Water-based white sealed primer and preparation method thereof

A sealing primer, white technology, applied in the direction of coating, etc., can solve the problems of not mentioning the sealing effect of wood coatings, not mentioning the effect of barium metaborate against tannic acid, etc., to achieve good sealing, excellent water resistance, environmental protection and the effect of less harm to humans and animals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

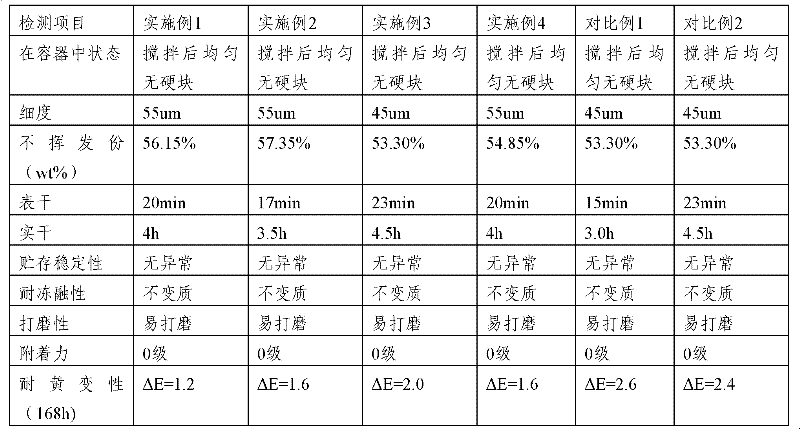

Examples

Embodiment 1

[0058] Example 1: Water-based white sealing primer A with anti-tannin properties

[0059] 1. Composition:

[0060] Element

Weight (kg)

CRAYMUL 2711

490

Busan 11-M1

80

DALPAD TM D.

25

Preventol D7F

2

Preventol A 21-D

5

BYK024

7

TEGO Dispers 760W

8

TS 6200

150

120

BYK345

3

4

PUR62

2

Thixol 53L

1

Deionized water

103

[0061] 2. Preparation method:

[0062] 1) First mix 95kg deionized water with DALPAD TM D. PreventolD7F, PreventolA21-D, BYK024, TEGO Dispers 760W were weighed into the dispersing tank, and started stirring at a medium speed;

[0063] 2) Add TS 6200, CC1500 calcium carbonate and Busan 11-M1 under medium speed stirring (800 rpm, abbreviated as 800 rpm), and disperse at 1200 rpm for 15 minutes;

[0064] 3) Reduce the speed to 80...

Embodiment 2

[0066] Example 2: Water-based white blocking primer B with anti-tannin properties

[0067] 1. Composition:

[0068] Element

Weight (kg)

CRAYMUL 2711

450

Busan 11-M1

80

DALPAD TM D.

22

Preventol BIT 20N

2

Preventol A 14-D

5

TEGO810

6

TEGO Dispers 740W

9

R-706

150

150

BYK345

3

Deionized water

116

3

PUR62

4

[0069] 2. Preparation method:

[0070] 1) First mix 105kg deionized water, DALPAD TM D. Weigh Preventol BIT 20N, Preventol A14-D, TEGO810, and TEGO Dispers 740W into the dispersing tank, and start stirring at a medium speed;

[0071] 2) Add R-706, CC1500 calcium carbonate and Busan 11-M1 under medium-speed stirring (850 rpm), and disperse for 15 minutes at 1200 rpm;

[0072] 3) Reduce the speed to 800 rpm, add CRAYMUL 2711 and BYK345 in turn, and...

Embodiment 3

[0074] Example 3: Waterborne White Sealing Primer C with Anti-Tannic Acid Properties

[0075] Preparation process is with embodiment 1, and difference is that each component of the water-based white sealing primer of the present embodiment is as follows:

[0076] Element

[0077] Adjust the pH to 9.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com