Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198results about How to "Improved chalking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphate film-coated powder and preparation method thereof

InactiveCN101045828AUniform particlesParticle size distribution andNon-macromolecular adhesive additivesOther chemical processesDepolymerizationDouble decker

This invention relates to a method of preparing envelope powder. The shattering, depolymerization and coating processed at same time, and solid phase acid-base reaction participate the method. This envelope powder possess double-decker or three-layer structure, inner core is composed by oxide or hydrate or inorganic oxysalt, crust composed by inorganic oxysalt, envelope by aluminum phosphate or boron phosphate. This low cost powder be able to used as fortifier, power stuff, colorant and so on, applied to plastic, rubber, ceramics, dope, binder and paper, set foundation for popularization of ultramicro and nanometer powder.

Owner:张义纲 +1

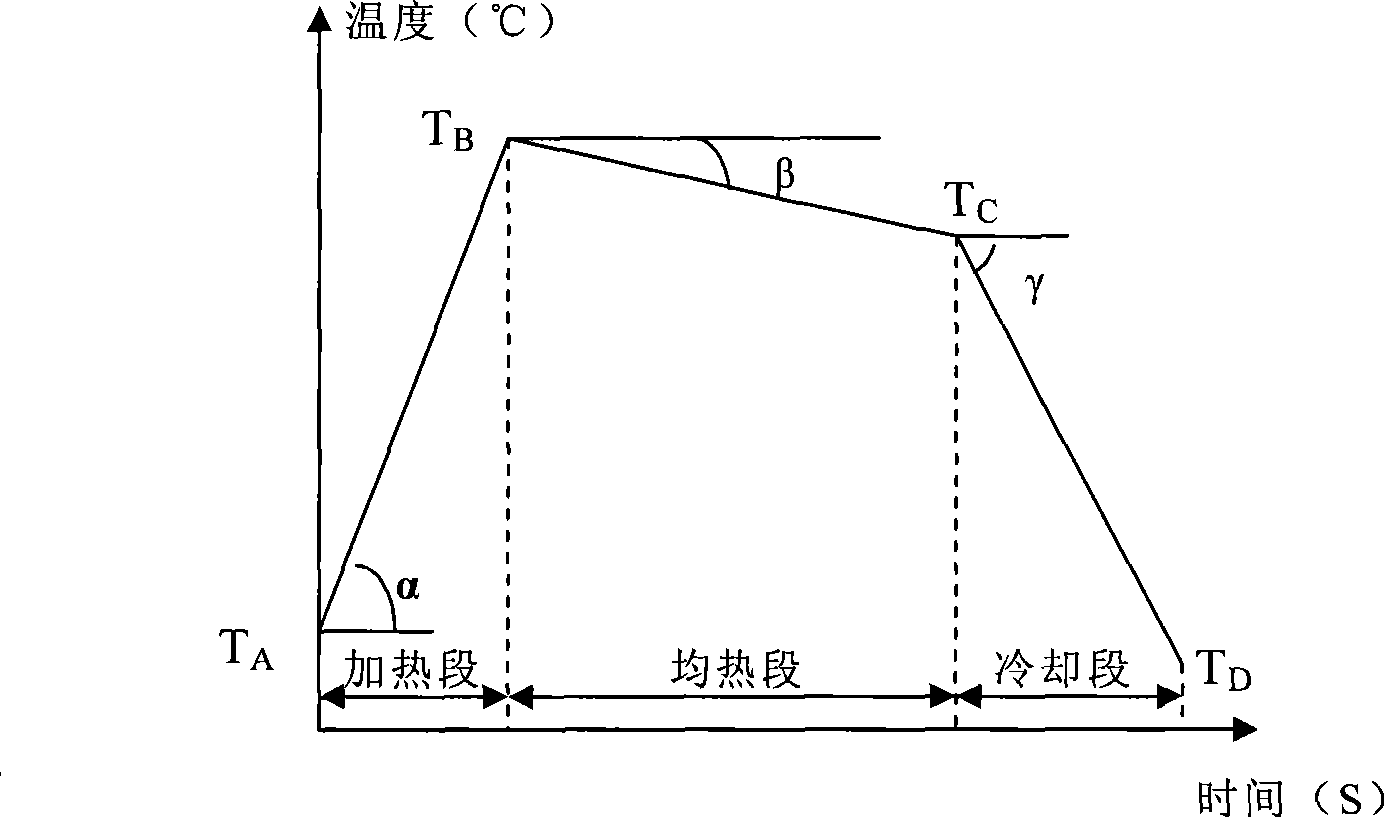

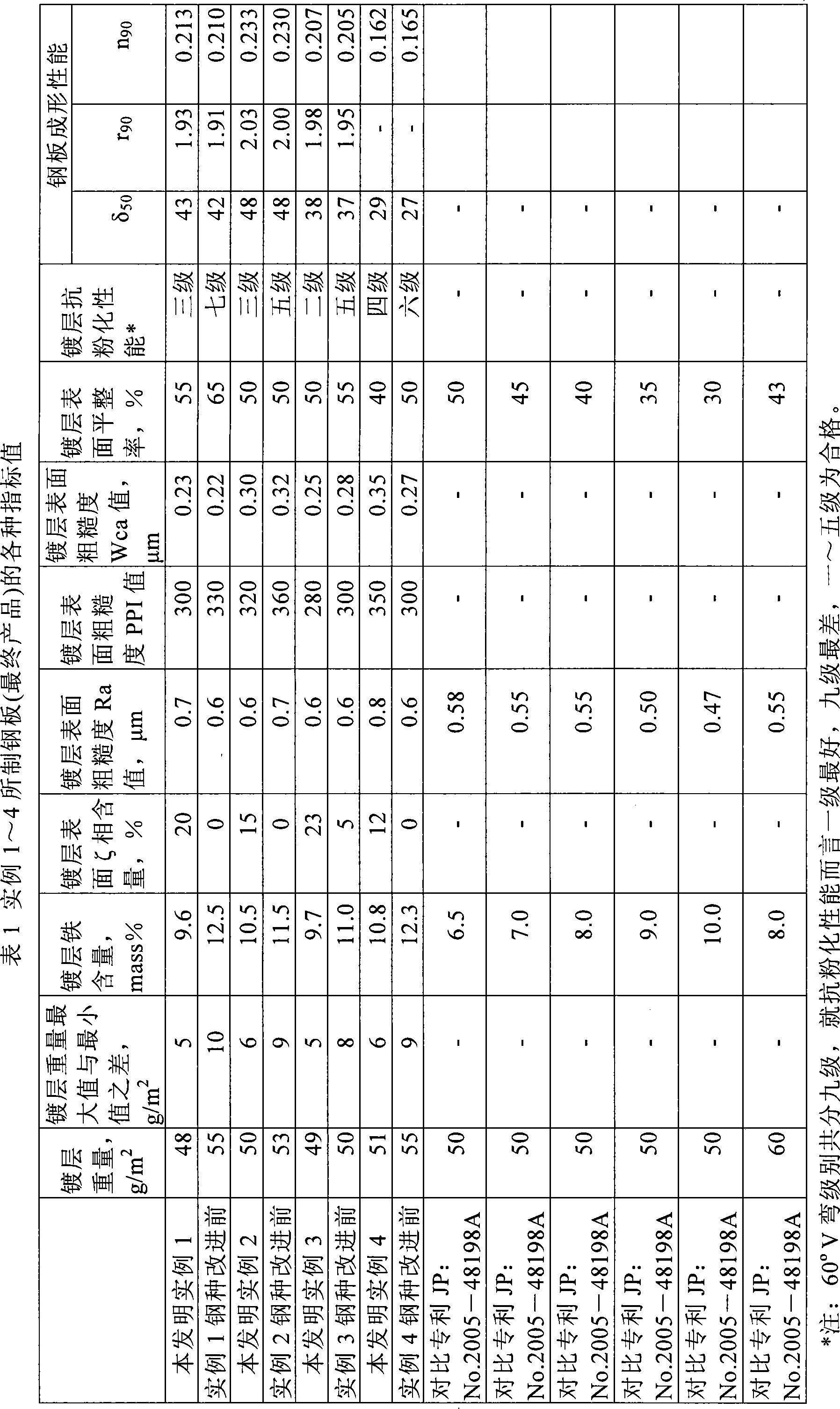

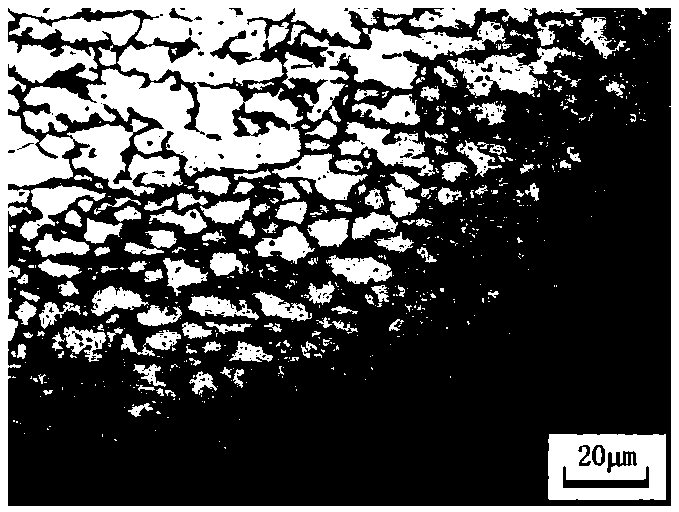

Method for controlling alloyed hot dip galvanizing steel plate coating phase structure and alloyed hot dip galvanizing steel plate

InactiveCN101376956AGood chalking resistanceGood stamping performanceHot-dipping/immersion processesFurnace typesSheet steelSurface roughness

The invention provides a method for controlling alloyed hot-dip galvanized cladding, in particular hot-dip galvanized steel sheet cladding phase structure. The method comprises the following steps: at least a set of strip steel which is provided with a steel stabilizing device and can stably control hot-dip galvanization process parameters and air knife parameters to obtain even thickness of the cladding is arranged between an air knife and a top roller; an inclined alloyed cladding heat treatment annealing curve with even temperature sections from high temperature to low temperature is selected and the strip steel is evenly alloyed, to improve the evenness of the alloying process and the alloying degree of the strip steel cladding; in addition, flat roll surface roughness and flat extensibility are selected, to control the cladding surface roughness and cladding surface flat rate and improve the shaping performance of the steel sheet. The invention also provides an alloyed hot-dip galvanized steel sheet manufactured by the method for controlling the alloyed hot-dip galvanized steel sheet cladding phase structure; the hot-dip galvanized steel sheet has excellent cladding powder resistance and shaping performance, and is very applicable to automobile internal and external plates as well as household electric appliance external plates.

Owner:BAOSHAN IRON & STEEL CO LTD

Weather-resistant exterior wall paint and preparation method thereof

InactiveCN102850878AImproves UV resistanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesCelluloseMoisture resistance

The invention relates to a weather-resistant exterior wall paint which comprises, by weight, 1 to 7 parts of cellulose, 0.5 to 2 parts of AMP-95, 100 to 200 parts of barite, 30 to 120 parts of calcined kaolin, 30 to 90 parts of a hydrophobic agent, 50 to 280 parts of rutile titanium dioxide, 8 to 30 parts of glycol, 8 to 38 parts of a film forming auxiliary agent, 0.5 to 2.5 parts of an antiseptic, 2.8 to 10 parts of a mildew inhibitor, 2 to 8 parts of a leveling agent, 250 to 500 parts of pure acrylic acid emulsion, 20 to 200 parts of silicone acrylic emulsion, 2 to 10 parts of a thickening agent and 200 to 380 parts of deionized water. The weather-resistant exterior wall paint provided by the invention can resist ultraviolet rays in the environment, overcomes the problems of fading and gloss loss of a coating, prolongs the service life of the coating and has good anti-fouling performance, rub resistance, chalking resistance, weather resistance, mildew resistance and moisture resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

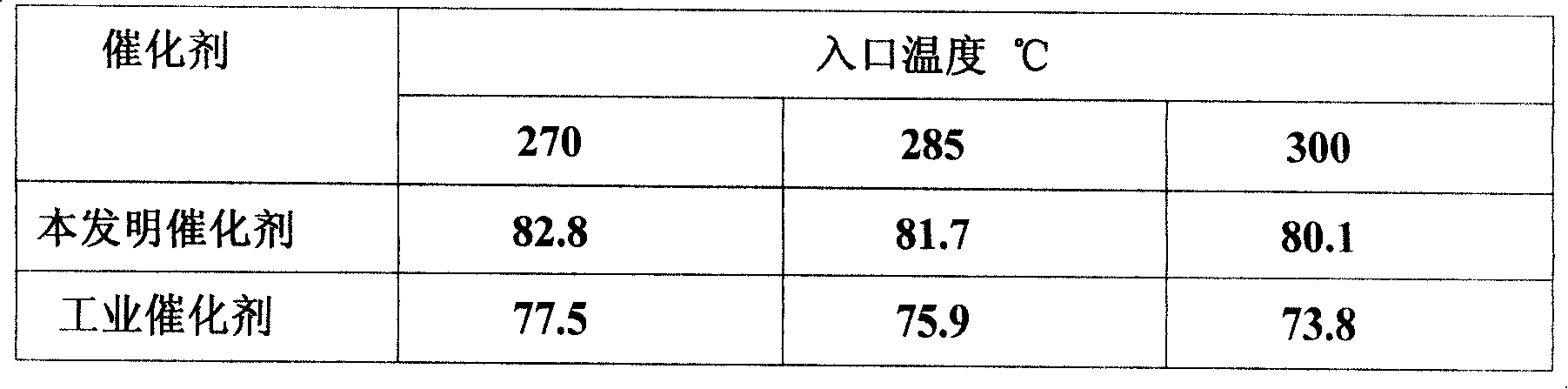

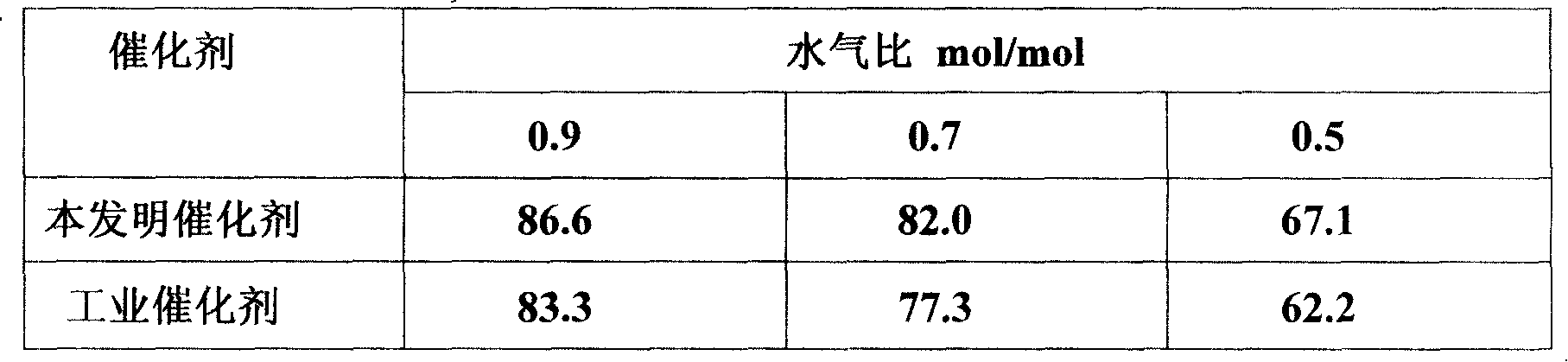

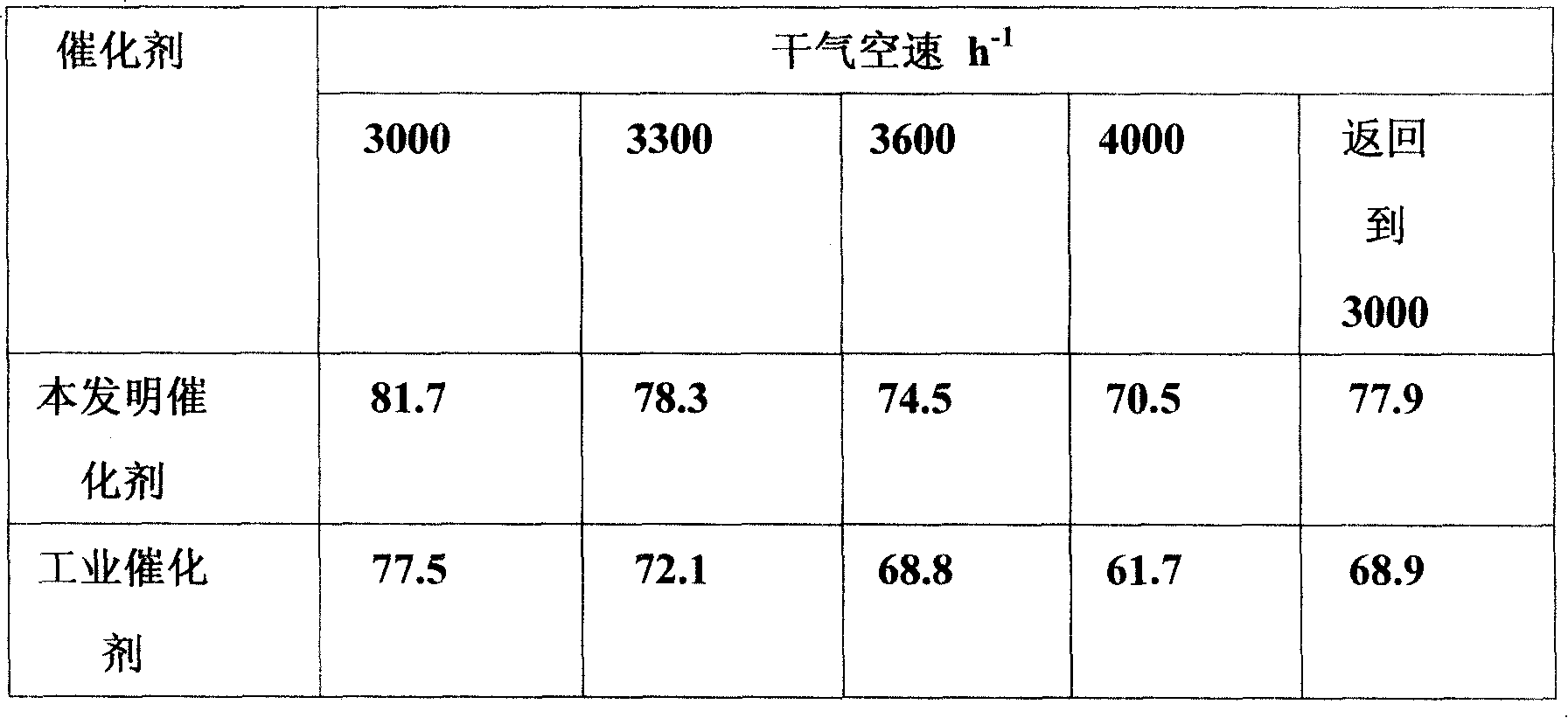

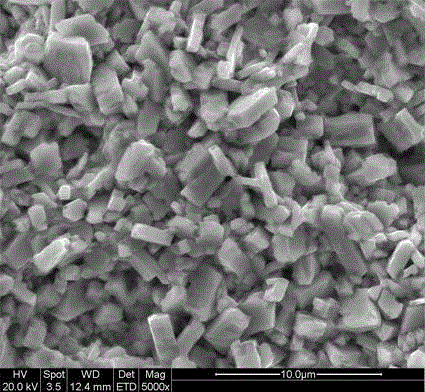

Polynary metal oxide catalyst and preparing process thereof

ActiveCN101199933AHigh activityHigh low temperature activityCatalyst carriersCombined combustion mitigationCerium(IV) oxideManganese

The invention discloses a multi-complex-metal-oxides catalyst and the preparation method. The catalyst carrier is multi-complex-metal-oxides solid alkali or surface solid alkali or the precursors of the solid alkali or surface solid alkali. The multi-complex-metal-oxides is complex oxides by combining two or more than two selections from alumina, titania, zirconium dioxide and ceria with one or more than one selections from magnesia, calcium oxide, baryta, potassium oxide and sodium oxide. Active ingredient is composed of cobalt oxides or / and nickel oxide and molybdenum trioxide or / and tungsten trioxide. The additive added to carriers or active components is the oxide of at least one of the following elements: cerium, lanthanum, zinc, zirconium, nickel or manganese. The invention has the advantages of high activity, high activity at low-temperature, high activity stability and wide temperature range of activity; high intensity, high intensity stability and high anti-hydration and anti-pulverization ability, wide water / gas ratio adaptability and wide range for impurity content. The catalyst of the invention is applied to the promotion of dirty water gas shift reaction.

Owner:汤海溶 +2

Water-based fluorocarbon top coat for wind-powered blades and method for preparing water-based fluorocarbon top coat

ActiveCN102675998AImprove adhesionGood flexibilityAntifouling/underwater paintsPaints with biocidesWater basedLow speed

The invention discloses a water-based fluorocarbon top coat for wind-powered blades and a method for preparing the water-based fluorocarbon top coat and relates to the field of protective paint. According to the water-based fluorocarbon topcoat for wind powered blades, through compounding an hydroxyl acrylic emulsion and a water-based fluorocarbon emulsion and crosslinking hydroxyl acyclic acid with isocyanate so as to form a netted film, thus the coating adhesion, flexibility, chemical medium resistance, wear resistance of a coating are increased; due to the addition of the water-based fluorocarbon emulsion, the weather fastness of the coating is improved, and the gloss retention, color retention and chalking resistance of the coating are excellent; under the condition of stirring a water-dispersed isocyanate curing agent at a lower speed, an ideal emulsion is formed easily through mixing, thereby ensuring the performance of paint; and because of the introduction of a light stabilizer, the lightfastness, color retention and chalking resistance of the coating are improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

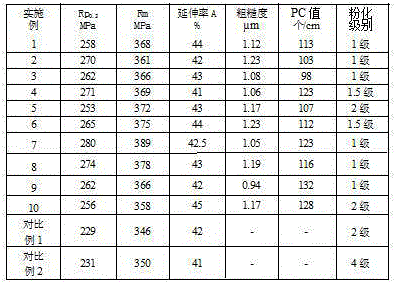

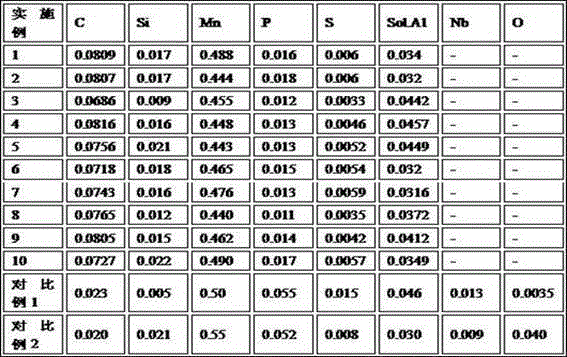

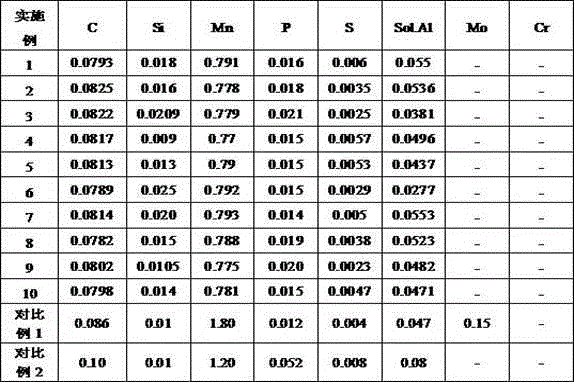

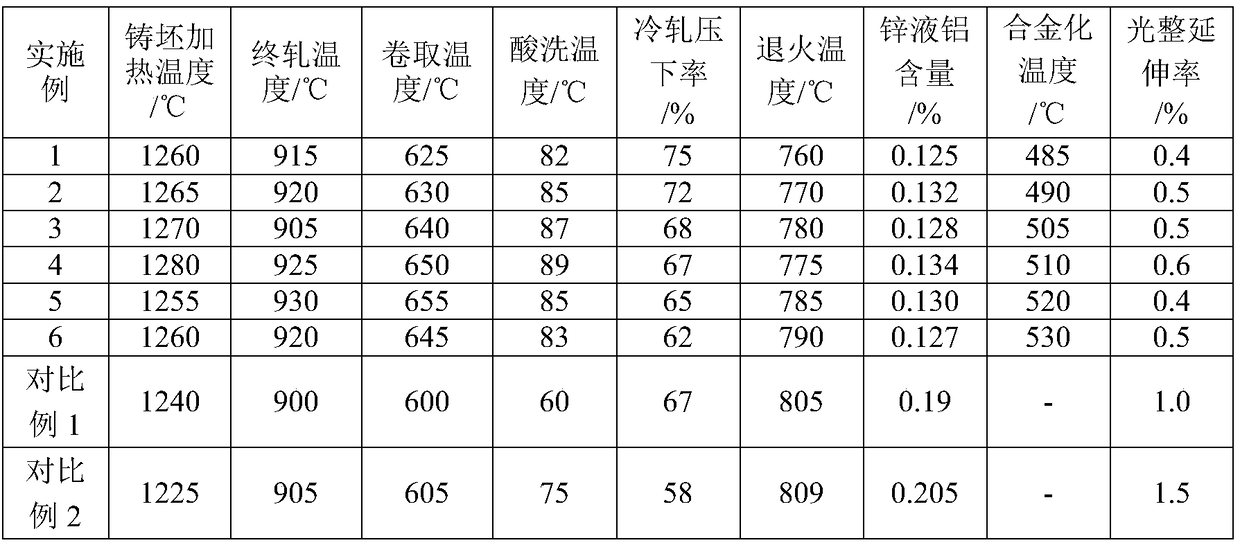

Automobile alloyed hot-dip galvanized steel with tensile strength of 340 MPa grade and production method thereof

ActiveCN104988389AHigh strengthGuaranteed mechanical propertiesHot-dipping/immersion processesContinuous annealingMechanical property

An automobile hot-dip galvanized steel with the tensile strength of 340 MPa grade comprises the components by the weight percentage: 0.06-0.10% of C, less than or equal to 0.03% of Si, 0.40-0.55% of Mn, 0.010-0.025% of P, less than or equal to 0.008% of S, and 0.020-0.070% of Als. A production method comprises the production steps: pretreatment of molten iron; smelting with a converter and treatment with an RH furnace; continuous casting; heating of a casting blank; hot rolling; coiling; pickling; cold rolling; continuous annealing; hot-dip galvanizing; alloying; and finishing. The mechanical properties can be ensured, that is to say, the yield strength is 250-280 MPa, the tensile strength is 340-390 MPa, the extension rate A is more than or equal to 40%, the roughness is 0.6-1.5 [mu]m, the PC value is more than or equal to 90 / cm, and the pulverization performance level does not exceed 2 grade; the automobile hot-dip galvanized steel has simple composition and process, also has relatively good plasticity, besides, has good anti-pulverization performance, and can be used for stamping complex automobile inner plates and structural parts.

Owner:武汉钢铁有限公司

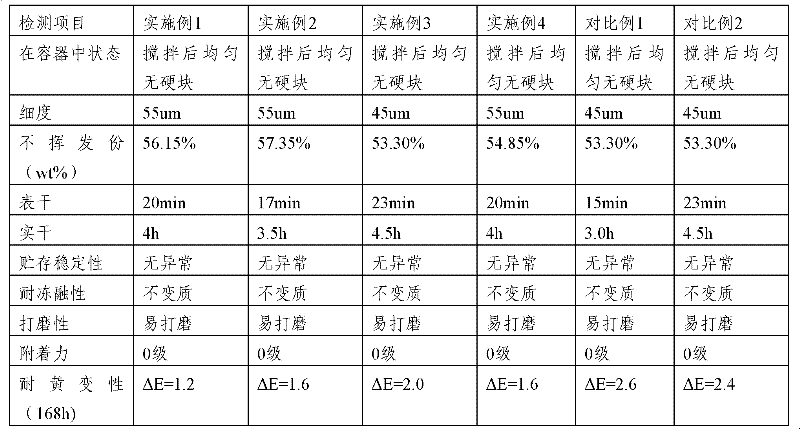

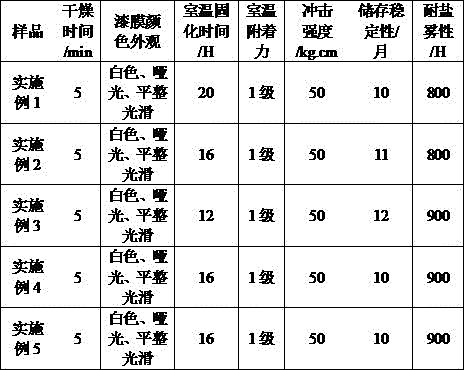

Water-based white sealed primer and preparation method thereof

The invention relates to a water-based white sealed primer and a preparation method thereof. The water-based white sealed primer comprises the following components in part by weight: 350 to 600 parts of water-based resin and 50 to 100 parts of modified barium metaborate. The water-based white sealed primer provided by the invention has performance of sealing wood tannic acid and has a durable and good sealing effect after construction on the base material containing the tannic acid, nicotine blot and water-based pigment. Water-based white wood coating is coated on the primer, so the water-based white wood coating is not polluted by the pollutants and is not discolored, and the primer has high rubbing property, covering power and corrosion resistance and can prevent wood from being rotten and deteriorated.

Owner:BEIJING ZHANCHEN CHEM +2

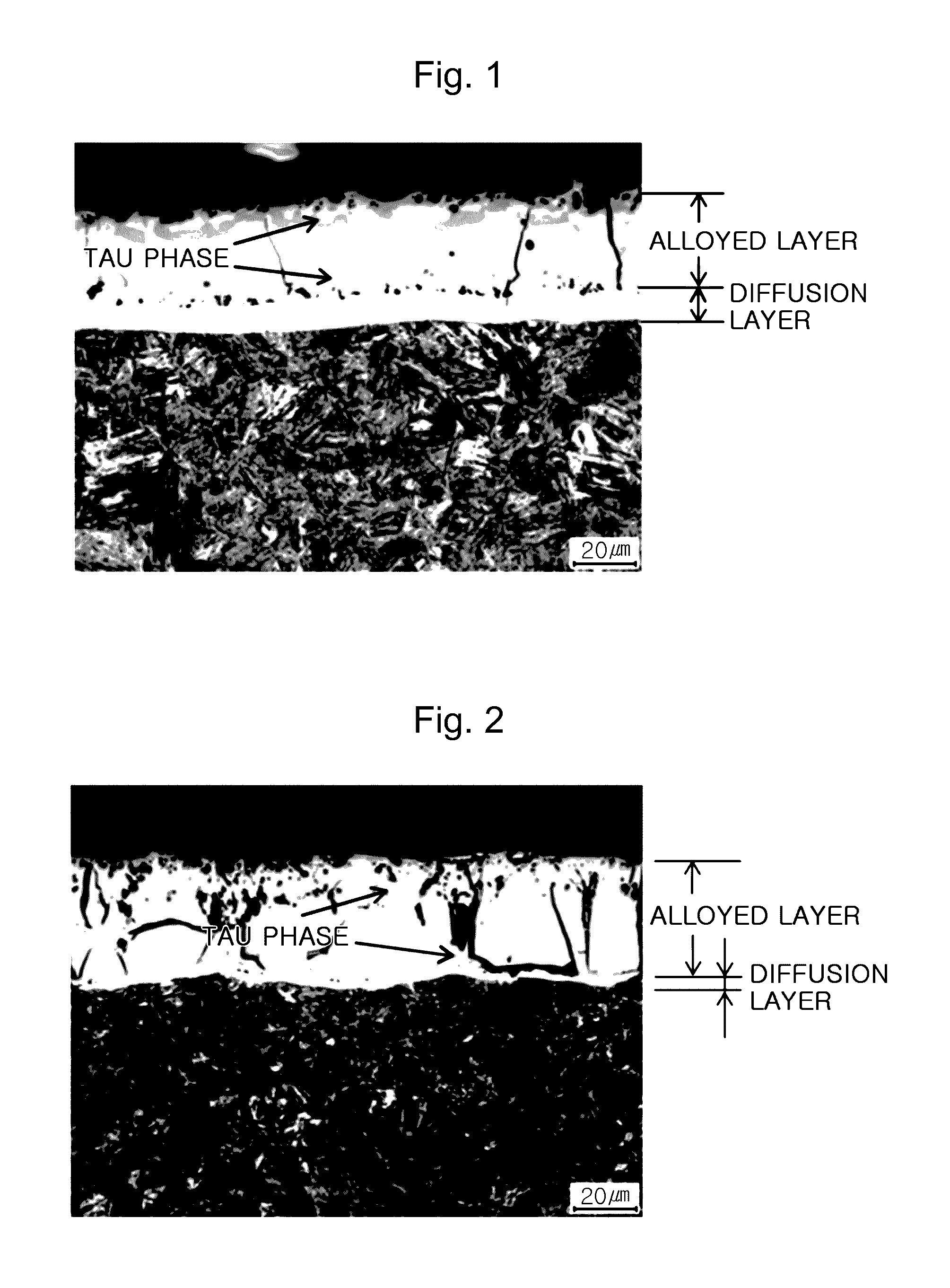

Hot press formed parts having excellent powdering resistance during hot press forming, and method of manufacturing the same

ActiveUS20160362764A1Minimizing detachmentImproved chalking resistanceHot-dipping/immersion processesFurnace typesAlloyDip-coating

Provided is a hot press-formed (HPF) member with excellent powdering resistance at the time of press forming. The HPF member includes a hot-dip coating layer containing Al on a surface of a base steel sheet. The base steel sheet includes, based on wt %, 0.18-0.25% of C, 0.1-1.0% of Si, 0.9-1.5% of Mn, 0.03% or less of P, 0.01% or less of S, 0.01-0.05% of Al, 0.05-0.5% of Cr, 0.01-0.05% of Ti, 0.001-0.005% of B, 0.009% or less of N, the balance Fe, and the other impurities. The hot-dip coating layer comprises a soft diffusion layer and a hard alloy layer. The alloy layer has a Tau phase in the range of 10-30%, in terms of area percent.

Owner:POHANG IRON & STEEL CO LTD

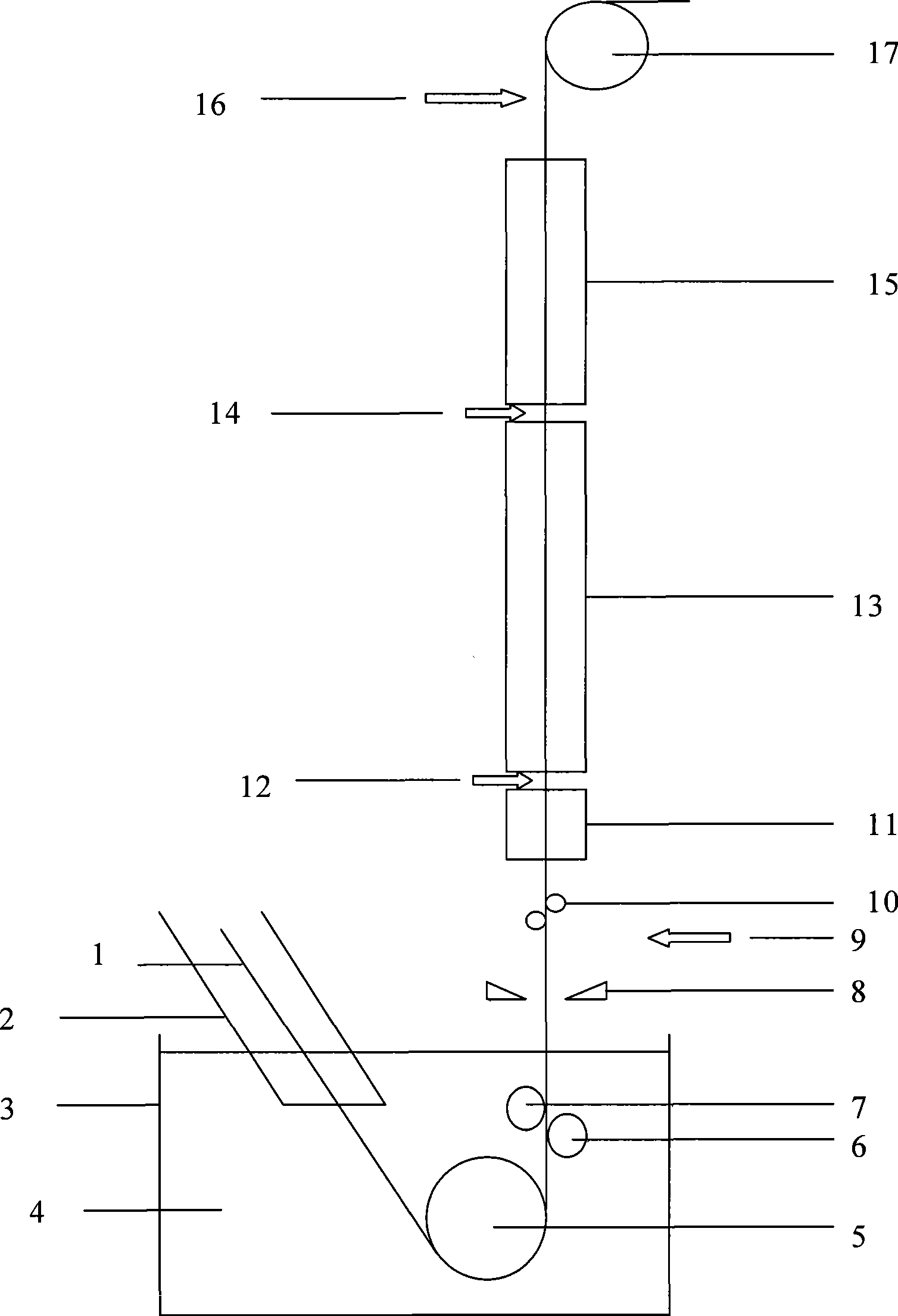

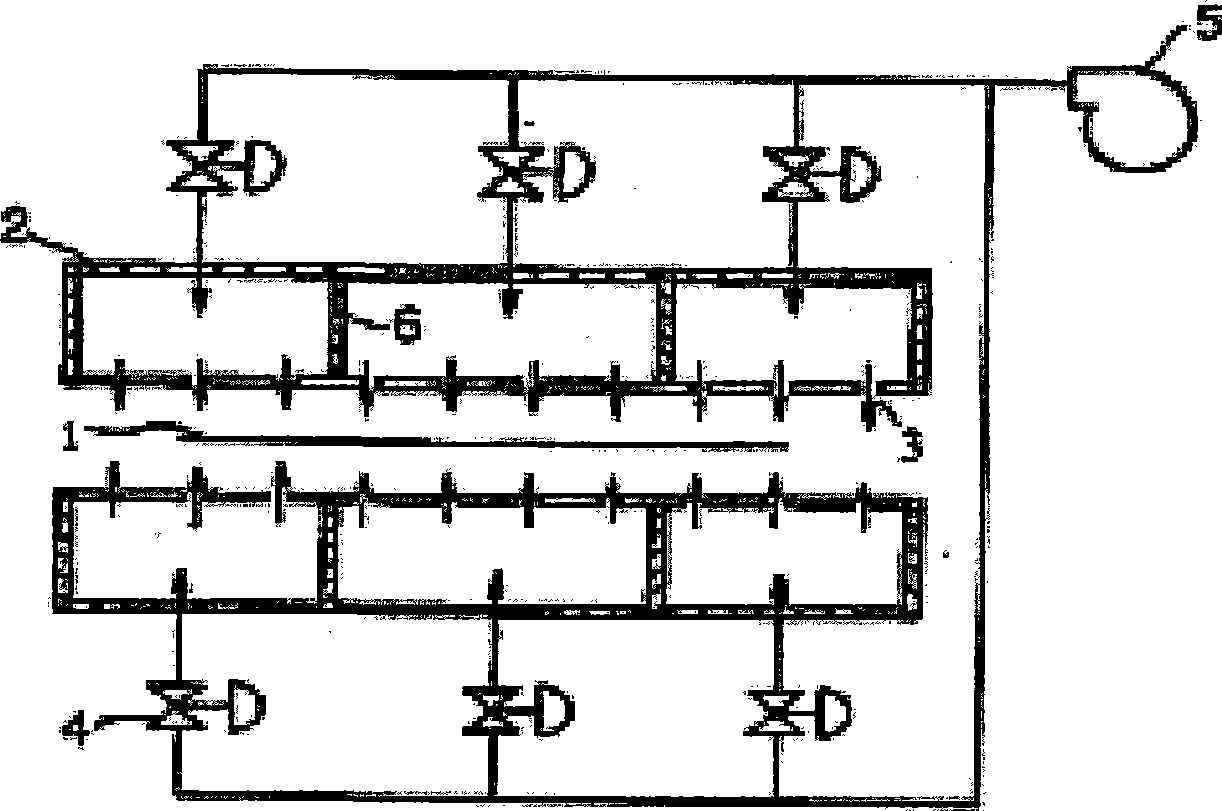

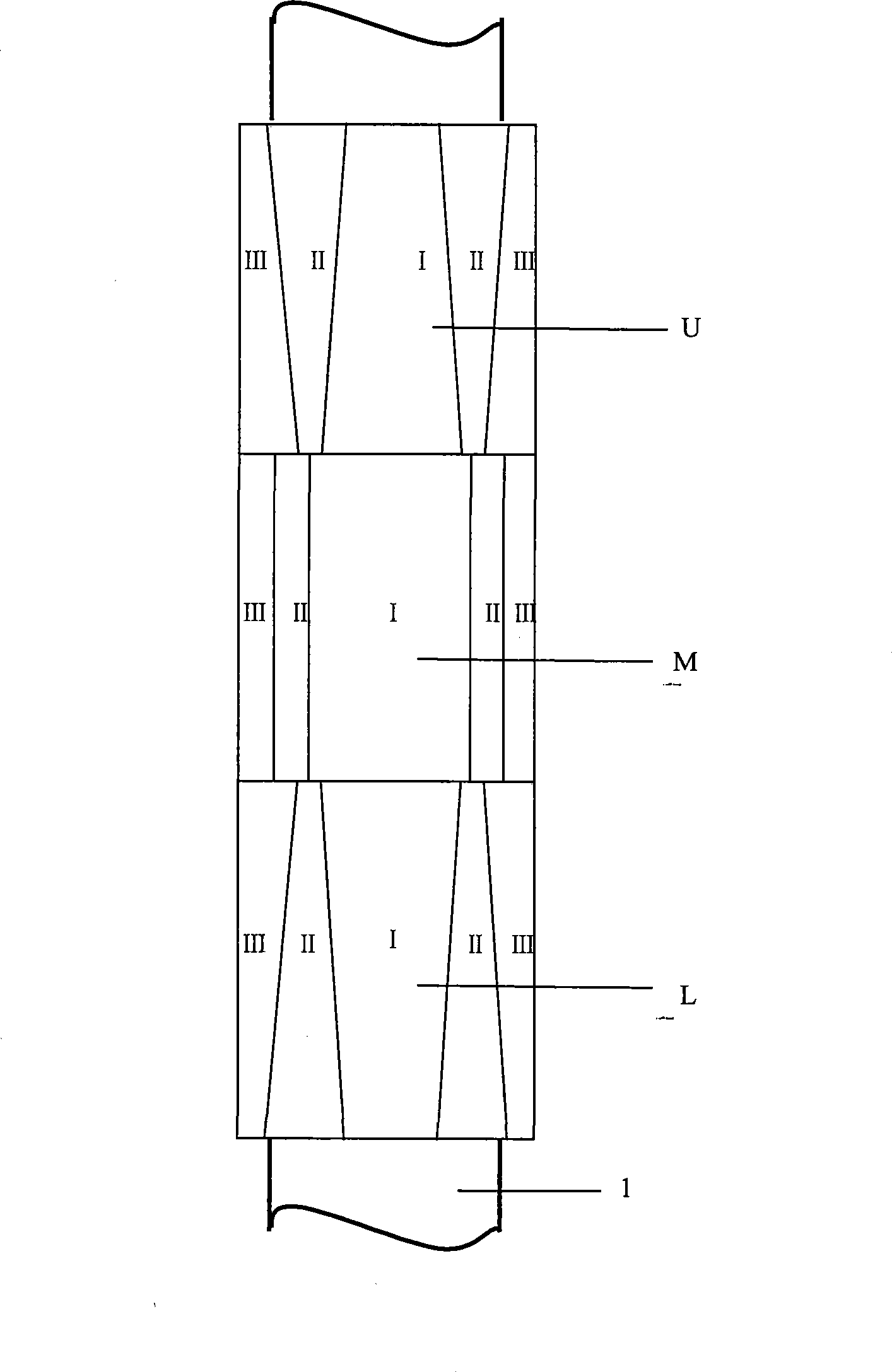

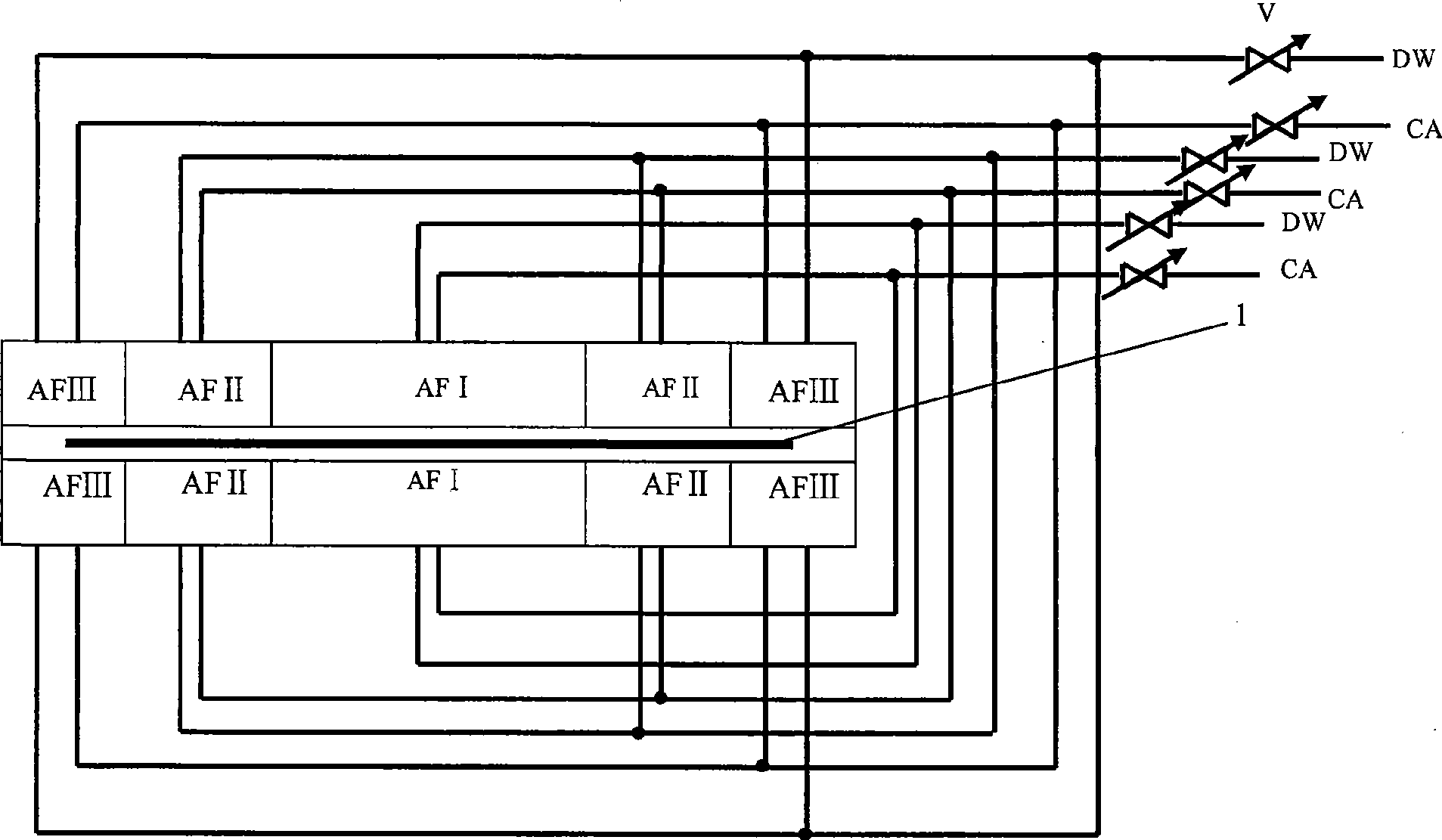

Alloying furnace cooling section strip steel cooling apparatus and cooling control method

ActiveCN101376960AExcellent chalking resistanceLow costHot-dipping/immersion processesFurnace typesUnit speedStrip steel

The invention relates to an alloying furnace cooling section air blasting and air-spray cooling composite cooling device and a cooling regulation method; the cooling device controls different areas along the width direction of the strip steel, and the cooling speed is adjustable along the width of the strip steel; the device is divided into a lower section, a middle section and an upper section along the rolling direction of the strip steel; the middle section is in an alternative deployment way of air blasting cooling and air-spray cooling; the lower and the upper sections are in a pure cooling deployment way; and all sections are grouped in the rolling direction of the strip steel; each group of cooling way can be singly controlled by a switch. The device can regulate the cooling speed after the alloying of the strip steel within quite a large range according to the requirement of an alloying annealing curve even at maximum unit speed, so as to manufacture an alloyed hot-dip galvanized steel sheet with excellent cladding powder resistance, and the evenness of the cladding alloying is very good.

Owner:BAOSHAN IRON & STEEL CO LTD

Automotive alloying hot-dip galvanized steel with tensile strength of 440 MPa and production method

InactiveCN104975226ASmall tissueUniform tissueHot-dipping/immersion processesContinuous annealingPre treatment

Automotive alloying hot-dip galvanized steel with tensile strength of 440 MPa comprises, by weight, 0.08%-0.11% of C, smaller than or equal to 0.03% of Si, 1.10%-1.40% of Mn, 0.015 wt%-0.030% of P, smaller than or equal to 0.010% of S and 0.020%-0.070 of Als. A production method comprises the production steps of hot metal pretreatment, converter refining and RH furnace treatment, continuous casting, casting blank heating, hot rolling, the first time of rapid cooling, reeling, acid pickling, cold rolling, continuous annealing, hot galvanizing, the second time of rapid cooling, alloying, the third time of rapid cooling and finishing. The yield strength of the automotive alloying hot-dip galvanized steel is 330-360 MPa, the tensile strength of the automotive alloying hot-dip galvanized steel is not lower than 440 MPa, the ductility of the automotive alloying hot-dip galvanized steel is larger than or equal to 32%, the roughness of the alloying hot-dip galvanized steel is 0.6-1.5 [u]m, and the PC value of the automotive alloying hot-dip galvanized steel is not smaller than 90 / cm; a galvannealed coating of the automotive alloying hot-dip galvanized steel is small, even and compact in tissue, the pulverization degree is not larger than 2, and the pulverization resisting capability is excellent. Meanwhile, ingredients and technology of the automotive alloying hot-dip galvanized steel are simple, cost is low, and production efficiency is high.

Owner:武汉钢铁有限公司

Cladded cement based artificial moulded stone material

InactiveCN101007727AImprove waterproof performanceImproved chalking resistanceDefoamerSilicate Cement

The invention discloses an artificial moulding stone of cladding cement base in the agricultural technical domain, which comprises the following parts: 25-30% common white silicate cement, 60-65% limestone particle, 5-10% zeolite powder, 1-1.5% resin powder, 0.15-0.18% high-effective dehydragent, 0.15-0.2% defoamer and 0.48-1.12% dye.

Owner:SHANGHAI JIAO TONG UNIV

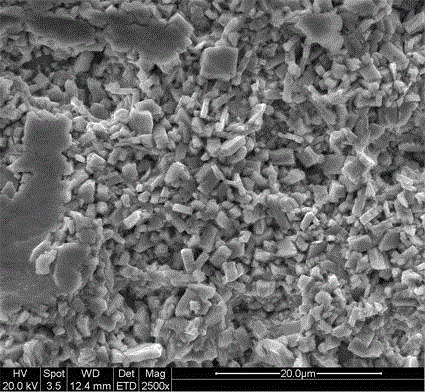

Preparation method for treating titanium white by high zinc salt

ActiveCN104817105AOrderly growth and adjustmentImprove conversion rateTitanium dioxideDecompositionPhosphate

The invention discloses a preparation method for treating titanium white by high zinc salt, and belongs to the field of titanium white powder production. The preparation method includes the process steps of mineral decomposition, titanium liquor purification, hydrolysis, washing, bleaching, rinsing, salt treatment, calcining, crushing and post-treatment. The preparation method is characterized in that bleached metatitanic acid added with rutile calcining seeds and qualified in rinsing is slurried by deionized water, and then salt treatment agents comprising crystalline phase control agents such as phosphoric acid or phosphate, potassium salt, the zinc salt and zircon salt are added. The high zinc salt is used for salt treatment and serves as a crystal accelerator and a crystal stabilizer for accelerating rutile crystal transformation, transformation rate is increased, the calcining temperature of the highest transformation rate is reduced, and weather resistance and pulverization resistance of products are improved. When crystal acceleration and crystal stabilization are enhanced, dosage of the phosphoric acid or phosphate is increased, the zircon salt is added, rutile crystal grain growth is regularly adjusted, and product performances are more superior.

Owner:江苏镇钛化工有限公司

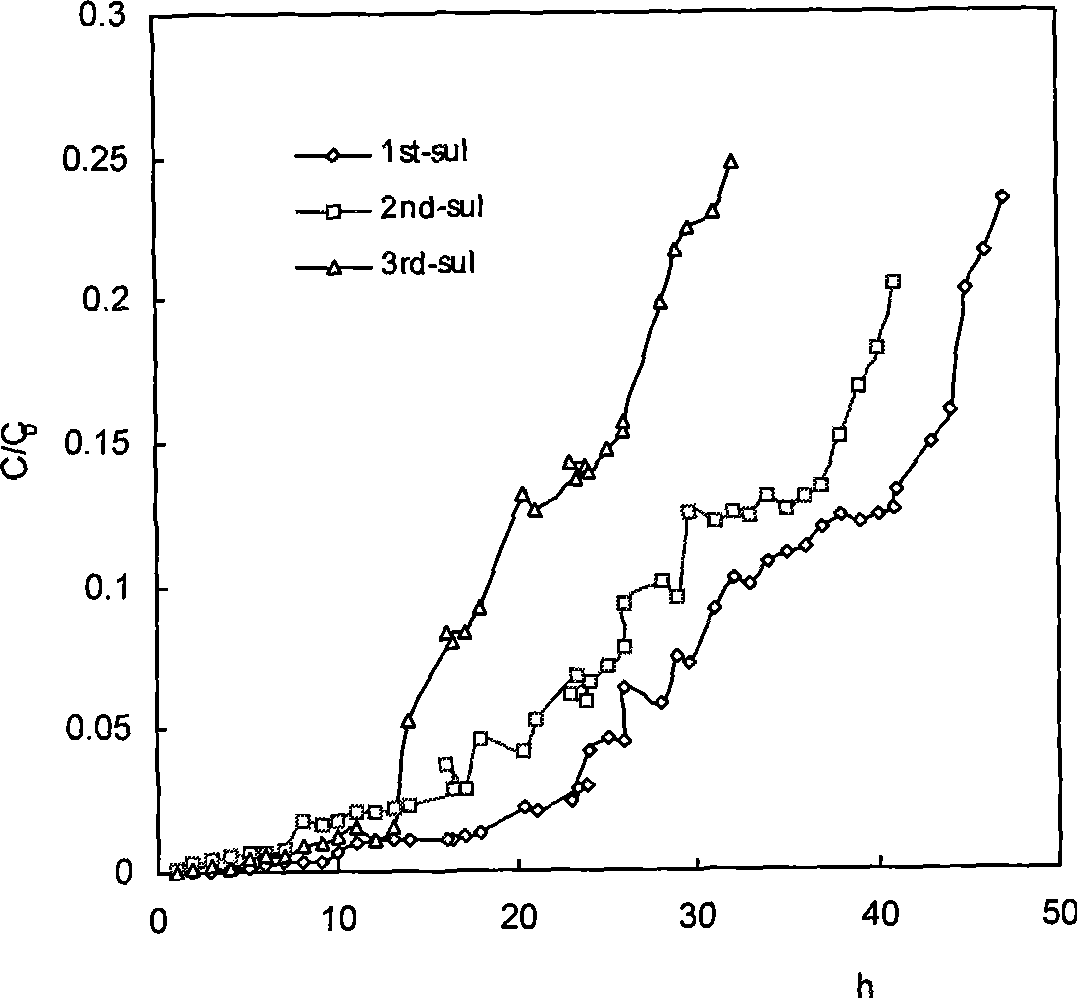

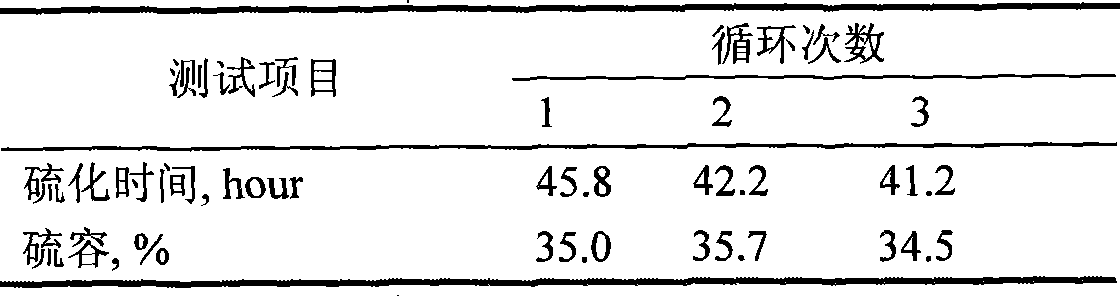

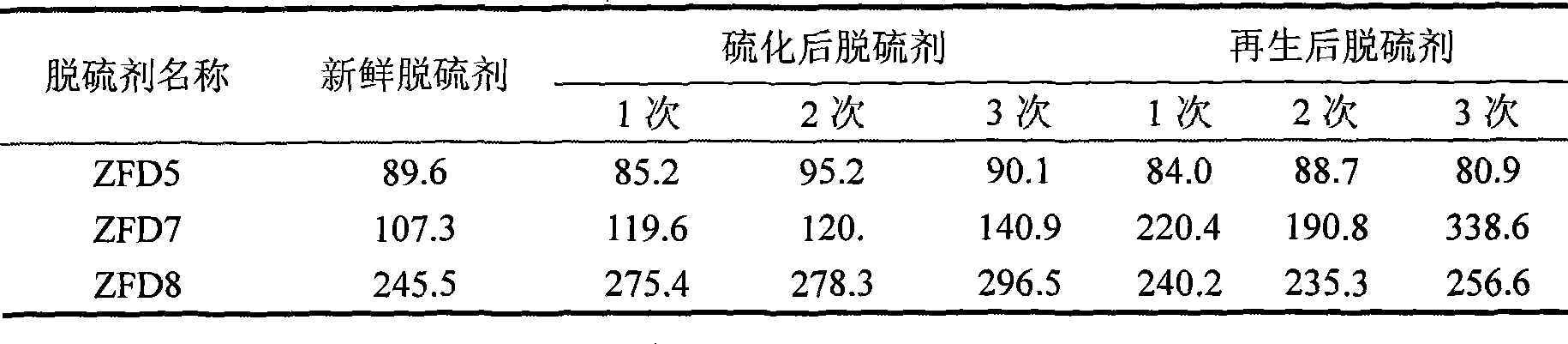

Anti-pulverization medium-high temperature coal gas zinc ferrite desulfurizer and preparation thereof

InactiveCN101440313AImprove desulfurization efficiencyStrong anti-powdering abilityGas purification by catalytic conversionFuel cellsMetallurgy

The invention relates to a high-temperature coal gas anti-chalking zinc ferrite desulfurizer, which belongs to the field of desulfurizer preparation. The desulfurizer consists of active components including 50 to 65 percent of zinc ferrite, 15 to 30 percent of clay addition agent, 6 to 12 percent of pore-forming material and the like. The active component zinc ferrite of the desulfurizer is prepared by adopting a coprecipitation method and is then added with a caking agent through the steps of grinding, mixing, extruding, high temperature calcinations and the like. The desulfurizer adapts to a fixed bed reactor at a desulfurization temperature of between 350 and 600 DEG C, and can be applied to key technology for integrated coal gasification combined cycle power generation and coal gasification fuel cell in the field of high-temperature gas purification and the field of feed gas desulfurization purification.

Owner:TAIYUAN UNIV OF TECH

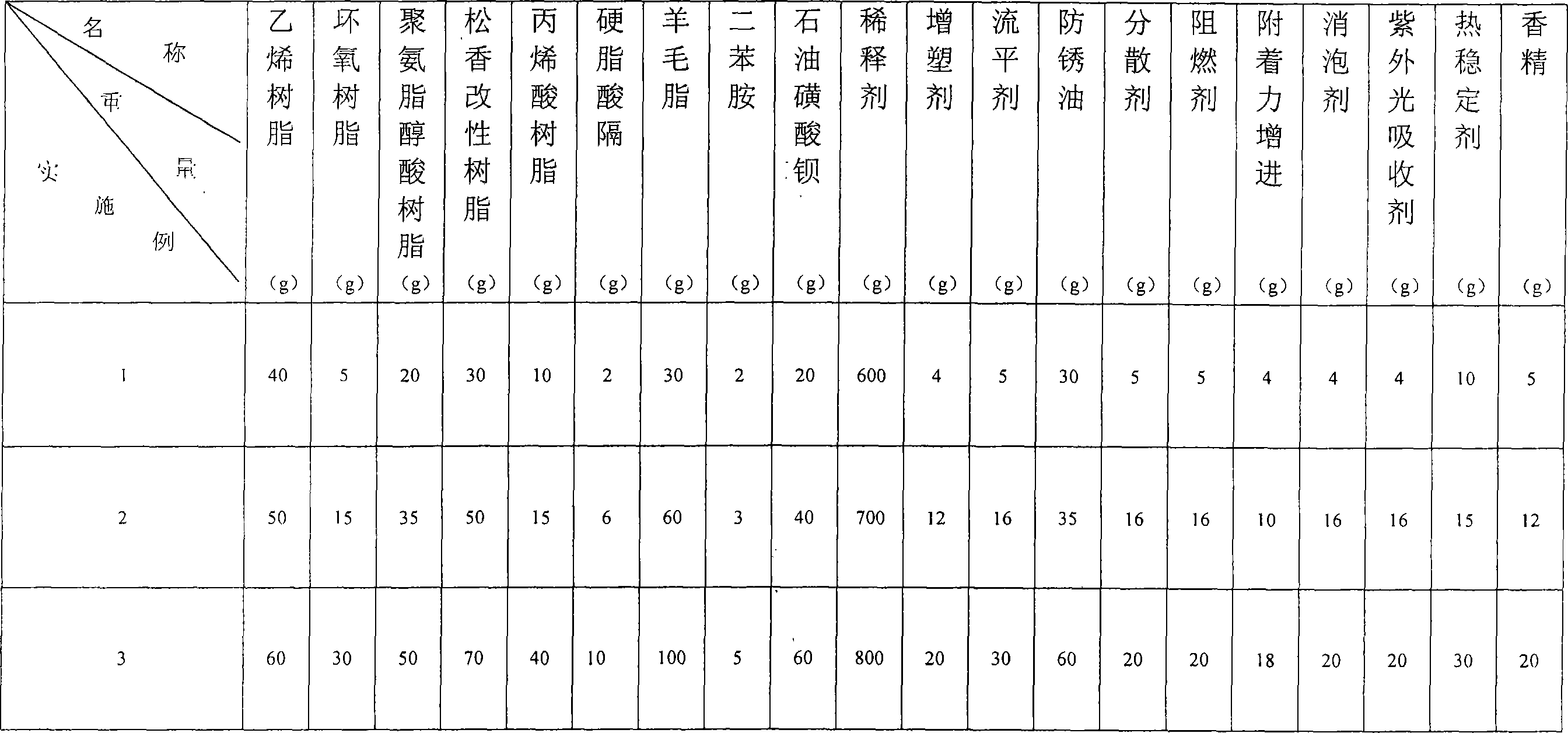

Coating material for high anticorrosive pack, and preparation method

InactiveCN101050329AExcellent physical and chemical propertiesGood chemical resistanceRosin coatingsAnti-corrosive paintsEpoxySolvent

This invention discloses a high-strength antirust packaging paint, which is composed of: ethylene resin, epoxy resin, polyurethane alkyd resin, rosin-modified resin, acrylate resin, cadmium stearate, lanoline, diphenyl amine, barium petroleum sulfonate, essence, antirust oil, plasticizer, heat stabilizer, antirust agent, diluting agent, adhesion promoter, leveling agent, UV absorbent, dispersant, defoamer and flame retardant. The packaging paint can be directly sprayed, soak-coated or brush-coated onto objects with any shape or appearance. A bright and smooth protective film is formed several minutes later. The protective film has high antirust performance, and can be stripped off for recycling.

Owner:郑州博庆环保科技有限公司 +2

Preparation method of titanium dioxide made with compound coating chlorination process

InactiveCN106009783AImprove dispersionImproved chalking resistancePigment treatment with non-polymer organic compoundsAluminium saltsDioxide titanium

The invention discloses a preparation method of titanium dioxide made with a compound coating chlorination process. Firstly, zirconium salt, silicon salt and aluminium salt are adopted for inorganic coating of titanium dioxide, and then an organic coating agent is used for coating. According to the method, an inorganic and organic novel compound coating technology is utilized, titanium dioxide is greatly improved in hydrophilicity, chalking resistance, lightening power, and color retention, and meanwhile the wettability, dispersity and covering power of titanium dioxide in a dispersion medium are improved. Compared with individual organic and inorganic coating agents, the titanium dioxide has better comprehensive performance.

Owner:YIBIN TIANYUAN GRP CO LTD

Novolac epoxy resin radiation protective paint and preparation method thereof

InactiveCN105694677AHigh transparencyHigh hardnessFireproof paintsAntifouling/underwater paintsEpoxyTemperature resistance

The invention provides a phenolic epoxy resin radiation protection coating, which comprises the following raw materials in parts by weight: 20-30 parts of phenolic epoxy resin, 10-15 parts of expanded graphite, 5-10 parts of carbon nanotubes, 1-30 parts of titanium dioxide 5 parts, 0.5-3 parts of hydroxypropyl methylcellulose, 8-14 parts of glass powder, 5-10 parts of talc powder, 8-12 parts of kaolin powder, 5-10 parts of perlite, 10-15 parts of wollastonite powder , 1-5 parts of dicyclopentenyloxyethyl acrylate and 20-30 parts of water. The present invention also provides a preparation method of the above-mentioned phenolic epoxy resin radiation protection coating. The components in the above-mentioned phenolic epoxy resin radiation-proof coating provided by the present invention cooperate with each other and complement each other, so that the coating has excellent anti-corrosion, radiation protection, antibacterial, flame-retardant, and anti-corrosion properties under the premise of maintaining good adhesion. High temperature, anti-cracking, anti-corrosion, resistance to alternating cold and heat, storage stability and other characteristics.

Owner:HUANGHE S & T COLLEGE

Strong-acid-resistant high-strength anticorrosive paint and preparation method thereof

InactiveCN104629588APlay the role of anti-corrosion protectionStrong scrub resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholEpoxy

The invention discloses a strong-acid-resistant high-strength anticorrosive paint which comprises the following components in parts by mass: 25-28 parts of epoxy resin, 22-26 parts of polyurethane, 9-13 parts of silicon dioxide, 5-7 parts of titanium dioxide, 3-6 parts of zinc powder, 2-5 parts of barium sulfate, 4-6 parts of graphite, 7-9 parts of diacetone alcohol, 5-9 parts of polytetrafluoroethylene, 7-11 parts of polydimethylsiloxane, 4-8 parts of carboxymethyl cellulose, 1-3 parts of tributyl phenol polyethenoxy ether and 33-45 parts of deionized water. The invention also discloses a preparation method of the strong-acid-resistant high-strength anticorrosive paint. The product can resist corrosion of strong acid and strong alkali, performs the protective and anticorrosive functions on equipment in extreme weather, and has the advantages of excellent mechanical properties, high scrub resistance, high aging resistance, high powdering resistance, higher weather resistance, higher wear resistance, better high-temperature resistance, high safety and environment friendliness.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

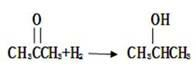

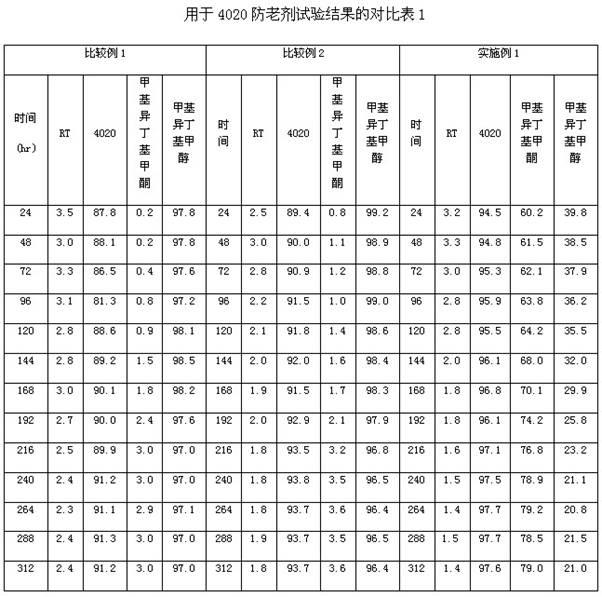

Modified condensation reduction alkylation catalyst

InactiveCN102319568AHigh strengthNot easy to pulverizeOrganic compound preparationAmino compound preparationKetoneSulfide

The invention belongs to the technical field of catalysts, and discloses a modified condensation reduction alkylation catalyst used in preparation of a rubber anti-aging agent 4020 by undergoing a hydrogenated reduction alkylation reaction on 4-aminodiphenylamine and methyl isobutyl ketone and preparation of a rubber anti-aging agent 4010NA by undergoing a hydrogenated reduction alkylation reaction on 4-aminodiphenylamine and acetone. The catalyst is a copper-series catalyst, and is mainly characterized in that: the catalyst contains a silicon element; and the molar ratio of copper to silicon is (0.5-10):1. Due to the adoption of the catalyst, a side reaction of ketone hydrogenation for generating an alcohol in the reacting process is suppressed remarkably, raw materials are saved, products 4010NA and 4020 are not required to be passivated by using 4-amino diphenylamine produced by reducing alkali sulfide at an earlier using stage, and unqualified products are avoided; and the catalyst has high intensity and long service life, and is not pulverized easily in the using process.

Owner:郝云青

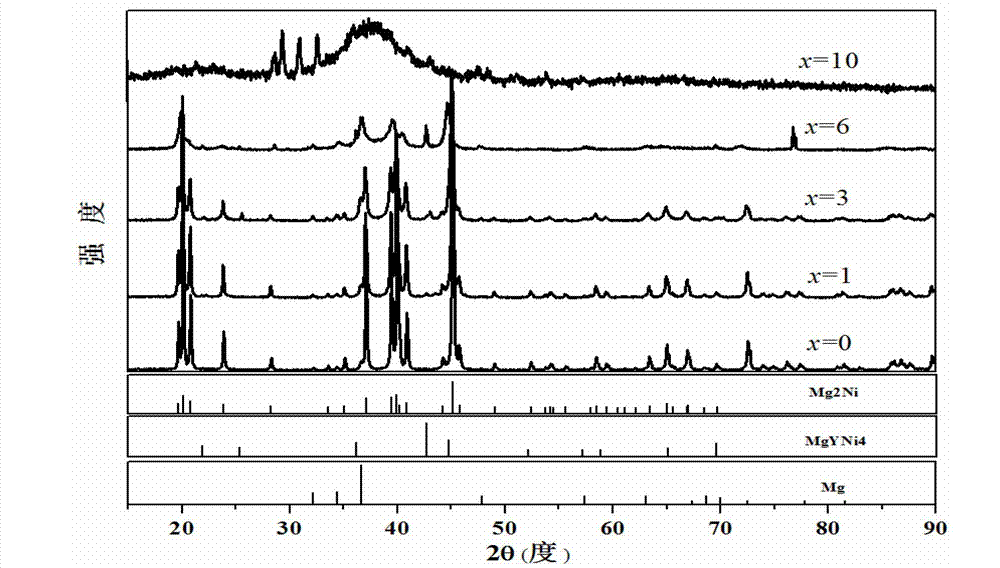

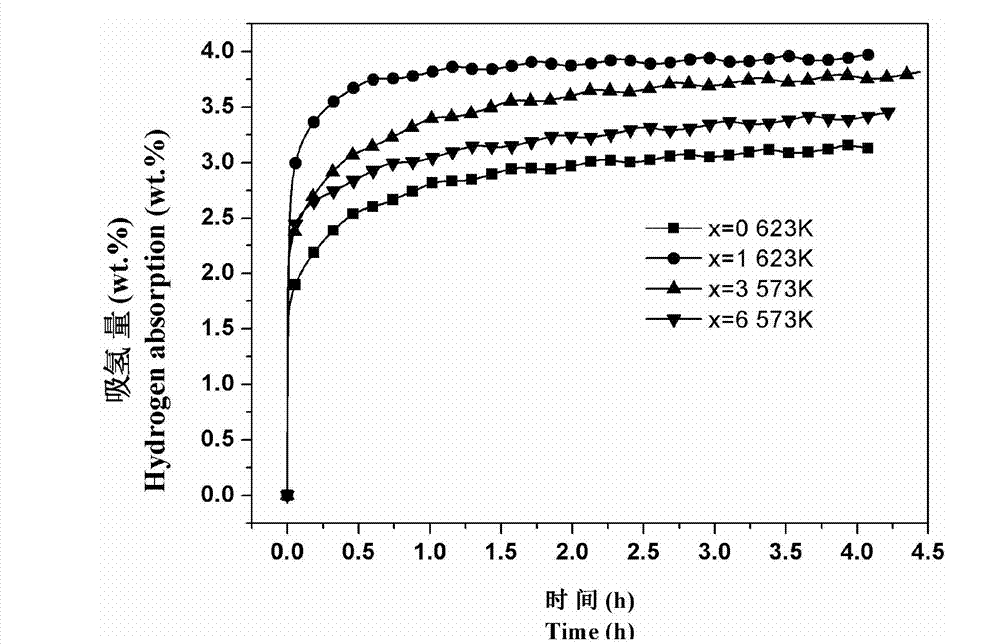

Magnesium-nickel-yttria hydrogen storage alloy thin belt and preparation method thereof

A magnesium-nickel-yttria hydrogen storage alloy thin belt and a preparation method thereof. The hydrogen storage material contains 67at.% of Mg, and 33at.% of nickel and yttrium, wherein yttrium accounts for 0-10at.%, and the rest is nickel. Yttrium is added in a form of a magnesium yttrium intermediate alloy; nickel is added in a form of briquetted nickel powder; a two-step method is adopted to prepare a mother alloy by smelting; and the prepared alloy is remelted and quenched in a single roller melt quenching furnace to obtain a thin belt namely the finished hydrogen storage material. The material provided by the invention improves the hydrogen storage capacity and hydrogen absorption-desorption kinetic properties of a Mg2Ni type hydrogen storage alloy, and overcomes the contradiction that hydrogen storage capacity and dynamic property of Mg base alloy can not be improved at the same time. The invention has the characteristics of simple preparation method, low cost, and low requirement on equipment and environment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Nano TiO2/nano ZnO compounded lubricating oil additive and preparation method thereof

The invention discloses a nano TiO2 / nano ZnO compounded lubricating oil additive and a preparation method thereof. The addition amount of the nano TiO2 / nano ZnO is 0.02-1%, the particle size of the nano TiO2 is 10-20nm, the particle size of the nano ZnO is 20-40nm, and the weight ratio of the nano TiO2 to the nano ZnO is 1:1, 1:2 or 2:1. The nano TiO2 / nano ZnO compound is coated with oleic acid in the preparation process to enhance the stability and form a barrier between the surface and ambient medium, thereby lowering the chemical activity of the nano TiO2 / nano ZnO, being beneficial to enhancing the dispersity, weather resistance and chalking resistance and enhancing the continuous stability; and the prepared lubricating oil can not have the phenomenon of precipitation or separation, and can be firmly attached to the friction surface to protect the surface, thereby lowering and transferring the friction factor and prolonging the service life of the lubricating oil. The lubricating oil has the advantages of superhigh abrasion resistance, and greatly enhanced extreme pressure performance and long-time abradability.

Owner:南宁飞日润滑科技股份有限公司

Hydroxyl acrylic emulsion for outdoor waterborne wood coating and preparation method thereof

InactiveCN106560494AIncrease elasticityImprove crack resistanceAnti-corrosive paintsGlycol methacrylateN-butyl acrylate

The invention discloses a hydroxyl acrylic emulsion for an outdoor waterborne wood coating and a preparation method thereof. The preparation method comprises the following steps: 1, weighing deionized water, a co-emulsifier, sodium carbonate and an emulsifier, adding the weighed materials into a reactor and carrying out uniform mixing under stirring at a uniform speed; 2, introducing nitrogen into the reactor and allowing temperature to rise to 80 DEG C; 3, adding an initiator solution into the reactor; 4, weighing a certain amount of alkyl methacrylate, styrene, n-butyl acrylate, trimethylolpropane triacrylate and a co-emulsifier and adding the weighed materials into the reactor via a dropwise monomer addition groove; 5, weighing a certain amount of n-butyl acrylate, styrene, a co-emulsifier, a molecular-weight regulating agent, t-butylaminoethyl metacrylate and 2-(methacryloyloxy)ethyl acetoacetate and adding the weighed materials into the reactor via the dropwise monomer addition groove; and 6, cooling the obtained emulsion to room temperature and then carrying out filtering and discharging. The hydroxyl acrylic emulsion obtained in the invention has a high cross-linking degree, good water resistance and weatherability, high hardness and excellent scratch resistance and can be extensively promoted and applied.

Owner:SHANGHAI M LAND CHEM CO LTD

Waterproof crack-resisting coating and preparation method thereof

InactiveCN107987647AHigh elongationResponsiveAntifouling/underwater paintsPaints with biocidesCelluloseCrack resistance

The invention discloses a waterproof crack-resisting coating and a preparation method thereof, and relates to the field of coating materials. The waterproof crack-resisting coating is prepared from the following components in parts by weight: 40 to 80 parts of elastic emulsion, 15 to 20 parts of ZnO-CeO2 particles, 10 to 30 parts of Portland cement, 20 to 40 parts of quartz sand, 10 to 30 parts ofcomplexing agent, 10 to 30 parts of cellulose, 10 to 30 parts of water reducing agent, 3 to 5 parts of defoaming agent, 3 to 5 parts of dispersing agent, 3 to 5 parts of leveling agent and 3 to 5 parts of thickening agent. The waterproof crack-resisting coating provided by the invention has the advantages of excellent waterproof and crack resistance, scrubbing resistance, pulverization resistance, stain resistance, weather fastness, good aging resistance, storage stability, low cost, greenness and environment friendliness.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Method for preparing passivation calcium oxide desulfurizer by utilizing carbide slag

InactiveCN102658007AAvoid pollutionReduce manufacturing costDispersed particle separationSlagMoisture resistance

The invention relates to a method for preparing a passivation calcium oxide desulfurizer by utilizing carbide slag, comprising the following steps: uniformly stirring carbide slag, filtering through three-stage vibrating screens, dehydrating by a plate and frame filter press to obtain calcium hydrate with the solid content of 65-75 %; adding a passivator and a reinforcing agent, mixing uniformly with stirring, carrying out extruding granulation to obtain particles with particle size of 0.5-1.5 mm; drying the particles with a chain dryer by using tail gases of a rotary kiln at 250-300 DEG C for 50-70 min, calcining at 1000-1100 DEG C for 50-70 min, and rapidly cooling by a cooler to obtain the product. According to the invention, the industrial waste residue-carbide slag is reasonably utilized, and the pollution of the carbide slag to the environment is avoided; by using the tail gases of the rotary kiln to dry, the waste gases are utilized, the energy consumption is low, and the production cost is low; the produced product has high desulphurization efficiency and short desulphurization time, and can save energy consumption; and the product has the advantages of moisture resistance, high anti-powdering performance, high utilization rate, low ton steel consumption, and long deposited time, and is beneficial for storage and transportation.

Owner:WUHAN JUNRONG TECH

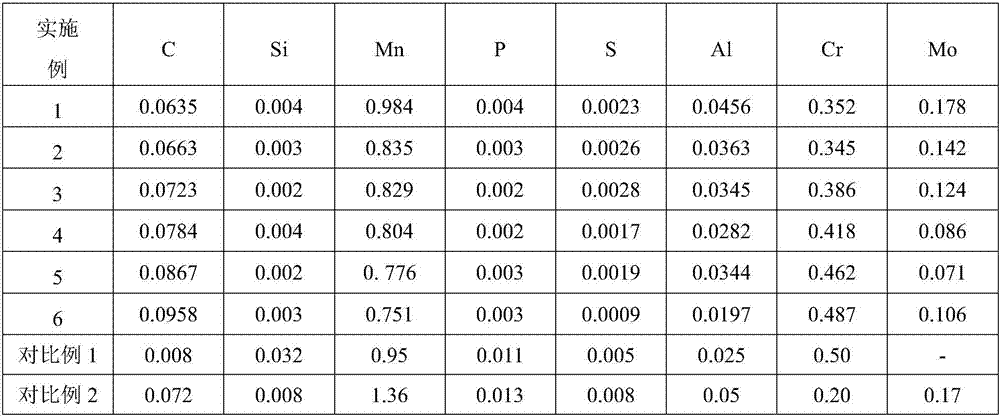

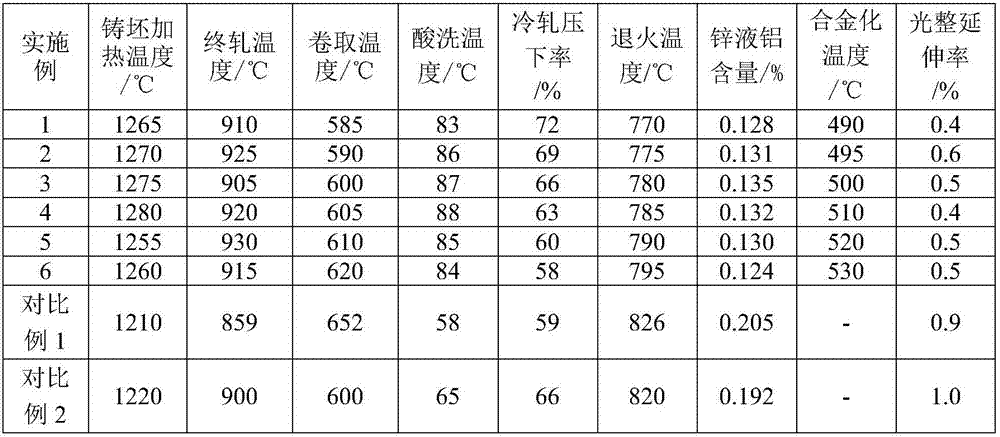

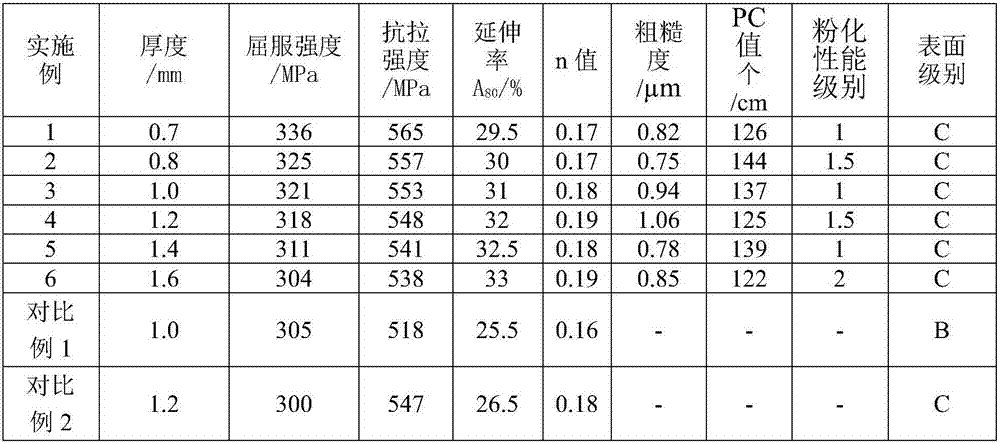

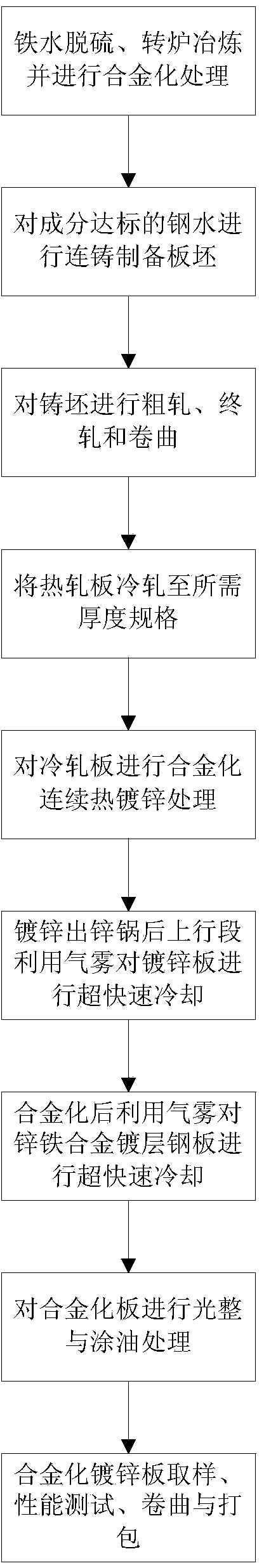

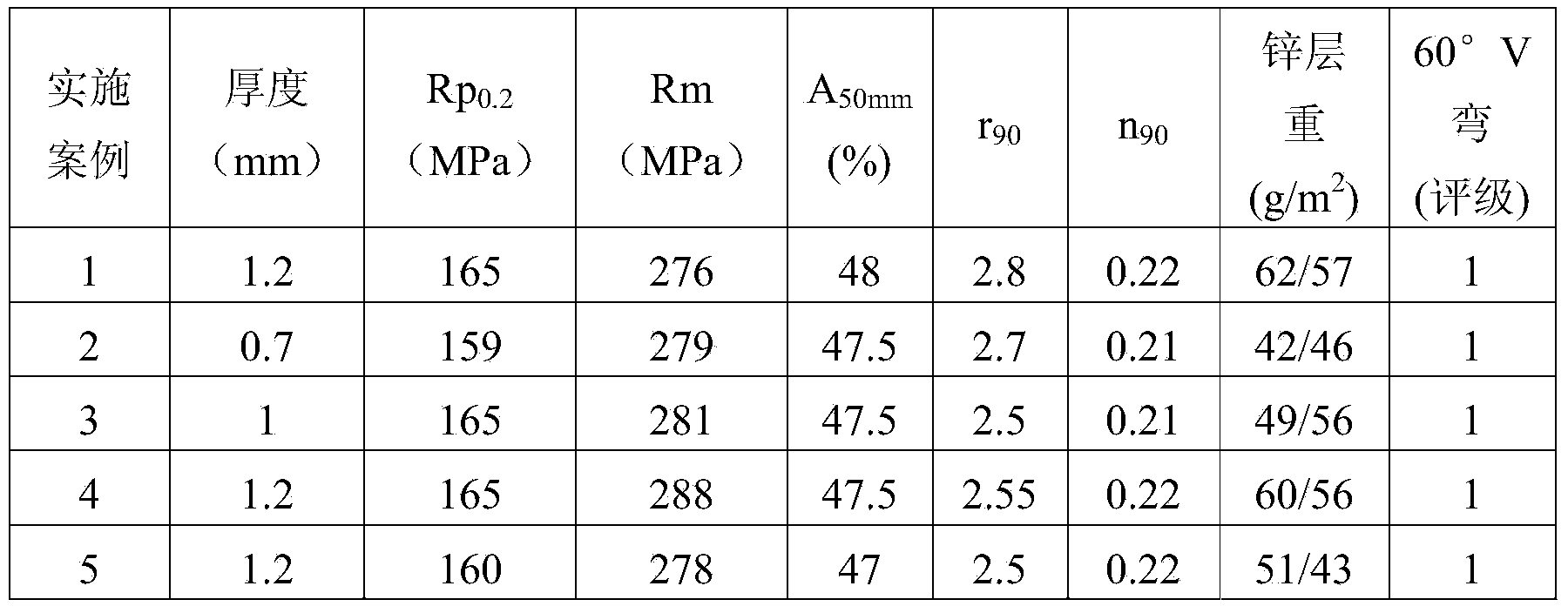

Manufacturing method of 500MPa-grade zinc-iron alloy coating dual-phase steel plate for automobile outer panel

The invention discloses a method for manufacturing a 500MPa-grade zinc-iron alloy coated dual-phase steel sheet for automobile outer panels, which is characterized in that it comprises the following steps: 1) after the steel is smelted, refined and continuously cast into billets, the cast billet is heated ; 2) rough rolling; 3) finish rolling; 4) coiling; 5) pickling; 6) cold rolling; 7) continuous annealing; 8) hot-dip galvanizing; 9) alloying; 10) Carry out lightening. The invention has the beneficial effects of excellent mechanical properties, good surface quality and excellent pulverization resistance.

Owner:武汉钢铁有限公司

Alloying hot-dip galvanized steel with tensile strength being 390 MPa-level and used for automobile and production method

ActiveCN105063475AV-bend pulverization level reductionSimple production processHot-dipping/immersion processesPre treatmentContinuous annealing

The invention provides alloying hot-dip galvanized steel with tensile strength being 390 MPa-level and used for an automobile. The alloying hot-dip galvanized steel comprises, by weight, 0.07%-0.10% of C, not larger than 0.03% of Si, 0.7%-1.0% of Mn, 0.010%-0.025% of P, not larger than 0.010% of S and 0.020%-0.070% of Als. The production method includes the steps of molten iron preprocessing; smelting with a converter and RH furnace processing; continuous casting, casting blank heating, hot rolling, coiling, acid pickling, cold continuous rolling, continuous annealing, hot galvanizing, alloying, finishing, on-line direct roller painting of self-lubricating paint and drying of a self-lubricating alloying plate. By means of the alloying hot-dip galvanized steel, it can be guaranteed that the yield strength ranges from 290 MPa to 320 MPa, the tensile strength ranges from 390 MP a to 440 MPa, the elongation percentage is not less than 36%, the roughness ranges from 0.4 microns to 1.0 microns, and the PC value is not less than 90; the ingredients and the technology are simple, and the cost is relatively lower; a better plasticity is achieved; meanwhile, through direct roller painting of a self-lubricating film, the pulverization level is upgraded to the first level; the pulverization resisting capability is excellent, and complex automobile inner plates and structural components can be stamped.

Owner:武汉钢铁有限公司

Novel coating having electromagnetic radiation resistance and anti-static function

A novel coating having electromagnetic radiation resistance and an anti-static function is characterized by comprising 85% of environment-friendly coating, 10% of carbon nano-tube, 1.5% of polypeptide molecules and 3.5% of conductive mica powder. Wet method muscovite serves as a substrate for the conductive mica powder, a nanotechnology is adopted, and a conductive oxide layer is formed on the surface of the substrate through surface treatment and semiconductor doping treatment. The long diameter of the carbon nano-tube is not larger than 150 nm. The problem that a coating manufactured according to a conventional preparation process does not have dual effects of static resistance and radiation resistance is solved, so that the construction becomes simple and convenient. The use range of the carbon nano-tube is expanded, the damage to the lung of the human body and the skin caused by the carbon nano-tube is reduced, the coexistence of people and the environment is harmonized while the energy saving and environmental protection are achieved, and the novel coating can well be used for oil tanks, gas stations, factories, homes and intensive radiation region environments near high-tension cables or substations and the like and the environment where the static requirements are high.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

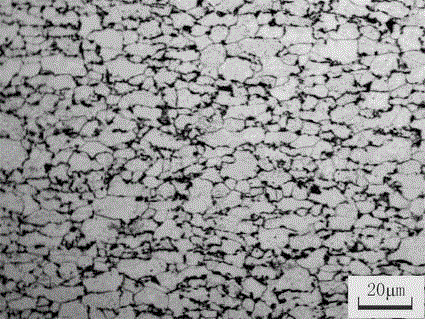

Method for producing steel plate with extra deep drawing iron and zinc alloy plating layer

InactiveCN104342541AImproved chalking resistanceCompact structureHot-dipping/immersion processesSheet steelUnit speed

The invention discloses a method for producing a steel plate with an extra deep drawing iron and zinc alloy plating layer. The method comprises the following steps of (1) desulfurizing, smelting in a converter furnace, and alloying; (2) continuously casting to prepare a slab; (3) setting the rough milling temperature of a casting blank as 1060-1100 DEG C, the final rolling temperature as 890-920 DEG C, and the coiling temperature as 680-730 DEG C; (4) performing cold rolling; (5) alloying a cold rolling sheet, performing continuous hot galvanizing treatment, setting the unit speed as 90-100 m / min, the heating temperature as 830-850 DEG C and the temperature of a quick cooling section as 500-520 DEG C, cooling a galvanized plate at an upward section after the galvanized plate is taken out of a zinc pot, setting the cooling speed as 40-60 DEG C / s, alloying, cooling the steel plate, and setting the cooling speed as 30-50 DEG C / s. The method has the advantages that the plating layer at the surface of the ultra deep drawing GA (galvanized alloy) plate has dense structure, and is free from obvious cracks and deficiencies, the crystal grain of iron and zinc alloy on the surface of the plating layer is fine and small, the size distribution is uniform, the chalking-resistant property of the alloying plating layer is excellent, and the method can be widely applied to the production field of automobile steel.

Owner:武钢集团有限公司

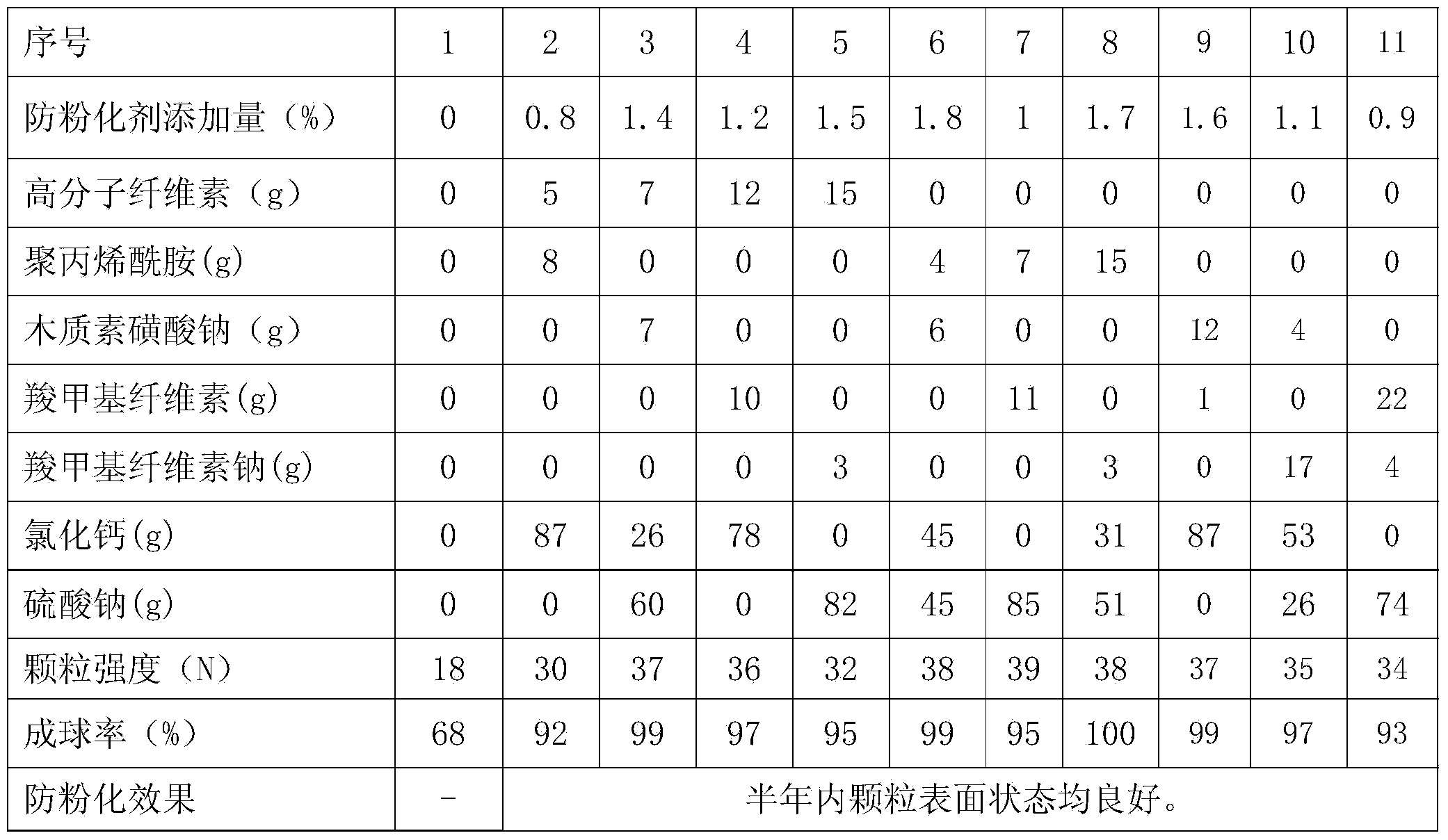

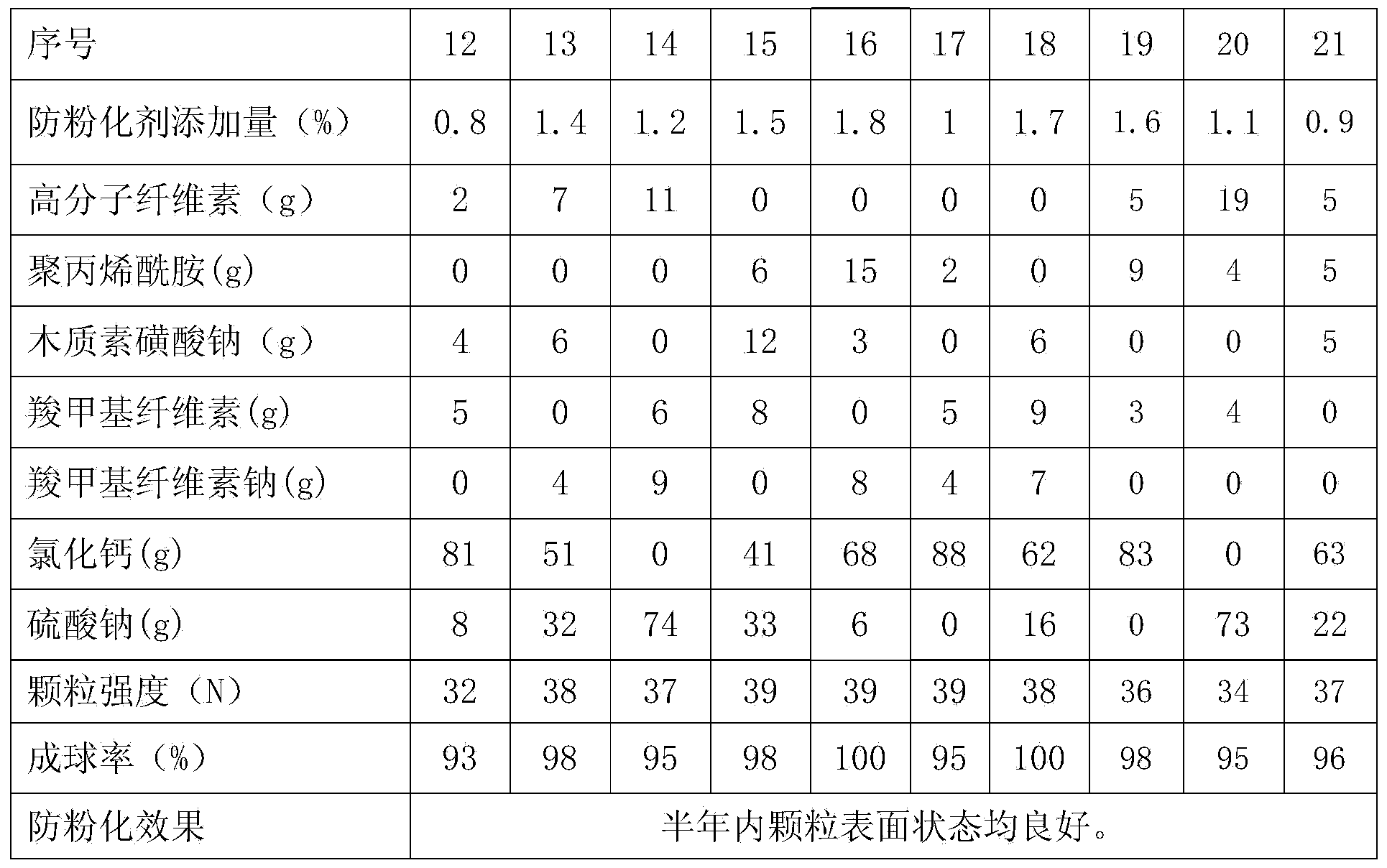

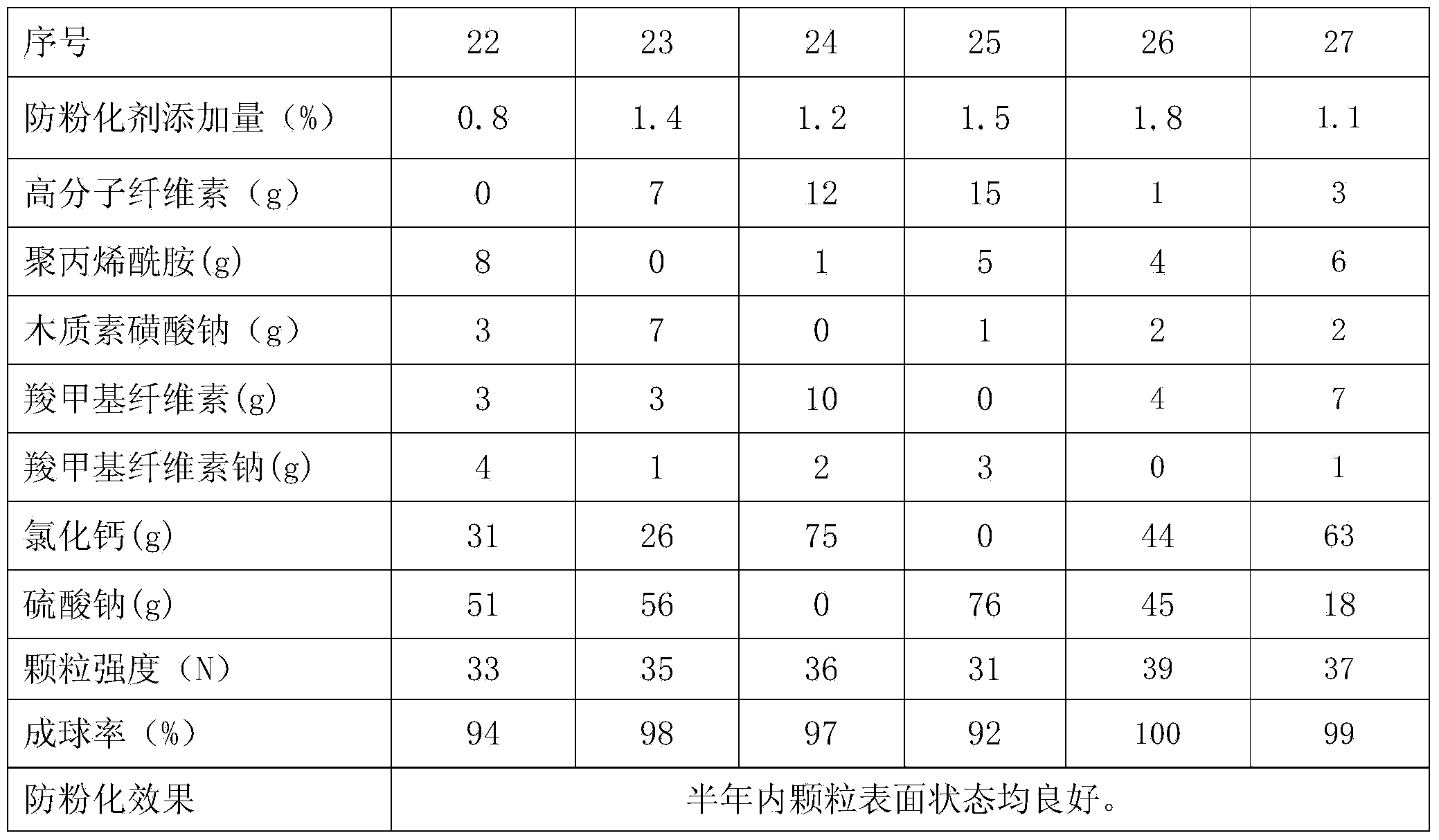

Compound fertilizer anti-pulverization agent and use thereof

The invention discloses a compound fertilizer anti-pulverization agent and a use thereof, relates to a chemical fertilizer addition agent, and especially relates to a compound fertilizer anti-pulverization agent. The invention aims at providing the compound fertilizer anti-pulverization agent which has strong anti-pulverization ability and has the functions of increasing the balling rate of a compound fertilizer, reducing the cost of compound fertilizer materials, enhancing the strength of fertilizer particles, reducing the agglomeration rate of the fertilizer and improving the whiteness of the fertilizer. The compound fertilizer anti-pulverization agent comprises a water-soluble macromolecule resin and an inorganic salt with water absorption effect. The compound fertilizer anti-pulverization agent has the advantages of being strong in compound fertilizer pulverization ability, quickly increasing the balling rate of the compound fertilizer, reducing the cost of compound fertilizer materials, enhancing the strength of fertilizer particle, reducing the agglomeration rate of the fertilizer and improving the whiteness of the fertilizer. The compound fertilizer anti-pulverization agent is applied to field of chemical fertilizer additives.

Owner:ANHUI FURUIXUE CHEM SCI & TECH INC

High-strength display shell and processing technology thereof

The invention discloses a high-strength display shell. The high-strength display shell comprises the following raw materials in parts by weight: 18-26 parts of glass fiber, 18-26 parts of carbon fiber, 10-12 parts of aluminum silicate fiber, 40-60 parts of ABS, 14-16 parts of thermoplastic polyurethane, 8-12 parts of silicon dioxide, 8-12 parts of modified wollastonite, 5-7 parts of hexamethylenetetramine, 10-20 parts of polyvinyl chloride micropowder, 2-6 parts of tributyl citrate, 2-6 parts of acid salt, 18-26 parts of polypropylene, 15-20 parts of polypropylene, 15-25 parts of polystyrene,14-26 parts of active calcium, 16-18 parts of lithopone, 12-15 parts of carbon black, 15-20 parts of high-elasticity rubber and the like. Through mixing of the glass fiber, the carbon fiber and the aluminum silicate fiber, a fiber material with high strength, strong toughness and good mechanical vibration resistance is obtained, and the fiber material is matched with the other components to prepare the display case with high strength, strong toughness and good mechanical vibration resistance, so that the current market demand is met.

Owner:合肥莫凡高科电子科技有限公司

450MPa-level zinc iron alloy clad layer double-phase steel plate for car outer plate and manufacturing method thereof

InactiveCN108754343AUniform color without defectsMeet the productionHot-dipping/immersion processesDouble phaseLevels zinc

The invention discloses a 450MPa-level zinc iron alloy clad layer double-phase steel plate for a car outer plate and a manufacturing method thereof. Chemical components of the steel plate comprise, byweight percent, 0.05-0.08% of C, smaller than or equal to 0.005% of Si, 0.70-1.00% of Mn, smaller than or equal to 0.005% of P, smaller than or equal to 0.003% of S, 0.010-0.050% of Als, 0.20-0.40% of Cr, 0.05-0.20% of Mo, and the balance Fe and inevitable impurities. According to the steel plate, by means of low-Si design, moderate Cr and Mo hardenability elements are added, by means of technology control, at the low cold speed, the product physical performance can reach the yield strength of 260-300 MPa, the extension strength is 470 MPa-520 MPa, the ductility A80 is 32-36%, the n value is0.18-0.20, the roughness degree is 0.5-1.2 micrometers, the PC value is 100-150 per cm, pulverization is at the level 1-2, the clad layer surface is uniform in color and free of defects, the pulverization resistant performance is excellent, and production and manufacture of car coverage parts can be achieved.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com