Modified condensation reduction alkylation catalyst

A catalyst and alkylation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, amino compound preparation, etc., can solve the problems of high raw material consumption, easy pulverization, waste of raw materials, etc. , to achieve the effects of good anti-powdering ability, side reaction suppression and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

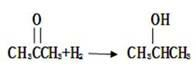

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Dissolve 250g of copper nitrate and 300g of zinc nitrate in 1L of water, heat to 50°C, dissolve 400g of sodium carbonate in 3L of water, and heat to 70°C, then slowly add sodium carbonate dropwise to the copper nitrate and zinc nitrate In the mixed solution, stir rapidly at the same time until pH = 7.5. Continue to stir at 70°C for 1 hour, then add 30g of silicon dioxide powder, stir for another 1 hour, then filter and wash, and dry the solid material at 120°C for 6 hours. Roast at 300°C for 2 hours, then add 2% graphite and 4% water to mix evenly, and press it into a tablet of Ф5×(4.5-5.5) mm with a tablet machine, so that the molar ratio of copper to zinc of the catalyst is 0.94 ; The molar ratio of copper to silicon is 2.1.

Embodiment 2

[0029] Example 2: Dissolve 500g of copper nitrate and 25g of zinc nitrate in 1L of water, heat to 50°C, dissolve 550g of sodium bicarbonate in 3L of water, and heat to 70°C, then slowly add the sodium bicarbonate solution dropwise to the copper nitrate and In the mixed solution of zinc nitrate, stir rapidly at the same time until the pH=7.5. Continue to stir at 70°C for 1 hour, then add 150g of silica powder, stir for another 1 hour, then filter and wash, and dry the solid material at 120°C 6 hours, roasted at 300°C for 2 hours, then add 2% graphite and 4% water to mix evenly, and press it into a tablet of Ф5×(4.5-5.5) mm with a tablet machine, and the catalyst copper zinc prepared in this way The molar ratio is 22.4; the copper-silicon molar ratio is 0.83.

Embodiment 3

[0030] Example 3: Dissolve 200g copper nitrate and 350g zinc nitrate in 1L water, heat to 50°C, dissolve 400g sodium carbonate in 3L water, and heat to 70°C, then slowly add the sodium carbonate solution dropwise to copper nitrate and zinc nitrate Stir rapidly at the same time until pH = 7.5. Continue to stir at 70°C for 1 hour, then add 5.6g of silicon dioxide powder, stir for another 1 hour, then filter and wash, and dry the solid material at 120°C for 6 hour, roasting at 300°C for 2 hours, then add graphite and 2% water to mix evenly, and press it into a tablet of Ф5×(4.5-5.5) mm with a tablet machine, so that the catalyst copper-zinc molar ratio is 0.64; The molar ratio of copper to silicon is 8.9.

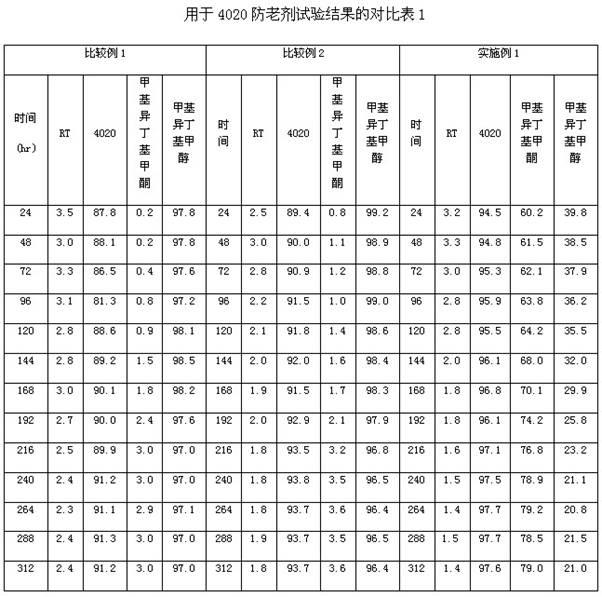

[0031] The performance comparison of embodiment catalyst and comparative example catalyst:

[0032] Evaluation method: The laboratory device completely simulates the large-scale industrial production device. The reactor is a Ф32 stainless steel tube with a length of 2m, and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com