Anti-pollution degerming nanofiber filter membrane and preparation method thereof

A technology of nanofiber and filter membrane, which is applied in the field of anti-fouling and degerming nanofiber filter membrane and its preparation, which can solve the problems of large molecular chain spacing, reduced flux and anti-pollution performance, and failure to meet the sterilization requirements of high-end fields. , to achieve the effects of improving mechanical strength, green environmental protection, realizing large-scale production, and easy realization of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

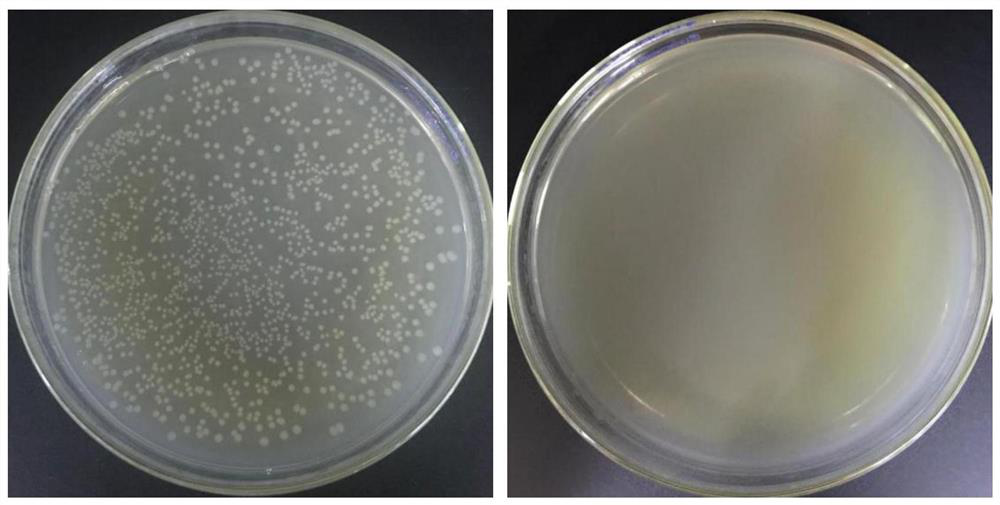

Examples

preparation example Construction

[0045] A preparation method of the above-mentioned antifouling and degerming nanofiber filter membrane, comprising the following steps:

[0046] S1. Prepare polyvinyl alcohol-ethylene copolymer nanofibers by melt blending phase separation method;

[0047] S2. Disperse the nanofibers obtained in step S1 in a mixed solution of isopropanol and deionized water with a mass ratio of 1:1, and stir evenly to obtain a polyvinyl alcohol-ethylene copolymer with a mass concentration of 5% to 20%. Suspension of nanofibers;

[0048] S3. Coating the polyvinyl alcohol-ethylene copolymer nanofiber suspension obtained in step S2 on a nonwoven fabric substrate, and drying at room temperature to obtain a nanofiber-coated filter membrane;

[0049] S4. The solution of the above-mentioned first grafting compound and / or the second grafting compound is soaked and adsorbed or coated on the surface of the nanofiber coating filter membrane obtained in step S3, and dried at room temperature;

[0050] S5...

Embodiment 1

[0056] An antifouling and degerming nanofiber filter membrane is prepared through the following steps:

[0057] S1. Prepare PVA-co-PE nanofibers by melt blending phase separation method, that is, blend and melt spin PVA-co-PE and cellulose acetate butyrate (CAB) to obtain composite fibers, and then use acetone to dissolve and extract the composite fibers. CAB in the fiber to obtain PVA-co-PE nanofibers with a diameter of 150nm;

[0058] S2. Disperse the PVA-co-PE nanofibers obtained in step S1 in a mixed solution of isopropanol and deionized water with a mass ratio of 1:1, and stir evenly to obtain PVA-co-PE with a mass concentration of 10%. PE nanofiber suspension;

[0059] S3. Coating the PVA-co-PE nanofiber suspension obtained in step S2 on a polypropylene nonwoven fabric substrate with an average pore size of 10 μm, and drying at room temperature to obtain a nanofiber-coated filter membrane; wherein , the thickness of the PVA-co-PE nanofiber coating is 6μm, and the avera...

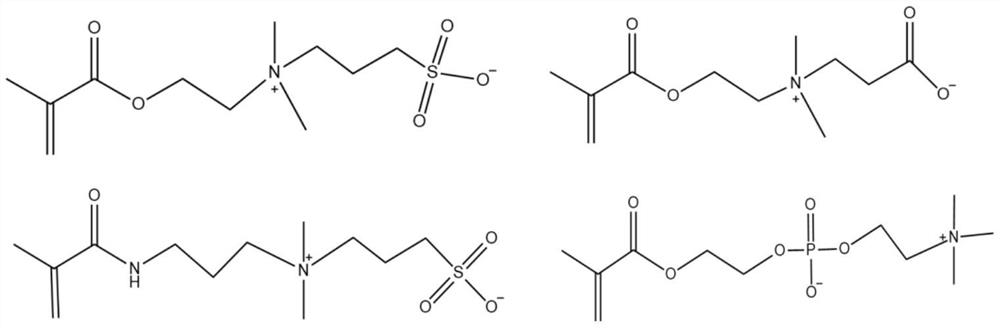

Embodiment 2

[0064] An antifouling and degerming nanofiber filter membrane, compared with Example 1, the difference is that step S4 is: the first graft compound with the following structural formula is prepared into a solution with a mass concentration of 10%, and then The nanofiber coating filter membrane obtained in step S3 is soaked in the solution for 30 minutes, and dried at room temperature;

[0065]

[0066] Others are substantially the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com