Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

221results about How to "Comfortable feet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

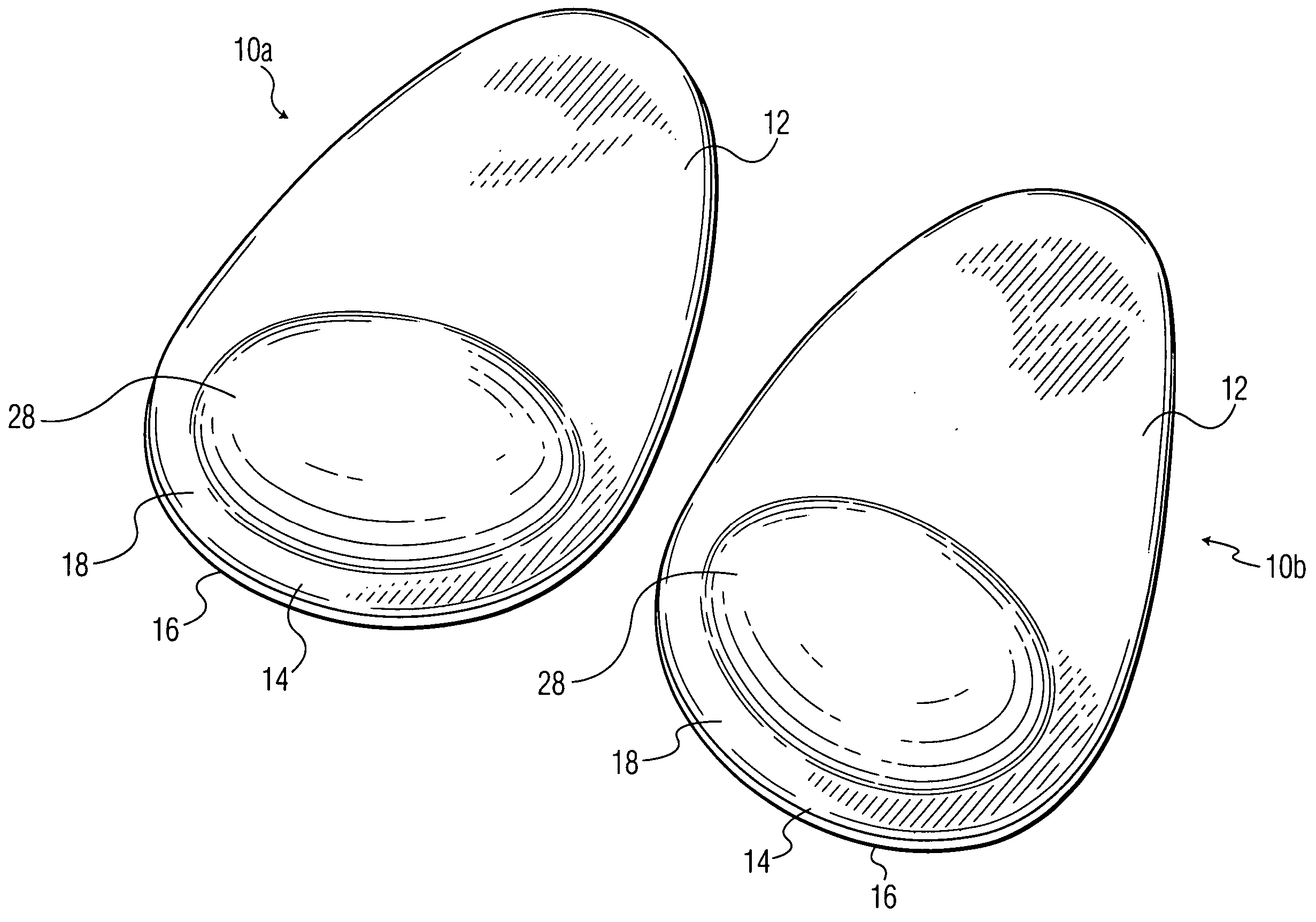

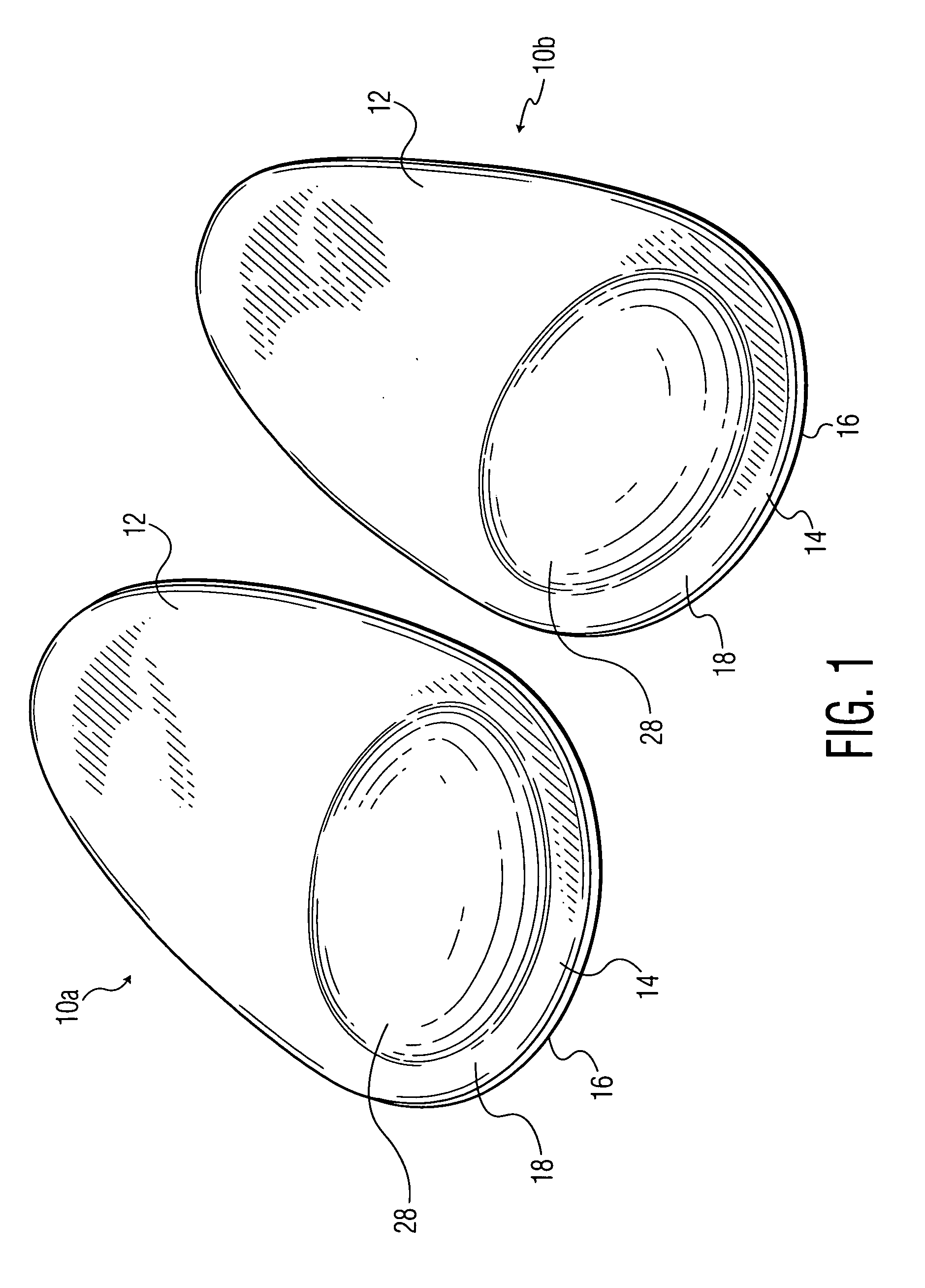

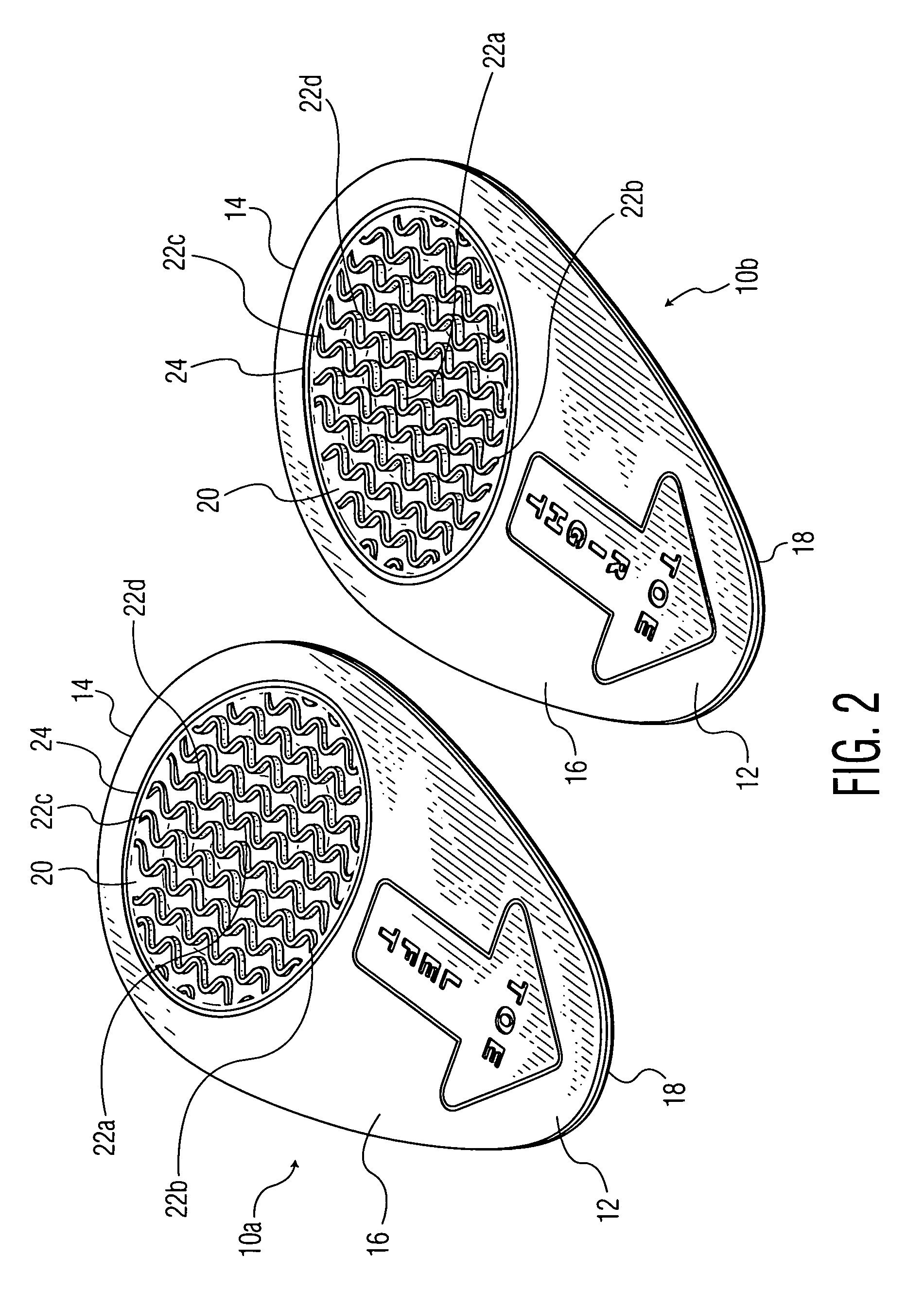

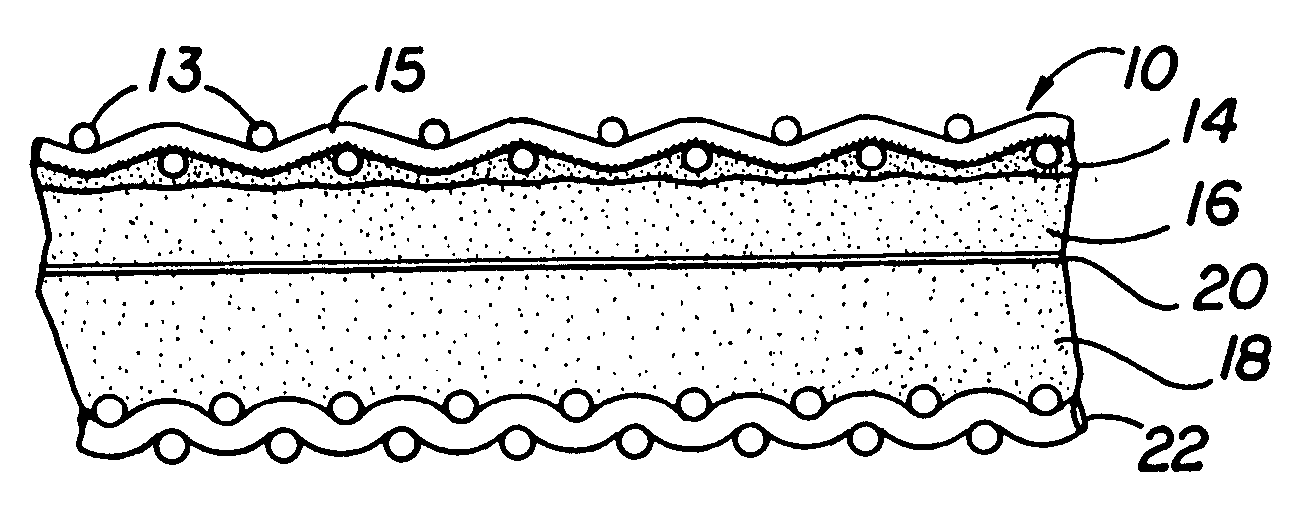

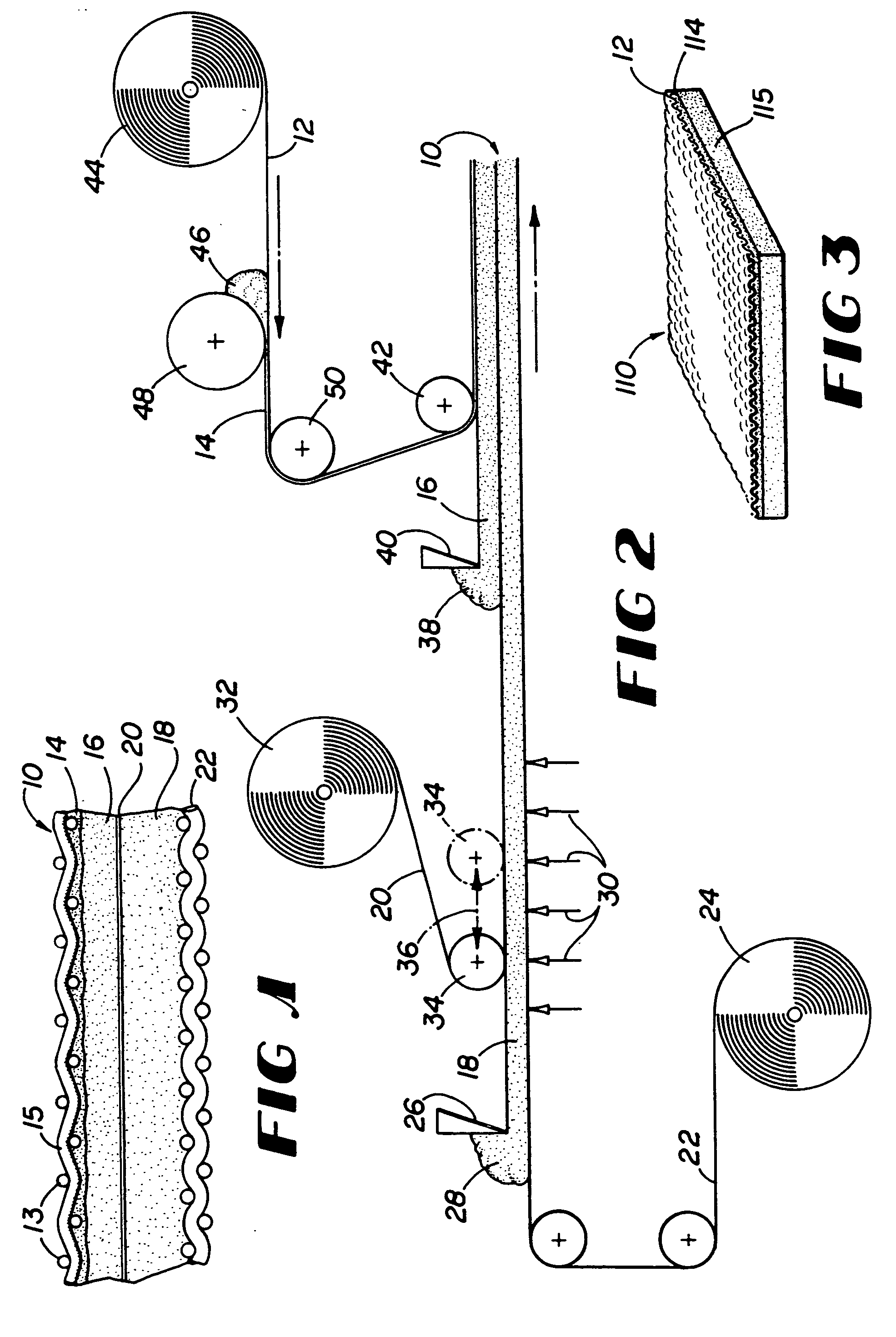

Ball of foot shoe inserts

A removable ball of the foot insert for placement into footwear at a position in correspondence with a forefoot portion of the footwear includes a substantially planar member made from a viscoelastic gel, the planar member including a lower surface and an upper surface, and a plurality of parallel, spaced apart, sinusoidally shaped spring walls formed from a viscoelastic gel and extending from the lower surface of the planar member at a predetermined area corresponding to a ball of the foot when the insert is inserted into the footwear, for separating bones of second and third metatarsals of the foot, the spring walls having heights that generally decrease outwardly from a center of the predetermined area, and the viscoelastic gel of the planar member having a hardness greater than a hardness of the viscoelastic gel of the spring walls.

Owner:MSD CONSUMER CARE INC

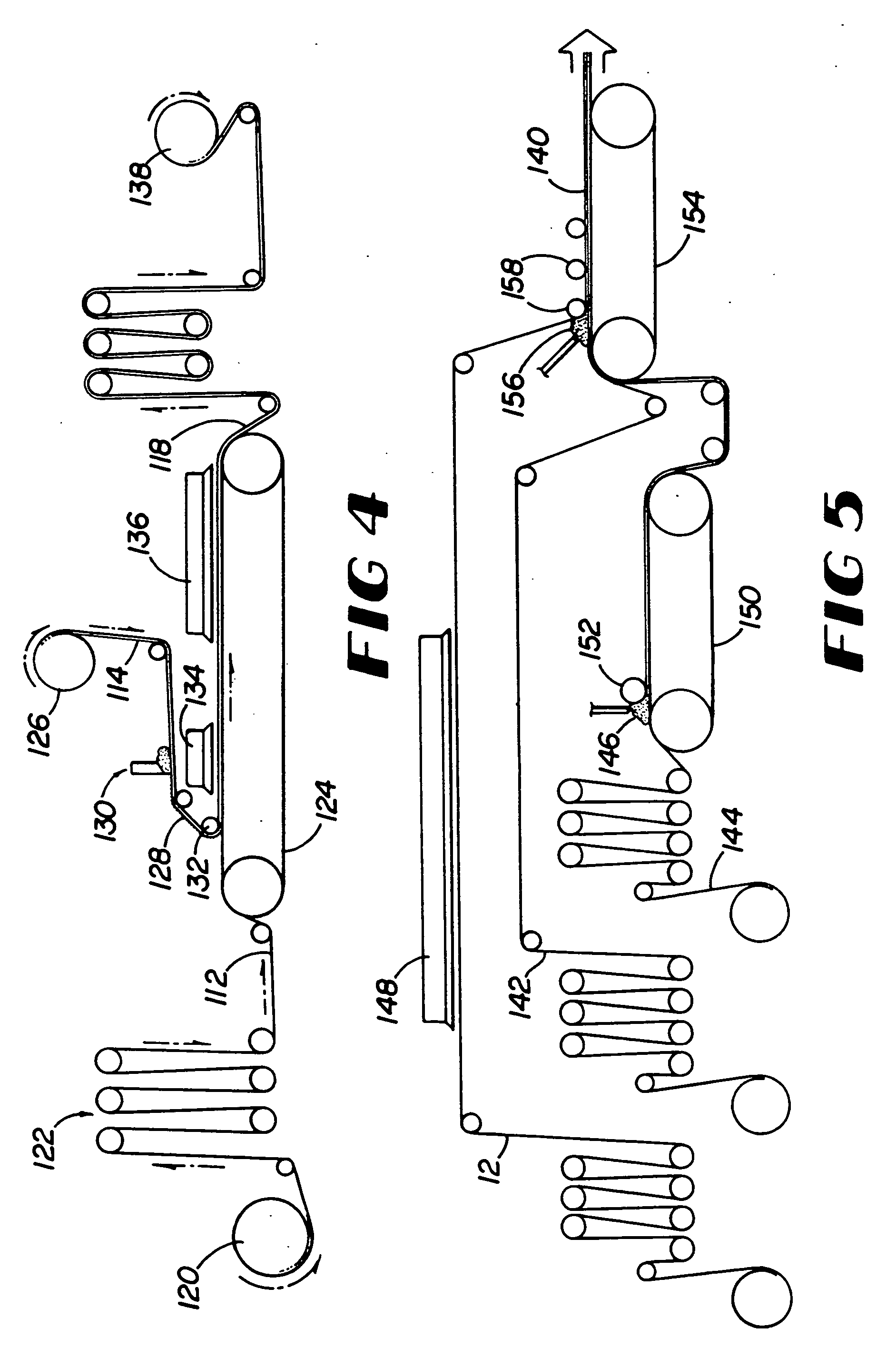

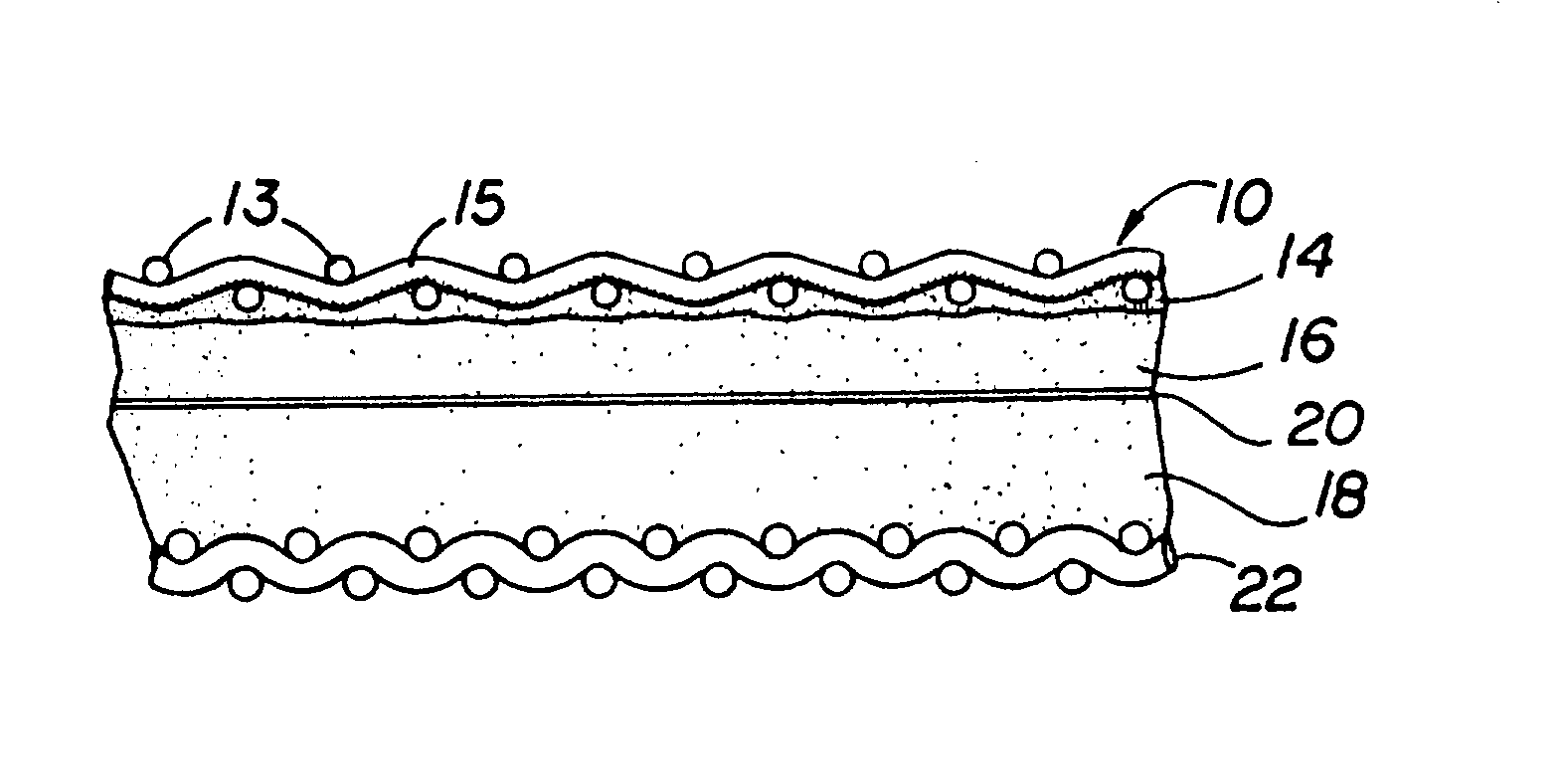

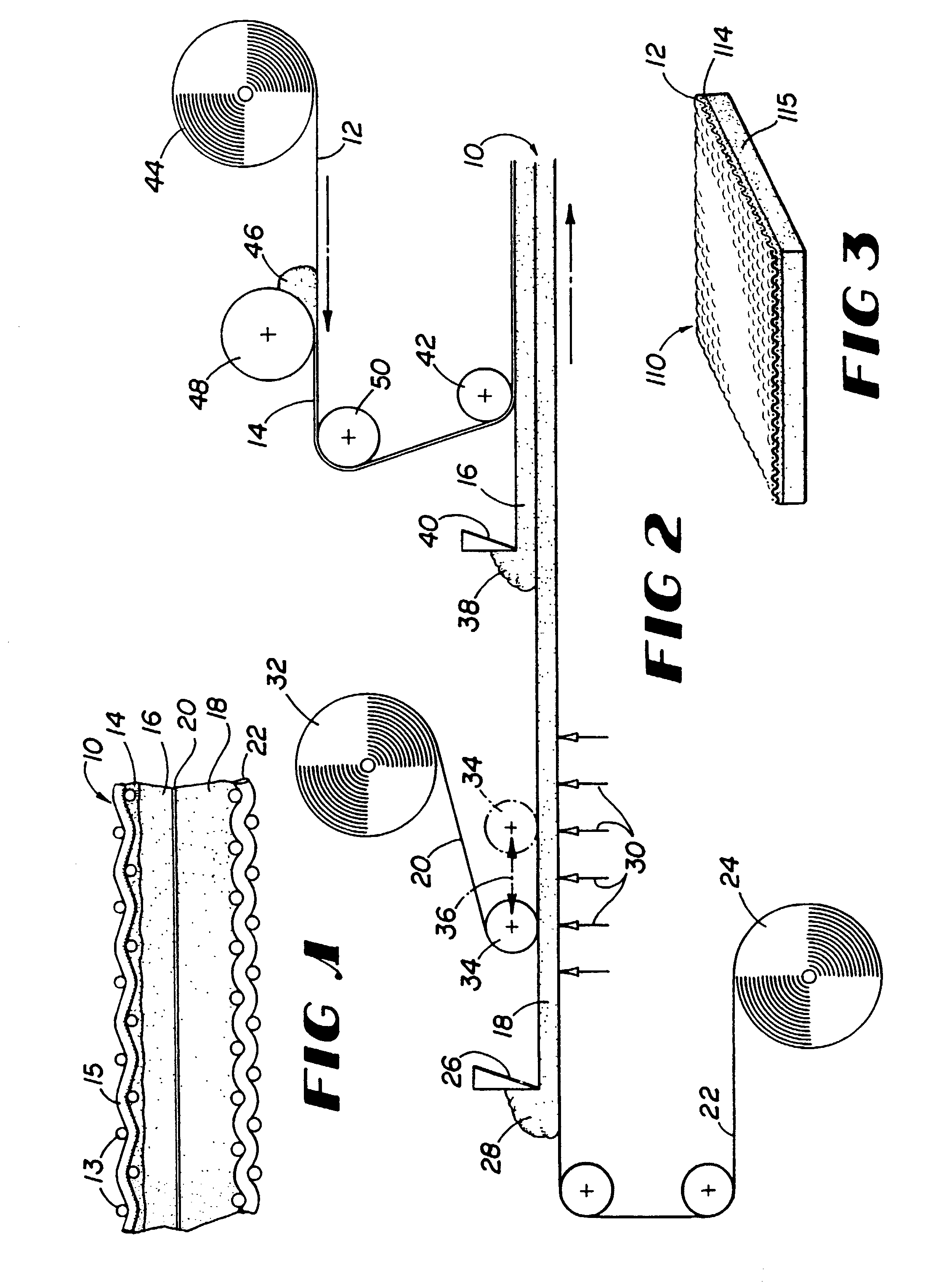

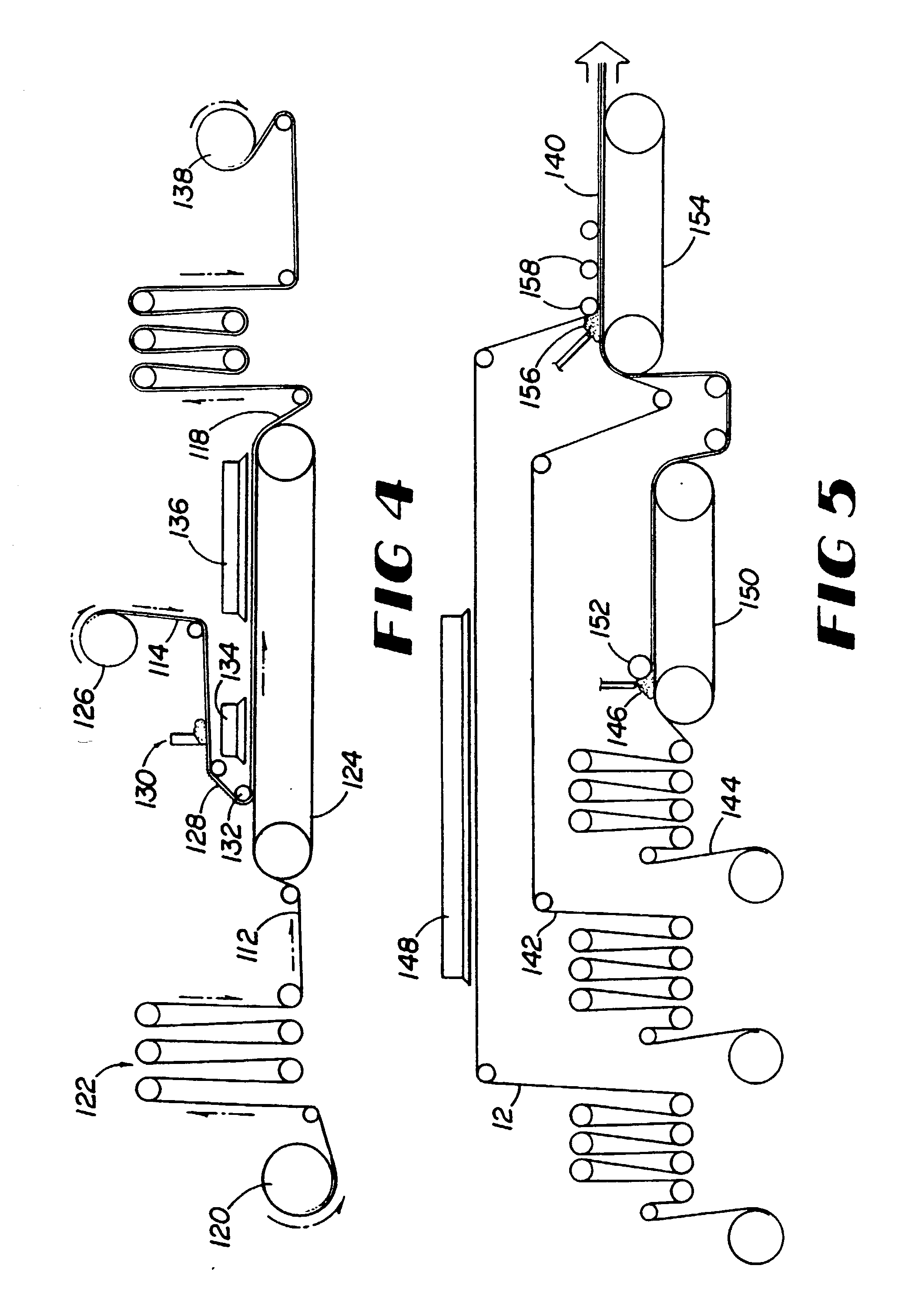

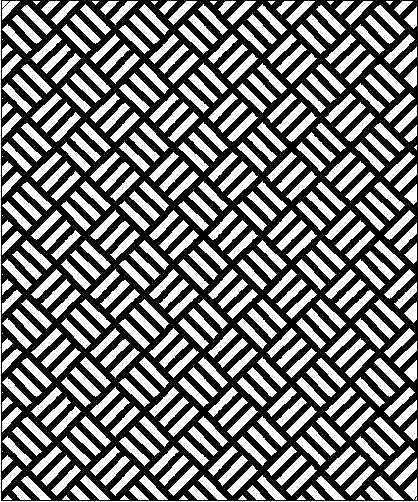

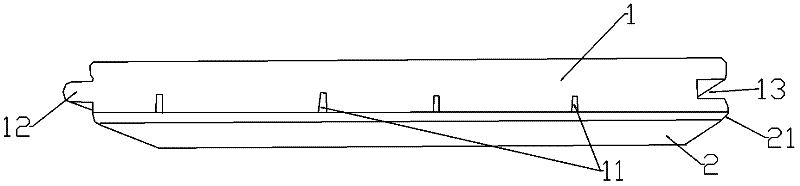

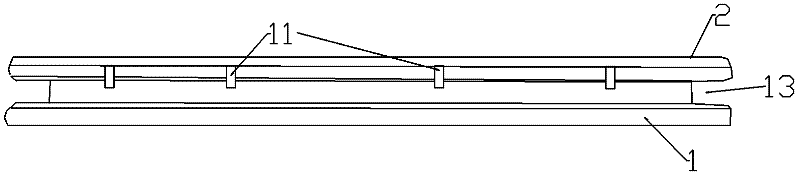

Floor covering with woven face

InactiveUS20040198120A1Increase rate of changeReduce the chance of changeSynthetic resin layered productsFloor coveringsYarnPolyester

Flooring that utilizes sophisticated, self-stabilizing, woven face fabric using relatively heavy "carpet weight" nylon, polyester, PTT or other yarns on modern Jacquard computer controlled looms to produce flat-weave fabrics that are bonded to engineered backing structures. Urethane modified bitumen may be used as a backing layer, and an optional latex precoat may be used on the fabric layer, together with an optional antimicrobial in the precoat.

Owner:SCOTT GRAHAM +2

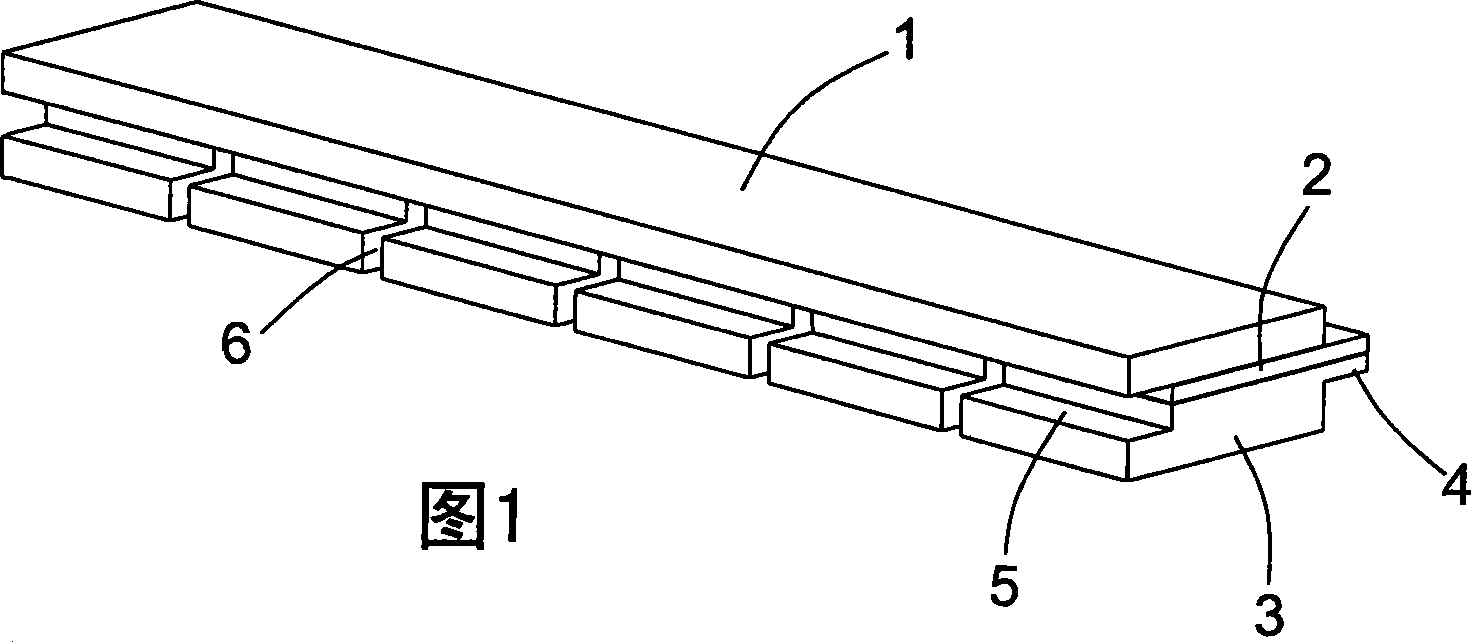

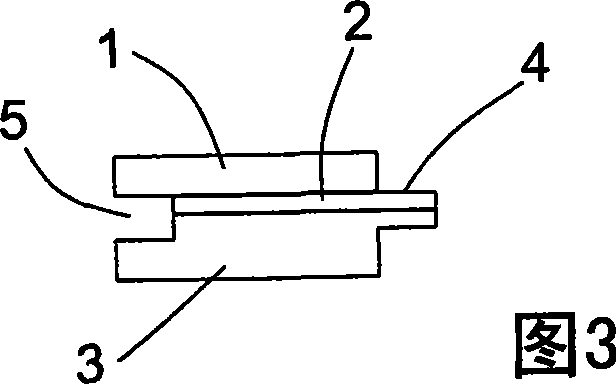

Terrestrial heat composite floor and manufacturing method thereof

ActiveCN101412238AEasy constructionDoes not affect strengthWood working apparatusFlooringHardnessWear resistance

The invention relates to a terrestrial heat composite floor board and a method for manufacturing the same. The method comprises the following processing steps: step A, preparation of face veneer, which is to process face veneer raw materials into sheets, and dry and balance the sheets; step B, preparation of middle veneer, which is to process middle veneer raw materials into sheets, and dry and balance the sheets; step C, preparation of bottom veneer, which is to process bottom veneer raw material into sheets, and dry and balance the sheets; step D, glue spreading; step E, blank assembling, which is to arrange the face veneer, the middle veneer, and the bottom veneer longitudinally, transversely, and longitudinally respectively according to wood grains; step F, hot pressing, which is to put the face veneer, the middle veneer, and the bottom veneer into a hot press to perform hot pressing; step G, conditioning, which is to put the floor board after the hot pressing and gluing into a balancing storeroom with constant temperature and humidity to keep stand and perform balance conditioning; step H, securing thickness and sanding; step I, mortice opening; step J, back trough opening; and step K, surface finishing, which is to adopt a roll painting process to lacquer the glued floor board. The composite floor board manufactured by the method has the characteristics of beautiful surface, hardness, wear resistance, good heat conductivity, high flexibility, and humiture change resistance.

Owner:FUSONG JINQIU WOOD CO LTD

Floor covering with woven face

InactiveUS20030114062A1Small thicknessNot easy to wearSynthetic resin layered productsWoven fabricsPolyesterYarn

Flooring that utilizes sophisticated, self-stabilizing, woven face fabric using relatively heavy "carpet weight" nylon, polyester, PTT or other yarns on modern Jacquard computer controlled looms to produce flat-weave fabrics that are bonded to engineered backing structures. Urethane modified bitumen may be used as a backing layer, and an optional latex precoat may be used on the fabric layer, together with an optional antimicrobial in the precoat.

Owner:SCOTT GRAHAM +2

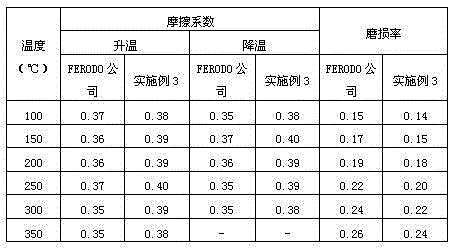

Ceramic brake pad of high-performing automobile

InactiveCN101555920AExtended service lifeImprove the lubrication effectFriction liningBoron nitrideCopper

A ceramic brake pad of high-performing automobile comprises the following components according to weight percentages: 7%-11% of ceramic fibre, 7-9% of glued aluminium silicate fibre, 5-8% of polyacrylonitrile fibre, 2-3% of aramid fibre 7-9% of red copper fibre, 7-10% of acicular aedelforsite fibre, 7-12% of barite, 7-9% of chromite, 1-2% of butyronitrile rubber, 7-11% of graphite particle, 0.2-0.5% of zinc oxide, 5-8.5% of calcined petroleum coke, 1-3% of expansion graphite, 6-10% of boron containing phenolic resin, 3-5% of magnetite, 1-1.5% of heavy-burned magnesia, 0.3-0.5% of modified whiten bead of resin acceptor, 3-5% of boron nitride and 0.3-0.5% of alumina; the invention can form excellent friction layer and transmission film in using process, thereby having good lubricating effect without damaging the couple plate; therefore, the service life of the friction material is greatly prolonged.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

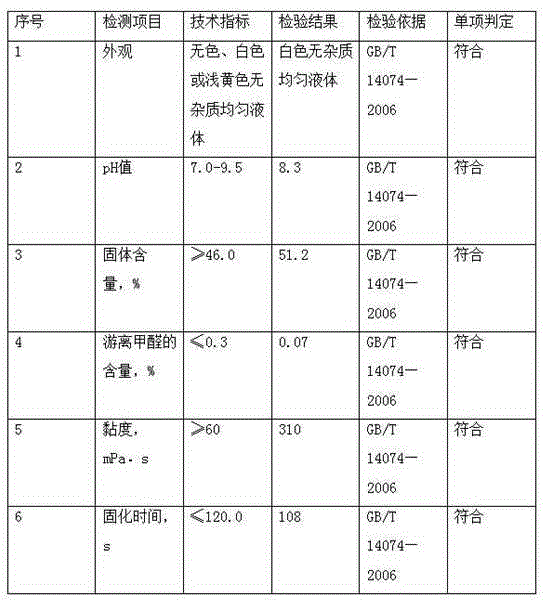

Production method for low-formaldehyde solid wood composite floor

ActiveCN105235024AAvoid gel effectLow residual formaldehydeLaminationLamination apparatusParquetinaSolid wood

The invention relates to a solid wood composite floor, in particular to a production method for a low-formaldehyde solid wood composite floor. The production method comprises the technological steps of wood plate slicing, drying, repairing, selecting, gluing, pre-pressing, hot pressing, edge cutting and sanding, and finished product obtaining. The key of the production method is that the residual amount of formaldehyde in adhesives is reduced by modifying the used urea-formaldehyde resin adhesives, so that the residual amount of the formaldehyde in the solid wood composite floor is reduced; by adopting high-quality plates and controlling process parameters in the production process, the quality of the produced solid wood composite floor is guaranteed. The content of the formaldehyde in the solid wood composite floor manufactured through the method is low, the quality of the floor is stable, and the floor is not prone to damage; the floor has the characteristics of being comfortable in foot feeling, resistant to abrasion, easy to install and clean, and high in stability.

Owner:DALIAN SHENGYU TECH DEV CO LTD

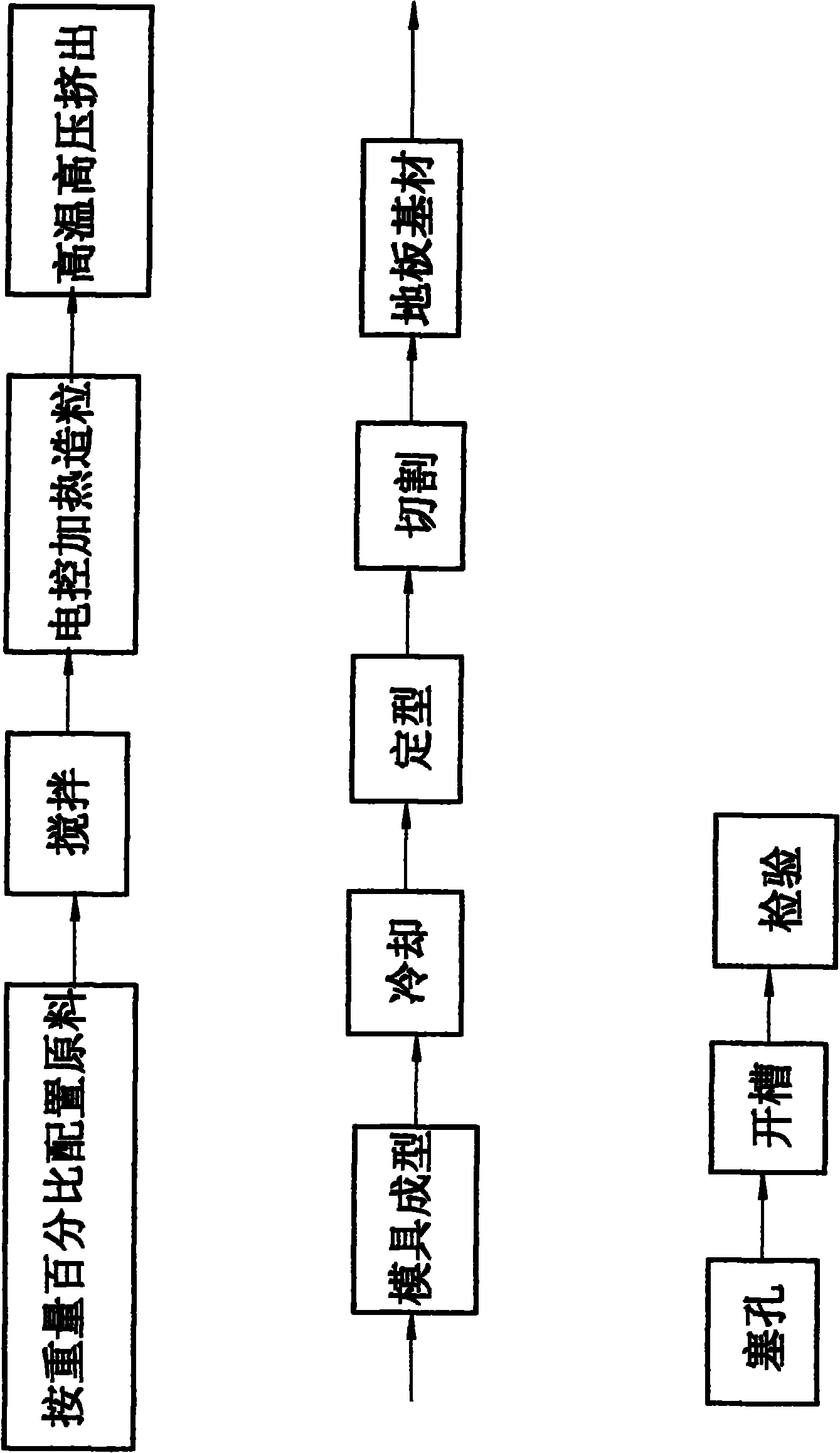

Stone-plastic wood floor and processing technology thereof

The invention relates to an indoor decorative material floor, in particular to a stone-plastic wood floor taking natural calcium carbonate stone powder, woody plant fiber powder and plastic renewable material as raw materials, and a processing technology of the stone-plastic wood floor. The stone-plastic wood floor comprises the following components by weight percent: 25%-35% of natural calcium carbonate with fineness of 500 meshes, 1% of acrylate polymer adhesive and 2% of compound stabilization modifying agent. The stone-plastic wood floor is characterized in that the floor also comprises 30-40wt% of regenerated plastic powder with the fineness of 40 meshes and 25-35wt% of woody fiber powder with the fineness of 80 meshes. The floor are processed by the processing technology to obtain pieces of floor sections with double-sided lock catch splicing structures; and the processing technology comprises a floor base material production technology and a surface treatment processing technology. The waste plastic regenerated material and woody fiber powder are fully utilized, thus wastes are turned into wealth; and the floor has the solidity of the stone product and the softness of the wood product, and the foot feeling is comfortable. The indoor decorative material floor has low cost, is convenient for installation, and time, labor and money are saved.

Owner:安徽温禾新材料科技股份有限公司

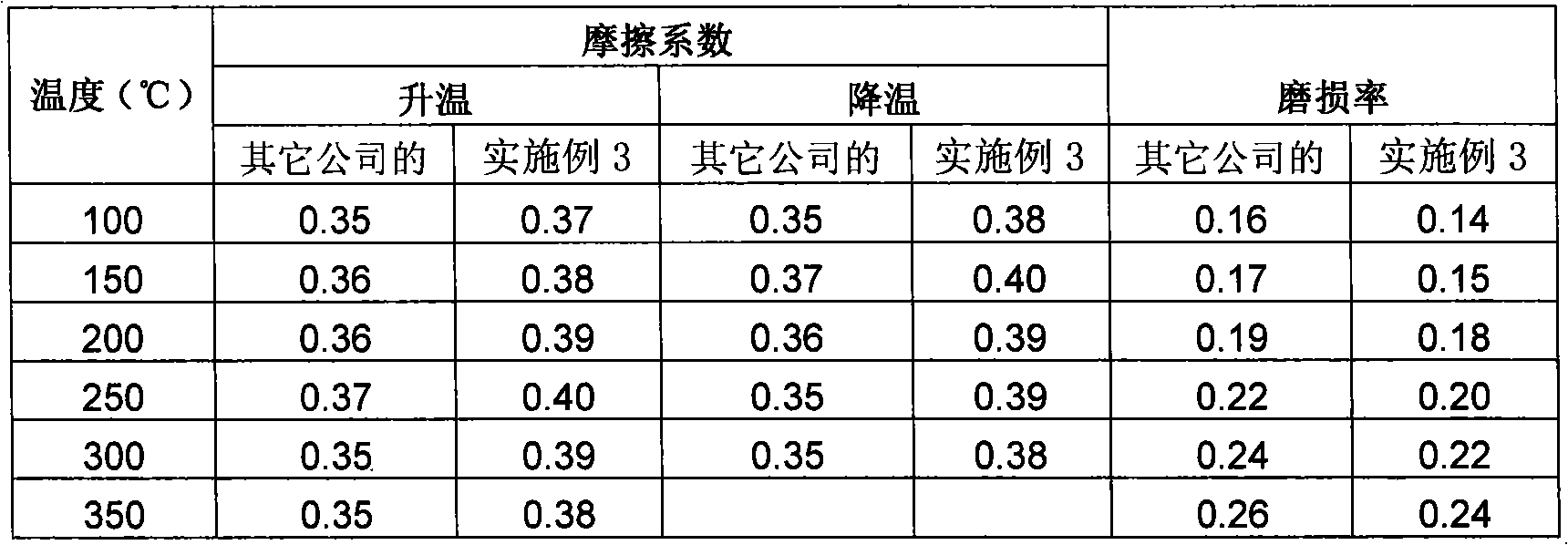

Friction material composition for ceramic brake pad

ActiveCN103059806AExtended service lifeFully playOther chemical processesFriction liningMagnesiumOxide

The invention relates to a friction material composition for a ceramic brake pad, which is mainly prepared from the following components in percentage by weight: 14-18% of mullite ceramic fiber, 10-13% of adhesive spray aluminum silicate fiber, 10-12% of aramid fiber pulp, 8-9% of red copper fiber, 8-10% of potassium titanate whisker, 3-5% of nano ferric oxide, 0.8-1% of aluminum hydroxide, 7-12% of barite, 8-10% of potash feldspar, 3-5% of chromite, 1-1.5% of magnesium hydroxide, 0.2-0.5% of zinc oxide, 7-11% of graphite particle, 6-9% of expanded graphite, 1-2% of nitrile-butadiene rubber and 6-10% of cashew shell oil modified phenolic resin. By reasonably matching multiple components, the invention ensures that the advantages of all the materials are sufficiently displayed in the friction material, thereby greatly prolonging the service life of the friction material. Compared with the existing ceramic brake pad, the ceramic brake pad provided by the invention has higher mechanical and braking properties at high temperature.

Owner:摩擦一号汽车科技(仙桃)有限公司

Bamboo-wood composite board and preparation method thereof

InactiveCN101745947AFully absorbedReach the designed drug loadingWood veneer joiningThermal compressionHigh surface

The invention relates to an anti-corrosion bamboo-wood composite board and a preparation method thereof. The preparation method of the anti-corrosion bamboo-wood composite board comprises the following steps: firstly preparing anti-corrosion bamboo strips and heat-treated wood; next, respectively assembling and compressing the anti-corrosion bamboo strips and the heat-treated wood into anti-corrosion bamboo wood and a heat-treated sheet material; and then carrying out assembling and hot compression on the anti-corrosion bamboo wood and the heat-treated sheet material to obtain the anti-corrosion bamboo-wood composite board. The bamboo-wood composite board prepared by the method of the invention has excellent corrosion resistance which reaches the corrosion resisting level specified in national standard GB / T13942.1-1992 Method for Laboratory Test of Natural Decay Resistance of Woods, and also has very high surface abrasion resistance and high mechanical strength which reach the national standards in GB / T 18103-2000 national composite floor.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Copper-free high-performance environment-friendly type friction material for saloon car and preparation method thereof

A copper-free high-performance environment-friendly type friction material for a saloon car and a preparation method thereof are provided. The friction material comprises the following components in parts by weight: 6-8 parts of phenolic resin, 2-4 parts of aramid fiber, 13-18 parts of an RB205 mixture, 15-20 parts of potassium titanate, 5-8 parts of calcium hydroxide, 20-25 parts of barium sulfate, 1-3 parts of artificial graphite, 3-5 parts of a cashew nut oil friction powder, 3-5 parts of antimony sulfide, 1-3 parts of a butyronityile rubber powder, 3-5 parts of mica, 4-6 parts of calcium silicate, and 1-3 parts of zirconia. The preparation method comprises the steps: a) weighing the component materials according to the formula ratio, and then dispersing into a uniform mixture; b) loading the mixture into a saloon car friction block dedicated die, carrying out hot press molding with the hot press duration time of not less than 5 minutes; and c) carrying out conventional heat treatment on the friction material after hot press molding, and after being fully cured, carrying out size and appearance machining into the product. The friction material has the advantages of excellent high-temperature characteristic, good abrasive resistance performance, good braking performance, reasonable price, recession resistance, high life, stable friction coefficient and the like.

Owner:ZHEJIANG HANGMO OUYI AUTOMOTIVE COMPONENTS

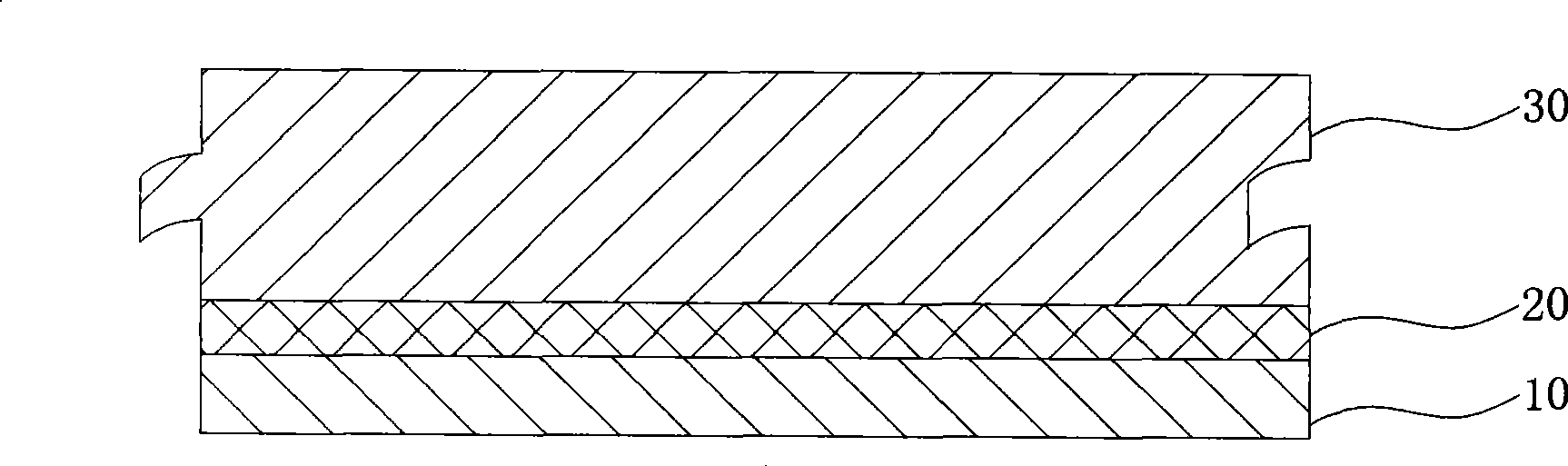

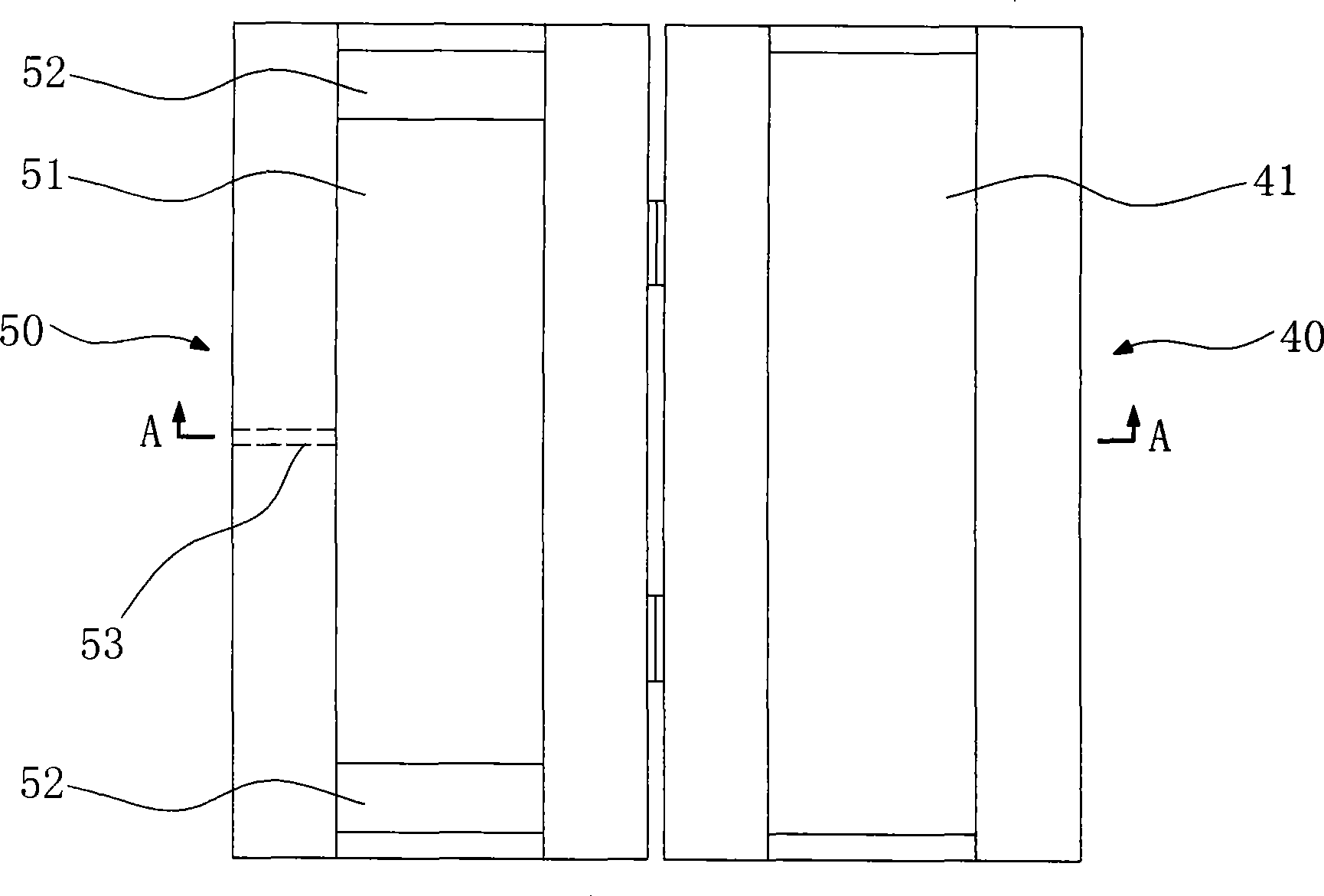

Novel composite flooring, mold thereof and processing method

The invention belongs to the technical field of floor, in particular to a novel composite floor, a die and a processing method thereof. The substrate of the composite floor is a plastic-wooden plate, the surface layer of the composite floor is a solid wood plate, and an elastic layer is arranged between the substrate and the surface layer. When the composite floor is processed, raw materials such as PVC resin and so on are mixed and extruded to obtain a PVC plastic-wooden plate; the PVC plastic-wooden plate taken as the substrate and the solid wood plate taken as the surface layer are placed into the die respectively, and polyurethane foam materials are injected to a space enclosed by the solid wood plate, the PVC plastic-wooden plate and the die through a passage on a base of the die, and is foamed; and the composite floor is pressed by a press machine after the polyurethane foam materials are foamed fully. The invention has simple processing and manufacturing, high production efficiency and low production cost; and the obtained composite floor is safe, environment-friendly, moistureproof, waterproof and mothproof, has soft and comfortable foot feeling, good temperature insulating effect and high service performance, and has good effect of vibration reduction and sound insulation because the polyurethane foam materials play a role of vibration reduction in the middle layer.

Owner:郎玉山

Method for processing assembling type bamboo floor

The invention discloses a processing method of an assembled bamboo floor, which utilizes bamboo with a short growth period and abundant resources as a raw material, and after selecting bamboo, breaking bamboo, cooking, drying, matching colors, cutting materials, assembling, and gluing, Put it in a hot press and glue it together, then polish it with a heavy sand machine, cut it with mechanical equipment, paint it and dry it, and then it will be the finished product. The whole assembly process is simple, practical, and the finished product has no peculiar smell, and the assembled bamboo floor has a compact structure, is not easy to deform, has good pressure resistance, and feels comfortable on the feet. It avoids mold, insects, deterioration and other phenomena during the use of bamboo flooring, and uses the top layer of bamboo chips, carbonized bamboo chips or other colored bamboo chips to be placed regularly in the top layer, which greatly enriches the surface of the bamboo floor. It has the advantages of anti-mildew, anti-corrosion, waterproof, not easy to deform, energy saving and environmental protection.

Owner:孙长桥

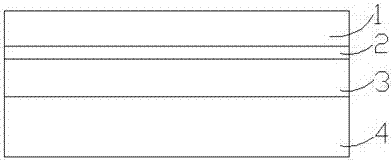

Elastic sound-absorbing PVC (Polyvinyl Chloride) floor and preparation method thereof

PendingCN107471803AElasticComfortable feetSynthetic resin layered productsLaminationNoise generationSound generation

The invention belongs to the field of PVC (Polyvinyl Chloride) floors and relates to an elastic sound-absorbing floor. The elastic sound-absorbing PVC floor comprises an elastic PVC transparent layer, a printing fabric layer, a base material layer and an elastic sound-absorbing layer which are arranged in sequence from top to bottom. The elastic sound-absorbing PVC floor has the advantages that due to use of highly-polymerized PVC, the transparent layer has elasticity and is comfortable in foot feel and low in noise; the base material layer has an effect of stabilizing the physical properties of the floor; the elastic sound-absorbing layer has a structure with convex and concave patterns, the part with the convex patterns has high elasticity and can generate elastic deformation when the floor is stepped, and the part with the concave patterns and the ground form a cavity so as to realize the effects of reducing sound generation and absorbing sound; and the elastic sound-absorbing layer and the other layers are laminated together by one time of heat lamination, so that the elastic sound-absorbing floor does not contain glue, VOC (Volatile Organic Compound) and formaldehyde, and is more environment-friendly.

Owner:HUIZHOU WEIKANG NEW BUILDING MATERIALS CO LTD

Film pressure coating as well as film pressure floor and preparation method of film pressure floor

ActiveCN109852112AImprove wear resistanceReduce external frictionPolyurea/polyurethane coatingsFlooringPhotoinitiatorChemistry

The invention provides a film pressure coating. The coating comprises a radiation-curable adhesive primer layer, a radiation-curable wear-resistant primer layer and a radiation-curable film pressure finish coat layer in sequence from the bottom to the top; the radiation-curable adhesive primer layer is a conventional adhesive primer; the radiation-curable wear-resistant primer layer comprises thefollowing components, in parts by mass: 10-60 parts of acrylic resin A, 10-60 parts of an acrylate monomer A, 2-7 parts of a photoinitiator A, 5-40 parts of wear-resistant particles A and 3-10 parts of an additive A; and the radiation-curable film pressure finish coat layer comprises the following components, in parts by mass: 2-20 parts of acrylic acid-modified organosilicon resin having inorganic powder affinity, 2-20 parts of a two-functional polyurethane acrylate resin, 10-40 parts of multi-functionality polyurethane acrylate resin, 5-50 parts of an acrylate monomer B, 2-7 parts of a photoinitiator B, 5-40 parts of wear-resistant particles B, and 3-10 parts of an additive B. The invention also provides a film pressure floor containing the above film pressure coating and a preparation method of the film pressure floor. The film pressure coating provided by the invention has the characteristics of excellent wear resistance, scratch resistance, long-lasting self cleaning and high hardness; and the prepared film pressure floor has the characteristics of a comfortable foot feeling, slitting slotting, greenness, environmental protection, energy saving and high efficiency.

Owner:HUNAN BANFERT NEW MATERIALS TECH

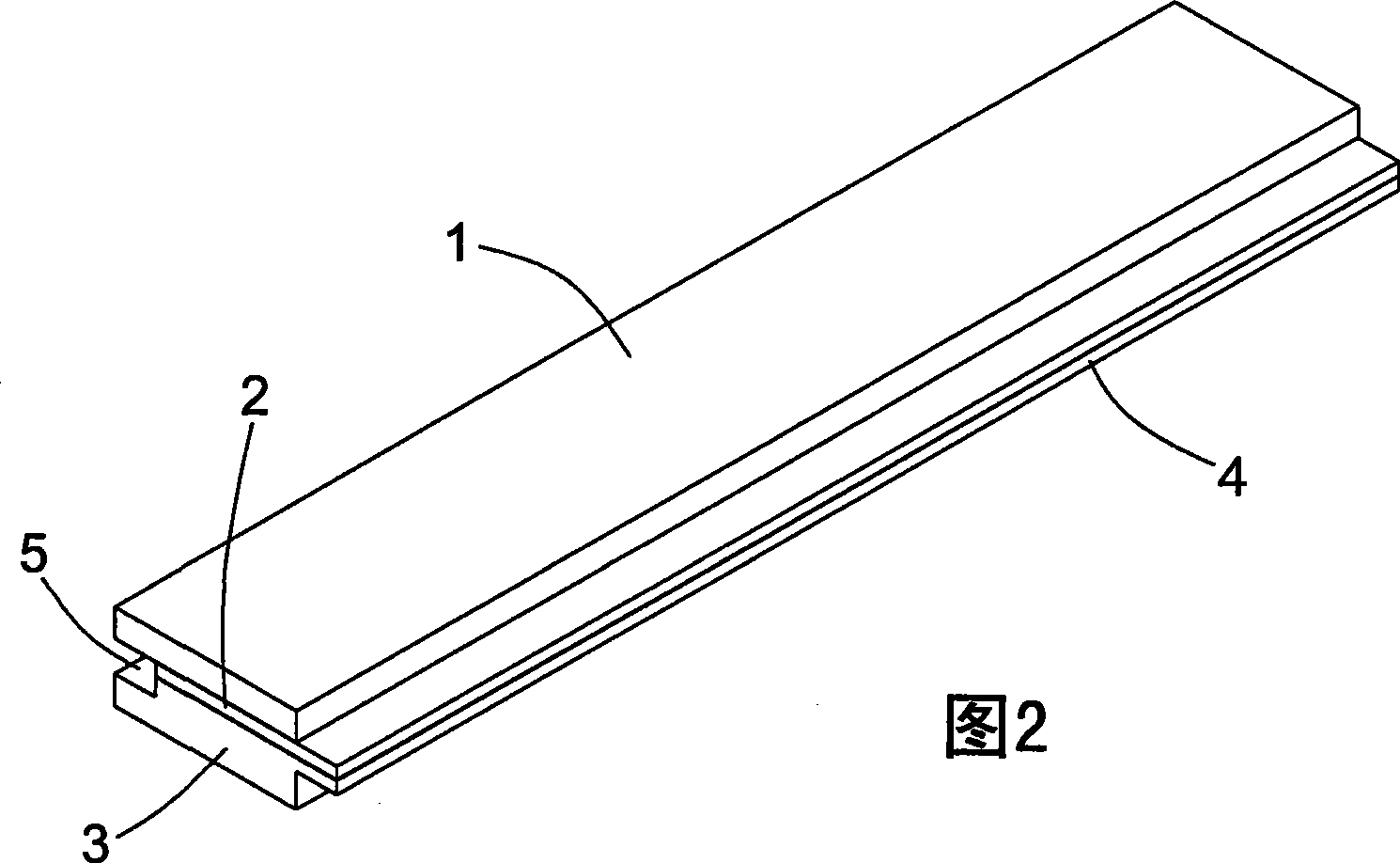

Solid wood foor

InactiveCN102561654AReduce harmDisperse impactWood layered productsFlooringSolid woodPolyvinyl chloride

The invention discloses a solid wood floor which is characterized by comprising a single-layer solid wood board and a PVC (Polyvinyl Chloride) board, wherein the PVC board is fixedly connected with the solid wood board; the back of the solid wood board is formed into unit area blocks through uniformly spaced grooves; the solid wood board has the water content of 5-8% and the thickness of 8-20mm after being dried in vacuum at the temperature of 40-60 DEG C; the thickness of the PVC board is 2-5mm; and the depth of each groove is 1 / 5-1 / 2 that of the solid wood board. The solid wood floor is simple in structure, stable in size, non-deformable, warp-proof, dampproof, waterproof, environment friendly, capable of absorbing sound, preventing noise, conducting heat and preserving heat, suitable for floor heating, small in coefficient of thermal expansion, stable, simple and rapid in installation and construction and capable of being used after 24h if being adhered by using special environment friendly floor glue.

Owner:GUANGZHOU PANYU KANGDA BOARD

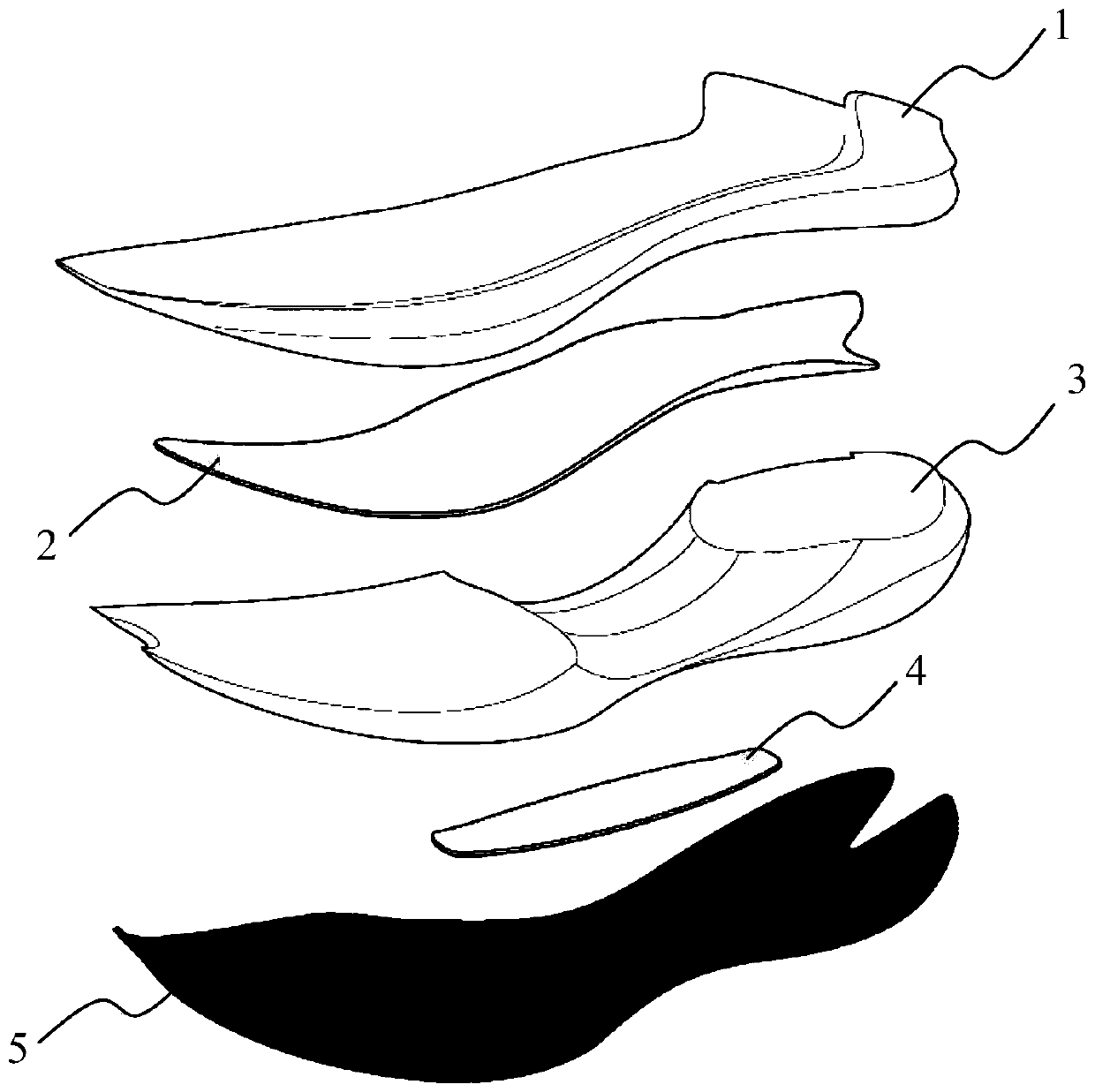

Comfortable heel type outsole shoes

The invention discloses comfortable heel type outsole shoes. Each shoe comprises a shoe main body, wherein the shoe main body comprises a shoe surface, a shoe pad, a shoe heel and a shoe outsole; and the shoe outsole comprises a bottom piece and an outsole middle section which is bonded with the bottom piece. The comfortable heel type outsole shoes are improved invention of the noticed patent 201010019544.4 of the inventor. Compared with the traditional shoes, the comfortable heel type outsole shoes disclosed in the invention have the greatest difference that insole waist iron and insole hard insertion are not included, are simple and convenient for operation, are firm, save labor and enable wearers to have comfortable foot feeling; the outsole middle sections of the comfortable heel type outsole shoes disclosed by the invention are dual-purpose and can be used for the inner part or outer part of shoes; and the invention is an innovative design which is convenient to design and use heels with different styles, can be designed into the other new style of soles, is convenient for production and design, is simple and convenient for operation, is firm, saves labor and enables the wears to have comfortable foot feeling, and a plurality of shoe styles with same heel heights can use the same outsole middle section. A shockproof piece is made of elastic materials, such as silica gel, and the like.

Owner:黎田建

Colored photoelastic polyester fine denier carpet yarn and preparation method thereof

ActiveCN102286819AIncrease productionLow priceYarnPigment addition to spinning solutionWeather resistanceEngineering

The invention relates to a colored glossy elastic polyester fine-denier carpet yarn and a preparation method. The carpet yarn is a plied yarn of 1,200 to 3,600dtex formed by at least two twisted polyester single yarns of 600 to 1,800dtex; and the twisted polyester single yarn is formed by multifilaments of a colored, glossy, fine-denier, profiled and three dimensional crimped polyester filament yarn. The preparation method comprises the steps: firstly, carrying out fibrous colored spinning procedures comprising spinning, false twist deformation and yarn doubling in the field of garment; secondly, obtaining three dimensional crimped polyester filament yarns with colors, fine-deniers and heteromorphous sections; and thirdly, obtaining colored, glossy and elastic polyester fine-denier carpetyarns through the post processing procedures comprising strand combing and sizing in the field of carpet yarns. The colored glossy elastic polyester fine-denier carpet yarn solves the problems of poor handfeel, resilience and dyeing property of the polyester fiber, not only can meet the requirements on the characteristics of carpet products, such as coverage, bulkiness, resilience, lodging resistance and foot-feel comfort, but also has the characteristics of high weather resistance, good color fastness, and energy-saving high-temperature high-pressure dyeing prevention.

Owner:CHANGZHOU LINGDA SPECIAL FIBER

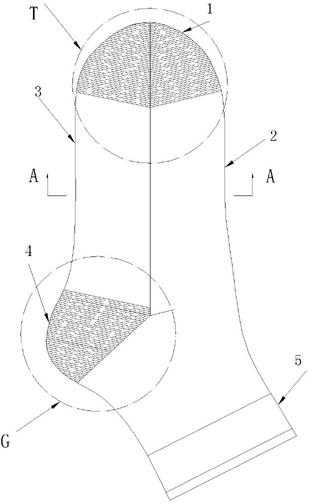

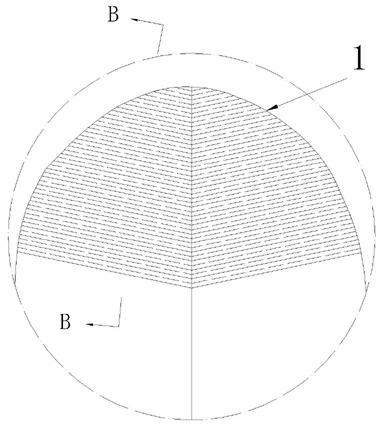

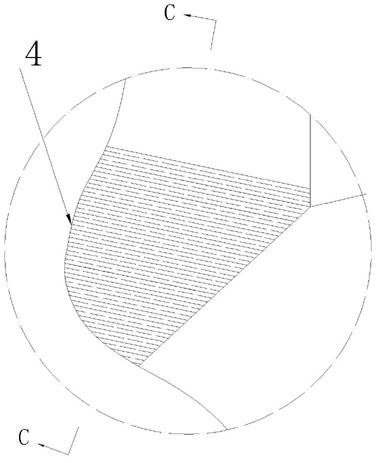

Socks containing silver fiber

The invention relates to a pair of socks containing silver fibers, which are weaved by yarns through adopting a special hosiery machine. Each sock comprises a sock head, a sock surface, a sock bottom, a sock heel and a sock leg in order, wherein at least one silver fiber is added to the sock head and the sock heel on the basis of the at least one original yarn; and the silver fiber and the yarn are tightly arranged in parallel or tightly interweaved. The yarn is any one of long staple cotton, mercerized cotton, combed cotton, blended cotton and acrylic, all wool, wool, blended wool and acrylic or bamboo fiber; the bottom yarn of each sock is made of terylene coating yarns or spandex coating yarns or nylon coating yarns or chinlon coating yarns, and the number of the yarns is 10 to 80. The socks containing silver fibers have the efficacies of stronger bacterium resistance, deodorization and sweat absorption, the effects of reducing static electricity, promoting blood circulation, eliminating foot swelling, and the like and the advantages of high air permeability, durability and comfortable foot feeling.

Owner:SHANGHAI AIFA INVESTMENT MANAGEMENT

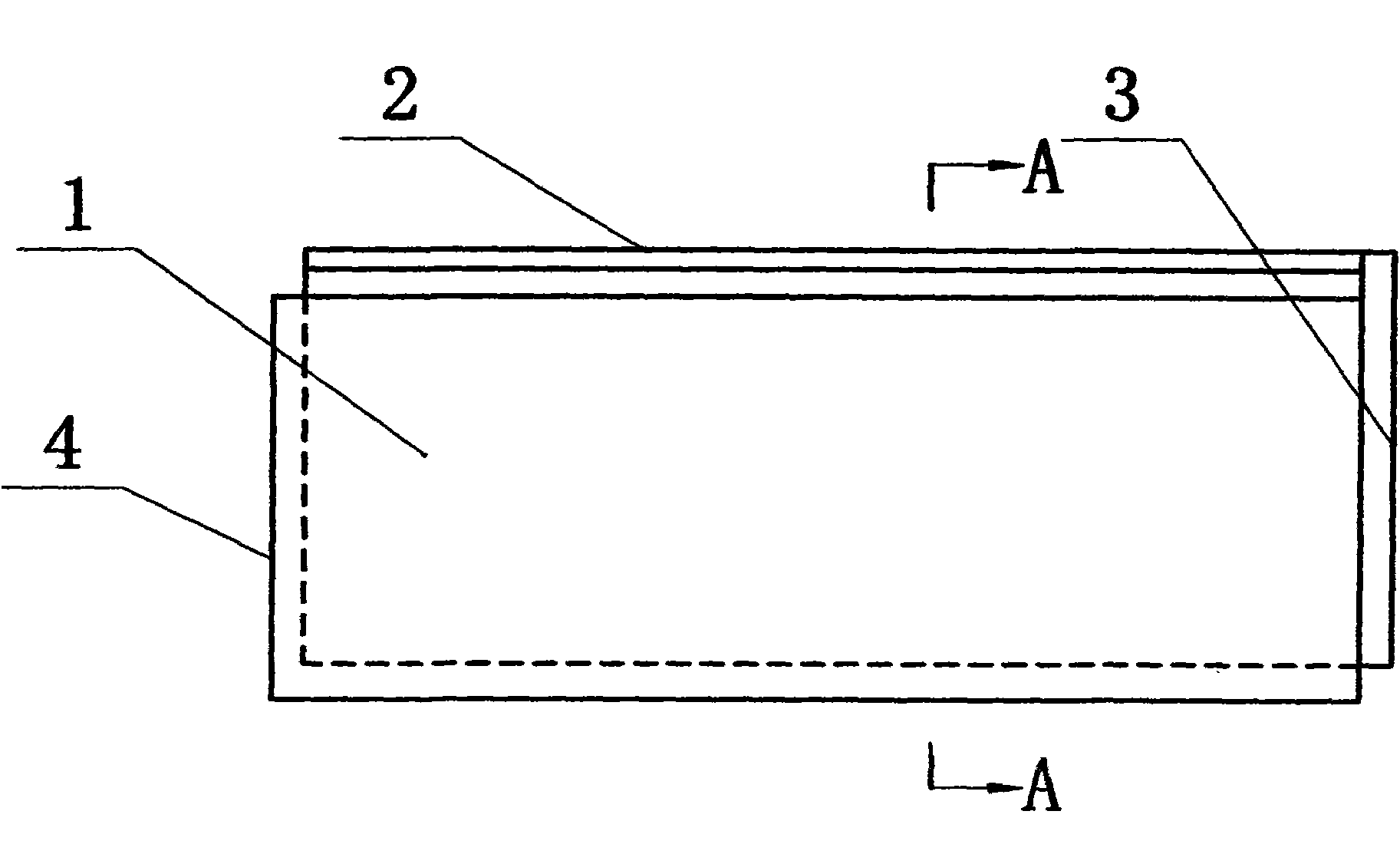

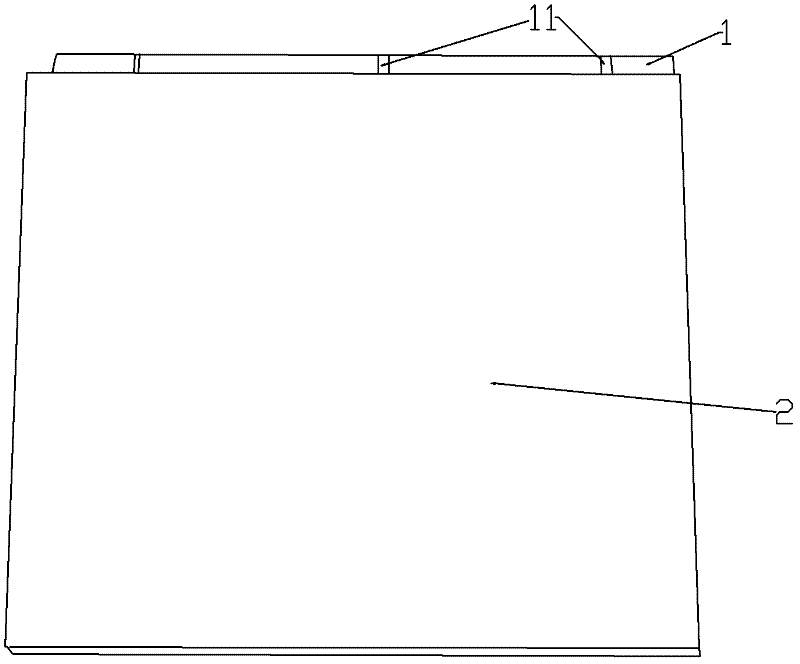

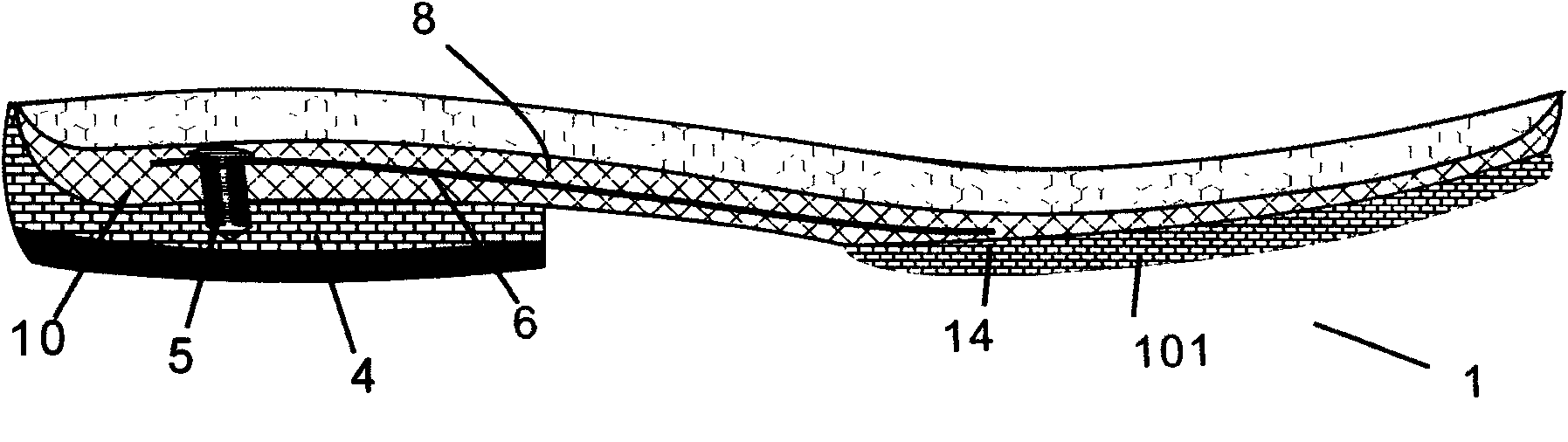

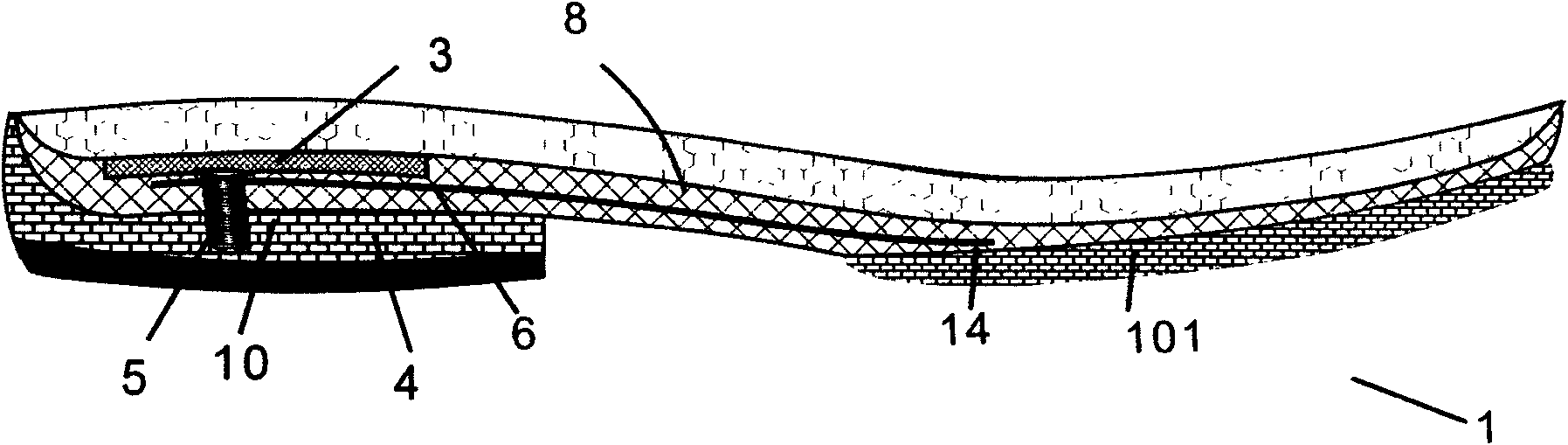

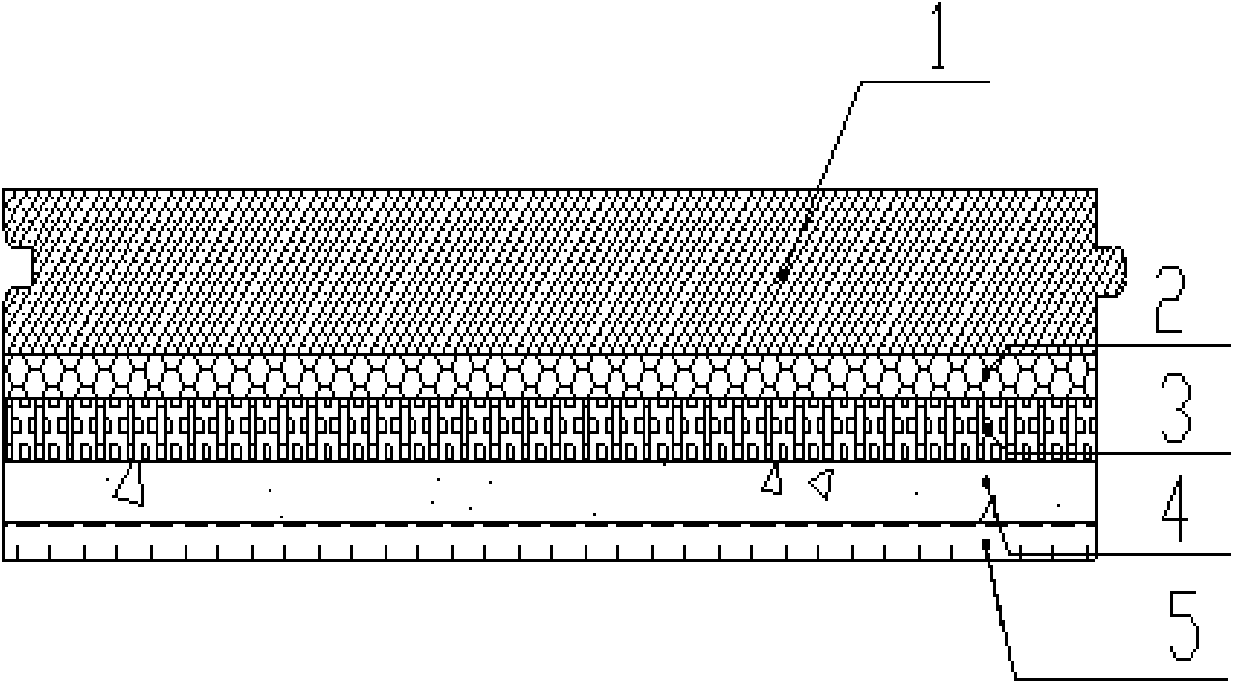

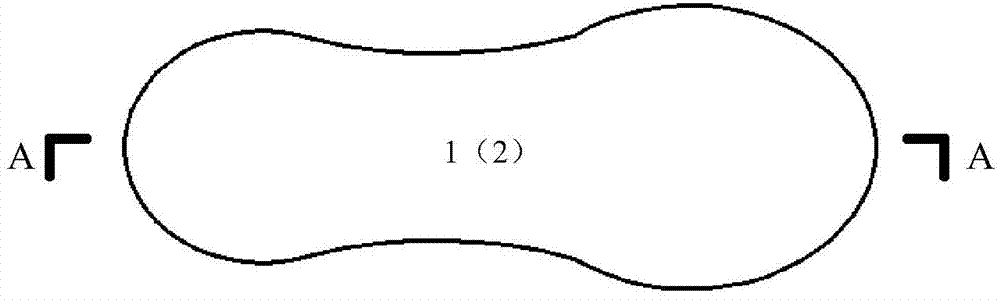

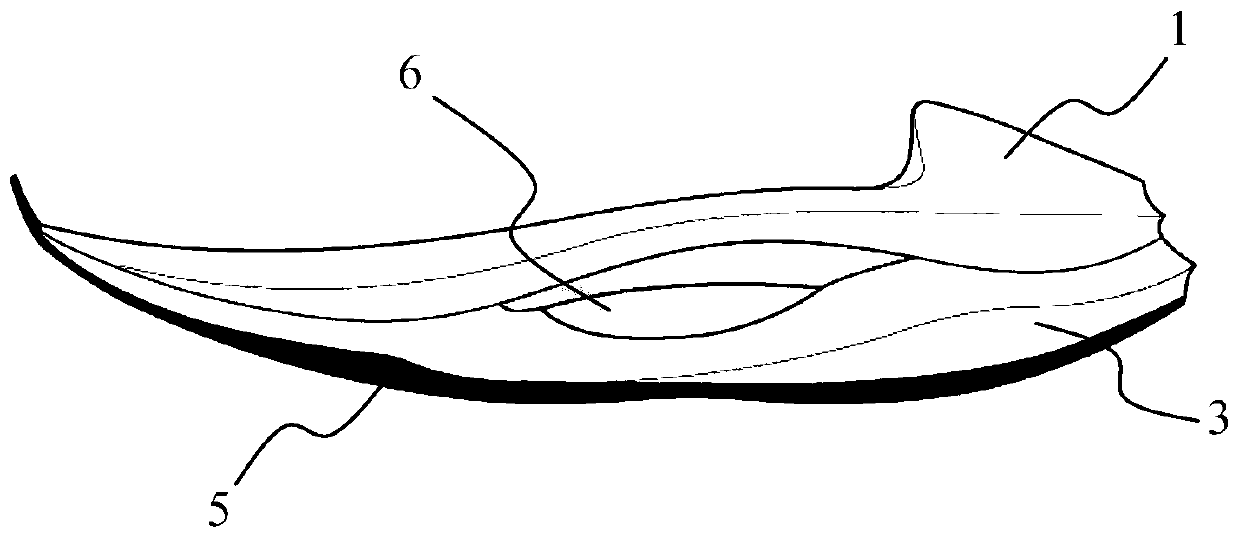

Method for heating wood geothermal floor and geothermal floor

ActiveCN101598362ALow priceGood for healthLighting and heating apparatusElectric heating systemInsulation layerElectric heating pads

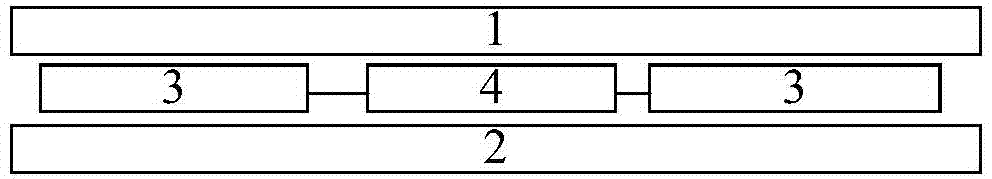

The invention discloses a method for heating a wood geothermal floor, which comprises the following steps: firstly, paving a damp-proof membrane 5 on a smooth floor; secondly, paving a heat insulation layer 4 on the damp-proof membrane 5, paving an electric heating pad 3 on the heat insulation layer 4, and paving an electromagnetic shielding layer 2 on the electric heating pad 3; and finally, paving wood floor 1 to achieve the heating of the wood geothermal floor. The invention also discloses corresponding geothermal floor. Compared with the conventional heating mode, the method has the advantages of no destruction to buildings, simple mounting, convenient use, low energy consumption and high heat utilization rate, and has good shielding effect on the electromagnetic wave radiation, an induced electric field and an induced magnetic field generated by a heating system; in the generated frequency range from 30 MHz to 1.5 GHz, the electromagnetic shielding effect (SE) can reach 30 to 60 dB; and when a double-layer electromagnetic shielding layer material of which the number is more than 60 is adopted, the value of the electromagnetic shielding effect (SE) can be more than 60 dB.

Owner:ZHEJIANG SHIYOU TIMBER

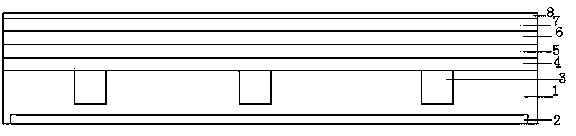

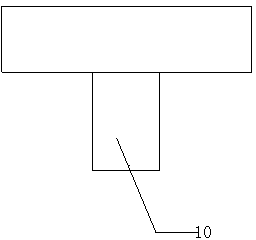

PVC (polyvinyl chloride) floor with noise reduction and elastic functions

ActiveCN104278816AEasy to fixElasticSynthetic resin layered productsGlass/slag layered productsHome usePolyvinyl chloride

The invention relates to a PVC (polyvinyl chloride) floor with noise reduction and elastic functions. The PVC floor comprises a base material layer, wherein an insulated waterproof MPPO (modified polyphenylene oxide) layer is embedded inside the underside of the base material layer. three moisture-proof noise-reduction holes are formed inside the base material layer, a middle layer is arranged above the base material layer, an elastic fiber layer is arranged above the middle layer, a fiber stabilized and reinforced layer is arranged above the elastic fiber layer, a PVC layer is arranged above the fiber stabilized and reinforced layer, a UV (ultraviolet) paint layer is arranged above the PVC layer, the elastic fiber layer is a warp and weft woven fiber layer formed by a soybean fiber layer or a linen fiber layer or the soybean fiber layer and the linen fiber layer, and one or two or three of vermiculite, foam glass and expanded perlite is / are arranged in the three moisture-proof noise-reduction holes. The PVC floor has moisture-proof, insulation, noise-reduction and worm damage prevention functions, also has elasticity, is suitable for home use, has comfortable foot feeling, has a simple structure, can be installed conveniently and has no gaps.

Owner:JIANGSU KENTIER WOOD

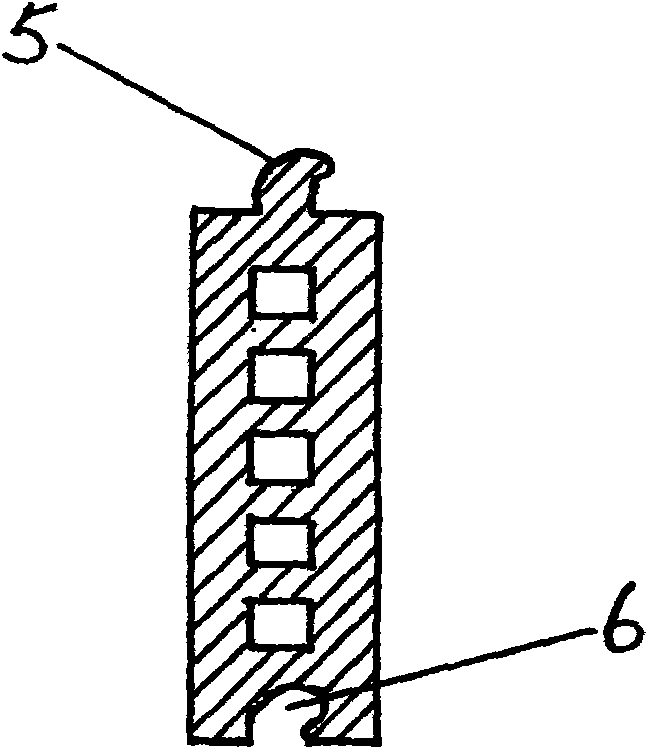

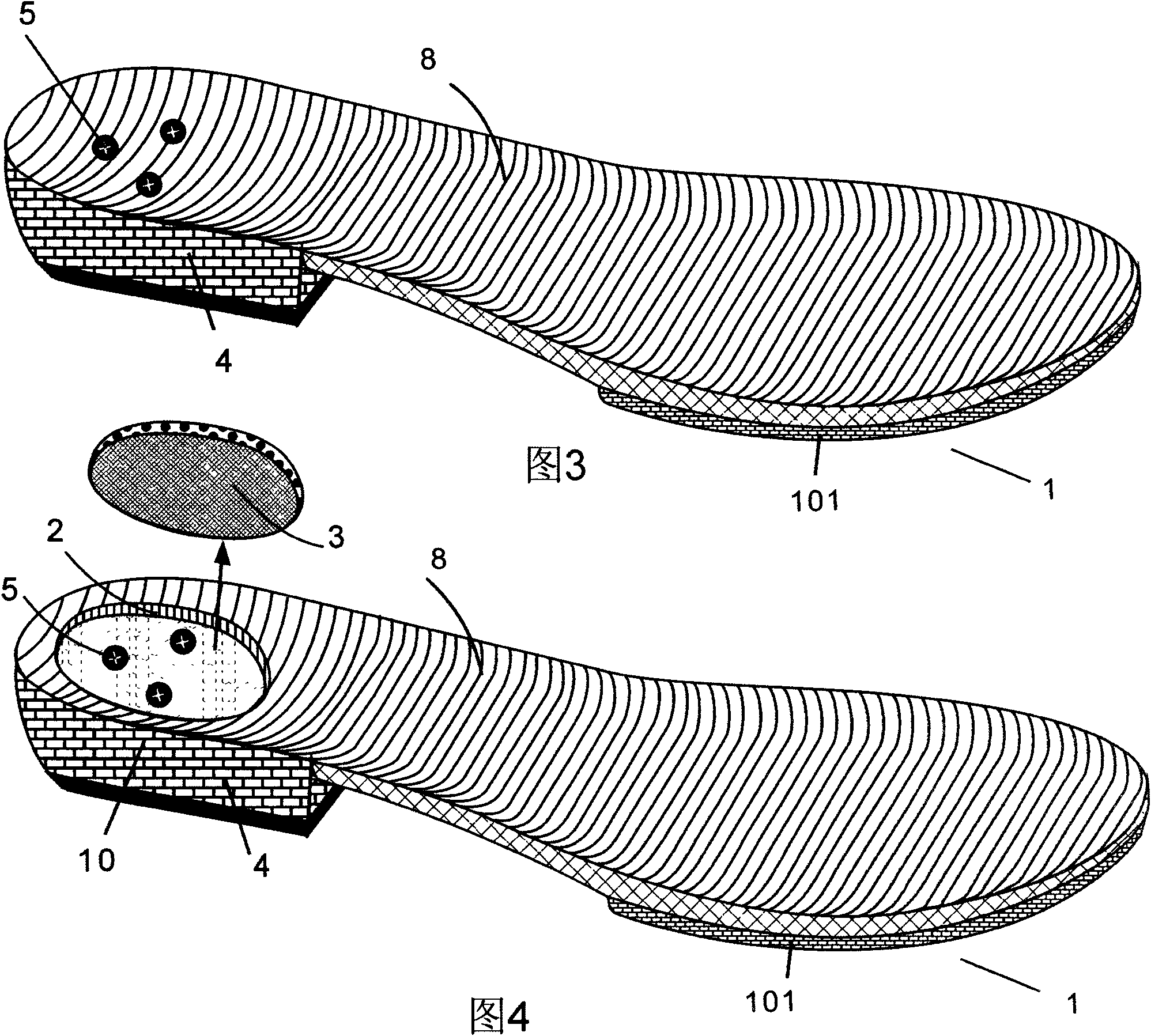

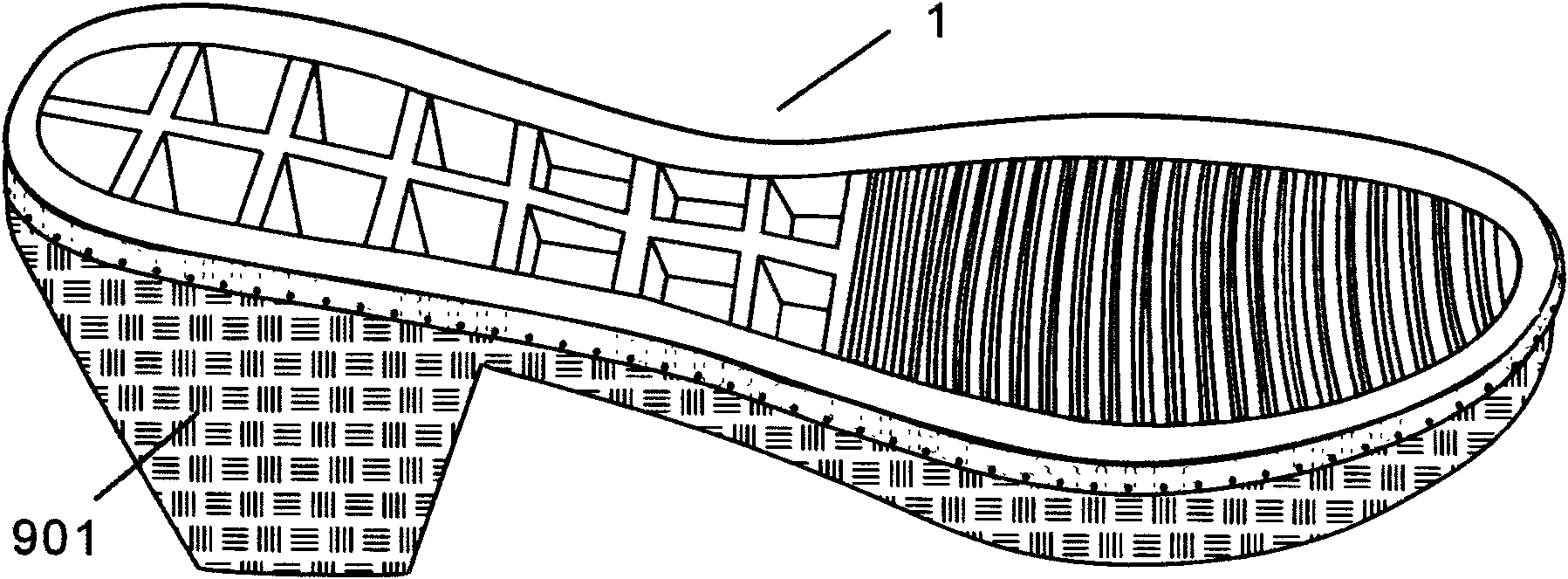

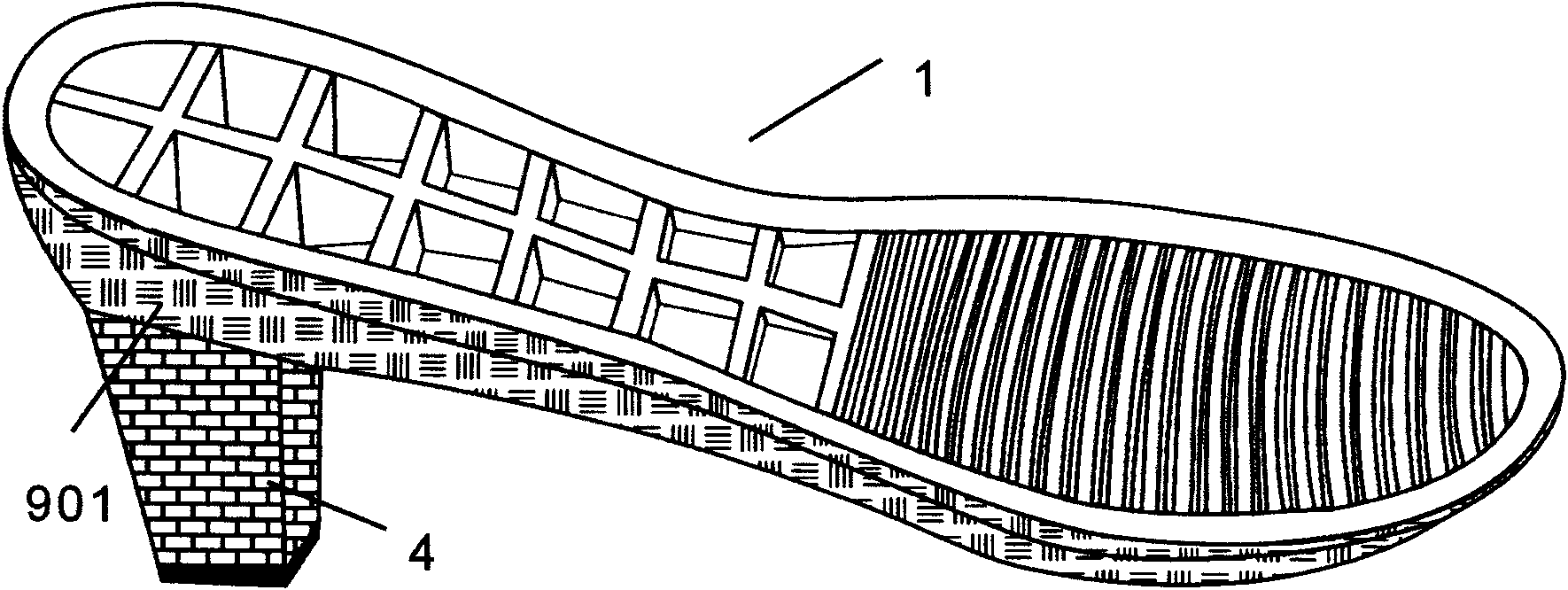

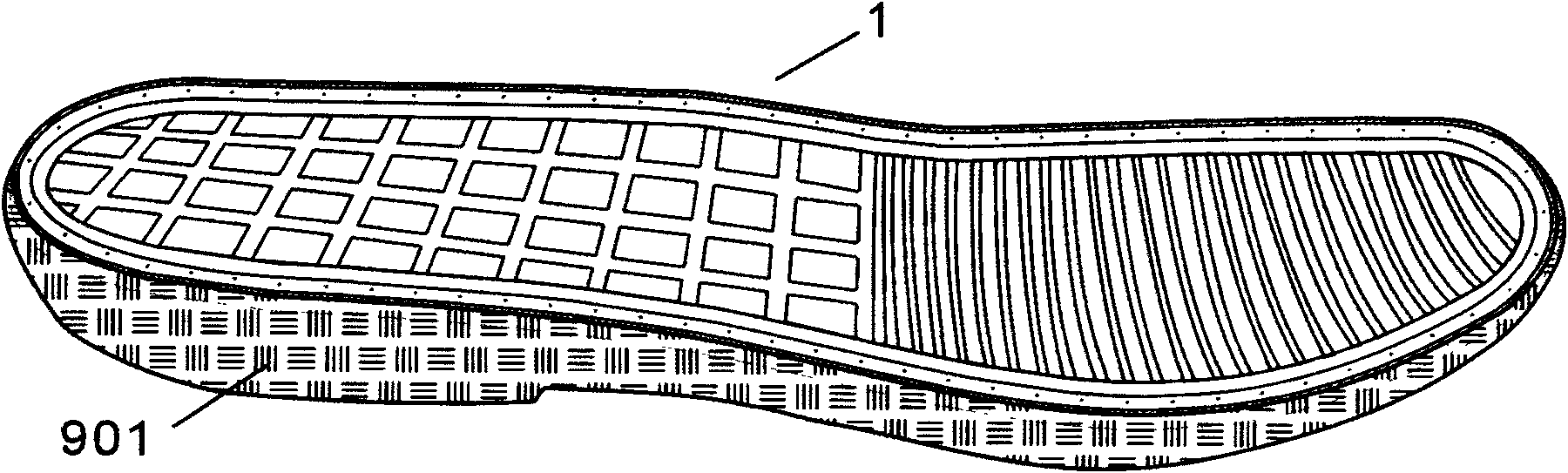

Insole-type piezoelectric generator

ActiveCN103580535ASimple structureComfortable feetPiezoelectric/electrostriction/magnetostriction machinesUpper teethPiezoelectric generator

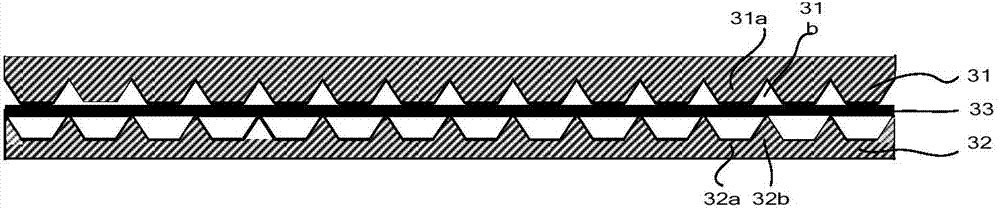

The invention provides an insole-type piezoelectric generator. The insole-type piezoelectric generator comprises an upper protective layer, a lower protective layer, at least one piezoelectric electricity generation unit and a power management module. The upper protective layer is placed above the lower protective layer, and the upper protective layer and the lower protective layer are both in an insole shape. The at least one piezoelectric electricity generation unit is placed between the upper protective layer and the lower protective layer. Each piezoelectric electricity generation unit comprises an upper tooth layer, a lower tooth layer and a piezoelectric thin film. The upper tooth layers are placed above the lower tooth layers. The lower surfaces of the upper tooth layers comprise upper racks and upper tooth grooves which are arranged in an alternating mode, the upper surfaces of the lower tooth layers comprise lower tooth grooves and lower racks which are arranged in an alternating mode, the upper racks are opposite to the lower tooth grooves, and the upper tooth grooves are opposite to the lower racks. The piezoelectric thin films are placed between the upper tooth layers and the lower tooth layers. The power management module is placed between the upper protective layer and the lower protective layer, and the power management module is connected with the piezoelectric thin films in all the piezoelectric electricity generation units. The insole-type piezoelectric generator is simple in structure, comfortable in foot feeling, and suitable for common shoes.

Owner:TSINGHUA UNIV

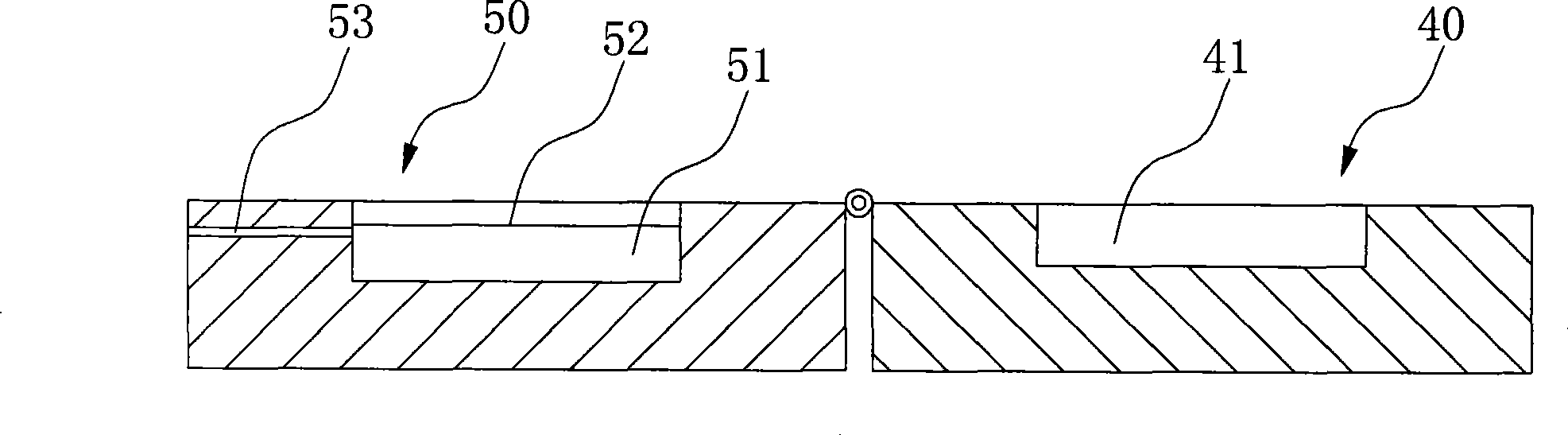

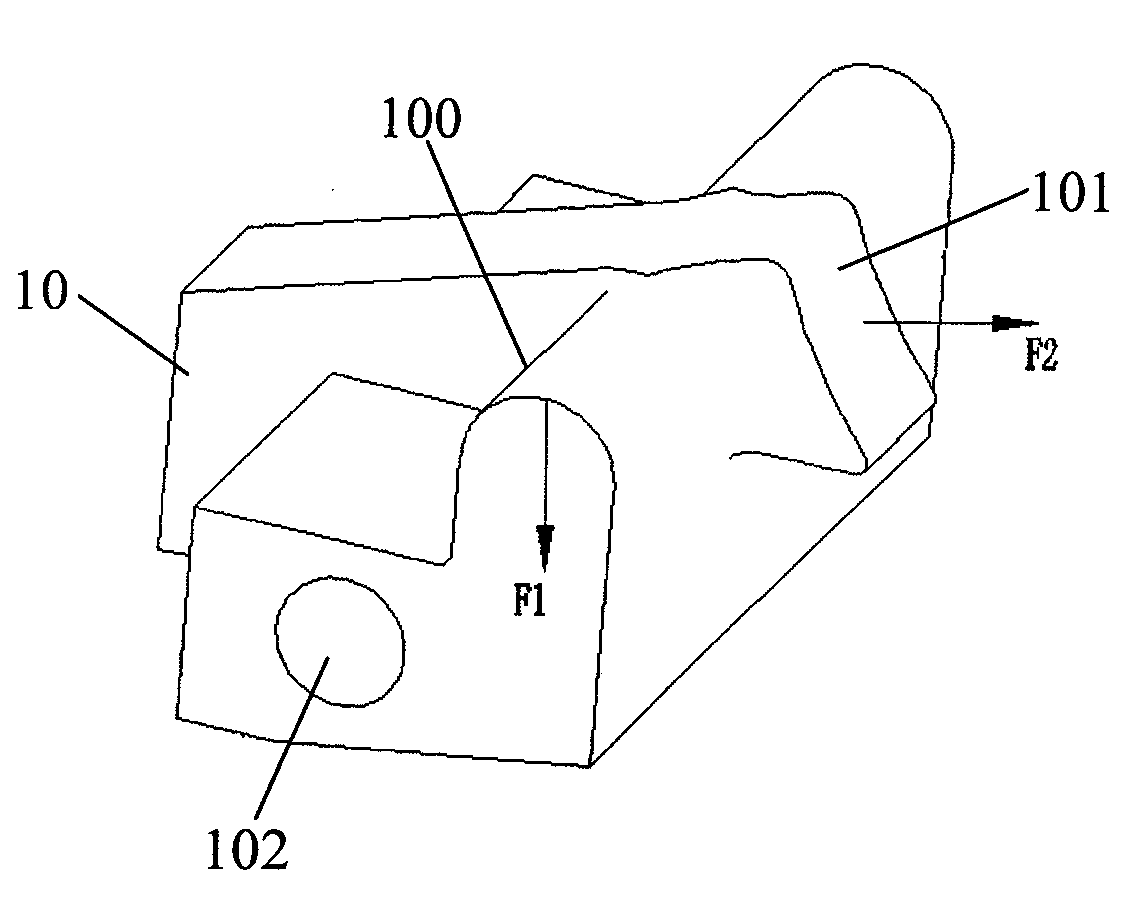

Floor type throttle

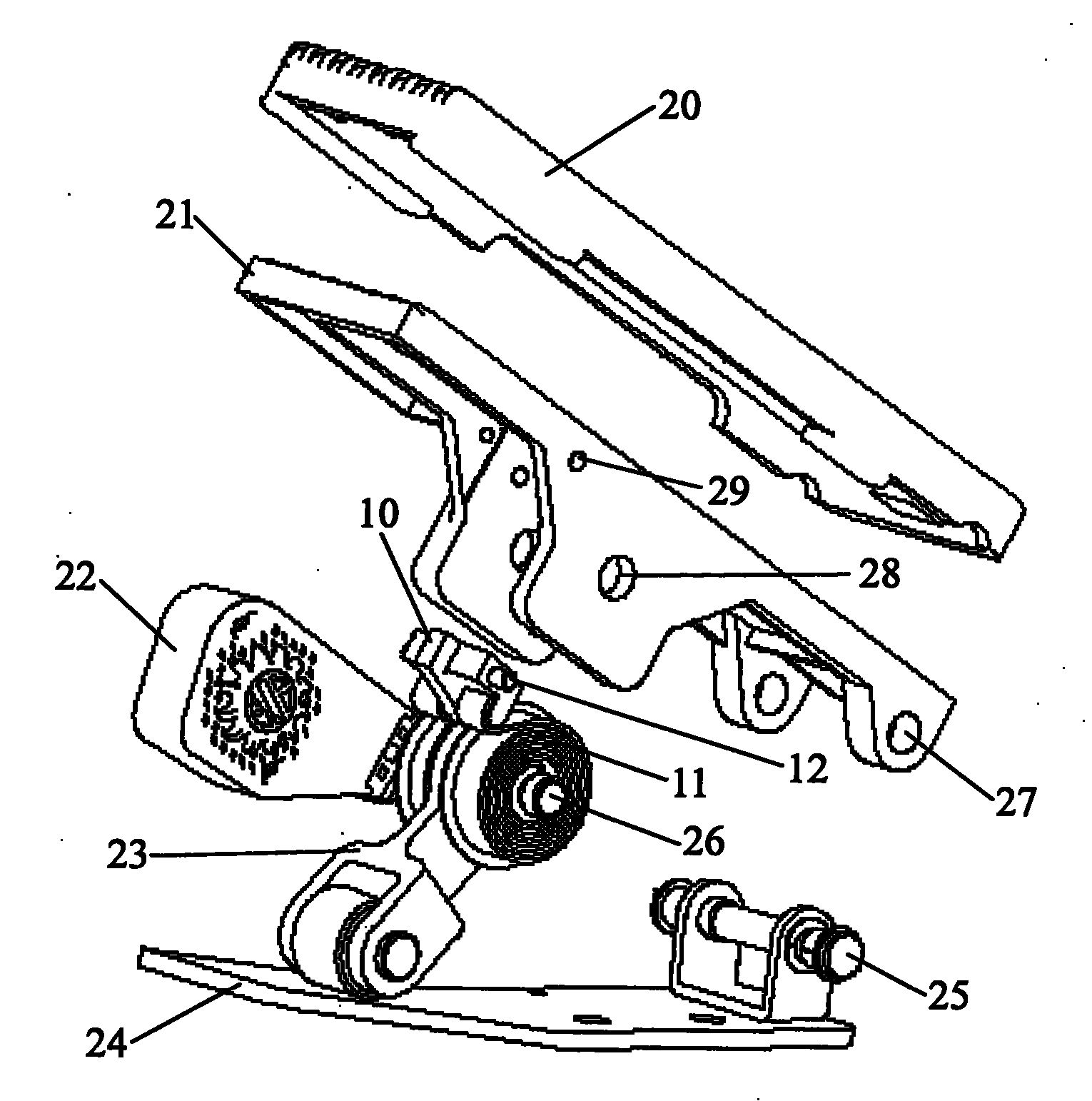

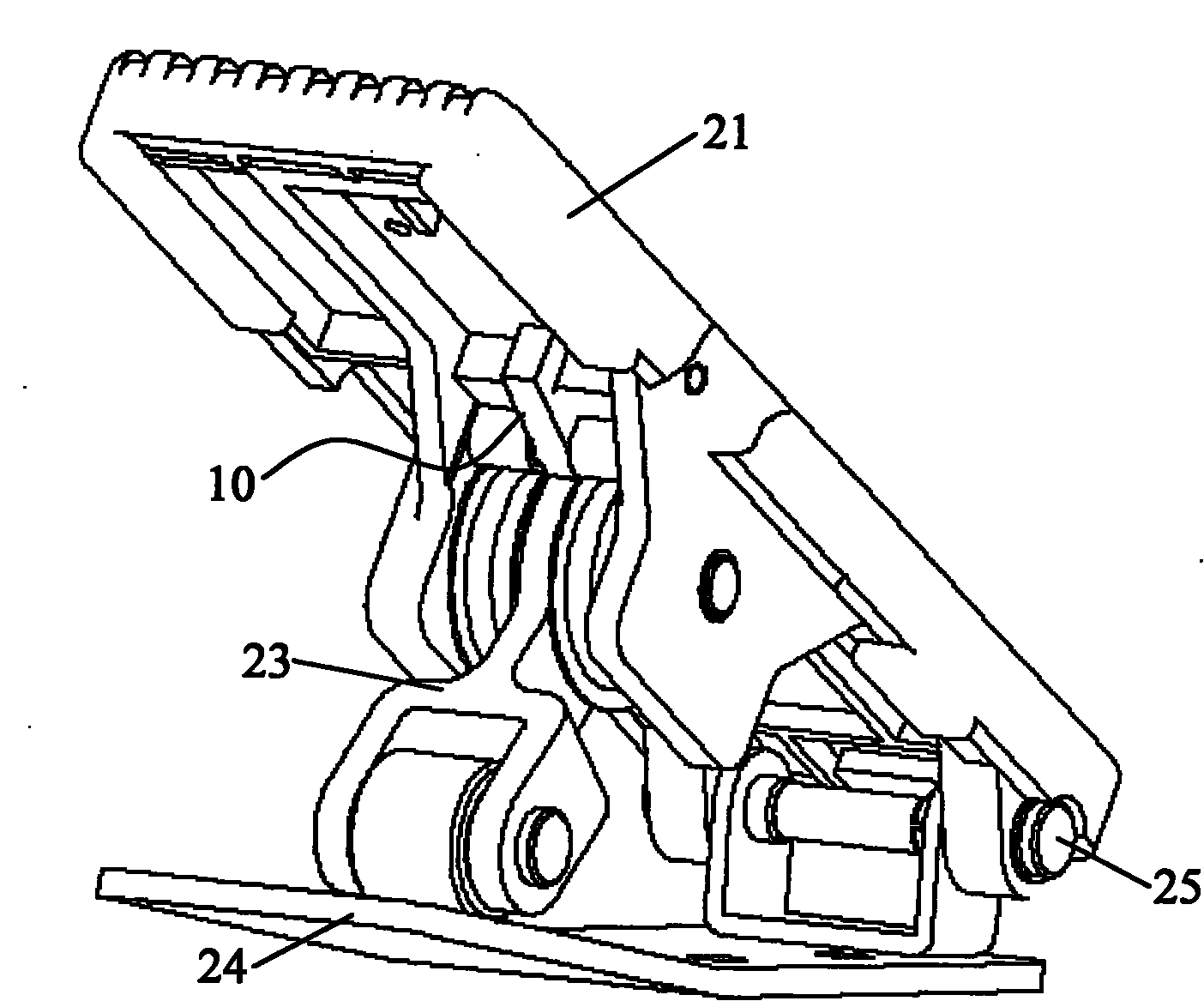

ActiveCN101804792AImprove stabilityReduce fuel consumptionPropulsion unit arrangementsElastomerPulp and paper industry

The invention provides a floor type throttle which comprises a bottom plate, a pedal, an angle sensor, a roller rod part and a damping block, wherein the bottom plate is rotatably connected with one end of the pedal, the angle sensor collects rotational angels between the bottom plate and the pedal, an elastomer is arranged between the bottom plate and the pedal, the roller rod part and the damping block are arranged below the pedal and used for supporting the pedal, the top end of the roller rod part is rotatably connected with the pedal, a rolling wheel is arranged at the bottom end of the roller rod part, the damping block is rotatably connected with the pedal through a rotary shaft and is provided with a friction surface and a lug, the friction surface is in sliding connection with the top surface of the roller rod part, and the lug is connected with the torque end of the elastomer. The invention can more comfortably and accurately control the angle of the pedal by increasing damping of the pedal of the throttle and can ensure that the throttle keeps better stability and the oil consumption is lowered in a vehicle under the complex road condition.

Owner:NANJING AOLIAN AE&EA

Comfortable hollow outsole

The invention discloses a comfortable hollow outsole. A shoe body consists of an upper, an insole and a sole. The sole comprises the outsole which is hollow. The outsole is characterized by avoiding using an insole hard midsole and an insole waist iron like the conventional sole. The comfort outsole does not adopt the insole waist iron and the insole hard midsole, grooves are formed at multiple positions on an internal heightening pad or shoe outsole or stabilizing body and shockproof sheets are placed in the grooves. The structure keeps the sole from contacting the insole hard midsole and the insole waist iron; the use of the shockproof sheets keeps the sole from contacting the hard midsole and the insole waist iron; and thus, the produced shoe make the foot more comfortable.

Owner:黎田建

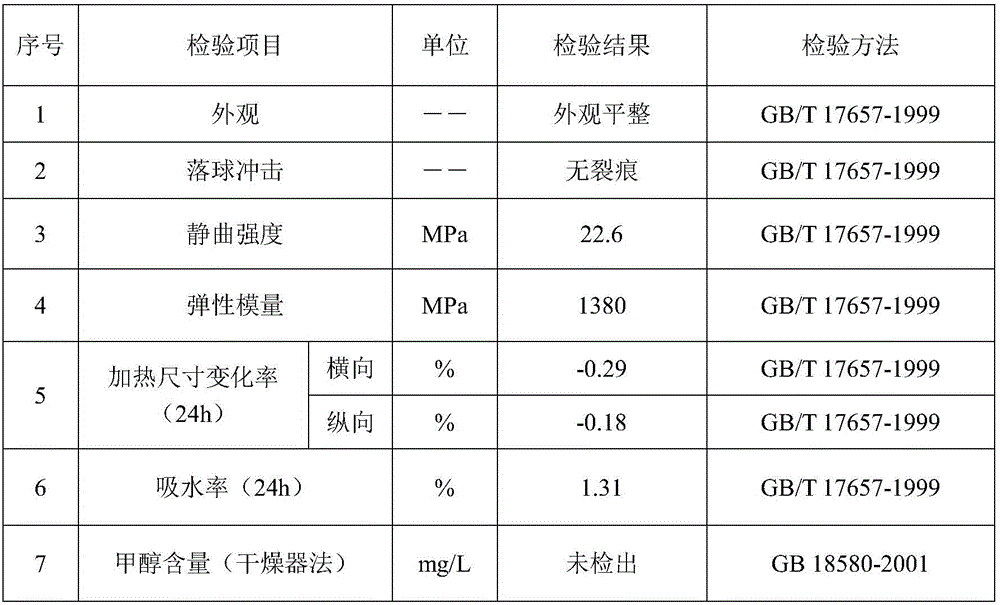

Semi-hard bamboo and wood fiber decorative base plate and preparation method and elastic self-adhesive floor

InactiveCN106336677AImprove toughnessImprove stabilityLamination ancillary operationsLaminationFiberPlasticizer

The invention provides a semi-hard bamboo and wood fiber decorative base plate, which is prepared from the following raw materials (by weight): 15-35% of bamboo and wood fiber powder, 25-45% of calcium carbonate, 10-25% of PVC resin, 4-10% of EVA, 3-5% of a heat stabilizer and 5-8% of a plasticizer. Static bending intensity, elasticity modulus and dimension variance rate under heat of the above semi-hard bamboo and wood fiber decorative base plate are good, and weight of the product is reduced to make the product have the same effect of cork wood. When walking on the product, no sound is generated and foot feels more comfortable. The invention also discloses a preparation method of the semi-hard bamboo and wood fiber decorative base plate and an elastic self-adhesive floor with the application of the semi-hard bamboo and wood fiber decorative base plate.

Owner:湖北格丽特新材料科技股份有限公司

Modified wood and its production process

InactiveCN1935475ADifferent functionsNo deformationWood treatment detailsWood impregnation detailsFiberHoneycomb structure

The present invention relates to a modified wood and its production process. It is characterized by that said invention adopts a vacuum equipment, and makes a modification sol be filled into the honeycomb structure of unsawn timber base material, solidified and combined together with unsawn timber base material fibre so as to obtain the invented modified wood.

Owner:周志邦

Noiseless comfortable rubber heel lift and preparation method thereof

The invention relates to the technical field of organic macromolecular compounds and provides a noiseless comfortable rubber heel lift and a preparation method thereof. The noiseless comfortable rubber heel lift comprises natural rubber, butadiene styrene rubber, butadiene-acrylonitrile rubber, high-styrene rubber, rubber powder, white carbon black, mineral oil, anti-aging agent, polyethylene glycol, silane coupling agent, zinc oxide, sulphur and vulcanization accelerating agent. The noiseless comfortable rubber heel lift has the advantages that the heel lift is elastic and noiseless, pressure and discomfort borne by the foot can be reduced, wearing comfort is improved, the trouble of noise is got rid of, and high wear-resisting and anti-slip performance and long service life are achieved.

Owner:MAOTAI FUJIAN SOLES CO LTD

Floor mounting bottom pad and its construction method

The floor mounting bottom pad is PVA sheet, and is spread on ground before direct laying wood floor board on the bottom pad. The construction process includes spreading the PVA bottom pad on cement ground or other ground while retaining expansion edge near wall, laying wood floor board, inserting pad strip in the expansion edge and installing the skirting board. The present invention has simple installation process, low cost, convenient maintenance, environment friendship, excellent sound and heat insulating performance, and is moistureproof, mothproof, ant-proof, nontoxic, smell-less and comfortable.

Owner:曾太亮 +1

Sole capable of improving boosting force, and shoe

The invention discloses a sole capable of improving boosting force. The sole comprises at least one elastic layer and at least one supporting layer, wherein the elastic layer and the supporting layerhave different elasticity and hardness, and are arranged in an overlapped mode to form a sole body; a hollow structure is arranged at the middle foot portion of the sole body; and the hollow structureenables the middle foot portion of the sole body to generate elastic deformation. According to the sole capable of improving the boosting force and a shoe in the invention, the whole sole is providedwith a linkage type force feedback mechanism, energy generated when a wearer treads the ground in every step can be recycled and released again when the wearer steps on the ground, and therefore, theboosting force of the sole is improved; the sole is good in supporting effect, better conforms to the movement gait of the foot of the human body, feels comfortable and has good elastic performance;and the shock absorption performance of the sole is good, and better buffer protection can be provided for the wearer.

Owner:LI NING CHINA SPORTS GOODS

Light rubber plastic foam material and production method and application thereof

The invention discloses a light rubber plastic foam material and a production method and application thereof. The material is characterized in that: the material comprises the following components in part by weight: 20 to 30 parts of natural rubber, 80 to 70 parts of EVA plastic granules, 3 to 4 parts of Ac foaming agent added based on 100 parts of rubber plastic main material, 2.5 parts of zinc oxide serving as a cross-linking agent added based on 100 parts of rubber plastic main material, and 1 part of sulphur and 0.1 part of accelerating agent TMTD added based on 100 parts of rubber plastic main material. The light rubber plastic foam material obtained by the production method has light and attractive appearance quality, realizes comfortable feeling when used for making soles and has an even and dense internal structure. The light rubber plastic foam material has the characteristics of high tensile strength, high tearing strength, good rebound resilience and low compression set.

Owner:沈中伟

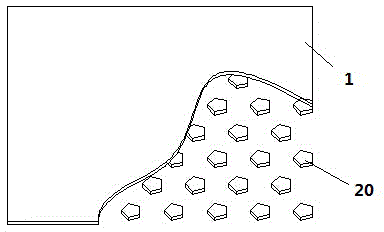

Multi-functional mildew-proof pad

The invention relates to home improvement supplies, in particular to a multi-functional mildew-proof pad. The multi-functional mildew-proof pad comprises a sound-proof layer and a plurality of support units located below the sound-proof layer; a gap between the support units forms a passage; each support unit is 1 to 1000 millimeters in width and 0.3 to 39 millimeters in height; the space between the adjacent support units is 0.5 to 500 millimeters; nano-silver anti-bacterial and mildew-proof grains or a nano-silver anti-bacterial and mildew-proof layer is arranged at the upper surface or lower surface of the sound-proof layer; the sound-proof layer is one or more of a full open-cell foamed material layer, a closed-cell foamed material layer and a semi-open-cell foamed material layer. The multi-functional mildew-proof pad is capable of effectively realizing air flow, moisture and mildew resisting, sound and noise reduction and comfortable foot feel and especially suitable for paving under floor or carpet.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com