Alloying furnace cooling section strip steel cooling apparatus and cooling control method

A technology of an alloying furnace and a cooling device, which is applied to the cooling device and cooling adjustment field of cooling strip steel in the cooling section of the alloying furnace, can solve the problems of low cooling capacity, unfavorable uniformity of coating thickness, strip steel vibration, etc., and achieves forming The effect of excellent performance and excellent anti-powder performance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

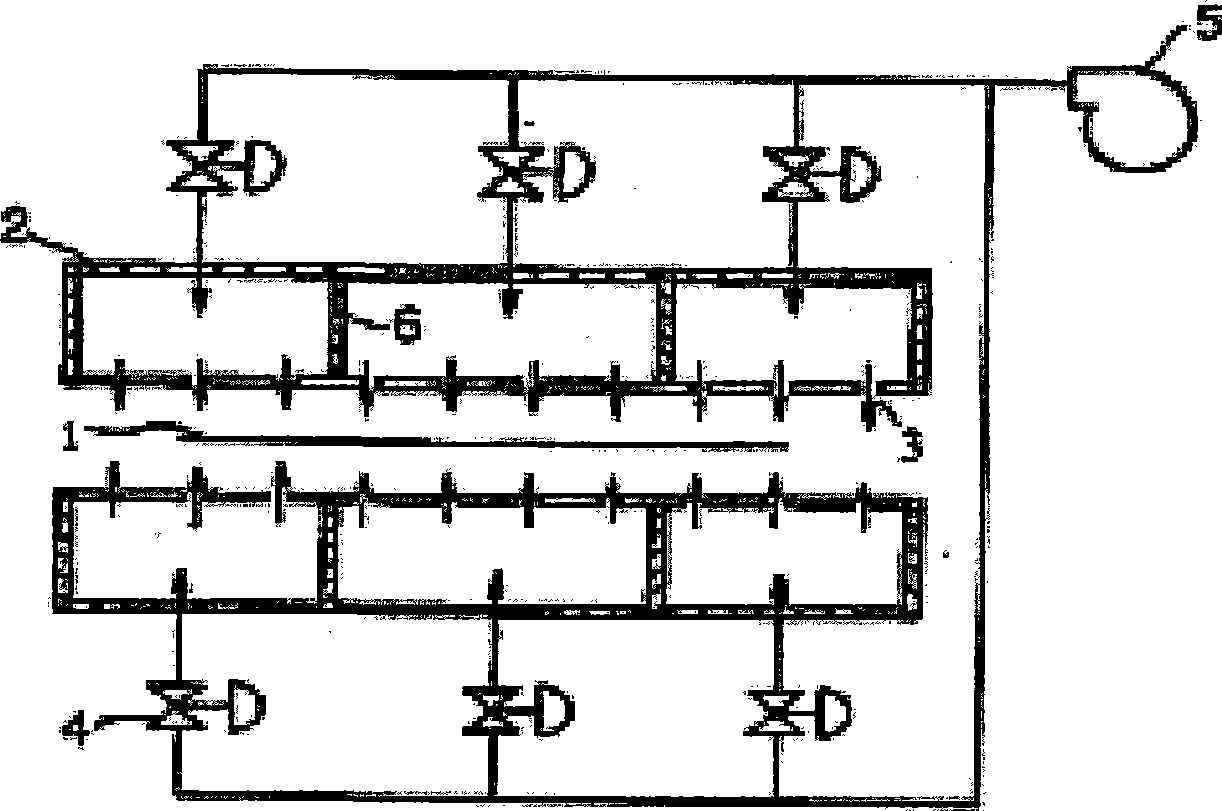

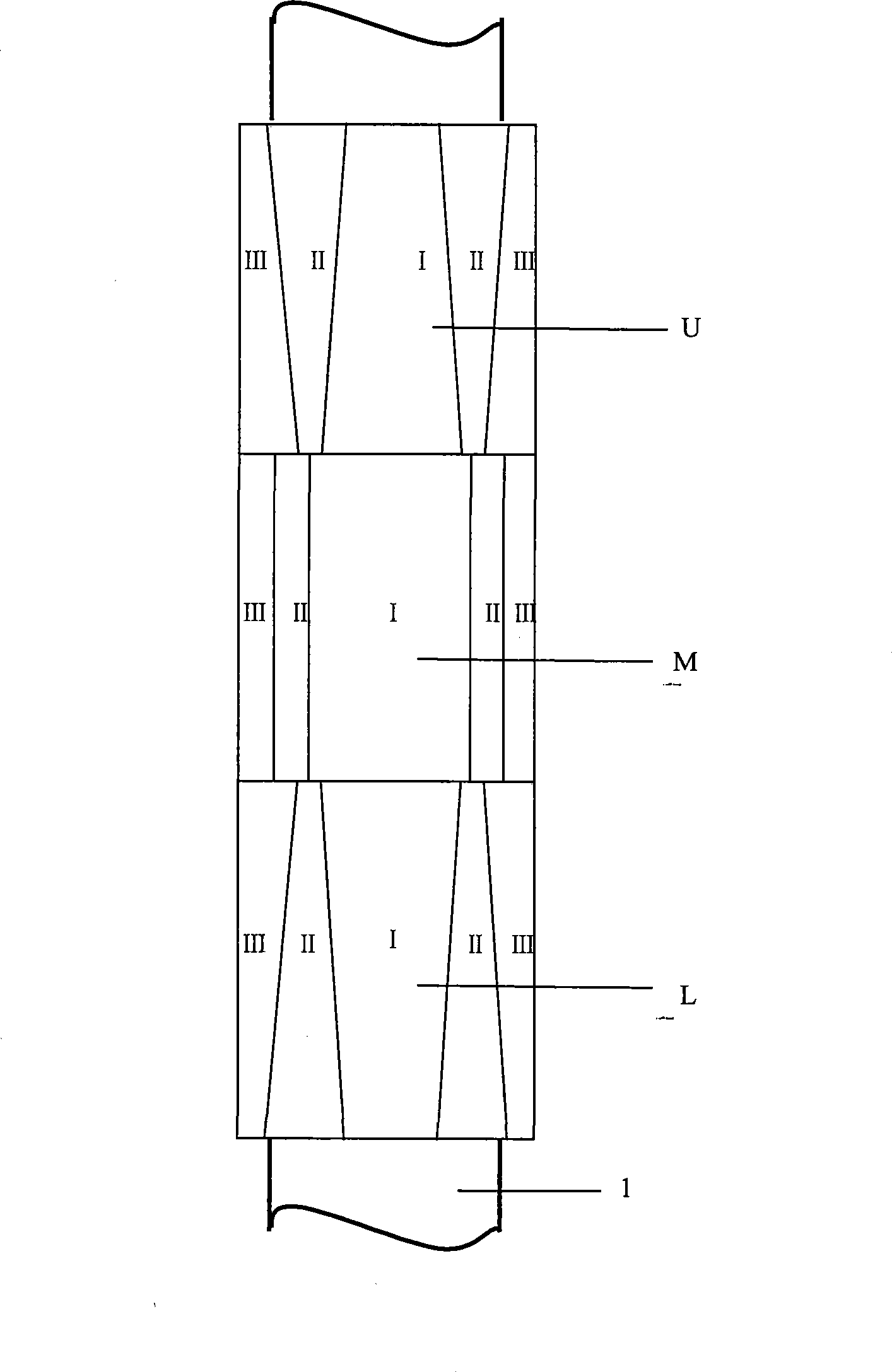

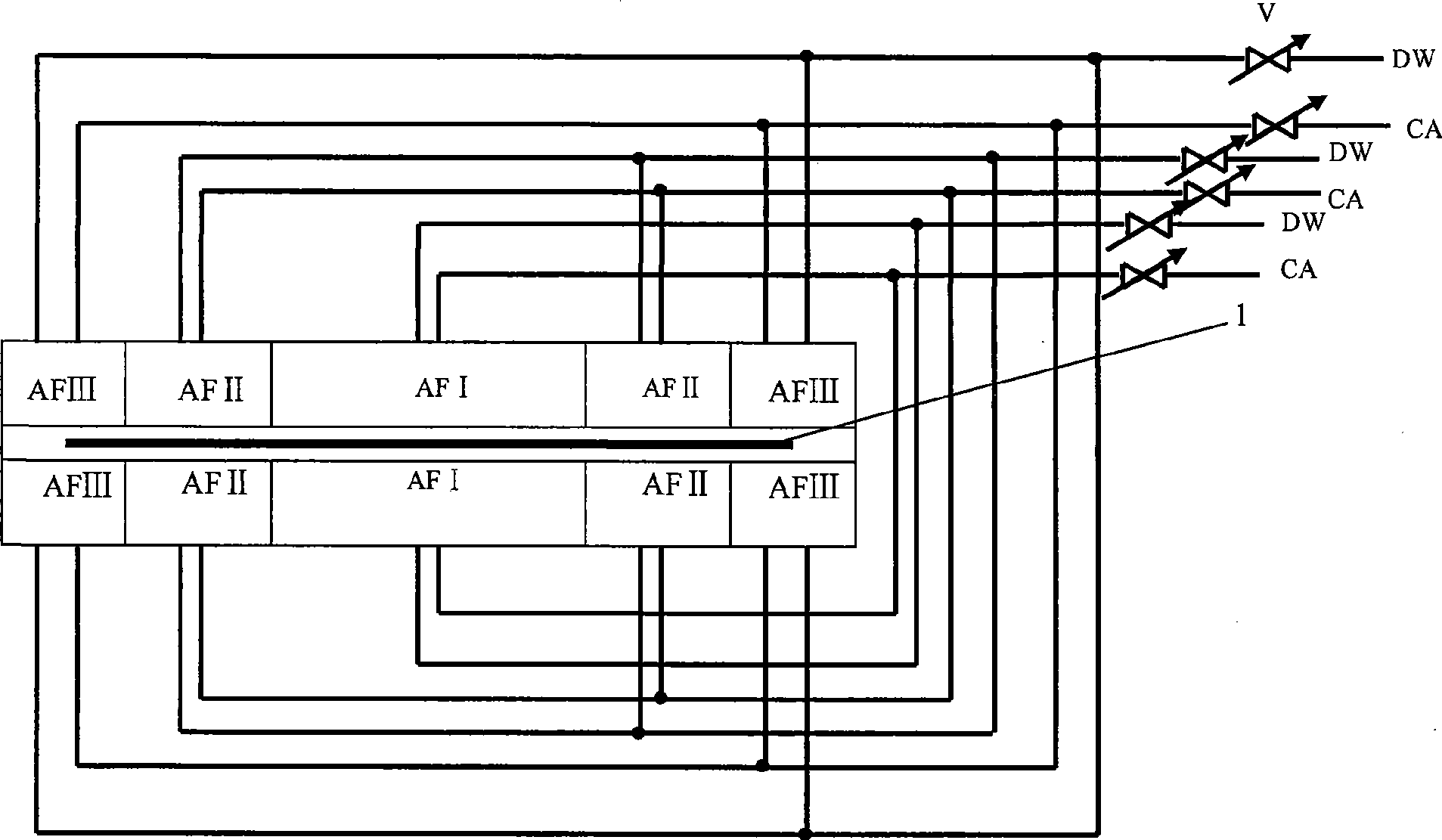

Method used

Image

Examples

Embodiment 1

[0031] Example 1: When the unit produces 1.2×1000mm 590MPa-level alloyed hot-dip galvanized dual-phase steel, the higher the cooling rate in the cooling section of the alloying furnace, the more favorable it is for the formation of the dual-phase structure of the dual-phase steel. Moreover, when the unit speed When the temperature is 80 m / min, the alloying temperature is around 480°C, and the strip temperature does not change much along the width direction. The capacity setting values of each unit of the cooling device are shown in Table 2. The anti-powdering properties of the obtained coatings are shown in Table 3. * Note: 60 o V-bend grades are divided into nine grades. In terms of powdering resistance, grade 1 is the best, grade 9 is the worst, and grades 1 to 5 are qualified.

[0032] Table 2 Capacity settings of each unit in the cooling section of the alloying furnace when producing 1.2×1000mm dual-phase steel

[0033] area

Zone 1 Ability Settings

(0~...

Embodiment 2

[0040] Example 2: When the unit produces 0.8×1400mm alloyed hot-dip galvanized bake-hardened steel, the strip steel is relatively wide. When the unit speed is 90 m / min, the alloying temperature is about 510°C, and the strip steel temperature is along the width direction The change is large, the temperature of the middle strip steel is obviously higher than the temperature of the strip steel on both sides, and the alloyed hot-dip galvanized bake-hardened steel coating is easy to pulverize, and increasing the cooling capacity is beneficial to improving the pulverization resistance of the coating. Therefore, the cooling device The capacity setting values of each unit are shown in Table 4. The anti-powdering properties of the obtained coatings are shown in Table 5.

[0041] Table 6 Capacity settings of each unit in the cooling section of the alloying furnace when producing 0.7×1500mm IF steel

[0042] area

Zone 1 Ability Settings

(0~100%) Zone 2 Ability Settin...

Embodiment 3

[0049] Embodiment 3: When the unit produced 0.7 × 1500mm alloyed hot-dip galvanized IF steel, although the width of the strip steel was wide, the alloying temperature of the IF steel was relatively low. When the speed of the unit was 80 m / min, the alloying temperature was at 450°C, therefore, the setting values of the capacity of each unit of the cooling device are shown in Table 6. The anti-powdering properties of the obtained coatings are shown in Table 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com