Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Oil generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil generation requires productive source beds of high organic carbon content. This source bed will be able to generate petroleum over a long period of time in which the beds are exposed to 3 stages of transformation: diagenesis, metagenesis, and catagenesis.

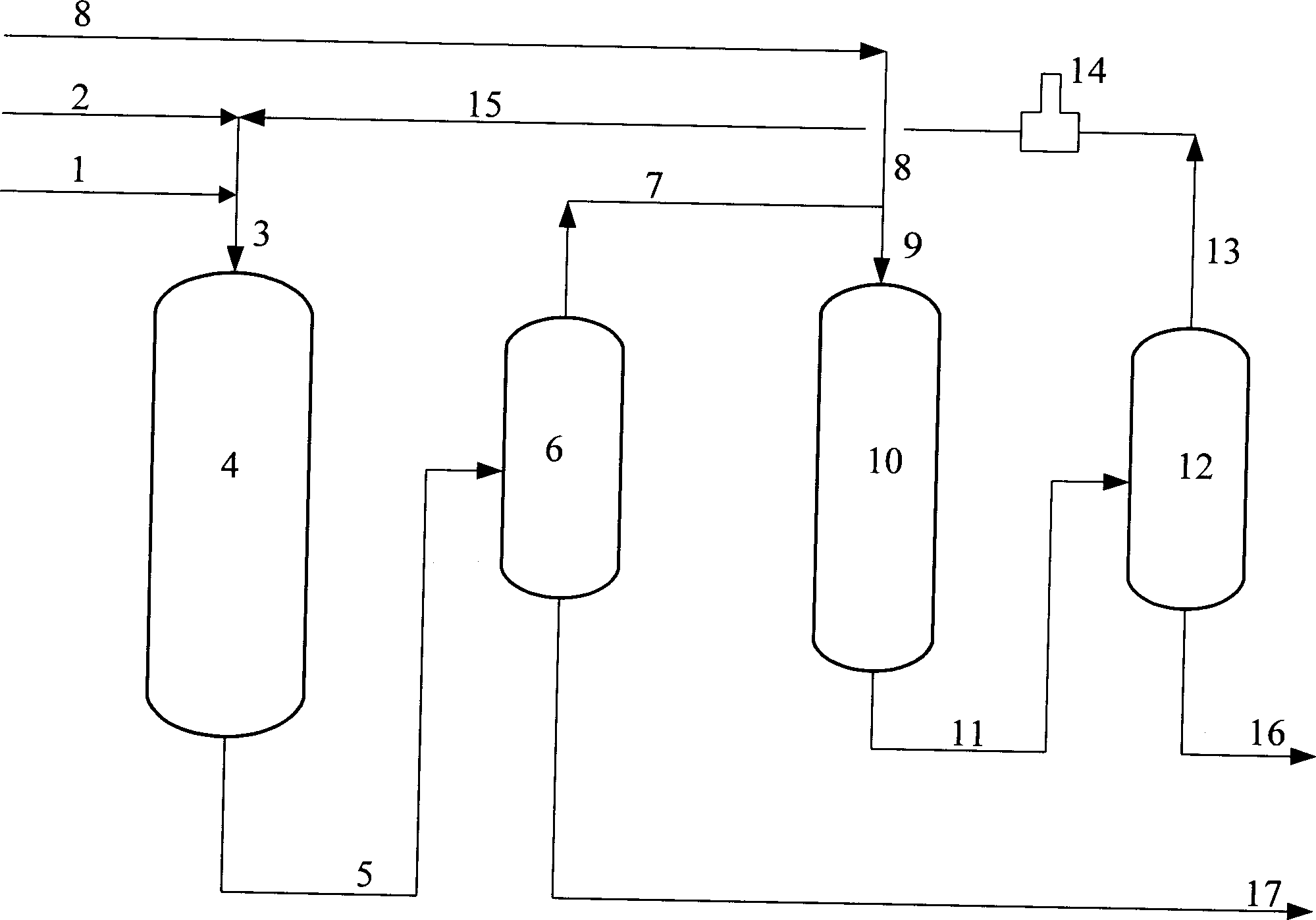

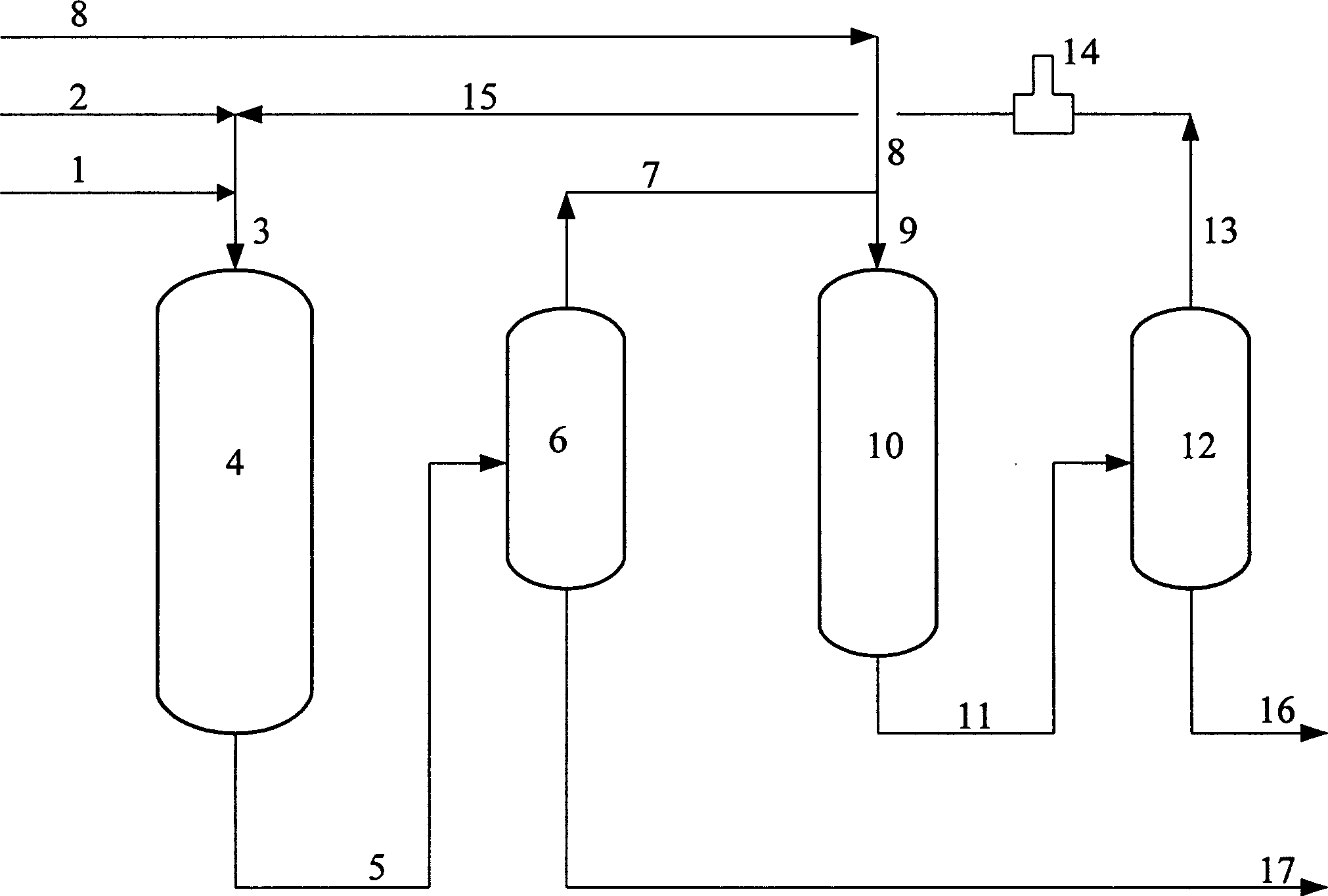

Method for reducing aromatic content of diesel oil in residual hydrogenation equipment

InactiveCN1400285AAchieve desulfurizationLow aromatic contentRefining by aromatic hydrocarbon hydrogenationHydrogenGas phase

The method for reducing aromatic hydrocarbon content in diesel oil in residual hydrogenation equipment is characterized by that the residual oil and hydrogen gas are fed into residual catalytic hydrogenation reactor, and the material flow obtained after reaction is fed into thermal high-pressure separator and separated into gas phase material flow and hydrogenated residuel oil, and gas phase material flow is mixed with diesel oil raw material, and fed into diesel oil catalytic hydrogenation reactor, and the reaction material flow is fed into cold high-pressure separator, and separated into gas and refined diesel oil generation oil, the gas is cleaned, pressurized and returned into residual hydrogenation reactor for circular use, and the refined diesel oil generation oil can be separated to obtain the diesel oil product whose aroamtic hydrocarbon content can be reduced by above 60%.

Owner:CHINA PETROLEUM & CHEM CORP +1

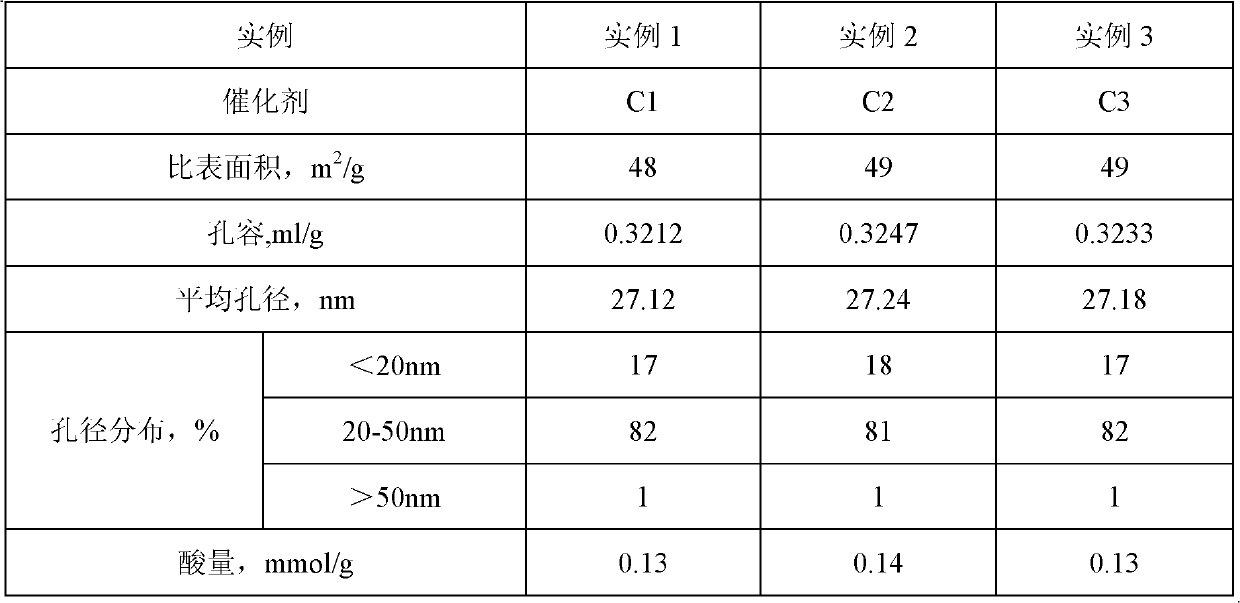

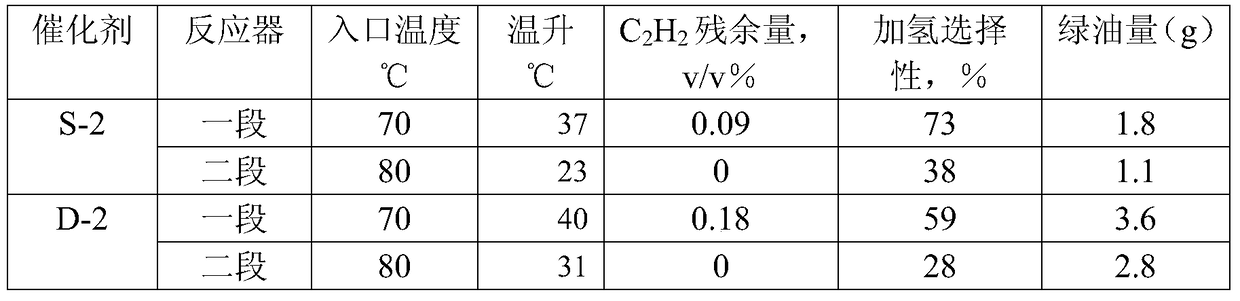

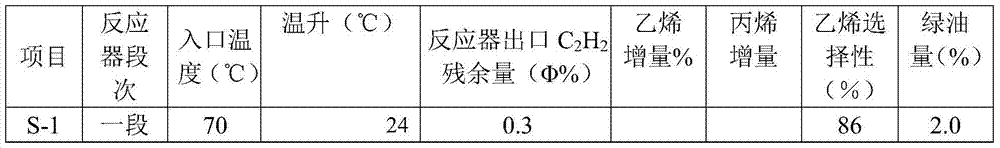

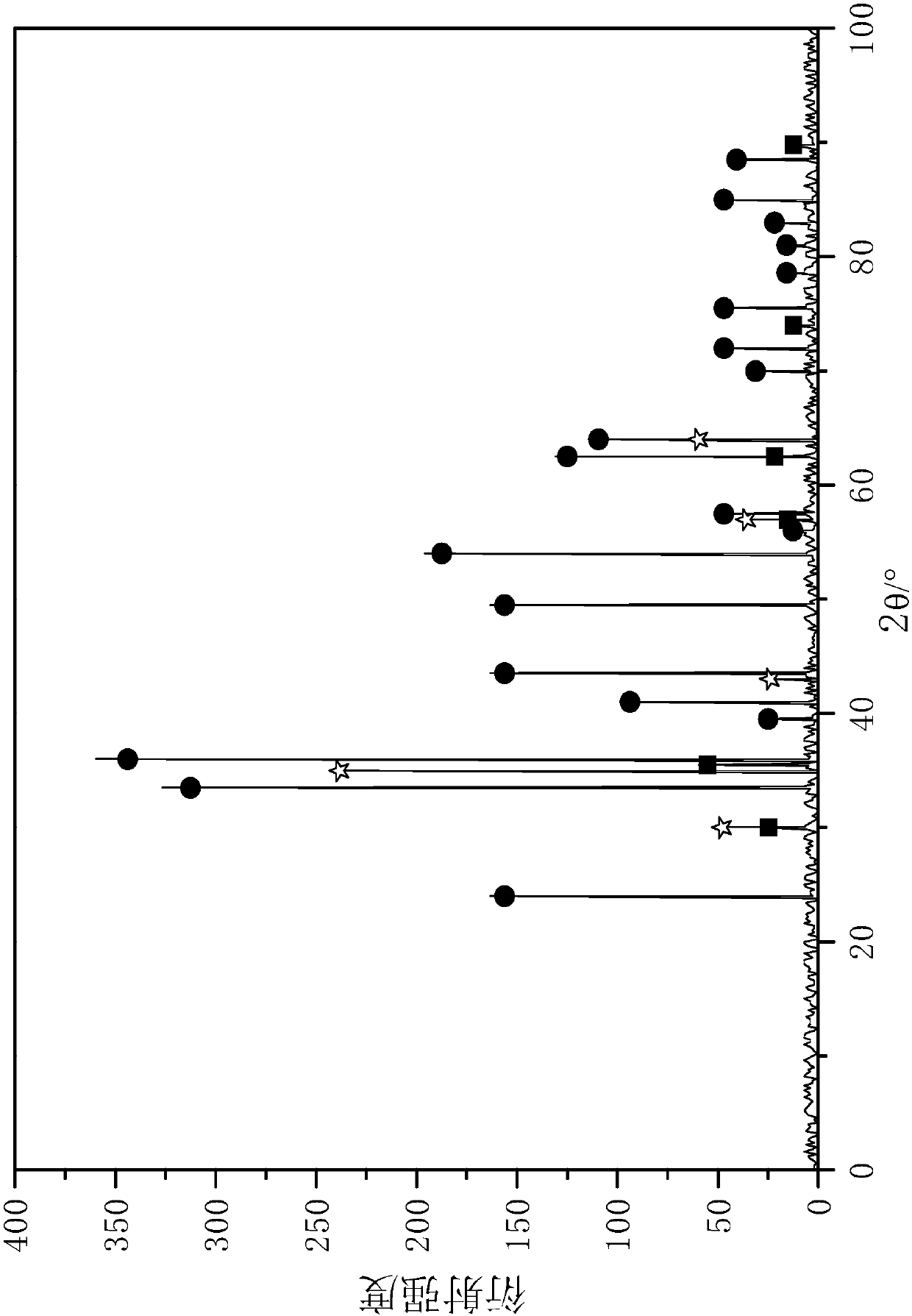

Preparation method of catalyst for selective hydrogenation of alkyne and alkadiene

InactiveCN103372432AGenerate good effectReduce churnHydrocarbon purification/separationHydrocarbonsAlkaline earth metalCerium

The invention relates to a preparation method of a catalyst for the selective hydrogenation of alkyne and alkadiene. A carrier of the catalyst is a compound of 30-99% of aluminum oxide, 1-50% of titanium oxide, 1-30% of magnetism oxide and 1-40% of zinc oxide based on the weight of the carrier of the catalyst as 100%; meanwhile, an alcohol reagent and an alkali metal or an alkaline-earth metal are used as modifying reagents; the preparation method is an acidity sol mixed kneading molding method; the active components of the catalyst comprise three or more of palladium, gold, silver, bismuth, cerium, lanthanum, tin and antimony, and a loaded solution of the active components is subjected to polymerization; the carrier of the catalyst prepared by the method has relatively low acid content; and the prepared catalyst shows up relatively appropriate reaction activity in the selective hydrogenation reaction of the alkyne and the alkadiene and has relatively good hydrogenation selectivity, relatively strong green oil generation resistance and relatively low palladium wastage rate.

Owner:PETROCHINA CO LTD

Antichlor and preparation method thereof

ActiveCN106861386ARaise the ratioEvenly dispersedGas treatmentDispersed particle separationAlkaline earth metalOrganic chloride compound

The invention discloses an antichlor and a preparation method thereof. The antichlor uses a composite oxide as a carrier to be loaded with oxides of alkali metal and / or alkaline earth; the composite oxide carrier contains theta aluminum oxide and calcium oxide. The composite oxide carrier is prepared by a coprecipitation method; calcium oxide is introduced into a carrier framework structure; the breakthrough chlorine content can reach 17.6 percent at the normal temperature. Through high-temperature roasting, the prepared aluminum oxide with the theta material phase structure reduces the surface hydroxyl quantity; the physical adsorption of HCl on the antichlor is reduced to the maximum degree; the phenomenon of antichlor surface acidity enhancement due to HCl physical adsorption concentration is reduced, so that the phenomenon of green oil generation through olefin polymerization due to acid catalysis is reduced; the phenomenon of organic chloride generation through reaction of olefin and HCl due to acid catalysis can be avoided. In addition, through the prepared composite oxide carrier, the intensity of the antichlor is obviously improved; the agglomeration or pulverization phenomenon under the water-containing steam work condition can be eliminated.

Owner:WANHUA CHEM GRP CO LTD

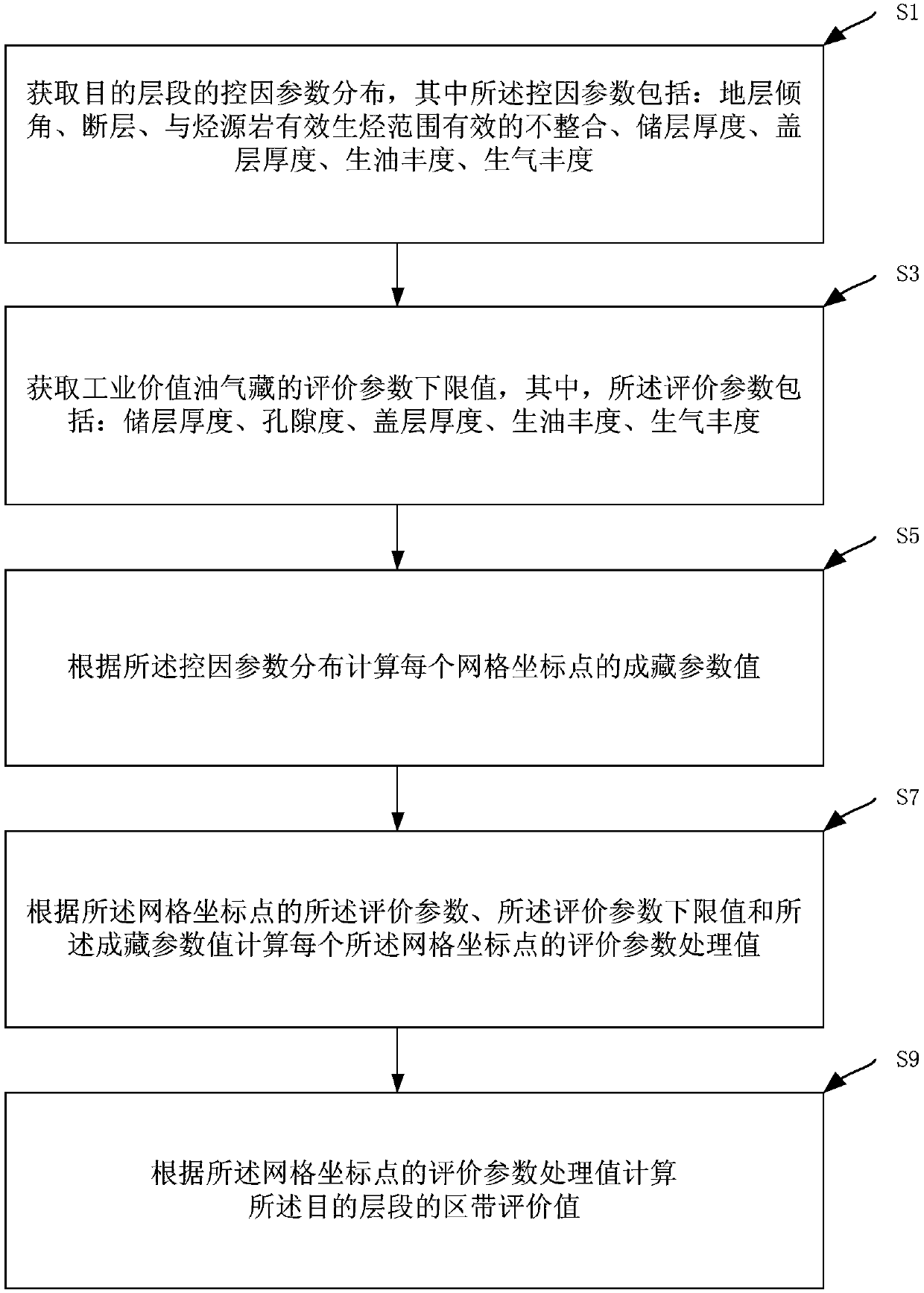

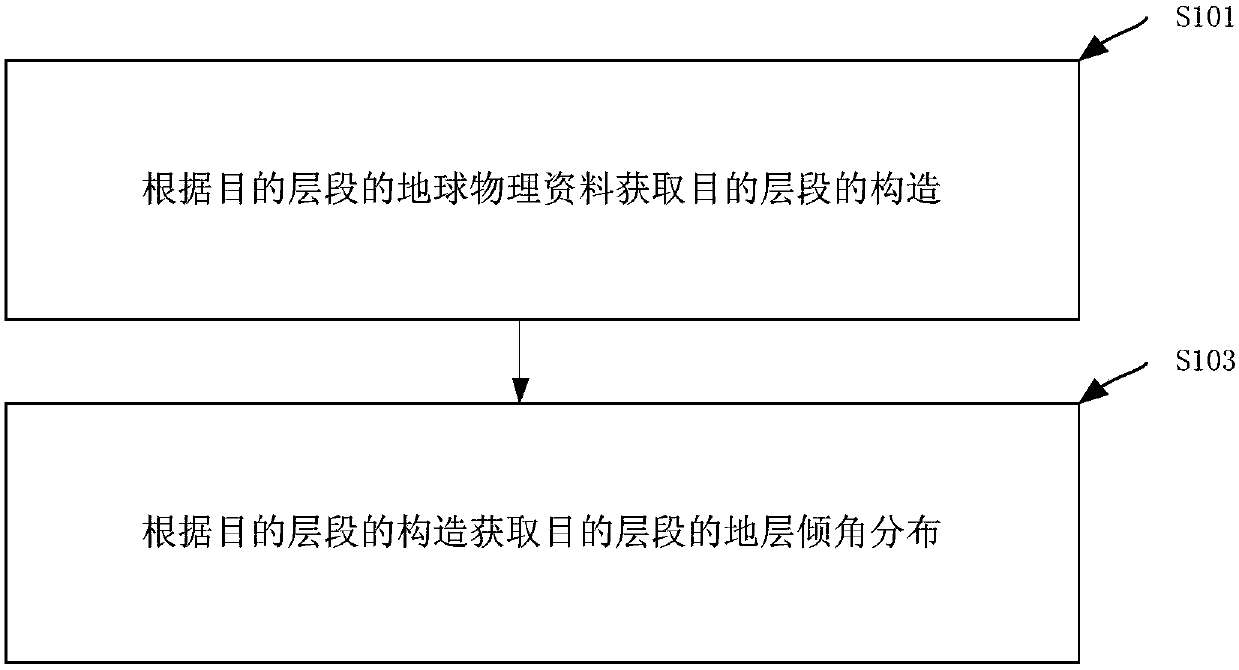

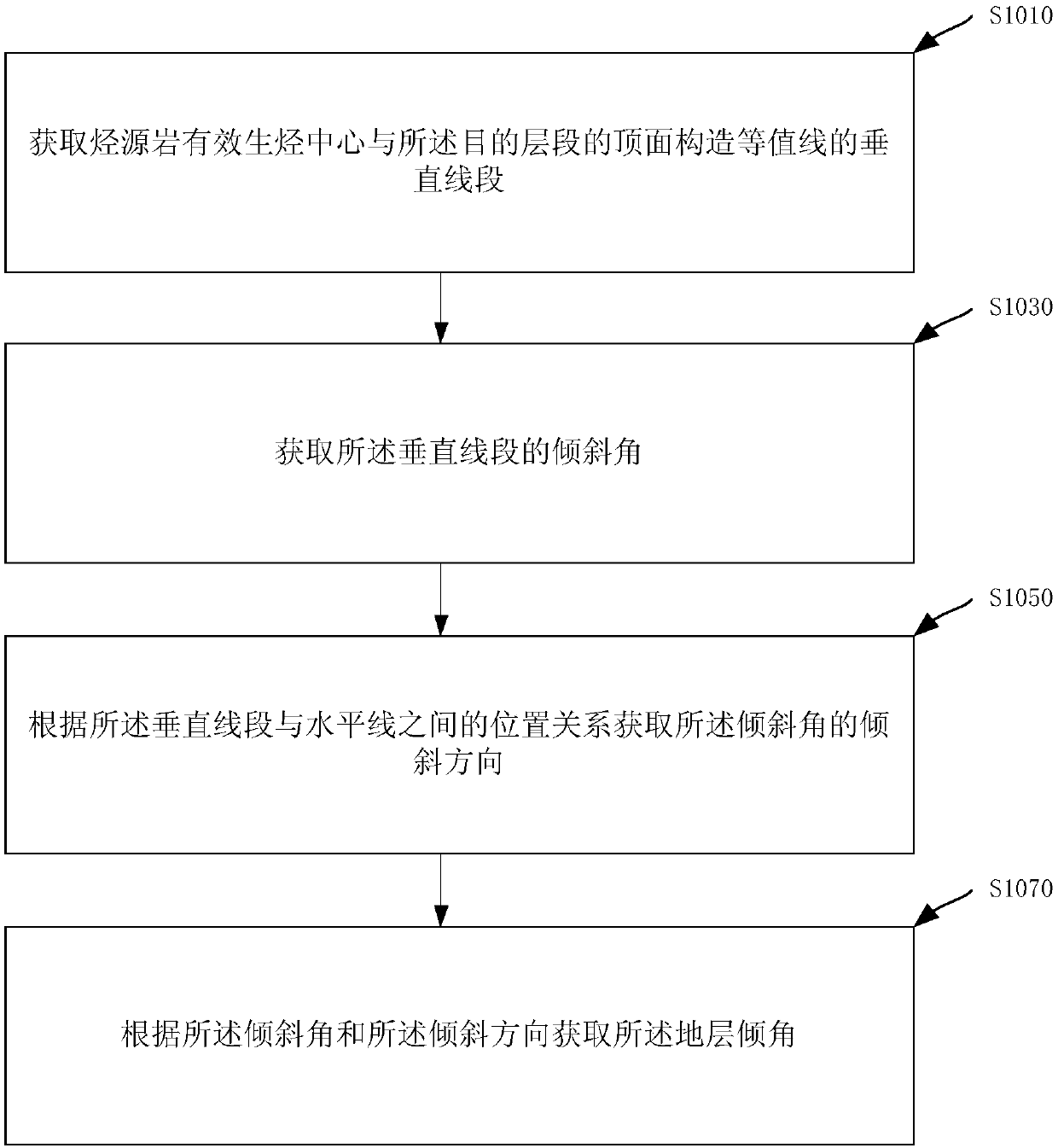

Oil-gas zone effective evaluation method and device

ActiveCN107807407ALower Exploration CostsImprove recognition rateGeological measurementsBorehole/well accessoriesPorosityLower limit

The invention provides an oil-gas zone effective evaluation method and device. The oil-gas zone effective evaluation method comprises control factor parameter distribution of an interval of interest,wherein control factor parameters comprise stratigraphic dip, fault, effective unconformity with effective hydrocarbon generation range of hydrocarbon source rocks, reservoir thickness, cover thickness, oil generation abundance and gas generation abundance; obtaining evaluation parameter lower limit of an industrial value oil and gas reservoir, wherein evaluation parameters comprise reservoir thickness, porosity, cover thickness, oil generation abundance and gas generation abundance; obtaining a reservoir formation parameter value of each grid coordinate point according to the control factor parameter distribution; obtaining an evaluate parameter processing value of each grid coordinate point according to the evaluation parameters of the grid coordinate point, the evaluation parameter lower limit and the reservoir formation parameter value; and obtaining a zone evaluation value of the interval of interest according to the evaluation parameter processing value of each grid coordinate point. The invention provides the oil-gas zone effective evaluation method and device capable of improving evaluation coincidence rate.

Owner:PETROCHINA CO LTD

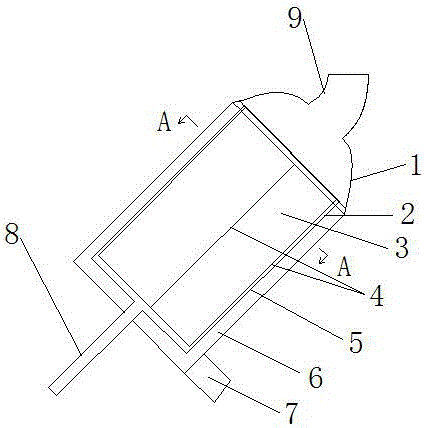

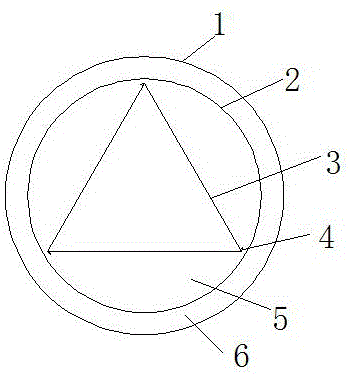

Edible oil press device

InactiveCN107351435AQuality is easy to controlOil flow speed upFatty-oils/fats productionPressesEdible oilOil generation

The invention discloses an edible oil pressing device, which comprises: a tank body, two hydraulic push rods arranged on the top surface of the tank body, the bottom ends of the hydraulic push rods are fixedly connected with a horizontally arranged pressing plate, and the tank body There is a support plate located directly below the press plate inside, and the left and right side walls of the tank body are screwed to connect the round side cover door. The press plate, side cover doors on both sides, and the support plate are surrounded by a seal The vacuum press chamber, the oil storage chamber is between the support plate and the bottom surface of the tank, and several overflow holes are opened on the support plate, and the overflow holes communicate with the vacuum press chamber and the oil storage chamber. Adopting the technical proposal, the structure is simple, the input cost is low, the oil is conveniently squeezed, and the degree of oil output from the squeezed grains is convenient to be visually observed, which in turn is beneficial to control the quality of the squeezed edible oil.

Owner:张辉

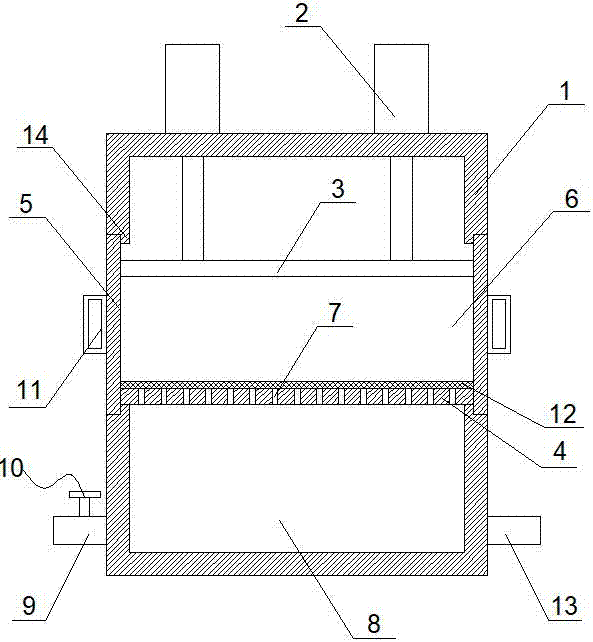

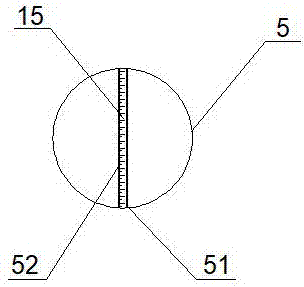

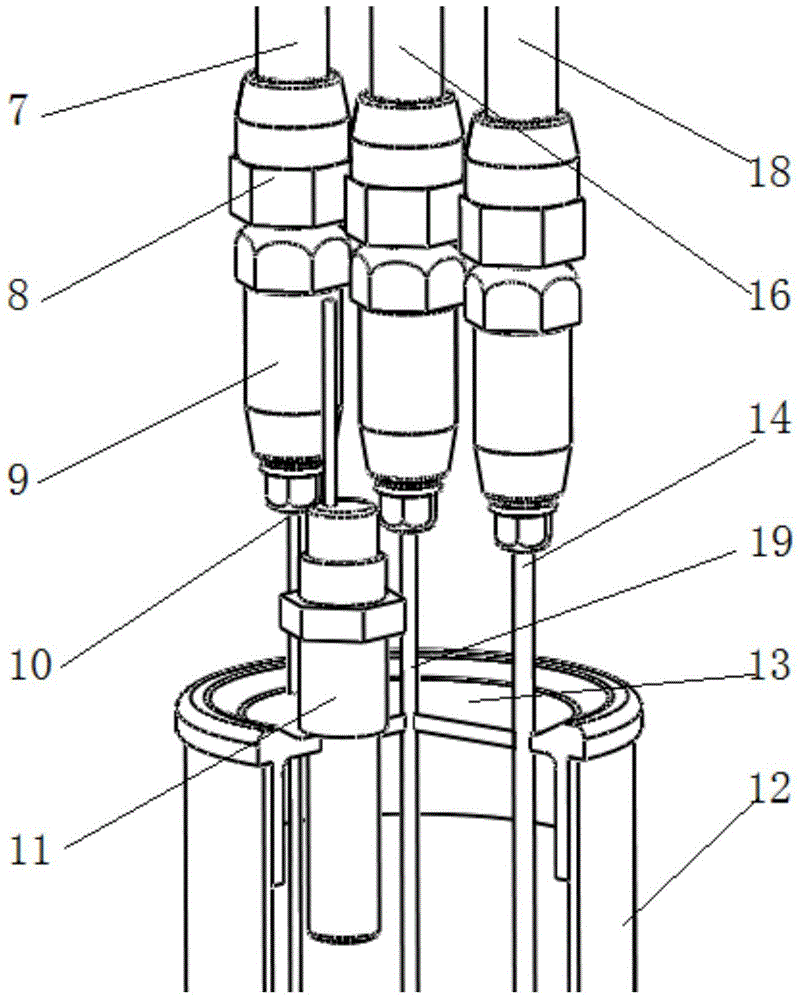

Apparatus for evaluating foam oil generation validity, and method thereof

ActiveCN104965062AAutomate your measurementsEasy to controlMaterial testing goodsPeristaltic pumpNon-contact ultrasound

The invention relates to an apparatus for evaluating the foam oil generation validity, and a method thereof, and belongs to the technical field of petroleum chemical engineering. The apparatus comprises a digital flow peristaltic pump, a gas flow meter, a sealed connection joint, a small-aperture syringe needle, a non-contact ultrasonic continuous liquid level sensor, an experiment container, a large-aperture syringe needle, a medium-aperture syringe needle, a test control panel and a computer, wherein the digital flow peristaltic pump, a gas supply flexible tube, the sealed connection joint and the syringe needles with different apertures are sequentially connected to form a gas feed experiment branch pipeline, and the digital flow peristaltic pump, the gas flow meter, the non-contact ultrasonic continuous liquid level sensor, the test control panel and the computer form a test control portion. The apparatus has the advantages of simple structure and convenient operation, and the apparatus and the method simultaneously have the advantages of realization of the automatic measurement and control of the computer, visualization of the generation, expansion and disappearance processes of foam oil, evaluation of the stability, the expansion and the gas capture ability of the foam oil, and practicability and capability of evaluation of the oil production enhancing mechanism of the foam oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

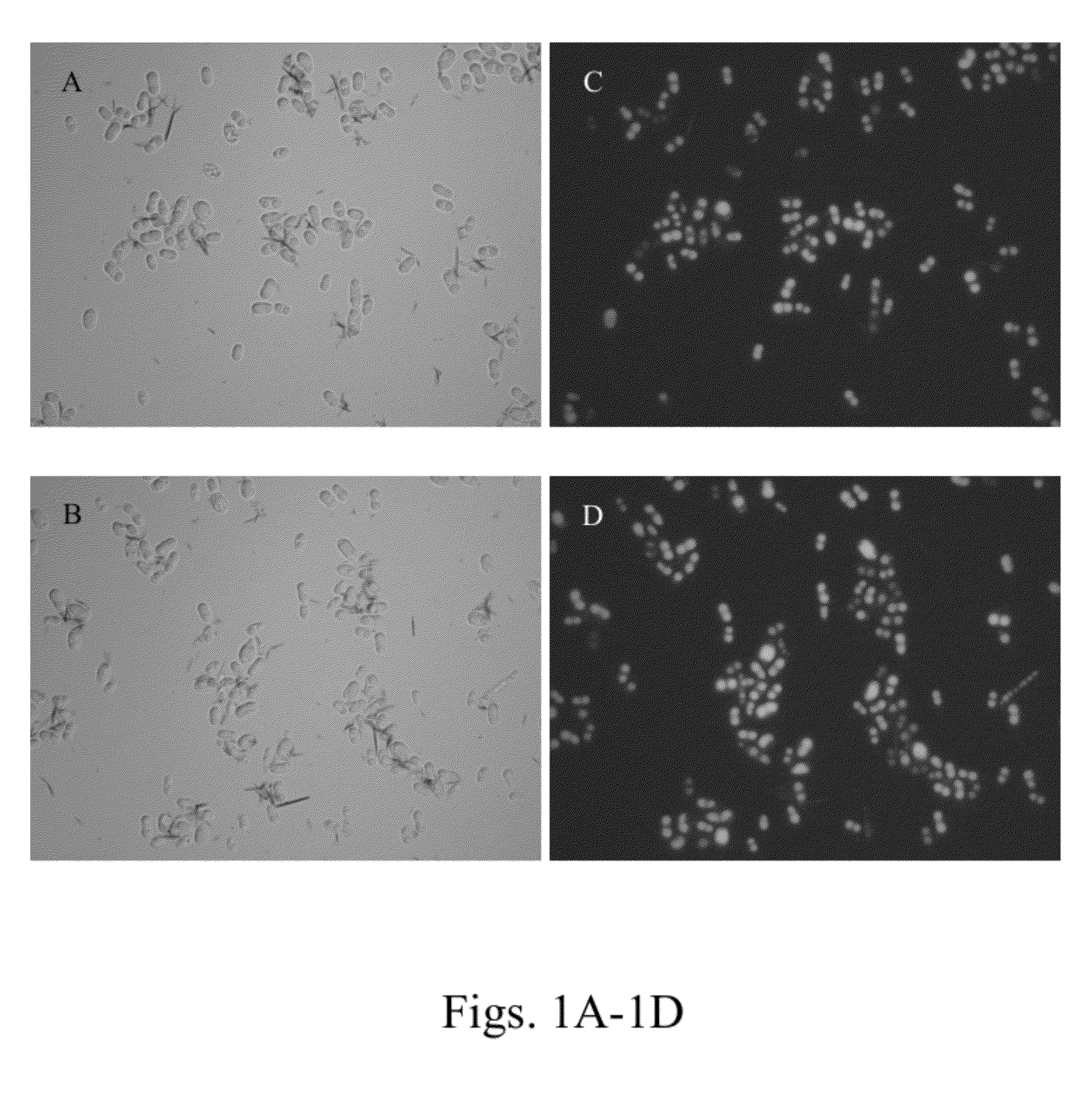

Sorokin chlorella synthetic starch defect type mutant strain and application thereof

ActiveCN107118968AImprove throughputPrecise screeningMicrobiological testing/measurementUnicellular algaeDiseaseGermplasm

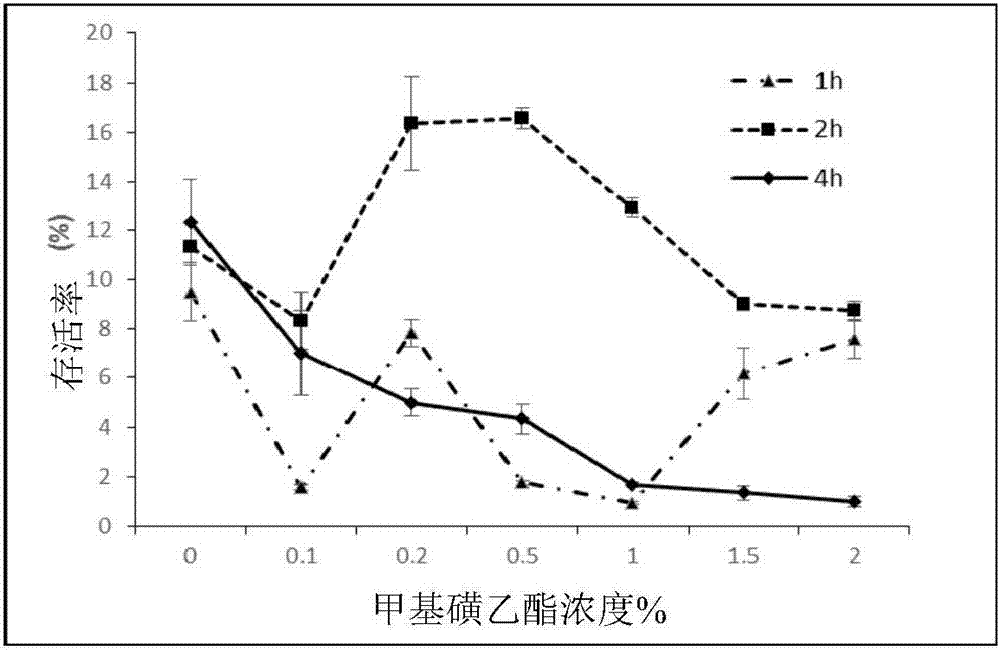

The invention provides sorokin chlorella synthetic starch defect type mutant strains GT-1-SLM1, GT-1-SLM2 and GT-1-SLM3 through mutation screening. The preservation numbers of the strains are respectively CGMCC No.13861, CGMCC No.13862 and CGMCC No.13863, and the strains are preserved in the China General Microbiological Culture Collection Center. As related channels or a small part of the channels for synthesizing starch through the strains are blocked, the content of starch in cells is remarkably reduced, the grease synthesis velocity is remarkably increased, and the highest grease content in the cells is remarkably increased. By adopting the mutant strains provided by the invention, the microalgae oil generation period can be shortened, so that the risk of disease infection in the culture period can be reduced, and meanwhile as biomasses have relatively high content of grease, later grease extraction and preparation processes can be simplified, and high-quality germplasm resources can be provided for industrialization of microalgae oil production.

Owner:GUOTOU BIO TECH INVESTMENT CO LTD

Rice bran candle and production method of same

The invention discloses a rice bran candle including a candle body and a wick. The candle body includes, by weight, 40-100 parts of rice bran wax, 0-60 parts of other wax, 0-0.2 parts of dyes, and 0-5 parts of spices, the wick is one of a cotton wick, a wood wick or a paper wick. The candle is low in residue, is free of oil generation and cracking, has good homogeneity and mutual solubility, is free of oil generation during a high temperature test and is free of cracking during a high and low temperature changing test, is improved in quality and reduced in cost by 20-40%. Flame height and combustion time of the candle reach the levels of other similar products.

Owner:DALIAN TALENT GIFT CO LTD

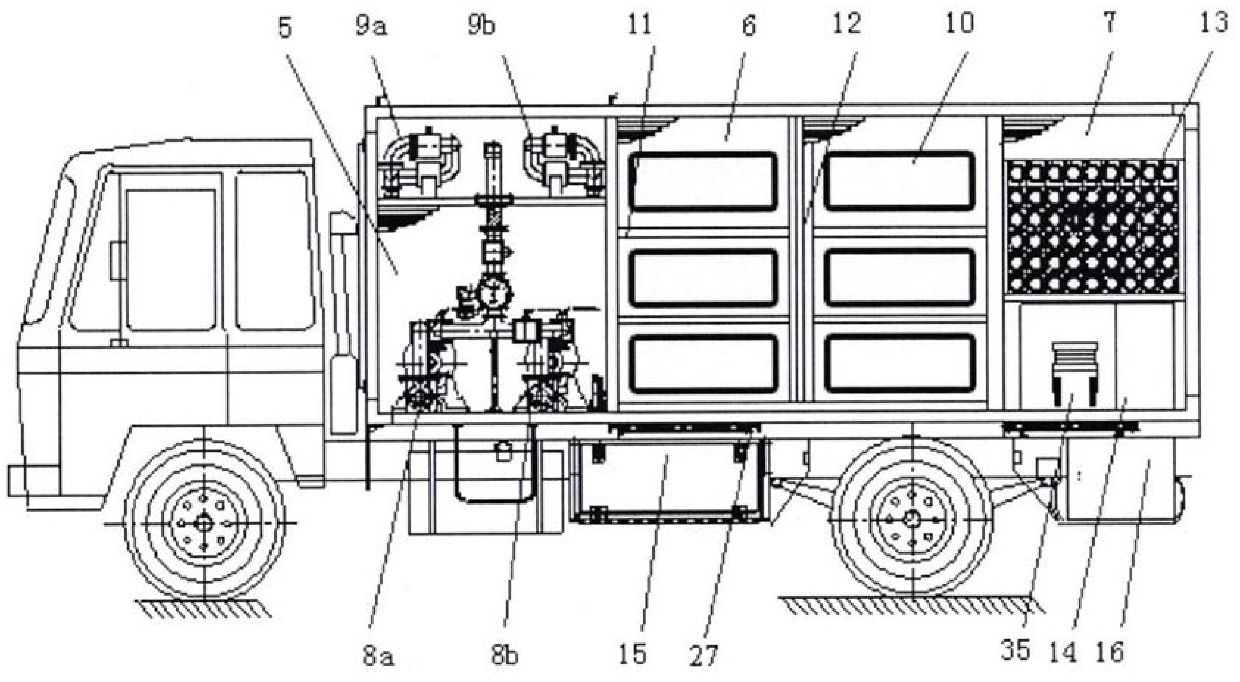

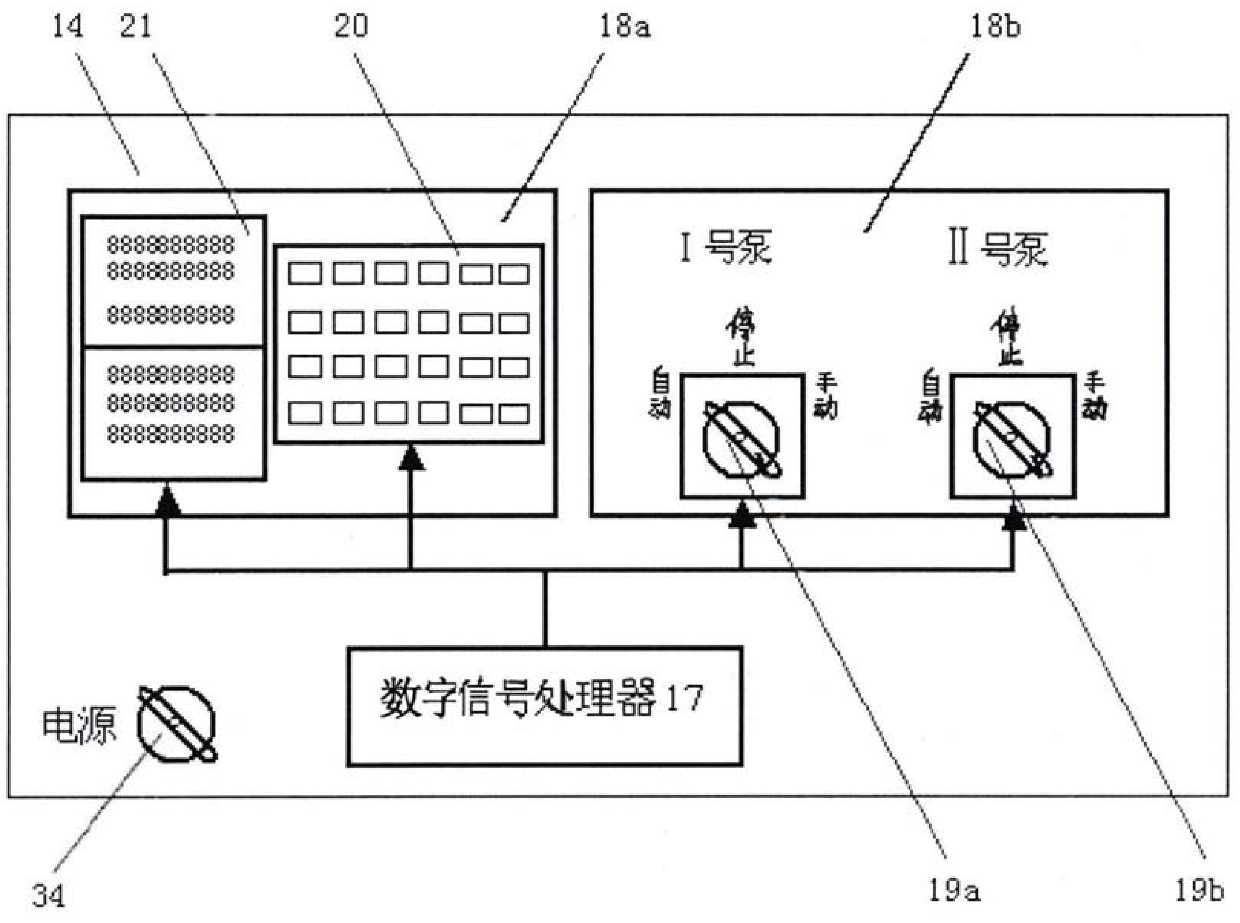

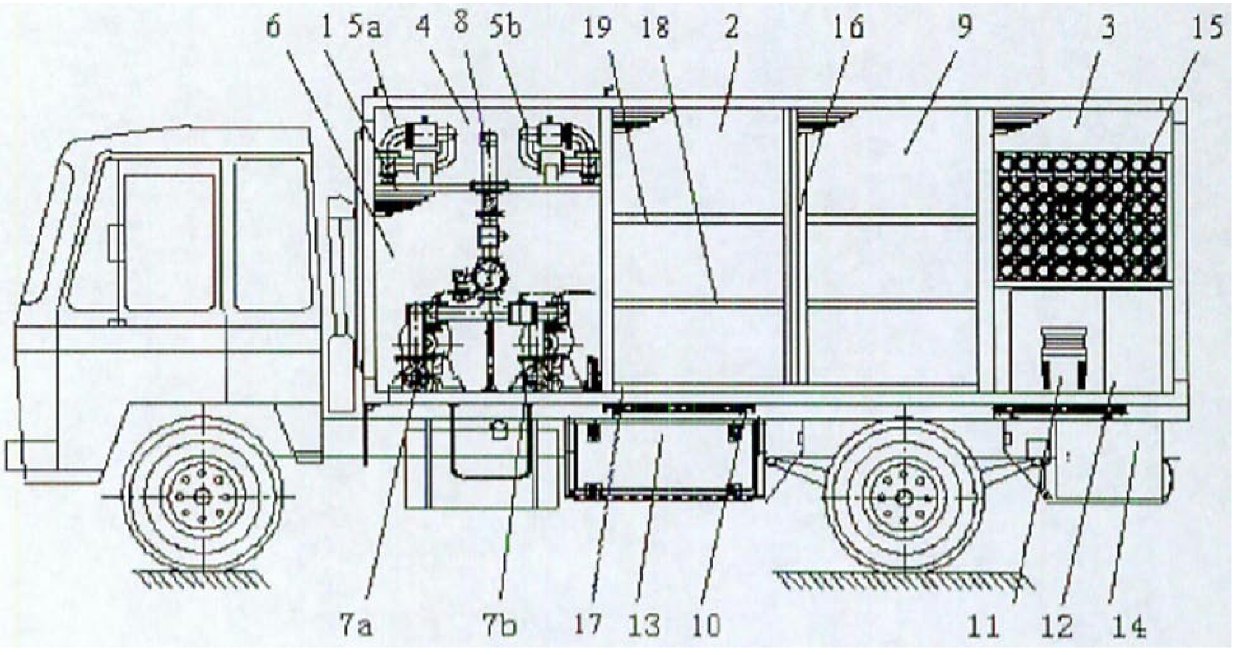

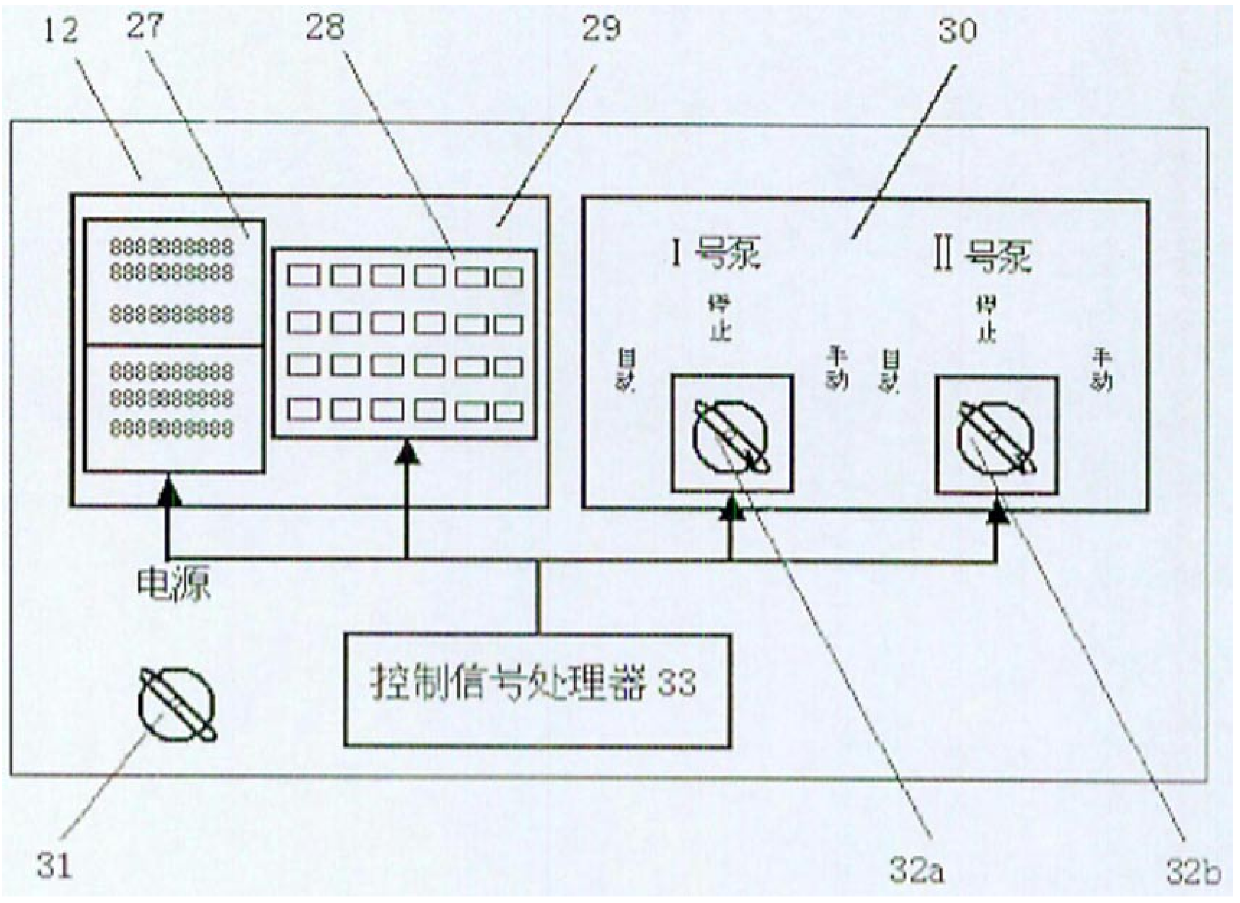

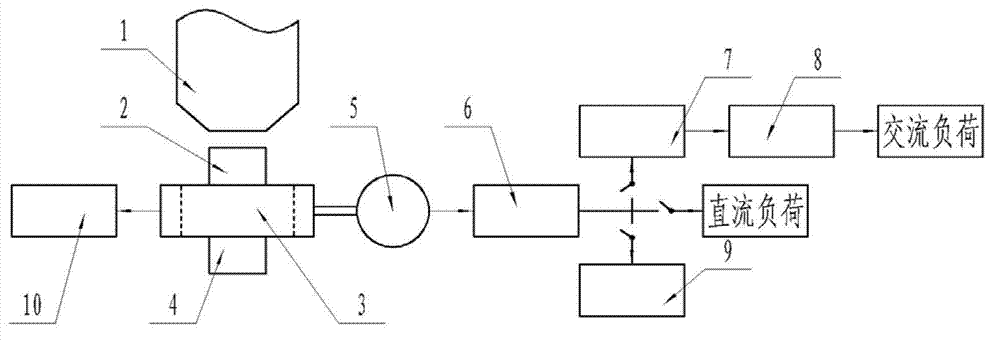

Field Fuel Digital Support System

InactiveCN106342070BFacilitate timely decision-makingReduce management linksLiquid transferring devicesCommand and controlDynamic monitoring

The field fuel digital guarantee system of the invention belongs to the technical field of vehicle refueling. The purpose is to realize the automation, digitization and information management of fuel supply in campaigns and field operations. It includes sending and receiving oil operation vehicles, command and control vehicles, and power supply trailers. The body of the sending and receiving oil operation vehicle is divided into three compartments. The front compartment is the room between the sending and receiving oil pump unit and the oil delivery crane; the middle compartment is the storage room for the soft oil tank, the rear compartment is the storage room for the connecting rubber hose, and the lower part is the operation control cabinet. Store connector accessories, power and signal cables under the chassis. The operation control cabinet is equipped with digital signal processor data processing software to manage automatic oil extraction and manual oil delivery; the command vehicle is equipped with an operation console and a satellite positioning communication system. The satellite positioning communication system includes a satellite signal receiving and transmitting antenna, a satellite communication transmitting and receiving integrated machine, etc. Advantages: ①Dynamic monitoring and real-time tracking, which is conducive to the decision-making of battlefield commanders; ②Self-service refueling, reducing management links; ③Reasonable structure and high degree of automation.

Owner:中国人民解放军北京军区油料训练大队 +1

Processing method for increasing oil extraction rate of paeonia suffruticosa Andr

InactiveCN106085584AImprove oil yieldHigh oil contentFatty-oils/fats refiningFatty-oils/fats productionPaeonia suffruticosaMicrowave

The invention discloses a processing method for increasing the oil extraction rate of paeonia suffruticosa Andr, and belongs to the technical field of edible oil processing. Oil of the paeonia suffruticosa Andr is extracted by the four steps of 1) microwave processing, 2) enzymolysis, 3) centrifugal extraction and 4) demulsification oil generation. The paeonia suffruticosa Andr is subjected to microwave processing, and the processing method has the advantages of reaction promoting high efficiency and strong selectivity, simplicity and convenience in operation, fewer by-products, high yield, easiness in product purification and the like; the oil extraction rate of the paeonia suffruticosa Andr can be remarkably increased, the oil of the paeonia suffruticosa Andr with high oil content can be maximally extracted by the processing method, the oil extraction rate is 45%-50% and is increased by 18-30 percentage points, and economic benefits are improved.

Owner:刘志峰

Method for producing oil by cystofilobasidium spp.

An oil generation system is provided. The oil generation system includes a saccharide; and a working microorganism reacting with the saccharide to produce an oil, wherein the working microorganism has a genus being a Cystofilobasidium.

Owner:JEN CATHOLIC UNIV

Sesame seed smashing device

The invention discloses a sesame seed smashing device.The device comprises a shell, a screen arranged in the shell, and a smashing blade arranged in the shell, wherein the shell is obliquely arranged, an opening is formed in the top of the screen, the smashing blade is arranged in the screen, the top of the smashing blade is connected and fixed to the shell, the screen and the shell are spaced, and the screen and the smashing blade are spaced; the space between the screen and the smashing blade serves as a feeding channel, the space between the screen and the shell serves as a discharging channel, the bottom of the screen is connected with a transmission shaft, and the transmission shaft drives the screen to rotate; a discharging port is arranged on the side wall of the bottom of the shell, and a feeding port is arranged on the top of the shell.The device has the advantages that smashing speed is increased, and oil generation during smashing is prevented; smashed sesame seeds with granularity meeting the discharging requirement are discharged in time through the screen, repeated cutting or grinding of finished granules in the smashing device is effectively reduced, and oil generation is further prevented.

Owner:WULI FENGXIANGYUAN SESAME FOOD

Field fuel delivery vehicle

InactiveCN106342043BCompact and reasonable structure designImprove support capabilitiesVehicle with raised loading platformTank vehiclesAutomatic controlField conditions

The utility model relates to a field oil receiving and sending oil operation vehicle, which is mainly used for setting up digital field oil depots. The shelter for oil delivery operation is divided into front cabin, middle cabin and rear cabin. The interior of the front cabin is divided into upper and lower floors. The upper layer is the crane tube room, and the lower layer is the pump room. There are two sets of pipeline systems and an electrostatic oil spill alarm system inside. There are two sliding doors on the top of the crane tube room that can be retracted freely. The middle cabin is a tank room for storing soft oil tanks and a set of hydraulic lifting system; the rear cabin is divided into upper and lower layers. It is divided into squares of the same size for storing polyurethane oil hoses. The lower layer is divided into two identical spaces, and the control cabinet, accessory box and two hydraulic trolleys are symmetrically placed. The control cabinet is driven by the oil pump motor. Controller and The fuel delivery controller is composed of two parts. The fuel delivery controller works under the unified and coordinated management of the CQM1H programmable control signal processor to realize the automatic control of sending and receiving oil. The invention reduces labor intensity, saves labor time, has a more reasonable structure, realizes automatic oiling under field conditions, and improves field oil supply capability.

Owner:中国人民解放军北京军区油料训练大队

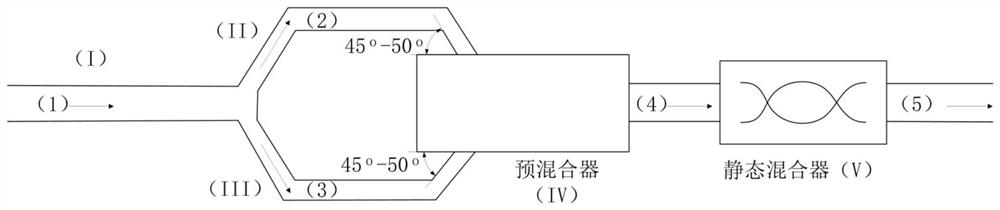

Low-pressure drop high-efficiency static mixing device and oil blending method beneficial to oil blending

ActiveCN108273403BFull and efficient mixingFlow mixersTransportation and packagingStatic mixerOil generation

Owner:EAST CHINA UNIV OF SCI & TECH

Petroleum low-temperature catalytic cracking catalyst and use method

ActiveCN104998625AImproving the Efficiency of Low Temperature Catalytic CrackingLow catalytic cracking temperatureCatalytic crackingPhysical/chemical process catalystsEvaporationFractionation

The invention discloses a petroleum low-temperature catalytic cracking catalyst and a use method, wherein the catalyst is boric acid. The use method of the catalyst comprises the following steps that A, firstly, heavy oil is put into a heating cracking furnace to be heated to be at the temperature of 100-150 DEG C, and dehydration is performed; B, then the boric acid with the weight of 0.8-1.2% the weight of the heavy oil is added and stirred in a heat preservation mode; C, then the mixture is gradually heated, oil generation starts at the temperature of 180 DEG C, the oil steam evaporation amount is maintained to be uniform and stable, oil products are recycled through fractionation and cooling, the oil products accounting for 60% of the total oil evaporation steam can be recycled at the temperature of 330 DEG C, then the mixture is warmed up to be at the temperature of 400 DEG C, the mixture is stopped from being warmed up, and the mixture is kept warm at the temperature of 400 DEG C until no oil is generated. The petroleum low-temperature catalytic cracking catalyst and the use method have the advantages that the catalytic cracking temperature is low, the efficiency of petroleum low-temperature catalytic cracking is improved, the reaction is accelerated, the production efficiency is improved, and therefore the reaction effect is better.

Owner:周华文

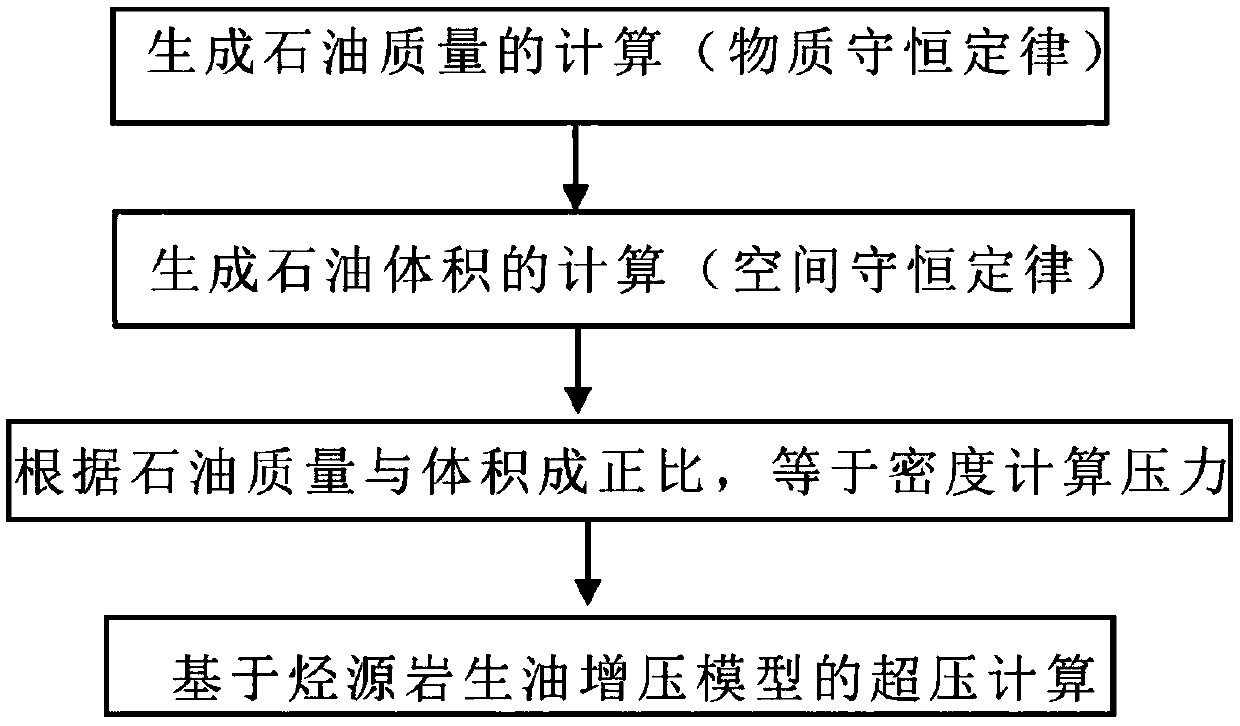

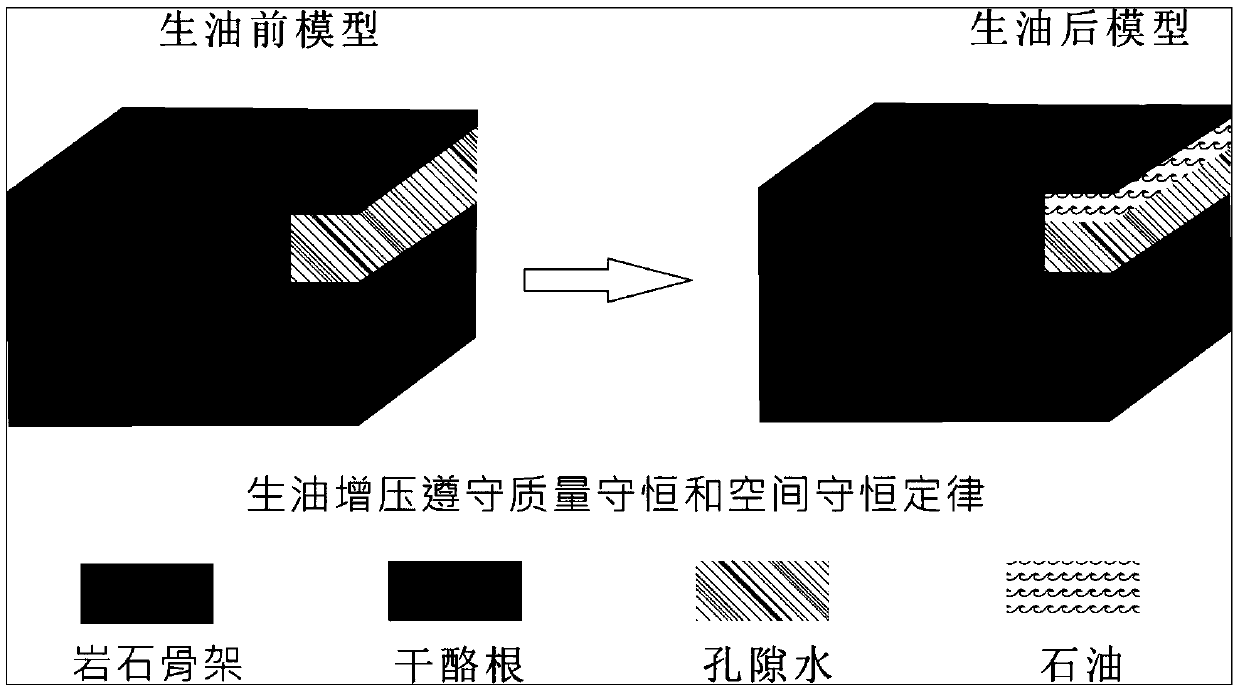

A method for calculating the overpressure of hydrocarbon source rocks based on the pressurization equation of oil generation

ActiveCN108984816AHigh precisionAccurately obtain overpressure valueDesign optimisation/simulationSpecial data processing applicationsKerogenPetroleum

A method for calculating the overpressure of hydrocarbon source rocks based on a pressurization equation of oil generation. Based on the oil generation of source rocks in petroliferous basins and theintrinsic relationship among kerogen, crude oil and pore water in terms of mass, volume and compression coefficient, a model of oil generation boosting calculation is established to calculate the overpressure and to improve the accuracy of overpressure value calculation, and technical support is provided for improving petroleum geological evaluation. The invention proposes an overpressure calculation method based on the pressurized source oil in accordance with the pressurized source oil model in China, which can effectively utilize the calculation formula and improve the calculation accuracyof the overpressure value.

Owner:XI'AN PETROLEUM UNIVERSITY

Carbon distillate post-hydrogenation method

ActiveCN105732279BIncrease incrementHigh hydrogenation selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrogenationFixed bedHydreliox

The invention relates to a post-hydrogenation method of carbon distillates. The fixed-bed reactor used for hydrogenation is located behind the demethanizer, and the carbon distillate from the front deethanizer in the ethylene unit is pressurized and hydrogenated. Enter the adiabatic bed reactor for selective hydrogenation. The fixed bed reactor is equipped with a Pd-Ni catalyst. During the preparation process, the catalyst is combined with a bipyridine derivative with a hydroxyl group through an alumina carrier. Hydroxybipyridine forms a metal complex with the active component; the method of the present invention greatly improves the activity and selectivity of the hydrogenation reaction compared to the traditional hydrogenation method, and the amount of green oil generated during the hydrogenation process is also greatly reduced. At the same time, the reduction of green oil makes the active center of the catalyst not covered by by-products, and the catalyst activity and selectivity are well maintained; the catalyst used in the present invention has excellent anti-impurity interference ability, and is especially suitable for S, As C2 hydrogenation unit with high impurity content.

Owner:PETROCHINA CO LTD

A kind of dechlorination agent and preparation method thereof

ActiveCN106861386BRaise the ratioEvenly dispersedGas treatmentDispersed particle separationAlkaline earth metalOrganic chloride compound

The invention discloses a dechlorination agent and a preparation method thereof. The dechlorination agent uses a composite oxide as a carrier to support oxides of alkali metals and / or alkaline earth metals, and the composite oxide carrier includes θ-type alumina and calcium oxide. The invention prepares the composite oxide carrier through the co-precipitation method, introduces calcium oxide into the carrier skeleton structure, and the penetration chlorine capacity can reach 17.6% at normal temperature. Through high-temperature calcination, the alumina with theta-type phase structure is prepared, which reduces the number of surface hydroxyl groups, minimizes the physical adsorption of HCl on the dechlorination agent, and reduces the acidity of the surface of the dechlorination agent due to the physical adsorption and concentration of HCl. Enhanced phenomenon, thereby reducing the acid-catalyzed olefin polymerization to produce green oil, and the acid-catalyzed reaction of olefins with HCl to form organic chlorides. In addition, the composite oxide carrier prepared by the invention significantly increases the strength of the dechlorination agent and eliminates the phenomenon of agglomeration or pulverization under the condition of water vapor.

Owner:WANHUA CHEM GRP CO LTD

A sesame crushing device

The invention discloses a sesame seed smashing device.The device comprises a shell, a screen arranged in the shell, and a smashing blade arranged in the shell, wherein the shell is obliquely arranged, an opening is formed in the top of the screen, the smashing blade is arranged in the screen, the top of the smashing blade is connected and fixed to the shell, the screen and the shell are spaced, and the screen and the smashing blade are spaced; the space between the screen and the smashing blade serves as a feeding channel, the space between the screen and the shell serves as a discharging channel, the bottom of the screen is connected with a transmission shaft, and the transmission shaft drives the screen to rotate; a discharging port is arranged on the side wall of the bottom of the shell, and a feeding port is arranged on the top of the shell.The device has the advantages that smashing speed is increased, and oil generation during smashing is prevented; smashed sesame seeds with granularity meeting the discharging requirement are discharged in time through the screen, repeated cutting or grinding of finished granules in the smashing device is effectively reduced, and oil generation is further prevented.

Owner:WULI FENGXIANGYUAN SESAME FOOD

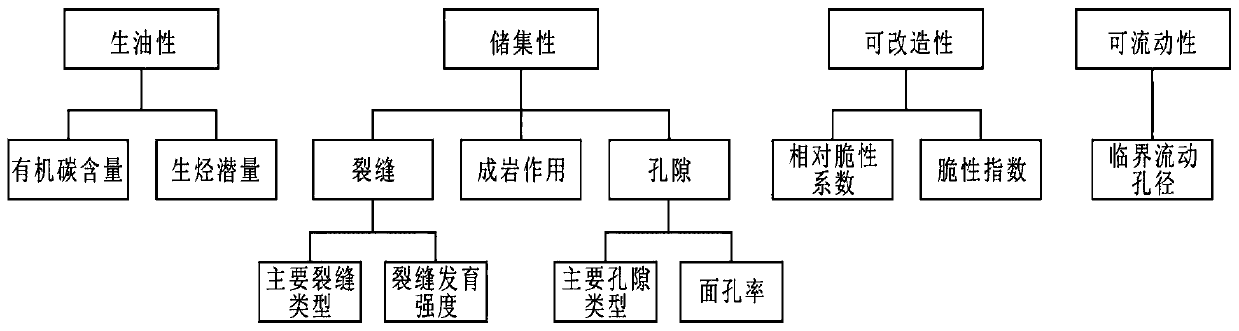

An evaluation method based on the effectiveness of shale reservoirs

The invention discloses an evaluation method based on the effectiveness of mud shale reservoirs. According to the characteristics of mud shale reservoirs, lithofacies is determined as the basic evaluation unit, and oil generation, storage, reformability and mobility are selected as evaluation contents, and then a systematic analysis of influencing factors is carried out to optimize organic carbon content and hydrocarbon generation potential. The quantity, fracture type and development intensity, pore type and porosity, diagenesis, relative brittleness coefficient and brittleness index and critical flow aperture are used as evaluation parameters, and the gray fuzzy mathematical method is used to obtain the mud shale reservoir type.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

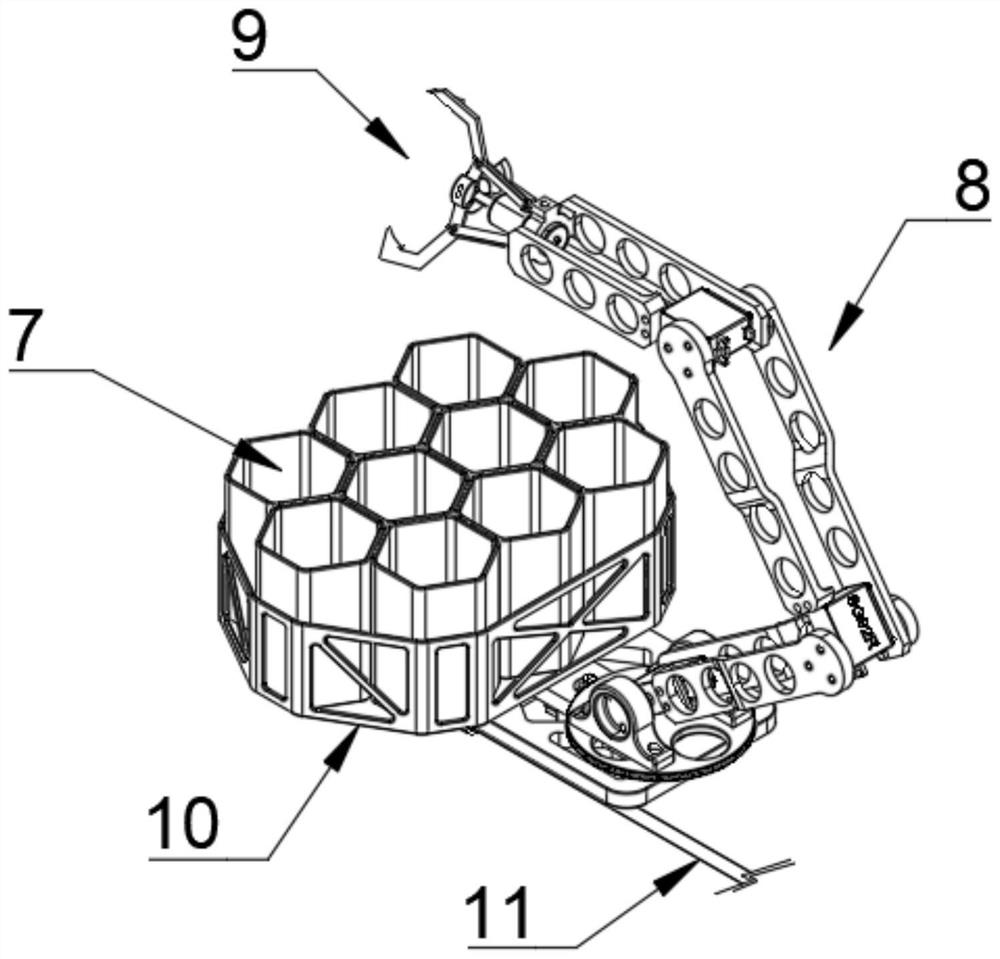

Grain-oil power generation assembly for silo

InactiveCN102767493AEfficient developmentEfficient use ofMachines/enginesMechanical power devicesFree fallingImpeller

The invention relates to a power generation assembly, in particular to a grain-oil power generation assembly for a silo, belonging to the technical field of new energy development. The grain-oil power generation assembly for the silo solves the defect that grain-flow potential energy in the silo is completely lost in the prior art, and mainly comprises a cylindrical silo, wherein an air seal machine connected with a booster engine is arranged on the bottom part of the silo; an impeller is arranged inside the air seal machine; a grain inlet is arranged above the impeller and a grain outlet is arranged below the impeller; the distance for the axle center of the air seal machine to deviate from the center of the grain inlet is larger than the inner radius of the grain inlet; a power generator and a rectifier are arranged on the downstream of the air seal machine in sequence; a storage battery and an inverter are in parallel arranged on the downstream of the rectifier; and a load controller is arranged on the downstream of the inverter. The grain-oil generation assembly for the silo is mainly used for grain-flow power generation, and further, can be used for potential energy power generation of other free falling materials.

Owner:崔忠艾

A kind of petroleum low-temperature catalytic cracking catalyst and using method

ActiveCN104998625BImproving the Efficiency of Low Temperature Catalytic CrackingLow catalytic cracking temperaturePhysical/chemical process catalystsCatalytic crackingFractionationEvaporation

The invention discloses a petroleum low-temperature catalytic cracking catalyst and a use method, wherein the catalyst is boric acid. The use method of the catalyst comprises the following steps that A, firstly, heavy oil is put into a heating cracking furnace to be heated to be at the temperature of 100-150 DEG C, and dehydration is performed; B, then the boric acid with the weight of 0.8-1.2% the weight of the heavy oil is added and stirred in a heat preservation mode; C, then the mixture is gradually heated, oil generation starts at the temperature of 180 DEG C, the oil steam evaporation amount is maintained to be uniform and stable, oil products are recycled through fractionation and cooling, the oil products accounting for 60% of the total oil evaporation steam can be recycled at the temperature of 330 DEG C, then the mixture is warmed up to be at the temperature of 400 DEG C, the mixture is stopped from being warmed up, and the mixture is kept warm at the temperature of 400 DEG C until no oil is generated. The petroleum low-temperature catalytic cracking catalyst and the use method have the advantages that the catalytic cracking temperature is low, the efficiency of petroleum low-temperature catalytic cracking is improved, the reaction is accelerated, the production efficiency is improved, and therefore the reaction effect is better.

Owner:周华文

A method for hydrogenation before deethanization of carbon distillate

ActiveCN105732278BSimple structureStrong alloy effectHydrocarbon by hydrogenationHydrocarbon purification/separationHydrogenation reactionFixed bed

The invention relates to a method for selective hydrogenation of carbon distillates, which adopts a pre-deethanizer pre-hydrogenation process, enters the top effluent from the pre-deethanizer tower in an ethylene plant into a fixed-bed reactor for selective hydrogenation, It is characterized in that the adiabatic bed reactor is equipped with a Pd-Au-based catalyst, and the catalyst is combined with a bipyridine derivative with a hydroxyl group through an alumina-based carrier during the preparation process, and the hydroxy-bipyridine derivative combined on the carrier has an activity The components form metal complexes; the method of the present invention can greatly improve the activity and selectivity of the hydrogenation reaction, reduce the amount of green oil produced, prolong the service life of the catalyst, and at the same time ensure that the hydrogenation of acetylene is qualified, effectively Increase device ethylene increment.

Owner:PETROCHINA CO LTD

A device for evaluating the effectiveness of foam oil generation

ActiveCN104965062BEasy to controlVisualization generationMaterial testing goodsPeristaltic pumpFoamy oil

The invention relates to an apparatus for evaluating the foam oil generation validity, and a method thereof, and belongs to the technical field of petroleum chemical engineering. The apparatus comprises a digital flow peristaltic pump, a gas flow meter, a sealed connection joint, a small-aperture syringe needle, a non-contact ultrasonic continuous liquid level sensor, an experiment container, a large-aperture syringe needle, a medium-aperture syringe needle, a test control panel and a computer, wherein the digital flow peristaltic pump, a gas supply flexible tube, the sealed connection joint and the syringe needles with different apertures are sequentially connected to form a gas feed experiment branch pipeline, and the digital flow peristaltic pump, the gas flow meter, the non-contact ultrasonic continuous liquid level sensor, the test control panel and the computer form a test control portion. The apparatus has the advantages of simple structure and convenient operation, and the apparatus and the method simultaneously have the advantages of realization of the automatic measurement and control of the computer, visualization of the generation, expansion and disappearance processes of foam oil, evaluation of the stability, the expansion and the gas capture ability of the foam oil, and practicability and capability of evaluation of the oil production enhancing mechanism of the foam oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Chemical oil generation detection system and equipment thereof

InactiveCN111650199AEfficient detectionGuaranteed detection efficiencyMaterial analysis by optical meansProgramme control in sequence/logic controllersPhysical chemistryEngineering

The invention provides a chemical oil generation detection system and equipment thereof. The system comprises an accommodating cavity, a detection device, a sampling device, an analysis device, a reaction device and a controller, whereinthe detection device is configured to detect a detection oil sample stored in the accommodating cavity; the sampling device is configured to be matched with the detection device for use and is used for sampling and detecting a detection oil sample; the analysis device is configured to analyze results of the detection device and the sampling device; and the reaction device is configured to collect the detection oil sample and discriminate substances in the detection oil sample. Calibration is carried out through the set liquid level quantity and the set weight; in the embodiment of the invention, the weighing sensing element and the liquid level sensing element also carry out calibration operation, and the calibration operation comprises calibration on the weight of the detection oil sample and the liquid level of the detection oil, so that the whole system has abundant application scenes, and the automatic detection capability of the whole system isimproved.

Owner:HEBEI CHEM & PHARMA COLLEGE

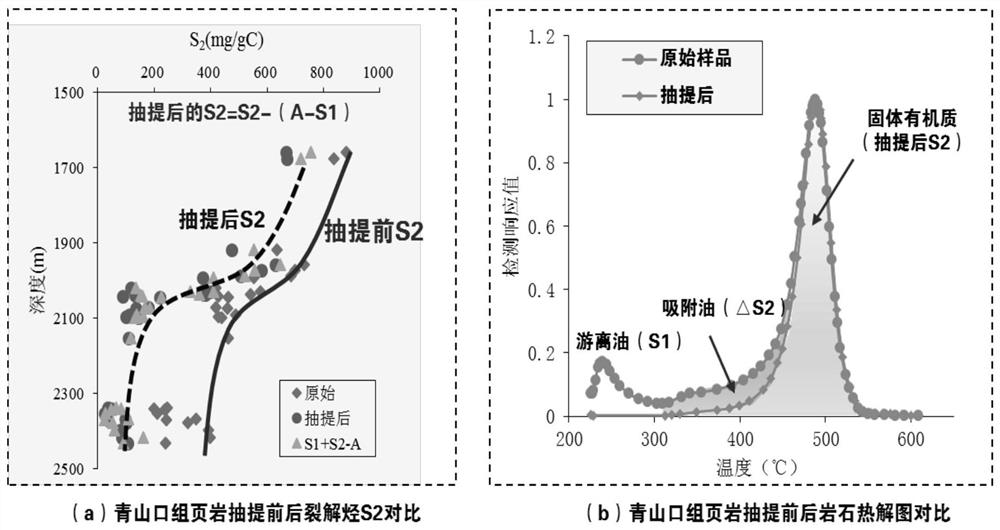

A method for evaluating the formation and evolution of continental shale oil in large freshwater lake basins

The invention discloses a method for evaluating the formation and evolution of terrestrial mud shale oil in a large freshwater lake basin. The method uses conventional drilling cores and geological experiment analysis, pressure-preserved and sealed coring, and frozen sample oil content calibration and logging technology. Combined method to evaluate shale oil content recovery, vertical sweet spot layer and plane sweet spot area; use depth, Ro, kerogen, chloroform bitumen "A", free oil, adsorbed oil, gas-oil ratio and other parameters , the formation and evolution evaluation model of continental shale oil was established, which met the needs of shale oil exploration. This method evaluates that the mass conversion of adsorbed oil to free oil at Ro1.1%-1.6% is the most favorable stage for the formation of shale oil, and shale oil at mature and highly mature stages is 1.5-3.5 times that of the classic oil generation model. The "sweet spots" of shale oil in the Liao Basin have been selected and breakthroughs in exploration have enabled the exploration depth to be extended to 2600m and the area of sweet spots to be expanded by 1.2 times, laying the material foundation for large-scale exploration of continental mud shale oil in large freshwater lake basins.

Owner:PETROCHINA CO LTD +1

Hydrogenation alkyne removal method for methanol-to-olefin process ethylene material

InactiveCN108250021AModerate reactivityGreat operating flexibilityHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsAlkyneOil generation

A hydrogenation alkyne removal method for a methanol-to-olefin process ethylene material is characterized in that an Fe-Co hydrogenation catalyst is used, a methanol-to-ethylene product is added to ahydrogenation reactor and undergoes selective hydrofining, a tiny amount of acetylene contained in tower top effluent obtained after alkali washing, drying, demethanation and deethanization of the methanol-to-ethylene product is adopted as a hydrogenation object, and a raw material mainly contains 99.9% or more (phi) of ethylene, 5-100 ppm of acetylene and 1-10 ppm of CO. Reaction conditions are as follows: the inlet temperature of the reactor is 30-80 DEG C, the reaction pressure is 1.5-3.0 MPa, and the space velocity is 2000-10000 h<-1>; the hydrogenation catalyst is a Fe-Co selective hydrogenation catalyst, and adopts a high temperature-resistant inorganic oxide as a carrier, the active components of the catalyst contain Fe and Co, and 100 mass% of the catalyst contains 2-6 mass% of Feand 0.5-1.5 mass% of Co; and the specific surface area of the catalyst is 10-200 m<2> / g, and the pore volume is 0.2-0.63 ml / g. The catalyst has the advantages of mild hydrogenation activity, excellentethylene selectivity, no ethylene loss and low green oil generation amount, and has a far lower cost than a precious metal Pd catalyst.

Owner:PETROCHINA CO LTD

Scientific demonstration device and method for deep earth petroleum generation principle

The invention discloses a scientific demonstration device for a deep earth petroleum generation principle, and the device comprises a gasification furnace which contains molten iron at the bottom, and is provided with a synthesis gas pipeline communicated with the interior of the gasification furnace at the top, an inorganic carbon spray gun, an inorganic water spray gun, an organic matter spray gun, and a Fischer-Tropsch synthesis tower; nozzles of the inorganic carbon spray gun, the inorganic water spray gun and the organic matter spray gun are all inserted into the molten iron, the inorganic carbon spray gun is used for blowing high-valence carbon element inorganic matter into the molten iron, and the inorganic water spray gun is used for blowing water-containing inorganic matter into the molten iron; the organic matter spray gun is used for spraying organic matters into the molten iron; and the Fischer-Tropsch synthesis tower is communicated with the synthesis gas pipeline and is used for synthesizing the gas generated by the gasification furnace into liquid hydrocarbon. The invention discloses a scientific demonstration method for a deep earth petroleum generation principle. According to the invention, demonstration of a certain petroleum formation reaction can be carried out visually and vividly.

Owner:杭州吉幔铁氢能科技有限公司

Method for reducing aromatic content of diesel oil in residual hydrogenation equipment

InactiveCN1212374CAchieve desulfurizationLow aromatic contentRefining by aromatic hydrocarbon hydrogenationHydrogenGas phase

The method for reducing aromatic hydrocarbon content in diesel oil in residual hydrogenation equipment is characterized by that the residual oil and hydrogen gas are fed into residual catalytic hydrogenation reactor, and the material flow obtained after reaction is fed into thermal high-pressure separator and separated into gas phase material flow and hydrogenated residuel oil, and gas phase material flow is mixed with diesel oil raw material, and fed into diesel oil catalytic hydrogenation reactor, and the reaction material flow is fed into cold high-pressure separator, and separated into gas and refined diesel oil generation oil, the gas is cleaned, pressurized and returned into residual hydrogenation reactor for circular use, and the refined diesel oil generation oil can be separated to obtain the diesel oil product whose aroamtic hydrocarbon content can be reduced by above 60%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for predicting saturability of crude oil, machinery equipment

ActiveCN108876898ASatisfy real-timeMeet the need for quick decision-makingImage generation3D modellingPorous mediumOil generation

The invention discloses a method and a device for predicting the saturability of crude oil, and machinery equipment. The method comprises the steps of acquiring a three-dimensional rock debris image through three-dimensionally reconstructing a rock debris sample; acquiring a three-dimensional porous rock debris medium structure by mapping the three-dimensional rock debris image, and acquiring andstoring pore information corresponding to each pore and flowing behavior control information of fluid flowing in the pores; simulating the flowing process of the fluid in the three-dimensional porousrock debris medium structure under the aid of the stored pore information and flowing behavior control information; and acquiring the saturability of crude oil through simulating a geological oil generation process of the rock debris. Storage optimization and access optimization are performed via the stored pore information and flowing behavior control information, so that a lot of branch judgmentoperations are not needed for acquiring the flowing behavior control information, the saturability of crude oil is acquired through simulating the geological oil generation process of the rock debris, the overall computing efficiency is improved, the data storage pressure is no longer generated, and the real-time and quick decision-making requirements of the project are truly met.

Owner:清能艾科(深圳)能源技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com