Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

A fully-drawn yarn and polyamide technology, which is applied in the field of chemical fibers, can solve the problems of inability to realize porous ultra-fine denier polyamide 6 fully-drawn yarn, inability to effectively adjust and control filaments, unstable melt-spinning forming, etc. , to achieve the effect of improving melt mixing uniformity and pressure stability, low cost and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

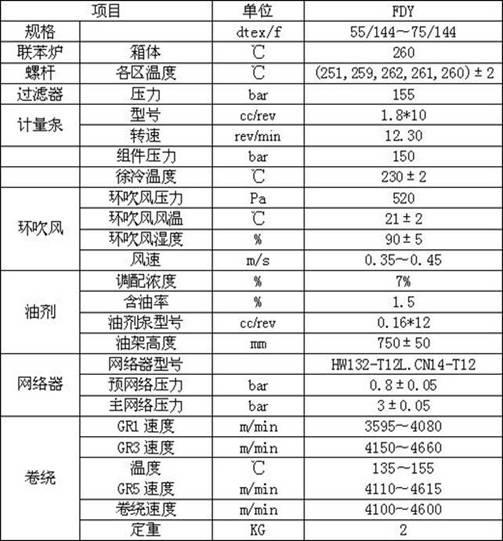

[0020] This embodiment provides a new 55dtex / 144f porous ultrafine polyamide 6 fully drawn yarn with excellent production performance. It is based on the production of conventional types of FDY equipment, including pre-crystallization, drying, screw melt extrusion device, install the additive injector on the feed port of the screw melt extrusion device, spinning box, metering pump, spinning assembly, spinneret In the plate spinning device, the Xu Leng heater is installed under the spinneret, and the heating area is 100-120mm in height; the ring blowing cooling device is installed under the Xu Leng heater; the oiling and bundling oil rack is installed under the ring blowing cooling device , The distance from the spinneret is 750±50 mm; the winding forming device includes the first, second and third drafting rolls, pre-network device, network device and winder.

[0021] The production process is as follows:

[0022] The relative viscosity of polyamide 6 chips is 2.70~3.10, the relat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com