Production of nano-SiO2 for coating carbonyl iron powder

A technology for coating carbonyl iron and carbonyl iron powder, which is applied in the production field of nano-SiO2 coating carbonyl iron powder, can solve the problems such as the inability to meet the specified indicators, and achieve the effect of good matching and improving the quality of the magnetic core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

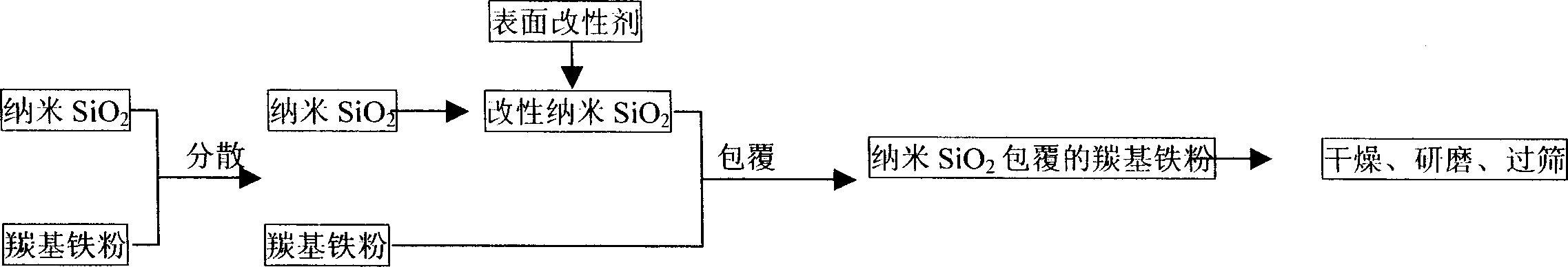

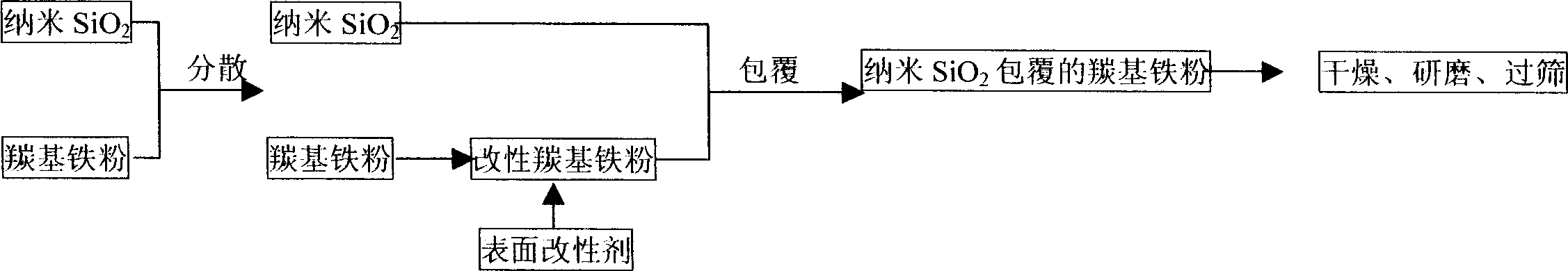

Method used

Image

Examples

example 1

[0016] Example 1: ① Take 70g nano-SiO 2 , 35g alkaline silane coupling agent, 5000g ethylene glycol, 10kg carbonyl iron powder for standby;

[0017] ② SiO2 2 For dispersion pretreatment; pour 35g of alkaline silane coupling agent into ball mill for 0.5h; add 5000g of ethylene glycol, and ball mill for 0.5h;

[0018] ③Put in 10kg of carbonyl iron powder, and mill in a ball mill for 1 hour, that is, the coating is completed;

[0019] ④Take out the coated product and dry it at 150°C for 1 hour under vacuum or protective atmosphere, grind, sieve, and pack.

[0020] Coated SiO produced by the production method of the present invention 2 Powder carbonyl iron powder has the following effects:

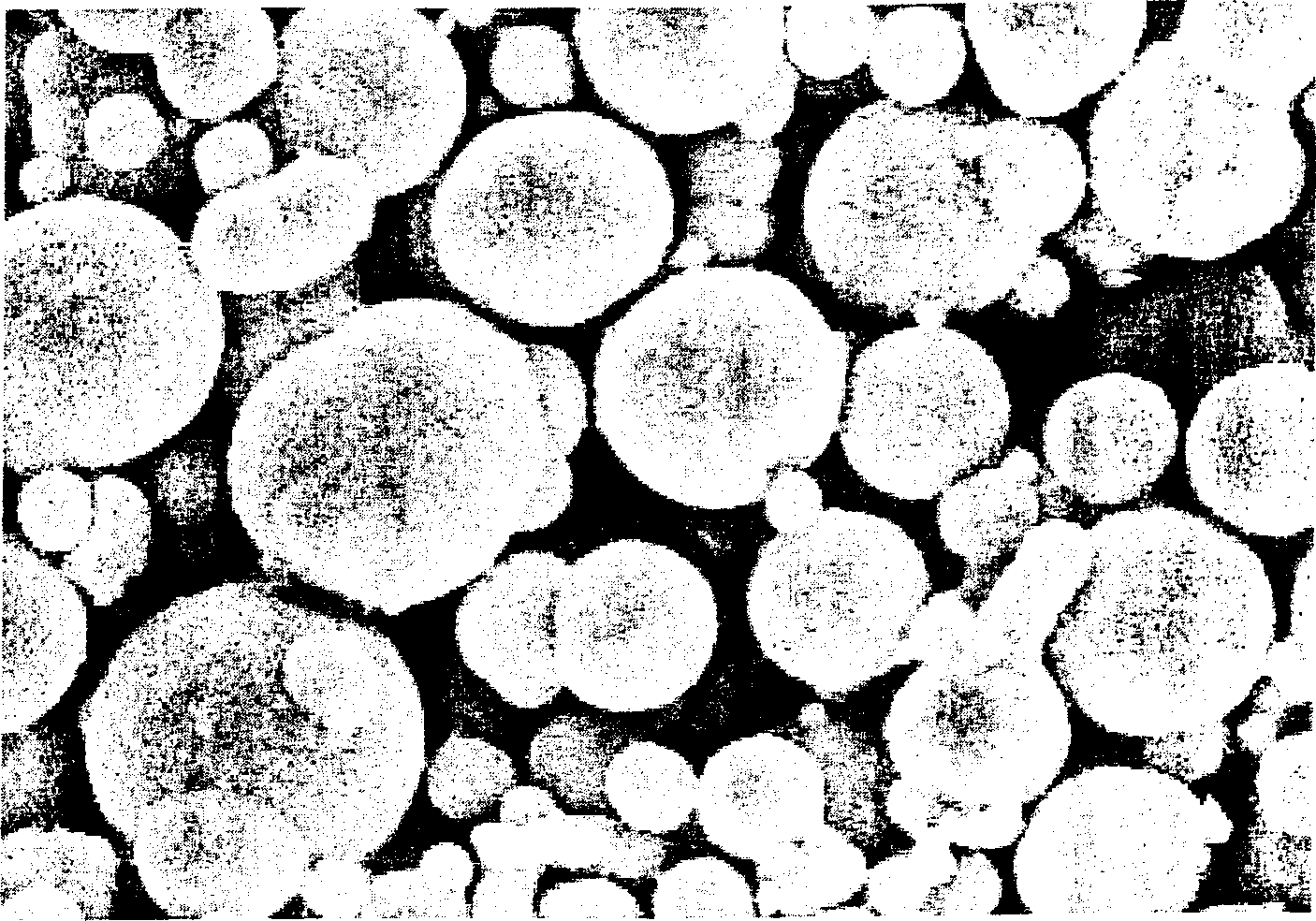

[0021] 1. Scanning and observing the surface, the surface is obviously covered with a layer of white SiO 2 powder; observed through cross-sectional scanning, the thickness of the coating is about 40nm, which is basically consistent with the particle size characterized by the coating, see ...

example 2

[0025] Example 2: ① Take 70g nano-SiO 2 , 160g alkaline silane coupling agent, 5000g ethylene glycol, 10kg carbonyl iron powder for standby;

[0026] ② Dispersion treatment of SiO 2 ;Pour in 160g of alkaline silane coupling agent and ball mill for 4.2h; add 5000g of ethylene glycol, and ball mill for 4.2h;

[0027] ③Put in 10kg of carbonyl iron powder after dispersion treatment, and ball mill in the ball mill for 4.5h, that is, the coating is completed;

[0028] ④ Take out the coated product and dry it at 100°C for 5.5 hours under vacuum or protective atmosphere, grind, sieve, and pack.

example 3

[0029] Example 3: ① Take 70g nano-SiO 2 , 280g alkaline silane coupling agent, 5000g ethylene glycol, 10kg carbonyl iron powder for use;

[0030] ② SiO2 2 Dispersion treatment; pour 280g of alkaline silane coupling agent into ball mill for 8h; add 5000g of ethylene glycol, and ball mill for 8h;

[0031] ③Put in 10kg of carbonyl iron powder after dispersion treatment, and ball mill in the ball mill for 8 hours, that is, the coating is completed;

[0032] ④Take out the coated product and dry it at 100°C for 10 hours under vacuum or protective atmosphere, grind, sieve, and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com