Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

310results about How to "Moisture wicking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabric product with antibiosis, deodorization, heat emission and cooling function

ActiveCN101144217AGood dispersionPhenomena that do not seriously degrade the functionWeft knittingWarp knittingAntibiosisMasterbatch

The present invention relates to a fiber product having the performances of antibiosis, odor elimination, heat dissipation and cooling. The present invention comprises woven fabric, knitted fabric, non woven fabric film or a combination body of the fabric and the film, and is made by weaving continuous filament fiber or short fiber having various different cross section shapes, sizes, colors, structures, etc. The fiber adopts sub-micron or nanometer powder with high heat diffusion coefficient and low heat conduction coefficient, and is added into thermoplastic plastic grains in a quantitative way after being decentralized with an interfacial agent. The thermoplastic plastic grains are fully mixed with the sub-micron or nanometer powder with the high heat diffusion coefficient and the low heat conduction coefficient by a mixing machine or a kneading machine or by utilizing the chemical synthesis method, and then are made into masterbatch with a granulating machine, finally the fiber product having the functions of antibiosis, odor elimination, heat dissipation and cooling can be made by using the melting, and the dry and the wet spinning technologies and through the pre-designed spinneret.

Owner:郑国彬

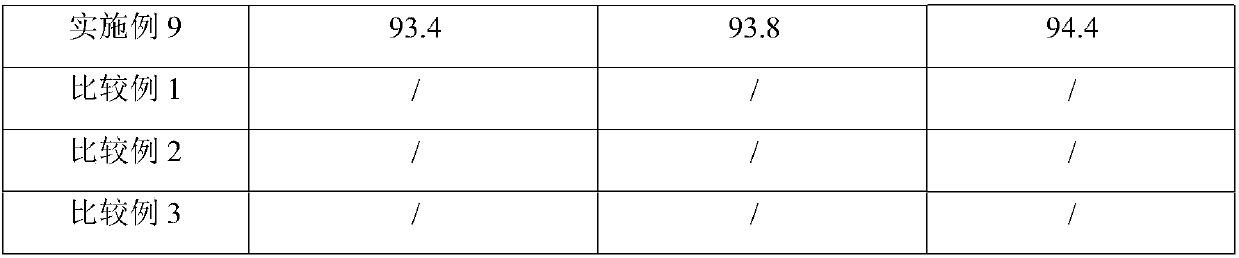

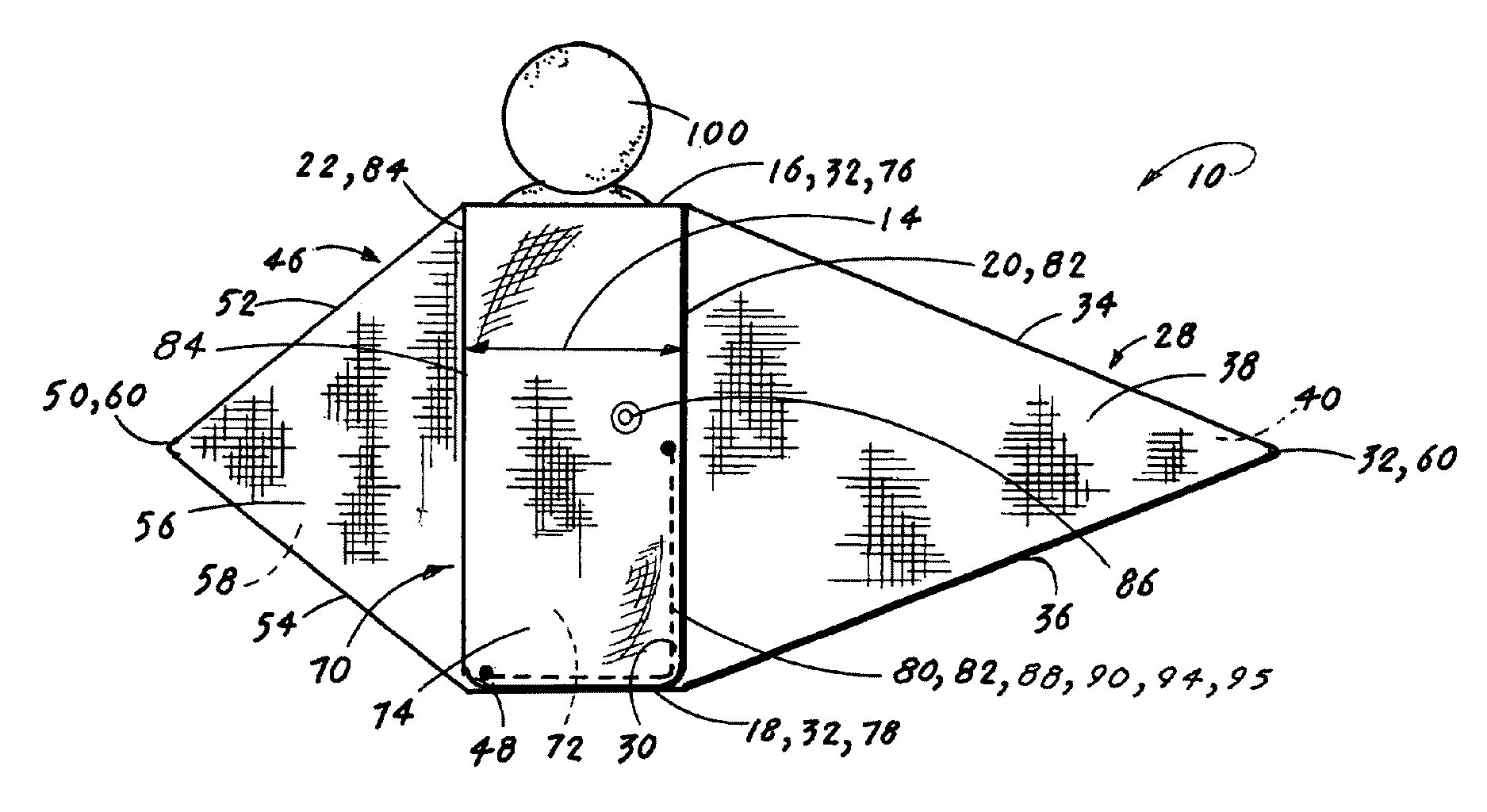

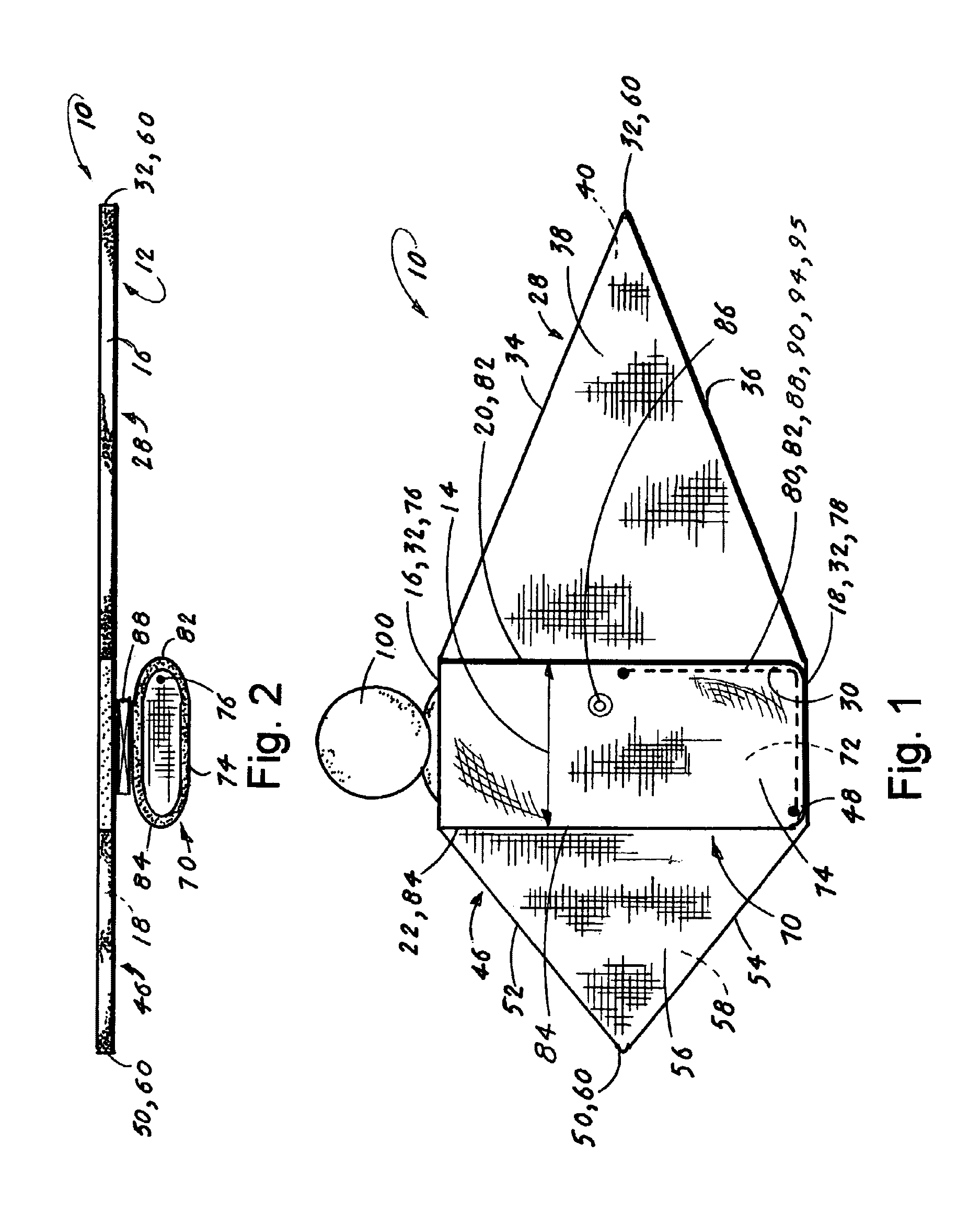

Sterilization wraps and methods for sterilizing articles

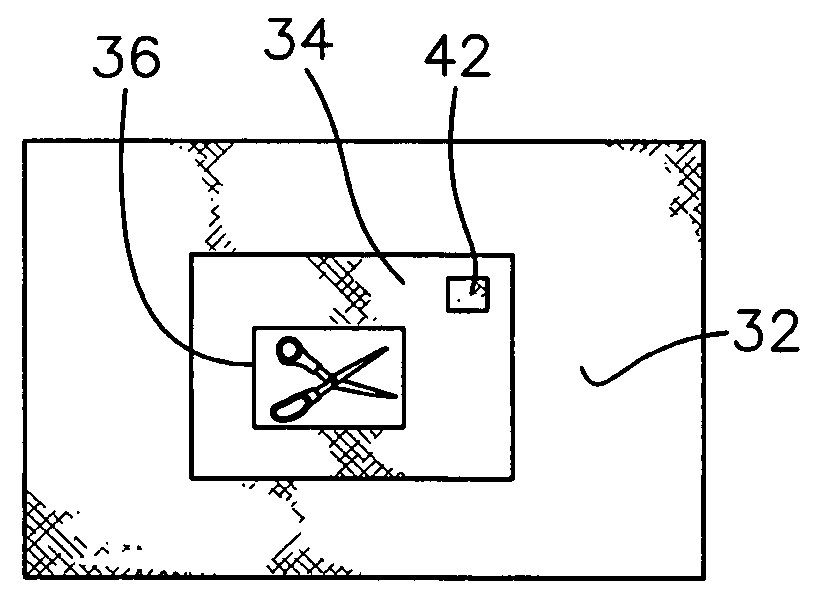

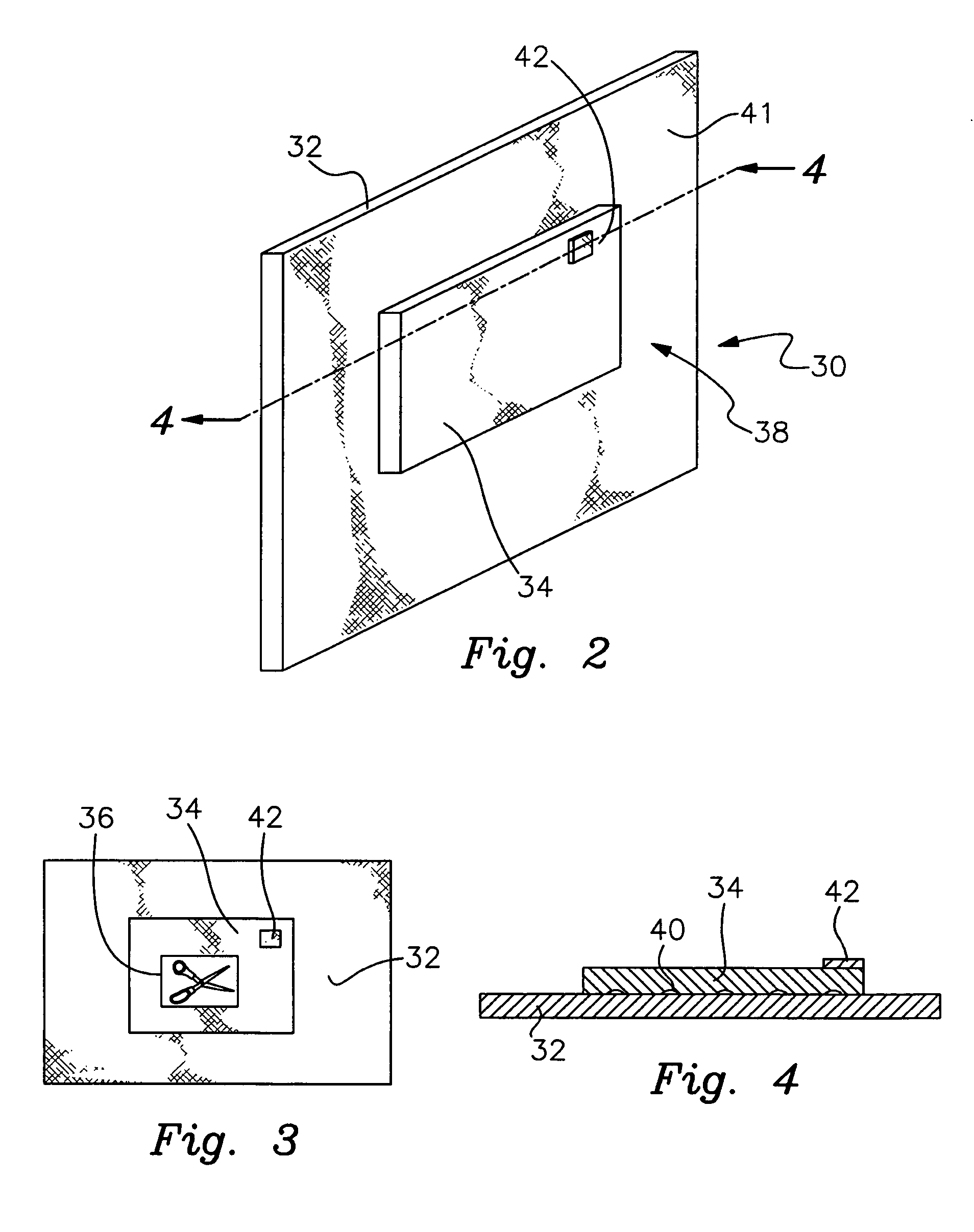

InactiveUS20050079093A1Easy to useLess-costly to manufactureSurgical furnitureSamplingAbsorbent materialSterility

There is provided an improved sterilization wrap and a method for using the improved sterilization wrap to sterilize an article. The wrap is made of at least one sheet, and preferably two sheets, of sterilization material and in some embodiments, includes an additional sheet which may be made of an absorbent material. The sheet of absorbent material may have a smaller perimeter than at least one sheet of sterilization material. One side of at least one sheet of sterilization material includes a central portion. The absorbent material may be attached to the central portion of at least one sheet of sterilization material. The article to be sterilized is placed on the sterilization wrap and is then wrapped. The absorbent material provides sterility protection for the article in addition to the at least one sheet of sterilization material and also wicks moisture away from the article after sterilization has taken place. A visual indicator may be provided to indicate whether or not the article has been exposed to adequate sterilization conditions.

Owner:ALLEGIANCE CORP

A two-component abnormity hollow high moisture absorption curling composite fiber and a preparation method thereof

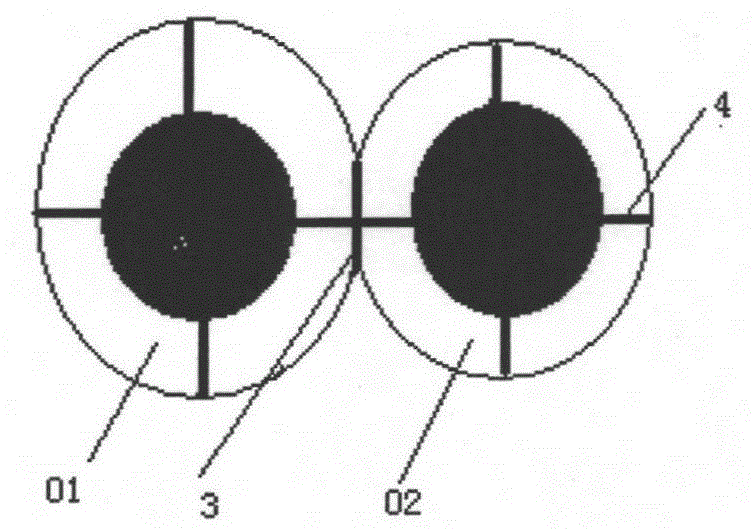

InactiveCN105177740AThree-dimensional apparent curl effect is goodBeautiful curly structureHollow filament manufactureFilament/thread formingFiberMoisture absorption

The invention provides a two-component abnormity hollow high moisture absorption curling composite fiber and a preparation method thereof; the preparation method comprises the following steps: spinning on a two-component composite spinning machine; enabling terylene melt to pass a first diversion hole of a first diversion slot on a melt distributing board, and to enter a first O-shape spinneret hole of a 8-shape spinneret hole; enabling polyamide 56 melt to pass a second diversion hole of a second diversion slot on the melt distributing board, and to enter a second O-shape spinneret hole of the 8-shape spinneret hole; using a bonding agent to firmly bond the melt flowing from the first and second O-shape spinneret holes into one body; using a side blowing mode to cool off the melt so as to obtain nascent fiber; carrying out post-treatment so as to obtain the two-component abnormity hollow high moisture absorption curling composite fiber. Finished product fabrics using the two-component abnormity hollow high moisture absorption curling composite fiber and the method has good moisture absorbable and breathable effect, is ventilating, anti-static, hollow, and warming.

Owner:DONGHUA UNIV

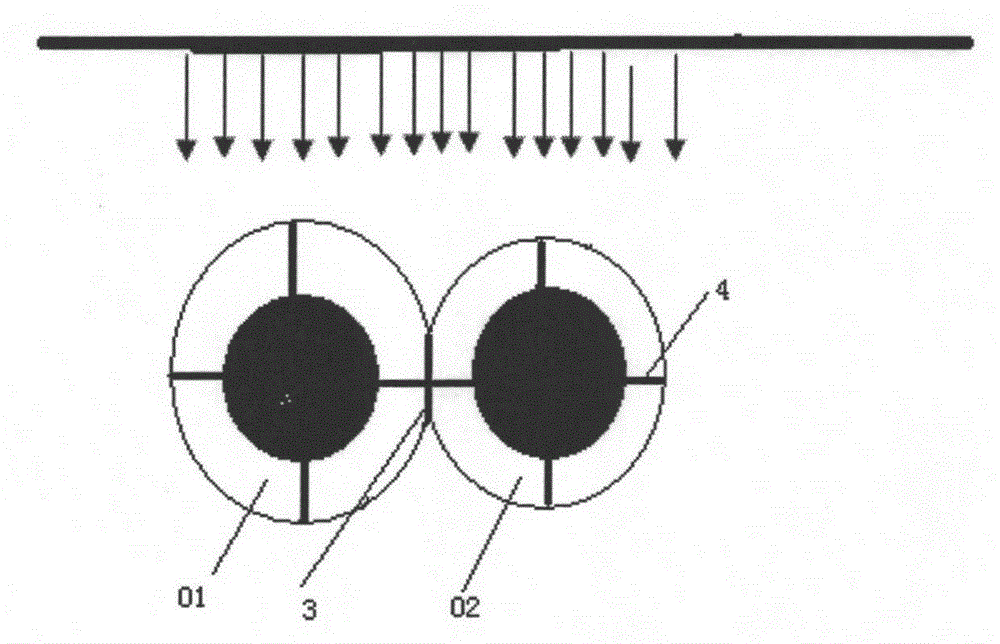

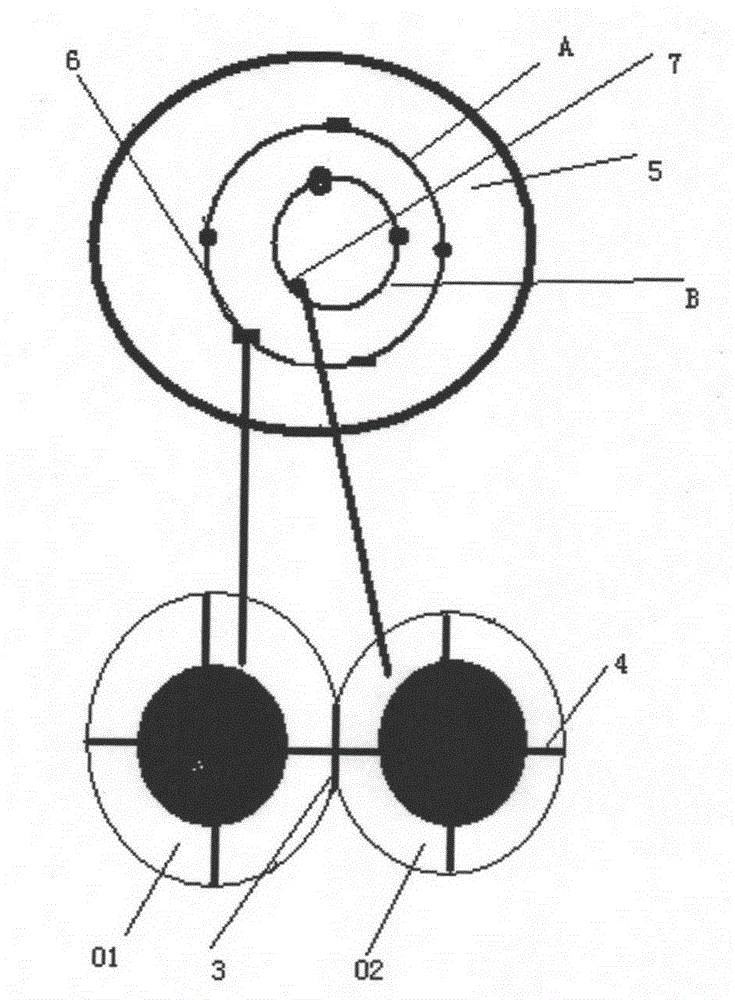

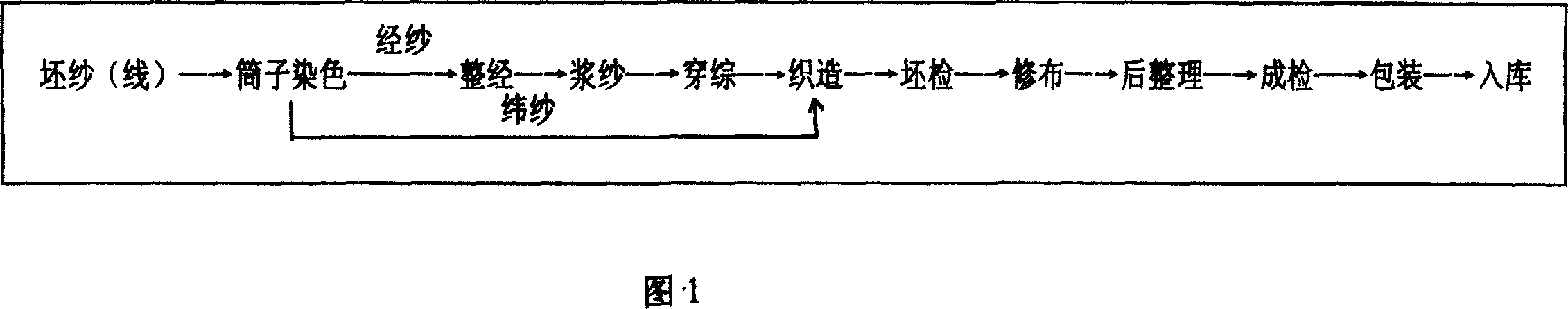

Moisture absorption sweat-releasing terylene and cotton blending coloured-woven blister fabric

A moisture absorption polyester fiber and cotton blended fabrics uses 60-70%multi grooves odd-shaped cross-section polyester fiber and cotton fiber blended spinning as material to build into 45S blended yarn and patches some of the 45S yarn into 45 / 2S blended yarn, cone dyeing these two kinds of yarns, with the 45S yarn as the twisted yarn and coiling it to the floor frame through beaming and slashing, coiling 45 / 2S yarn to the bubble shaft, through filling yarn to knit with 45S yarn, adjusting the conveying warp run-in rate of slashing and the bubble shaft 1:1.2-1.3, using all loose dressing of the grey cloth without adding any oil as auxiliary agent in the dressing process. It is beautiful and comfortable, cool, difficult to fold and low in cost.

Owner:华明浩

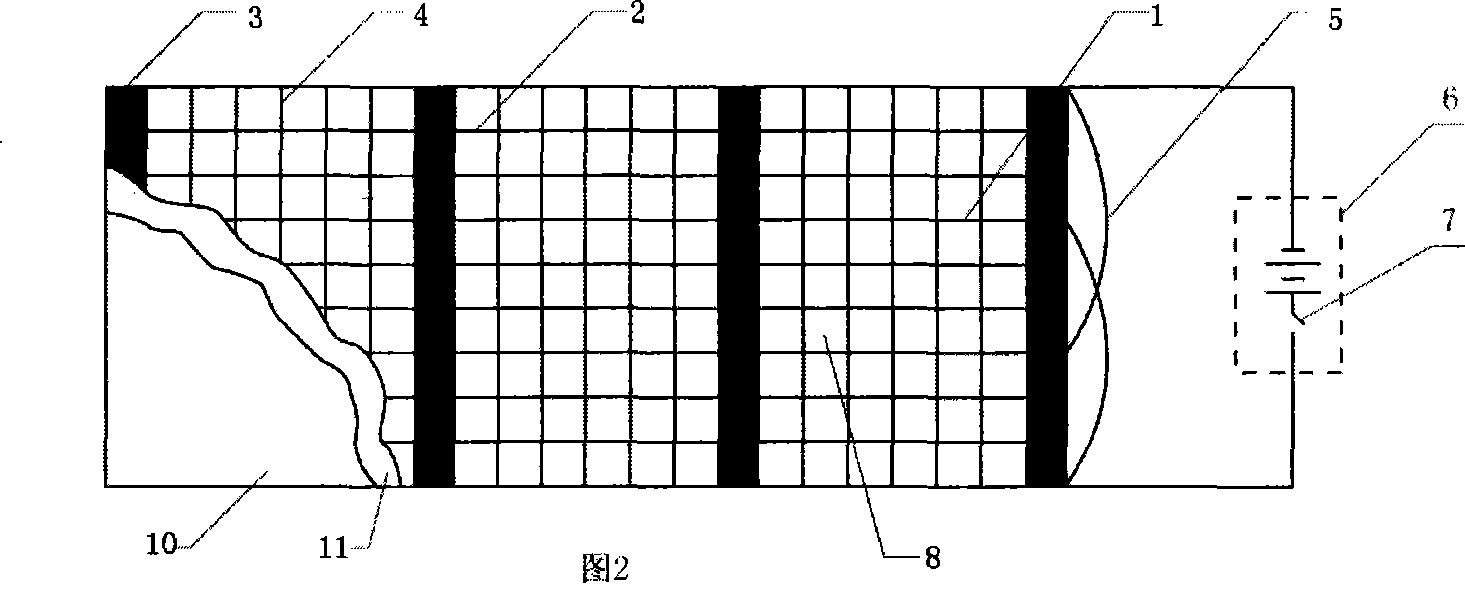

Carbon heating clothes and preparation method thereof

ActiveCN101396176AHeating up fastTastelessOhmic-resistance heatingGarment beltsSmart polymerEngineering

The invention relates to a garment and a preparation method thereof, in particular to a carbon heating garment taking carbon conductive yarns as a heating element and a preparation method thereof. The outside of the rear piece of the carbon heating garment is provided with a pocket which is positioned near the lumbar vertebrae of a human body; and the pocket is provided with a carbon heating sheet sewn and packed by nano bamboo charcoal knitted fabric, connecting wires and intelligent polymer lithium battery pack; the carbon heating sheet is connected with the anode and the cathode of the lithium battery pack by the connecting wires; and the carbon heating sheet is compounded by pressing and rolling carbon conductive fabric with an environment friendly polyurethane thin film or vinyl acetate thin film. The garment has the advantages of fast heating and temperature rise, no odor, no pollution and good effect, and the garment is an ideal warm garment with heat supply function.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

Loofah antimicrobial health-care material and uses thereof

InactiveCN101347131AStrong specific surface areaFast adsorption-desorption speedBiocideDisinfectantsBiotechnologyFiber

The present invention provides four loofah vegetable sponge antibacterial health care materials and the application thereof. The four loofah vegetable sponge antibacterial health care materials are mainly characterized in that the four materials all contain the loofah fiber component and have the approximately same efficacy of antibacterial health care; wherein, material A contains loofah vegetable sponge fiber tablet or loofah vegetable sponge fiber powder, loofah vegetable sponge fiber active carbon or loofah begetable sponge fiber compound active carbon and bamboo pyroligneous antibacterial liquor; material B contains loofah vegetable sponge fiber tablet or loofah vegetable sponge fiber powder and loofah vegetable sponge fiber active carbon or loofah vegetable sponge fiber compound active carbon; material C contains loofah vegetable sponge fiber tablet or loofah vegetable sponge fiber powder and bamboo pyroligneous antibacterial liquor; material D contains loofah vegetable sponge fiber active carbon or loofah vegetable sponge fiber compound active carbon and bamboo pyroligneous antibacterial liquor. The materials of the present invention are taken as the additive in preparing antibacterial health care fiber and textile, washing product, craftwork, vessel, present box and packaging box, sports article, furniture and paint or building decoration material or are used for purifying water and air and absorbing harmful substances.

Owner:袁会文

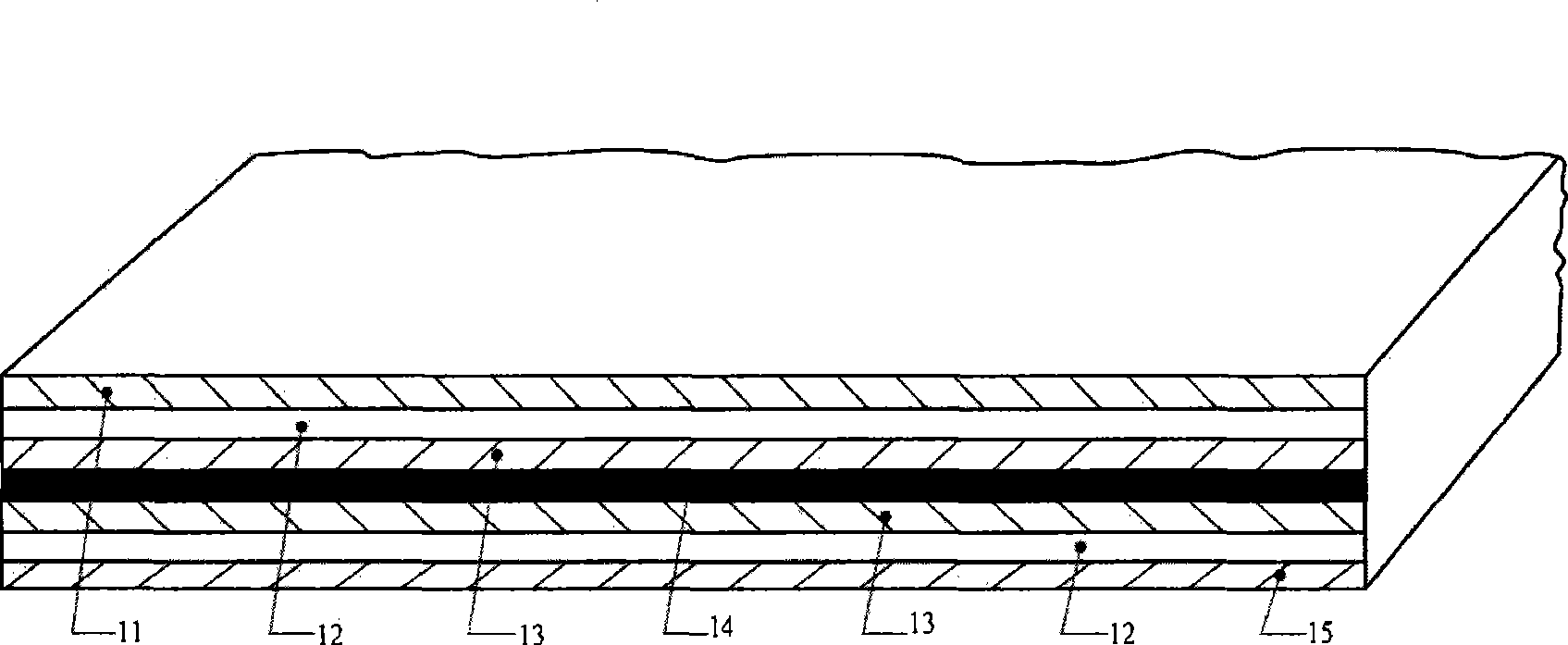

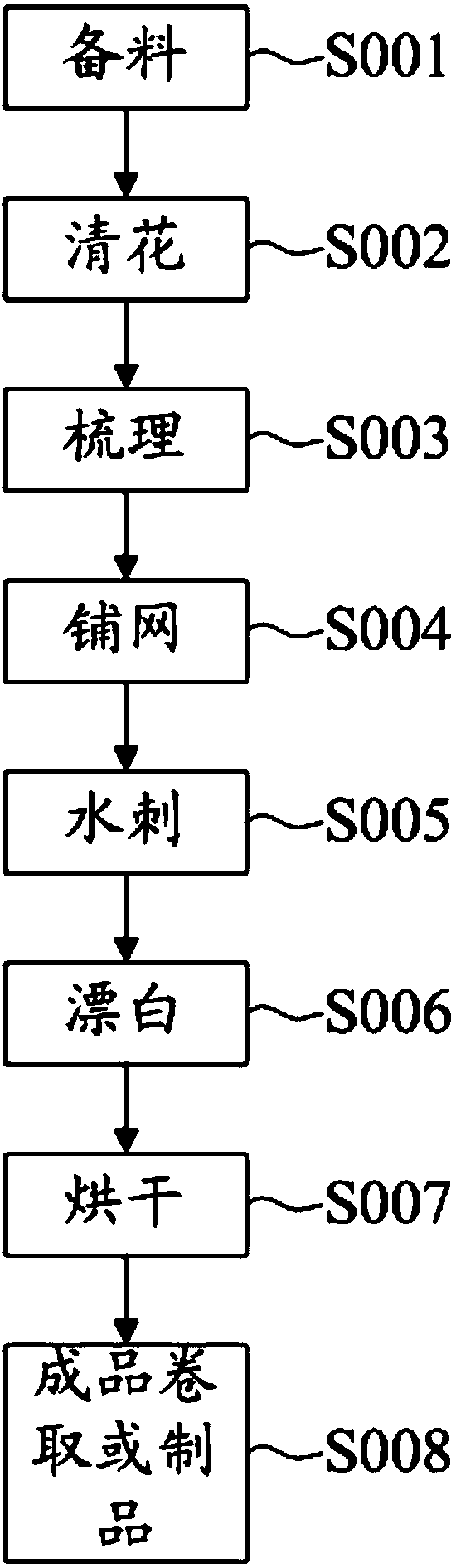

Kapok spunlace non-woven fabric, preparation method thereof and product of kapok spunlace non-woven fabric

InactiveCN107916499ABreathableWarm and antibacterialNon-woven fabricsMaterials preparationForeign matter

The invention discloses a kapok spunlace non-woven fabric, a preparation method thereof and a product of the kapok spunlace non-woven fabric. The preparation method of the kapok spunlace non-woven fabric comprises the following steps: material preparation: independently preparing kapok fibers, or uniformly mixing the kapok fibers with one or more of other natural fibers and chemical fibers to obtain mixed fibers; blowing: removing impurities from the prepared kapok fibers or mixed fibers, and sieving out foreign matters; carding: opening the blown kapok fibers or mixed fibers into single fibers at first, and then smoothly combing the single fibers; carrying out lapping; carrying out spunlace; carrying out bleaching; carrying out drying; and rolling a finished product or obtaining a product. Because the kapok fibers have characteristics of lightness and softness, breathability, high wet permeability, high degree of hollowness, anti-bacterial property, mothproof property and mildew proofproperty. The kapok spunlace non-woven fabric is prepared by the spunlace non-woven process, chemical auxiliaries are not added in a whole fabric forming process, and therefore, the prepared kapok spunlace non-woven fabric has the advantages of warming and bacteria inhibition, lightness, softness and comfort, dryness and breathability and the like.

Owner:WINNER MEDICAL CO LTD +1

Taxus chinensis viscose blended yarn and preparation method thereof

The invention relates to a Taxus chinensis viscose blended yarn. A preparation method of the Taxus chinensis viscose blended yarn includes the following steps of cotton assorting, blowing, cotton carding, drawing, roving and yarn spinning, and is characterized in that the cotton assorting step includes: mixing 10-50% of Taxus chinensis viscose with 50-90% of blended fibers; the blowing step includes: blowing fibers obtained in the cotton assorting step on a cotton breaking machine; the cotton carding step includes: carding the blown fibers on a cotton carding machine to obtain Taxus chinensis fiber card silver; the drawing step includes: drawing the Taxus chinensis fiber card silver on a drawing machine and obtaining drawn silver fibers after drawing; the roving spinning step includes: roving the drawn silver fibers on a roving machine to obtain rovings; and the yarn spinning step includes: spinning the rovings on a spinning machine to obtain Taxus chinensis viscose blended yarns. The Taxus chinensis viscose blended yarn is made from Taxus chinensis with the anticancer function, and textiles made of the Taxus chinensis viscose blended yarns have the advantages of smoothness and fineness and has the healthcare function.

Owner:无锡红豆织造有限公司

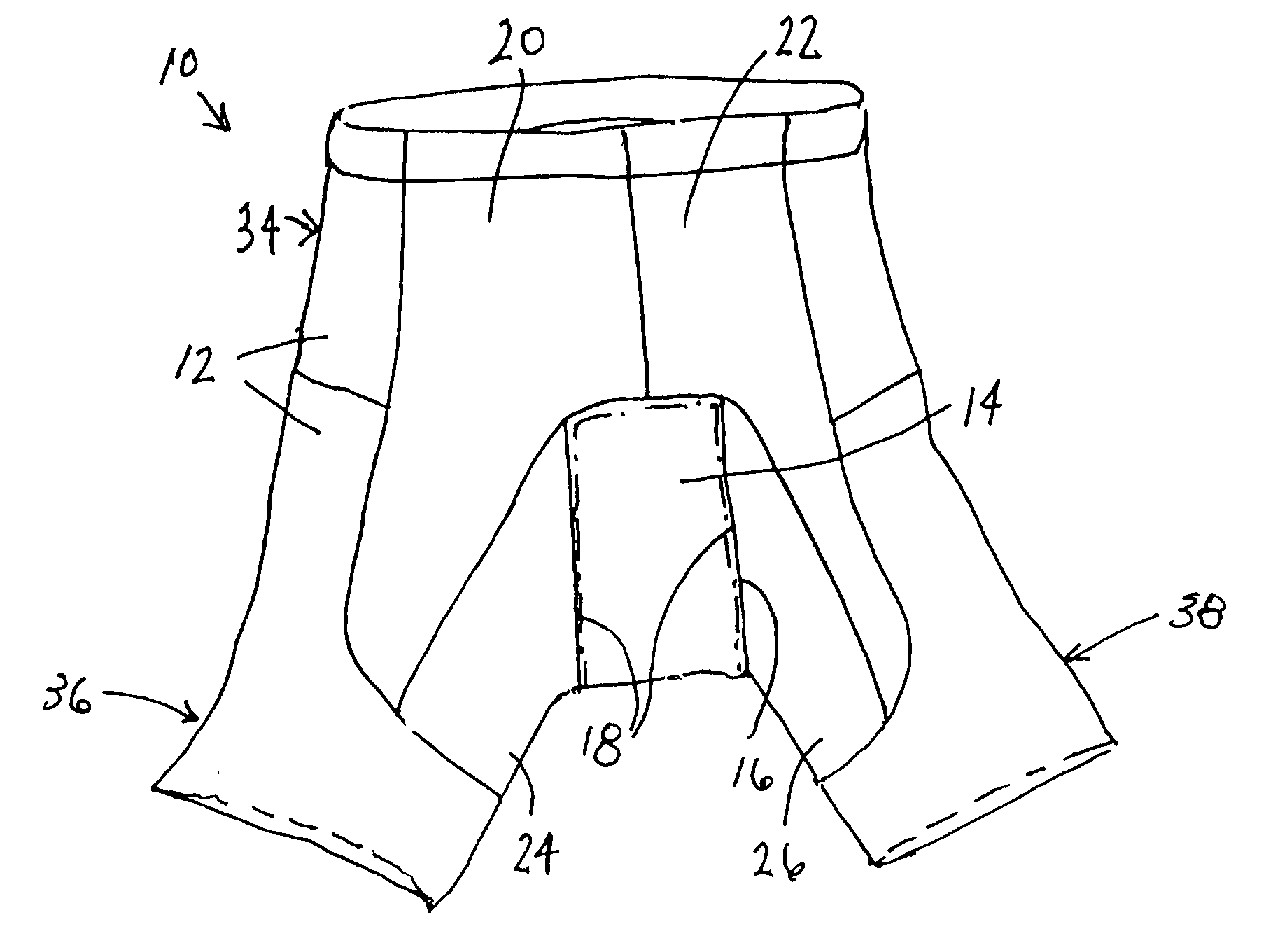

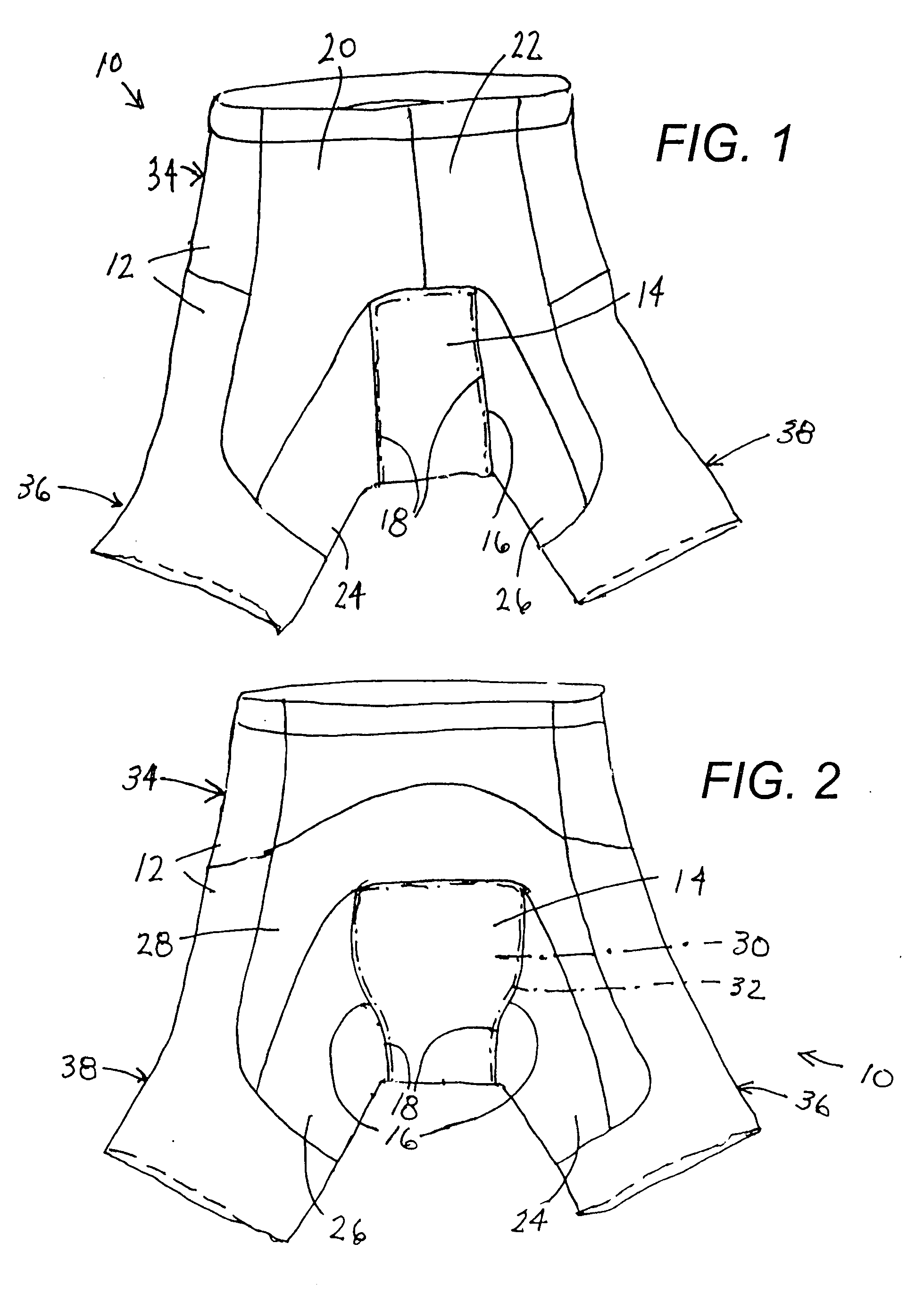

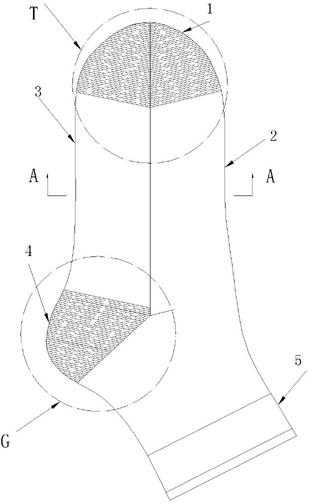

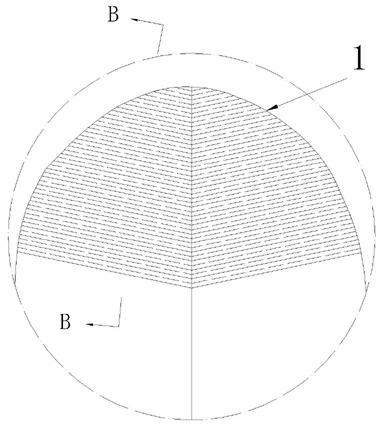

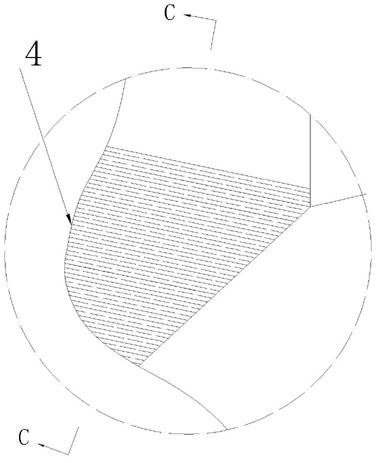

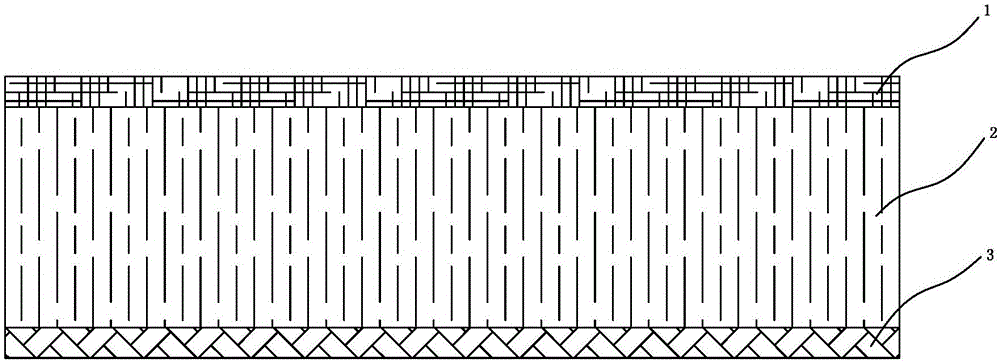

Cycling shorts and associated method of manufacture

InactiveUS20070294803A1Increase flexibilityImprove fitTrousersProtective garmentAbsorbent materialBiomedical engineering

Cycling shorts are constructed from a plurality of panels of stretchable fabric material and a crotch pad of absorbent material. The fabric material has a first thickness, while the pad material has a second thickness substantially greater than the first thickness. The pad has a plurality of edges joined to edges of selected ones of the panels disposed adjacent to and contiguous with the pad.

Owner:K 2 CORP

Method for processing super-soft home textile fabric

ActiveCN102978959ANo pollution in the processRich sourcesBiochemical fibre treatmentDyeing processDefibrillationEnzyme

The invention aims to disclose a method for processing a super-soft home textile fabric. The method comprises the following steps: mixing, gray fabric pretreatment, primary fibrillation, enzyme treatment, dyeing, secondary fibrillation, softening and resin finishing. Compared with the prior art, the super-soft home textile fabric is formed by interweaving gossamer and high-grade cotton spun yarn, due to dyeing and finishing special process treatment, the gossamer fibrillation is controlled to obtain a flock effect, the style characteristics of the gossamer and cotton mixed fabrics are improved, enzyme treatment defibrillation is used for achieving the flock effect, the traditional napping process is avoided, the operation is simple, the process flow is shortened, the energy consumption is reduced, and the aim of the method is fulfilled.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Multifunctional fiber with moisture absorption and perspiration, antibacterial and heating functions and preparation method of multifunctional fiber

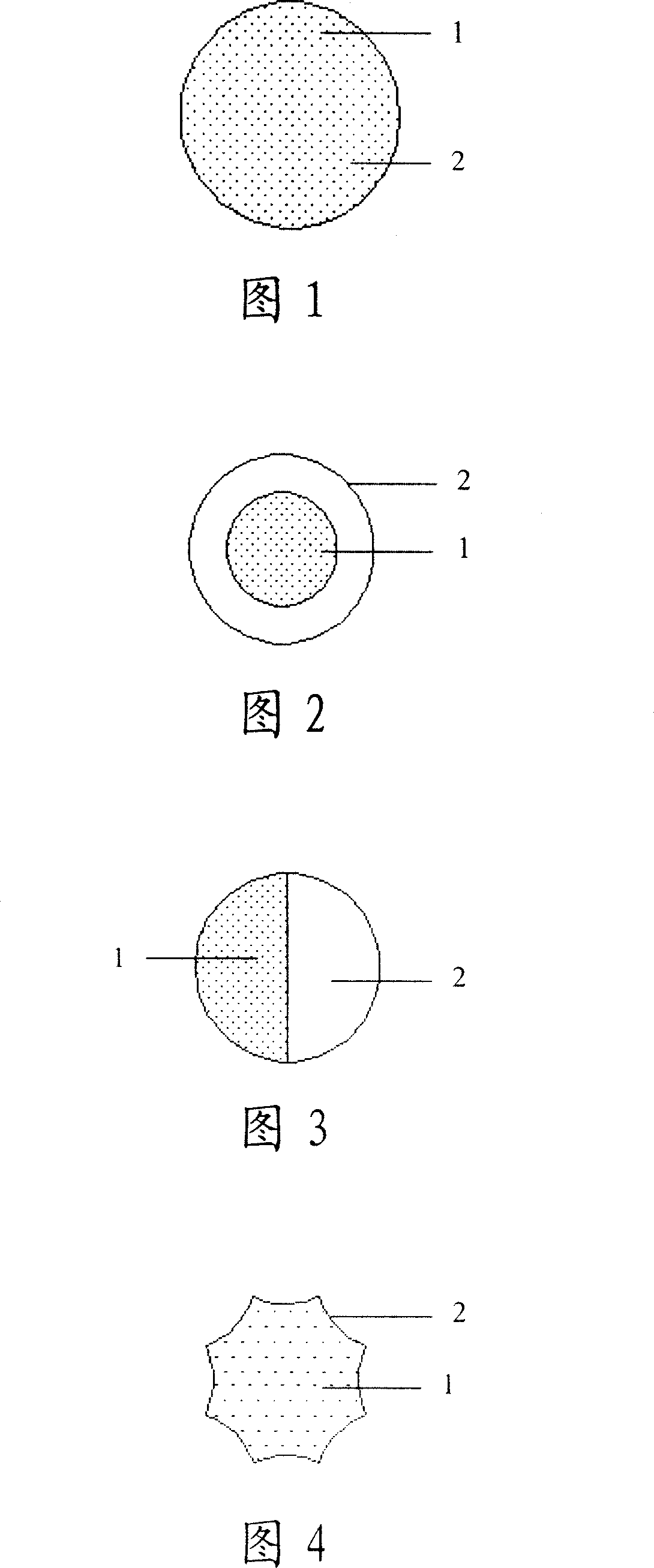

ActiveCN106835348AIncrease surface areaImprove moisture wickingFilament/thread formingConjugated synthetic polymer artificial filamentsPerspirationAbnormal shapes

The invention discloses a multifunctional fiber with moisture absorption and perspiration, antibacterial and heating functions and a preparation method of the multifunctional fiber and belongs to the technical field of functional fiber materials. The multifunctional fiber disclosed by the invention comprises a multifunctional fiber body; the multifunctional fiber body is composed of a fiber skin layer and a fiber core layer; the section shape of the fiber body is of an abnormal structure that a plurality of convex abnormal-shape structures are uniformly and outward formed on the round circumference; the fiber skin layer is formed by bundling bacterium-inhibiting fiber monofilaments together in parallel; the fiber core layer is formed by bundling heating fiber monofilaments together in parallel. The fiber with moisture absorption and perspiration, antibacterial and heating functions is prepared through a melting spinning technology and can be used for the field of smart clothing.

Owner:WUHAN TEXTILE UNIV

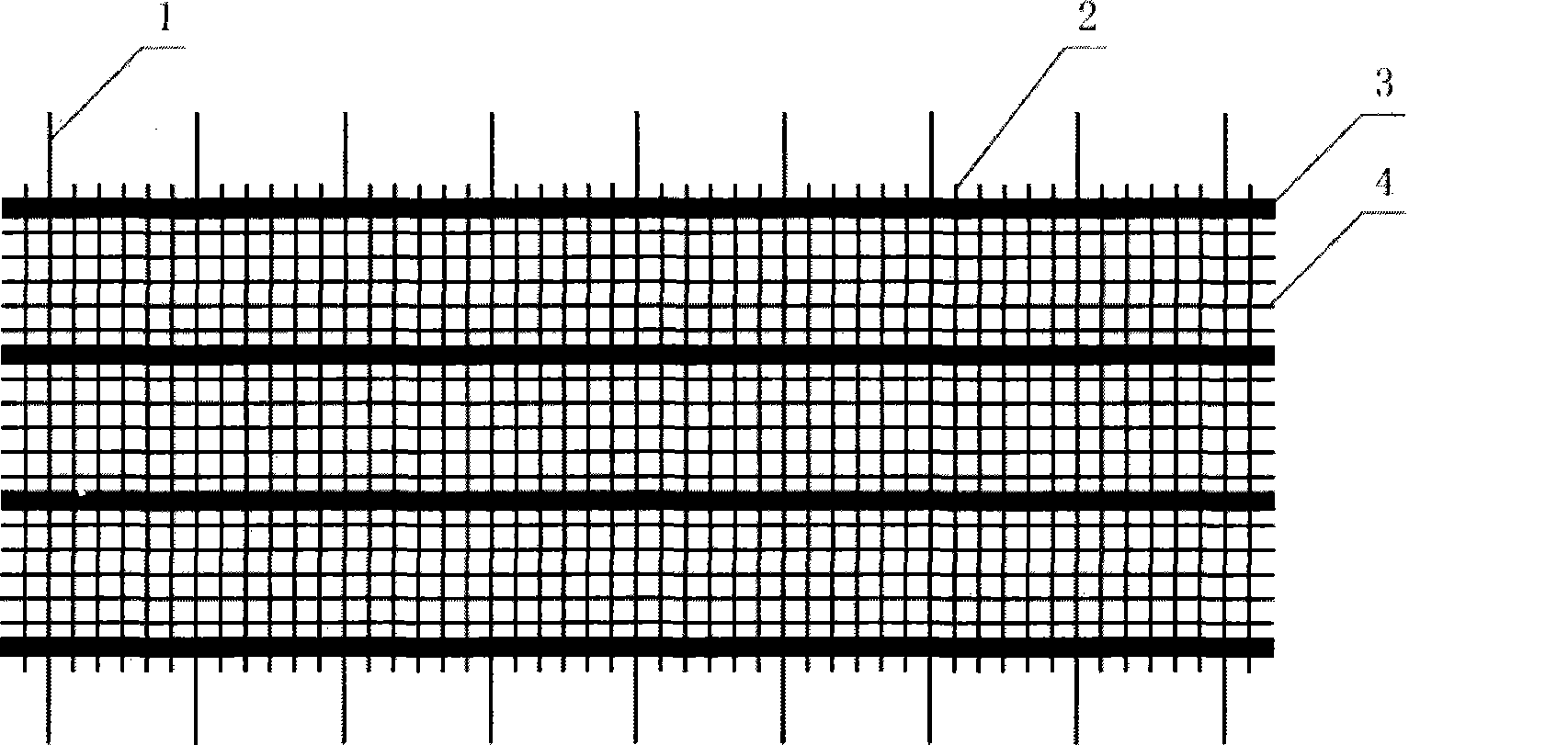

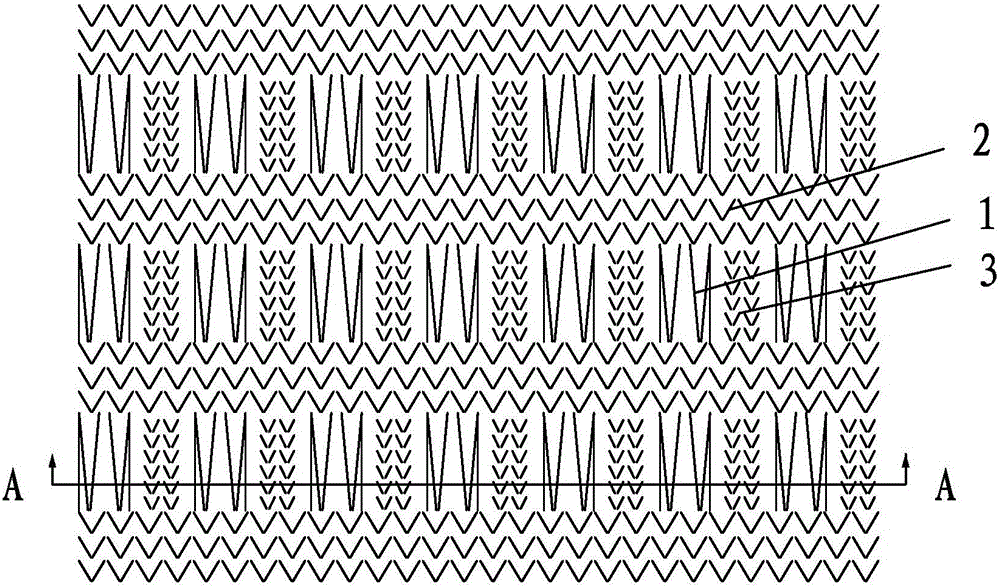

Ultra-light double-sided weft knitted checkered fabric with moisture absorption and sweat releasing functions and production method of checkered fabric

ActiveCN105839280AMoisture wickingFunctionalWeft knittingHeating/cooling textile fabricsWoven fabricAfter treatment

The invention provides ultra-light double-sided weft knitted checkered fabric with moisture absorption and sweat releasing functions. The ultra-light double-sided weft knitted checkered fabric with the moisture absorption and sweat releasing functions is interwoven by 50D / 48F fine-denier polyester filaments and 50D / 48F fine-denier polyester draw texturing yarn through moisture absorption and sweat releasing treatment, and the mass ratio of the fine-denier polyester filaments to the fine-denier polyester draw texturing yarn is 65%:35%. The invention further provides a production method of the ultra-light double-sided weft knitted checkered fabric with the moisture absorption and sweat releasing functions. The production method comprises a knitting procedure and an after-treatment procedure. The fine-denier polyester filaments and the fine-denier polyester draw texturing yarn are adopted for loop formation and inactive weaving, so that the fabric not only is light in mass, but also has a concave-convex three-dimensional effect and good breathability; the mass ratio of the fine-denier polyester filaments to the fine-denier polyester draw texturing yarn is controlled to be 65%:35% accordingly, the woven fabric has good elasticity and facilitates movement of people; with adoption of the moisture absorption and sweat releasing functional finishing, reduction cleaning and pickling technologies, the fabric has good moisture absorption and sweat releasing functions and feels soft.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Method for making cool colored special-shaped super fine denier polyester filaments

InactiveCN104532377AMoisture wickingCool and comfortableArtificial thread manufacturing machinesFilament/thread formingFiberPolyester

The invention relates to a method for making cool colored special-shaped super fine denier polyester filaments. The method comprises the steps of (1) making cool colored master batches, and (2) making cool colored special-shaped super fine denier fibers. In the step of making the cool colored special-shaped super fine denier fibers, firstly, extrusion mixing and fusing are conducted on 1-20 parts of cool colored master batches and 80-90 parts of polyester chips through a screw machine to obtain a melt, and spinning is conducted through a spinneret plate; secondly, cross air blasting is conducted on slivers obtained through spinning so that spun filament fibers can be obtained through cooling and solidification; thirdly, oil is applied to the solidified spun filament fibers, wherein the weight concentration of an oiling agent is 10-18%, and the rotating speed of an oiler is 4-6 rpm; fourthly, spun filaments are taken-up through a coiler under the temperature of 24-28 DEG C and the relative humidity of 45-65% after being oiled, and then the cool colored special-shaped super fine denier fibers are obtained. According to the method, the cooling function of a cool auxiliary, the wicking effect of the super fine denier fibers and the sweat releasing function of special-shaped fibers are combined, in other words, three physical modification methods are combined, and the obtained fibers have a dry fit function and feel cool and comfortable.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD +1

Ice feeling finishing agent and preparation method thereof

The invention belongs to the technical field of printing and dyeing auxiliaries, particularly relates to an ice feeling finishing agent and a preparation method thereof. The ice feeling finishing agent mainly comprises raw silicone oil, an emulgator, a cosolvent, glacial acetic acid and water, wherein the raw silicone oil is prepared by adding 99-99.5% of silicone oil, 0.01-0.9% of a silane coupling agent and 0.01-0.1% of a catalyst into a reaction kettle for reaction. According to the ice feeling finishing agent and the preparation method thereof, provided by the invention, primary amine or / and secondary amine is / are introduced onto the molecular chain of silicone oil, therefore the hydrophilic performance of the overall molecular structure is improved, fabric subjected to finishing of the finishing agent has air-permeating, moisture permeating, moisture-absorbing and sweat releasing functions, at the same time can maintain a certain humidity, and enables people to have a feeling of comfortableness and coldness after wearing the clothes subjected to finishing; besides, the ice feeling finishing agent has excellent stability, thoroughly overcomes the defects that the conventional amino silicon oil is prone to demulsification, floating and roll sticking, can easily produce oil spots, and is not easy to repair.

Owner:珠海华大浩宏新材料有限公司

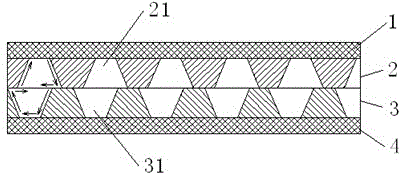

Multifunctional composite fabric

InactiveCN102452194AAesthetically pleasingImprove insulation effectSynthetic resin layered productsYarnSurface layer

The invention relates to multifunctional composite fabric, which comprises a surface layer, an inner layer and an intermediate layer combined and sewed together. The surface layer is formed by triangular abnormal chinlon yarns and cotton threads interweaved. The intermediate layer is a moisture absorption and sweat releasing fiber layer and the inner layer is a heat insulating layer. The surface layer, the intermediate layer and the bottom layer are superposed and sewed and composited by cotton or silk or artificial fiber according to a regulated trace. The sewed and composited fabric is washed by water or washed by water after being dyed, and then the open area of the sewed and composited fabric is hollowed. The invention has the advantages of environmental protection, heat insulation and moisture absorption and sweat releasing.

Owner:CHANGSHU XINTEDU GARMENTS

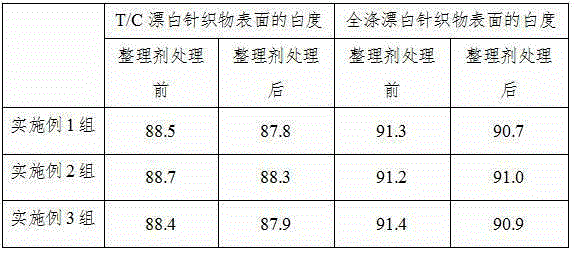

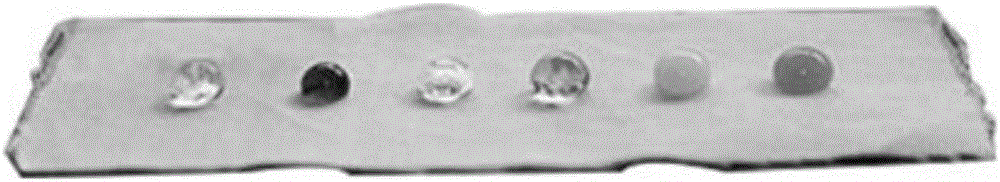

Finishing method of multifunctional textile

InactiveCN106480741AHas wash fastnessGood hydrophobic and oleophobic self-cleaning functionLiquid repellent fibresVegetal fibresCooking & bakingCross-link

The invention discloses a finishing method of a multifunctional textile. One surface of the textile has a water-and-oil-repellent antifouling function, and the other surface of the textile has oleophilic and hydrophilic moisture absorption and sweat releasing functions. The method comprises steps as follows: dip-coating of the textile in a cross-linking agent solution, spraying of oleophilic and hydrophilic components, spraying for the other surface of the textile by the oleophilic and hydrophilic components as well as pre-drying and baking for the textile after finishing. The single surface of the textile after finished with the method has a self-cleaning function, the other surface can be worn next to the skin and has the comfortable moisture absorption and sweat releasing functions, two surfaces with different functions both have certain water resistance, raw materials are widely sourced, a technology is simple and easy, the raw materials have certain compatibility with other textile finishing auxiliaries, and the method can be applied to the functional afterfinish field of the textile.

Owner:GUANGZHOU UNIVERSITY

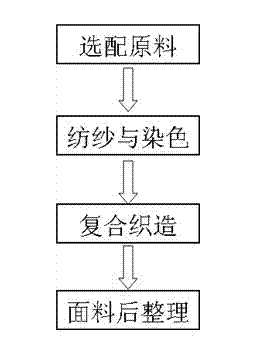

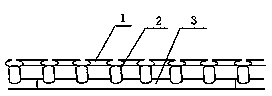

Method for preparing multifunctional fabric

InactiveCN102776683AProcess arrangement is reasonableScience of preparationWeft knittingYarnDyeingMultiple function

The invention provides a method for preparing a multifunctional fabric. The preparation method comprises the following steps: a) selecting and preparing raw materials; b) spinning and dyeing; c) composite weaving; and d) after finishing of the fabric. The invention discloses the method for preparing the multifunctional fabric; the preparation method is rational in procedure arrangement, scientific and effective in preparation links and simple to perform; the prepared fabric not only has the excellent functions of efficient anti-bacterium, heat preservation and health care, but also has the better properties of moisture absorption, no sweat, wear resistance and softness; and therefore, the multifunctional fabric is an ideal fabric of which underclothes and shirts are made.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

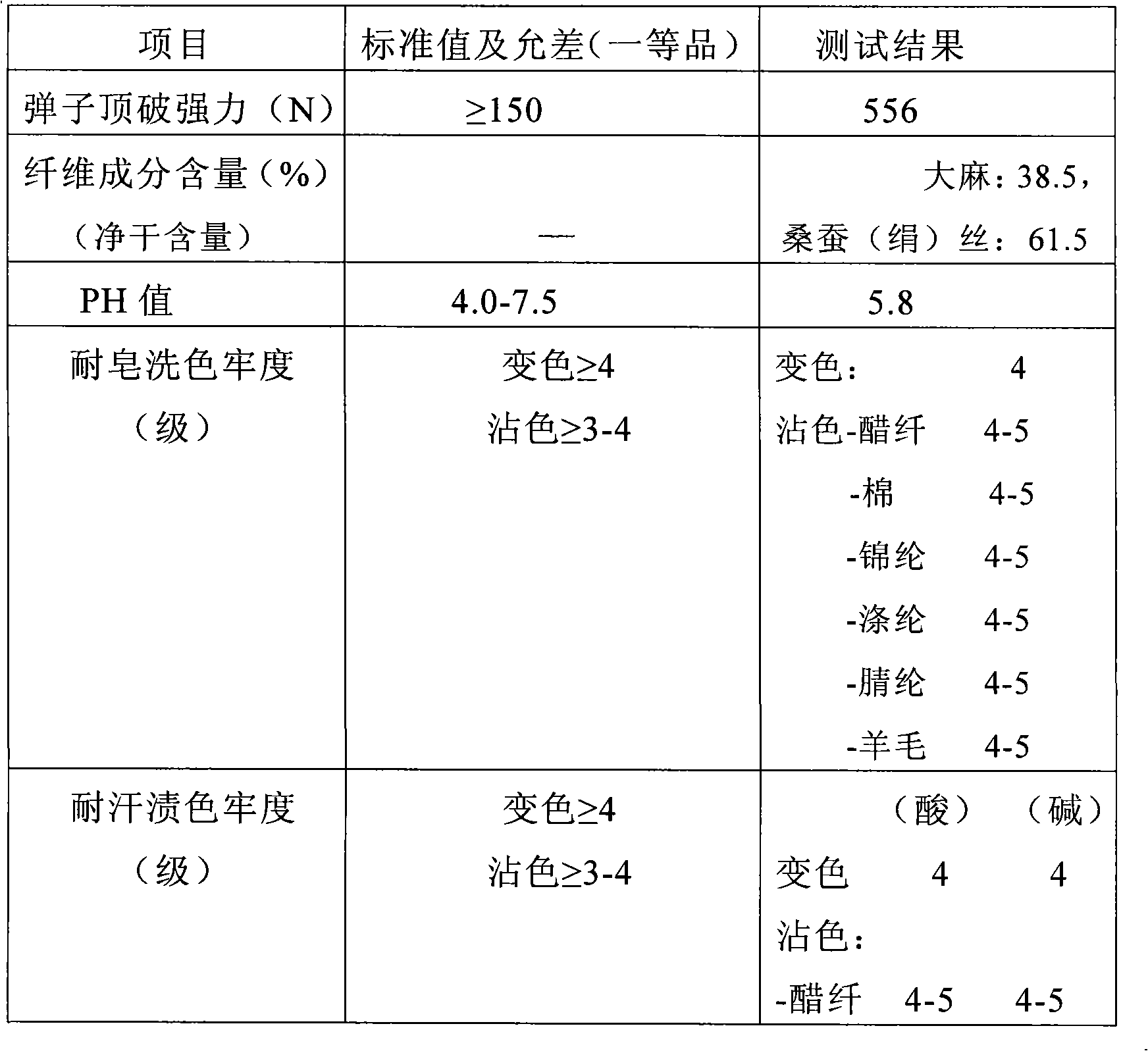

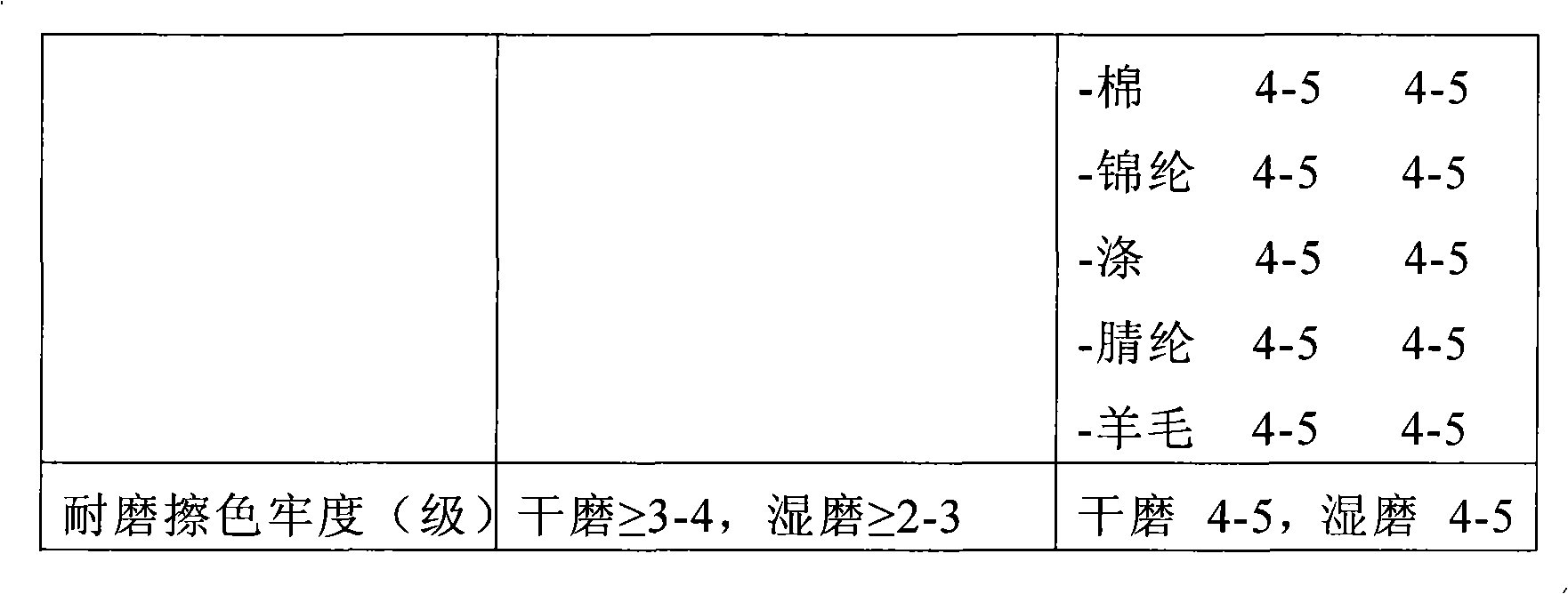

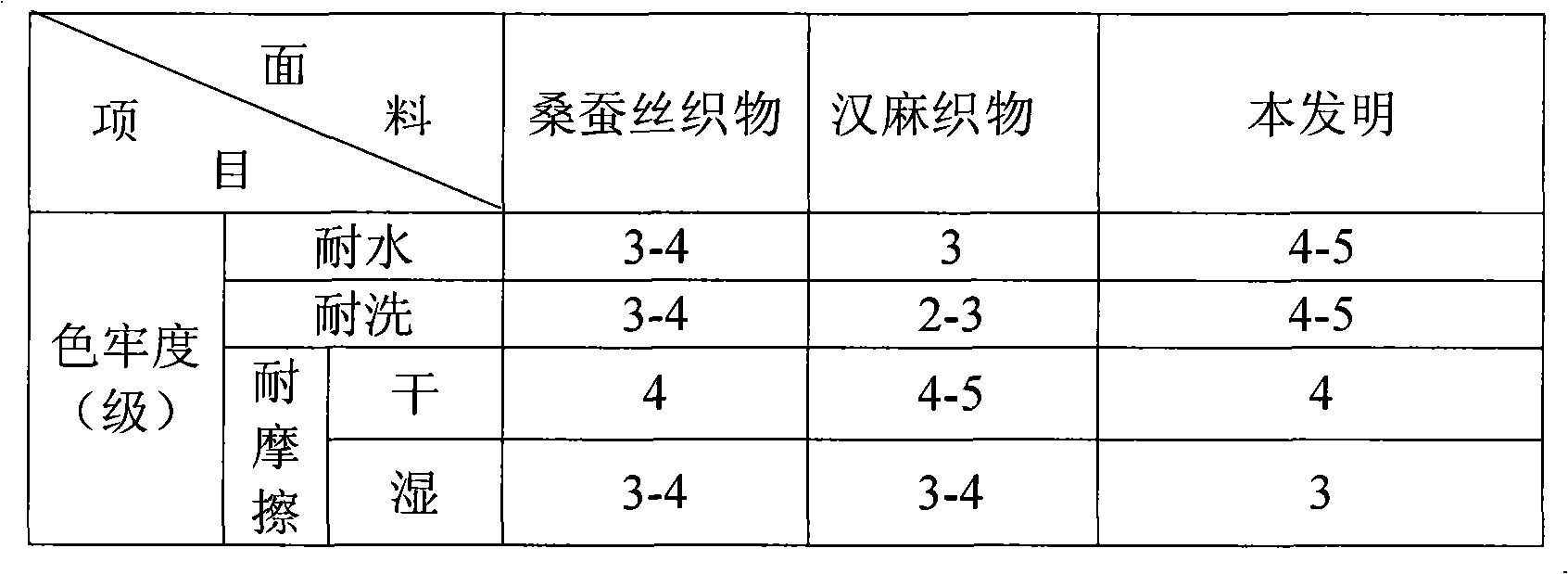

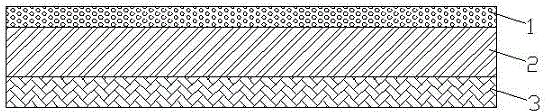

Hemp/silkworm (kiginu) silk high-count blended knitted fabric and manufacturing method thereof

InactiveCN102021725AEasy to absorb moistureMoisture-wickingMercerising of indefinite length fabricsWeft knittingYarnUltraviolet radiation

The invention belongs to the technical field of textile fabrics and relates to a manufacturing method of hemp / silkworm silk high-count blended knitted fabric. The manufacturing method comprises a line-forming technique and a cloth-forming technique, wherein the line-forming technique comprises the following steps: high-count blended yarn forming, triple singeing treatments, mercerization, degumming, dyeing, silk turning, spooling and the like of the hemp / silkworm silk; and the cloth-forming technique comprises the following steps: card nepremoval, humidifying, weaving, primary singeing treatment, mercerization, softening treatment, sizing, pre-shrinking, batching package and the like. The high-count blended knitted fabric has functions of antibacterium, bacteriostasis and ultraviolet radiation resistance, has good humidity-absorbing and air-permeable performances, high temperature resistance, softness and comfortableness, and can meet different requirements of crowds at all ages and all levels.

Owner:佛山市欧诗顿服饰有限公司

Quick-drying air permeable fabric

InactiveCN102975402AImprove waterproof performanceMoisture wickingSynthetic resin layered productsPolyesterSurface layer

The invention discloses a quick-drying air permeable fabric. The quick-drying air permeable fabric comprises a waterproof air permeable film on the surface layer, a moisture absorption layer on the intermediate layer and a sweat discharging air permeable layer on the inner layer, wherein the waterproof air permeable film is a polyvinyl chloride waterproof air permeable film; the moisture absorption layer is blended and knitted from porous polyacrylonitrile fibers and polyester fibers; and the sweat discharging air permeable layer is knitted from warps with wefts, wherein the warps are blended and knitted from polyester fibers and spun silk fibers, while the wefts are blended and knitted from viscoses and fibrilia. The polyvinyl chloride waterproof air permeable film in one-way permeation from inside outwards is adopted, and is good in waterproofness, and simultaneously capable of osmosing water outwards; the porous polyacrylonitrile fibers and the polyester fibers are blended so that most of moisture can be absorbed and simultaneously transferred outwards; and every two of the polyester fibers, the spun silk fibers, the viscoses and the fibrilia are blended, respectively, so that the quick-drying air permeable fabric is capable of absorbing moisture and discharging sweat and absorbing the sweat stain on the surface of the human body; and besides, as the moisture is transferred outwards, the interior is kept dry and comfortable.

Owner:WUJIANG GAOFA TEXTILE

Maize-fiber cashmere shell-fabric and producing method

InactiveCN101070660AImprove flame retardant performanceSolve brittle, hardWarp knittingHeating/cooling textile fabricsFiberEngineering

The invention relates to a plush shell fabric manufactured by unmixed corn fiber and its production method. It is made by 100 percent corn fiber. Its production way is composed by spinning and dyeing two sections. Said spinning part is that as following: first make corn fiber yarn unreeled and warped; then make corn fiber yarn spun into plush gray fabric according to spinning parameter using warp knitting loom; finally cut it off and pack it. Said dyeing part comprises plush fabric's repacking and suturing the end, pilling, preheating stereotypes, overflowing and scouring at normal temperature, dyeing, cleaning, drying, finalizing the size, scalding brightly, shearing, packing into final goods. And temperature of preheating stereotypes is 115 Deg.C to 130 Deg.C, the time is 20 to 30 seconds; the dyeing temperature is 80 Deg.C to 110 Deg.C, the dyeing time is 30 to 40 minutes; the temperature of stereotype is 115 Deg.C to 130 Deg.C, stereotype time is 20 to 30 seconds. The invention solves the problem of art temperature after corn fiber dyed when arranging it, also solve the problem of corn fiber's crisp, hard and easily fracture.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Method for making multifunctional different-functional China-hemp elastic knitted fabric

ActiveCN104278422AFacilitated DiffusionAchieve quick drying effectSucessive textile treatmentsWeft knittingPolyesterYarn

The invention discloses a method for making a multifunctional different-functional China-hemp elastic knitted fabric. The process flow of the method comprises the steps of spinning, winding, knitting, printing and dyeing, after finishing and inspection. The fabric consists of a surface layer and an inner layer, wherein the outer surface of the inner layer is covered with the surface layer; the inner layer is a China-hemp fiber layer; the surface layer is a moisture absorbing and quick drying polyester fiber layer; the China-hemp fiber layer is connected with the polyester fiber layer in a weaving manner through a middle connecting layer; the polyester fiber layer is woven into an air-permeable mesh structure with grooves; the China-hemp fiber layer is woven into a planar structure; fibers are special-shaped fibers, have large surface areas, and are provided with the grooves. The surface fiber layer is woven into the air-permeable mesh structure; the grooves are 0.5*3 millimeters, and are distributed uniformly, so that outward dispersion of water is facilitated; meanwhile, liquid-state water in the China-hemp fiber layer is transmitted or dispersed effectively by using the capillary action of the fiber groove structure, and is conveyed onto the outer surface of the fabric by means of gaps between fibers and China-hemp yarns or gaps among fibers.

Owner:JIHUA 3542 TEXTILE CO LTD

Method for preparing ultraviolet light polymerization environment-friendly antibacterial acrylic ester medical pressure sensitive adhesive product

ActiveCN102898970ANo pollutionImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerAdhesive cement

The invention discloses a method for preparing an ultraviolet light polymerization environment-friendly antibacterial acrylic ester medical pressure sensitive adhesive product. The method comprises the following steps of: (a), preparing an acrylic ester oligomer; (b), uniformly mixing protective colloid, a broad-spectrum antibacterial medicine, a polymer elastomer and the acrylic ester oligomer; and (c), dissolving the mixture mixed in the step (b) in a polymerizable monomer to obtain pressure sensitive adhesive cement capable of coating at normal temperature, coating the pressure sensitive adhesive cement on a base material, and performing ultraviolet light polymerization to obtain the medical pressure sensitive adhesive product. The medical pressure sensitive adhesive product is environment-friendly and antibacterial, has good adhesion property on skins, and can well absorb moisture and release sweat; when the pressure sensitive adhesive product is pasted and removed, a user does not feel pain, and residual adhesives are avoided; and the medical pressure sensitive adhesive product has good biocompatibility, does not irritate the skins, and can effectively prevent infection of wounds or surgical incision sites.

Owner:ZHENDE MEDICAL CO LTD

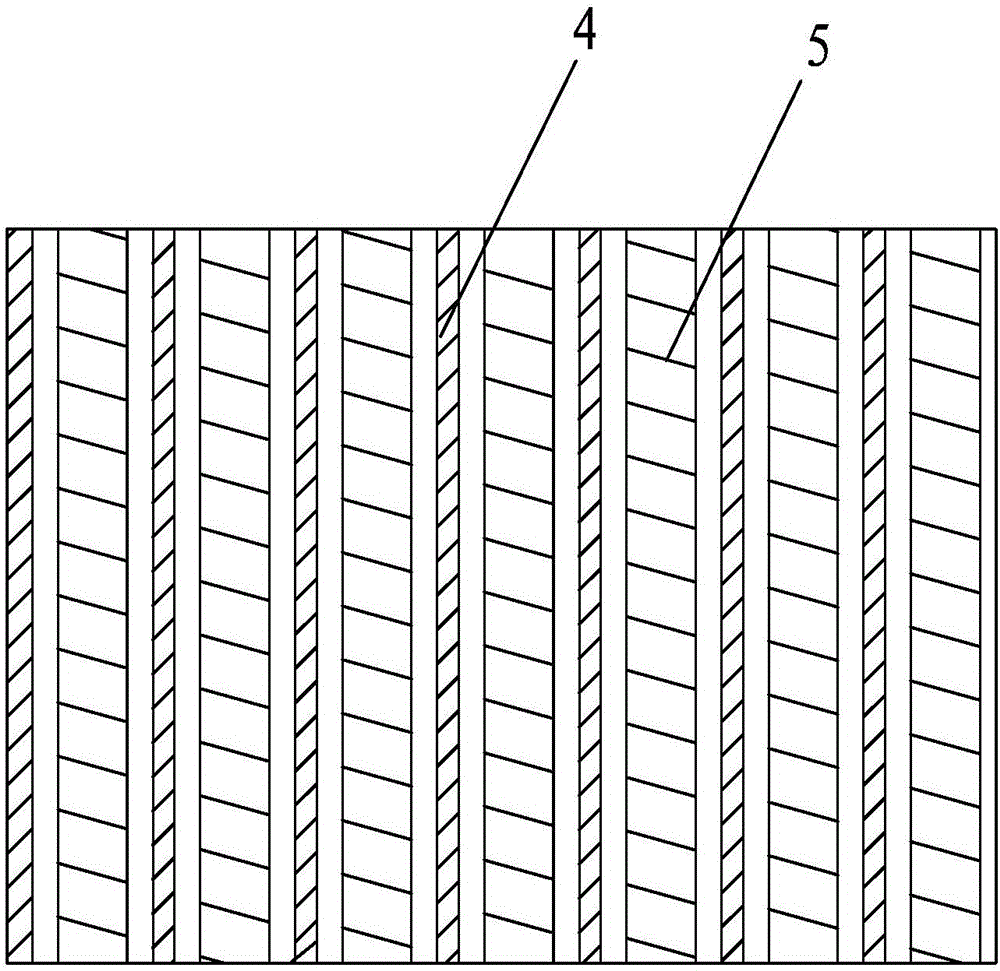

Waterproof breathable type knitted fabric

InactiveCN104441796AImprove wearing comfortMoisture wickingSynthetic resin layered productsClothingsEngineeringAirflow

The invention discloses a waterproof breathable type knitted fabric, which sequentially comprises an upper waterproof layer, an upper breathable layer, a lower breathable layer and a lower waterproof layer from outside to inside, wherein a plurality of upper breathable holes are evenly distributed in the upper breathable layer; a plurality of lower breathable holes are evenly distributed in the lower breathable layer; and the upper breathable holes and the lower breathable holes are distributed in a staggered manner. Through the manner, the fabric disclosed by the invention can form an airflow channel in the fabric, so that the fabric has the characteristics of being hygroscopic, sweat-releasing, waterproof, breathable, comfortable to wear and the like.

Owner:JIANGSU JINCHENZHEN TEXTILE

Three-dimensional curled elastic fiber and preparation method thereof

ActiveCN107574507ANo peelingGood thermodynamic compatibilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterPolymer science

Owner:JIANGSU DESAI CHEM FIBER

Skin core porous type anti-mosquito antibacterial fiber and preparation method thereof

InactiveCN107699983AGood anti-mosquito effectGood antibacterial effectArtificial filament heat treatmentMelt spinning methodsSurface layerPolymer resin

The invention provides skin core porous type anti-mosquito antibacterial fiber. The skin core porous type anti-mosquito antibacterial fiber comprises a composite structure of a core layer and a skin layer; nanometer holes are uniformly distributed in the skin layer uniformly and the diameter of each hole is below 400 nm; the core layer mainly comprises polymer resin and an anti-mosquito agent; andthe skin layer mainly comprises a graphene material and polymer resin. A preparation method comprises the following steps: (A) blending the graphene material, insoluble salt of calcium and / or bariumand polymer resin to serve as the skin layer, blending the anti-mosquito agent and the polymer resin to serve as the core layer, compounding the components of the skin layer and the core layer to perform melt spinning, and enhancing elasticity to obtain composite fiber; and (B) performing acid treatment on the surface of the composite fiber to prepare holes, thereby obtaining the skin core poroustype anti-mosquito antibacterial fiber. According to the embodiment of the invention, nanometer holes are distributed in the surface layer of the fiber, the anti-mosquito agent of the core layer can slowly release outwards through the holes, and a durable anti-mosquito effect is given to the fiber. The graphene added in the skin layer can give high antibacterial and bacteriostatic effects to the fiber.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Infant swaddling

ActiveUS20170049158A1Reduce riskFacilitates capillary actionSleeping rugBlanketRectal temperatureEngineering

Infant swaddling allows an infant to be comfortably and easily swaddled. The swaddling includes a pouch featuring a lower end that can be opened and closed to allow an infant's soiled diaper to be easily removed and replaced or to take a rectal temperature. The swaddling can include a blanket that comprises a first blanket flap and a second blanket flap and that can be removably attached to the pouch. The swaddle is used by placing one of the blanket flaps over the pouch, and then placing the other blanket flap over the pouch.

Owner:ZEIDMAN HINDI R

Socks containing silver fiber

The invention relates to a pair of socks containing silver fibers, which are weaved by yarns through adopting a special hosiery machine. Each sock comprises a sock head, a sock surface, a sock bottom, a sock heel and a sock leg in order, wherein at least one silver fiber is added to the sock head and the sock heel on the basis of the at least one original yarn; and the silver fiber and the yarn are tightly arranged in parallel or tightly interweaved. The yarn is any one of long staple cotton, mercerized cotton, combed cotton, blended cotton and acrylic, all wool, wool, blended wool and acrylic or bamboo fiber; the bottom yarn of each sock is made of terylene coating yarns or spandex coating yarns or nylon coating yarns or chinlon coating yarns, and the number of the yarns is 10 to 80. The socks containing silver fibers have the efficacies of stronger bacterium resistance, deodorization and sweat absorption, the effects of reducing static electricity, promoting blood circulation, eliminating foot swelling, and the like and the advantages of high air permeability, durability and comfortable foot feeling.

Owner:SHANGHAI AIFA INVESTMENT MANAGEMENT

Anti-bacterial fabric for shoes and production process thereof

Provided is anti-bacterial fabric for shoes and a production process thereof. Warp-knitted spacer fabric is adopted and comprises a surface layer for decoration, an inner layer in contact with the skin, and a spacing layer arranged between the surface layer and the inner layer. The inner layer is formed in such a manner that far infrared polyester fibers and chinlon-based cupric ion anti-bacterial fibers are interwoven. The far infrared polyester fibers serve as the spacing layer. In a bacteriostatic test of fabric, the bacteriostasis rate of Candida albicans reaches at 95.76%, the bacteriostasis rate of trichophyton rubrum reaches at 96.96%, the bacteriostasis rate of staphylococcus aureus reaches at 99.23%, and the bacteriostasis rate of colibacillus reaches at 99.99%. The anti-bacterial fabric has composite functions of heat preservation, bacteria prevention, health care, moisture conductivity and perspiration.

Owner:HAIXI NEW TEXTILE MATERIAL OF JINJIANG IND TECH ACAD +1

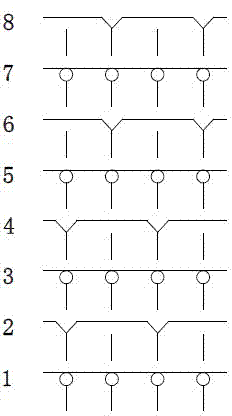

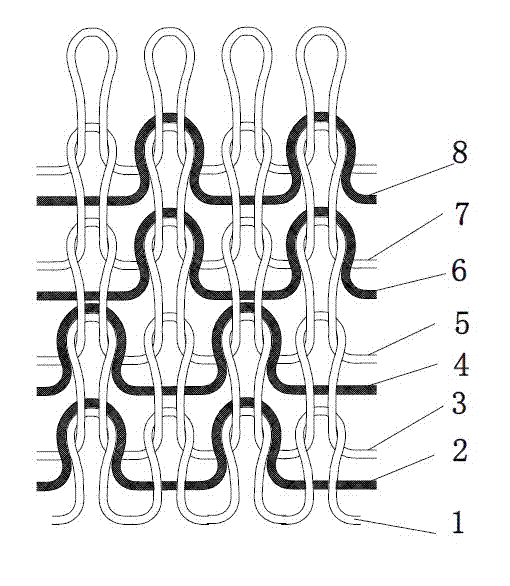

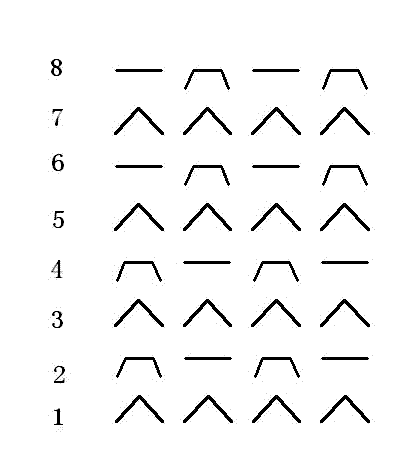

Jean fabric and manufacturing method thereof

The invention discloses jean fabric which is characterized in that the minimal weave repetition of the jean fabric comprises eight stitch rows and four stitch columns, wherein the first, the third, the fifth and the seventh rows / columns are full-loop weave structures formed by blue yarns and spandex yarns, and the second, the fourth, the sixth and the eighth rows / columns are tuck weave / welt weave interlaced structures formed by hair white yarns. A manufacturing method of the jean fabric comprises the following steps of: dying yarns, weaving, reorganizing and water shaping after unloading. Compared with the prior art, the jean fabric has the following advantages and effects: the jean fabric has coarse texture, is better in elasticity than the common woven jean fabrics, is made of pure cotton, has moisture-absorbing, sweat-removing, antibacterial, deodorant, UV-resistant and warm-keeping effects, is about 190 G in weight, has soft feeling and light weight, can be washed to fade or change the color so as to obtain a desired style of the clothing, and shows both the style of jean fabric and the elegance of knitted fabric.

Owner:JIAXING GANGHENG KNITTING

Preparation method of taxus chinensis viscose fibers

InactiveCN102586918AMoisture wickingHas functional health effectsArtificial filaments from viscoseCellulose material pulpingFunctional healthTaxus mairei

The invention relates to a preparation method of taxus chinensis viscose fibers. The preparation method is characterized by comprising the following technological steps of: tabletting a taxus chinensis raw material, washing tablets in hot water, and placing the tablets in an alkali liquor for stewing; continuously washing the tablets in hot water after stewing; beating the tablets in a beating machine to obtain pulp, and desanding the pulp; concentrating the pulp in a thickner after desanding, and bleaching the concentrated pulp; continuously concentrating the bleached pulp, manufacturing paper with pulp after concentration, and obtaining the taxus chinensis pulp; soaking the taxus chinensis pulp in a NaOH solution, squeezing after soaking to obtain fine materials, carrying out yellowing treatment on the fin materials to obtain mucilage glue, spinning the mucilage glue in a spinning coagulating bath, and obtaining the taxus chinensis viscose fibers. Taxus chinensis with the anti-cancer effect adopted in the preparation method is made into the taxus chinensis viscose fibers; the taxus chinensis viscose fibers have good spinning processability; manufactured textiles has the advantages of smoothness, fineness and the like, has the functional health-care effect and is beneficial to promoting the sleep.

Owner:WUXI HODOHOME GARMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com