Edible oil press device

A technology for edible oil and press board, which is applied in the direction of press, fat oil/fat production, and fat production, etc., can solve the problems of high input cost, the taste of edible oil cannot be optimized, and the structure of the pressing device is complicated, so as to achieve the control of quality, The effect of accelerated oil flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

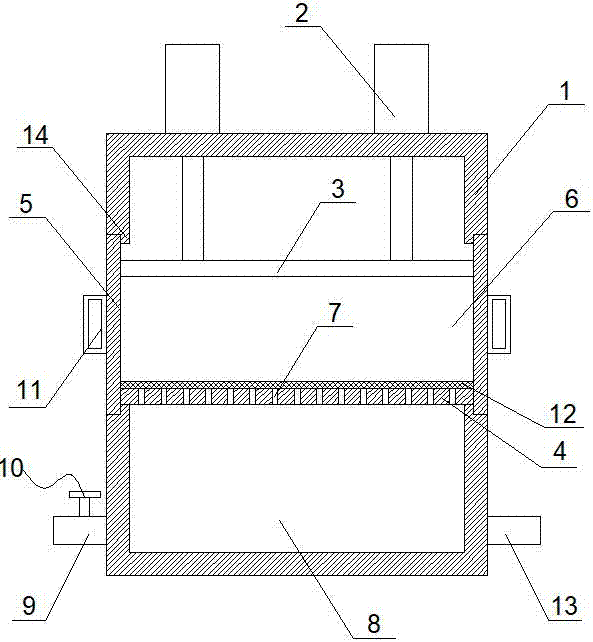

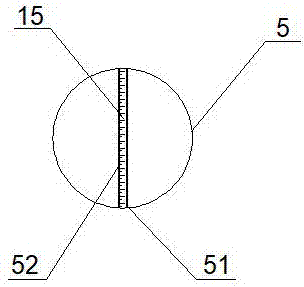

[0015] like Figure 1-3 As shown, the present invention discloses an edible oil pressing device, comprising: a tank body 1, two hydraulic push rods 2 arranged on the top surface of the tank body 1, the bottom ends of the hydraulic push rods 2 are fixedly connected to a horizontally arranged Squeeze plate 3, the inside of the tank body 1 is provided with a support plate 4 located directly below the press plate 3, and the left and right side walls of the tank body 1 are screwed to connect the circular side cover door 5, and the side cover door The outer wall of the 5 is provided with a handle 11 for easy operation, and the handle 11 is provided for conveniently operating the side cover door 5 to be screwed open or closed. Sealed vacuum press chamber6.

[0016] Between the support plate 4 and the bottom surface of the tank body 1 is an oil storage chamber 8, and a plurality of overflow holes 7 are opened on the support plate 4, and the overflow holes 7 communicate with the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com