Real-time control-based natural gas liquefied raw gas filtering device

A technology of real-time control and filtering device, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of natural gas raw gas cannot be fully filtered and the filter medium is saturated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

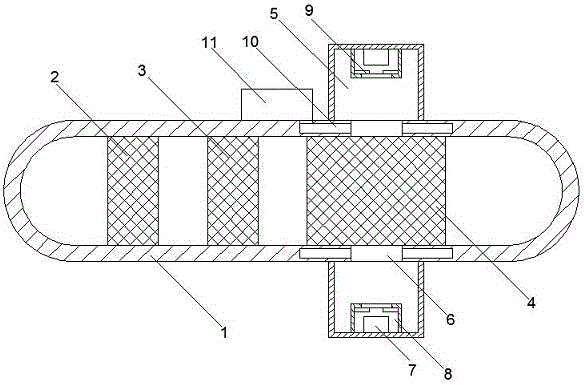

[0014] Such as figure 1 A natural gas liquefaction raw gas filter device based on real-time control is shown, which includes a filter kettle body 1, and a solid particle filter layer 2, a dehydration layer 3 and an acid gas filter layer 4 are sequentially arranged inside the filter kettle body 1, and the solid particle Activated carbon is arranged inside the filter layer 2, and molecular sieves are respectively arranged in the dehydration layer 3 and the pickling gas filter layer 4; The chamber 5 extends along the side wall of the filter kettle body 1 , the pickling gas collection chamber 5 is connected to the inside of the filter kettle body 1 through a collection pipe 6 , and a plurality of air pumps 7 are connected to the pickling gas collection chamber 5 .

[0015] As an improvement of the present invention, in the pickling gas collection chamber 5, a plurality of collection pipes 6 correspond to a plurality of air pumps 7, and each air pump 7 is arranged above the axial e...

Embodiment 2

[0018] As an improvement of the present invention, in the pickling gas collection chamber 5, each air pump 7 is connected to a heating chamber 8, and an electric heat source 9 is arranged inside the heating chamber 8. By adopting the above technical scheme, it can heat the air pump through the heating chamber, so that while the air flow generated by the air pump controls the pressure in the pickling gas filter layer, the temperature can also be effectively controlled, so that the acid The discharge and collection efficiency of scrubbing gas under high temperature is significantly improved.

[0019] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0021] As an improvement of the present invention, in the filter kettle body 1, the corresponding position of the pickling gas filter layer 5 is provided with a condensation jacket 10, which extends between the outer wall and the inner wall of the filter kettle body 1, and the condensation jacket The sleeve 10 communicates with a condensing agent tank 11 arranged outside the filter kettle body 1 . By adopting the above technical solution, the cooling jacket can be used to cool the acid-washed gas filter layer, so that the adsorption effect of the acid-washed gas filter layer can be improved under low temperature.

[0022] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com