Method for preparing butanediol by carrying out two-stage catalytic hydrogenation on butynediol

A technology for producing butynediol and butanediol, which is applied in the field of hydrogenation and can solve problems such as environmental pollution, undisclosed catalyst preparation methods, and decreased reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

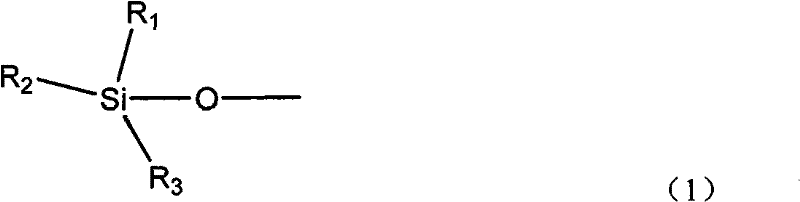

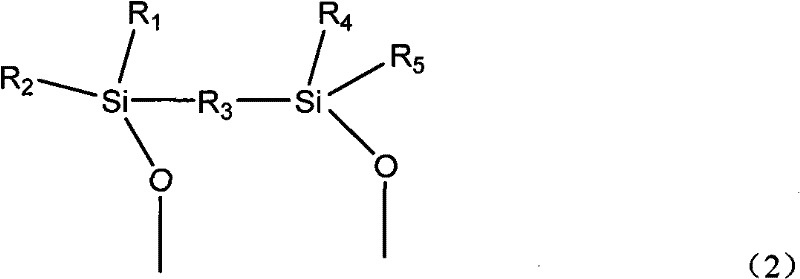

Method used

Image

Examples

Embodiment 1

[0053] (1) One stage bed hydrogenation

[0054] The raw material is purified aqueous solution containing 40wt% butanol diol, and the catalyst is Ni / Al 2 o 3 (Ni: 26.0wt%; silane group content is 3.75wt%, produced by Beijing Research Institute of Chemical Industry), using a fixed-bed reactor to evaluate catalyst performance, the reaction temperature is 130 ° C, the pressure is 2.0MPa, the hydrogen / phenylacetylene molar ratio is 8:1, the volume space velocity is 50h -1 . Catalyst evaluation after 200h by TG-MS (synchronous thermal analyzer coupled with mass spectrometer, synchronous thermal analyzer: NETZSCH, STA 449 C Jupiter, mass spectrometer: NETZSCH, QMS 403 C Aolos, the following examples are the same) analysis and calculation The amount of carbon deposited on the catalyst. The reaction result is: the conversion rate of butynediol is 100%, the conversion rate of butenediol is 85%, and the carbon deposition amount of the catalyst is 65 mg / g.

[0055] (2) Two-stage bed ...

Embodiment 2

[0058] (1) One stage bed hydrogenation

[0059] The raw material is purified aqueous solution containing 46wt% butanol diol, and the catalyst is Pd-Ag / Al 2 o 3 (Pd: 0.45wt%; Ag: 0.20wt%; Silane group content is 3.26wt%, produced by Beijing Research Institute of Chemical Industry), using a suspended bed reactor to evaluate catalyst performance, the reaction temperature is 65 ° C, the pressure is 1.5MPa, The hydrogen / phenylacetylene molar ratio is 10:1, and the volumetric space velocity is 50h -1 . After 200 h of catalyst evaluation, the carbon deposition amount of each catalyst was calculated by TG-MS analysis. The reaction result is: the conversion rate of butynediol is 100%, the conversion rate of butenediol is 78%, and the carbon deposition amount of the catalyst is 58 mg / g.

[0060] (2) Two-stage bed hydrogenation

[0061] The catalyst is Ni-Cu / Al 2 o 3 (Ni: 23.0wt%; Cu: 2.1wt%; Silane group content is 2.87wt%, produced by Beijing Research Institute of Chemical Industr...

Embodiment 3

[0063] (1) One stage bed hydrogenation

[0064] The raw material is purified aqueous solution containing 35wt% butanol diol, and the catalyst is Pd / Al 2 o 3 (Pd: 0.60wt%; silane group content is 4.02wt%, produced by Beijing Research Institute of Chemical Industry), using a suspended bed reactor to evaluate catalyst performance, the reaction temperature is 60 ° C, the pressure is 3.0MPa, the hydrogen / phenylacetylene molar ratio is 8:1, and the volumetric space velocity is 50h -1 . After 200 h of catalyst evaluation, the carbon deposition amount of each catalyst was calculated by TG-MS analysis. The reaction result is: the conversion rate of butynediol is 100%, the conversion rate of butenediol is 76%, and the carbon deposition amount of the catalyst is 54 mg / g.

[0065] (2) Two-stage bed hydrogenation

[0066] The catalyst is Ni-Cu-Zn / Al 2 o 3 (Ni: 22.0wt%; Cu: 2.3wt%; Zn: 1.6wt%; silane group content is 2.28wt%, produced by Beijing Research Institute of Chemical Industr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com