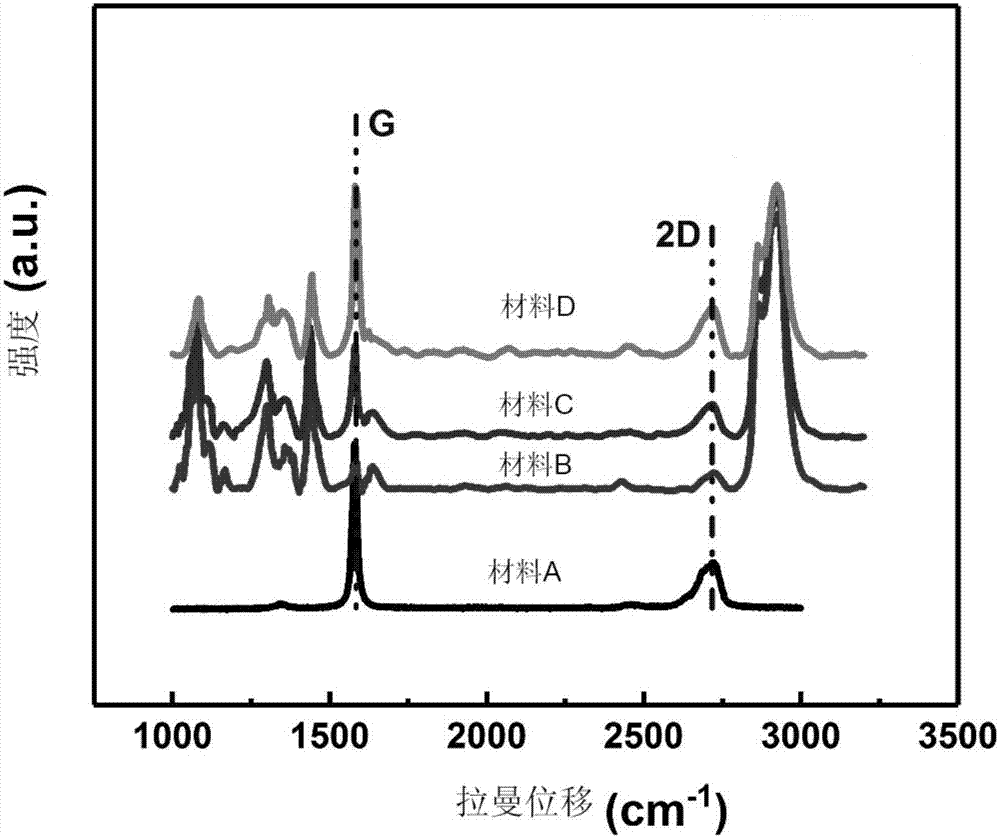

Novel functional graphene composite fiber, and preparation method and application thereof

InactiveCN107488891AGood antibacterial effectImprove antistatic performanceConjugated synthetic polymer artificial filamentsYarnFiberGraphene nanoplatelet

The invention provides a novel functional graphene composite fiber, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, adding graphene nano-sheets into a molten polymer material, and carrying out melt mixing to uniformly mix the graphene nano-sheets with the polymer material in order to obtain a mixture A, wherein 100 wt% of the mixture A contains 20-30 wt% of the graphene nano-sheets; 2, granulating the mixture A to obtain graphene composite master batches; and 3, carrying out melt mixing and spinning on the graphene composite master batches and the polymer material to obtain the novel functional graphene composite fiber, wherein 100 wt% of the novel functional graphene composite fiber contains 1-4 wt% of the graphene nano-sheets. The invention also provides the novel functional graphene composite fiber prepared through the preparation method. The graphene composite fiber has certain strength, softness and hygroscopicity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Production process of high-strength vortex spinning viscose yarn

InactiveCN108517598ALess production processIncrease productionContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to a production process of a high-strength vortex spinning viscose yarn. The production process includes the following steps that viscose staple fiber is selected as a vortex spinning raw material; the staple fiber is processed by using a blowing-carding process to obtain fiber card slivers, specifically the staple fiber is subjected to opening, impurity removing and uniformmixing through opening and cleaning units firstly, the fiber is conveyed to a carding machine through a continuous feeding box, and fiber bundles are combed into a single fiber state by using the carding machine to form the fiber card slivers; the fiber card slivers are drawn through three paths for combination and drafting, so that the fiber is straight and parallel to obtain fiber drawn slivers;the fiber drawn slivers are sent to vortex spinning equipment for spinning, and spinning spindles are heated by using a high temperature compressed air heating method in the spinning process, so thatthe fiber drawn slivers after entering nozzles are spirally wrapped into yarns on the surfaces of the spinning spindles in a high temperature environment to form a cone yarn which is the high-strength vortex spinning viscose yarn. The production process has the advantages of less production process, large output and less labor, and the produced viscose yarn has the advantages of high strength, softness and comfort, good moisture absorption and the like.

Owner:SUZHOU JIANGSAI TEXTILE TECH CO LTD

Production method and device for special crystal cotton fiber

The invention discloses a production method and device for special crystal cotton fiber. The invention is aimed at providing a production method for special crystal cotton fiber. The glazed flat POY raw silk is used as raw material, and the raw silk is introduced into a tow raw silk tube through the silk frame hanging wire device at the same time so that the tow directly enter into a first roller through a silk guider; compressed air network is performed before entering into the first roller; the tow enters into the an upper heating box for low-temperature tensile deformation; then the tow enters into a cooling plate to be stretched, cooled and sized and enters into a false twister for false twisting so that the tow has a good bulkiness; then the tow enters into a lower heating box for sizing; the sized tow is sent out through a third roller and then fully oiled on an oil wheel through a silk guider, and then the tow enters into a spindle derivation friction roller for winding formation. By means of the production method and device, the special crystal cotton fiber with the characteristics of strong fabric gloss, soft and comfortable surface, good post-hair style and good hair straightness, anti-pilling, stain resistance and rigidity is produced.

Owner:桐乡市中洲化纤有限责任公司

Woven fabric capable of releasing negative ions and preparation method thereof

InactiveCN105155030AImprove the environmentImprove the defect of single functionConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsNoise reductionIon

The invention discloses woven fabric capable of releasing negative ions. The woven fabric is woven by warp yarn and weft yarn through an air jet loom, and the warp yarn and the weft yarn are prepared from raw materials in parts by weight as follows: 25-35 parts of polypropylene resin, 18-22 parts of polyethylene, 1-2 parts of silica, 3-5 parts of tourmaline powder, 15-20 parts of alginate fiber, 18-28 parts of Bamdal fiber, 24-30 parts of fine denier polyamide yarn, 4-5 parts of polyethylene wax, 3-6 parts of methylene diphenyl diisocyanate, 10-14 parts of methyl acrylate, 2-4 parts of folium artemisiae argyi, 3-5 parts of mint, 80-100 parts of 1-butyl-3-methylimidazolium acetate, 100-110 parts of 1-allyl-3-methylimidazolium chloride, an appropriate amount of water and 4-7 parts of an auxiliary. The fabric has multiple functions, can release the negative ions, improves the inner environment of an automobile and has the advantages of noise reduction, thermal insulation, moisture absorption, breathability, wear resistance, waterproofness, pilling resistance and the like, further, the production is simple and easy, and the cost is low.

Owner:安徽省中日农业环保科技有限公司

Antibacterial comfortable underwear knitted fabric

InactiveCN110281618AAntibacterial comfortGood antibacterial and deodorant effectSynthetic resin layered productsFiberYarn

The invention discloses antibacterial comfortable underwear knitted fabric. The knitted fabric comprises a underwear knitted fabric body, underwear outer layer fabric and underwear inner layer fabric, wherein the underwear knitted fabric body is formed by connecting the underwear outer layer fabric and the underwear inner layer fabric by spinning and weaving. The underwear inner layer fabric of the antibacterial comfortable underwear knitted fabric disclosed by the invention is composite fiber yarn made by mixing chitin fiber yarn and bamboo fiber yarn, and the chitin fiber yarn per se has excellent antibacterial and bacteriostatic effects; meanwhile, bamboo quinone in the bamboo fiber yarn has antibacterial, anti-mite and deodorant properties, and chlorophyll and copper chlorophyll in the bamboo fiber yarn have relatively good deodorant effect, so that the antibacterial comfortable underwear knitted fabric has the antibacterial and deodorant effects.

Owner:JIHUA 3542 TEXTILE CO LTD

Dope-dyed polyester knitted looped fabric

InactiveCN102154768ASimple processing technologyImprove insulation effectWeft knittingYarnPolyesterYarn

The invention discloses a dope-dyed polyester knitted looped fabric, which has a double-sided looped fabric structure. The looped fabric is characterized by comprising post-dyed polyester fibers, polyester-stainless steel composite fibers and polyester coconut carbon yarns, wherein the polyester coconut carbon yarns constitute the basic tissue of the double-sided looped fabric structure; the post-dyed polyester fibers and the polyester-stainless steel composite fibers are interwoven with the basic tissue to constitute a protruding front-face pile loop positioned on one side of the basic tissue; and the polyester coconut carbon yarns and the polyester-stainless steel composite fibers are interwoven with the basic tissue to constitute a protruding back-face pile loop positioned on the other side of the basic tissue. The dope-dyed polyester knitted looped fabric has the advantages of electromagnetic wave protection, electrostatic prevention, permanent electric conductance, high-temperature resistance, cutting resistance, friction resistance, filterability, noise absorption and isolation performance, simple machining process, heat preservation, pilling resistance, and the like.

Owner:BOYANG COMPOSITE FABRIC TECH KUSN

Viscose mercerized cloth production process

The invention discloses a viscose mercerized cloth production process. The viscose mercerized cloth production process sequentially includes production procedures of cloth distribution, cloth loosening, pre-setting, double-sided singeing, mercerizing, neutralizing, selvedge sewing, dyeing, dewatering, in-process inspection, scotching, setting and QC (quality control) finish inspection. The viscose mercerized cloth production process is mainly innovative in after-finishing processing, and by means of mercerization for innovation, high fitness, high comfort, pilling resistance and surface glossiness of cloth are realized. Mercerized cloth produced according to the viscose mercerized cloth production process has advantages of high surface glossiness, low hairiness, comfort in touching and wearing, excellent pilling resistance, high moisture absorptivity, softness, excellent draping property, high fitness and the like.

Owner:FOSHAN DONGCHENG LIYI TEXTILE CO LTD

Method for producing modified cation polyester filament and product thereof

ActiveCN102094256BBionic features are obviousLow boiling water shrinkageMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterPolymer science

The invention belongs to the field of manufacture of chemical fibers, in particular to a method for producing a modified cation polyester filament imitating a cellulose fiber. The method comprises the following steps of: preparing modified cation polyester; carrying out melting spinning by aiming at the characteristics of the modified cation polyester to obtain an orientated filament; and carrying out false twisting on the orientated filament under the condition of a special elasticizing process. The invention also provides a modified cation polyester filament prepared with the production method. The cation polyester filament disclosed by the invention has favorable fuzzing and pilling resistance, can be dyed at normal pressure without high-temperature and high-pressure conditions, saves the dyeing cost and has bright color after being dyed and high skin intimacy, and the hygroscopicity is better than that of common cation terylene filament.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Environment-friendly wool and SRN fiber blending jacquard warm-keeping knitted fabric

The invention relates to knitted fabrics, in particular to an environment-friendly wool and SRN fiber blending jacquard warm-keeping knitted fabric. The weaving process of the knitted fabric includes the step of conducting blending and combing of 60wt%-80wt% of wool and 20wt%-40wt% of SRN fibers, pre-drawing, lap forming and doubling, carding, spooling and twist setting to obtain blended yarn; the step of conducting blended yarn union dyeing sequentially including the procedures of single-face singeing, scouring and bleaching, sizing, mercerizing, dispersed thermosol dyeing and topping, wherein gas singeing is specifically adopted in the single-face singeing process, singeing is conducted twice at the front sides of two burners, the travel speed is 80 m / min-85 m / min, topping is conducted after dispersed thermosol dyeing, and reactive dye or indanthrene dye is adopted for topping; the step of conducing weaving, wherein the dyed blended yarn is woven into the fabric through an MACH-2 sheet forming computerized flat knitting machine, and the two faces of the fabric are of different structures; the step of conducting aftertreatment, wherein a hyperbranched polyether amidogen modified polysiloxane finishing agent is adopted for conducting aftertreatment on the fabric. The fabric has the advantages of being soft, fluffy, capable of keeping warm and having tender luster, anti-pilling, anti-wrinkling, stiff, smooth, quick-drying and anti-ultraviolet.

Owner:POLARGOOSE CLOTHING

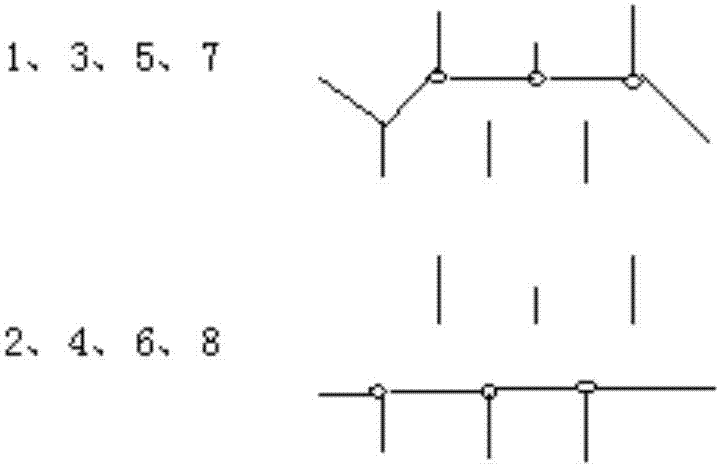

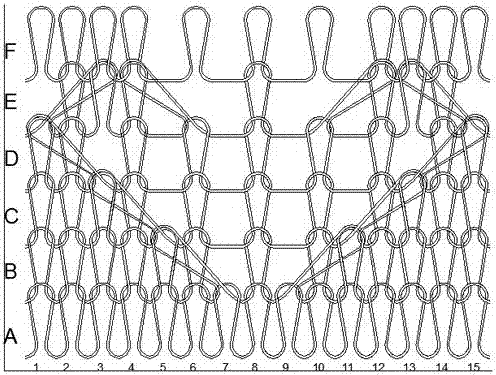

Comfortable and natural type OPTIM fiber, pima cotton, real silk and cashmere mixture knitting yarn knitted fabric structure

The invention relates to a comfortable and natural type OPTIM fiber, pima cotton, real silk and cashmere mixture knitting yarn knitted fabric structure. The structure comprises a basic stitch and a lace stitch. The lace stitch comprises a plurality of independent units. Each independent unit comprises six transverse columns A, B, C, D, E and F and fifteen longitudinal columns, wherein each transverse column corresponds to one piece of yarn; the transverse columns A, B, E and F each comprise fifteen coils, the transverse column C comprises thirteen coils, and the transverse column D comprises eleven coils. The structure is simple, and the manufactured comfortable natural type OPTIM fiber, pima cotton, real silk and cashmere mixture knitting yarn knitted fabric has the advantages of being hydrophilic, soft, smooth, breathable, thin, light, fluffy, capable of achieving heat preservation, glossy, gentle and the like, and has the functions of being durable, resistant to static electricity, resistant to pilling, resistant to fouling and the like.

Owner:POLARGOOSE CLOTHING

Modal mercerized cloth production process

InactiveCN106120224AShinyAnti-pillingShrinkingMercerising of indefinite length fabricsEngineeringMoisture absorption

The invention discloses a modal mercerized cloth production process. The modal mercerized cloth production process sequentially includes production procedures of cloth distribution, cloth loosening, pre-setting, double-face singeing, mercerizing, neutralizing, selvage stitching, dyeing, dewatering, in-process inspection, scotching, shaping and QC (quality control) finish inspection. The modal mercerized cloth production process is mainly innovated in after-finishing processing by mercerization, and cloth surface glossiness, pilling resistance, high comfort and high fitness are realized. The mercerized cloth produced according to the process has advantages of high cloth surface glossiness, low hairiness, comfort in handfeel and wearing, excellent pilling resistance, excellent moisture absorption performance, softness, high drapability, high fitness and the like.

Owner:FOSHAN DONGCHENG LIYI TEXTILE CO LTD

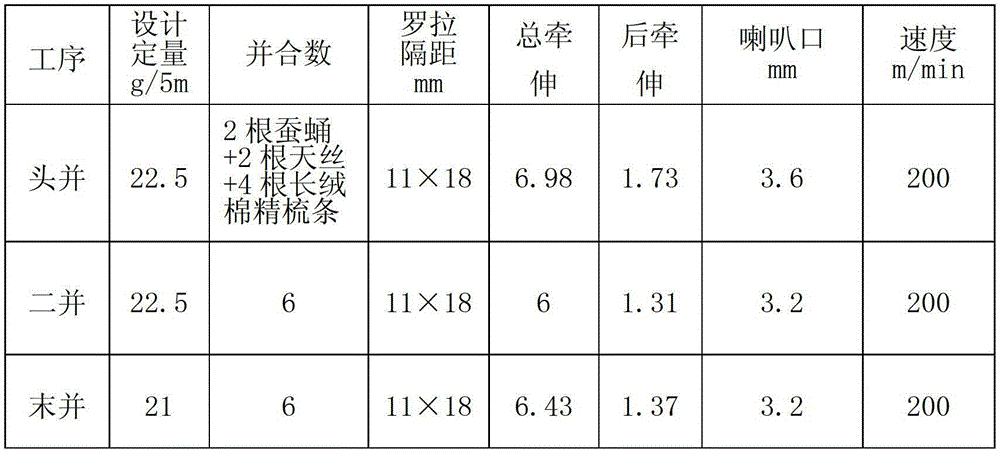

Silkworm chrysalis protein fiber tencel blended yarn and manufacturing method thereof

The invention provides silkworm chrysalis protein fiber tencel blended yarn which is little in hairiness, high in anti-abrasion performance, strong in strength, and close to skin, beauties the skin, is ventilated, and refreshes feeling. The yarn is made of 20% of silkworm chrysalis protein fibers, 30% of tencel fibers and 50% of long stapled cotton in a compact spinning mode. The invention further provides a manufacturing method of the embedded spinning china-hemp native fiber multi-component blended yarn. The method includes the following steps: after the silkworm chrysalis protein fibers and the tencel fibers are preprocessed, the silkworm chrysalis protein fibers and the tencel fibers are respectively slivered through blowing and cotton carding processes, respectively pre-combined, mixed with long staple combed cotton three times on a drawing machine, roved, spun in a compact mode, and spooled to form the yarn.

Owner:JIANGSU YDTEX GRP LTD

Preparation method and product of comprehensive easy-care wool tops

InactiveCN111139641AAntibacterialBreathableBiochemical fibre treatmentLight resistant fibresWool fiberChemical engineering

The invention discloses a preparation method and a product of comprehensive easy-care wool tops. The preparation method comprises the following steps of: carrying out raw material preparation; carrying out anion treatment, i.e., padding wool fibers in anion solution, after completing padding, washing with deionized water, then taking out the wool fibers and carrying out natural air-drying; carrying out flame retardant treatment; carrying out oxidation descaling treatment, i.e., impregnating the flame retardant wool fibers with degradation fluid, after completing impregnation, rinsing with clear water, and then drying; loading nanometer titania, i.e., placing the wool fibers into titania solution, placing the titania solution into a sealed container, gradually heating, after finishing loading, repeatedly washing with deionized water, and drying to obtain wool fibers loaded with the nanometer titania; and preparing the wool tops. In the preparation method, by a series of machining treatment such as anion treatment, flame retardant treatment, oxidation descaling treatment and loading of the nanometer titania on the wool fibers, the comprehensive easy-care wool top product with antibacterial, breathable, anti-pilling shrink-proof and self-cleaning functions can be prepared.

Owner:张家港保税区宇联羊毛工业有限公司

Production method of bamboo charcoal polyester filament yarn

InactiveCN103184562AImprove performanceQuality improvementFilament/thread formingMonocomponent polyesters artificial filamentPolymer scienceSpinning

The invention provides a production method of bamboo charcoal polyester filament yarn. PET fondant and nanometer-stage bamboo charcoal master batch are taken as raw materials. The method comprises the following steps of: respectively transmitting and drying the two material materials, passing through an injection molding machine, extruding in a fusing way, spinning, forming in a cooling way by cross air blowing, applying oil to an oil mouth, previously stitching, discharging by a draw-off godet, stitching and forming in a coiling way, wherein the content of the nanometer-stage bamboo charcoal master batch is 23-27%. The production method of the bamboo charcoal polyester filament yarn has the following technical effects: the produced bamboo charcoal filament yarn is good in performance and stable in quality, wherein the linear density is 138dtex, the breaking strength is 2.1cN / dtex, the elongation at break is 136.8%, and the yarn unevenness is 0.8%.

Owner:JIANGSU TONGHAI THREAD

Blending process of cashmere and bamboo fiber blended yarns

The invention relates to a blending process of cashmere and bamboo fiber blended yarns. The blending process specifically comprises the following steps that 1, cashmere raw materials sequentially undergo the processes of cashmere mixing, cashmere combing, primary mixing, secondary mixing, combing, gilling, gill preparation, re-combing, primary needling and secondary needling, and cashmere tops areobtained; 2, bamboo fiber raw materials sequentially undergo the processes of opening picking, combing and primary drawing, and bamboo fiber tops are obtained; 3, the cashmere tops and the bamboo fiber tops are mixed, and the mixed tops sequentially undergo the processes of cotton spinning, secondary drawing, roving, spinning and spooling, and finally the cashmere / bamboo pulp fiber blended yarnsare obtained. By adopting the blending process, the properties of cashmere and bamboo fiber are optimized, and the advantages of the two types of fiber are fully played, so that the blended yarns havethe advantages of keeping warm, being soft and good in elasticity and having luster and have antibacterial, deodorizing, anti-ultraviolet, antistatic and anti-pilling functions.

Owner:内蒙古帕阑蒂科技发展有限公司

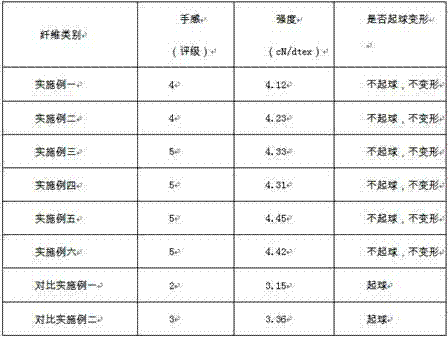

A kind of production method of cationic compound imitation cotton yarn

ActiveCN103320923BDyeableHygroscopicFilament/thread formingMonocomponent polyesters artificial filamentTextile fiberMachining

The invention relates to the field of textile fibers and provides a method for producing cationic type composite cotton yarn imitation threads to solve the problems of cotton fiber imitation polyester filaments. Cationic polyesters are used as raw materials to be produced into cationic POY / FDY (ITY) composite fibers through a POY / FDY composite fiber one-step spinning device, and the POY / FDY (ITY) composite fibers are subjected to false twisting machining to be produced into cationic composite cotton yarn imitation threads. The cotton yarn imitation threads produced through the method are provided with appearance characteristics of cotton yarn and good in hygroscopicity, dyeing property and pilling resistance.

Owner:杭州逸暻化纤有限公司

A method for producing a blended yarn containing 11 different fibers

The invention discloses a blended yarn containing 11 different fibers, belongs to the technical field of textile, and specifically relates to a technological method for producing the blended yarn. The weight percentage composition of the blended yarn comprises: 32 to 36% of Tencel Sun, 5 to 8% of silver ion antibacterial glue, 6 to 9% of aloe fiber, 2 to 6% of rose fiber, 2 to 6% of modal, 2 to 4% of viscose fiber, 2 to 6% of cotton fiber, 2 to 6% of Tencell A100, 5 to 8% of copper ammonia fiber, 8 to 11% of ramie fiber, and 8 to 11% of bamboo fiber. The textile technology used by the blended yarn containing 11 different fibers is capable of adequately blending the different fibers, achieving the adequate blending between cell fibers, and solving the problem of inadequate blending of the blended yarn containing multiple compositions; and using the half-free end handing spinning technology of the air-jet vortex spinning, and wrapping and twisting the outer fibers under the reaction of the high-speed vortex in a nozzle chamber through the air twisting. The yarn is smoother and cleaner, straight, and rigid, and has the advantages of fluff and pilling resistance, absorption, quick dry and the like.

Owner:DEZHOU HUANYUAN ECOLOGICAL TECH

Cotton linen blended fabric and anti-pilling smoothening sorting method thereof

The invention discloses a cotton linen blended fabric and an anti-pilling smoothening sorting method thereof. The cotton linen blended fabric comprises an anti-pilling sorting and smoothening sortingprocess, wherein polyurethane resin and magnesium chloride are used for sorting so as to improve the anti-pilling performance of the fabric, so that the economic value and the practicability of the fabric can be improved. The fabric and the method have the beneficial effects that the cotton linen blended fabric prepared by the method has anti-pilling performance and smoothness; the pilling rate isreduced, so that the economic benefits and the practicability of the fabric can be improved.

Owner:JIANGSU DONGYING CLOTHING CO LTD

Production method of flax blended knitting yarns

The invention discloses a production method of flax blended knitting yarns. In the method, flax and modal fibers are blended according to a ratio of 15:85 to 85:15. The method comprises a spinning process and a rotor spinning process. The modal fibers selected in the invention are the most ideal material for light and thin knitted fabrics for their sweat-absorbing, thermal-insulation and cooling properties and integration of the comfortableness of cotton, the drapability of adhesive, the strength of terylene and the handfeel of real silk. The flax-modal blended knitting yarns exploit development space for high-quality flax light and thin knitted fabrics. Although the flax and modal fibers are susceptible to generating hairiness, the rotor spinning used in the invention is one-step bobbin forming and therefore reduces the hairiness of finished fibers and ensures the knitted fabrics are clear and full in appearance. The rotor spun yarns also have the advantages of few yarn faults, high elasticity, pilling resistance, wear resistance and the like. The method has the advantages that: the process flow is short; the cost is low; high grade flax knitting yarns with high balance of various performance indexes such as high fineness, little hairiness, yarn levelness and soft handfeel; and the application value in textile processing field is high.

Owner:QIQIHAR UNIVERSITY

Preparation method of natural green wall cloth

The invention discloses a preparation method of natural green wall cloth. The wall cloth comprises the following raw materials of, by weight, 10-18 parts of sisal, 50-150 parts of flax, 5-35 parts ofactivated carbon particles, 1-8 parts of coconut fiber, 3-15 parts of preservative, 2-40 parts of calcium-free filler, 1-38 parts of talcum powder, 5-40 parts of diatomaceous earth, 1-9 parts of wastepaper and 18-25 parts of additive. The preparation method of the wall cloth comprises the following steps that homogenizing is carried out, wherein the preservative and the additive are weighed according to the proportion ratio, the preservative and the additive are poured into a homogenizer with a temperature control system, the temperature of the homogenizer is controlled at 150 DEG C to 180 DEG C, and stirring is carried out for 25-40 minutes to obtain a mixture A. According to the preparation method, the preparation process is simple, convenient, rapid and easy to operate; the requirements of clean production are met, and the product is safe, environment-friendly, non-toxic, harmless and degradable.

Owner:安徽盛世碧美实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com