Field fuel delivery vehicle

A technology for operating vehicles and oil materials, which is applied in the field of field oil sending and receiving operations, can solve the problems of cumbersome refueling operation process, lack of automation, and high manual work intensity, so as to overcome the cumbersome and laborious process of oil distribution, reduce labor intensity, and improve support capabilities Effect

Inactive Publication Date: 2010-12-15

中国人民解放军北京军区油料训练大队

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

To refuel the next oil truck, the above actions need to be repeated, and the refueling operation process is relatively cumbersome

In addition, the "battle field oil depot" adopts manual control for sending and receiving oil, and the loading and unloading of software oil tanks is also completely carried by manpower, without automatic functions, resulting in high manual work intensity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

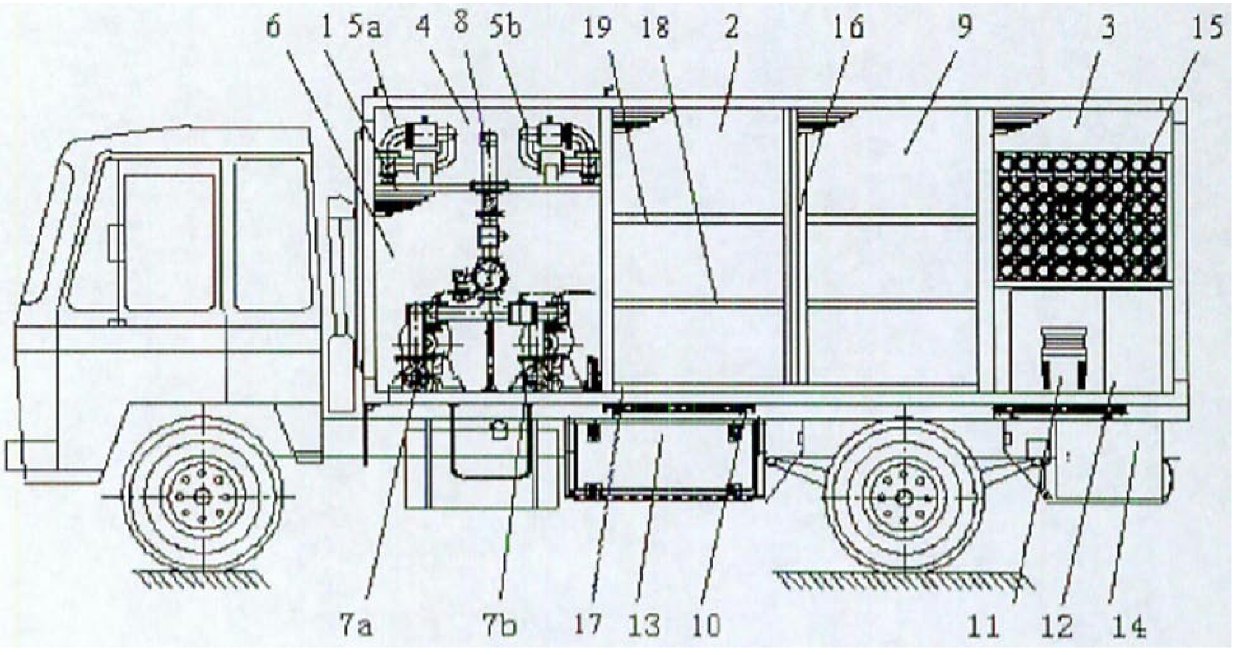

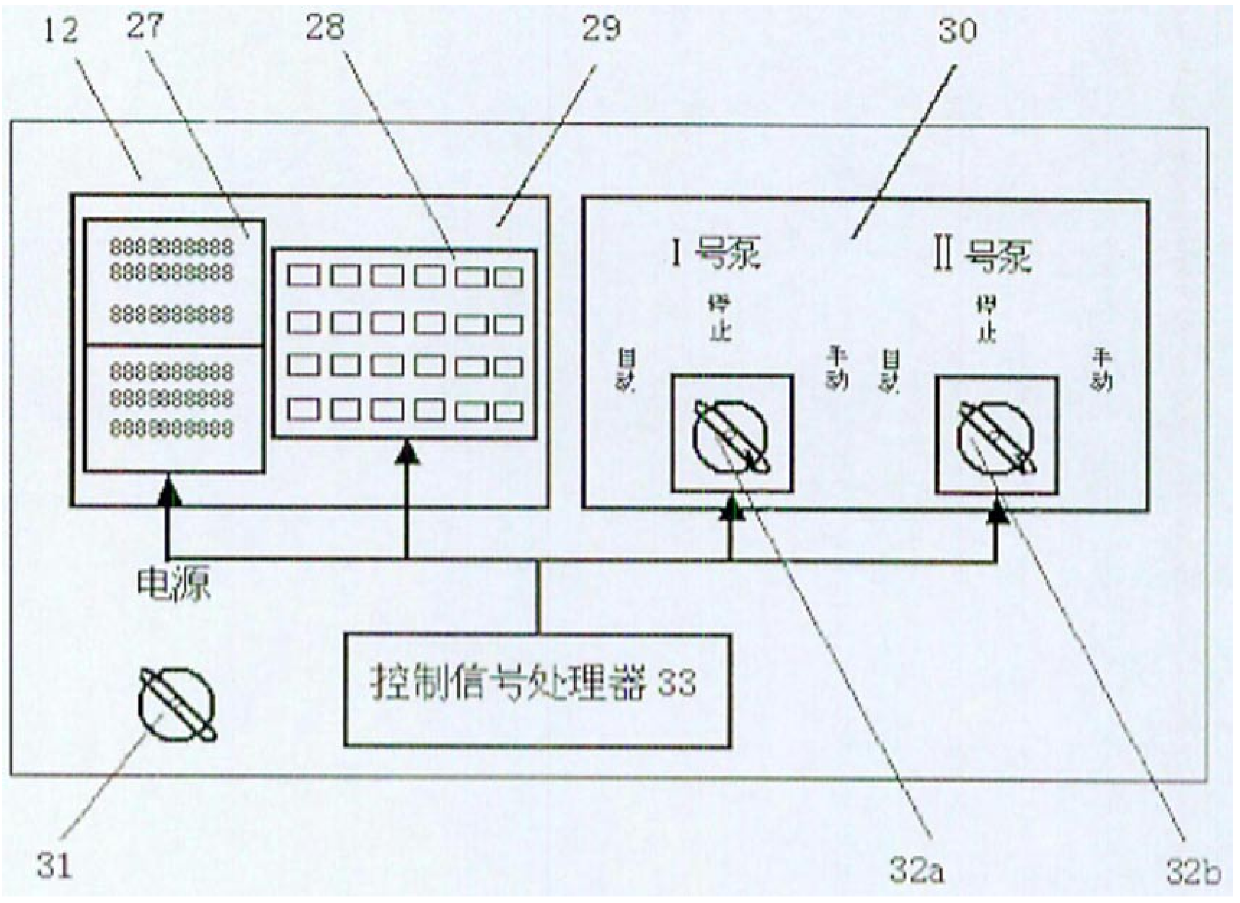

The utility model relates to a field oil receiving and sending oil operation vehicle, which is mainly used for setting up digital field oil depots. The shelter for oil delivery operation is divided into front cabin, middle cabin and rear cabin. The interior of the front cabin is divided into upper and lower floors. The upper layer is the crane tube room, and the lower layer is the pump room. There are two sets of pipeline systems and an electrostatic oil spill alarm system inside. There are two sliding doors on the top of the crane tube room that can be retracted freely. The middle cabin is a tank room for storing soft oil tanks and a set of hydraulic lifting system; the rear cabin is divided into upper and lower layers. It is divided into squares of the same size for storing polyurethane oil hoses. The lower layer is divided into two identical spaces, and the control cabinet, accessory box and two hydraulic trolleys are symmetrically placed. The control cabinet is driven by the oil pump motor. Controller and The fuel delivery controller is composed of two parts. The fuel delivery controller works under the unified and coordinated management of the CQM1H programmable control signal processor to realize the automatic control of sending and receiving oil. The invention reduces labor intensity, saves labor time, has a more reasonable structure, realizes automatic oiling under field conditions, and improves field oil supply capability.

Description

Field fuel receiving and dispatching vehicle technical field The invention relates to field oil sending and receiving operations, in particular to a field oil sending and receiving operation vehicle, which is mainly used for setting up digital field oil depots and providing oil support for combat troops under field conditions. Background technique The existing field oil supply of the group army is to use the "campaign field oil depot" (see the "Field Oil Equipment and Application" textbook, Beijing Military Region Oil Training Brigade, March 2003 edition), which consists of three identical units, each unit Capacity 400 meters 3 , each unit sends and receives oil, stores oil, and transports and loads it on a fully loaded and unloaded vehicle-mounted pallet, and the parts of sending and receiving oil and oil storage are concentrated in a combined compartment. Its combined compartment includes a set of engine pump sets and internal pipelines, placed in the rear compartment o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B60P3/22B60P1/44

Inventor 李连聪张文峰刘永明王国水裴英民陈涛张波郇栋

Owner 中国人民解放军北京军区油料训练大队

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com