Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75 results about "4-aminodiphenylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing 4-nitrodiphenylamine and 4-nitrosodiphenylamine from carbanilide

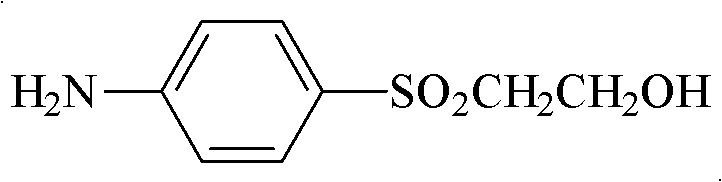

InactiveUS6137010AHigh yieldImprove responseOrganic compound preparationAmino preparation by hydrogen substitutionAniline4-aminodiphenylamine

This invention relates to a process for preparing 4-nitrodiphenylamine and 4-nitrosodiphenylamine to be used for 4-aminodiphenylamine as an intermediate of antiozonant, wherein carbanilide is reacted with nitrobenzene in the presence of an appropriate base, while simultaneously adding aniline to the mixture so as to regenerate some amounts of carbanilide as a starting material. According to this invention, 4-nitrodiphenylamine and 4-nitrosodiphenylamine can be prepared in a higher selectivity and conversion rate via a continuous reaction by recycling carbanilide, a starting material, while adding a certain amount of aniline during the process. Further, the amount of waste water can be significantly reduced compared to the conventional method without any corrosive materials harmful to the environment.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

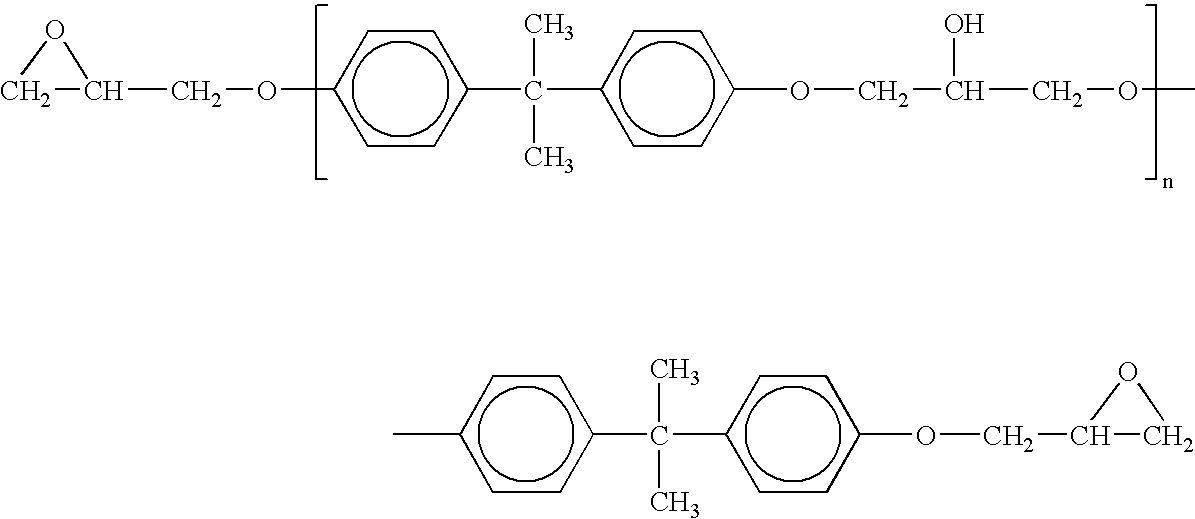

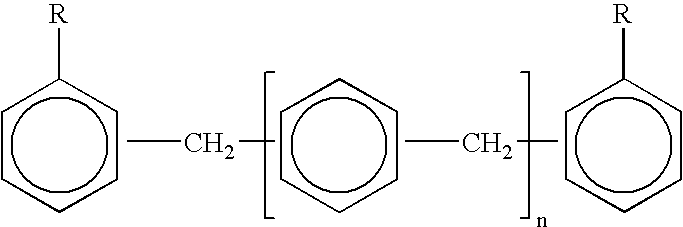

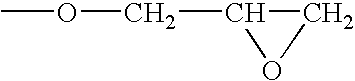

Epoxy resin curing agents and epoxy resin compositions

InactiveUS7008555B2Low viscosityImprove mechanical propertiesOrganic chemistryOther chemical processesEpoxyN-phenyl-p-phenylenediamine

Owner:APPLIED POLERAMIC

Method of preparation of 4-aminodiphenylamine

InactiveUS6388136B1Easy accessHigh yieldAmino preparation from aminesOrganic compound preparationLiquid mediumOxygen

A method of preparing 4-aminodiphylamine through an intermediate preparation of 4-nitrodiphenylamine and / or 4-nitrosodiphenylamine and / or their salts by reaction of aniline with nitobenzene in a liquid medium at a temperature of 50 to 130° C., under normal or reduced pressure, in an inert atmosphere or in the presence of air oxygen, with subsequent hydrogenation of an intermediate of 4-nitrodiphenylamine and / or nitrosodiphenylamine and side products, and by isolation of 4-aminodiphenylamine and the side products of unconverted raw materials.

Owner:DUSLO A S

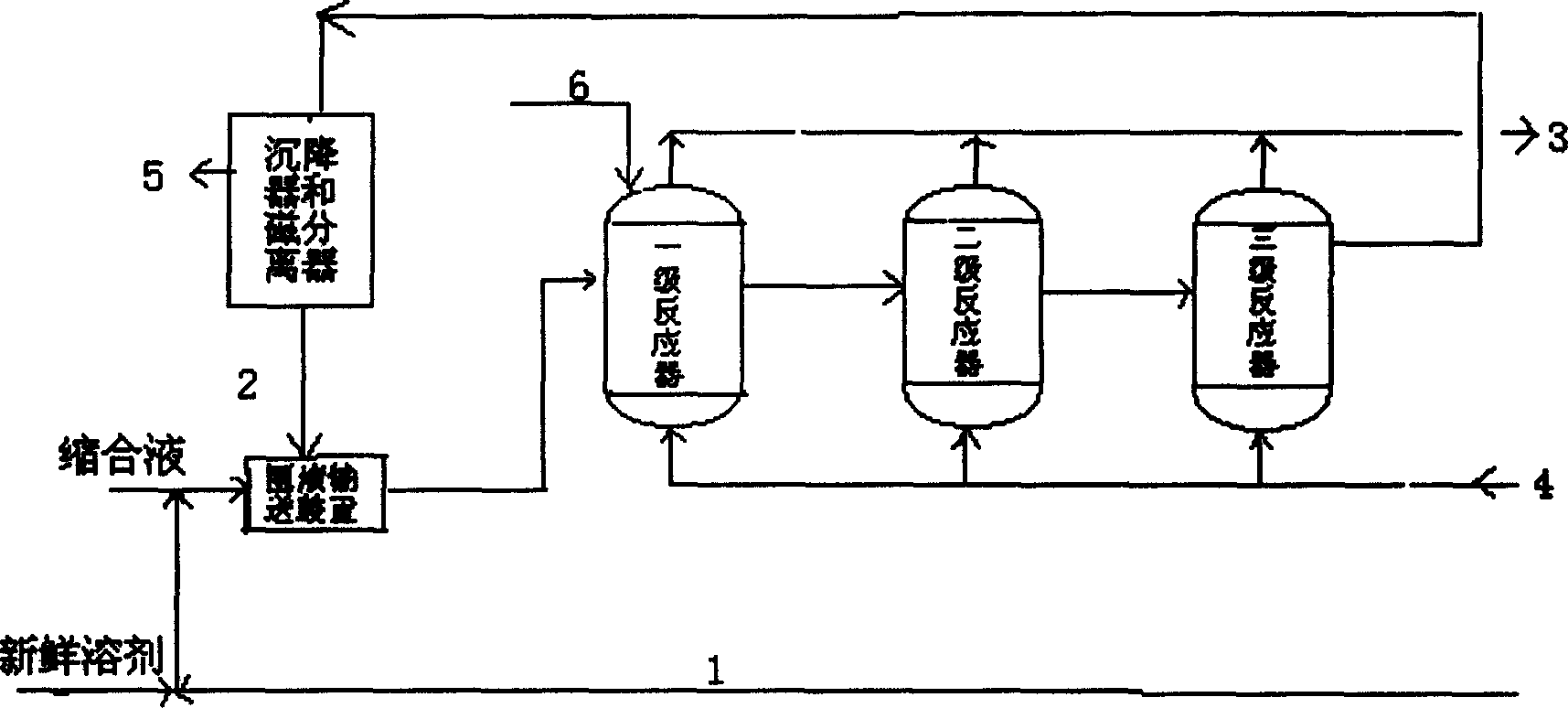

Method for continuous hydrogenation preparation of 4-amino diphenylamine

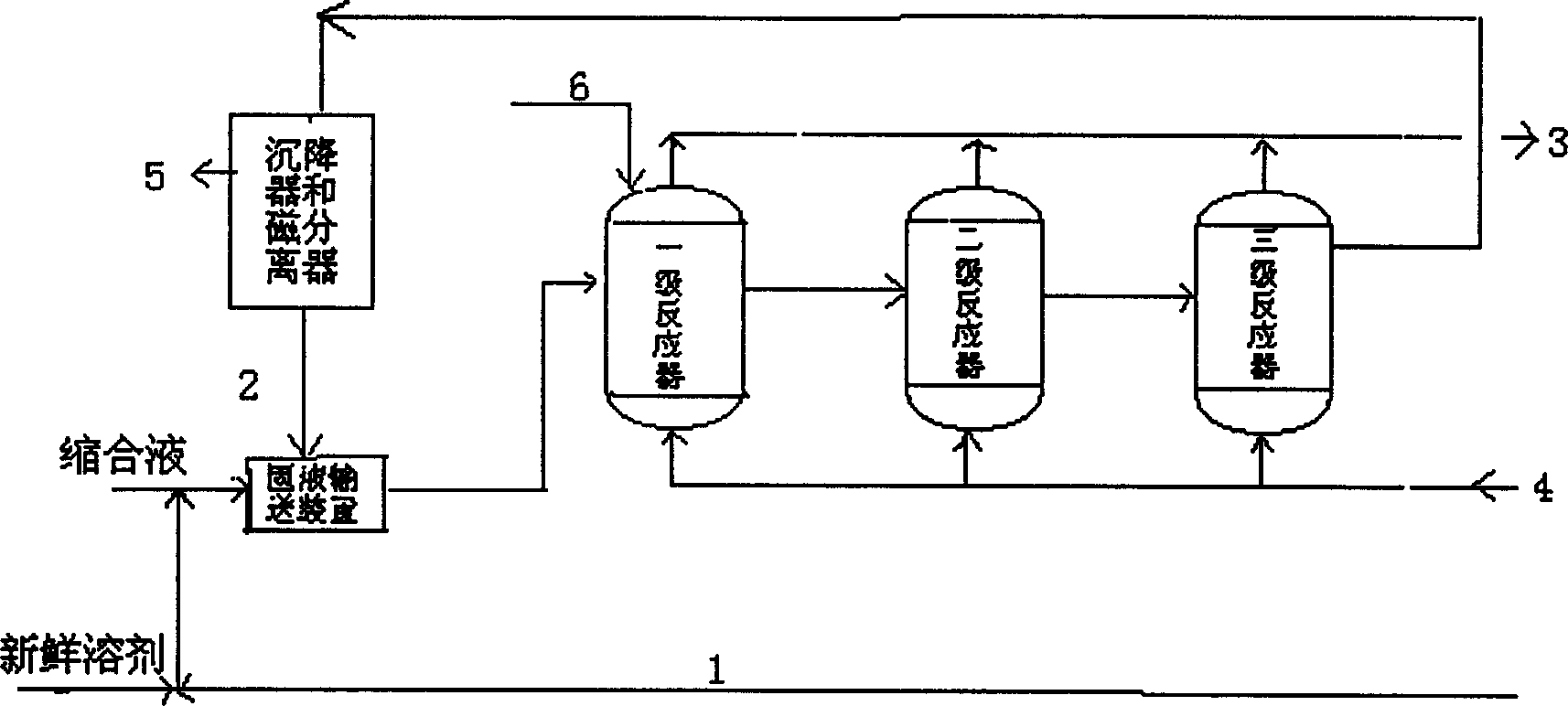

ActiveCN1470498ASolve the problem of single consumptionOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationHydrogenation reaction

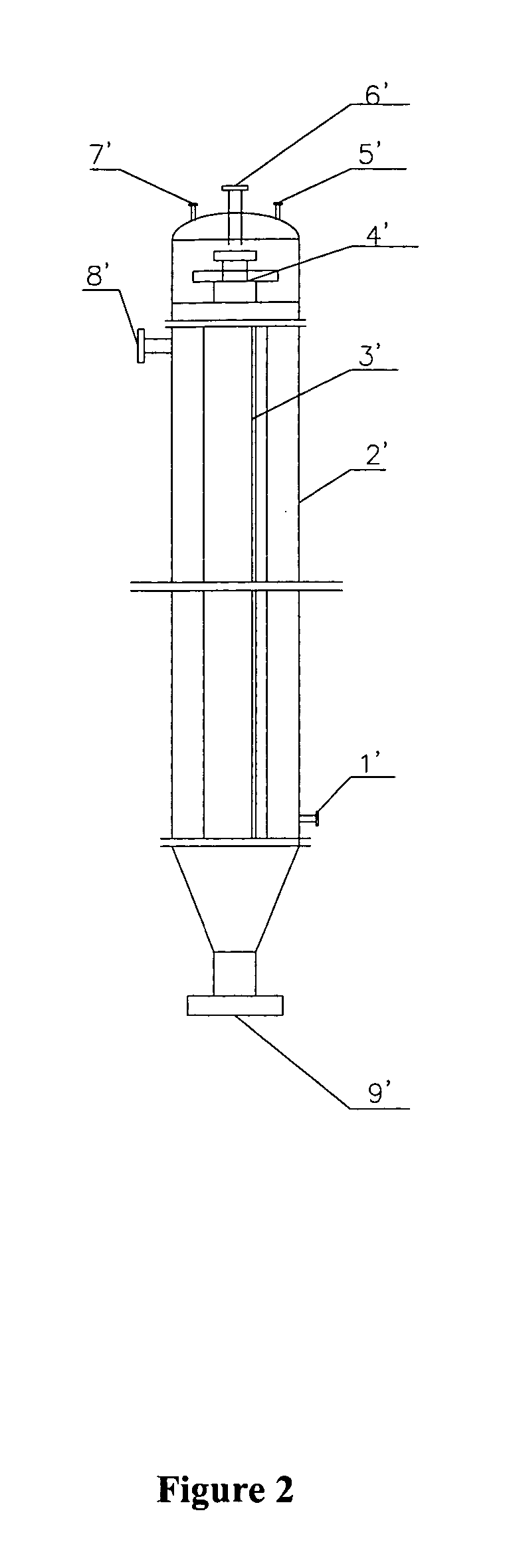

The present invention discloses a method for preparing 4-aminodiphenylamine by continuously hydronating condensate obtained from the reaction by using nitrobenzol and phenylamine as raw material and adopting compound powdered catalyst. i,e, adopts a catalyst and hydrogen gas circulation and solvent circulation combined new process to make the hydrogenation reaction be implemented under the condition of high-concentration, low-temp. and low pressure. The invented catalytic hydrogenation conversion rate can be up to 100%, and its selectivity is greater than 99%, and it is suitable for industrial production of 4-aminophenylamine.

Owner:JIANGSU SINORGCHEM TECH CO LTD

Process for preparing 4-aminodiphenylamine

ActiveUS20050240058A1Increase rangeHigh yieldAmino compound purification/separationOrganic compound preparationAniline4-aminodiphenylamine

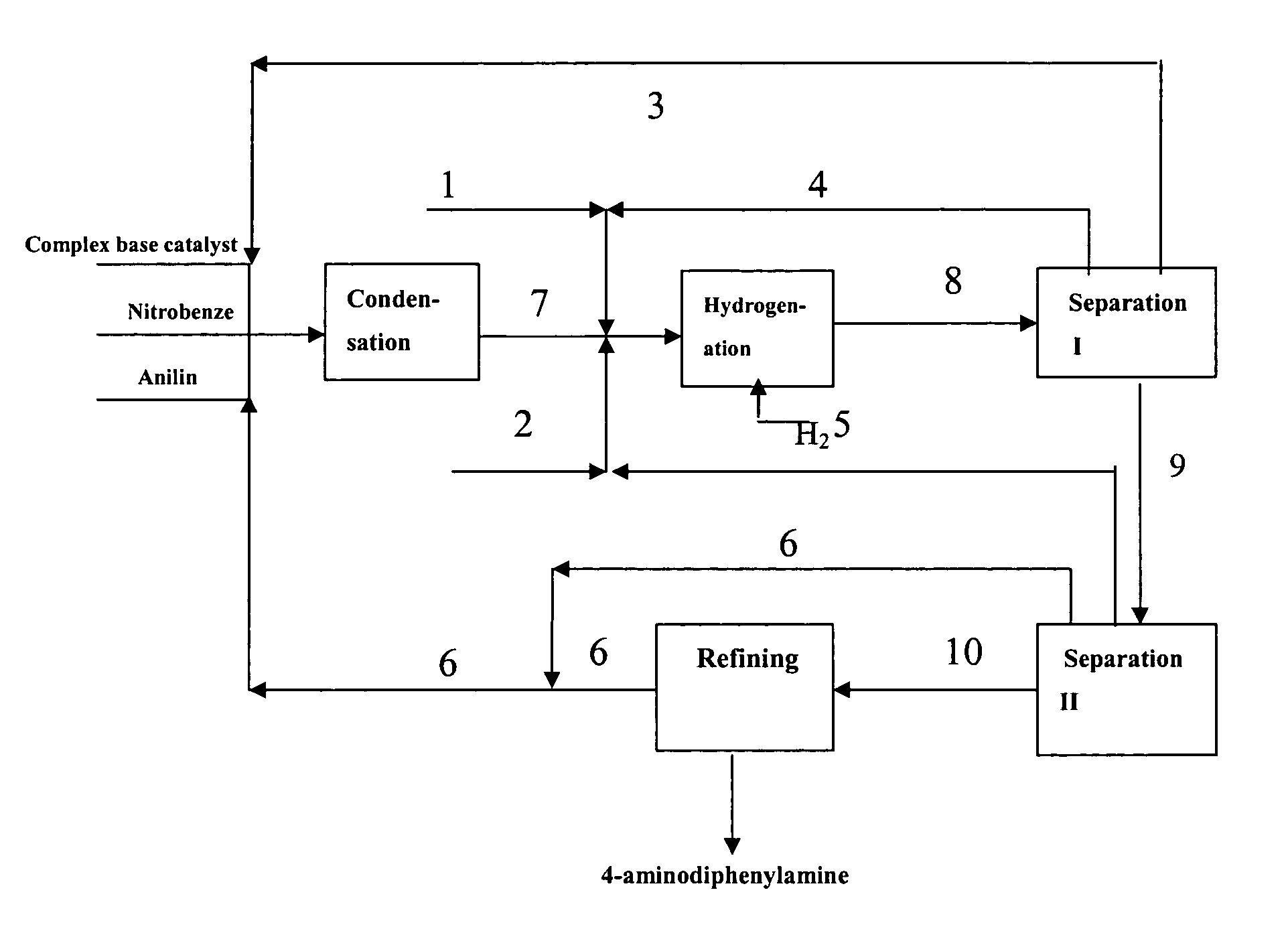

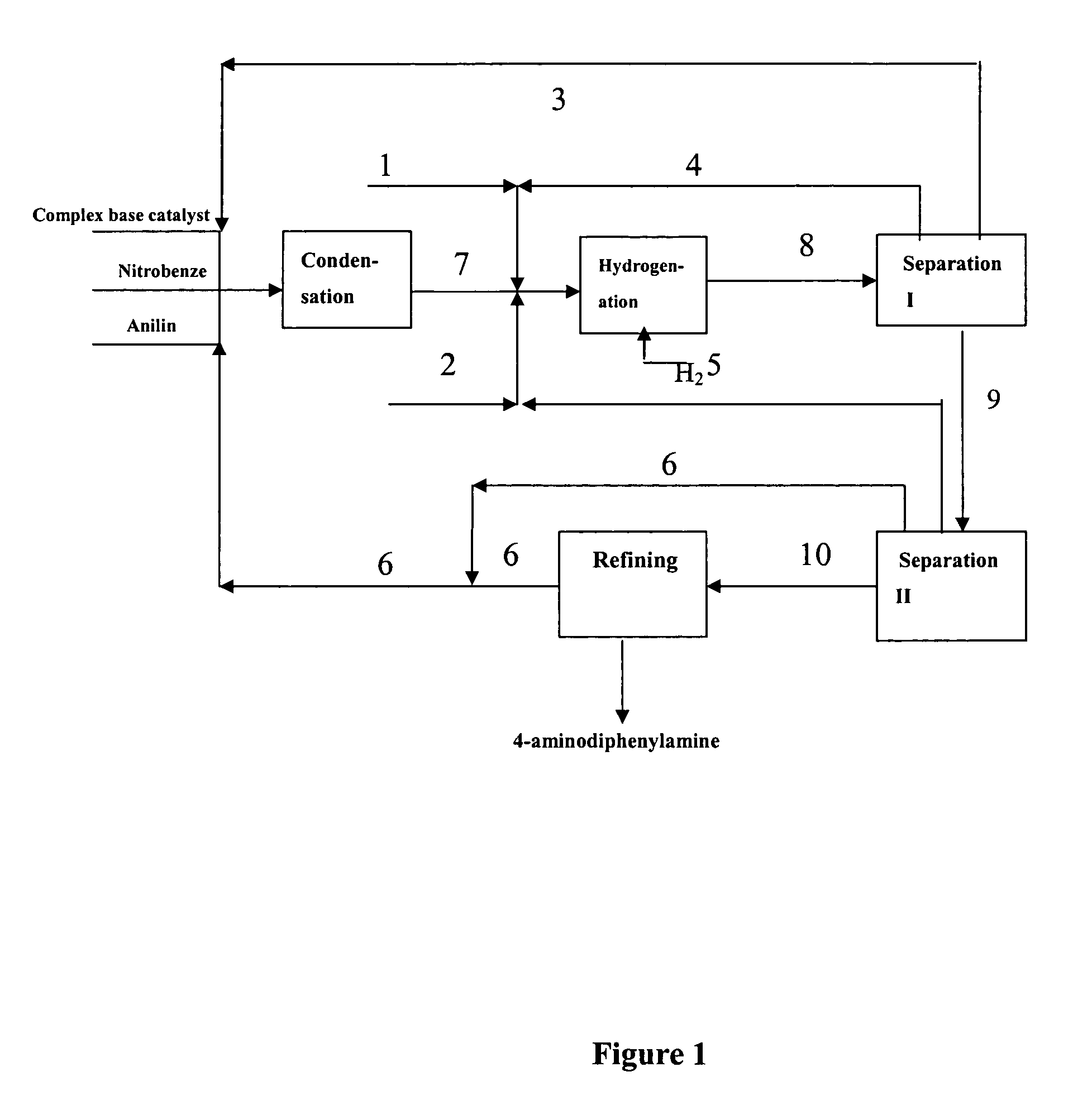

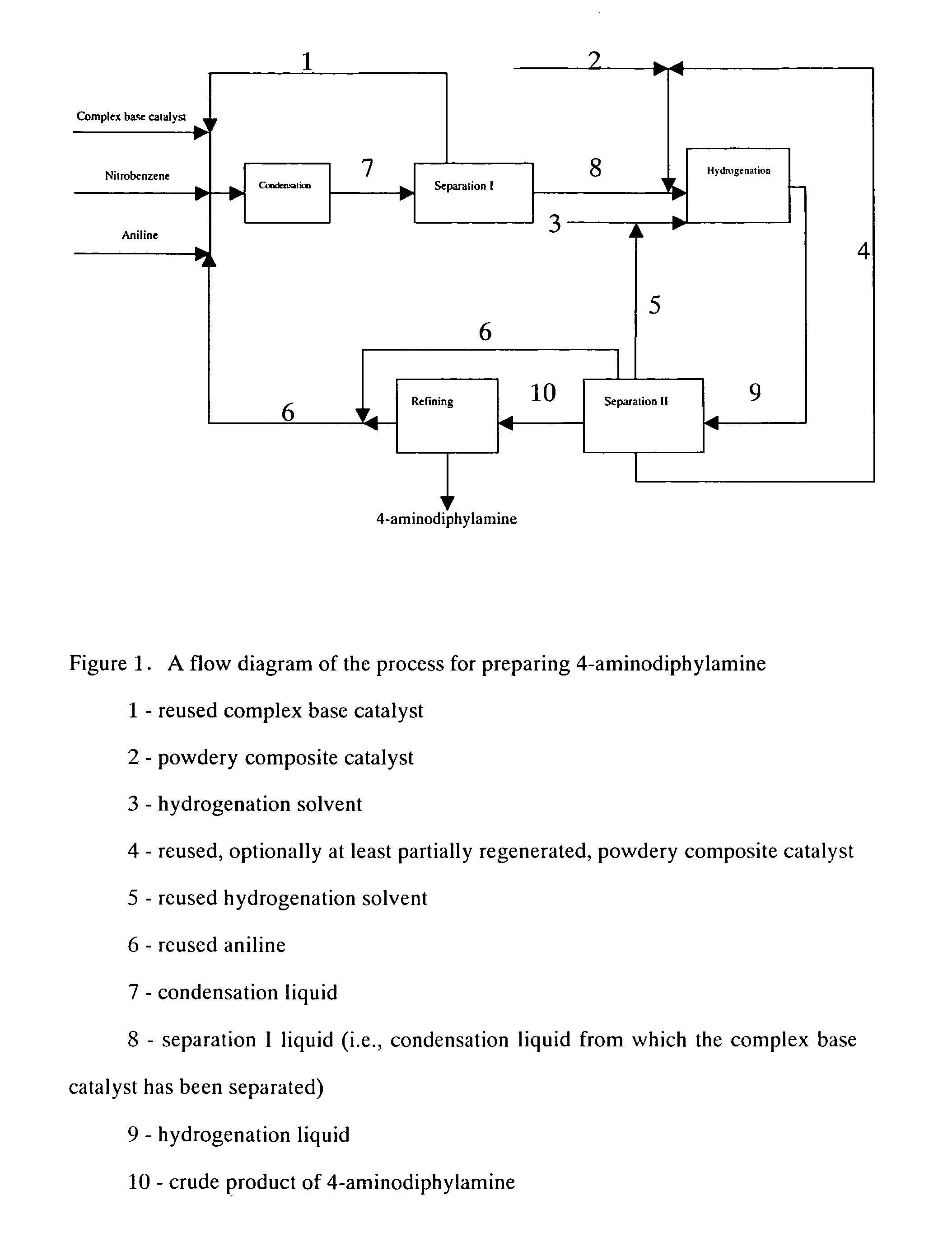

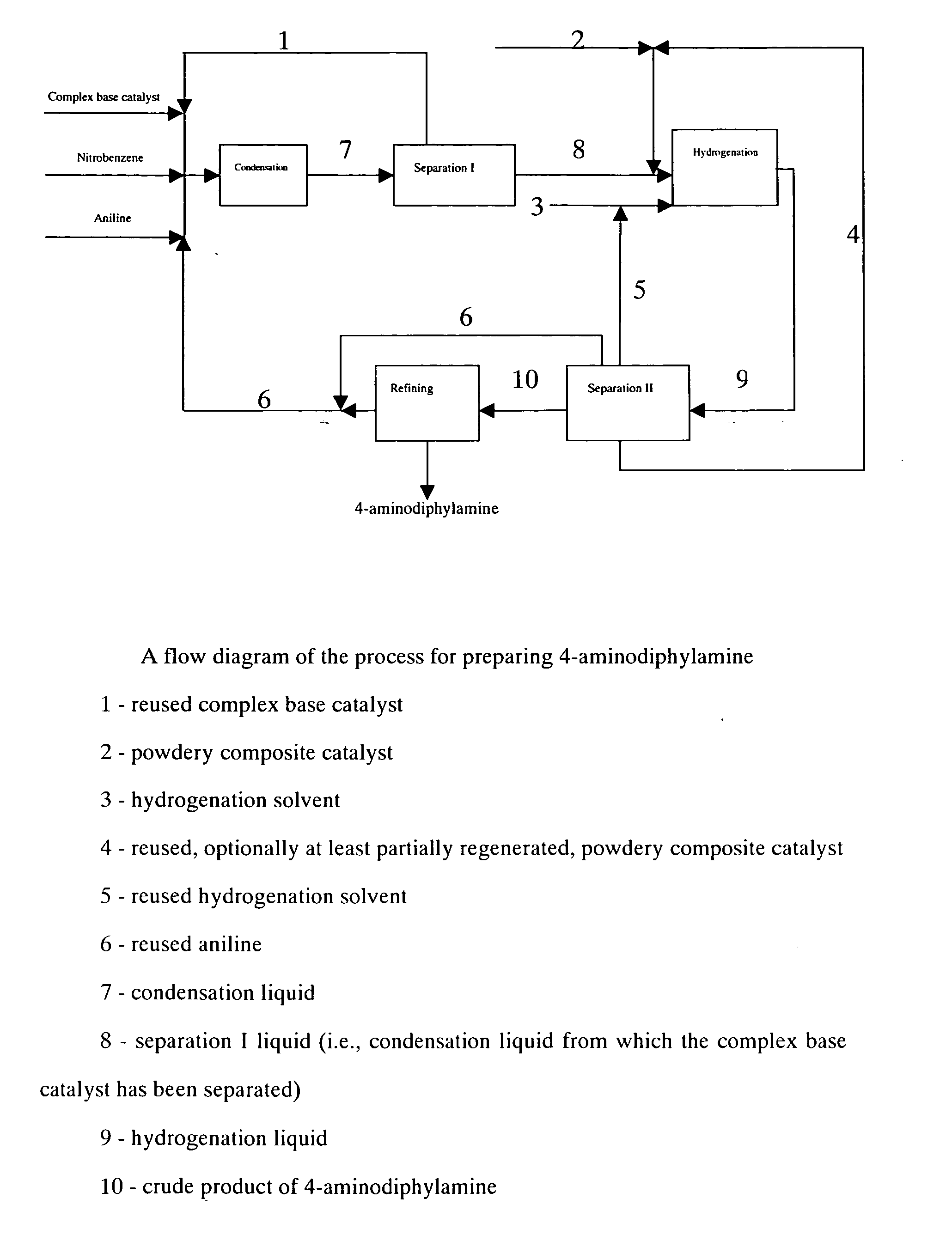

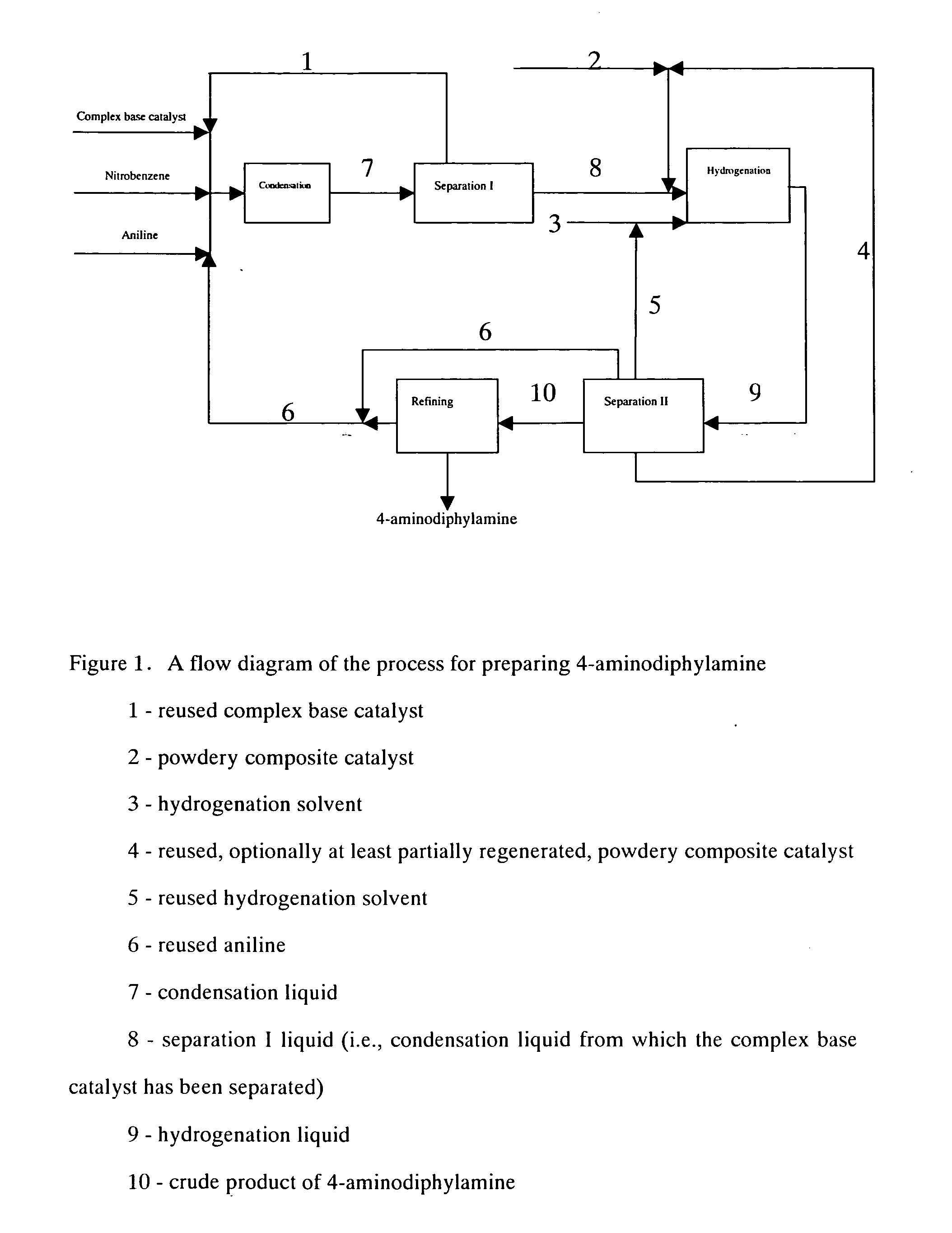

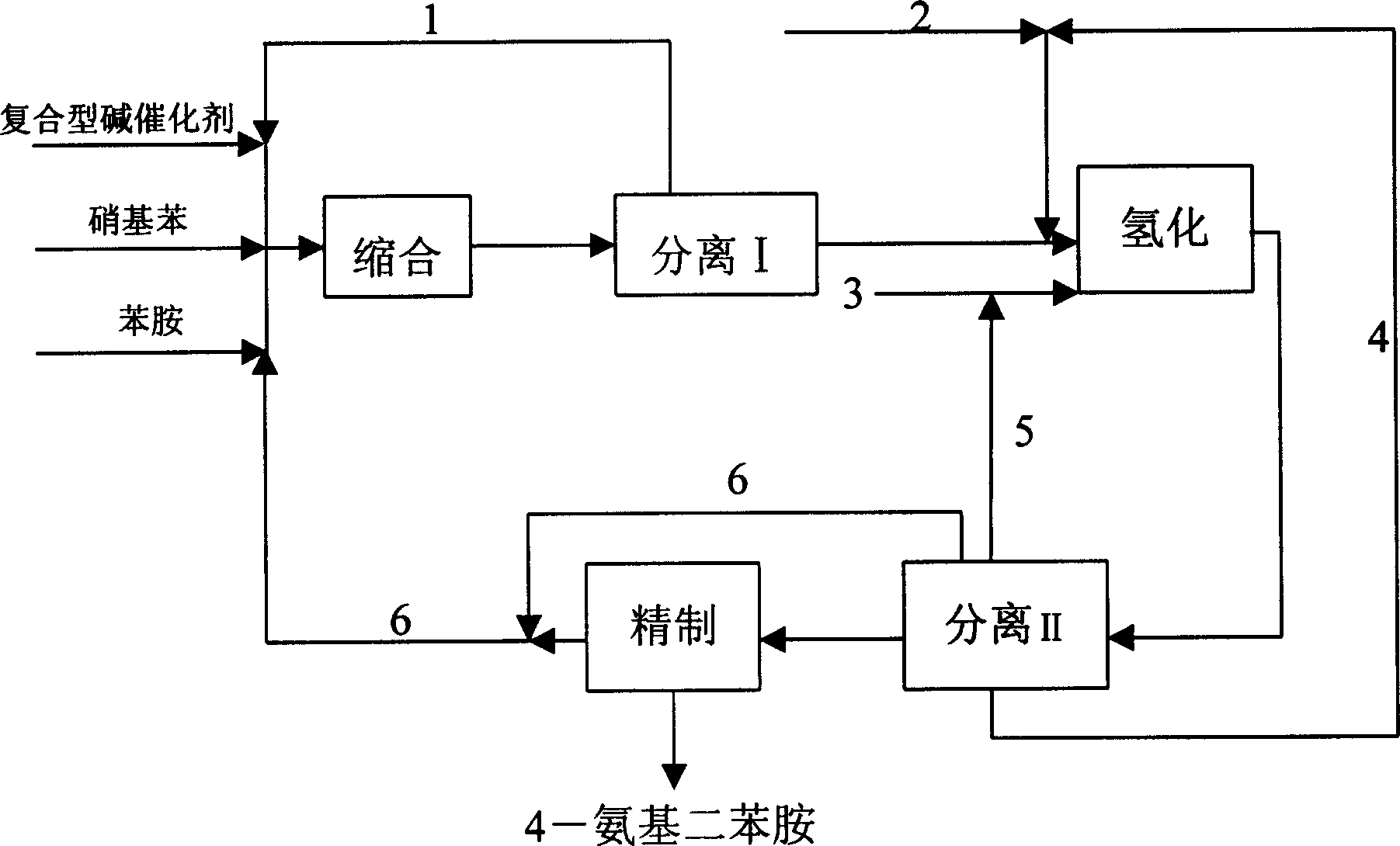

A process for preparing 4-aminodiphenylamine using nitrobenzene and aniline as raw materials, a complex base catalyst as the condensation catalyst, and a powdery composite catalyst as the hydrogenation catalyst. The process has 5 process stages including condensation, hydrogenation, separation I, separation II, and refining.

Owner:SENNICS CO LTD

Method for preparing 4-aminodiphenylamine

InactiveCN102060714AHigh purityReduce pollutionOrganic compound preparationAmino compound preparationActivated carbonHydrogen

The invention discloses a method for preparing 4-aminodiphenylamine, which comprises the following steps: (1) mixing aniline and an alkali water solution, and distilling out aniline-water azeotrope; (2) adding nitrobenzene to react; (3) adding water and a hydrogenation catalyst, and introducing hydrogen gas; (4) carrying out solid-liquid separation to separate the hydrogenation catalyst and a liquid phase, returning the hydrogenation catalyst to the step (3) or returning the hydrogenation catalyst to the step (3) after regeneration, separating the liquid phase to obtain an organic phase and an alkali water solution, rectifying the organic phase to obtain 4-aminodiphenylamine and aniline, and returning the aniline to the step (1); and (5) returning the alkali water solution to the step (1) or returning the alkali water solution to the step (1) after the alkali water solution is treated by activated carbon. In the method disclosed by the invention, the activated carbon is used for treating the circulating alkali water solution so as to remove impurities, thereby improving the purity of the circulating alkali water solution and avoiding the use of an expensive electrolytic process. Thus, the invention has the advantages of short process route and low equipment investment, is simple to operate, lowers the operating cost and reduces the environmental pollution.

Owner:天津市有机化工一厂 +1

Process for preparing 4-aminodiphenylamine

ActiveUS7176333B2Amino compound purification/separationOrganic compound preparationHydrogenation reactionAniline

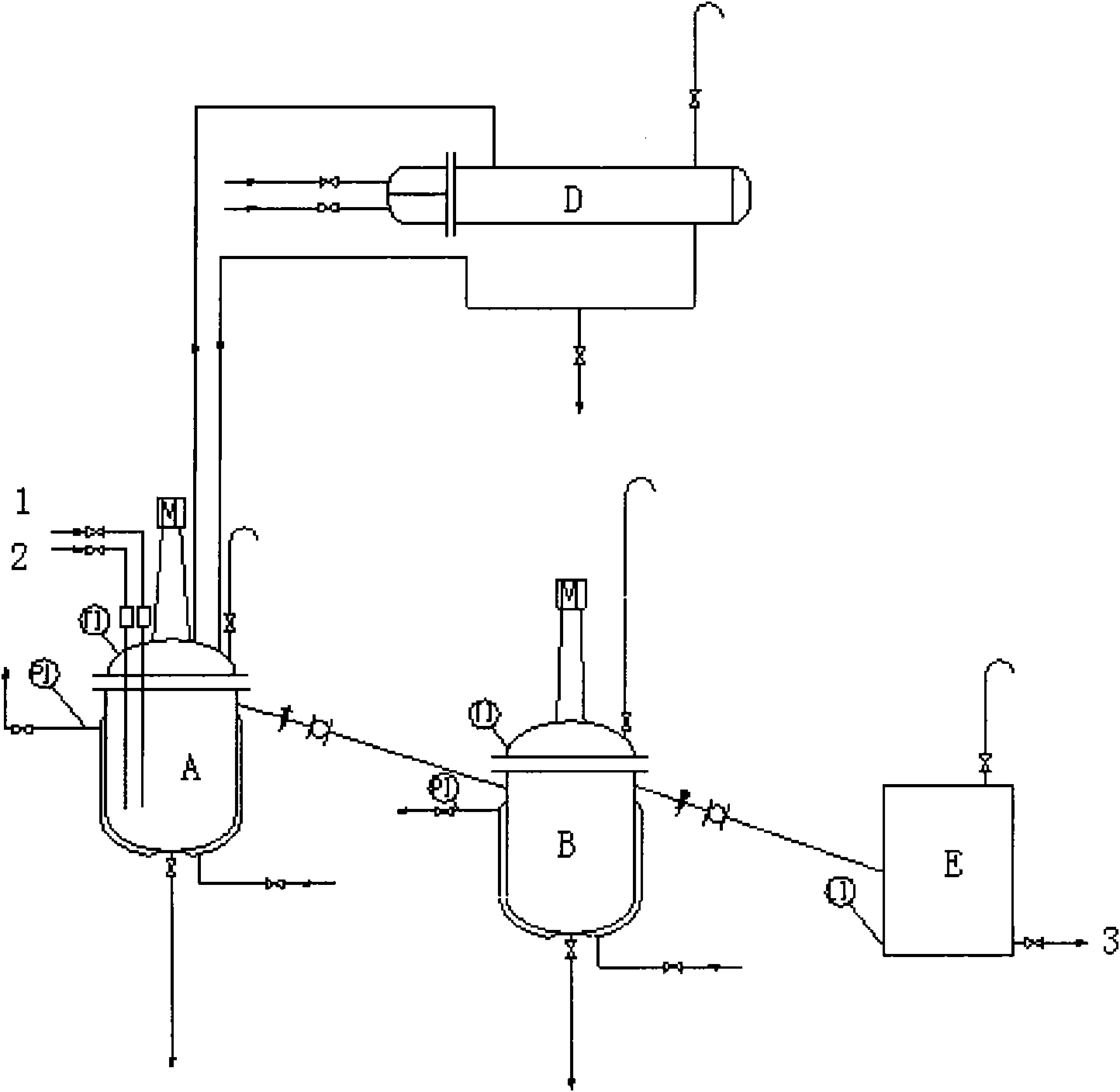

The present invention discloses a process for preparing 4-aminodiphenylamine, which process uses nitrobenzene and aniline as raw materials, a complex base catalyst as condensation catalyst and a powdery composite catalyst as hydrogenation catalyst, and comprises five process stages: condensation; separation I; hydrogenation; separation II; and refining. The process can be continuously carried out. By selecting a complex base catalyst to catalyze the condensation reaction and separating it prior to the hydrogenation, the problem that the complex base catalysts thermally decompose in the hydrogenation reaction is avoided, the selectable range of hydrogenation catalysts is largely enlarged so that it is possible to select cheaper hydrogenation catalyst, and the selection of production process and equipment is easier and further industrialization is easier. The complex base catalysts used in the present invention are inexpensive and have higher catalytic activity. The process can be carried out at mild conditions and can adapt to broad range of water content, by-product is less and conversion and selectivity are higher. The operational strength is low, no corrosive liquid is produced, and environment pollution is reduced. The purity of 4-aminodiphenylamine prepared can exceed 99 wt.-%, and the yield in the industrial production process can be over 95%.

Owner:NONGYUE WANG & GUANGQIANG SHI +1

Preparation method of 4-aminodiphenylamine

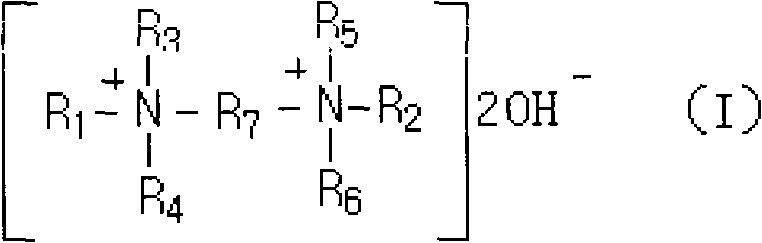

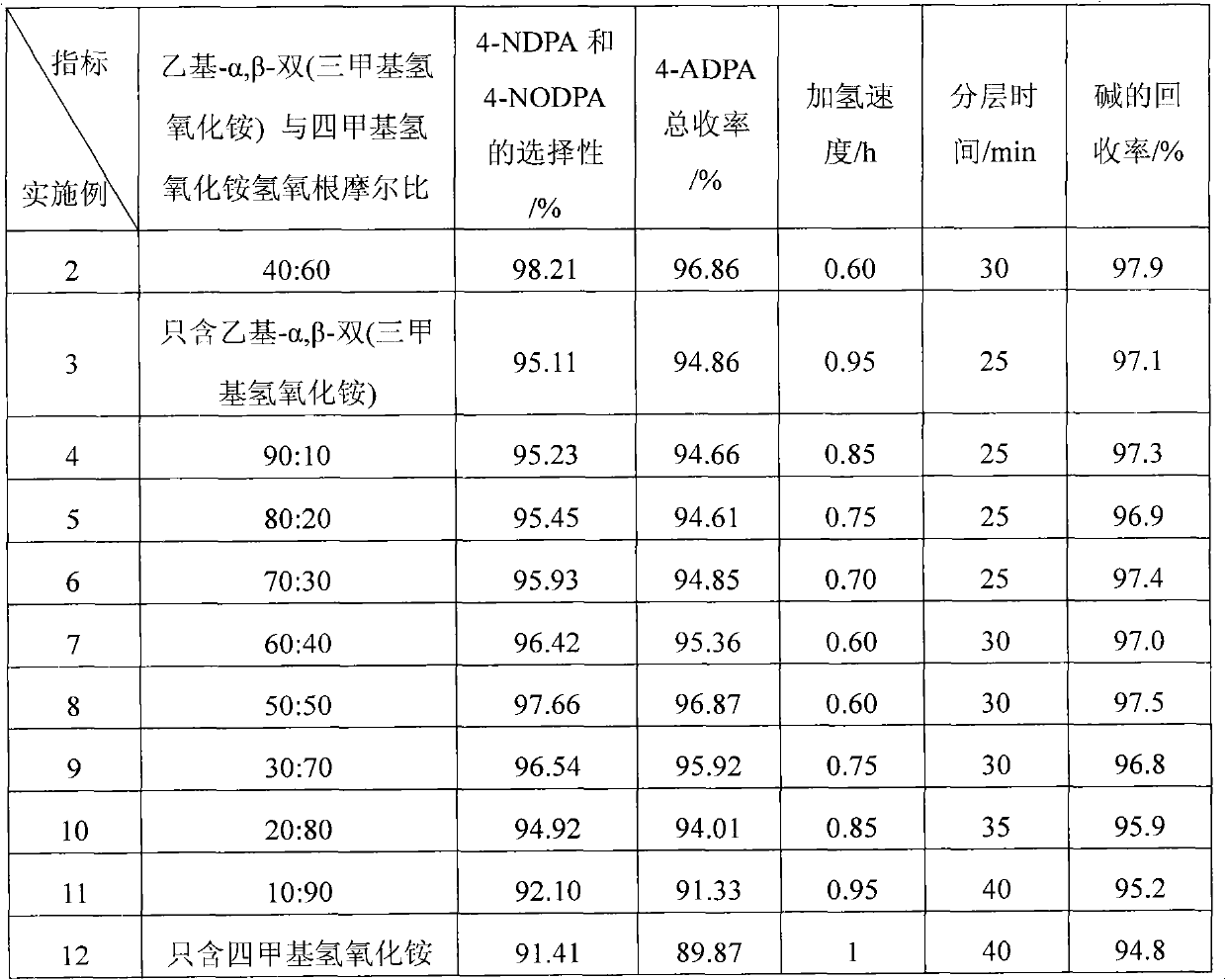

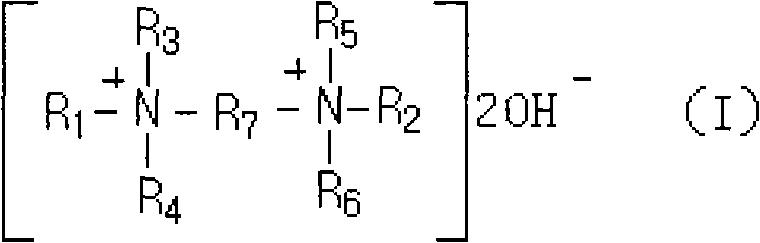

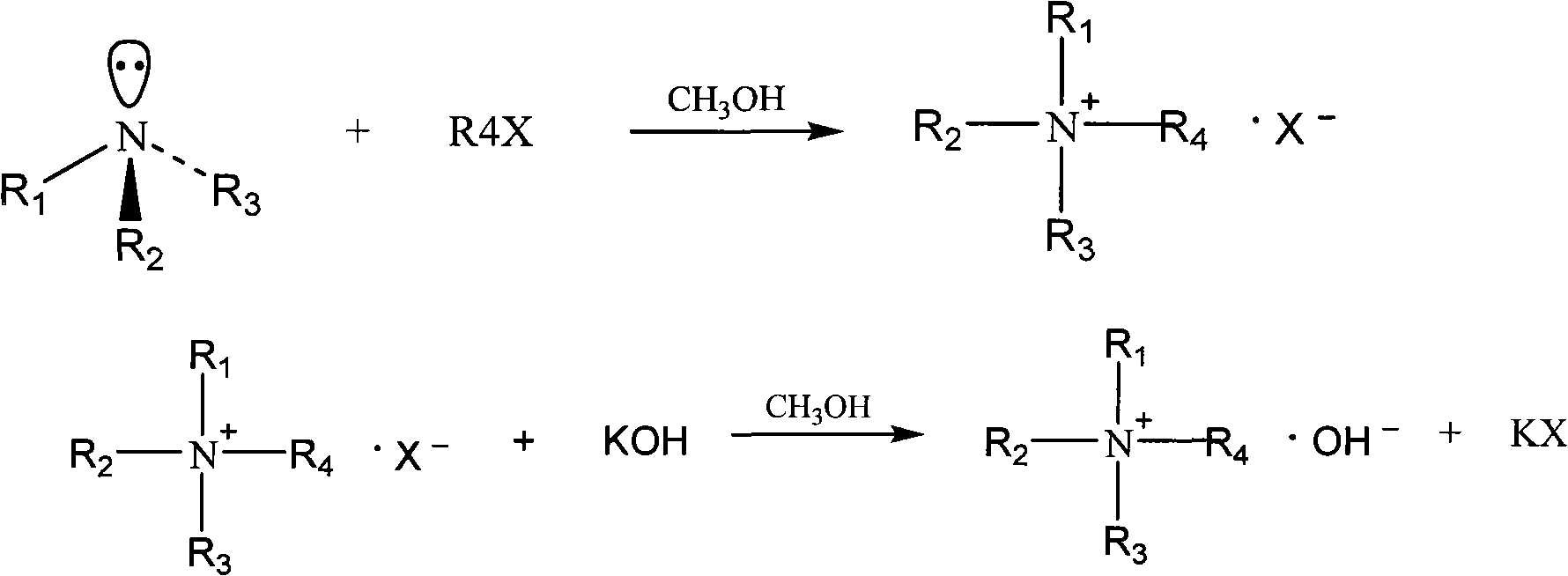

ActiveCN101830811AHigh recovery rateGood alkali stabilityOrganic compound preparationAmino compound preparationTetramethylammonium hydroxideAlkoxy group

The invention discloses a preparation method of 4-aminodiphenylamine, wherein a self-made mixture of bis-quaternary ammonium base and tetramethylammonium hydroxide with low price and good heat stability is used as a base catalyst for a condensation reaction of nitrobenzene and aniline. The bis-quaternary ammonium base has the structure of a general formula (I), wherein R1 and R2 are mutually independent alkyls of C1-C18 and preferentially of methyl, ethyl, n-propyl, isopropyl, allyl, butyl or dodecyl; R3, R4, R5 and R6 are mutually independent straight chain or branch chain alkyls of C1-C6 and preferentially of methyl, ethyl or propyl; and R7 is an alkylene or alkoxy substituted alkylene of C2-C6 and preferentially of ethylidene, propylidene, 2-methoxypropylidene, 2-ethyoxylpropylidene orbutylidene. The preparation method has the advantages that the selectivity of the nitrobenzene in the condensation reaction and the yield of the 4-aminodiphenylamine are high; the hydrogenation speedof a base-containing condensation liquid is high; a hydrogenation liquid has high layering speed and no emulsification phenomenon; and the base has good stability and is not easy to disintegrate, thereby the recovery rate of the base catalyst is improved and the production cost is reduced.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Method for preparing 4-aminodiphenylamine

InactiveUS7157605B2Cheap methodDelayed reaction timeAmino compound purification/separationOrganic compound preparationTetramethylammonium hydroxideHydrogen

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Modified condensation reduction alkylation catalyst

InactiveCN102319568AHigh strengthNot easy to pulverizeOrganic compound preparationAmino compound preparationKetoneSulfide

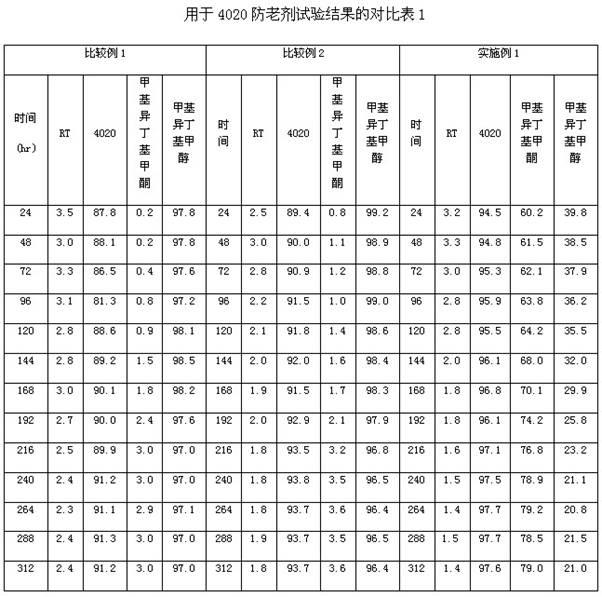

The invention belongs to the technical field of catalysts, and discloses a modified condensation reduction alkylation catalyst used in preparation of a rubber anti-aging agent 4020 by undergoing a hydrogenated reduction alkylation reaction on 4-aminodiphenylamine and methyl isobutyl ketone and preparation of a rubber anti-aging agent 4010NA by undergoing a hydrogenated reduction alkylation reaction on 4-aminodiphenylamine and acetone. The catalyst is a copper-series catalyst, and is mainly characterized in that: the catalyst contains a silicon element; and the molar ratio of copper to silicon is (0.5-10):1. Due to the adoption of the catalyst, a side reaction of ketone hydrogenation for generating an alcohol in the reacting process is suppressed remarkably, raw materials are saved, products 4010NA and 4020 are not required to be passivated by using 4-amino diphenylamine produced by reducing alkali sulfide at an earlier using stage, and unqualified products are avoided; and the catalyst has high intensity and long service life, and is not pulverized easily in the using process.

Owner:郝云青

Preparation method for tetra-alkyl ammonium hydroxide and application

InactiveCN101870659ALow costReduce energy consumptionAmino preparation from aminesOrganic compound preparationTetramethylammonium hydroxideAlkaline earth metal

The invention discloses a preparation method for tetra-alkyl ammonium hydroxide. The preparation method is implemented by the following technical scheme: performing a reaction on trialkylamine and alkyl halide in a single organic solvent to obtain tetra-alkyl ammonium halide; performing ion exchange on the tetra-alkyl ammonium halide and an oxide or a hydroxide of an alkali metal or an alkaline earth metal in the presence of an organic solvent; and obtaining the aqueous solution of the tetra-alkyl ammonium hydroxide by after-treatment. The method has the advantages of convenient raw material source, low cost, simple preparation process, high halide ion-exchange rate and the like. The tetra-alkyl ammonium hydroxide prepared by adopting the method is particularly suitable to be used as a base catalyst, which is used for the condensation of nitrobenzene and aniline for generating 4-nitrodiphenylamine and / or 4-nitrosodiphenylamine and the reduction for generating 4-aminodiphenylamine by hydrogenating. Therefore, the conversion rate of the nitrobenzene is greater than or equal to 99.5 percent and the selectivity is up to over 92 percent.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Method for improving 4-amino diphenylamine yield

ActiveCN1865224AEasy to controlHigh yieldOrganic compound preparationAmino compound preparation by condensation/addition reactionsAlcoholHydrogenation reaction

This invention provides a method for improving the yield of 4-aminodiphenylamine, comprising: use nitrobenzene and phenylamine as raw material to conduct condensation and hydrogenation reactions, where the nitrobenzene is added in to start the condensation reaction when the mole ratio of water and alkaline in the catalyst is 4-6:1, and stop the reaction when the mass percentage of the alcohol compounds in the reaction solution becomes less than 0.3%. This invention is characterized in that it can precisely control the water content by detecting the alcohol compounds during the condensation reaction, so as to efficiently prevent the decomposition of condensing catalyst, obtain a high production yield, and accomplish the repeated use of the catalyst.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing 4-aninodiphenylamine

InactiveCN1202073CLow priceReduce manufacturing costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenation reactionSolvent

The invention discloses a method for producing 4-aminodiphenylamine by using nitrobenzene and aniline as raw materials. The composite base catalyst and composite powder catalyst corresponding to condensation and hydrogenation reactions are respectively selected. The whole process consists of condensation, hydrogenation, The separation and recovery of the composite base catalyst and the recovery and recovery of the regenerated composite powder catalyst, the separation and recovery, and the application of hydrogenated solvent, aniline, and refining constitute a cyclic process flow, and the preparation method is continuously performed. The two catalysts selected in the present invention are cheap and have high catalytic activity; the reaction conditions are mild and the by-products are few; the whole preparation process is continuous, suitable for industrial-scale production, and the content of the prepared 4-aminodiphenylamine is higher than 99% (weight %) ), the yield of industrial scale production is higher than 92%.

Owner:JIANGSU SINORGCHEM TECH CO LTD

Method for preparing 4-aminodiphenylamine

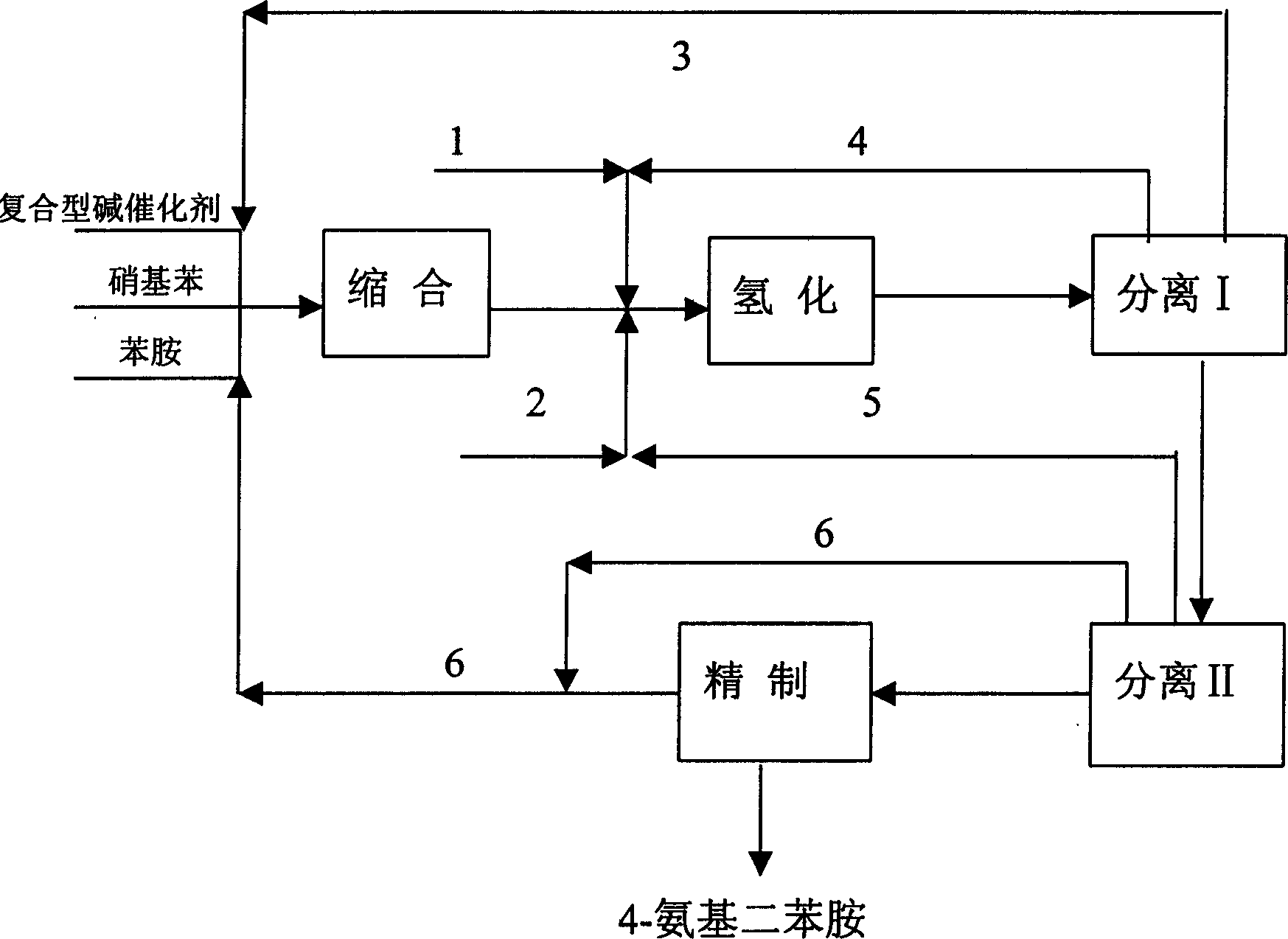

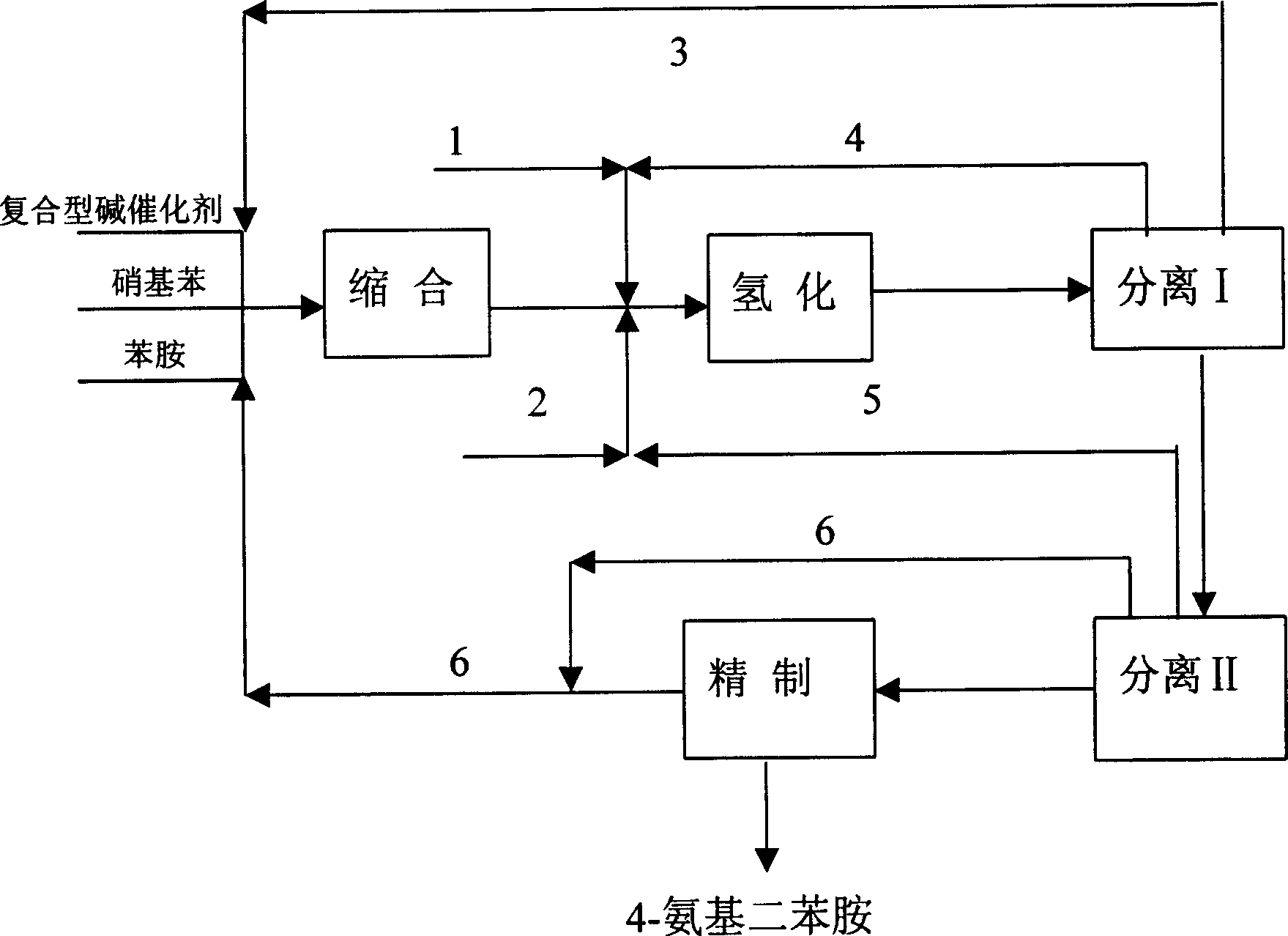

InactiveCN1460673ALow priceReduce manufacturing costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolventAniline

The method for producing 4-aminodiphenylamine by using nitrobenzene and phenylamine as raw material uses composite alkaline catalyst and composite powder catalyst and adopts a circulating technological process formed from five procedures of condensation, hydrogenation, separating and recovering the above-mentioned catalysts, separating and recovering hydrogenation solvent and refining to implement the method. The technological process is suitable for industrial production.

Owner:JIANGSU SINORGCHEM TECH CO LTD

Process for preparing 4-aminodiphenylamine

ActiveUS20050065376A1Increase rangeHigh yieldAmino compound purification/separationOrganic compound preparationHydrogenation reactionAniline

The present invention discloses a process for preparing 4-aminodiphenylamine, which process uses nitrobenzene and aniline as raw materials, a complex base catalyst as condensation catalyst and a powdery composite catalyst as hydrogenation catalyst, and comprises five process stages: condensation; separation I; hydrogenation; separation II; and refining. The process can be continuously carried out. By selecting a complex base catalyst to catalyze the condensation reaction and separating it prior to the hydrogenation, the problem that the complex base catalysts thermally decompose in the hydrogenation reaction is avoided, the selectable range of hydrogenation catalysts is largely enlarged so that it is possible to select cheaper hydrogenation catalyst, and the selection of production process and equipment is easier and further industrialization is easier. The complex base catalysts used in the present invention are inexpensive and have higher catalytic activity. The process can be carried out at mild conditions and can adapt to broad range of water content, by-product is less and conversion and selectivity are higher. The operational strength is low, no corrosive liquid is produced, and environment pollution is reduced. The purity of 4-aminodiphenylamine prepared can exceed 99 wt.-%, and the yield in the industrial production process can be over 95%.

Owner:NONGYUE WANG & GUANGQIANG SHI +1

Production method of 4-aminodiphenylamine

InactiveCN101863778AHigh purityShort processOrganic compound preparationAmino compound preparationAlkaline waterActivated carbon

The invention discloses a production method of 4-aminodiphenylamine, which comprises the following steps of: (1) mixing phenylamine and alkaline water solution, distilling out phenylamine-water azeotrope; (2) adding nitrobenzene for reaction; (3) adding water, Ni-B amorphous alloy catalyst, and filling hydrogen; (4) carrying out solid-liquid separation, separating out Ni-B amorphous alloy catalyst and liquid phase, and returning the Ni-B amorphous alloy catalyst back into the step (3); separating the liquid phase to obtain organic phase and alkaline water solution, carrying out rectification on the organic phase to obtain the product 4-aminodiphenylamine, recovering phenylamine, and returning the phenylamine back into the step (1); and (5) returning the alkaline water solution which is separated out back into the step (1), or treating the alkaline water solution by activated carbon and then returning back in the step (1). The method is simple, improves the purity of circulating alkaline water solution, avoids using expensive electrolytic process, shortens the process flow, is low in equipment investment, has simple operation, and can remarkably reduce the operation cost.

Owner:TIANJIN YIHUA CHEM +1

Preparation process of 4-amino diphenylamine

The invention relates to a method for preparing 4-aminodiphenylamine by a nitrobenzene method. It mainly solves the need to use precious metals in the catalyst in the past technology, which makes the catalyst preparation cost high; the main impurities produced in the process, azobenzene oxide / azobenzene and / or hydroazobenzene need to be recovered separately or only pure raw materials can be used question. In the present invention, condensation reaction occurs with aniline and nitrobenzene in the presence of water and alkali, and then the condensation liquid containing strong alkali or strong organic base is reacted with water and alkali in the presence of skeleton nickel, especially modified skeleton nickel catalyst. Aromatic amine is used as a solvent, and the technical scheme of hydrogenation reduction reaction to generate 4-aminodiphenylamine solves this problem well, and realizes nitro, nitroso, azo or / and oxidized diphenylamine in one step through hydrogenation reduction reaction. The reduction of nitrogen compounds can be used in the industrial production of 4-aminodiphenylamine.

Owner:CHINA PETROLEUM & CHEM CORP +2

Solid base catalyst and method for making and using the same

ActiveUS20130079560A1Efficient and predictableReduce the amount requiredMolecular sieve catalystsOrganic compound preparation4-aminodiphenylamineInorganic chemistry

A solid base catalyst having a carrier, an organic base, and an inorganic base. Both of the organic base and inorganic base are loaded on the carrier. The solid base catalyst is especially suitable for the synthesis of 4-Aminodiphenylamine (4-ADPA).

Owner:SENNICS CO LTD

Method for preparing 4-amino diphenylamine

InactiveCN1470497AReduce pollutionAvoid heat-sensitive decomposition problemsOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsCyclic processHydrogenation reaction

The present invention discloses a method for producing 4-aminodiphenylamine by using nitrobenzol and phenylamine, and is characterized by that the compound alkali catalyst and compound powdered catalyst which are correspondent to the condensation and hydrogenation reaction are respectively selected and used, and successively undergone the circular process including the procedures of condensation,separating compound alkali catalyst, hydrogenation, separating and hydrogenating solvent, compound powdered catalyst and phenylamine and refining, and its preparation process can be continuously implemented. Said two catalysts are high in catalytic activity, and the content of 4-aminodiphenylamine in the product can be up to 99 wt%, and its industrial production yield rate is greater than 92%.

Owner:JIANGSU SINORGCHEM TECH CO LTD

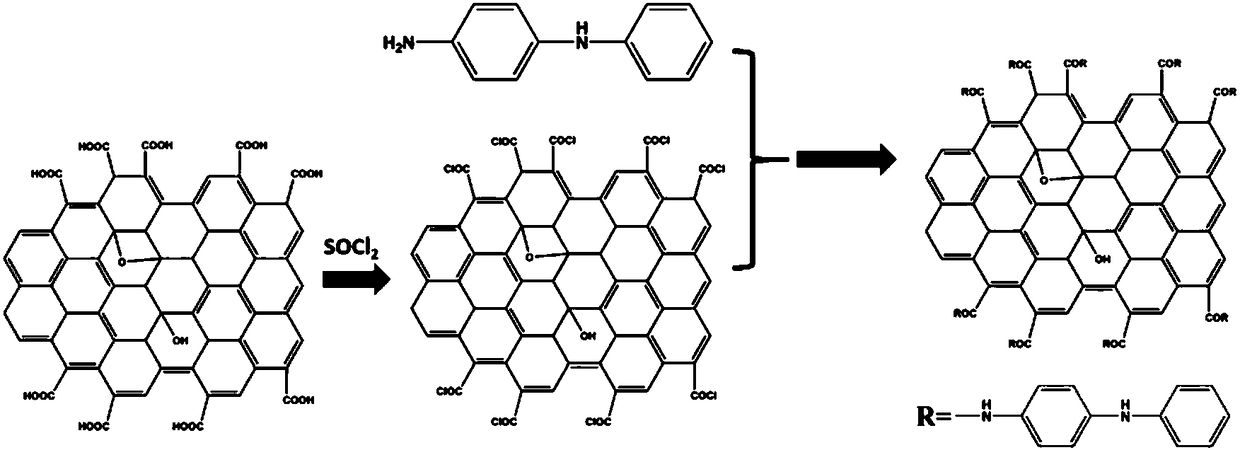

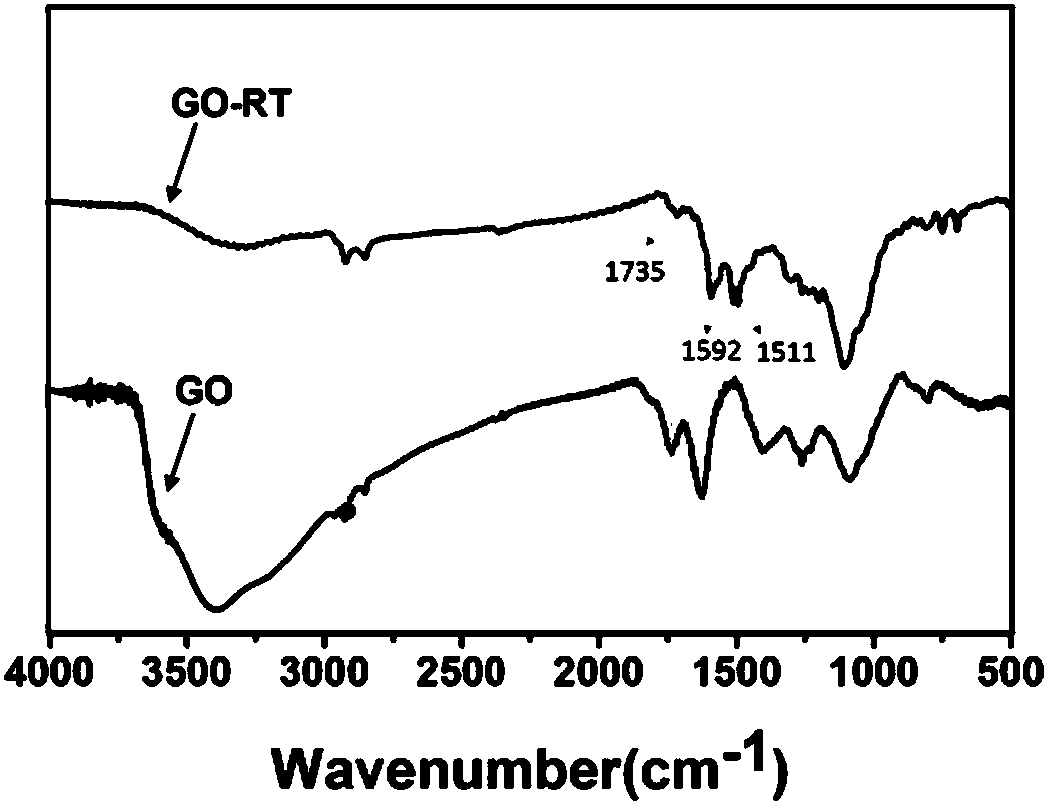

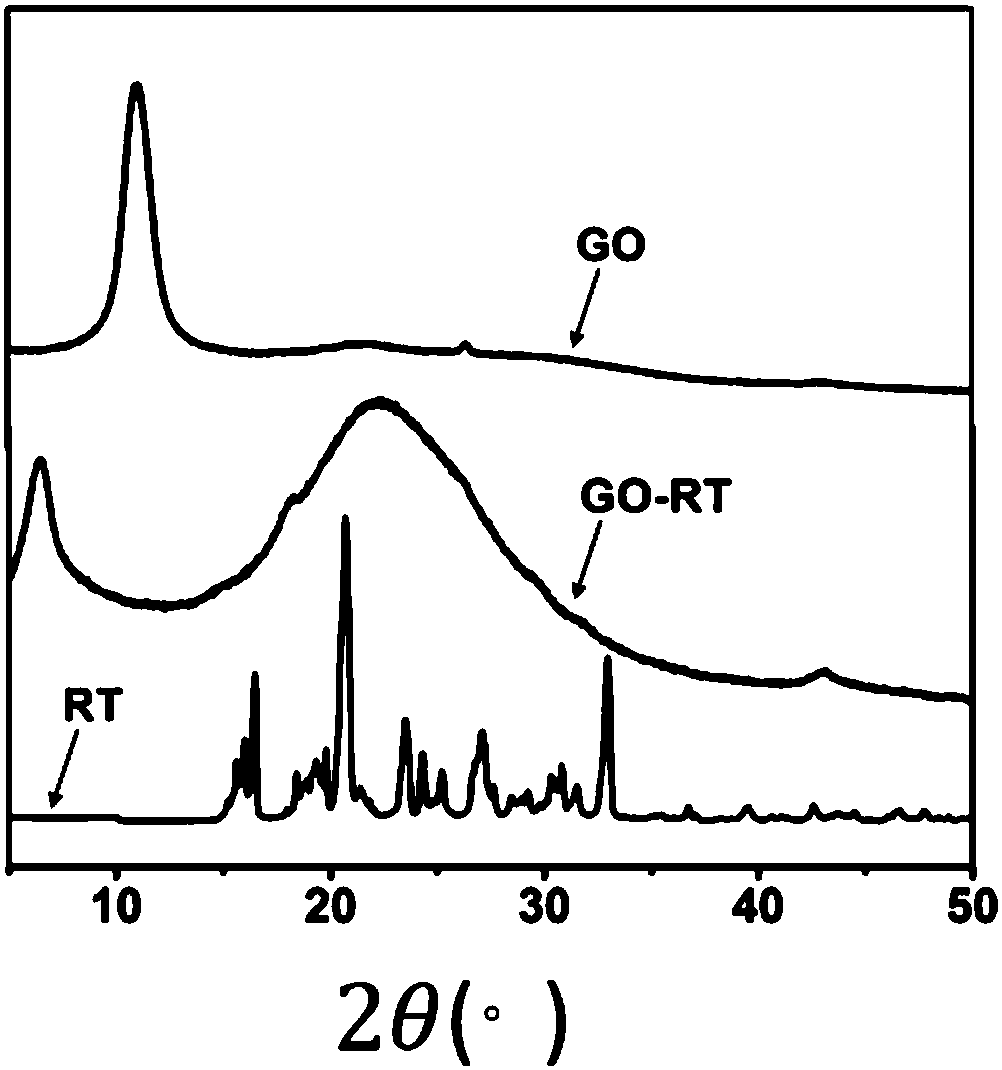

Non-mobility graphene oxide grafted anti-aging agent and preparation method thereof

InactiveCN108503888ALarge specific surface areaImprove mechanical propertiesStructural formula4-aminodiphenylamine

The invention provides a non-mobility graphene oxide grafted anti-aging agent and preparation method thereof. 4-aminodiphenylamine is used for carrying out grafting modification on graphene oxide by so as to enable a hydroxyl group in the carboxyl group of graphene oxide to be replaced with an R group, wherein the structural formula of the R group is described in the description; the grafting rateof the R group is 7-15wt%. The preparation method comprises the following steps: (1) dissolving graphene oxide into thionyl chloride, carrying out a refluxing reaction, separating out a reaction product, and washing to remove thionyl chloride so as to obtain thionyl chloride modified graphene oxide; (2) adding the thionyl chloride modified graphene oxide into dimethylformamide, carrying out ultrasonic treatment to enable the thionyl chloride modified graphene oxide to be fully dissolved, and dissolving 4-aminodiphenylamine into dimethylformamide; then, mixing the thionyl chloride modified graphene oxide solution with the 4-aminodiphenylamine solution, carrying out a refluxing reaction and solid-liquid separation, and fully soaking the obtained solid phase in absolute ethanol, separating out the soaked solid product, and drying to obtain the non-mobility graphene oxide grafted anti-aging agent.

Owner:SICHUAN UNIV

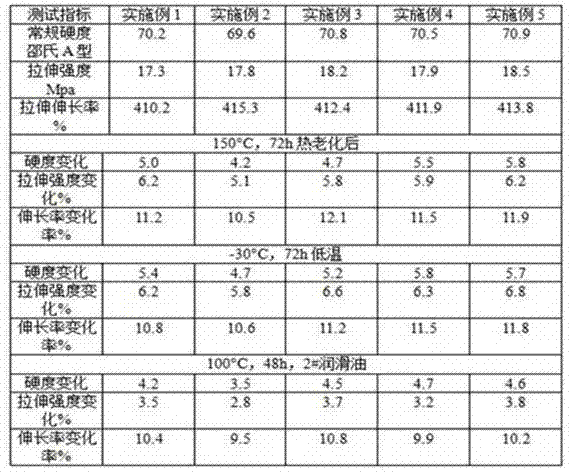

Environmentally friendly anti-high and low temperature rubber oil-sealing material and preparation method thereof

Owner:ANYANG INST OF TECH

Process for preparing 4-aminodiphenylamine

ActiveUS20120053367A1Increase rangeHigh yieldOrganic compound preparationAmino compound preparation by condensation/addition reactionsChemical compositionPhenazine

A method for refining an organic composition containing 4-aminodiphenylamine, aniline, azobenzene, and phenazine, having the steps of feeding the organic composition to a first rectification column, producing a first effluent composition containing aniline, azobenzene, phenazine, and a small amount of 4-aminodiphenylamine at the top of the first rectification column and a second effluent composition containing crude 4-aminodiphenylamine at the bottom of the first rectification column, feeding the second effluent composition to a second rectification column, and producing a 4-aminodiphenylamine composition at the top of the second rectification column and a residual composition at the bottom of the second rectification column.

Owner:SENNICS CO LTD

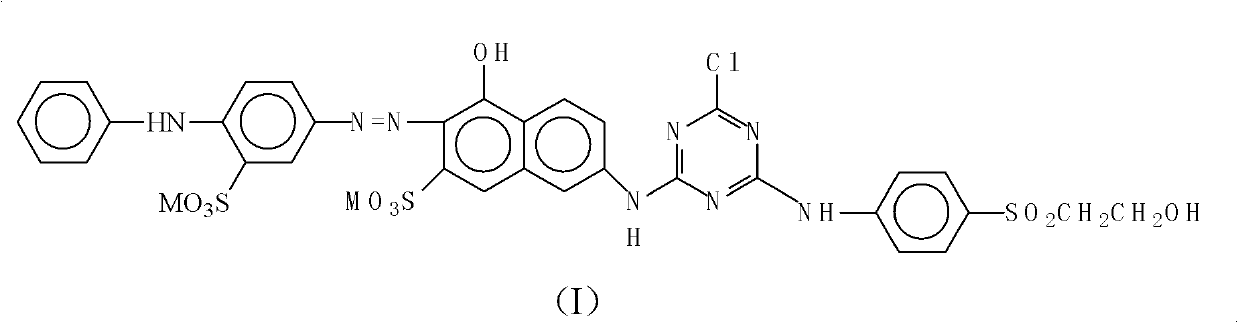

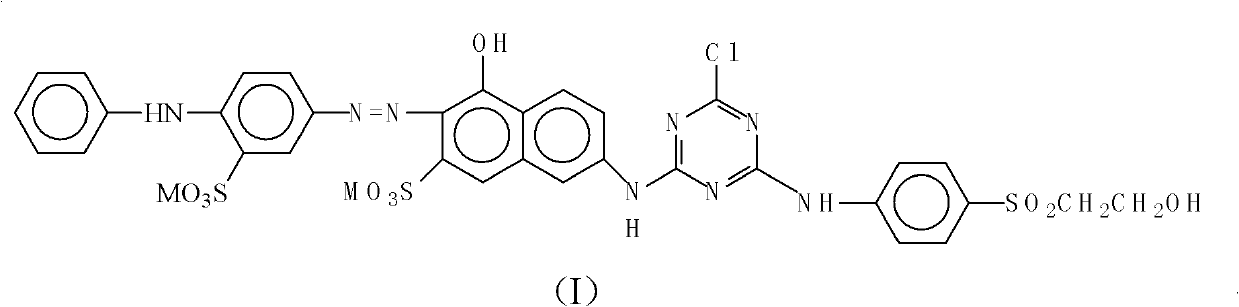

Dye suitable for nylon dyeing

The invention relates to a dye suitable for nylon dyeing, which is a compound shown by the following formula (I). The preparation method comprises the following steps: a. adding a para-beta-hydroxyethyl sulfonyl aniline solution into a cyanuric chloride solution to react to obtain a primary condensation solution, and adding J acid into the primary condensation solution to obtain a secondary condensation solution; b. adding a hydrochloric acid solution and a sodium nitrite solution into 4-aminodiphenylamine-2-sulfoacid to react under the condition that the PH is less than 2, and eliminating excessive nitrous acid by utilizing sulfamic acid to obtain a heavy nitrogen solution; c. dropwisely adding the heavy nitrogen solution obtained in step b into the secondary condensation solution obtained in step a to obtain a coupling reaction solution; d. heating the coupling reaction solution obtained in step c, and hydrolyzing under the condition that the pH is equal to 8-11; e. filtering the hydrolyzed reaction solution obtained in step d to remove waste residue, and collecting the filter liquor; f. regulating the colored light and intensity of the filter liquor in step e; and g. carrying out spray drying on the color solution in step f to obtain the final product in the formula (I).

Owner:TIANJIN DEK CHEM

Catalyst for preparing 4-aminodiphenylamine and preparation method of catalyst

ActiveCN106179332AHigh activityHigh selectivityOrganic compound preparationAmino compound preparationActivated carbonActive component

The invention relates to a catalyst for preparing 4-aminodiphenylamine and a preparation method of the catalyst, and specifically provides a preparation method of a palladium / carbon catalyst for preparing the 4-aminodiphenylamine through hydrogenation. The catalyst is characterized in that activated carbon is used as a carrier, palladium is used as an active component, and a preparation process comprises the steps of pretreating the activated carbon, performing impregnation, performing reduction, performing washing, performing drying and the like. The prepared catalyst is used for a catalytic hydrogenation process of preparing the 4-aminodiphenylamine by a nitrobenzene method. Raw materials for preparing the catalyst disclosed by the invention are easy to obtain, the technology is simple, and the catalyst is used for preparing the 4-aminodiphenylamine through the hydrogenation, is high in activity and good in stability, and has good application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for refining 4-amino diphenylamine

InactiveCN1470499AHigh yieldIncrease contentAmino compound purification/separationDistillationAniline

The present invention relates to a method for refining 4-aminodiphenylamine by adopting three-column continuous rectification and intermittent distillation. The crude product of 4-aminodiphenylamine can be obtained by rectification in the column No.1, and the substances of phenylamine, phenazine and azobenzene can be obtained at the top of column, said crude product can be purified in column No.2, in the column No.3 the phenylamine is separated, and the intermittent column can be used for making batch distillation of 4-aminophenylamine made up by using column bottoms of column No.2 and returning it into column No.2 for refining it. The yield rate of its whole process can be raised to 99% from 94%, and the content of 4-aminodiphenylamine in the finished product is greater than 99 wt%, at the same time the phenylamine can be recovered, and can be used.

Owner:JIANGSU SINORGCHEM TECH CO LTD

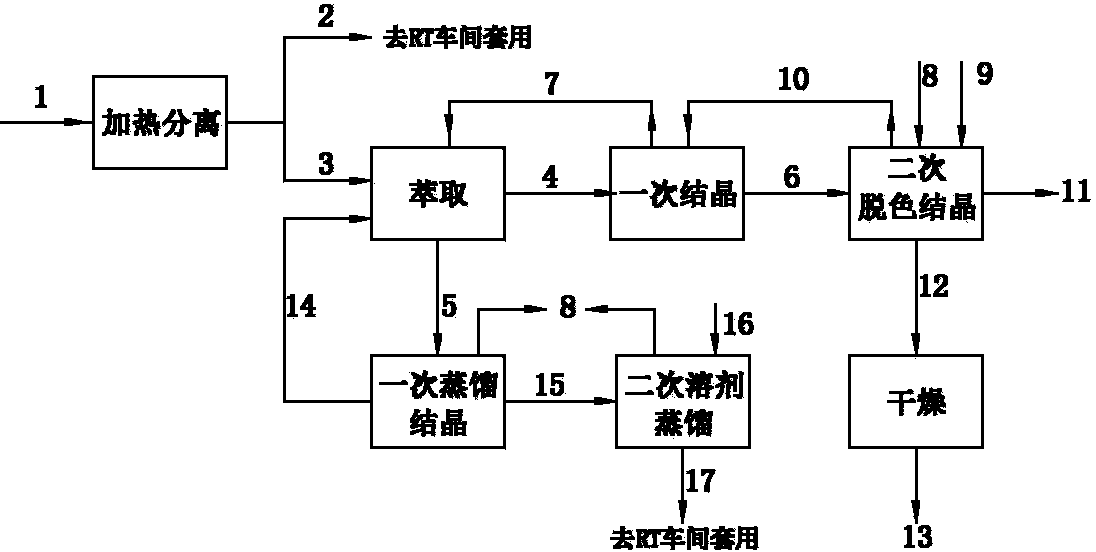

Method for extracting high-purity phenazine from RT base (4-Aminodiphenylamine) byproduct waste material

The invention discloses a method for extracting high-purity phenazine from an RT base byproduct waste material, belonging to the technical field of refining of the phenazine. The technical problem to be solved is to provide a method for extracting the phenazine from the RT base byproduct waste material, wherein the product is high in purity and bright in color and gloss, the amount of used solvents is small and the recycle rate of the solvents is high. The method comprises the following steps: separation by heating, extraction, primary crystallization, secondary decoloration and crystallization, drying, primary distillation and crystallization and secondary solvent distillation, wherein due to the step of the separation by heating, the amount of the used solvents in the extraction step and the crystallization step is reduced, and an active carbon decoloration step is added, so the product purity is stable and not lower than 99.8% and the product is also brighter in color and gloss and totally meets the requirements of all markets including a pharmaceutical-grade market; due to the addition of the secondary distillation, the recycle rate of the solvents is as high as 99.5%, the consumption of purifying solvents is reduced, and the amount of the solvents introduced to an RT production system causes no burthen to an existing RT production system.

Owner:张国柱

Preparation method of rubber antioxidant 4030

InactiveCN103102275ASolving Supply BottlenecksRealize mass productionOrganic compound preparationAmino compound preparationPolymer scienceAntioxidant

The invention relates to a preparation method of a rubber antioxidant, in particular to a rubber antioxidant 4030. The preparation method comprises the steps of mixing, synthesizing, separating and purifying. According to the preparation method, the rubber antioxidant 4030 is produced by adopting p-phenylenediamine as a raw material instead of a process route with scarce 4-aminodiphenylamine as the raw material, the material supply bottleneck is solved, and mass production of the rubber antioxidant 4030 can be realized.

Owner:JIANGSU GUOLI CHEM TECH

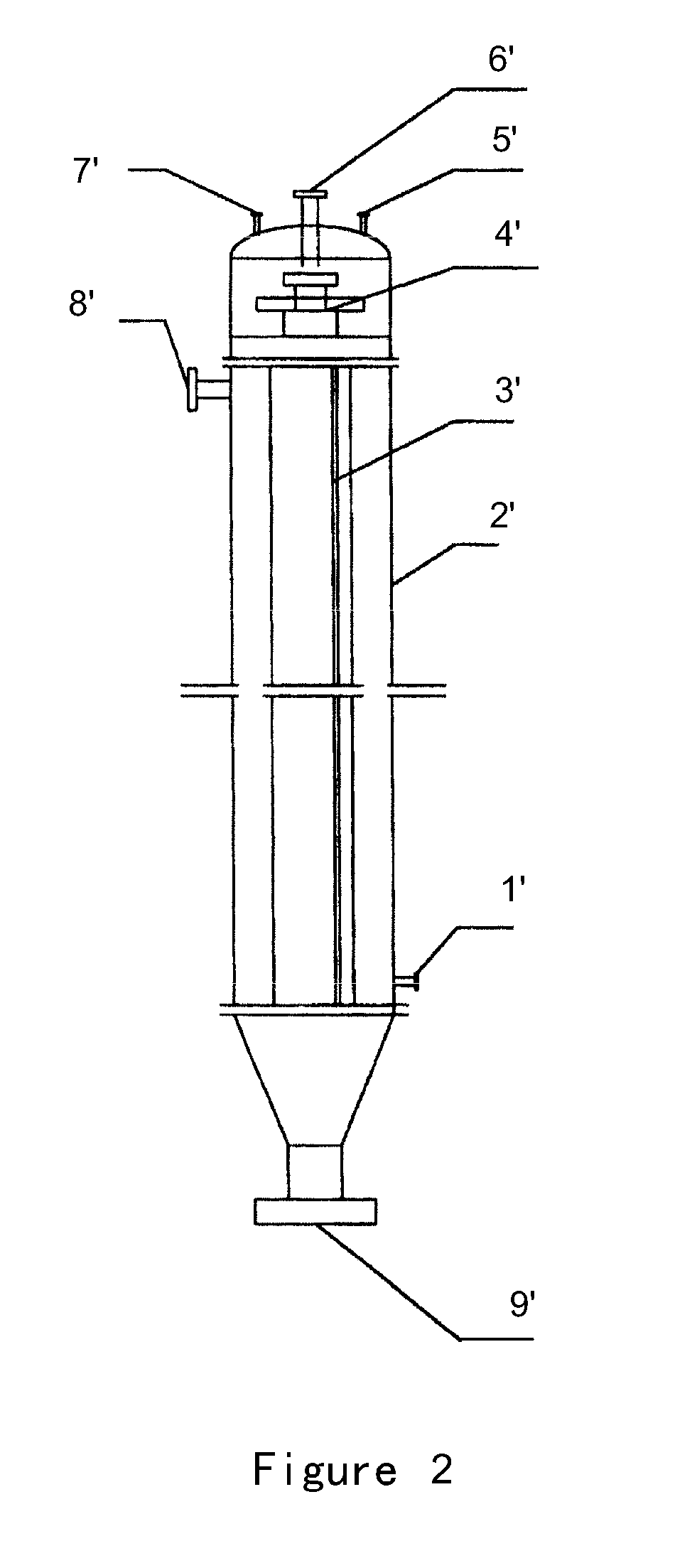

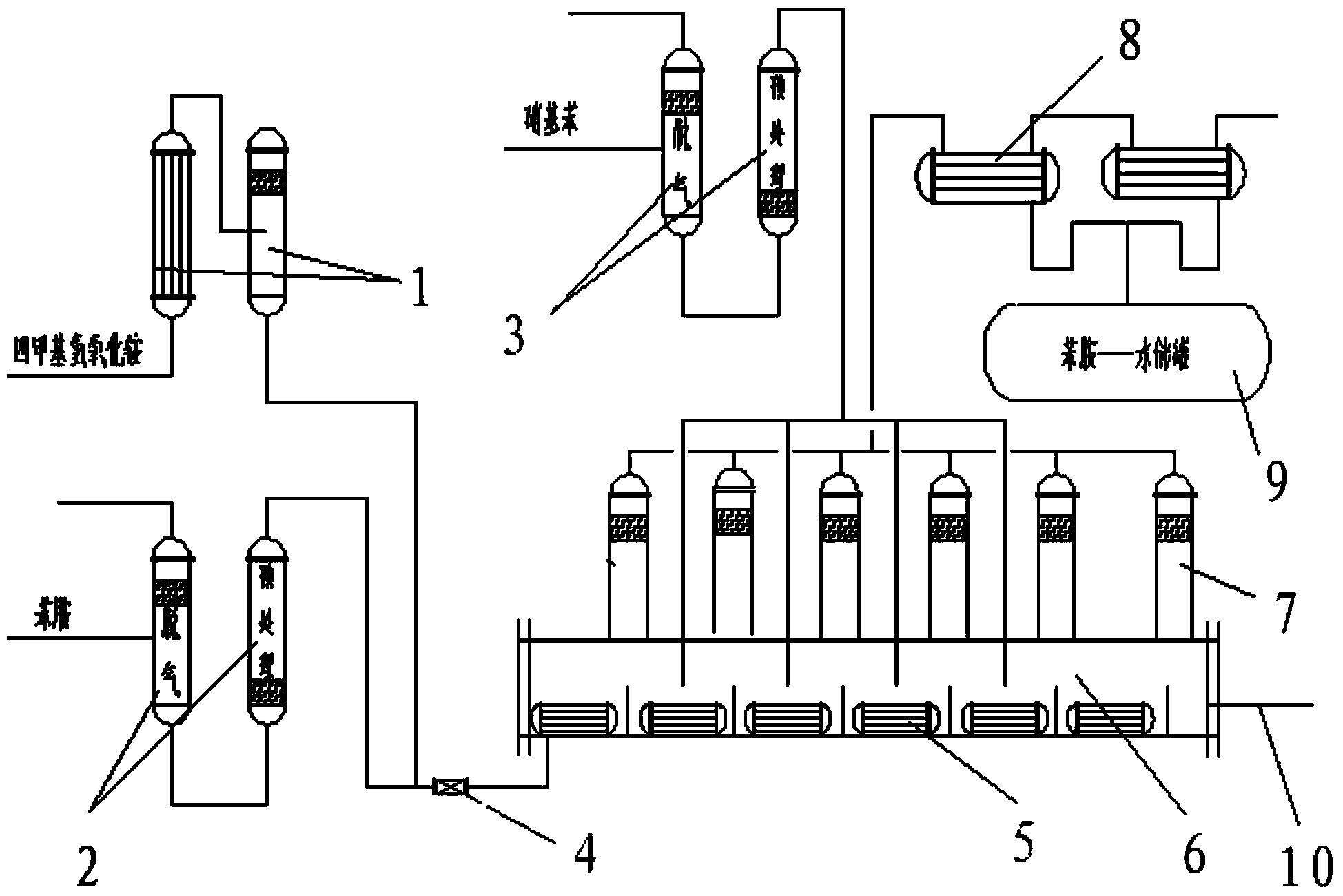

Production equipment and production technology of precursor of 4-aminodiphenylamine

ActiveCN103819346AReduce spoilageReduce consumptionAmino compound preparation by condensation/addition reactionsHydrogenAlkali metal oxide

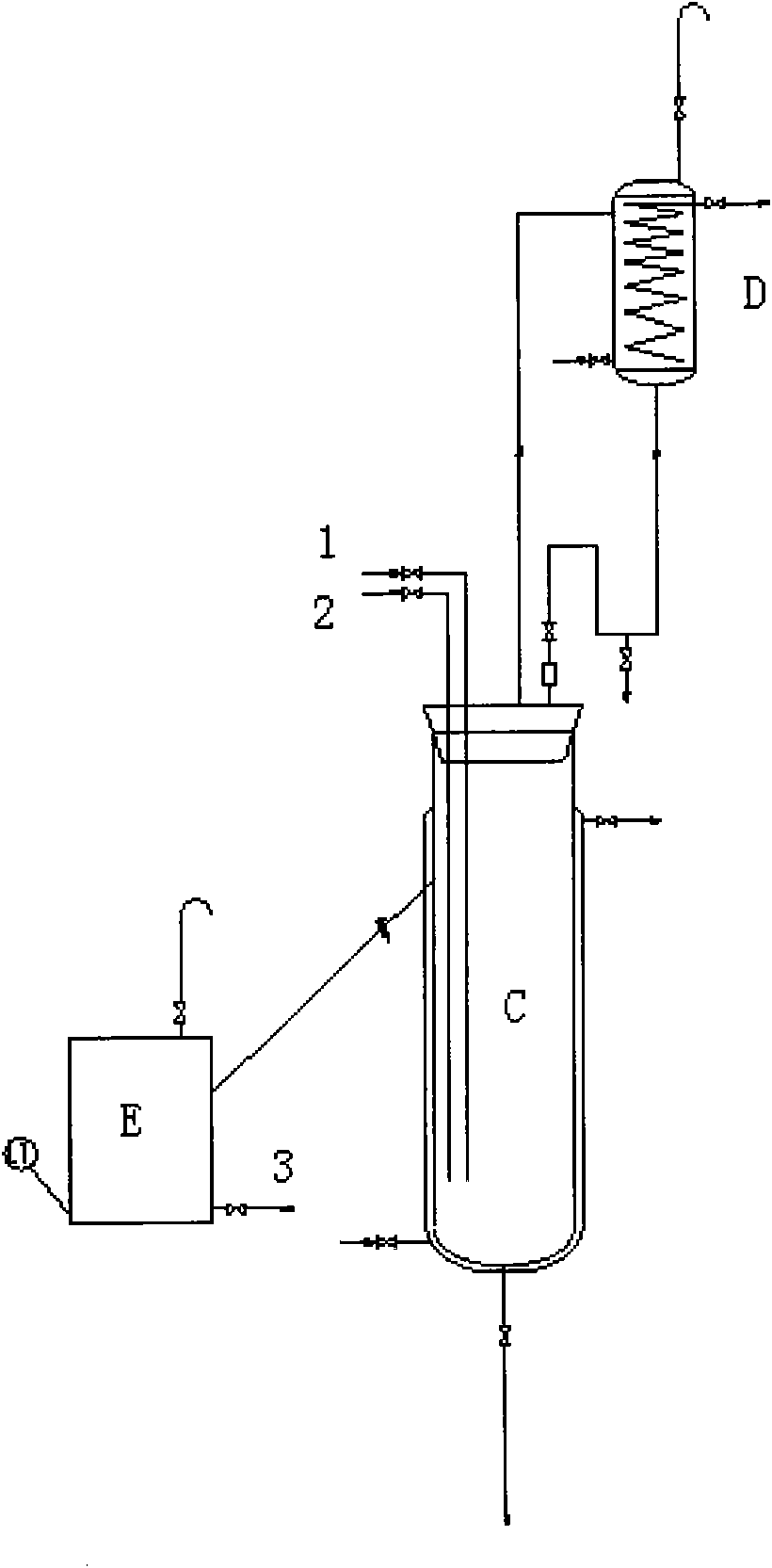

The invention relates to a production technology of a precursor of 4-aminodiphenylamine. The technology comprises the following steps: respectively processing and degassing nitrobenzene and phenylamine through an alkali metal oxide or a hydroxide; continuously feeding the processed phenylamine and concentrated quaternary ammonium alkali catalyst to a tubular condensation reactor by flow measurement according to a certain ratio after concentrating the quaternary ammonium alkali catalyst in vacuum; firstly, reacting the phenylamine to form aniline anions; continuously adding the processed nitrobenzene at different positions of the tubular condensation reactor from a plurality of points and controlling the water yield, so that the anions generate 4-nitrosodiphenylamine and 4-nitrodiphenylamine condensed liquid by replacing hydrogen reaction on nitrobenzene by nucleophilic addition. The technology disclosed by the invention is reasonable in steps and composition and advanced in equipment, and is used raw material enters a continuous production device of a high-efficiency reactor pipeline after being pretreated under a totally-enclosed condition, so as to produce the 4-nitrosodiphenylamine and the 4-nitrodiphenylamine.

Owner:SHANDONG SUNSINE CHEM

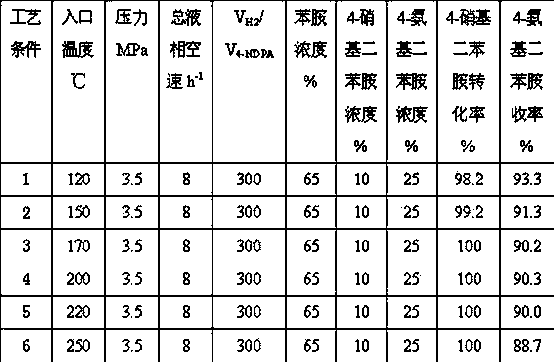

Method for continuously synthesizing 4-aminodiphenylamine

ActiveCN103420849AOrganic compound preparationAmino compound preparationHydrogenation processReaction temperature

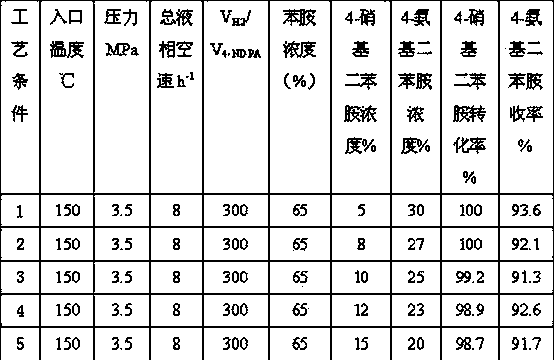

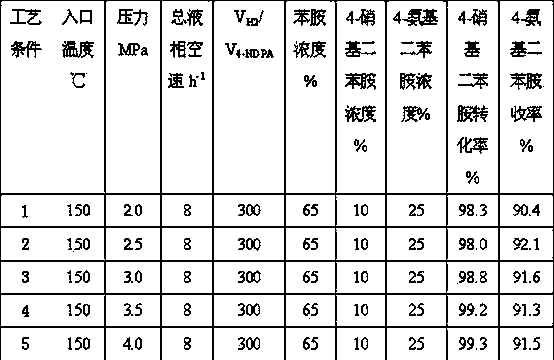

The present invention relates to a method for synthesizing 4-aminodiphenylamine, wherein problems of low raw material conversion rate and low product yield of the existing 4-nitrodiphenylamine batch hydrogenation process are mainly solved with the present invention. The technical scheme is that: a Ni base catalyst is adopted, the raw material adopts aniline as a solvent, 4-nitrodiphenylamine weight content in the reaction solution is 5-20%, 4-aminodiphenylamine weight content is 20-30%, and 4-nitrodiphenylamine is continuously synthesized at a reaction temperature of 100-250 DEG C under a reaction pressure of 2.0-4.0 MPa at the total liquid phase space velocity of 6.0-16.0 h<-1> according to a hydrogen / 4-nitrodiphenylamine volume ratio of 200-600:1. With the present invention, the problems in the prior art are well solved, and the method can be used for industrial production of continuous 4-nitrodiphenylamine synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for continuous hydrogenation preparation of 4-amino diphenylamine

InactiveCN1185207CSolve the problem of single consumptionOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationHydrogenation reaction

The present invention discloses a method for preparing 4-aminodiphenylamine by continuously hydronating condensate obtained from the reaction by using nitrobenzol and phenylamine as raw material and adopting compound powdered catalyst. i,e, adopts a catalyst and hydrogen gas circulation and solvent circulation combined new process to make the hydrogenation reaction be implemented under the condition of high-concentration, low-temp. and low pressure. The invented catalytic hydrogenation conversion rate can be up to 100%, and its selectivity is greater than 99%, and it is suitable for industrial production of 4-aminophenylamine.

Owner:JIANGSU SINORGCHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com