Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151results about How to "Mothproof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

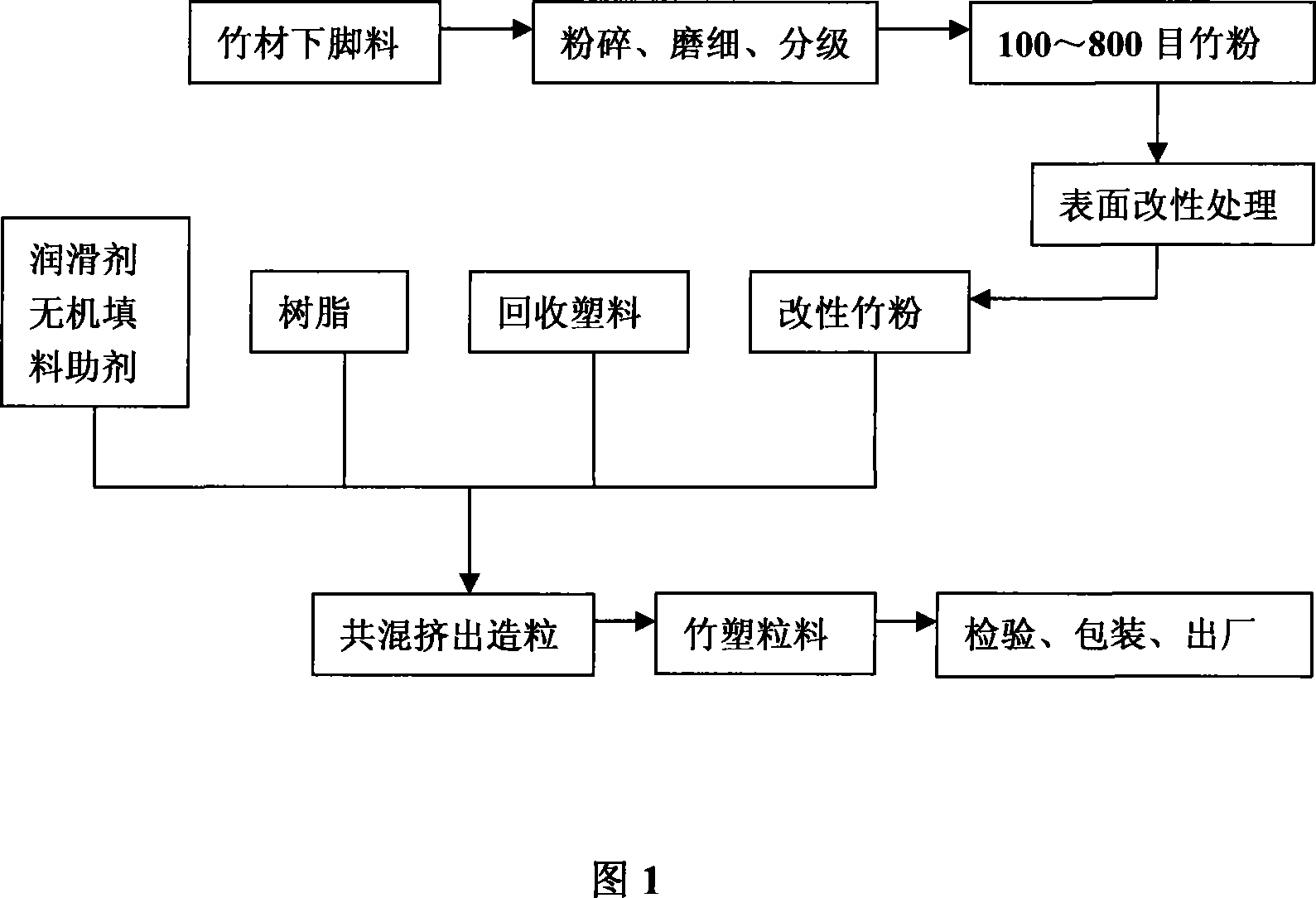

Bamboo-plastic composite material

The invention provides a bamboo-plastic composite material which is obtained by that raw materials such as plastic, recycled waste plastics, bamboo powder, modifier, chemical agent, lubricant, etc. are mixed in different proportions and extruded out to get series bamboo-plastic granule; the invention can be used for manufacturing different products such as bamboo-plastic boards, wood-plastic composite profiles and wood-plastic tubular products, etc. through extruding. The series bamboo-plastic granule can be produced in a continuous large volume and is characterized in that the production efficiency is high, the cost is low and the performance-price ratio is high, etc. The series bamboo-plastic granule can be used for replacing wood, and the cost thereof is lower than wood-plastic materials while the mechanical strength thereof is higher than wood-plastic materials, therefore the series bamboo-plastic granule can be widely popularized for use. The series bamboo-plastic granule is a novel cyclically reutilized material resource after wood-plastic material.

Owner:戴福寿 +1

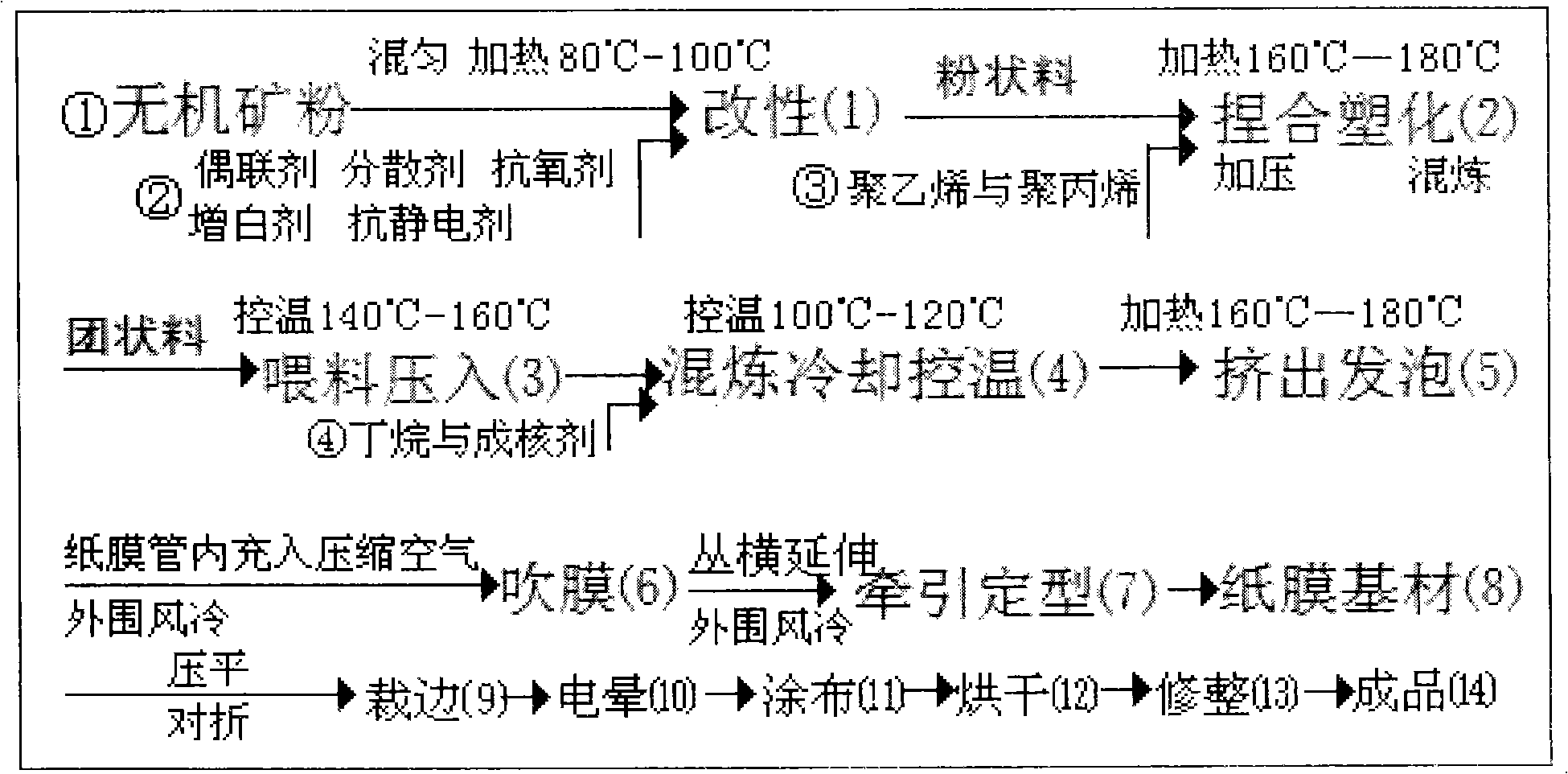

Stone papermaking method

InactiveCN101831835AControl the amount of inflationLight weightInorganic fibres/flakesSpecial paperFilm baseWhite powder

The invention discloses a stone papermaking method, which is characterized by comprising the following steps: adding 2 to 2.5 weight percent of auxiliary agent such as stearic acid and the like into 70 to 80 percent of natural inorganic ore powder such as heavy calcium, light calcium, talcpowder, titanium white powder and the like serving as main raw materials to modify the raw materials, adding 18 to 11.5 weight percent of polyethylene and 9 to 5 weight percent of polypropylene into the raw materials, and mixing, plasticizing and kneading the mixture to form a bulk material; and performing double-fold feed on the bulk material, pressing the bulk material into a paper film extruder, injecting 0.5 weight percent of butane and 0.5 weight percent of nucleating agent into the extruder, mixing and heating the mixture, extruding a paper film, then foaming, blowing, drawing, cooling and shaping the paper film to form a paper film base material, and forming a stone paper finished product through corona, coating, drying and finishing. The gram weight of stone paper is reduced by physical micro-foaming technology. The method has the advantages of simple manufacturing process, low cost, dry production, use of few water circulating cooling machines, no three-waste discharge and pollution avoidance.

Owner:山西典石晨晶科技有限公司

Environment-friendly flame-retardant thermal insulation mortar adopted with rice hulls

The invention belongs to the technical field of building materials, and particularly relates to an environment-friendly flame-retardant thermal insulation mortar adopted with rice hulls. The preparation method includes taking ordinary Portland cement, coal ash and slag powder as cementing materials and the rice hulls and sand as fine aggregates; adding a water reducing agent, redispersible latex powder and a graft copolymer (CMC-g-PMMA) of carboxymethyl cellulose and methyl methacrylate as plant fiber surface treating agents. The environment-friendly flame-retardant thermal insulation mortar adopted with the rice hulls has the advantages of being simple in construction, low in cost, small in self-weight, environment-friendly and energy-saving due to the full usage of crop waste, good in economical and social benefits, provided with performances of damp and moth proofing, frame retardance and thermal insulation, and suitable for building and plastering construction of wall materials.

Owner:TONGJI UNIV

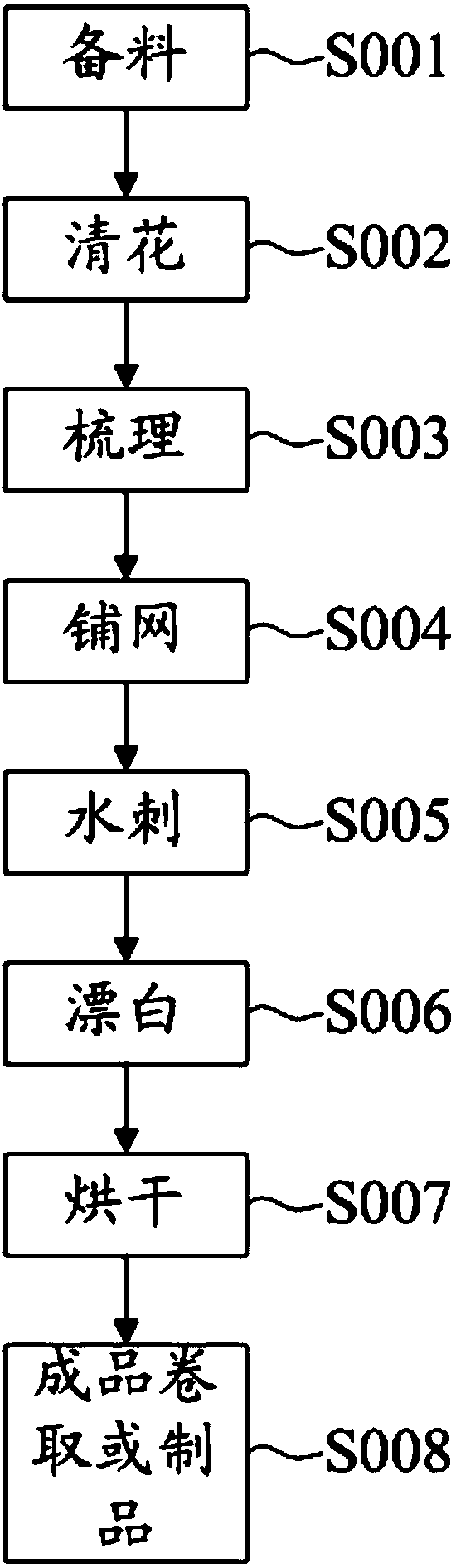

Production method of kapok fiber spunlaced nonwoven fabric

InactiveCN103205862AKeep natural propertiesMaintain propertiesNon-woven fabricsVegetal fibresKapok fiberPulp and paper industry

The invention belongs to the technical field of weaving, in particular to a production method of kapok fiber spunlaced nonwoven fabric. The method includes: pretreating kapok fiber to improve spinnability; using a weighing curtain feeder to feed kapok fiber into a blowing-carding device for opening, blending and purification; using an induced fan to collect web in a blowing-carding machine to feed into a tiny dust removing device for further dust removing and opening; connecting the tiny dust removing device with a spunlaced line carding machine, carding the fiber into web on the spunlaced line carding machine, cross lapping, spunlacing to form fabric, coiling, degreasing and bleaching, drying and slitting to obtain the finished product. The method is safe, environment-friendly, energy-saving, efficient, high in automation level, and advanced in spunlaced kapok nonwoven fabric weaving, and various characteristics of fiber raw materials are protected effectively.

Owner:蒋海彦

Kapok spunlace non-woven fabric, preparation method thereof and product of kapok spunlace non-woven fabric

InactiveCN107916499ABreathableWarm and antibacterialNon-woven fabricsMaterials preparationForeign matter

The invention discloses a kapok spunlace non-woven fabric, a preparation method thereof and a product of the kapok spunlace non-woven fabric. The preparation method of the kapok spunlace non-woven fabric comprises the following steps: material preparation: independently preparing kapok fibers, or uniformly mixing the kapok fibers with one or more of other natural fibers and chemical fibers to obtain mixed fibers; blowing: removing impurities from the prepared kapok fibers or mixed fibers, and sieving out foreign matters; carding: opening the blown kapok fibers or mixed fibers into single fibers at first, and then smoothly combing the single fibers; carrying out lapping; carrying out spunlace; carrying out bleaching; carrying out drying; and rolling a finished product or obtaining a product. Because the kapok fibers have characteristics of lightness and softness, breathability, high wet permeability, high degree of hollowness, anti-bacterial property, mothproof property and mildew proofproperty. The kapok spunlace non-woven fabric is prepared by the spunlace non-woven process, chemical auxiliaries are not added in a whole fabric forming process, and therefore, the prepared kapok spunlace non-woven fabric has the advantages of warming and bacteria inhibition, lightness, softness and comfort, dryness and breathability and the like.

Owner:WINNER MEDICAL CO LTD +1

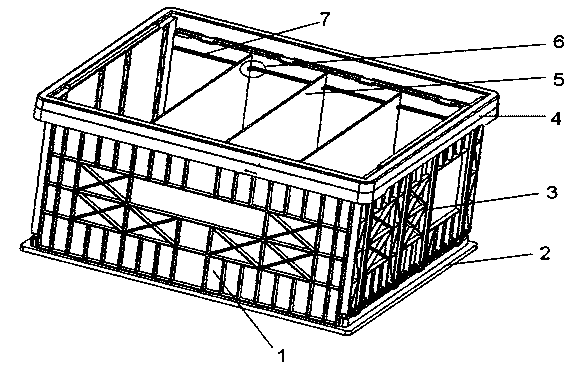

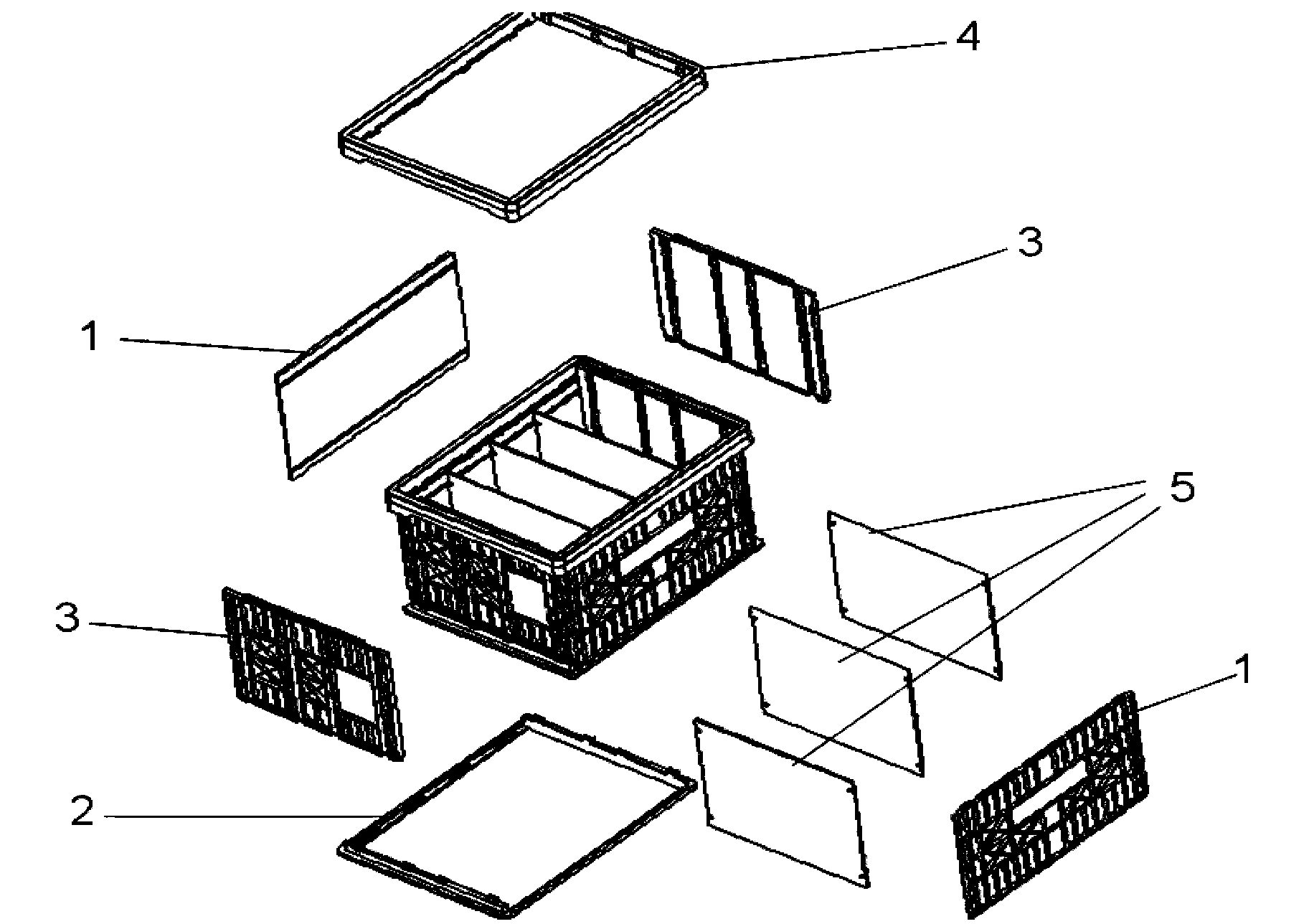

Adjustable transfer box

Owner:HEFEI GENIUS NEW MATERIALS

Sterilization processing method of rattan plaited article materials

InactiveCN104476639ASimple processing methodInsect-resistantBiocideWood treatment detailsMildewSoftening

The invention provides a sterilization processing method of rattan plaited article materials, and belongs to the technical field of rattan plaited article production. The sterilization processing method comprises following steps: rattan is harvested, and each 10 to 20 strips are bonded with a consistent direction so as to obtain one bouquet of rattan; the bonded rattan bouquets are immersed in a processing solution with the end tip of rattan upward, and are exposed to sunlight for 3 to 6 h; leaves of the rattan bouquets are removed, the rattan bouquets are dried with hot air, wherein at a first stage, the rattan bouquets are dried to medium dry, and are subjected to moisture retention for 30 to 50 min for a first time with softening steam, at a second stage, the rattan bouquets are dried to be sixty percent dry, and are subjected to moisture retention for 1 to 3 h for a second time with softening steam, and at a third stage, the rattan bouquets are dried to be eighty percent dry; and the processed rattan bouquets are stored at shade places for natural air drying. According to the sterilization processing method, the fresh rattan is processed firstly; the sterilization processing method is simple, is capable of realizing sterilization, insect prevention, moth prevention, and mildew and rot prevention, and prolonging service life of rattan plaited articles; the obtained steam used for softening is capable of realizing rattan softening, and volatile substances contained by the steam is capable of realizing sterilization and fragrance improvement of rattan.

Owner:ANHUI HONGFU CRAFTS

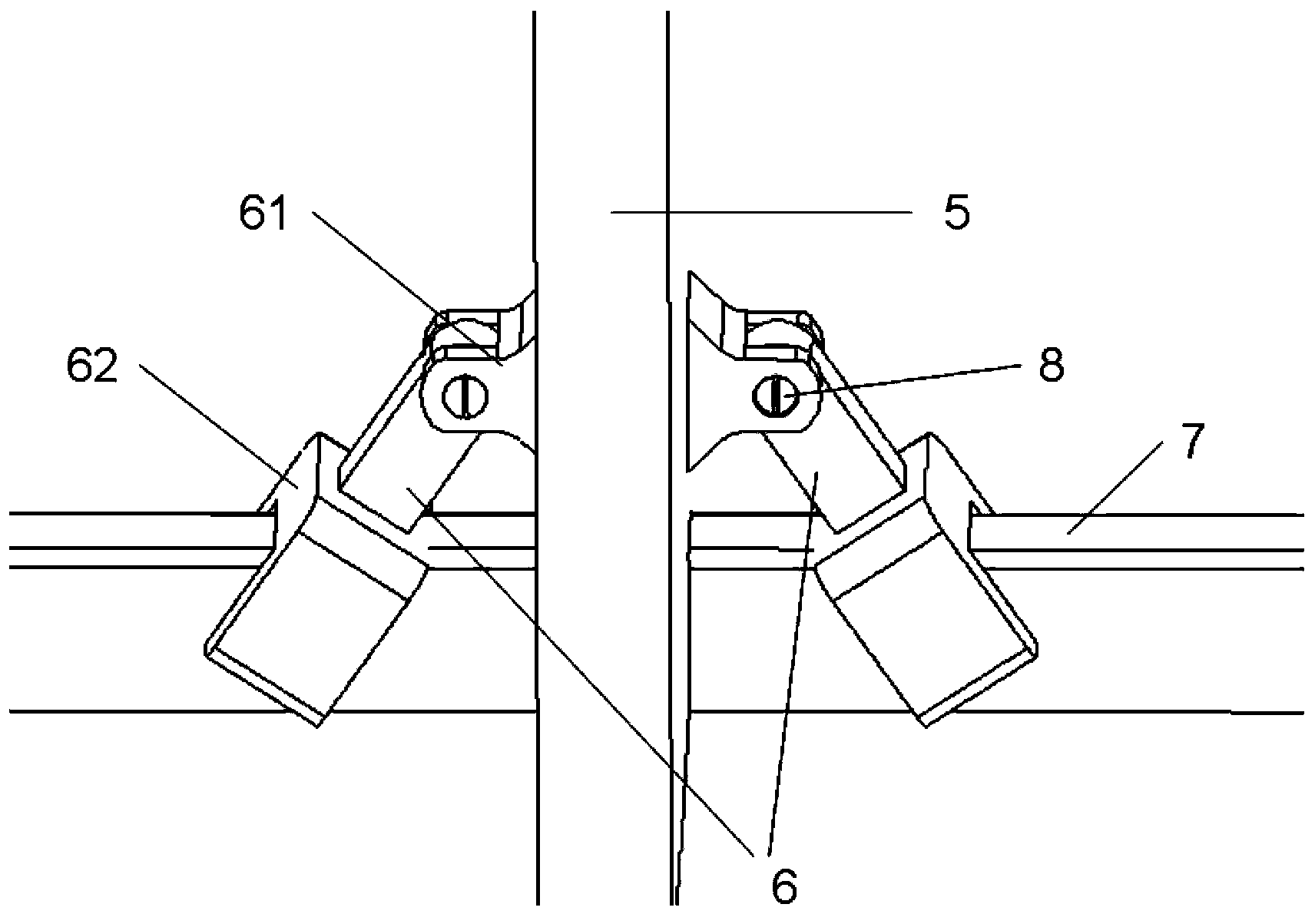

Preparation method of ceramic plate decorative painting through colored engraving

The invention relates to a preparation method of a ceramic plate decorative painting through colored engraving. The method comprises the following steps: 1), a protective film is attached to the surface of a ceramic plate; 2), sidelines of a specified figure are engraved on the surface of the ceramic plate by a laser engraving machine; 3), the protective film at a to-be-etched part is removed so as to expose an engraving surface; 4), the surface of the ceramic plate is eroded by an abrasive material at a high flow rate, so that an uncolored solid figure is formed through engraving on the ceramic surface with the protective film removed, the pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 5), sand blasting is at least performed on a to-be-colored part of the surface of the ceramic plate so as to at least remove a glaze layer of the to-be-colored part and form a frosted surface, the sand blasting pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 6), the frosted surface of the ceramic plate prepared in the step 5) is cleaned and dried, a pattern is spray-printed and drawn, and a protective glaze layer is spray-printed; 7), the ceramic plate prepared in the step 6) is sintered rapidly.

Owner:MONALISA GRP CO LTD

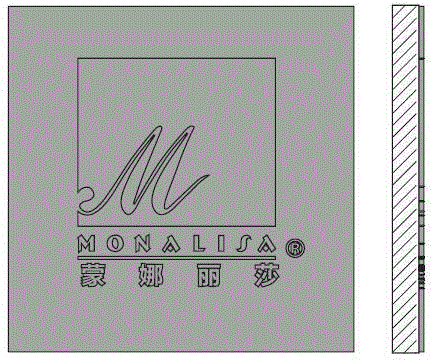

Calcium silicate high-filling polymer modified paper

InactiveCN102011347ALow lateral shrinkageWith whitenessSpecial paperPaper/cardboardLinear low-density polyethyleneCalcium silicate

The invention relates to calcium silicate high-filling polymer modified paper, which is compounded and formed by three layers of non-plant fiber calcium silicate substrates, wherein the first layer and the third layer are prepared from 2 to 6 percent of ethylene bis stearamide, 8 to 23 percent of high-density polyethylene, 3 to 9 percent of metallocene polyethylene, 0 to 1 percent of low-molecular polyethylene, 50 to 60 percent of activated calcium silicate, 10 to 25 percent of calcium silicate inorganic powder and 0 to 3 percent of addition agents, the first layer and the third layer accounts for 25 percent of the weight of the paper, the second layer is prepared from 50 to 60 percent of activated calcium silicate powder, 10 to 25 percent of calcium silicate, 2 to 9 percent of styrene-butadiene block copolymer, 7 to 21 percent of high-intensity polyethylene materials, 4 to 8 percent of linear low-intensity polyethylene and 0 to 3 percent of addition agents, and the second layer accounts for 50 percent of the weight of the paper. The modified paper has the same appearance, whiteness, sizing degree, opacity, strength, toughness and rigidity as plant fiber paper and has simple production processes, no bacteria and poison; and because the product is used for packing paper and can replace the traditional plastic packing paper, a great amount of petroleum can be saved.

Owner:宋旭

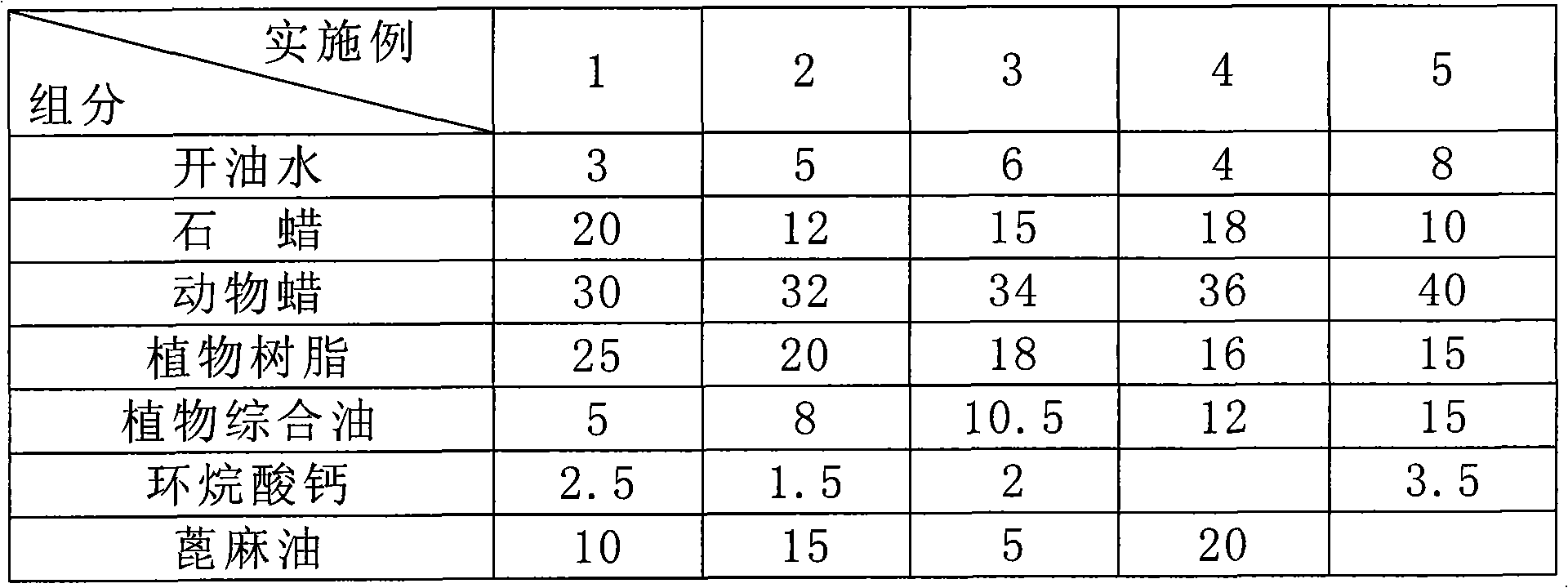

Environmental protection type wood wax oil and preparation method thereof

InactiveCN101659832AWide variety of sourcesLow priceWax coatingsNatural resin coatingsParaffin waxPropolis

The invention provides an environmental protection type wood wax oil and a preparation method thereof, belonging to the technical field of chemical products. The wood wax oil and the preparation method solve the problems that the existing wood wax oil has higher production cost, unreasonable compatibility between raw materials, and poorer uniformity after being mixed. The wood wax oil is preparedby the following components according to part by weight: 3-8 parts of boiled oil water, 10-20 parts of paraffin wax, 30-40 parts of animal wax, 15-25 parts of propolis and 5-15 parts of plant composite oil. The preparation method has simple process flow, few steps, wide raw material sources and low cost; and the prepared product has better uniformity, low toxicity, no pollution and the effects ofmould proof, moisture proof, damp proof, moth proof, surface conservation, beautification and the like.

Owner:王增平

Sterilizing processing liquid for processing rattans

InactiveCN104397071ASimple processing methodInsect-resistantBiocidePest repellentsBiotechnologyOyster

The invention provides a sterilizing processing liquid for processing rattans, and relates to the technical field of rattan-weaved product production. The processing liquid is composed of the following raw materials in parts by weight: 3 to 7 parts of andrographis paniculata, 2 to 4 parts of cordate houttuynia, 1 to 3 parts of basil, 2 to 4 parts of wild chrysanthemum, 3 to 7 parts of tribulus terrestris, 2 to 4 parts of prunella vulgaris, 3 to 6 parts of santal, 4 to 8 parts of honeysuckle flower, 3 to 7 parts of purslane, 2 to 4 parts of perilla leaf, 2 to 5 parts of Chinese magnoliavine, 2 to 5 parts of hairyvein agrimony, 1 to 3 parts of tabasheer, 2 to 4 parts of fructus forsythiae, 2 to 4 parts of yellow gentian, 2 to 4 parts of rhizoma atractylodis, 2 to 4 parts of eupatorium, 1 to 3 parts of cyrtomium rhizome, 1 to 3 parts of common cnidium fruit, 1 to 3 parts of rheum officinale, 1 to 3 parts of stemona, 2 to 4 parts of smoke stalk, 1 to 3 parts of oyster, and 3 to 7 parts of tree peony bark. In the processing method, live rattans are processed by the provided liquid. The processing method is simple. The processed rattans are sterilized and have the functions of insect resistance, mothproof property, and mold resistance. The service life of rattan-weaved products can be prolonged. The prepared softening steam can soften the rattans, and the volatile substances in the steam can sterilize the rattans and increase the aroma of the rattans.

Owner:ANHUI HONGFU CRAFTS

Pollution-free pine timber modifying method and composition

A pine timber modification method is to eliminate its turpentine oil, fix its rosin and inject water-soluble resin capable of being cured. After deoiling and rosin fixing at 80-105 deg.C and under normal pressure for 3-10 hr, the pine timber is vacuum pumped for 0.5-1 hr, made to suck water-soluble fireproof polymer resin under 0.09-0.095 MPa vacuum and soaked for 1-5 hr under normal pressure. The deoiling and rosin fixing composition contains water-soluble nitogen-contained organic compound, magnesium, salt, boric acid, emulsifier, penetrant, and has pH value of 7.5-8.0. The pint timber thus processed has no rosin overflow and deformation, high strength and durability, and certain fireproof performance.

Owner:陈万利 +2

Environment-friendly plant fiber wood-plastic composite material and preparation method thereof

The invention provides an environment-friendly plant fiber wood-plastic composite material and a preparation method thereof. The environment-friendly plant fiber wood-plastic composite material is prepared from the following components serving as base stock by weight percent: 50-90% of plant fibers, 5-40% of waste polystyrene plastic recovery particles and 5-10% of styrene butadiene styrene (SBS), as well as a proper amount of an assistant-silane coupling agent and stearic acid, wherein the use amount of the silane coupling agent accounts for 1-10wt% of the plant fibers while the use amount of the stearic acid accounts for 2-5wt% of the plant fibers. The environment-friendly plant fiber wood-plastic composite material has the advantages of insect prevention, moth resistance, chemical corrosion resistance, large additive amount of cellulose, high physical and mechanical strength, low cost, easy decomposition and wide application, and is environment-friendly.

Owner:广东普科特粉末涂料有限公司

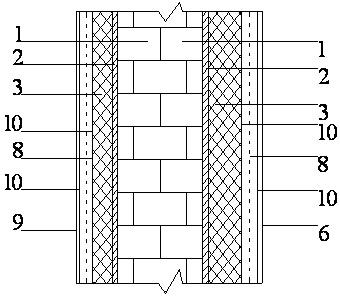

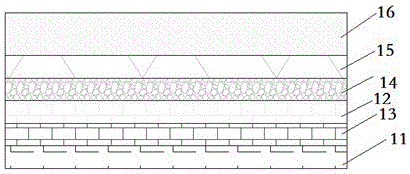

Construction waste-containing high-strength light-weight composite PC (polycarbonate) mortar board for prefabricated building

The invention provides a construction waste-containing high-strength light-weight composite PC (polycarbonate) mortar board for a prefabricated building. The mortar board comprises an inner PC board layer, an outer PC board layer and a filling material layer arranged between the inner PC board layer and the outer PC board layer. A preparation method of the mortar board comprises the following steps of performing hammering, vibrating, crushing, grinding and other processes on concrete and brick slag in construction wastes to form a regenerated building aggregate; performing high-speed rotation on the regenerated building aggregate to obtain regenerated micro powder, and collecting the regenerated micro powder; mixing the regenerated building aggregate, the regenerated micro powder, a polymer, cement, rice hulls and straws, basalt fibers and glass fibers, ceramsite and other auxiliaries to obtain the PC board layers; mixing polystyrene foam, asbestos foam or nano-sized aerogel with the polymer to obtain the filling material layer; and finally, compounding the PC board layers and the filling material layer to obtain the construction waste-containing high-strength light-weight composite PC mortar board for the prefabricated building. The preparation method is simple; and as regenerated building agricultural wastes are taken as a large part of raw materials, on the basis of guaranteeing high strength and light weight, the cost is reduced, and the mortar board is green and environment friendly.

Owner:SHAOXING YISHENG MORTAR

Base fabric material for embroidery and embroidery thread

The invention relates to a base fabric material for embroidery and an embroidery thread. The base fabric material is characterized by comprising following paper base fabrics: writing paper, copying paper, decorating paper, newspaper, coated paper, offset paper, halftone paper, plate paper, cellophane, one-side / two-side transparent glazed paper, synthetic fabric paper, cast coated paper, coating paper, cartridge paper, wallpaper, brown paper, parchment, foaming paper, packaging paper, honeycomb paper, waterproof paper, fireproof paper and mothproofing paper; and following paperboard base fabrics: a case board, a straw board, a white board, a binding paperboard, compound multi-layer paper and a corrugated board. The embroidery thread comprises a plant fibre thread, an animal fiber thread, a chemical fiber thread, a metal fiber thread and a mixed fiber thread. An embroidery product manufactured by the base fabric material and the embroidery thread can be used for decorating and finishing walls, table-boards, ground and furniture, can be used permanently or temporally, has waterproof, mothproof and fireproof performances, is durable, is long in service life, and has good environmental performance.

Owner:单虹岩

Thermal light and thin fabric

InactiveCN103668662AStrong hygroscopicityGood warmth retentionWoven fabricsYarnEnvironmentally friendlyYarn

The invention discloses thermal light and thin fabric which is formed by interweaving of A yarn and B yarn, wherein the A yarn comprises, by mass, 60%-75% of wool fibers and 25%-40% of bamboo-carbon fibers, the B yarn comprises, by mass, 50%-60% of kapok fibers, 20%-30% of mulberry silk fibers and 10%-20% of modal fibers, and both the A yarn and the B yarn are formed through twisting by means of the siro spinning technology. In this way, the fabric is light and thin, breathable, good in thermal performance, capable of inhibiting and resisting bacteria, non-toxic, harmless, environmentally friendly, and safe.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

Integrally formed carriage plate for van and manufacturing technology

ActiveCN105128487AImprove performanceWaterproofSynthetic resin layered productsLaminationManufacturing technologyVacuum pressure

The invention relates to an integrally formed carriage plate for a van and a manufacturing technology. The outer layer of the carriage plate is made of glass steel, and a PVC foam plate is adopted as an interlayer. The technology comprises the following steps that 1, demoulding material processing and room-temperature curing are performed; 2, a surfacing mat, a composite mat, the PVC foam plate and a diversion composite mat are laid; 3, omega tubes and a winding pipe are fixed, sealing adhesive tapes are bonded, and a demoulding cloth and a vacuum bag are laid to form a vacuum system; 4, the vacuum system is connected with a resin collector in a sealed mode, and the leakproofness of the vacuum system is detected; 5, vacuum pressure maintaining is performed; 6, resin is prepared and poured in a vacuum mode; 7, solidifying, demoulding and postprocessing are performed. Compared with prior art, the PVC foam plate is used as the interlayer, and therefore the advantages of being capable of achieving water resistance, flame retardance, acid and alkali resistance, moth proofing, light mass, high hardness, heat preservation, sound insulation and shock absorption; vacuum infusion and integrally forming are achieved, and therefore the two surfaces of the carriage plate are smooth.

Owner:JIANGSU YUEKE NEW MATERIAL

Paper pulp moulded plastic products and manufacture thereof

InactiveCN101285283AGood fiber flexibilityHas acid and alkali resistancePulp beating methodsNon-woody plant/crop pulpFiberYellow green color

The invention relates to a paper pulp mould product which is antimicrobial and rotproof, protects the environment and can be used for a long time. The technical point is to prepare the paper pulp mould product by using the paper pulp made of Chinese stellera roots. The paper pulp mould product has the advantages that the fiber flexibility is good, the product is not crisp, the product is antimicrobial and rotproof as well as mothproof and acid and alkali resistant, etc., is suitable for a long-time storage, has the natural straw yellow green color and is particularly suitable for storing valuables and valuable medical materials for a long time.

Owner:张雪峰

Pulverized coal ash foamed sheet

The invention relates to a pulverized coal ash foamed sheet, which can be widely applied into indoor floors and outdoor wallboards. The pulverized coal ash foamed sheet is characterized by comprising the following raw materials in percentage by weight: 40-48% of polyvinylchloride resin, 30-40% of pulverized coal ash, 10-15% of aedelforsite, 1.5-2.5% of stabilizer, 2-3.5% of foaming modifier, 0.5-1.5% of foaming agent, 2-5% of calcium stearate, 0.5-1.5% of PE (polyethylene) wax, and 1-2% of sodium bicarbonate. The pulverized coal ash foamed sheet is formed by comprising the following steps: conducting high-temperature coupling cross-linking reaction to the raw materials, pelletizing into particles, extruding and forming by applying a special equipment die, and conducting three-dimensional surface patterns pressing. The pulverized coal ash foamed sheet has the advantages of being water-proof, flame-retardant, corrosion-resistant, moth-proof, acid-base-proof, cold-heat-resistant, impact-proof, and zero-formaldehyde, as well as the advantages of being light in weight, good in wood textures, excellent in machining performance, capable of recycling, and the like.

Owner:崔海明

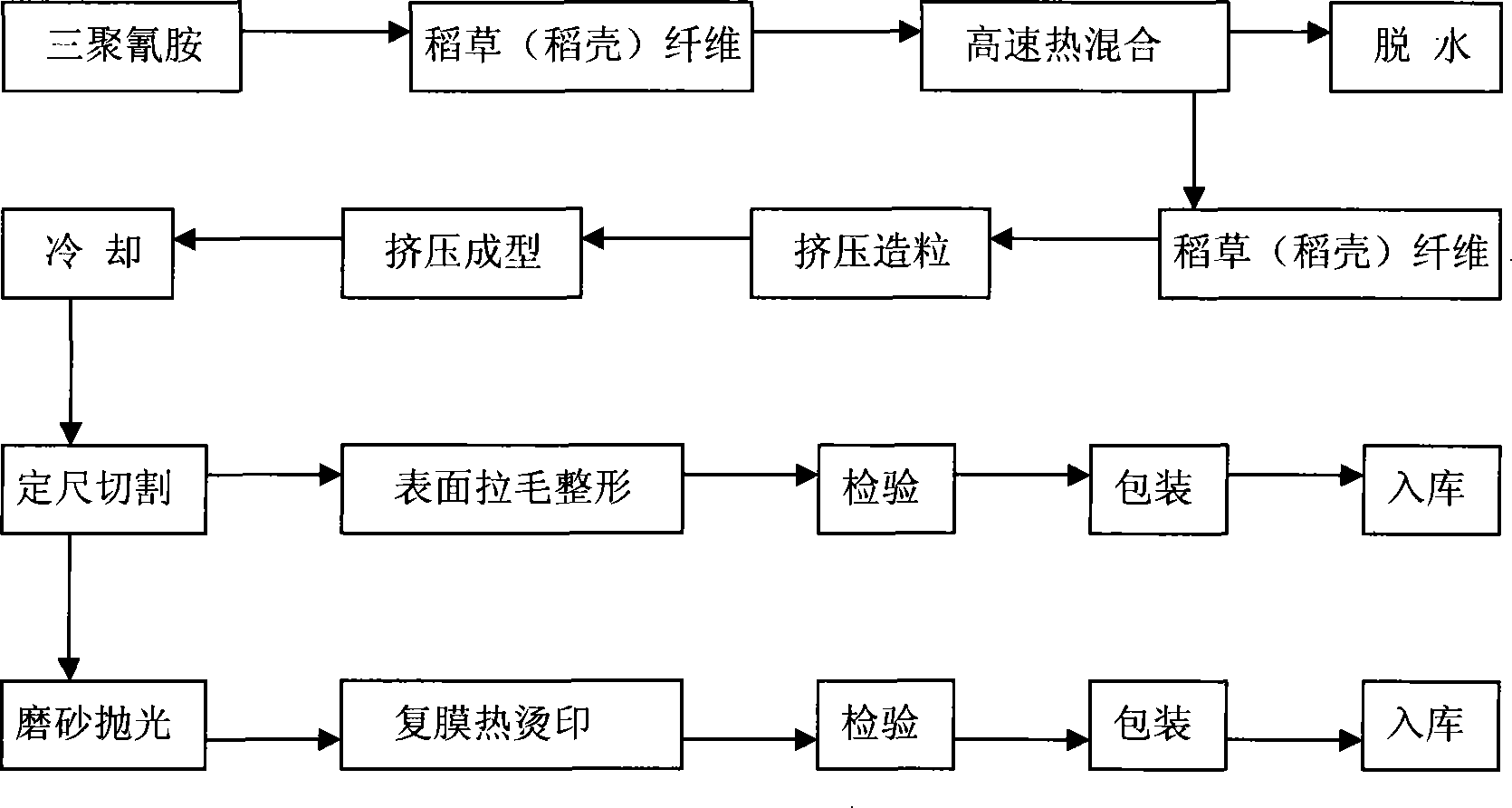

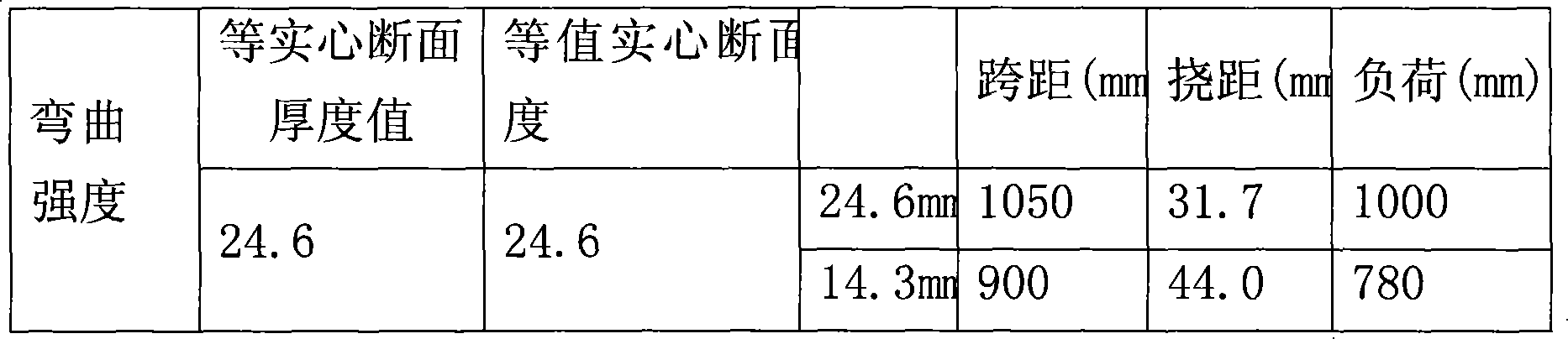

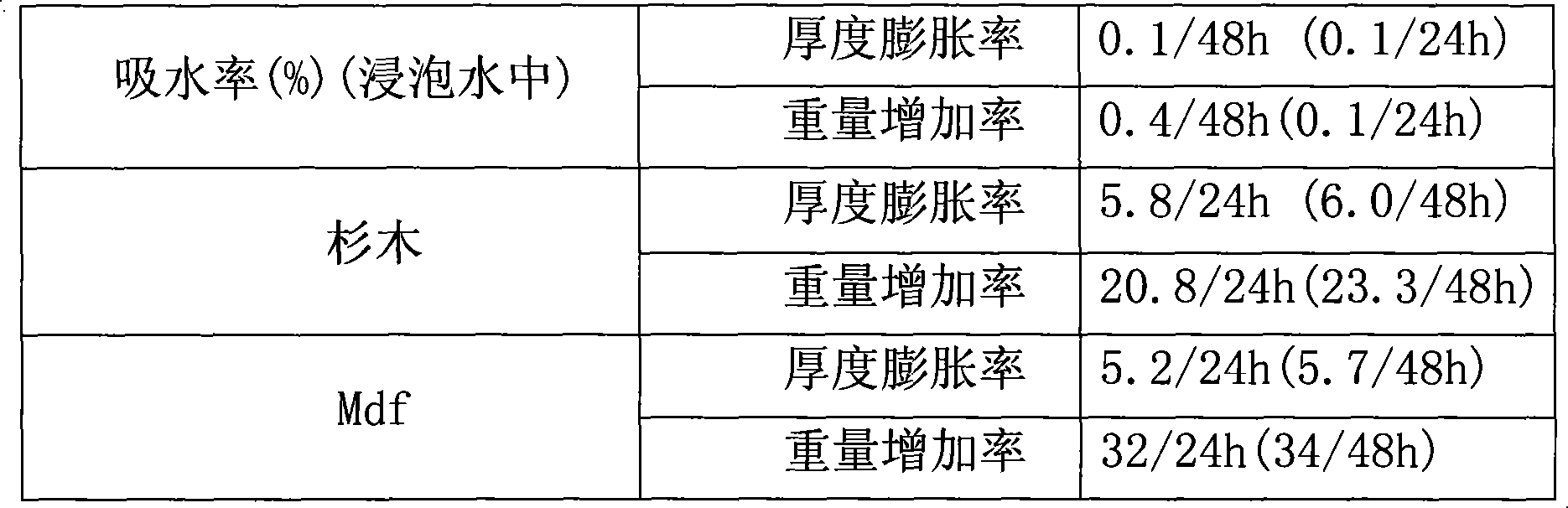

Straw, rice hull fibre base wood-plastic composite material and manufacture method thereof

InactiveCN101245189AAvoid rough surfacesImprove physical and mechanical propertiesRice strawMelamine resin

The invention relates to a wood plastic composite material and a preparation method thereof, in particular to a straw, a rice husk fiber base wood plastic composite material and a preparation thereof. The straw and the rice husk fiber base wood plastic composite material comprise the following components according to weight percentage: melamine resin: 3.5 percent; the straw and the rice husk fiber or the mixture of the straw and the rice husk: 60 percent; polyethylene with low density: 32 percent; solubilizer: 2 percent and lubricant: 2.5 percent. The wood plastic composite type building material of the invention adopts high technology, and utilizes waste plastics and a large amount of straw (rice straw, rice husk) powder to mix and extrude various formed hollow sectional materials of wood plastic at high temperature by fiber strengthening, and the wood plastic composite material is a typical environmental-friendly material. The wood plastic composite material is characterized by sun block, waterproof, anti-moth, anti-freezing and anticorrosion, and the wood plastic composite material without formaldehyde is strong in wood sense, high in surface hardness, strong in wear resistance, good in antiaging, long in service life, easy in processing, is suitable for the preferable material of decoration indoors and outdoors, and is similar to wood in shape but better than wood in property.

Owner:SHAOXING YINYING TEXTILE

Preparation method for decorative picture of thousand-layer carved ceramic plate

The present invention relates to a preparation method for a decorative picture of a thousand-layer carved ceramic plate. The method comprises: 1) covering a layer of protective film on a surface of a ceramic plate; 2) using a laser carving machine to carve edge lines of a predetermined pattern on the surface of the ceramic plate, wherein the pattern comprises a plurality of parts; 3) removing the protective film gradually from each part of the pattern, and carving with sandblast until a complete multi-layer carved pattern is formed, wherein a sandblasting pressure adopted in the sandblasting carving is 1-10 kg / m<3>, and a flow rate is 5-20 m<3> / min; 4) sandblasting the surface of the ceramic plate to remove a glazed layer on the surface of the ceramic plate and form a frosted surface, wherein the sandblasting pressure is 1-10 kg / m<3>, and the flow rate is 5-20 m<3> / min; 5) after the frosted surface of the ceramic plate prepared in the step 4) is cleaned and dried, jet printing and drawing the pattern, and then jet printing a protective glazed layer; and 6) sintering the ceramic plate prepared in the step 5) rapidly.

Owner:MONALISA GRP CO LTD

High-performance fireproof composite sheet material and preparation method thereof

PendingCN109609067AImprove fire resistanceHigh bonding strengthNon-macromolecular adhesive additivesLamination ancillary operationsSodium silicateAdhesive

The invention relates to a high-performance fireproof composite sheet material and a preparation method thereof. The high-performance fireproof composite sheet material comprises two upper and lower steel plates and a fireproof layer arranged between two steel plates, wherein the fireproof layer and two upper and lower steel plates are bonded by a high-viscosity adhesive which is composed of a component A and a component B; the component A is prepared from the following raw materials by weight: 80 to 100 parts of modified phenolic resin, 80 to 100 parts of modified epoxy resin, 40 to 60 partsof butyronitrile, 40 to 50 parts of polyvinyl butyral, 40 to 50 parts of a silane coupling agent, 5 to 10 parts of inorganic fireproof fiber, 2 to 5 parts of hollow microsphere and 2 to 5 parts of expanded vermiculite; and the component B is prepared from the following raw materials by weight: 30 to 50 parts of sodium silicate, 10 to 20 parts of hexamethylenetetramine, 10 to 20 parts of magnesiumoxide powder, 10 to 15 parts of high aluminum powder and 1 to 1.5 parts of sodium hexametaphosphate. Compared with the prior art, the sheet material provided by the invention has significant fire-retardant performance, can be rapidly expanded or carbonized once a fire disaster occurs, has long duration of fire resistance and high surface strength, and is insusceptible to cracking.

Owner:HEBEI JUNHUI SECURITY TECH CO LTD

Decorative wall board with air purification function

InactiveCN107327102AGood adsorption and ventilationImprove living environmentCovering/liningsSynthetic resin layered productsActivated carbonWoven fabric

A decorative wall board with an air purification function comprises an anti-bacterial non-woven fabric. An activated carbon fiber layer, an anion air purification layer, a waterproof breathable membrane and a bamboo charcoal wall board body are sequentially bonded on the anti-bacterial non-woven fabric in a hot-pressing mode, and according to the anion air purification layer, by weight, 4 parts of tourmaline powder, 2 parts of lanthanide series rare earth compound salt, 2 parts of nanometer titanium dioxide, 3 parts of activated carbon powder and 0.5 part of nano silver are loaded on polyester fiber. According to the decorative wall board with the air purification function, a traditional anion adding material is utilized, and the activated charcoal powder and the small amount of nanometer silver are added, so that release of anions is effectively promoted, and meanwhile the effects of sterilization and disinfection can further be achieved.

Owner:ANHUI SANPIN TECH SERVICE CO LTD

Plantation wood modification processing method

InactiveCN104858953AImprove permeabilityGood application effectRadiation/waves wood treatmentWood treatment detailsMicrowaveHardness

The invention discloses a plantation wood modification processing method including steps of preliminary selection, drying and microwave processing; preparation of a modification agent; preparation of a modification solution; vacuum impregnation and post drying. The beneficial effect is that through use of microwave treatment, the permeability of plantation wood is improved, the modification processing effect is improved, the processed wood has flame retardant, smoke suppression, anticorrosive, moth-proofing, color distortion preventing, good erosion resistance and other advantages, and the surface hardness, wear resistance, impact strength, waterproof property and the like are significantly improved, so that the application effect and fields of the plantation wood are well improved, and the plantation wood modification processing method has the very high practical value and promotion prospects.

Owner:王玉燕

Cotton wool and chitin blended yarn

The invention discloses a cotton wool and chitin blended yarn comprising a cotton fiber, a wool fiber and a chitin fiber which have a blending ratio of (55-60):(25-30):(10-15). Through blending the cotton fiber, the wool fiber and the chitin fiber, the defect that the common yarn is simplex in function is overcome, and the cotton wool and chitin blended yarn provided by the invention is good in elasticity and soft in handfeeling, and also has the effects of antibiosis, deodorization, itching relief, mothproofing and the like.

Owner:高健

Floor board with environment-friendly, waterproof and flame-retardant functions and preparation method thereof

ActiveCN105885302AImprove flame retardant performanceImprove waterproof performanceCovering/liningsFlooring insulationsAgricultural engineeringLubricant

The invention relates to a floor board with environment-friendly, waterproof and flame-retardant functions and a preparation method thereof, and the floor board solves the technical problems that the current floor board is poor in flame resistance, poor in water resistance, easy to deform and crack, and not environmentally-friendly. The floor board comprises the following components in parts by weight: 30-35 parts of CPE, 10-20 parts of EVA, 40-50 parts of PVC, 12-20 parts of activated calcium carbonate powder, 0-2 parts of a lubricant and 0-1 part of OA6. The floor board with environment-friendly, waterproof and flame-retardant functions and the preparation method thereof are widely used for floor boards and preparation methods thereof.

Owner:WEIHAI HEGUANG FLOOR CO LTD

Mouthwash

InactiveCN105919915ASignificant hemostasisSignificant anti-inflammatory effectCosmetic preparationsToilet preparationsPropolisAdditive ingredient

The invention discloses mouthwash, and belongs to the technical field of oral cleaning hygiene products. The mouthwash comprises the following components in percentage by mass: 95 to 96% of purified water, 2.5 to 4% of a humectant, 0.25 to 0.5% of a pH regulator, 0.2 to 0.3% of an oral care agent, 0.3 to 0.4% of a flavoring agent, 0.05 to 0.2% of a preservative, 0.08 to 0.2% of flavor component, and 0.05 to 0.1% of caramel color. According to the mouthwash, active components such as a propolis extract and a tea leaf extract are extracted from natural raw materials; the components in the formula play the intrinsic effects and are reasonably mixed to complement each other, so that the mouthwash is remarkable in bleeding stopping effect and anti-inflammatory effect, and has the functions of cleaning, preventing tooth decay, and whitening; the mouthwash tastes fresh and is easily accepted by people.

Owner:美伊琳水科技(北京)有限公司

A kind of environment-friendly and energy-saving paper-faced wall panel and its manufacturing method

InactiveCN102294858ASimple preparation processHigh speedSynthetic resin layered productsDomestic articlesEnvironmental resistanceEngineering

The invention relates to an environmentally-friendly and energy-saving paper wall board and a manufacturing method thereof. The environmentally-friendly and energy-saving paper wall board is characterized in that a board core is arranged between two composite surface layers composed of coveing papers and non-woven fabrics, the board core is prepared from the following raw materials in parts by weight: 20-50 parts of crop straw, 15-40 parts of light burned magnesium, 3-9 parts of white latex, 10-30 parts of expanded poly styrol powder and 11-33 parts of water, and the thickness of the board core is 60-300mm. Compared with the prior art, the invention has the beneficial effects that: 1) primary compression moulding is adopted, no heating or drying is required; 2) the product has the advantages of environmental friendliness, energy conservation, light weight, high compression strength, low cost and the like; 3) the crop straw and the expanded poly styrol powder are all abandoned resources, thus the effects of environmental protection and energy conservation are achieved; and 4) the environmentally-friendly and energy-saving paper wall board provided by the invention is applicable to multiple civil buildings and can be well matched and connected with various frame structures, steel structures and heterotype structures.

Owner:乔刚

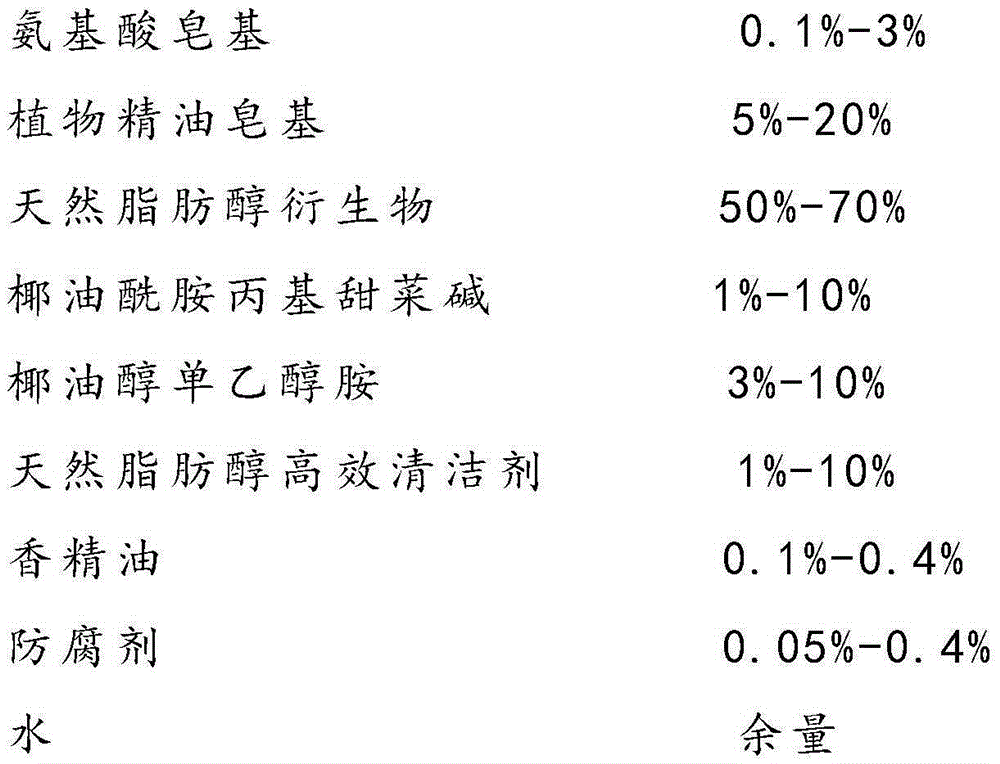

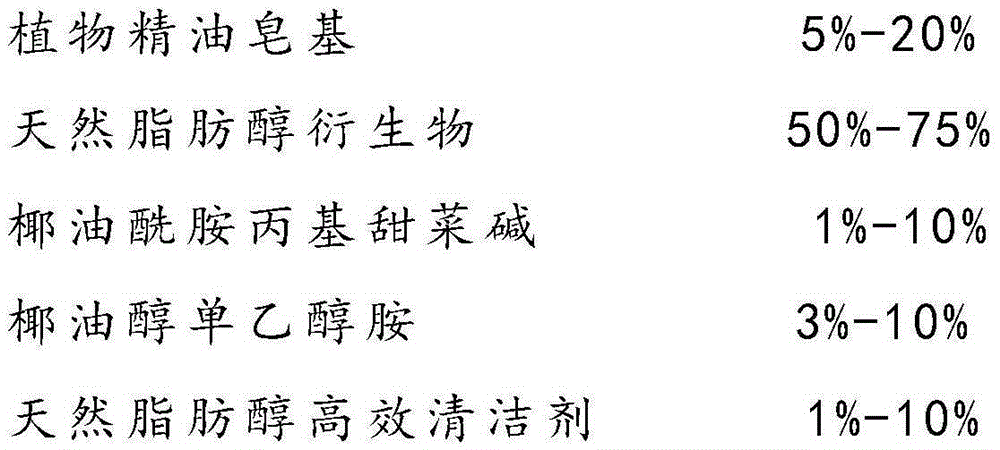

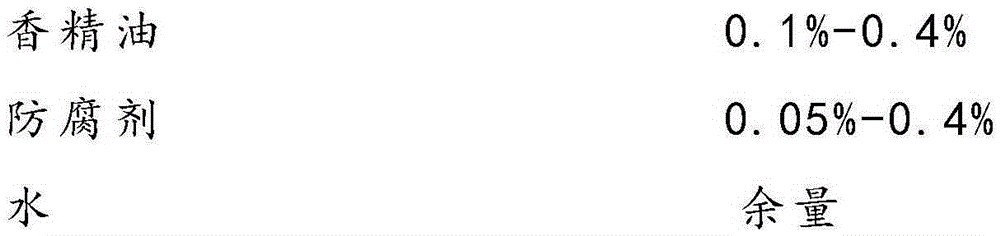

Laundry tablet

InactiveCN105296252AWon't spillEasy to useSurface-active non-soap compounds and soap mixture detergentsDetergent powders/flakes/sheetsPreservativeCocamidopropyl betaine

The invention discloses a laundry tablet. The laundry tablet comprises amino acid soap, vegetable essential oil soap, natural fatty alcohol derivative, cocamidopropyl betaine, dodecylalcohol monoethanolamine, natural fatty alcohol high-efficiency cleaning agent, essential oil, preservative and water. All raw materials are sequentially and uniformly mixed according to a weight ratio to obtain a mixture, and then the mixture is subjected to tabletting, sliced, coated and packed to form a finished product. By adopting a super-concentration nano technology, a washing product is made into a tablet shape, the size is small, no space is occupied, the laundry tablet can be carried along in business trip and touring; moreover, the cleaning capacity is higher compared with the equal amount of the washing product, the laundry tablet can be immediately dissolved in cold and hot water and also can be biologically degraded, the environment-friendly technical effect is guaranteed, more easiness in storage is realized, the situation such as leakage, caking and softening waste can be avoided, a nonwoven fabric after the laundry tablet is used can be used as a piece of cleaning cloth, and multiple functions can be realized.

Owner:张盛城

Plate and its production method

The invention discloses a sheet material and relative producing method. Said sheet material is formed by two enforcement layers and one intermediate structural layer. Wherein, the structural layer comprises mineral powder, light material powder, adhesive agent and plasticizer, while the plasticizer is formed by glass fiber mesh cloth and adhesive agent. And the inventive method comprises: preparing material, mixing material, laying, pressurizing, solidification, and demouding and incising, maintaining, drying, and detecting. The main raw material of sheet material is mineral powder which can be resistant to fire and water, without formaldehyde and radioactivity, which is environment-friendly. The basic material of said sheet material is light plant powder; therefore, the invention has better processing property and lower breakage rate, while it can be used in furniture, decoration and separation.

Owner:曾友余

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com