Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

380results about How to "Not easy to pulverize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing 1, 4-butynediol and preparation method thereof

InactiveCN103480382ALarge external specific surfaceHigh activityMetal/metal-oxides/metal-hydroxide catalystsDeposition precipitationCopper oxide

The invention discloses a catalyst for preparing 1, 4-butynediol and a preparation method of the catalyst for preparing 1, 4-butynediol. According to the method, acidized nano-silica is adopted as a carrier, the adopted nano-silica has a large outer specific surface, a dipping method and a deposition-precipitation method are used for adsorbing copper and bismuth on the carrier, so that the catalyst comprises 35-65% of copper oxide by mass, and meanwhile silica sol is added, so that the catalyst is more stable and abrasion resistant. The prepared catalyst is good in activity, high in selectivity and strength, not prone to pulverizing in the process of using and capable of keeping high activity.

Owner:大连瑞克科技股份有限公司

Catalyst for producing 1.4-butynediol and preparation method of catalyst

ActiveCN102950002AEasy to prepareSimple manufacturing methodOrganic compound preparationHydroxy compound preparationSlurry reactorPtru catalyst

The invention discloses a catalyst for producing 1.4-butynediol and a preparation method of the catalyst, belonging to the technical field of load type catalysts for a slurry reactor. The catalyst for producing 1.4-butynediol is characterized in that nanosilicon dioxide is used as a carrier, the nanosilicon dioxide has larger external specific surface area, copper and bismuth are absorbed on the carrier by adopting an impregnation and deposition-precipitation method, so that the catalyst contains 35-65 percent of copper oxide, and then a defined amount of silica sol is added, and through a specific forming method, the granularity of the catalyst is between 1micrometer and 50 micrometers. The prepared catalyst has the characteristics of good activity, high selectivity, high strength, easiness in separation, high particle uniformity, and difficulty in pulverization in a use process; and the preparation method of the catalyst is simple and easy to operate and good in repeatability.

Owner:河北瑞克新能源科技有限公司

Denitrifying catalyst and preparation method thereof as well as flue gas denitrifying method

ActiveCN102114423AHigh porosityHigh catalytic efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberCarboxymethyl cellulose

The invention relates to a denitrifying catalyst and a preparation method thereof as well as a flue gas denitrifying method. The preparation method of the denitrifying catalyst comprises the following steps: mixing, aging, drying and calcining, wherein in the mixing step, ITAC-14-7A, CTAC-115, stearic acid, deionized water, ammonia, lactic acid, glass fiber, wood pulp, water, an ammonium metavanadate solution, carboxymethyl cellulose and polyoxyethylene are mixed by a mixer. The denitrifying catalyst prepared by the method has high-efficiency denitrifying efficiency.

Owner:江苏万德环保科技有限公司

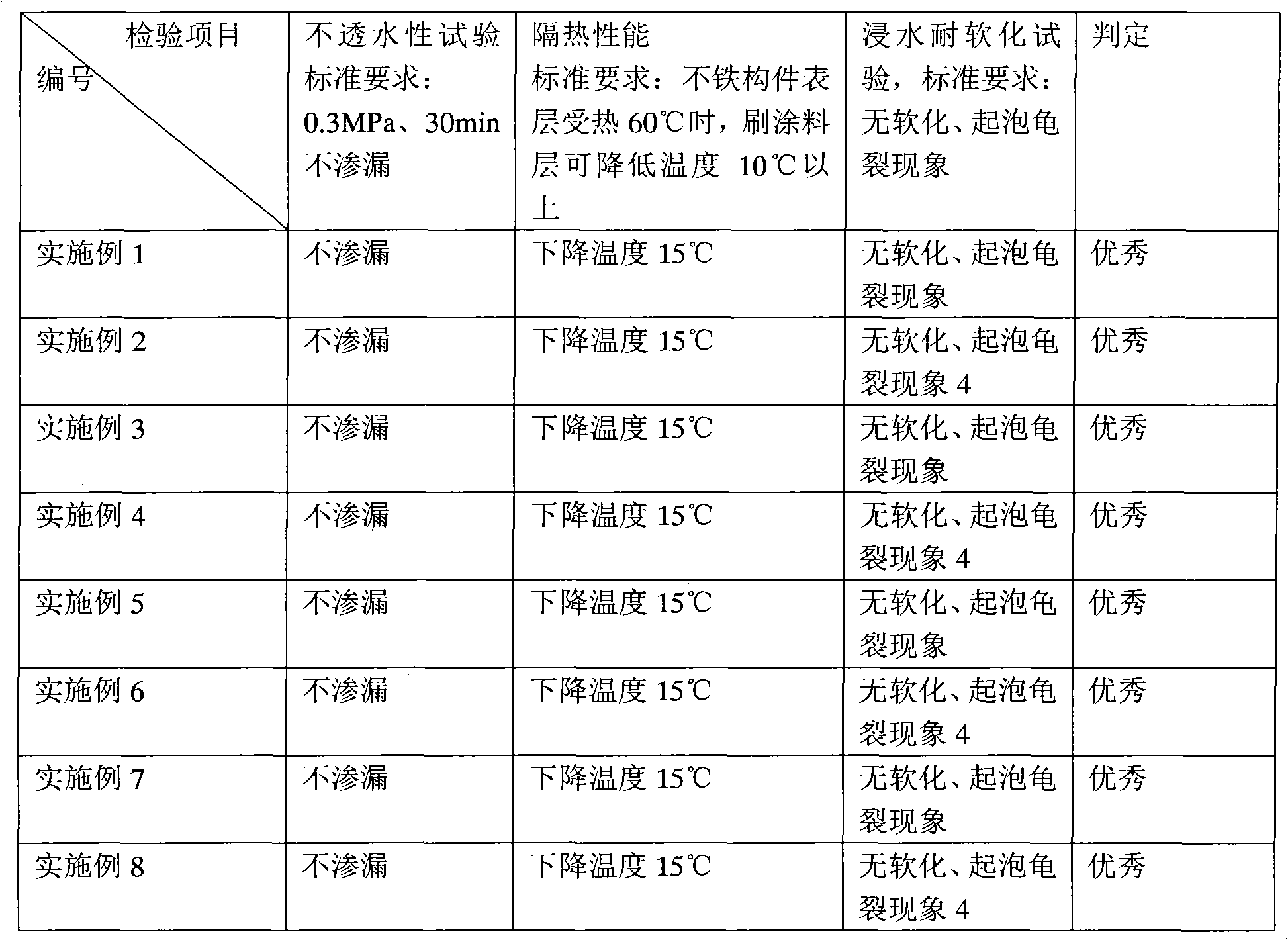

Heat insulation waterproof waterborne coating

InactiveCN101831219AImprove performance qualityImprove film qualityCoatingsCarvacryl acetateDefoamer

The invention discloses a heat insulation waterproof waterborne coating which comprises the following compositions in percentage by weight: 40-48wt% of film forming emulsion, 41-54 wt% of pigment filler, 2.77-8 wt%of additive and the balance of clear water, wherein the film forming emulsion is ethylene-vinyl acetate copolymer EVA and acrylic copolymer emulsion, the pigment filler is one or multiple kinds of titanium dioxide, mica powder, heavy calcium powder, light calcium powder, talcum powder, kaolin, phosphatic powder and hollow tiny glass powder or all of the substances, and the additive is one or multiple kinds of dispersant, lubricant, flow agent, defoamer, plasticizer, antifreeze and preservative or all of the substances which are usually used by technicians of the field. The coating has the advantages of excellent heat insulation and waterproof performance, favorable environmental protection, difficult pulverization, fast drying and simple and convenient construction.

Owner:HUIZHOU GUCHENG TECH

Composite heat-insulating material and preparation method thereof

The invention relates to a composite heat-insulating material, comprising the following ingredients: 0.4-10 wt% of sepiolite, 0-5 wt% of brucite, 0-15 wt% of alumina silicate fiber, 5-10 wt% of asbestos fiber, 0.5-8 wt% of aerogel, 0-12 wt% of diatomite, 0-3 wt% of bentonite, 1-5 wt% of perlite, 0.5-5 wt% of dispersant, 0.1-1 wt% of polyvinyl alcohol, 0-1 wt% of soluble glass, 0-0.015 wt% of sodium cetanesulfonate, and the balance consisting of clear water. The invention also discloses a preparation method of the composite heat-insulating material. The composite heat-insulating material disclosed herein has low heat-insulating coefficient, good flexibility, and high tensile strength, and is difficult to pulverization. In addition, the method has the advantages of simple process, high production efficiency, and low energy consumption.

Owner:张永武

Method for preparing butanediol by carrying out two-stage catalytic hydrogenation on butynediol

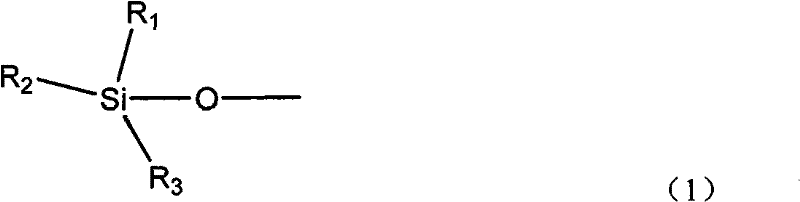

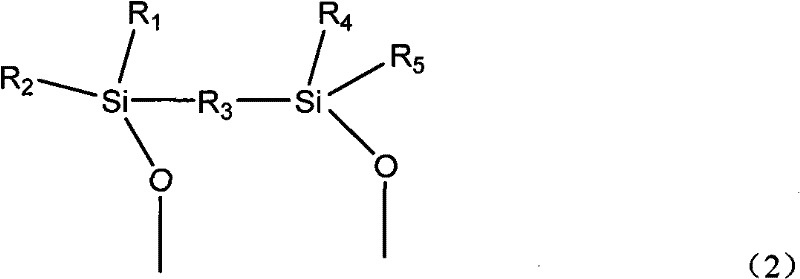

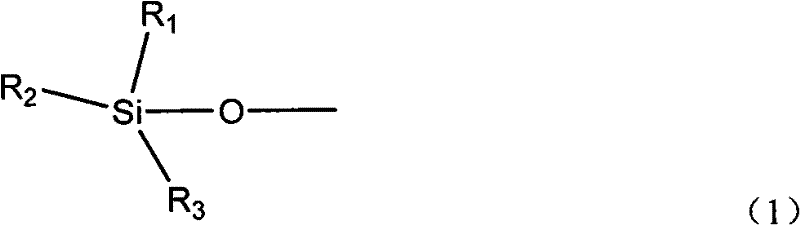

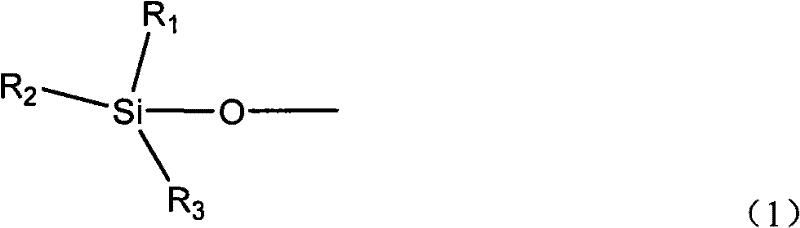

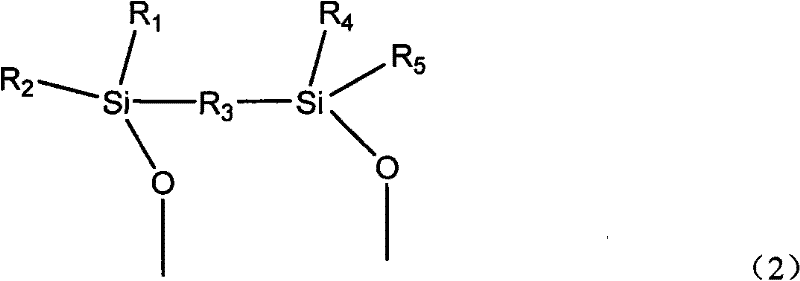

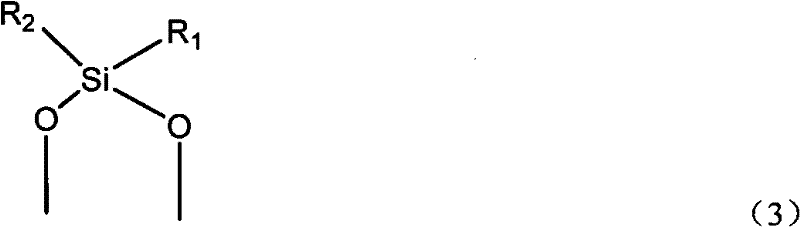

ActiveCN102408307AHigh mechanical strengthNot easy to pulverizePreparation by hydrogenationSilanesCarbon deposit

The invention relates to a method for preparing butanediol by carrying out two-stage bed catalytic hydrogenation on butynediol. Aiming at the requirements on the suitability for a reaction system which contains water or fluctuating water content in a process for preparing the butanediol by carrying out two-step hydrogenation on the butynediol, and the inhibition on the generation of carbon deposit, the inventor proposes that: a hydrogenation catalyst A and a hydrogenation catalyst B in a two-stage bed respectively contains a carrier, a metal active component and silane groups, further, the silane groups are grafted through a silylanizing treatment, wherein the content of the silane groups in the total weight of the hydrogenation catalysts is 0.1-12 wt%. Compared with the prior art, under the premise of ensuring that the hydrogenation catalysts have better activity and better selectivity, the method provided by the invention has obvious raw material suitability, and the presence of water hardly influences on the catalytic performance of the hydrogenation catalysts; and meanwhile, the generation of the carbon deposit on the surfaces of the catalysts can be obviously inhibited, and the service life of the catalysts is prolonged, so that the hydrogenation reaction system can have a longer stable running cycle.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional deoxidizer, preparation and applications thereof

InactiveCN105363406AHigh deoxygenation depthLarge capacityOther chemical processesDispersed particle separationActive componentCarbonate

The present invention relates to a multifunctional deoxidizer and a preparation method thereof, wherein the multifunctional deoxidizer comprises a suitable metal carbonate, a proper amount of an activity promoter and a proper amount of a structure support monomer. During a multifunctional deoxidizer production process, a thermal decomposition (calcination) method is used to decompose a metal carbonate to form the active component of the metal oxide deoxidizer while release carbon dioxide gas, such that a large number of uniform adsorption pore sizes having the carbon dioxide molecule size are formed in the multifunctional deoxidizer, and the pore size can deeply adsorb a lot of water and carbon dioxide. According to the present invention, the novel gas purification material is provided, the production process can be simplified, the production energy source and the materials can be saved, and the production cost and the consumption can be reduced; and the energy saving and consumption reducing industrial policy direction in the country new material and new technology application can be met.

Owner:王雅坤

Raw material for increasing quality of low-rank coal by present tamping coke oven

ActiveCN104327873ASolve the low utilizationSolve the problem of overcapacity in the coking industrySpecial form destructive distillationEngineeringActive ingredient

The invention provides a raw material for increasing quality of low-rank coal by a resent tamping coke oven. The raw material comprises low-rank coal and an auxiliary agent. The auxiliary agent is an organic binder with weightlessness being less than 50% under destructive distillation isolated from the air at 850 DEG C. Preferably, the organic binder is asphaltene with softening point being greater than 100 DEG C. By using the raw material as a raw material for increasing quality of low-rank coal by the use of a tamping coke oven, the problem that present tamping coke ovens have low availability and excess capacity exists in the coking industry is solved, and the problem that application of low-rank coal is limited because there is no large-scale industrial equipment is also solved. After the auxiliary agent is mixed with low-rank coal, active ingredients in the auxiliary agent are beneficial to degradation of high-molecular polymers in the low-rank coal at high temperature and fracture of macromolecules in the low-rank coal. Thus, output of oil gas is raised during the technological process, and the total output of oil gas is increased by more than 10%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

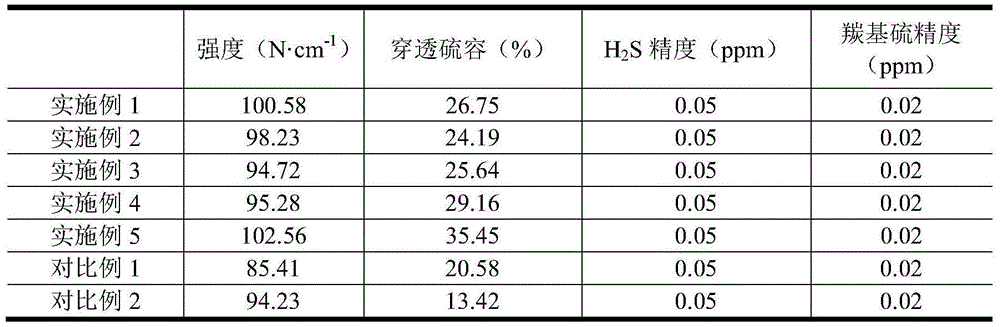

Desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time

ActiveCN104437074AHigh mechanical strengthEvenly distributedDispersed particle separationCarbonyl sulfideAccelerant

The invention discloses a desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time. The desulfurizing agent is prepared through the following steps that S1, a compound containing zinc, a binder and an accelerant are mixed, kneaded and formed; S2, a mixture formed after mixing, kneading and forming in the S1 is dried, and then a dried desulfurizing carrier precursor is obtained; S3, the desulfurizing carrier precursor obtained in the S2 is calcinated, and then a desulfurizing agent carrier is obtained; S4, the desulfurizing agent carrier is impregnated in a first copper salt solution, and copper active components are loaded on the desulfurizing agent carrier, wherein the first copper salt solution is an ammonium hydroxide solution of basic cupric carbonate; S5, an impregnated sample obtained in the S4 is dried and calcinated, and then the desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time is obtained. The obtained desulfurizing agent is high in strength and not prone to pulverization, the impregnation effect of the active components is better, and hydrogen sulfide and carbonyl sulfide impurities in a high-temperature industrial gas source can be efficiently removed at the same time.

Owner:SHENYANG SANJUKAITE CATALYST

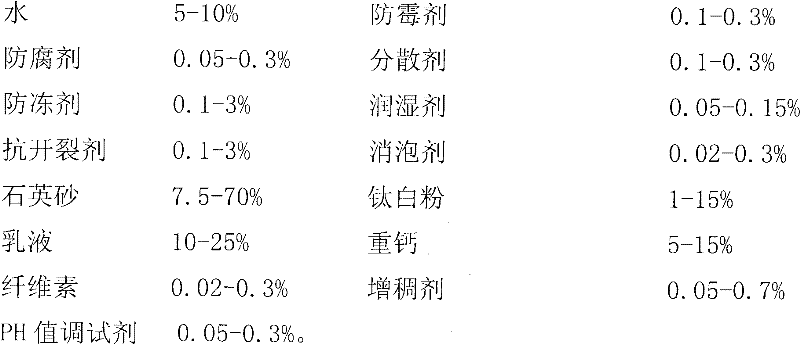

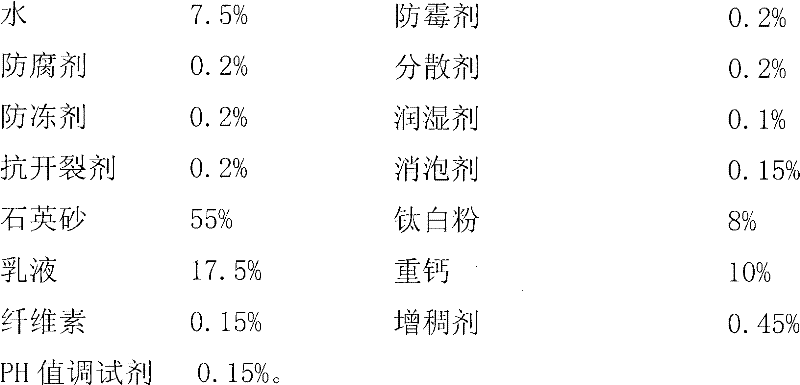

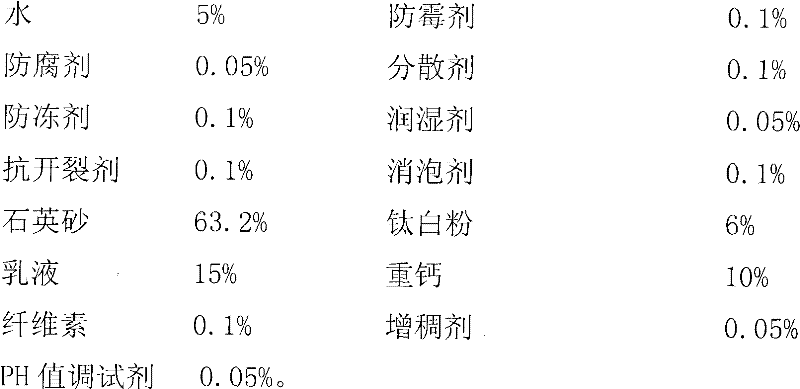

Special flexible texture coating for external heat insulating wall, and preparation method thereof

The invention discloses a special flexible texture coating for an external heat insulating wall. The coating is characterized by: 1) mixing water, an antimildew agent, a preservative, a dispersing agent, a wetting agent, a antifoaming agent, titanium pigment and calcium carbonate according to a mass ratio, followed by carrying out high speed dispersion to provide a spare use; 2) then mixing an emulsion, quartz sand and the antifoaming agent according to a mass ratio, followed by being added to the prepared mixed solution from the step 1), then carrying out medium-speed stirring; 3) mixing cellulose and the water according to a mass ratio, and carrying out stirring to prepare a mixed material of the cellulose to provide a spare use; 4) adding the mixture prepared through medium-speed stirring to the mixed material of the cellulose to carry out stirring, such that the mixed material of the cellulose can provide uniform thickening effect; 5) carrying out a color treatment for the finished product from the step 4). The coating provided by the present invention has characteristics of free of crack, high cohesional strength, effective prevention from coating deterioration, good water resistance, excellent penetration resistance, excellent flexibility. With the coating provided by the present invention, the fine cracks can be filled so as to prolong a service life of the external heat insulating wall and effectively protect buildings.

Owner:SHANDONG QINHENG TECH

Moulded coal raw material suitable for low rank coal upgrading technology

ActiveCN104479709ASolve the low utilizationImprove qualitySpecial form destructive distillationBriquetteCoal water

The invention provides a moulded coal raw material suitable for low rank coal upgrading technology, the moulded coal raw material includes a low rank coal moulded coal body formed by low rank coal and an additive, the additive is an organic binder, air isolation destructive distillation weight loss of the organic binder at 850 DEG C is less than 50%; the moulded coal raw material also includes a non low rank moulded coal layer externally coating the low rank coal moulded coal body, the non low rank moulded coal layer is prepared from one or a plurality of medium rank coal, high rank coal or medium-high rank coal, and the adding amount of the low rank coal is 60-80wt% of the moulded coal raw material. The moulded coal raw material not only solves the problems of low using degree of a stamped coke oven and excess production capacity of coking industry in the prior art, and solves the problems of restricted application due to no large-scale industrial equipment in view of the low rank coal, after the additive is mixed with the low rank coal, effective components in the additive contribute to degradation of polymer in low rank coal at high temperature and fracture of polymer in the low rank coal so as to improve the oil and gas yield in technical process.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Production process of ureaformaldehyde humic acid organic fertilizer

InactiveCN103204745ASolve the shortcomings of high moistureHigh granulation rateFertilizer mixturesHardnessOrganic fertilizer

The invention belongs to the technical field of production of compound fertilizers, relating to a production process of ureaformaldehyde humic acid organic fertilizer. The production process comprises the steps of activating and fermenting organic raw materials, preparing granulating base stock, granulating, processing granules, coating and the like, wherein humic acid and dung of cows and sheep containing straws are fermented together; the disadvantage that moisture in dung is high is solved; the balling rate is high since activated humic acid is used for granulating; the water content is low; coal consumption is low when the ureaformaldehyde humic acid organic fertilizer is dried; the temperature is low; beneficial microbial strains in the organic raw material are effectively preserved; the ureaformaldehyde humic acid organic fertilizer has ureaformaldehyde humic acid film-forming property and slow-release property; the ureaformaldehyde humic acid organic fertilizer produced by using the process disclosed by the invention has slow-release property and high hardness which is averagely 5-7N higher than that of the ordinary humic acid organic fertilizer, is hardly pulverized, and is low in production cost and strong in production continuity and operability.

Owner:付增传

Oxidative desulfurization process for continuous regeneration of desulfurizing agent

ActiveCN104548934AWide variety of sourcesImprove solubilityDispersed particle separationFixed bedProcess engineering

The invention discloses an oxidative desulfurization process for continuous regeneration of a desulfurization agent. The process is characterized by comprising the following steps: hydrogen sulfide-containing gas and oxygen-containing gas are in contact with the desulfurization agent at a desulfurization agent bed layer in a fixed bed reactor for oxidative desulfurization and desulfurization agent regeneration reaction, purified gas is discharged from the top of the reactor, catalytic cracking diesel is introduced in a reaction process for dissolving elemental sulfur generated in the regeneration reaction, and the catalytic cracking diesel in which elemental sulfur is dissolved flows out of the reactor and is subjected to solid-liquid separation for recycling. According to the process, the desulfurization precision is high, the desulfurization agent is long in service life, the operation is simple, and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of aluminum alloy electrophoresis wood grain profile

InactiveCN102031549AAvoid appearance defects of leaky bottomAvoid Cosmetic DefectsAnodisationDecorative surface effectsWeather resistanceElectrophoresis

The invention relates to a manufacturing method of an aluminum alloy electrophoresis wood grain profile, comprising the following multiple steps of: degreasing the conventional aluminium alloy base materials; washing; carrying out acid etch; washing; carrying out alkali etch; washing; neutralizing; washing; carrying out anodic oxidation; washing; washing by using pure water; carrying out electrolytic coloring; washing; washing by using the pure water; washing by using hot water; carrying out electrophoresis; washing; washing; dripping for drying; curing; and carrying out transfer printing on wood grains. The manufacturing method of the aluminum alloy electrophoresis wood grain profile is characterized in that the curing temperature of electrophoretic paint is 190-200 DEG C, and the curing time is 24-26 minutes; the transfer printing temperature is 185-190 DEG C, and the transfer printing time is 23-23.5 minutes, thus an aluminum alloy electrophoresis wood grain profile product is obtained. The aluminum alloy electrophoresis wood grain profile product has uniform coating, high adhesive force and good coverage, thereby preventing the appearance defects caused by the bottom leakage of a powder coating; and in addition, the invention has the advantages of high glossiness, brilliant and beautiful color, wonderful feeling of color change and diversity, high corrosion resistant capacity, good weather resistance and difficulty of chalking or fading.

Owner:JILIN LIYUAN REFINED

Ultra-light-weight foam concrete and manufacturing method of same

InactiveCN102863193AReduce dry densityLow thermal conductivityCeramicwareFoam concreteThermal insulation

The invention relates to an ultra-light-weight foam concrete and a manufacturing method of the same. The manufacturing method comprises the following steps of: slowing stirring water, a cementing material, a water reducer and basalt fiber at a speed of 120rpm for 2 minutes after being mixed uniformly, quickly stirring the water, the cementing material, the water reducer and the basalt fiber at a speed of 240rpm for 2 minutes, mixing foam and cement paste, adding hydroxyethyl methyl cellulose into the mixture, stirring the mixture at a speed of 120rpm for 2 minutes to obtain paste, pouring the paste into a mould, putting the paste into a curing chamber for standard curing after being demoulded, and standing the paste for 28 days to obtain the ultra-light-weight foam concrete. Compared with the prior art, the ultra-light-weight foam concrete provided by the invention has the advantages of small dry density, low thermal conductivity and high compressive strength, can be made into a sheet material with a fire rating A and applied in an external thermal insulation system, and has the advantages of short curing time and no easy for surface pulverization.

Owner:WUHAN UNIV OF TECH

Coking process raw materials

The present invention provides coking process raw materials, which comprise low-rank coal and an auxiliary agent, wherein the auxiliary agent is an organic binder with air isolated dry distillation weightlessness of less than 50% at a temperature of 850 DEG C, and preferably the organic binder is asphaltene with a softening point of more than 100 DEG C. According to the present invention, with the raw materials, the problems of low existing stamp-charging coke oven utilization rate and excess coking industry production capacity are solved, and the problem that the application of the low-rank coal is limited due to no large-scale industrial equipment is solved; and after the auxiliary agent and the low-rank coal are mixed, the degradation of the macromolecule polymer in the low-rank coal at the high temperature and the breaking of the macromolecule in the low-rank coal are easily achieved through the effective components in the auxiliary agent so as to improve the oil gas yield during the process, wherein the total amount of the oil gas is increased by more than or equal to 10%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Coking process containing low-rank coal

ActiveCN104263395ASolve application limitationsSolve the low utilizationSpecial form destructive distillationIndustrial equipmentCoke oven

The invention discloses a coking process containing low-rank coal. The coking process comprises the following steps: (1) crushing low-rank coal, and mixing with an auxiliary agent to form a low-rank coal raw material; (2) firstly performing pressure forming on one or more of crushed middle-rank coal, high-rank coal or intermediate-high-rank coal to form a non-low-rank-coal type coal bed; and adding the low-rank coal raw material on the non-low-rank-coal type coal bed, and continuously performing pressure forming on the low-rank coal raw material to form a low-rank coal type coal bed which is positioned on the non-low-rank-coal type coal bed so as to form a final molded coal raw material; and (3) pushing the molded coal raw material into a coke oven for coking, wherein the weight loss of the auxiliary agent caused by destructive distillation in isolating air at 850 DEG C is less than that of 50% of an organic binding agent. By adopting the coking process containing the low-rank coal disclosed by the invention, the problems of low availability of an existing tamping coke oven and excess capacity in the coking industry can be solved, and the problem that the application of the low-rank coal is limited because no large-scale industrial equipment is provided also can be solved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Load type manganese and copper series deoxidizer and preparation method and application thereof

ActiveCN101703919AMaintain deoxidation performanceHigh mechanical strengthOther chemical processesAluminium silicatesHigh concentrationIon exchange

The invention discloses a preparation method and application of a load type manganese and copper series deoxidizer. The load type manganese and copper series deoxidizer comprises a carrier and an active compound oxide, wherein the carrier is alumina and X-type or Y-type molecular sieves; the active compound oxide comprises a copper oxide, a manganese oxide and a metal assistant oxide; the spherical alumina carrier can be directly soaked with a mixed solution of an active component to obtain the strip-shaped deoxidizer; and the powder of the X-type or Y-type molecular sieve needs to carry out ion exchange firstly and then is kneaded with the mixed solution of the active component and a binding agent, extruded into strips and roasted to obtain the formed strip-shaped deoxidizer. The formed strip-shaped deoxidizer needs to be reduced and activated at certain temperature when in use, can not only remove the tiny oxygen contained in inert atmosphere, but also continuously remove the tiny oxygen contained in higher-concentration to high-purity carbonic oxide, and has high mechanical strength, difficult pulverization in the using process and difficult temperature runaway of pretreatment reduction.

Owner:BEIJING PEKING UNIV PIONEER TECH

Method for preparing cyclohexane by hydrogenating benzene

ActiveCN102408297AHigh mechanical strengthNot easy to loseOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrogenationSilanesCarbon deposit

The invention relates to a method for preparing cyclohexane by hydrogenating benzene. According to the requirements of adaptability to water content fluctuation of a reaction system and inhibition of carbon deposit in the process of hydrogenating the benzene at present, hydrogen / benzene mixed gas in a certain molar ratio is introduced into a reactor and contacted with a benzene hydrogenation catalyst to prepare the cyclohexane at the inlet temperature of between 100 and 320 DEG C under the reaction pressure of 0.1 to 4.0MPa, wherein the hydrogenation catalyst comprises a carrier, metal active ingredients and a silane group which is grafted by silylation and accounts for 0.1 to 15 weight percent of the catalyst. Compared with the prior art, the method has the advantages that: the method is high in raw material applicability on the premise of ensuring that the benzene hydrogenation catalyst has high activity and selectivity, and the catalytic performance of the benzene hydrogenation catalyst is almost not influenced by trace water; meanwhile, the carbon deposit on the surface of the catalyst can be obviously inhibited, the service life of the catalyst is prolonged, and the catalyst has a long stable operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Porous honeycomb type denitration catalyst for ship denitration, preparation method and application thereof

InactiveCN104815644AHigh compressive strengthNot easy to pulverizeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHydroxypropylmethyl celluloseIon

The invention provides a porous honeycomb type denitration catalyst for ship denitration, a preparation method and application thereof. The preparation method includes mixing, aging, drying and roasting steps. The mixing step includes adding titanium dioxide, stearic acid, deionized water, ammonia water, lactic acid, glass fiber, short fiber and ammonium metavanadate, an ammonium metatungstate solution, hydroxypropyl methyl cellulose and polyethylene oxide into a mixing roll to conduct high speed mixing for over 7 hours. The catalyst provided by the invention can meet the demands of marine high power diesel engine exhaust gas denitration. The denitration catalyst prepared by the catalyst preparation method provided by the invention has the advantages of high compression strength, difficult pulverization, long service life, easy molding and demoulding in the making process, ideal porosity, high catalytic efficiency, low catalyst dosage, and low cost, etc.

Owner:NANTONG YATAI ENG TECH

Method for removing phenylacetylene in presence of styrene

ActiveCN102408299AReduce generationExtended service lifeHydrocarbon purification/separationCatalyst activation/preparationHydrocarbon mixturesSilanes

The invention relates to a method for removing phenylacetylene in the presence of styrene. According to the requirements of adaptability to water or water content fluctuation of a reaction system and inhibition of carbon deposit in the selective hydrogenation process of the phenylacetylene at present, a hydrogen / phenylacetylene hydrocarbon mixture in a certain molar ratio is introduced into a reactor and contacted with a hydrogenation catalyst to remove the phenylacetylene at the inlet temperature of between 10 and 120 DEG C under the pressure of 0.1 to 4.0MPa, wherein the hydrogenation catalyst comprises a carrier, metal active ingredients and a silane group which is grafted by silylation and accounts for 0.1 to 15 weight percent of the catalyst. Compared with the prior art, the method has the advantages that: the method is high in raw material applicability on the premise of ensuring that the catalyst in the method has high activity and selectivity, and the catalytic performance of the selective hydrogenation catalyst is almost not influenced by trace water; meanwhile, the carbon deposit on the surface of the catalyst can be obviously inhibited, the service life of the catalyst is prolonged, and the catalyst has a long stable operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of poisoning-resistant catalyst for unsaturated oil hydrogenation

ActiveCN102513114AHigh strengthStable physical parametersFatty acid hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltHydrogen

The invention discloses a preparation method of a poisoning-resistant catalyst for unsaturated oil hydrogenation. The preparation method is characterized by comprising the following steps of 1, putting an alkaline precipitator solution into a reactor, and heating to a temperature of 60 to 70 DEG C, 2, adding a mixed solution of a soluble nickel salt, a ferric salt and a rare earth salt into the heated alkaline precipitator solution with stirring in a period of 1 to 2 hours, 3, then fast adding alumina carriers into the mixed solution obtained by the steps 2, stirring for 0.5 to 1 hour, filtering, and washing by deionized water until acid radical ions are removed completely, and 4, drying at a temperature of 110 to 120 DEG C for 4 to 5 hours, crushing, and carrying out hydrogen feeding at a temperature of 400 to 500 DEG C for 2 to 3 hours to obtain the poisoning-resistant catalyst for unsaturated oil hydrogenation, wherein an Ni / Fe atomic ratio of the soluble nickel salt to the ferric salt is in a range of 5 to 25 and the poisoning-resistant catalyst for unsaturated oil hydrogenation contains 30 to 50 wt% of nickel, 2 to 5 wt% of iron, 0.5 to 1.0 wt% of a rare earth salt of cerium and 0.5 to 1.0 wt% of a rare earth salt of lanthanum.

Owner:CHINA NAT OFFSHORE OIL CORP +1

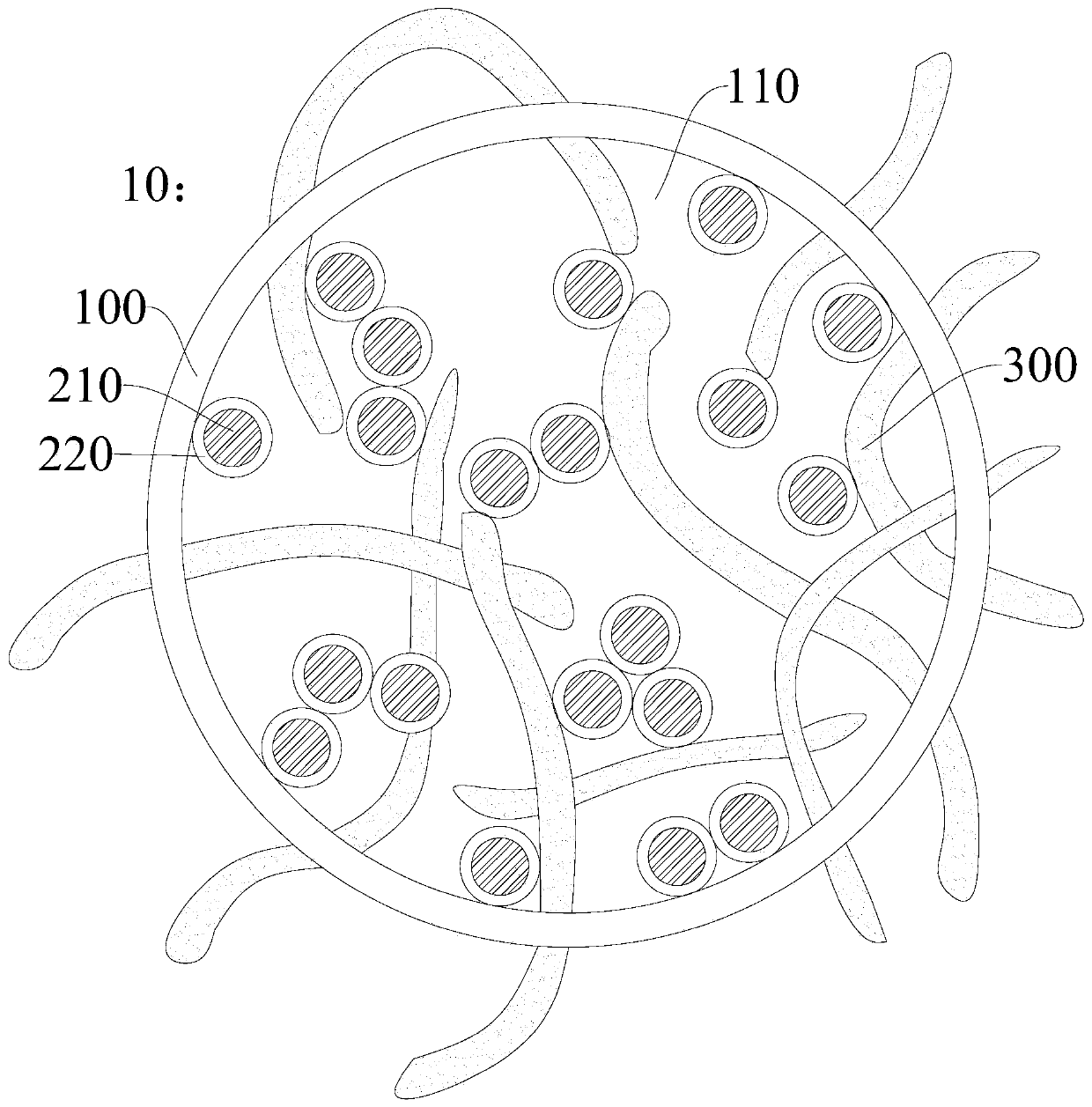

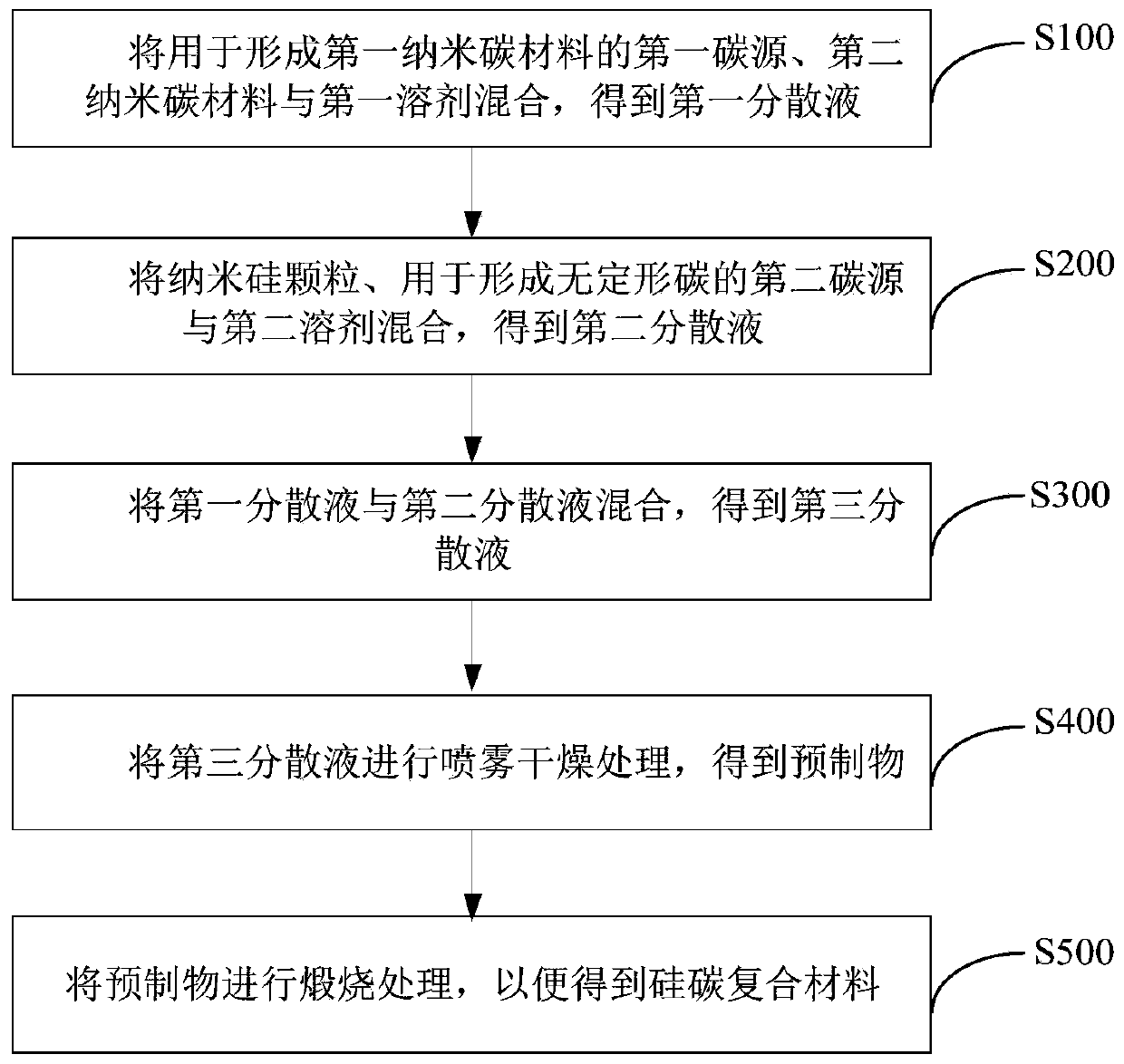

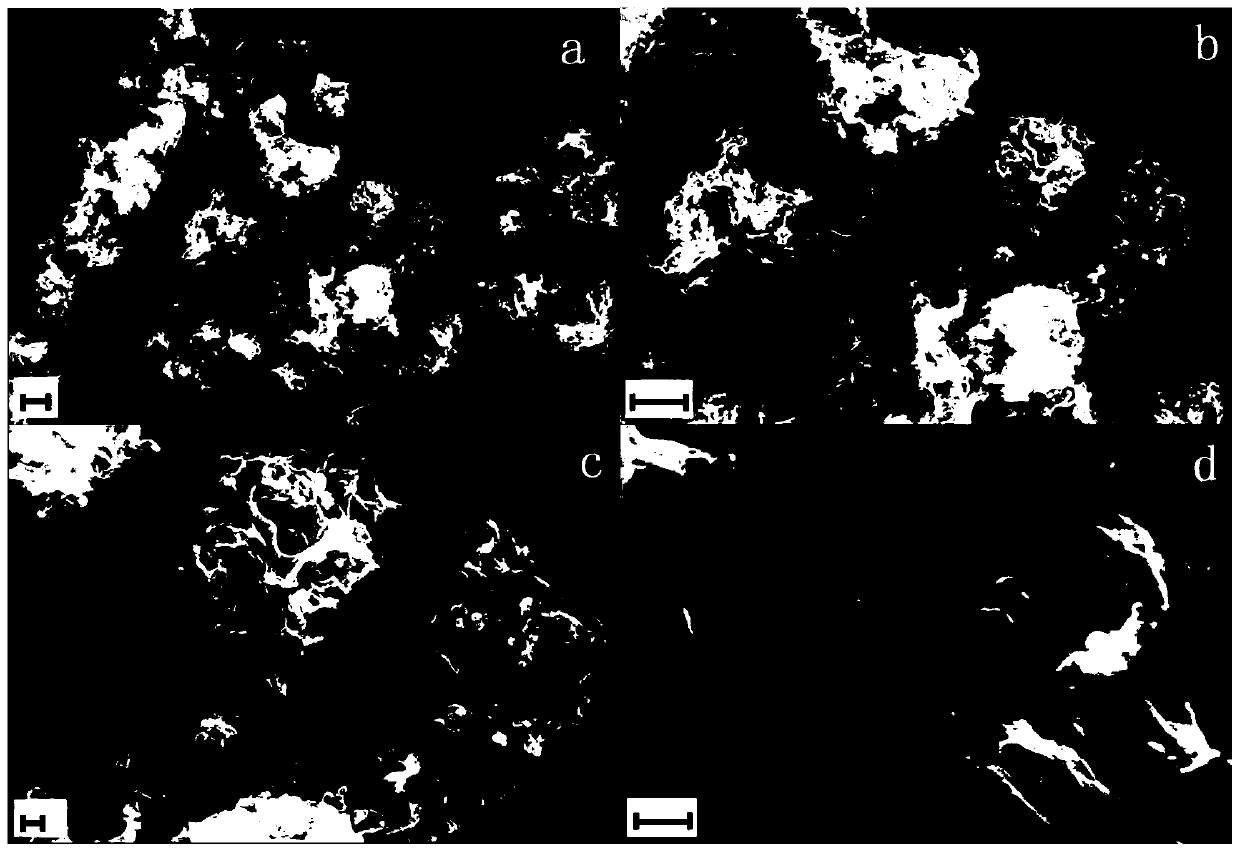

Silicon-carbon composite material, preparation method thereof, negative electrode, power battery and electric automobile

InactiveCN110148732AImprove conductivityIncrease capacityMaterial nanotechnologyCharging stationsCarbon compositesMicrosphere

The invention provides a silicon-carbon composite material, a preparation method thereof, a negative electrode, a power battery and an electric automobile. The silicon-carbon composite material comprises a housing layer, core-shell microspheres and a second nano-carbon material, wherein the material of the housing layer includes a first nano-carbon material, and an accommodating space is defined inside the housing layer; each core-shell structure microsphere is located in the accommodating space and provided with a core and a shell layer, the shell layer coats the core, the core includes nano-silicon particles, and the shell layer includes amorphous carbon; and the second nano-carbon material is linear, one part of the second nano-carbon material is located in the accommodating space, andthe other part of the second nano-carbon material is arranged in the first nano-carbon material in a penetrating manner. The silicon-carbon composite material can be used as a negative electrode material of the power battery, has the advantages of good conductivity, high capacity, good rate performance, and is not easy to expand or be powdered, high in stability and good in cycle performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Lightweight plastering gypsum and preparation method thereof

The invention discloses lightweight plastering gypsum. The lightweight plastering gypsum comprises the following raw materials by weight: 450-550kg of ardealite, 400-500kg of heavy calcium, 45-55kg ofglass bead, 0.2-0.4kg of PE gypsum retarder, 1-3kg of cellulose H620 and 0.2-0.4kg of starch ether. Compared with the prior art, the lightweight plastering gypsum disclosed by the invention has the beneficial technical effects that the lightweight plastering gypsum has the advantages of durability, large binding strength, difficult powdering, no cracking, no hollowing and no powder fall and the like, the use in the building industry can be better met and the service life is prolonged.

Owner:贵州砂浆博士科技有限公司

Antichlor and preparation method thereof

ActiveCN106861386ARaise the ratioEvenly dispersedGas treatmentDispersed particle separationAlkaline earth metalOrganic chloride compound

The invention discloses an antichlor and a preparation method thereof. The antichlor uses a composite oxide as a carrier to be loaded with oxides of alkali metal and / or alkaline earth; the composite oxide carrier contains theta aluminum oxide and calcium oxide. The composite oxide carrier is prepared by a coprecipitation method; calcium oxide is introduced into a carrier framework structure; the breakthrough chlorine content can reach 17.6 percent at the normal temperature. Through high-temperature roasting, the prepared aluminum oxide with the theta material phase structure reduces the surface hydroxyl quantity; the physical adsorption of HCl on the antichlor is reduced to the maximum degree; the phenomenon of antichlor surface acidity enhancement due to HCl physical adsorption concentration is reduced, so that the phenomenon of green oil generation through olefin polymerization due to acid catalysis is reduced; the phenomenon of organic chloride generation through reaction of olefin and HCl due to acid catalysis can be avoided. In addition, through the prepared composite oxide carrier, the intensity of the antichlor is obviously improved; the agglomeration or pulverization phenomenon under the water-containing steam work condition can be eliminated.

Owner:WANHUA CHEM GRP CO LTD

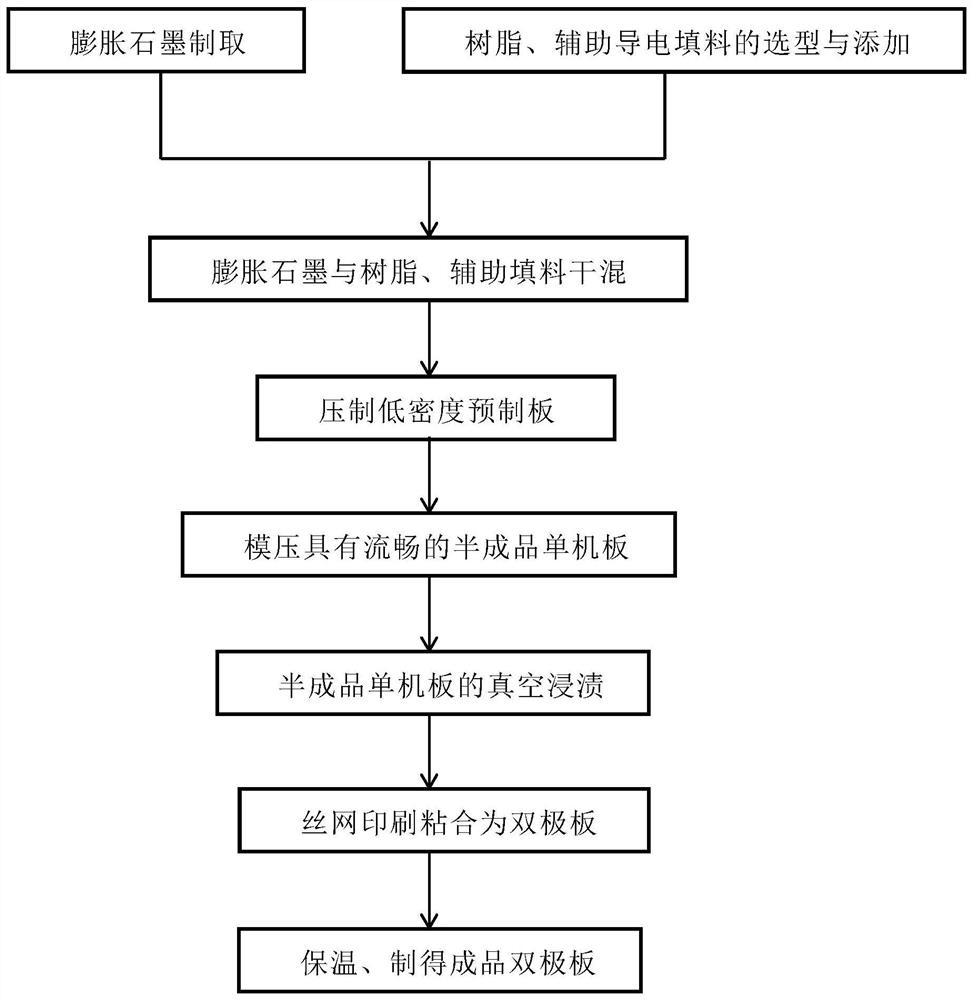

Preparation method of composite graphite bipolar plate

PendingCN112290040AReduce manufacturing costEase of mass productionFinal product manufactureFlat articlesCompression moldingScreen printing

The invention discloses a preparation method of a composite graphite bipolar plate. The preparation method comprises the following steps: by using graphite ore as a raw material, preparing expanded graphite at high temperature; mixing resin with an auxiliary conductive filler to obtain a first mixture; performing dry mixing on the expanded graphite and the first mixture to obtain a second mixture,and pressing the second mixture into a low-density prefabricated slab; carrying out mould pressing on the low-density prefabricated slab, and pressing a flow field on the upper surface or the upper and lower surfaces to manufacture a semi-finished monopole plate comprising a hydrogen flow field monopole plate and an oxygen flow field monopole plate; carrying out vacuum impregnation on the semi-finished monopole plate; and bonding the hydrogen flow field monopole plate and the oxygen flow field monopole plate by using a silk-screen printing technology through a bonding agent (mould pressing) to form a bipolar plate, and heating and curing to obtain the composite graphite bipolar plate. A compression molding process is adopted, so that the preparation method is more suitable for batch production, shortens the processing period and reduces the production cost; and the composite graphite bipolar plate is excellent in various performance indexes such as conductivity, density, air tightness, mechanical lightness and corrosion resistance.

Owner:JIANGSU QINGNENG NEW ENERGY TECHNOLOGIES CO LTD +1

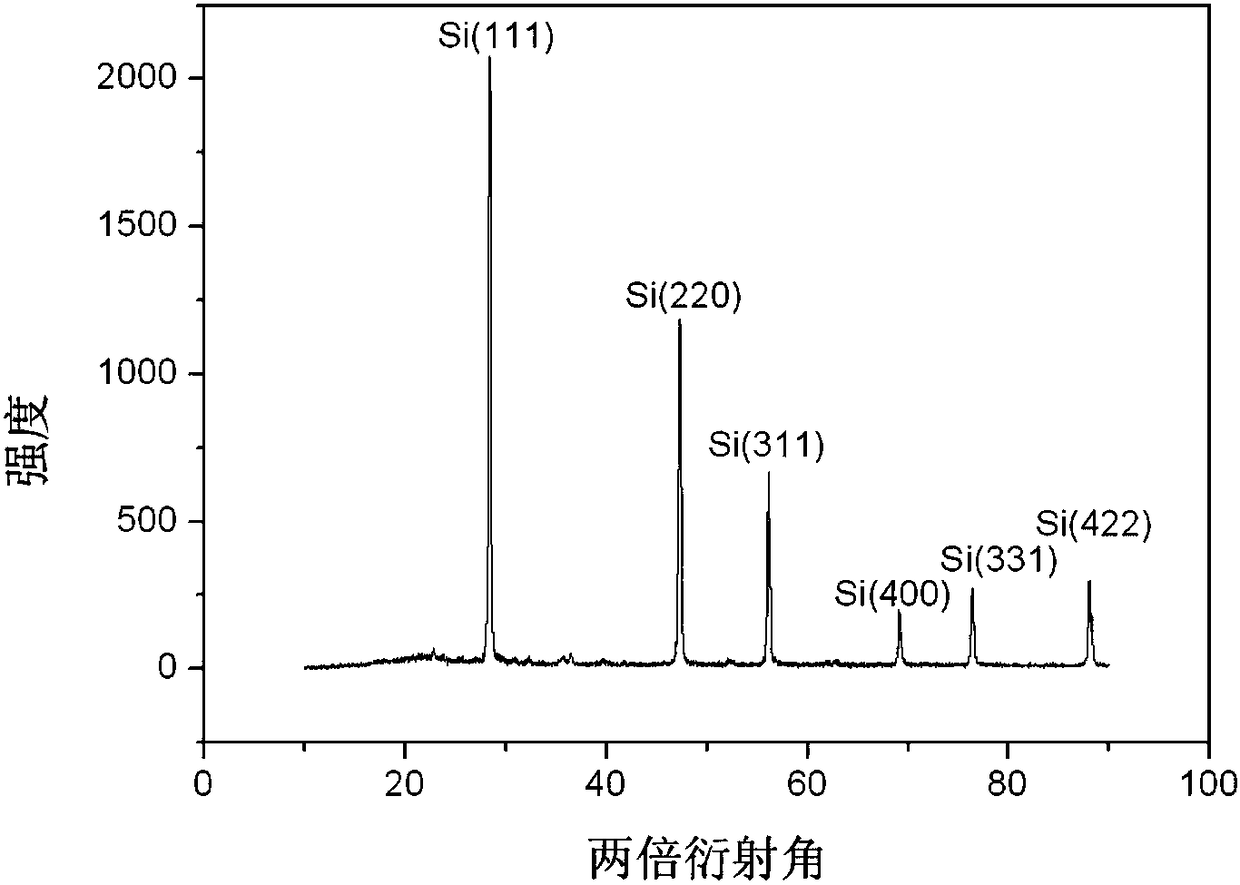

Negative pole active material for silicon-based lithium ion battery and preparation and application thereof

ActiveCN108615854AImprove conductivityNot easy to pulverizeCell electrodesSecondary cellsPolypyrrolePorous silicon

The invention provides a negative pole active material for a silicon-based lithium ion battery and preparation and application thereof. The negative pole active material of the silicon-based lithium ion battery comprises porous reduced graphite oxide and a porous silicon material coated with conductive polymerization attached to the pores of the porous reduced graphite oxide; the porous reduced graphite oxide has a pore diameter of 50 nanometres-2 micrometers; a conductive polymer coating layer has a thickness of 50 nanometres-200 micrometers; the porous silicon has a pore diameter of 100 nanometres-300 nanometres. The conductive polymer is one or more of polyaniline, polypyrrole and polythiophene. When the material is applied to a negative pole of the lithium ion battery, the material hasthe significant advantages of difficult pulverization, good stability, a large number of cycles and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Al-Ca-Mg-Fe alloy for final deoxidisation of molten steel and its preparation

An AlGaMgFe alloy for final deoxidization of molten steel contains Al (30-60%), Ca (2-15%), Mg (2-15%), Si (0-3%) and Fe (rest) and is prepared through proportionally mixing silica rock, lime, coke and iron filings, smelting to obtain low-Si ferrocalcium, adding Al, Mg and Fe, and smelting. It can improve the mechanical performance of steel and prevent the sprute from being blocked, and has desulfurizing effect.

Owner:郭庆成

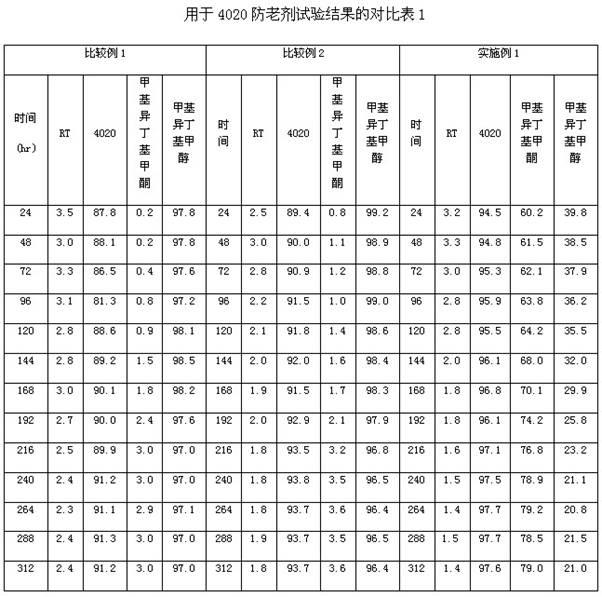

Modified condensation reduction alkylation catalyst

InactiveCN102319568AHigh strengthNot easy to pulverizeOrganic compound preparationAmino compound preparationKetoneSulfide

The invention belongs to the technical field of catalysts, and discloses a modified condensation reduction alkylation catalyst used in preparation of a rubber anti-aging agent 4020 by undergoing a hydrogenated reduction alkylation reaction on 4-aminodiphenylamine and methyl isobutyl ketone and preparation of a rubber anti-aging agent 4010NA by undergoing a hydrogenated reduction alkylation reaction on 4-aminodiphenylamine and acetone. The catalyst is a copper-series catalyst, and is mainly characterized in that: the catalyst contains a silicon element; and the molar ratio of copper to silicon is (0.5-10):1. Due to the adoption of the catalyst, a side reaction of ketone hydrogenation for generating an alcohol in the reacting process is suppressed remarkably, raw materials are saved, products 4010NA and 4020 are not required to be passivated by using 4-amino diphenylamine produced by reducing alkali sulfide at an earlier using stage, and unqualified products are avoided; and the catalyst has high intensity and long service life, and is not pulverized easily in the using process.

Owner:郝云青

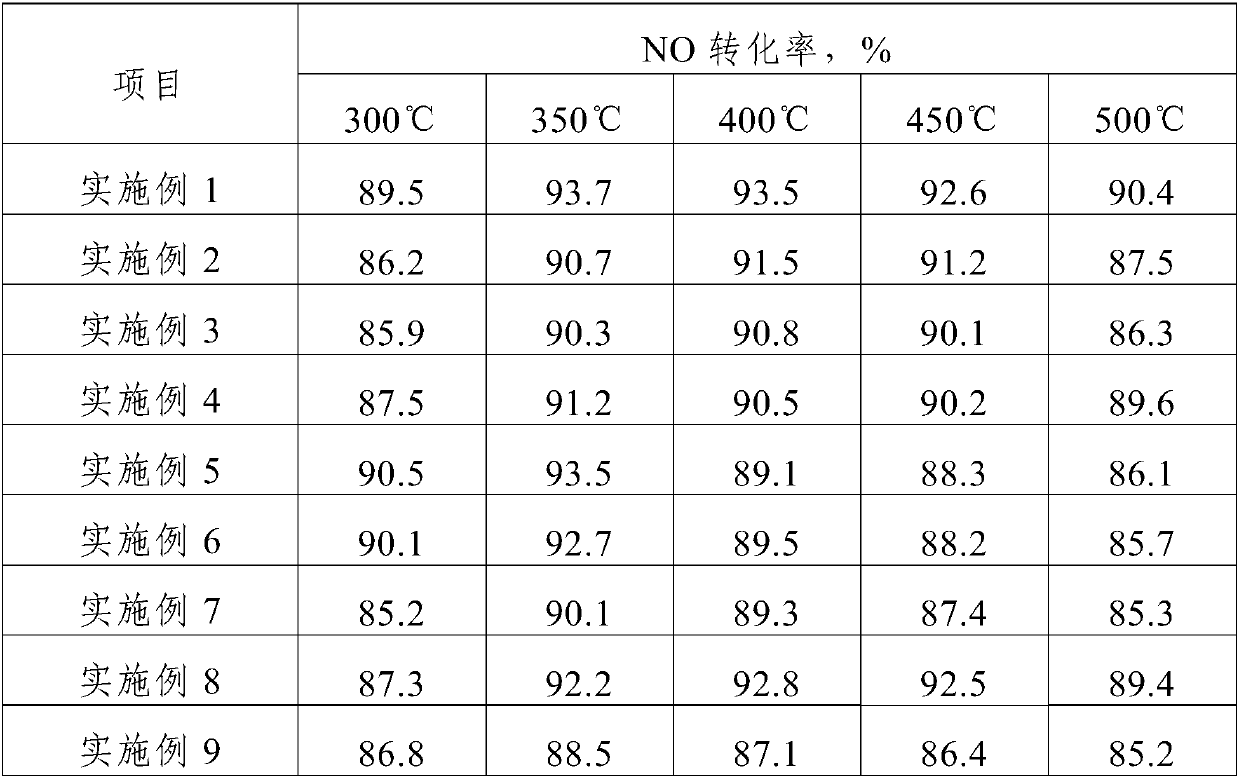

Preparation method of supported medium and high temperature denitration catalyst

InactiveCN107754849ANot easy to pulverizeExtended service lifeMolecular sieve catalystsDispersed particle separationMolecular sieveHot Temperature

The invention discloses a preparation method of a supported medium and high temperature denitration catalyst. The method comprises the following steps: 1, dissolving a soluble active metal component precursor salt and a soluble auxiliary metal component precursor salt into deionized water to obtain a transparent impregnation solution; 2, impregnating a molecular sieve carrier for 6h-24h, filtering, drying at temperature of 80-120 DEG C for 12h-24h to obtain a catalyst precursor; 3, putting the catalyst precursor in a heat treatment furnace, heating to 300 DEG C-400 DEG C, calcining while introduction of air for 1h-3h, heating up to 600-800 DEG C, calcining for 2h-6h, and cooling to obtain the supported medium and high temperature catalyst. The supported medium and high temperature denitration catalyst prepared by the method has high strength, is not easy to pulverize, has long service life, and has low catalyst bulk density. The catalyst has a NO conversion rate of 85% or more at a suitable application temperature of 300 to 500 DEG C.

Owner:XIAN ORIGIN CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com