Kapok spunlace non-woven fabric, preparation method thereof and product of kapok spunlace non-woven fabric

A technology of spunlace non-woven fabrics and kapok, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as poor cohesion rate, inability to make textiles, poor spinnability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, a method for preparing a kapok spunlace nonwoven fabric is provided, and the method is used to prepare a kapok spunlace nonwoven fabric containing kapok fibers.

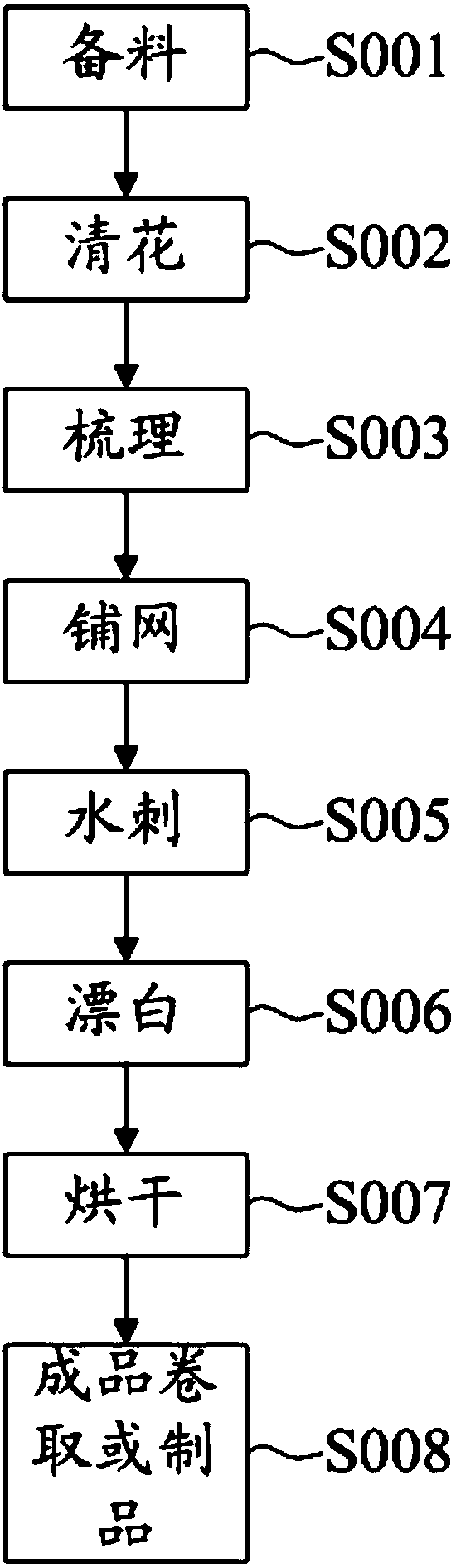

[0026] Such as figure 1 Shown, this preparation method comprises the steps:

[0027] S001: Prepare materials;

[0028] The kapok fiber is prepared separately, or the kapok fiber is uniformly mixed with one or more other natural fibers and chemical fibers to prepare mixed fibers, wherein other natural fibers include cotton fibers, hemp fibers, etc., and chemical fibers include regenerated fibers, synthetic fibers, Inorganic fibers etc. In this embodiment, other natural fibers and chemical fibers are selected from cotton fibers for illustration. In other embodiments, hemp fibers, or a mixture of cotton fibers and hemp fibers can be selected, or other natural fibers and chemical fibers can be added.

[0029] When mixing, the kapok fiber and cotton fiber are evenly mixed into a mixed fiber. ...

Embodiment 2

[0047] This embodiment provides a kapok spunlace nonwoven fabric. The kapok spunlace nonwoven fabric of this example is prepared by the preparation method in the first embodiment above. The prepared kapok spunlace non-woven fabric has no chemical additives, has the advantages of keeping warm and antibacterial, soft and comfortable, dry and breathable, and is suitable for the production of medical and sanitary products to meet people's daily needs.

Embodiment 3

[0049] This embodiment provides a kapok spunlace nonwoven product, such as medical and sanitary products such as facial masks, sanitary napkins, sanitary pads, paper diapers, and adult incontinence products. The kapok spunlace nonwoven fabric product in this embodiment includes the kapok spunlace nonwoven fabric in the above-mentioned embodiment 2, so that the kapok spunlace nonwoven fabric product has the advantages of keeping warm and antibacterial, soft and comfortable, dry and breathable, etc., and satisfies the needs of people. increasing usage requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com