Anti-bacterial fabric for shoes and production process thereof

A technology for antibacterial fabrics and shoes, applied in textiles and papermaking, layered products, knitting, etc., can solve the problems of not having far-infrared heat preservation function, cracking of coated fabrics, etc., achieve good moisture-conducting function, increase content, reduce The effect of the cutting and sewing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

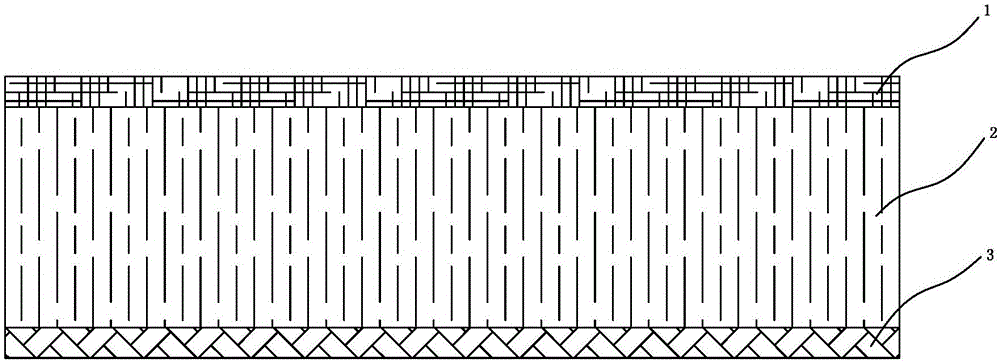

[0021] refer to figure 1 As shown, a kind of antibacterial fabric for shoes adopts warp-knitted spacer fabric, and the warp-knitted spacer fabric adopts double-needle-bar Jacquard warp knitting machine to knit and includes a decorative surface layer 1, an inner layer 3 that contacts the skin and is arranged on the surface and the inner layer. Spacer layer 2 between layers 1, 3.

[0022] The inner layer 3 is made of FDY / 70D / 24f nylon-based copper ion antibacterial fiber and 75D / 72f far-infrared polyester fiber. It is woven, and the weaving method is as follows: it is formed by three bars GB1, GB2, and GB3 that only lay yarn on the front needle bed. GB1 forms the knitting structure of the front needle bed, and Jacquard bars GB2 and GB3 form an integral shape. Large flower pattern; the spacer layer 2 is woven by 75D / 72f far-infrared polyester fiber, which increases the content of thermal insulation fibers, and the far-infrared polyester is composed of multiple monofilaments, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com