Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163results about How to "Convenience film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel blue emitters for use in organic electroluminescence devices

ActiveUS20050175857A1Excellent thermal stabilityStrong thermal stabilitySilicon organic compoundsDischarge tube luminescnet screensOrganic electroluminescenceHalogen

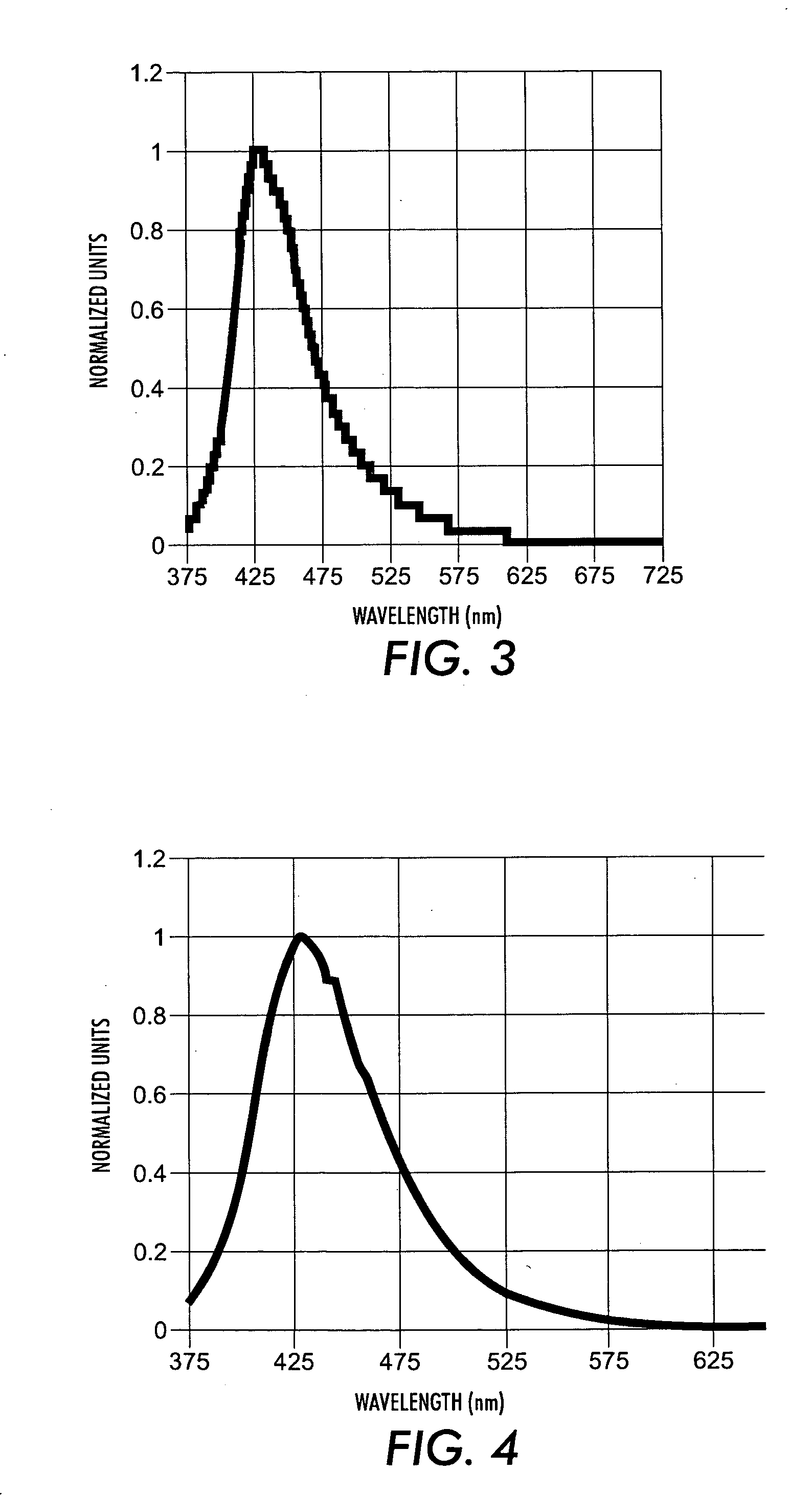

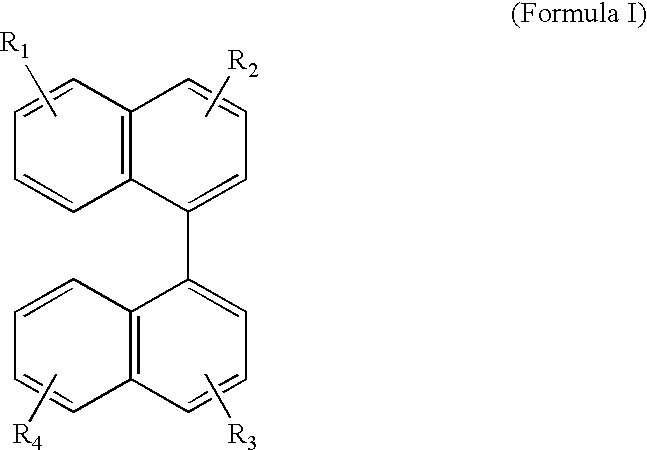

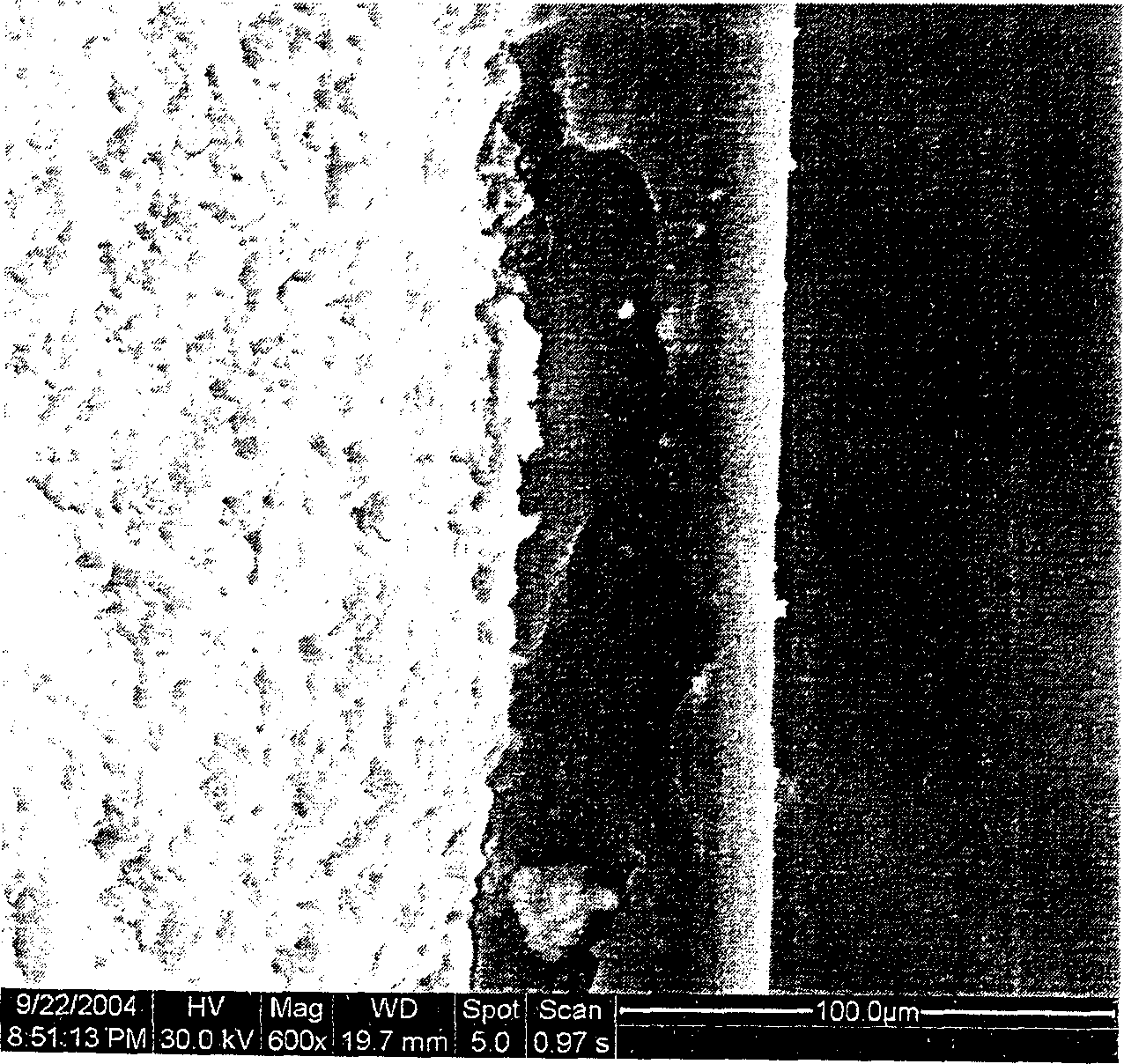

An electroluminescent (EL) is provided comprising an anode, an organic electroluminescent element, and a cathode wherein the electroluminescent element contains, for example, a fluorescent 1,1′-binaphthyl derivative component of Formula (I) wherein R1, R2, R3 and R4 are individual substituents or a group of substituents, each of which may be selected from the group consisting of hydrogen, or alkyl of from 1 to about 25 carbon atoms; an alicyclic alkyl of from 3 to 15 carbon atoms; an aryl or substituted aryl with about 6 to about 30 carbon atoms; carbon atoms from 4 to 24 necessary to complete a fused aromatic ring of naphthalene, anthracene, perylene and the like; an alicyclic alkyl group with from about 3 to about 15 carbon atoms; a silicon atom which can be substituted with a trimethyl, diphenylmethyl, triphenyl group and the like; heteroaryl or substituted heteroaryl of from 5 to 24 carbon atoms, carbon atoms necessary to complete a fused heteroaromatic ring of furyl, thienyl, pyridyl, quinolinyl and other heterocyclic systems; an alkoxy, amino, alkyl amino or aryl amino of from 1 to about 25 carbon atoms; a halogen, a cyano group, and the like.

Owner:LG DISPLAY CO LTD

Organic and inorganic composite hydrophobic film and its preparing process

ActiveCN1724127AEasy to prepareThe requirements for inorganic support are not highSemi-permeable membranesAlcoholAqueous solution

A composite organic-inorganic hydrophobic membrane for separating alcohol or other organic substances from aqueous solution is composed of inorganic ceramic substrate and organic polydimethyl siloxane layer. Its preparing process includes such steps as dissolving polydimethl siloxane in n-heptane, adding ethy / silicate, ultrasonic dispersing, dripping tin dibutyl bilaurate in it, stirring, de-foaming, coating it one said substrate, solidifying while cross linking, thermal drying, immersing in acetone for 30 min, and thermal drying.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

Method for preparing sweet apricot kernel

InactiveCN101273788AGood film formingGood compactnessFruit and vegetables preservationConfectioneryChemistryPrunus amygdalus

The invention provides a preparing method for sweet almond, the method solves the problems that the surface of the existing sweet almond obtained by frying technique is easy to fall off, and the grease is easy to be oxidized and rancid so as to cause short storage period, etc. The preparing method of the invention comprises the following steps that: firstly, polysaccharides solution of pullulan with a certain concentration is prepared, and then is divided into two parts, wherein, one part is used for soaking the almond until the solution is blotted by the almond, and the other part is used for frying and spraying the almond in a stir pan at the same time in the process of frying, thus leading the fried almond to have a layer of dense protective membrane wall; the preparing method of the invention has simple formula and easy control of technique, the prepared product has good taste and complete surface, and the dense protective membrane wall lead the product to have longer protection period and better appearance than the product obtained by the prior manufacturing technique.

Owner:广东富味健康科技有限公司

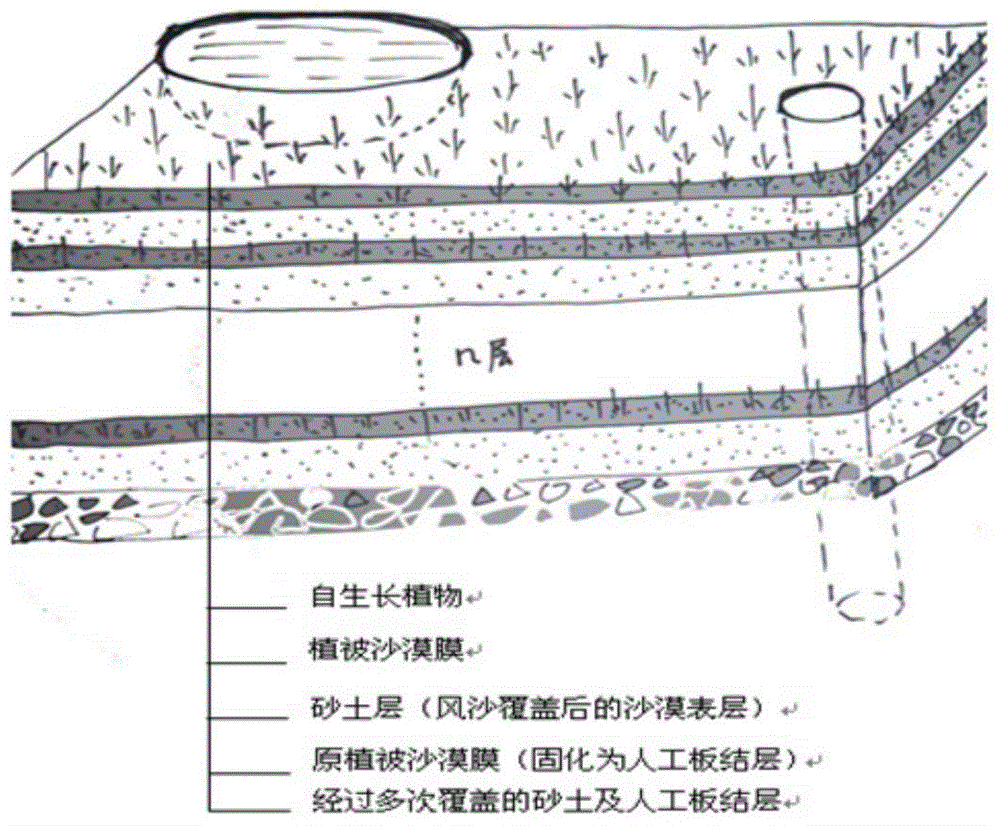

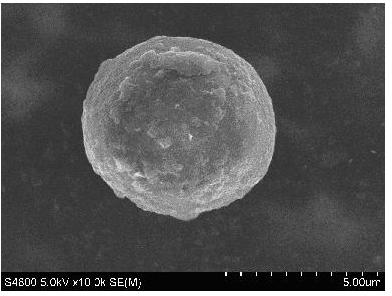

Process for producing rare earth metal-based permanent magnet having corrosion-resistant film

InactiveUS6376089B1Improve corrosion resistanceImprove adhesionPretreated surfacesInorganic material magnetismAlkali ionsRare earth

The present invention provides a process for producing a rare earth metal-based permanent magnet having, on its surface, a corrosion-resistant film containing inorganic fine particles having a specific average particle size and dispersed in a film phase formed from a silicon compound. In a heat treatment for forming a film by a hydrolyzing reaction and a thermally decomposing reaction of the silicon compound, followed by a polymerizing reaction, a stress is generated within the film by the shrinkage of the film. In the corrosion-resistant film formed by the producing process according to the present invention, however, such stress is dispersed by the presence of the inorganic fine particles and hence, the generation of physical defects such as cracks is inhibited. In addition, voids between the adjacent inorganic fine particles are filled with the film phase formed from the silicon compound and hence, the formed film is dense. Further, no alkali ions are contained in the film and hence, the film itself is excellent in corrosion resistance. Yet further, the film has an excellent close adhesion to the magnet achieved by an excellent reactivity with the surface of the magnet.

Owner:HITACHI METALS LTD

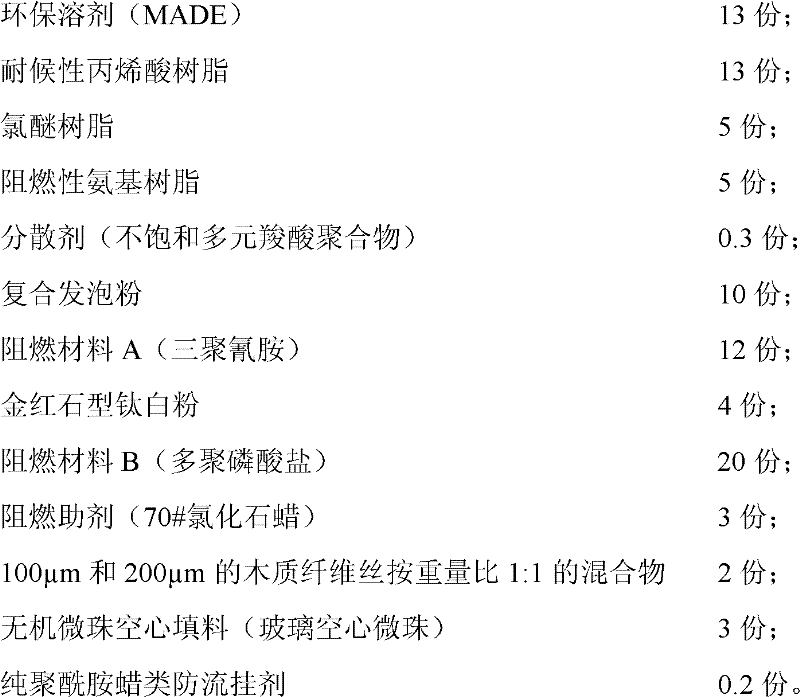

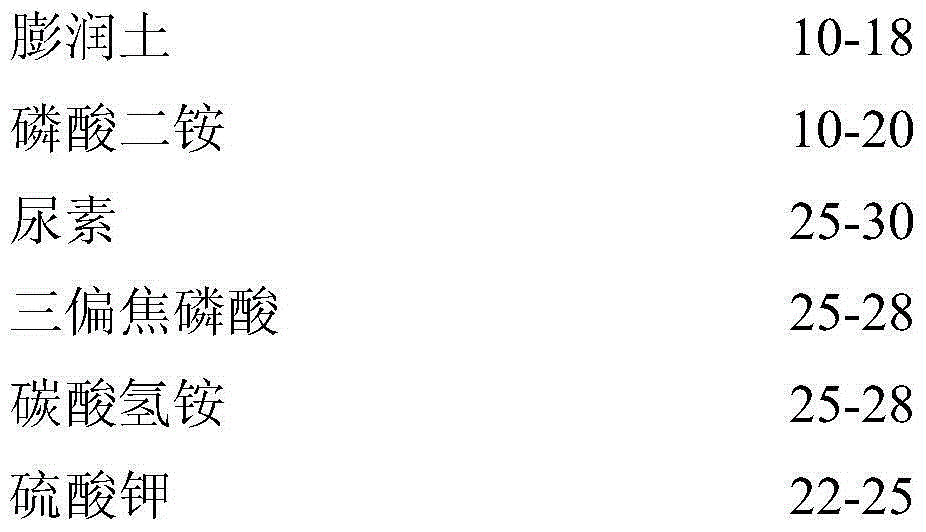

Fire retardant coating and preparation method thereof

ActiveCN102408802AExcellent weather resistanceStrong adhesion and durabilityFireproof paintsSolventWeather resistance

The invention discloses a fire retardant coating, which comprises the following components: an environment-friendly solvent, weather-proof acrylic resin, chlorinated polyether resin, flame retardant amino resin, a dispersing agent, composite foaming powder, a flame retardant material A, titanium white, a flame retardant material B, a flame retardant aid, wood fibers, an inorganic microbead hollowfiller and an anti-sagging agent. The invention also provides a preparation method for the fire retardant coating. The fire retardant coating can be coated on various substrates, is extra-thin, efficient and durable, is specially used outdoors, is resistant to the fire combustion of hydrocarbons, and has high chemical properties such as weather resistance, acid resistance, alkali resistance and the like, high adhesion and an attractive decorative effect, and paint films are fine; the fire retardant coating is uniformly expanded, and has a special foam structure and a high fireproof effect; and the product is environment-friendly and pollution-free, a production process is simplified, and the fire retardant coating is convenient to construct and can be used for coating with various fireproof requirements.

Owner:WUXI HUHUANG PAINT

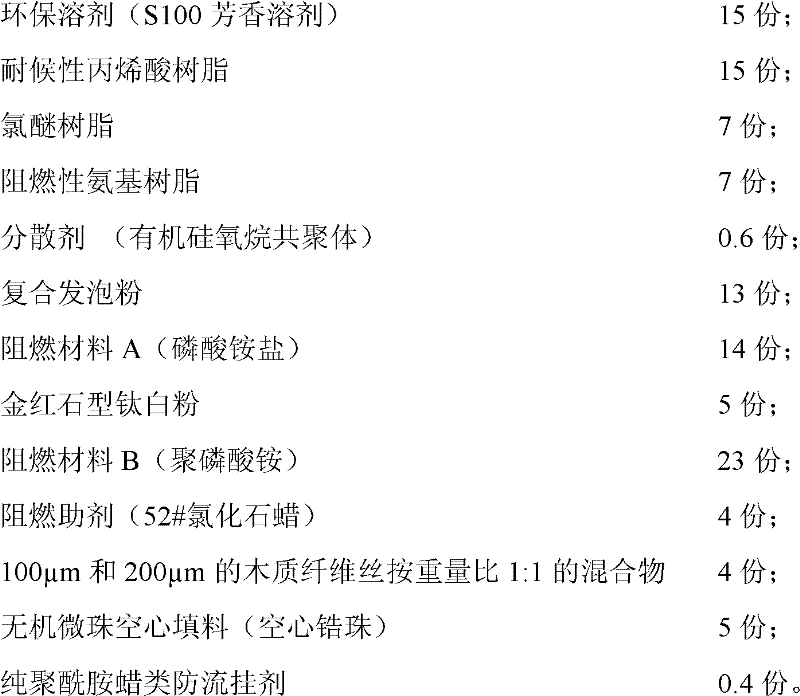

Water-retention and sand-fixing liquid mulching film and preparation method thereof

InactiveCN104804140AStrong water absorptionIncrease contactPlant protective coveringsCross-linkMoisture permeation

The invention relates to a water-retention and sand-fixing liquid mulching film and a preparation method thereof, and belongs to the technical field of agricultural production. The liquid mulching film comprises components in parts by weight as follows: 30-50 parts of ultrafine silica sol or nano-silica, 40-100 parts of carboxymethyl cellulose, 20-30 parts of N-isopropylacrylamide, 1-5 parts of ferrocene, 0.02-0.3 parts of a cross-linking agent and 0.4-1.2 parts of an initiator, wherein the solid content of the ultrafine silica sol is 10wt%-30wt%, and the particle size of silica is 1-100 nm. The liquid mulching film forms colloid easily with water, soil particles can be connected, structureless and dispersed sand soil is connected to form an elastic stable object, and a net-shaped film with good film performance and high strength is formed; one the one hand, surface pores of soil can be sealed, and soil moisture volatilization is blocked; on the other hand, moisture permeation is not inhibited, good water retention, soil moisture preservation and sand fixing functions are realized, and the performance of a desert and dry soil is improved effectively.

Owner:JIAXING GUOXING NEW MATERIAL TECH CO LTD

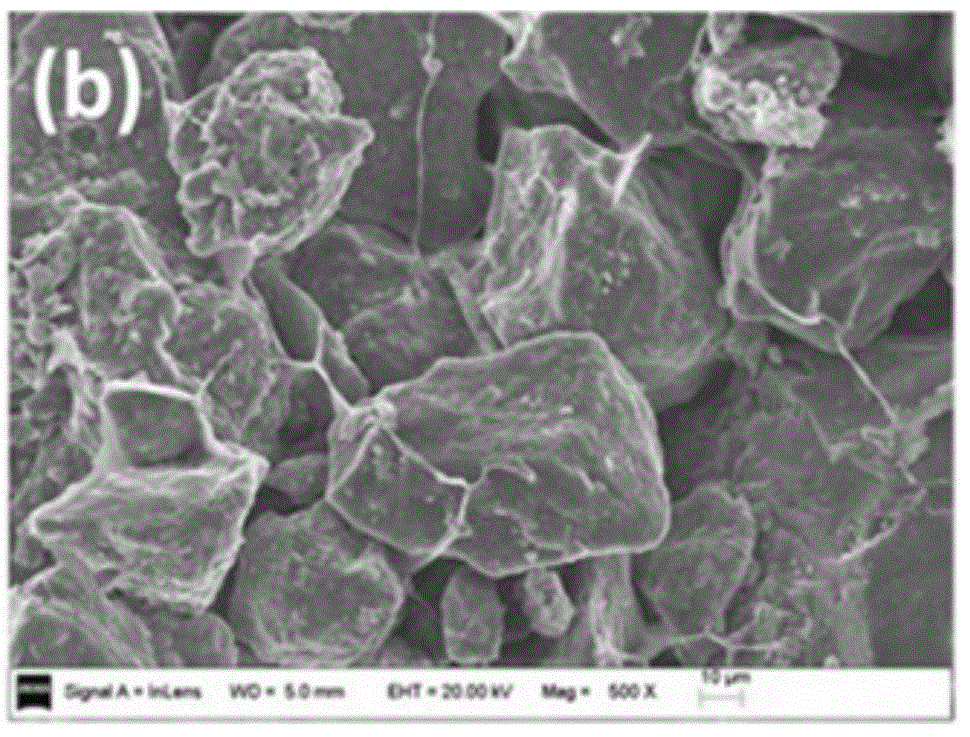

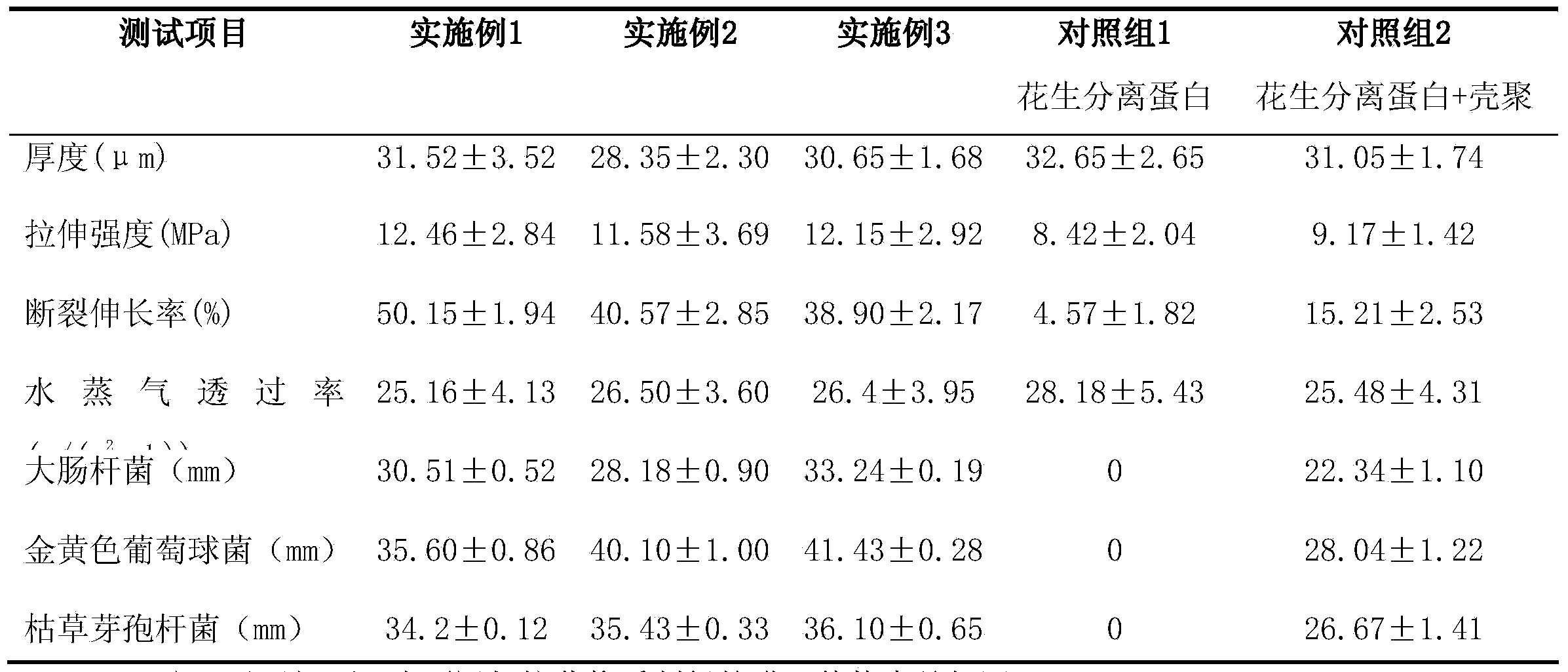

Edible peanut protein isolate antimicrobial coating and preparation method thereof

InactiveCN103937272AImprove featuresImprove anti-corrosion performanceFlexible coversWrappersWater bathsWater vapor

The invention discloses an edible peanut protein isolate antimicrobial coating and a preparation method thereof. The method comprises the following steps: (1) dissolving peanut protein isolate; (2) dissolving chitosan; (3) uniformly mixing a peanut protein isolate solution with a chitosan solution; (4) adding glycerin as a plasticizer; (5) promoting the dissolution by use of an ultrasonic water bath; (6) adding a clove essential oil component and a nisin component; (7) homogenizing; (8) degassing; (9) coating; and (10) drying and uncovering the coating. The antimicrobial coating disclosed by the invention not only can be used for preferably preventing migration of oxygen, carbon dioxide and water vapor but also is nontoxic and harmless to a human body and edible.

Owner:QINGDAO AGRI UNIV +1

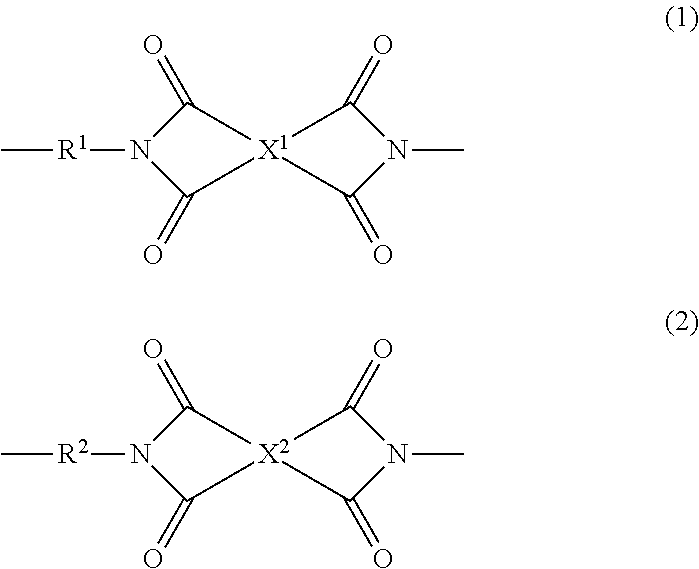

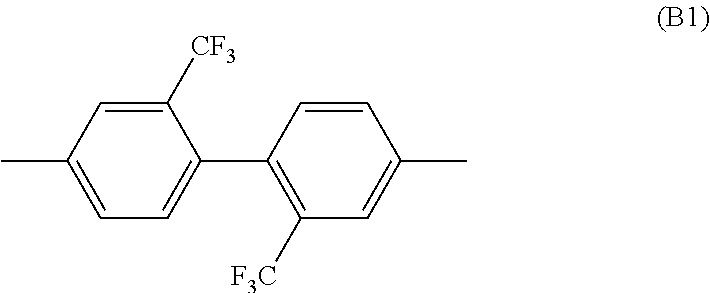

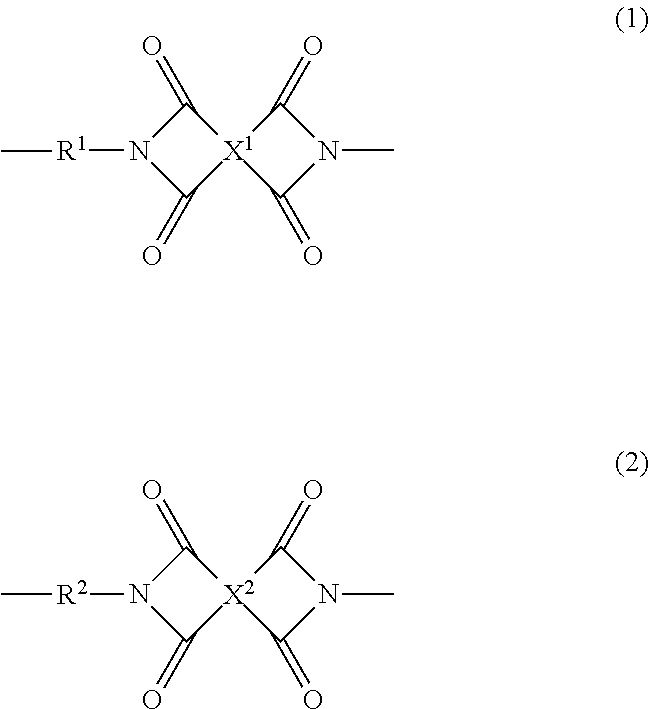

Polyimide resin

InactiveUS20160137789A1Improve heat resistanceHigh transparencyOrganic chemistrySynthetic resin layered productsCarbon numberOrganic group

A polyimide resin contains repeating structural units represented by formulas (1) and (2), wherein the content of the repeating structural unit represented by formula (2) relative to the total of the repeating structural unit represented by formula (1) and the repeating structural unit represented by formula (2) falls within a specific range and the content of the divalent group represented by the following structural formula (B1) falls within a specific range:X1 represents a tetravalent group containing an alicyclic hydrocarbon structure and having a carbon number of from 4 to 22. X2 represents a tetravalent group containing an aromatic ring and having a carbon number of from 6 to 22. R1 and R2 each independently represent a divalent organic group, and the content of the divalent group represented by the following structural formula (B1) relative to the total of R1 and R2 is from 80 to 100 mol %:

Owner:MITSUBISHI GAS CHEM CO INC

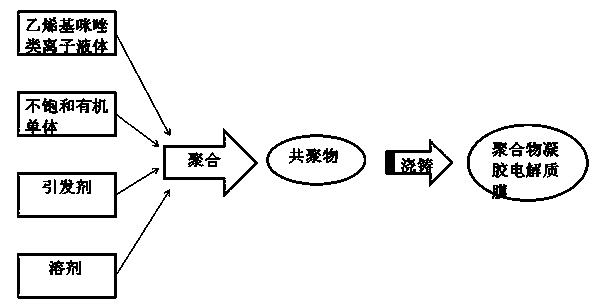

Preparation method of conductive copolymer film

InactiveCN103467655AGood film formingConvenience filmOrganic conductorsPolymer scienceElectrochemical window

The invention provides a preparation method of a conductive copolymer film. The preparation method comprises the steps of performing graft copolymerization on conductive vinyl imidazolium-based ionic liquid and unsaturated organic monomers in mole ratio of 1:0.1-1:5 to form a copolymer, and then processing the copolymer by adopting a casting method to form a polymer gel electrolyte film. The prepared polymer gel electrolyte has good film-forming property, high film-forming flexibility, high conductivity (10<-2>-10<-3>s.m<-1>), wide electrochemical window (3-5V) and high thermal stability (200-400 DEG C). The required raw materials are cheap, the operation process is simple, and the product performance is good, and therefore, the preparation method has importation popularization significance in the field of solid electrolyte films.

Owner:CENT SOUTH UNIV

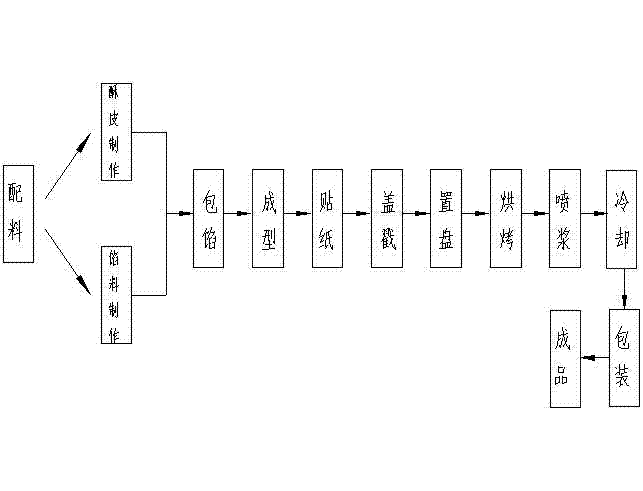

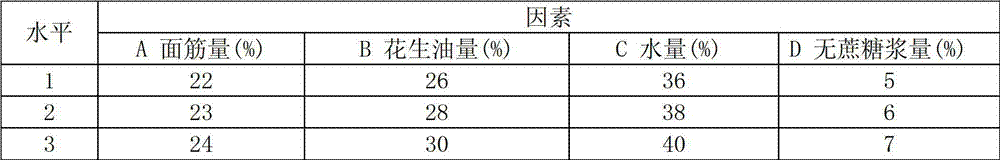

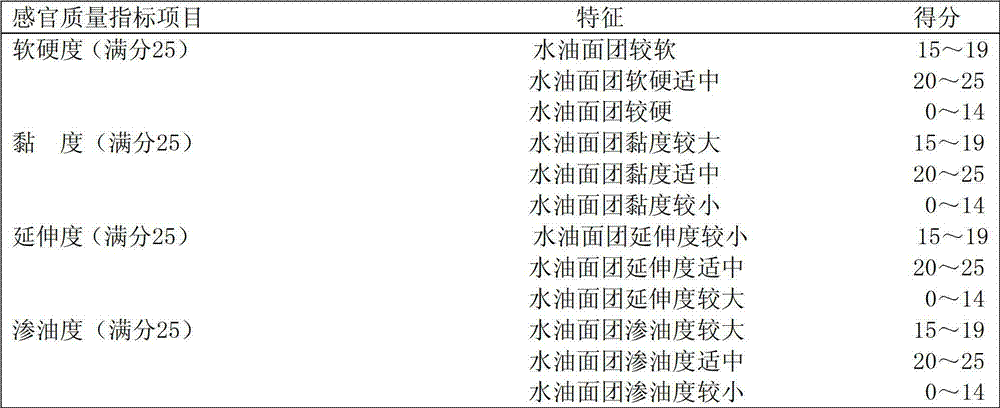

Suzhou-style mooncake with good cake crust sensation quality and production technology of mooncake

InactiveCN102919332AImprove qualityConducive to processBakery productsClear LayerAdditive ingredient

The invention relates to a production technology of a Suzhou-style mooncake with good cake crust sensation quality. The production technology of the Suzhou-style mooncake with good cake crust sensation quality comprises the following steps of: (1) preparing ingredients; (2) making crisp crust and fillings, wherein the crisp crust making comprises the following step of preparing water and oil doughs, oil crisp doughs and crisp crust doughs; (3) wrapping the fillings and forming; (4) baking; and (5) cooling. According to the production technology, the cake crust formulation is adjusted appropriately; the cake crust of the prepared Suzhou-style mooncake has favorable comprehensive sensory quality, and the Suzhou-style mooncake with good cake crust sensation quality has the advantages of low sweetness, clear layers, crisp taste, complete cake crust and nutrition and health.

Owner:苏州稻香村食品工业有限公司

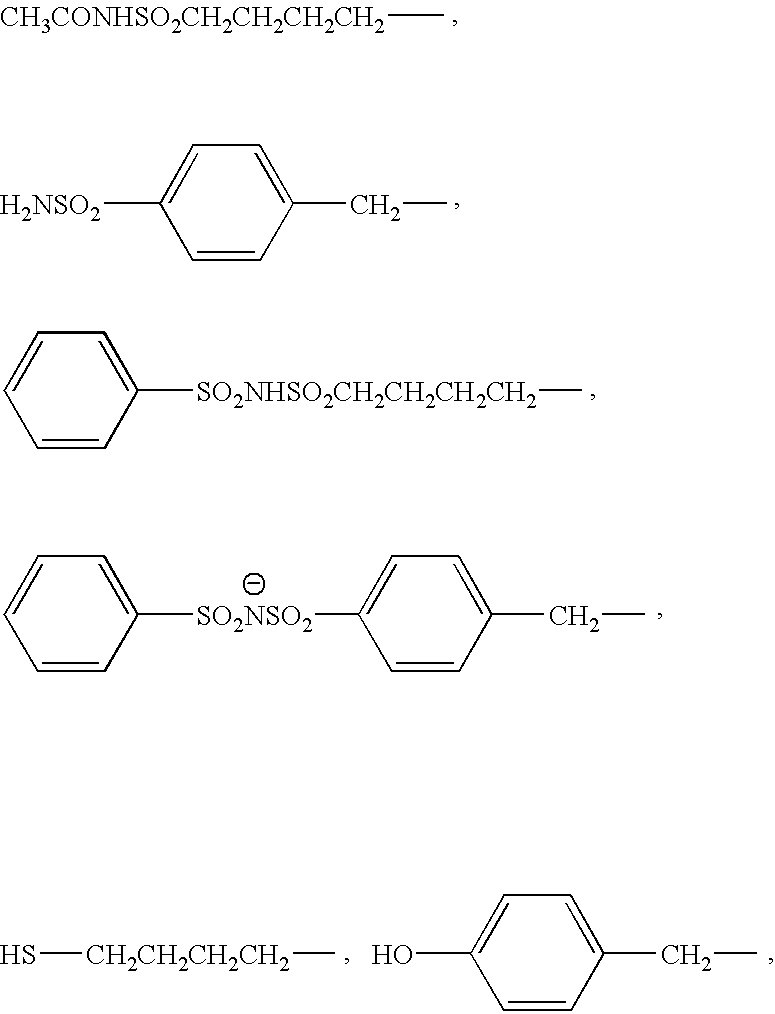

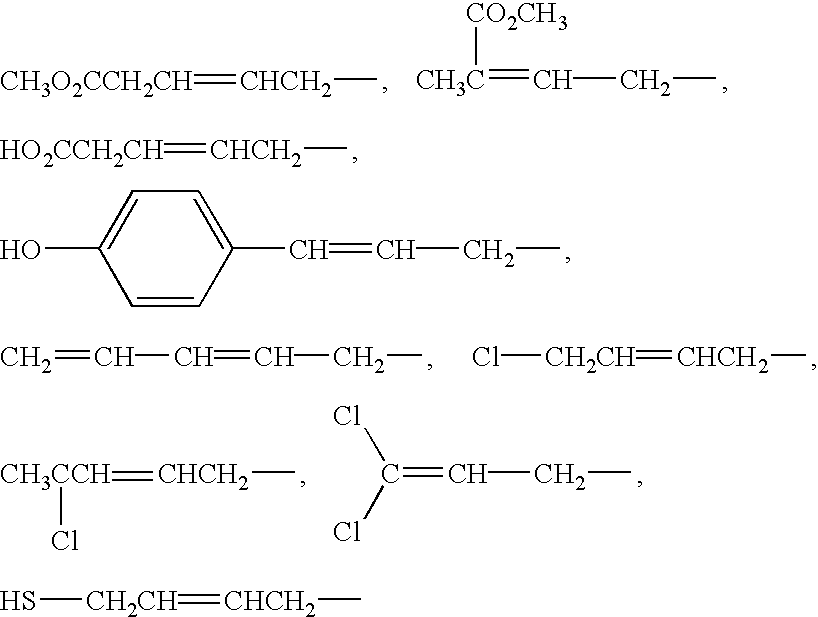

Photosensitive composition and negative working lithographic printing plate

InactiveUS6858373B2Convenience filmEnhance layeringPhoto-taking processesRadiation applicationsPlanographic printingPolymer chemistry

A photosensitive composition comprising a resin containing a repeating unit corresponding to a monomer having a structure represented by formula (I) defined in the specification, and a negative working lithographic printing plate having a negative working photosensitive layer comprising the above-described photosensitive composition.

Owner:FUJIFILM CORP

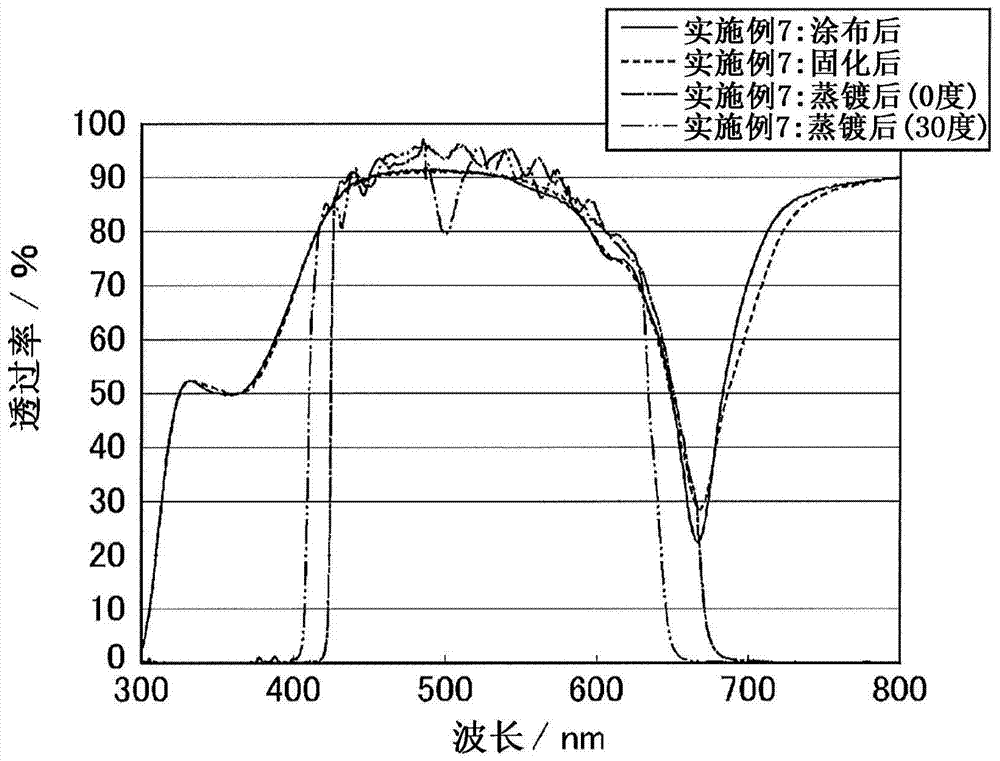

Resin Composition For Laminating And Use Thereof

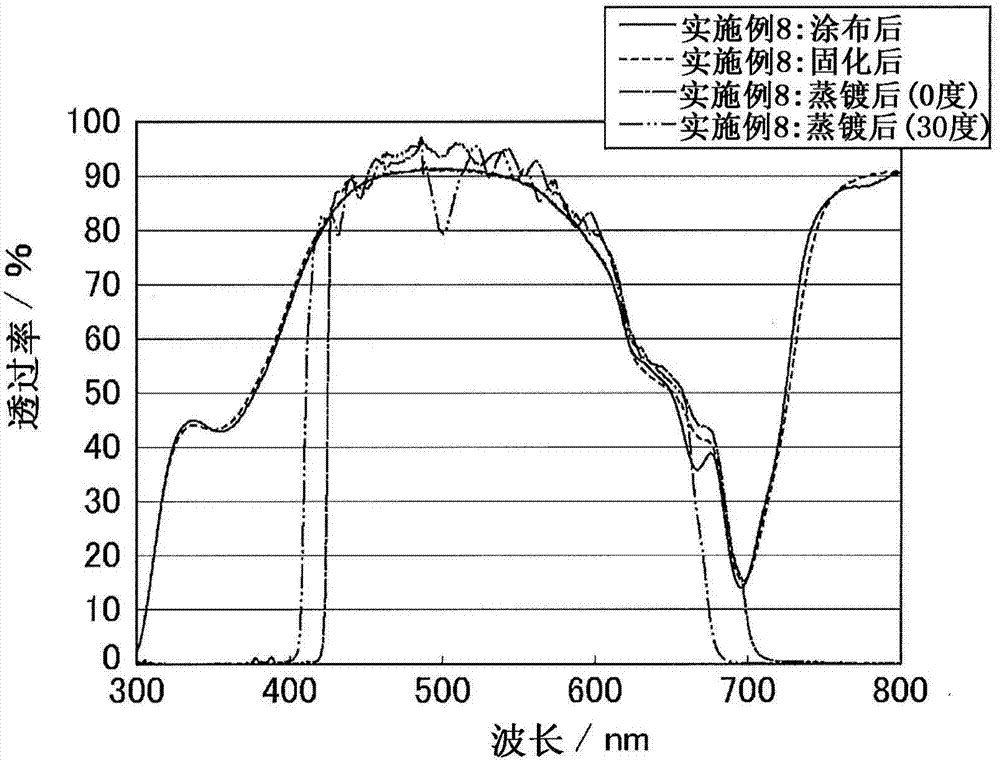

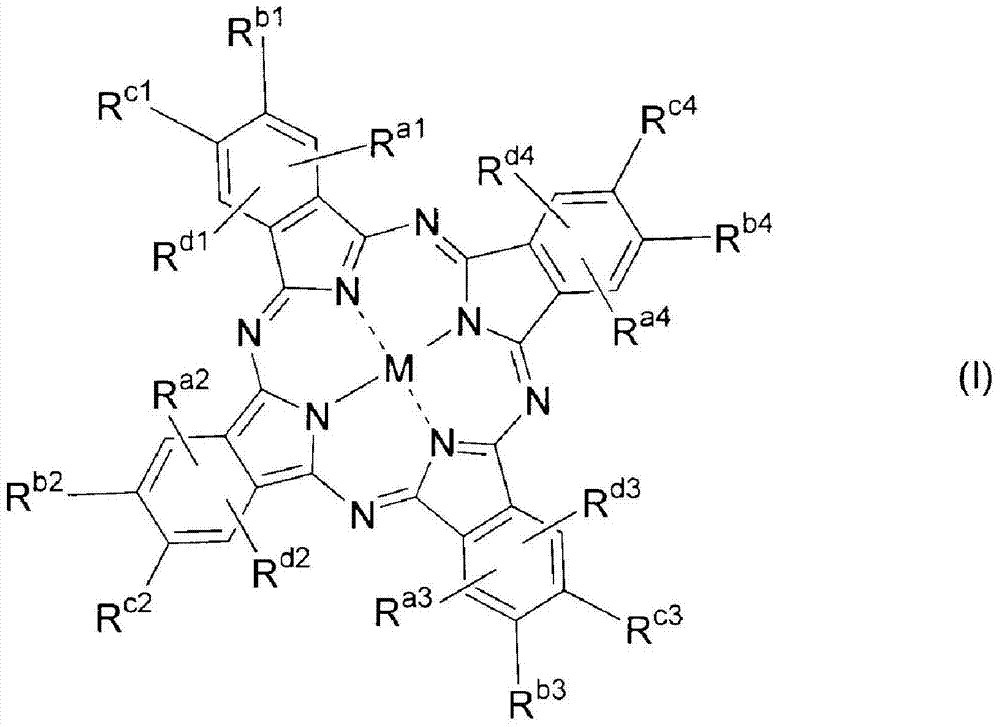

ActiveCN103923438AConvenience filmGood adhesionCamera filtersOptical elementsPolymer scienceEthylene oxide

The invention relates to a resin composition for laminating and use thereof. The invention provides the resin composition for laminating, which is used as a material for forming a layer on the substrate and has excellent heat resistance, and a laminate member which is obtained through forming the resin composition for laminating on the substrate and has excellent heat resistance. The invention further provides a light selective transmission filter and an image photographing element which are obtained through utilizing the laminate member. The resin composition for laminating according to the invention is used as the resin composition of the material for forming layer on the substrate, wherein the resin composition contains epoxyethane compound with more than one epoxyethane ring in one module and a pigment. The epoxyethane compound comprises a compound with hydroxyl and / or an ester group. The pigment contains the pigment component which has an absorption peak in a waveband of 600nm-900nm.

Owner:NIPPON SHOKUBAI CO LTD

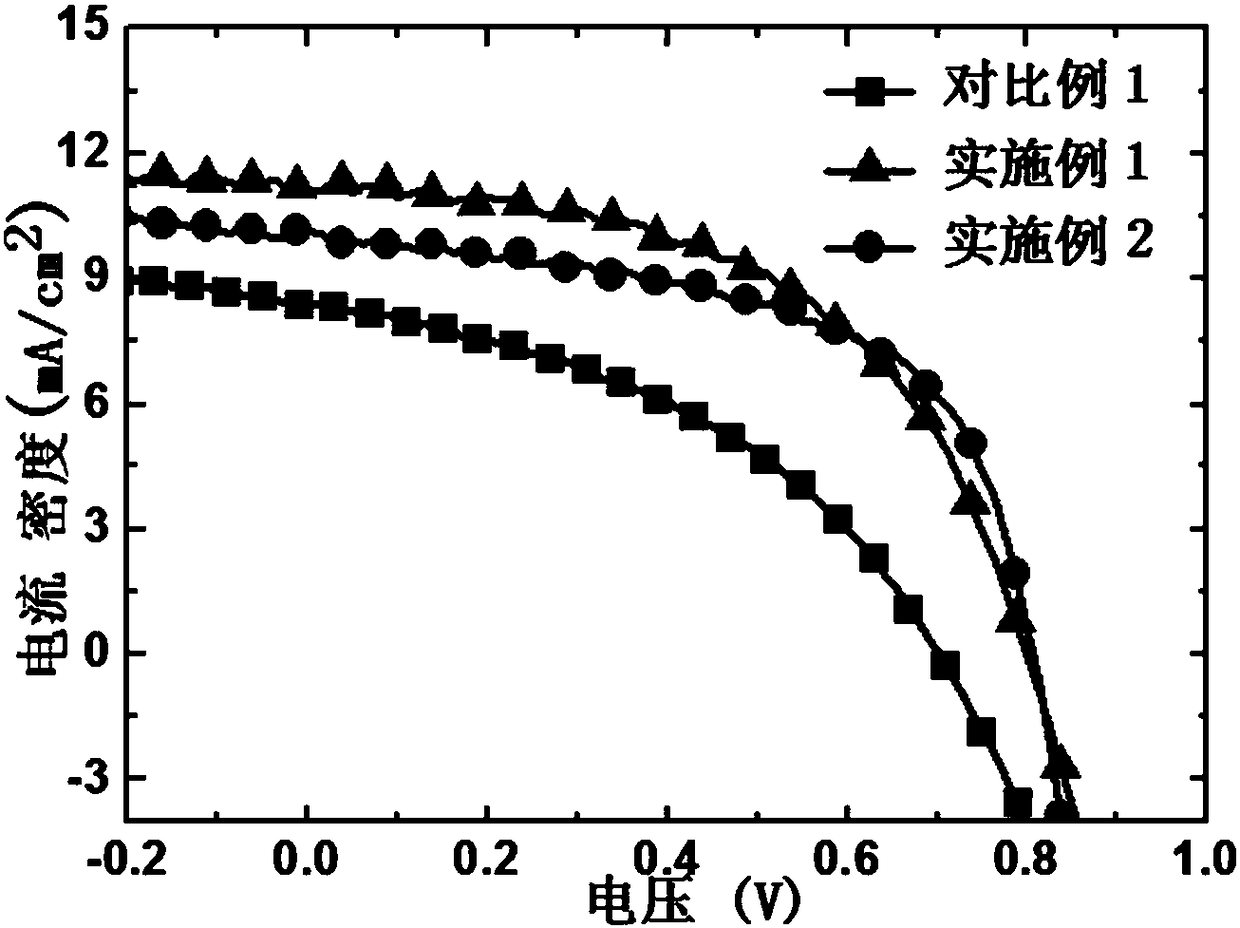

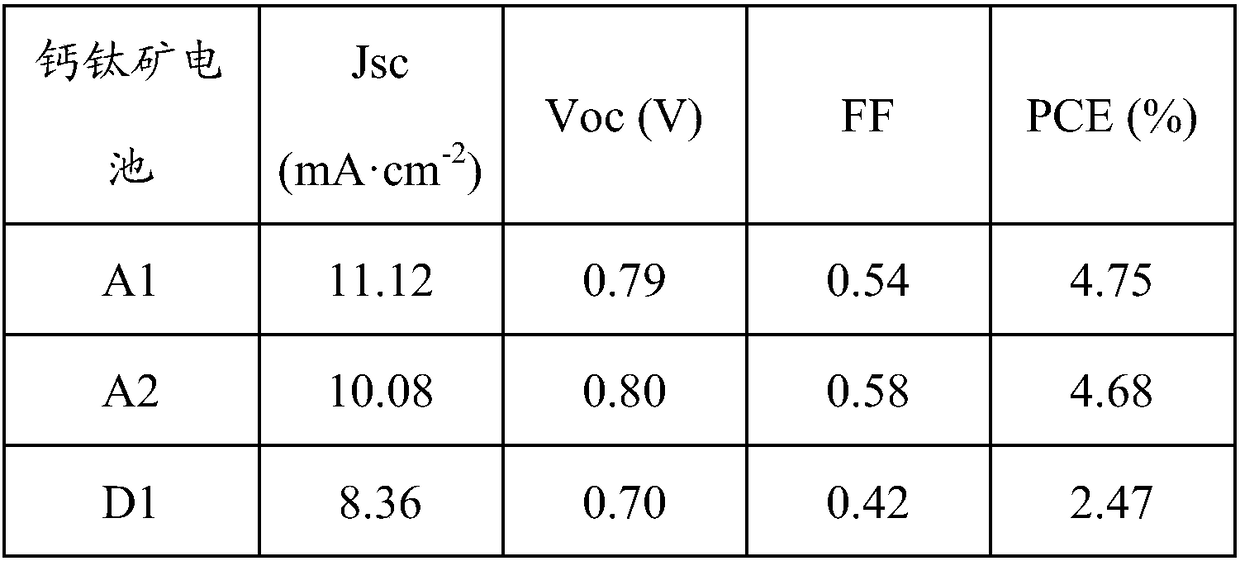

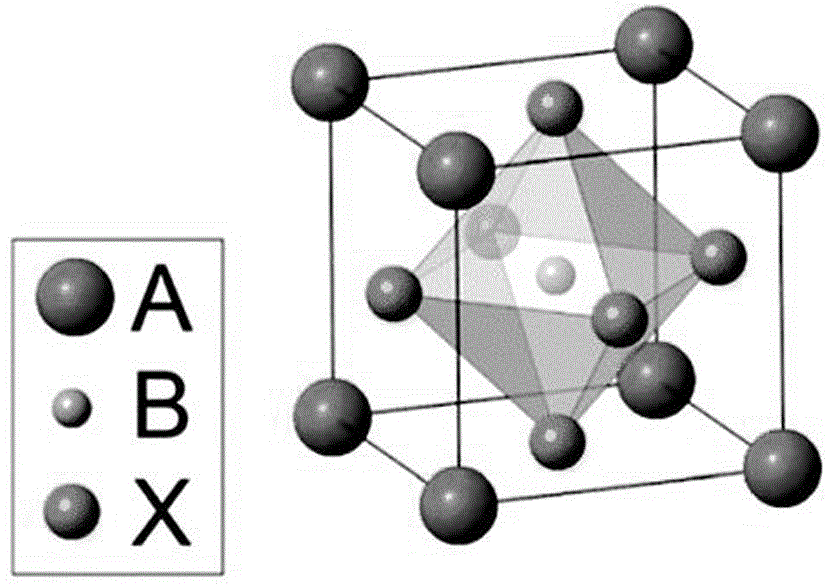

Spray coating solution, perovskite layer, preparation method of perovskite layer and perovskite cell

ActiveCN108057590AGood film formingImprove continuityFinal product manufactureSolid-state devicesAlcoholSpray coating

The invention relates to the photovoltaic field, in particular to a spray coating solution used for preparing a perovskite layer. The spray coating solution comprises a mixed solvent and a perovskitematerial. The mixed solvent is formed by mixing acetonitrile and an amine solution. The solute of the amine solution is at least one of methylamine, propylamine and butyl amine. The solvent of the amine solution is at least one of methyl alcohol, ethyl alcohol and tetrahydrofuran. According to the spray coating solution, the acetonitrile and the amine solution are used as the mixed solvent to dissolve the perovskite material, after spray coating and annealing, the obtained perovskite layer is good in film-forming property and continuity, the film is provided with few holes and is smooth, uniform and good in quality, and therefore the property improvement of a perovskite cell is facilitated. In addition, by the adoption of the spray coating solution, the annealing temperature is low, the utilization rate of the materials is high, and therefore the production cost of the perovskite layer is lowered. The invention further discloses a preparation method of the perovskite layer, the perovskite layer and the perovskite cell.

Owner:KUNSHAN GCL OPTOELECTRONIC MATERIAL CO LTD

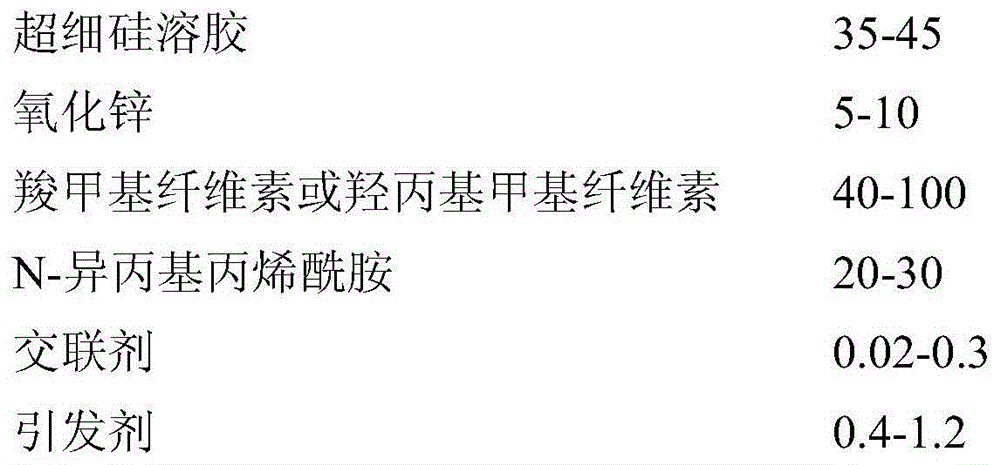

Liquid fertilizing and water-retaining mulching film and preparation method thereof

InactiveCN104804141AImprove physical and chemical propertiesIncreased water-stable aggregatesPlant protective coveringsFertilizer mixturesCross-linkUltra fine

The invention relates to a liquid fertilizing and water-retaining mulching film and a preparation method thereof and belongs to the technical field of agricultural production. The liquid mulching film comprises components in percentage by mass as follows: 1%-10% of a modified macromolecular composite polymer and 90%-99% of a fertilizing agent; the modified macromolecular composite polymer comprises components in parts by weight as follows: 35-45 parts of ultra-fine silica sol, 5-10 parts of zinc oxide, 40-100 parts of carboxymethylcellulose or hydroxypropyl methyl cellulose, 20-30 parts of N-isopropylacrylamide, 0.02-0.3 parts of a cross-linking agent and 0.4-1.2 parts of an initiator; the solid content of the ultra-fine silica sol is in a range of 10-30wt%, and particle sizes of silica in the ultra-fine silica sol are in a range of 1-100 nm. The prepared liquid mulching film can significantly increase the water-retention rate of soil and improve physical and chemical properties of the soil, can be completely degraded, is free of pollution and can substitute for plastic mulching films on a large scale.

Owner:CHANGZHOU GUOBO NEW MATERIAL TECH CO LTD

Super environmental protection latex paint with zero VOC

An environment protection type emulsoid paint without VOC is prepared from water, sodium polyacrylate "5040", hydroxyethyl cellulose "250HBR", mineral oil modified silicone BYK-003, titanium white powder, filming agent and assistant. Its advantages are high hardness and adhesion, high resistance to dirt, zero VOC and no poison and harm.

Owner:FOSHAN FEIHONG COATING

Environment-friendly bulk coal overlapping restrainer and method of producing the same

InactiveCN101429421AWith bondingWith thickeningOther chemical processesCarboxymethyl celluloseOrganic matter

The invention discloses an environment-friendly type separate coal covering inhibitor, which comprises the following components in weight percentage: 0.05 to 2.00 percent of carboxymethyl cellulose, 0.50 to 2.50 percent of glycerin, and the balance being water. The invention also provides a method for preparing the environment-friendly type separate coal covering inhibitor. The preparation method comprises the followings steps: a reaction kettle is added with water accounting for 80 percent of total water quantity, added with the carboxymethyl cellulose, started to be stirred, added with the glycerin when the carboxymethyl cellulose is completely dissolved, evenly stirred, added with the remained water accounting for 20 percent of total water quantity, and evenly stirred so as to obtain the finished product. The inhibitor has reasonable formula and is easy to purchase; because the materials are organic matters, the inhibitor does not affect the fuel value of coal after spraying; moreover, the inhibitor also has the advantages of low cost, convenient use, obvious dustlaying and loss prevention effects, obvious economic and ecological benefits, simple production process, no secondary pollution during processing and using, safe use and no toxic and side effects.

Owner:XIAN UNIV OF SCI & TECH

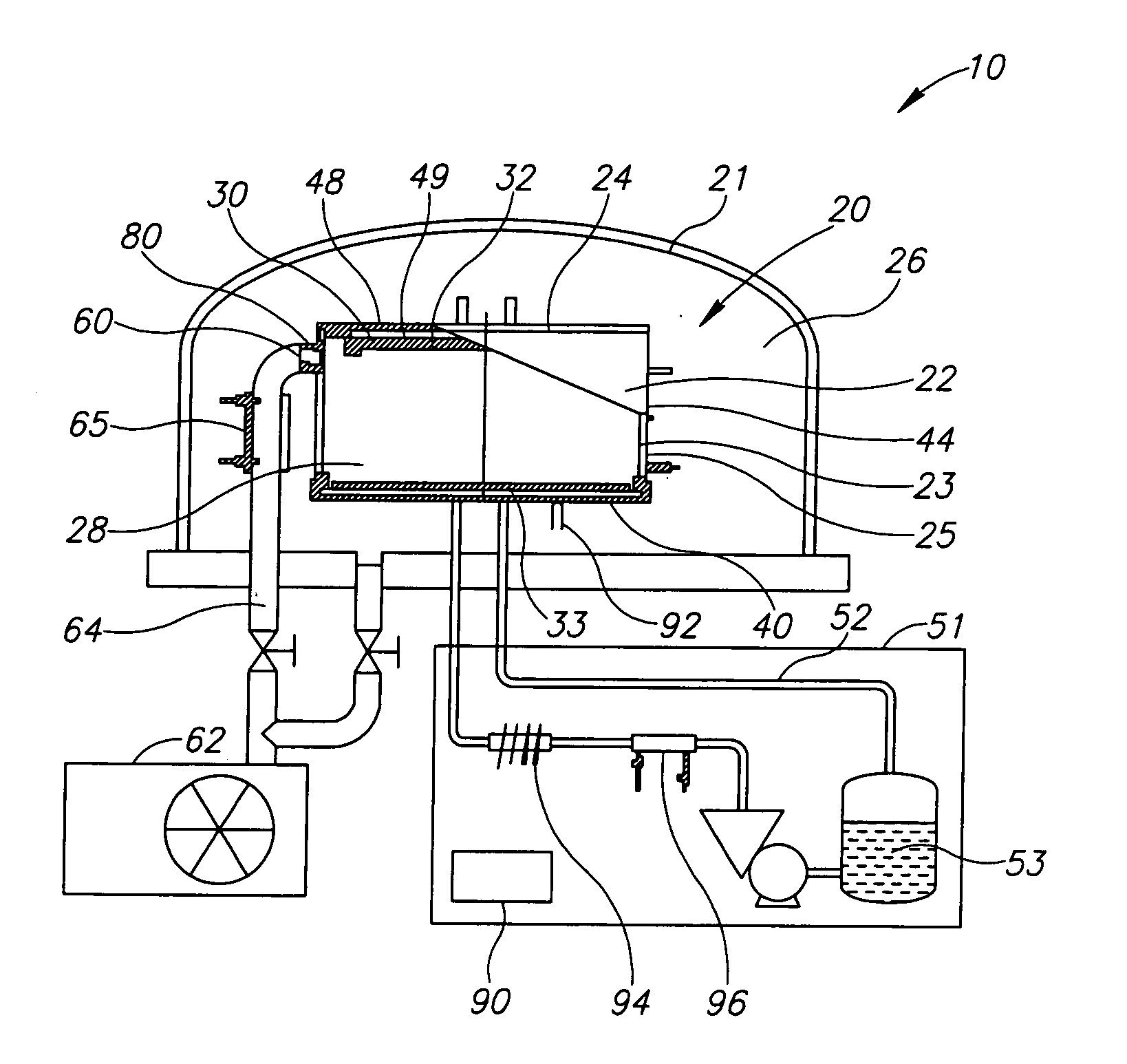

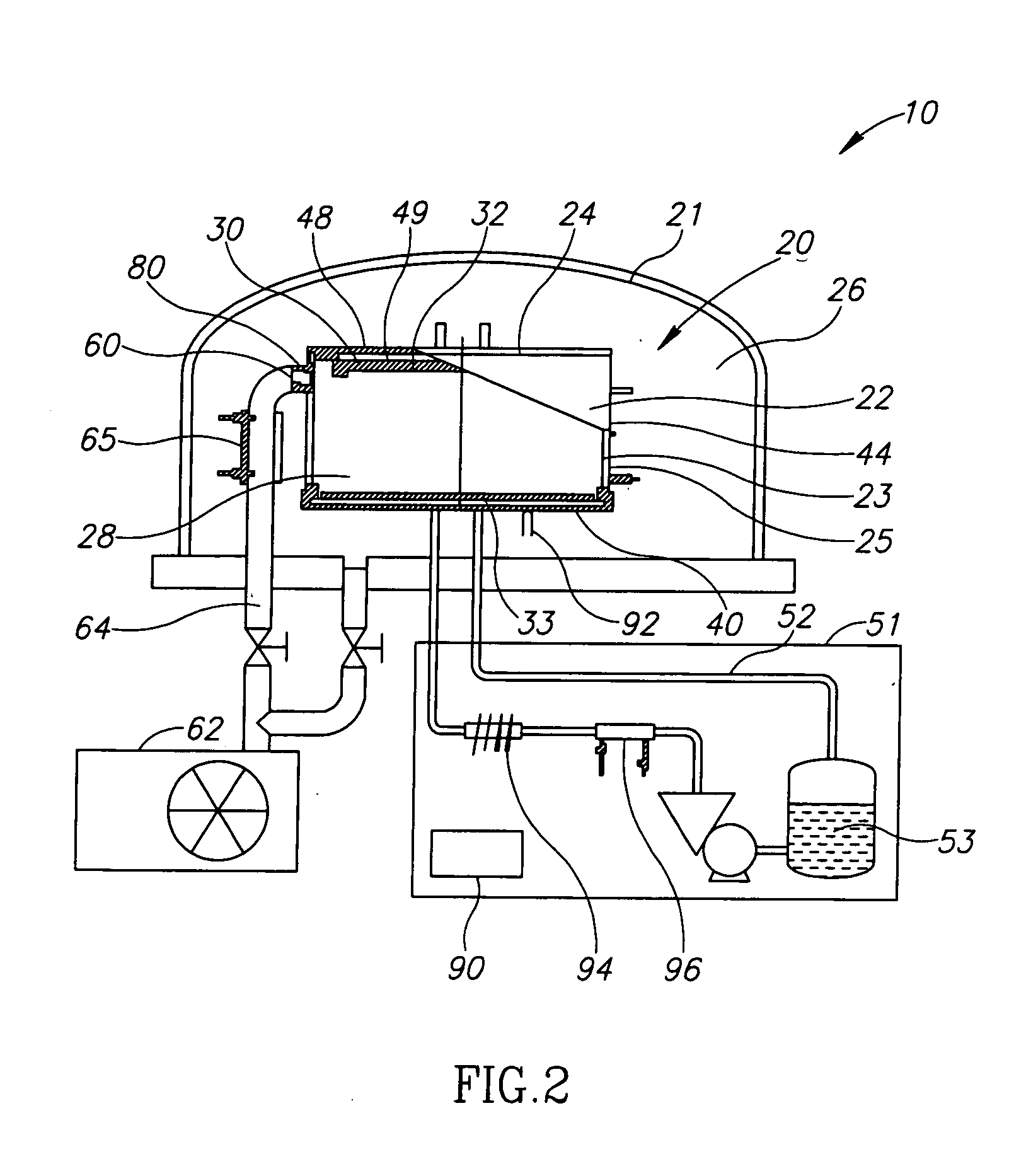

Method and apparatus for applying a polycrystalline film to a substrate

InactiveUS20050160979A1Less massOptimal directional growth of filmLiquid surface applicatorsVacuum evaporation coatingElectrical and Electronics engineeringTemperature control

A film deposition system for depositing a polycrystalline film on a large area substrate. The system includes a chamber formed of a set of walls, the set of walls defining at least three temperature zones within the chamber. Each of the walls is thermally insulated from the other walls forming the chamber. The system further includes a vacuum source, a set of heat sources, and a plurality of temperature detectors for detecting the temperature of the walls in the set of walls. Temperature control modules monitor and control the temperature in each of the temperature zones. The temperature control modules maintain predetermined temperatures in the walls so that the total mass of film-forming material lost through parasitic losses is less than the film mass deposited on the large area substrate. A method for depositing a polycrystalline film is also described.

Owner:REAL TIME RADIOGRAPHY

Camouflage paint

InactiveCN105602395AEasy to prepareImprove stabilityPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxySolvent

The invention relates to a camouflage paint. The camouflage paint comprises the following raw materials in parts by weight: 30-45 parts of amine cured epoxy resin, 15-30 parts of aliphatic polyurethane, 1-3 parts of an anti-aging agent, 3-6 parts of an inorganic nano-material, 1-15 parts of a camouflage pigment composition, 2-5 parts of talcum powder, 1-5 parts of a delustering agent, 0.5-2.5 parts of a film forming auxiliary agent, and 40-60 parts of a solvent. The provided camouflage paint has the advantages of simple preparation method, good stability, and excellent film forming ability when used for coating, a camouflage purpose can be realized by a camouflage pigment mixture, addition of the anti-aging agent provides good aging-resistance performance to the paint, service life of the paint can be prolonged, and protection function for a target object can be effectively enhanced.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

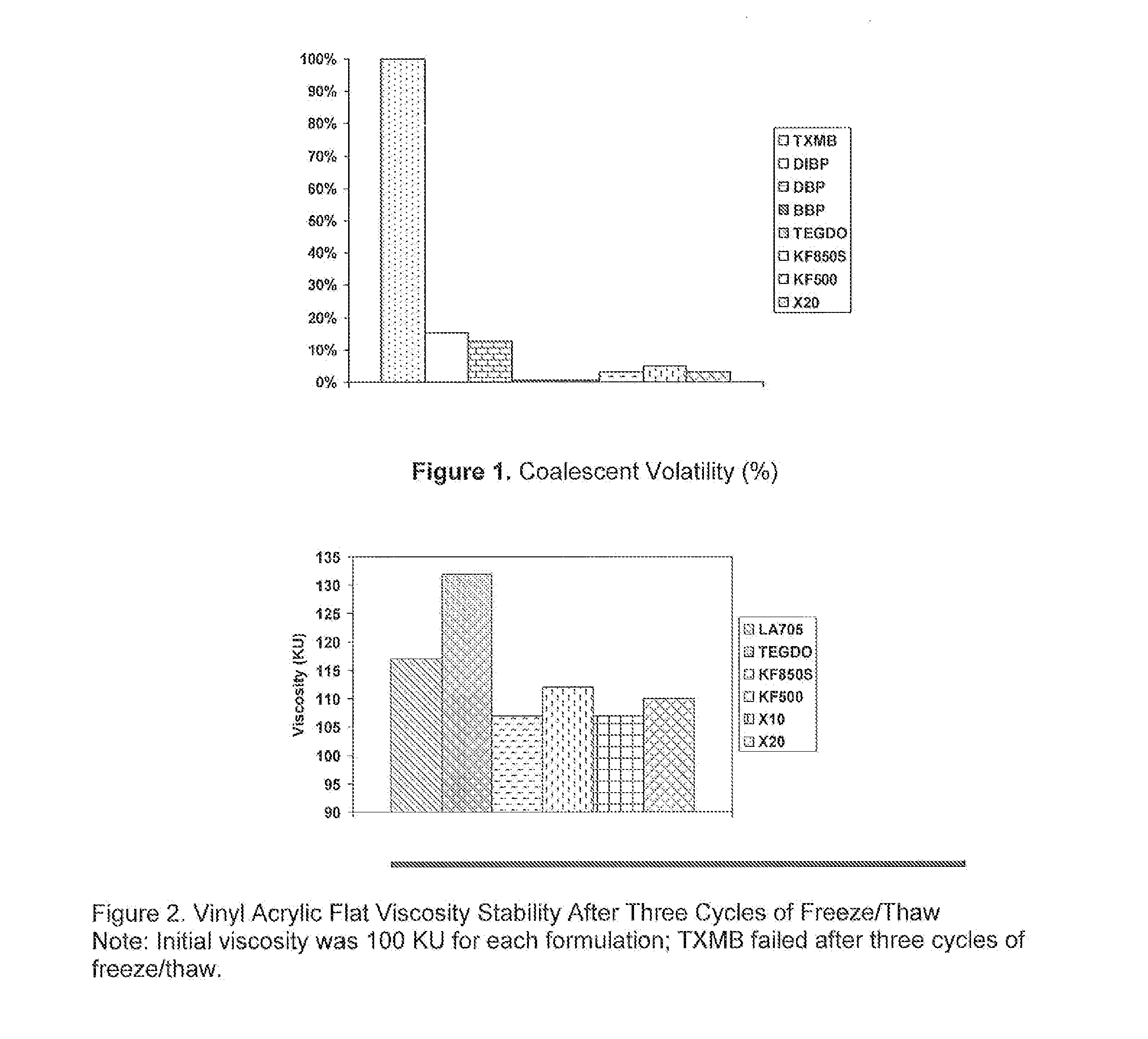

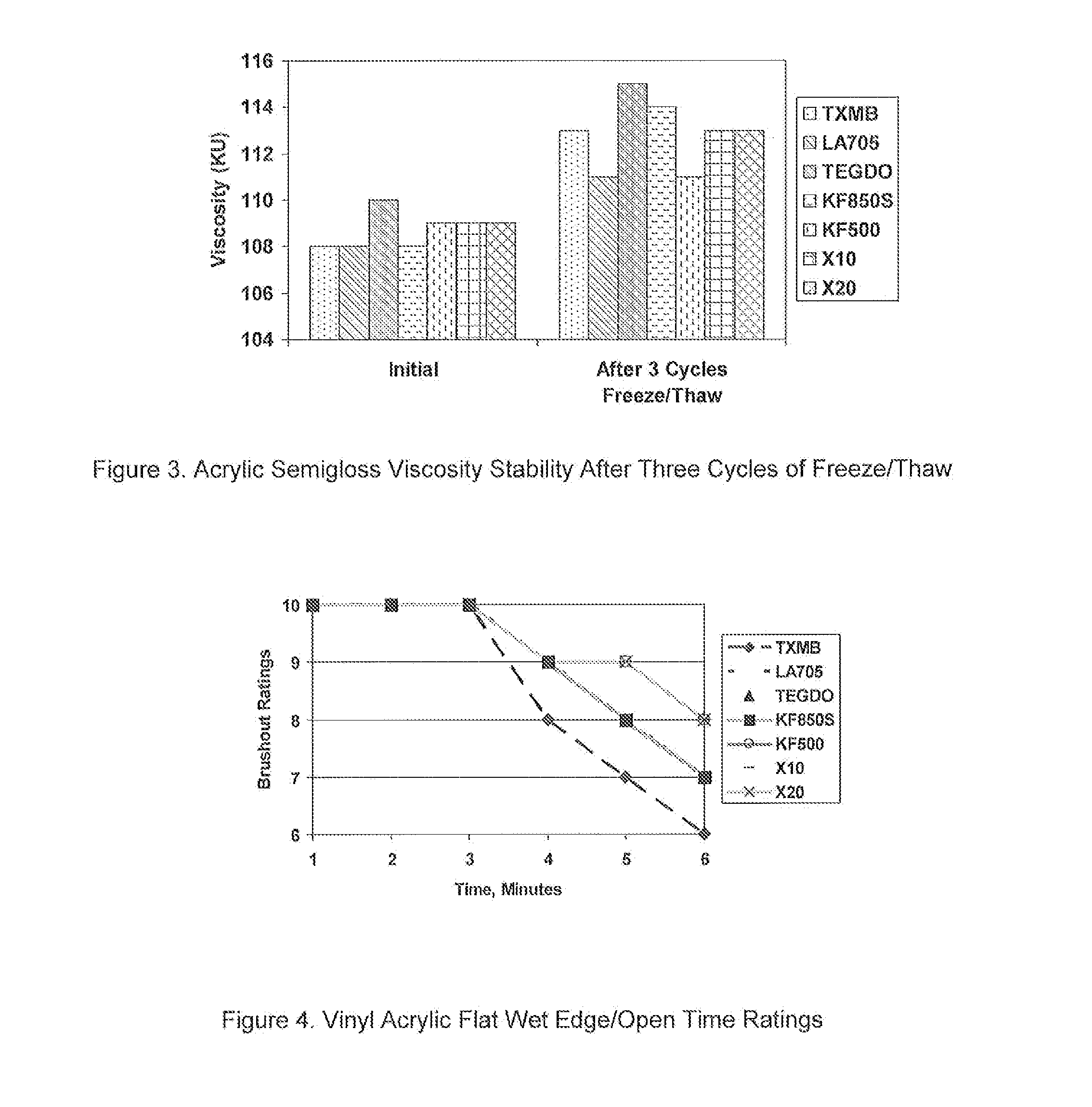

Dibenzoate plasticizers/coalescent blends for low VOC coatings

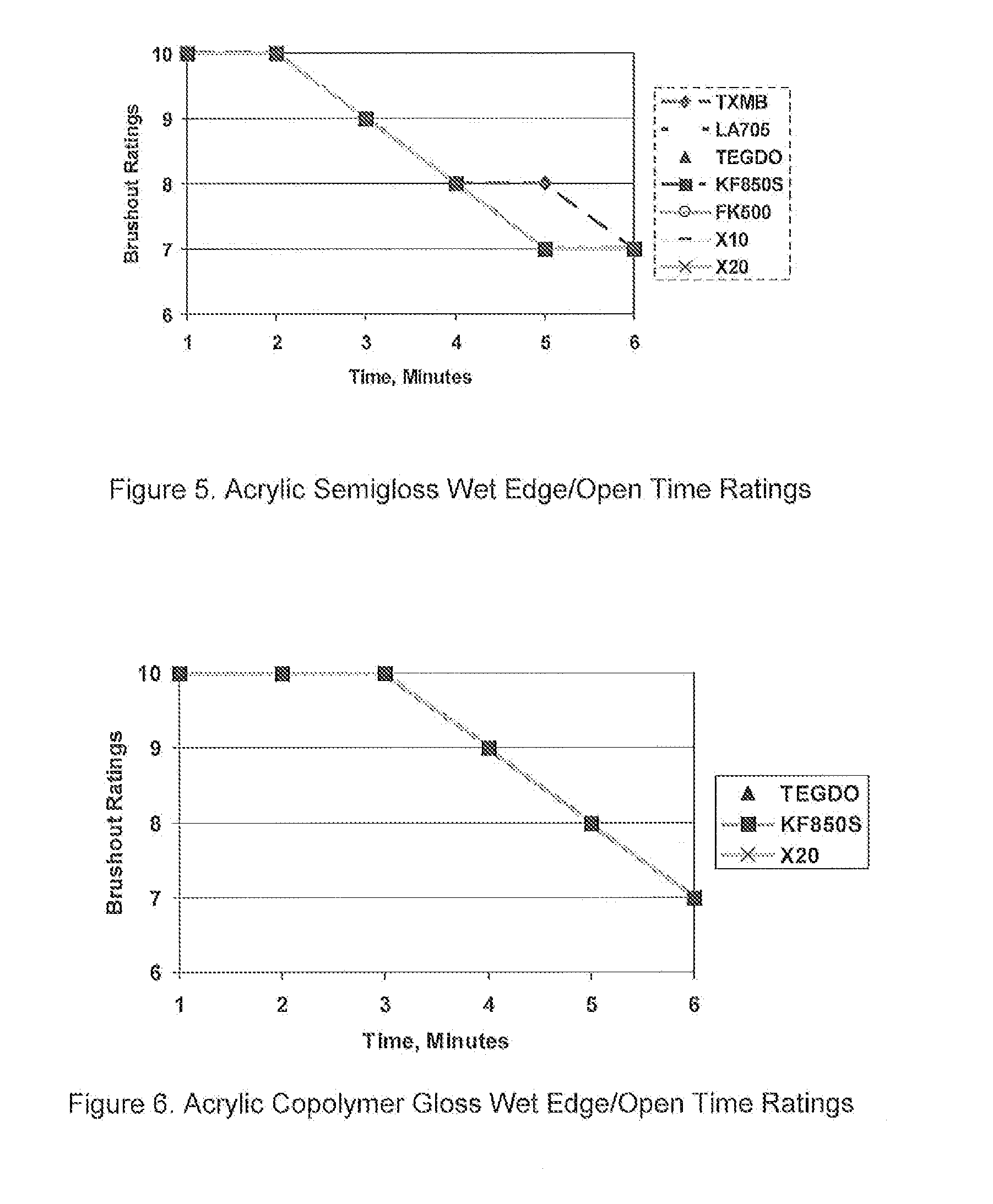

ActiveUS20130274395A1Reduce volatilityGood performance benefit in glossNon-macromolecular adhesive additivesInksEmulsionDiethylene glycol

A novel, low volatility, non-phthalate plasticizer / coalescent blend for use in paints and other polymeric coatings comprises a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate. The triblend when used in a paint or other coatings achieves a low VOC paint or coating having stable viscosity after three freeze / thaw cycles and equivalent or superior wet edge / open time ratings, gloss ratings, scrub resistance and block resistance when compared to traditional coalescents, including without limitation high VOC coalescents, low VOC non-dibenzoate coalescents and other dibenzoate blends. The triblend may be used as a substitute or alternative coalescent in latex and acrylic emulsion coatings, among others, to achieve a lower VOC content without sacrificing performance properties.

Owner:EMERALD KALAMA CHEM

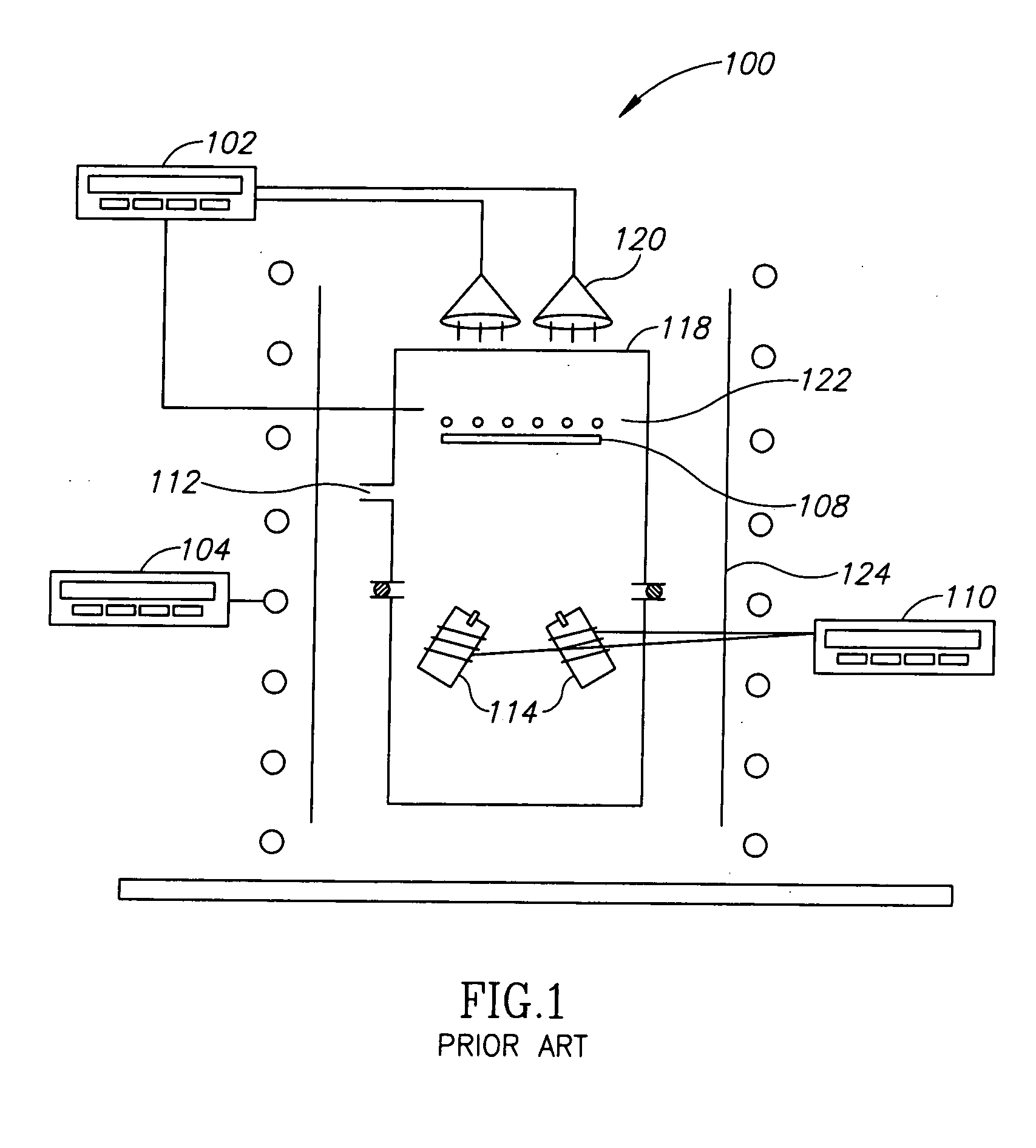

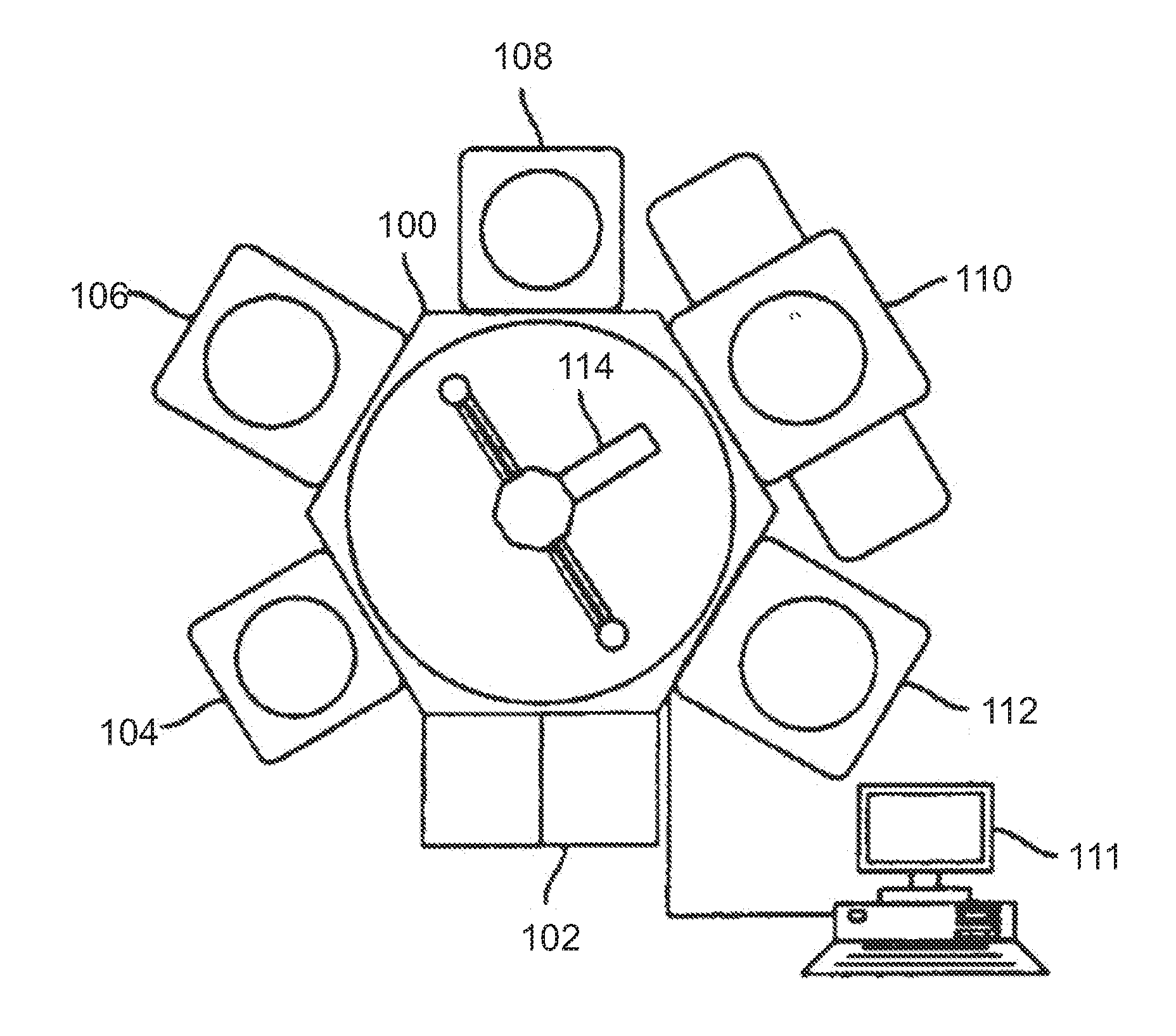

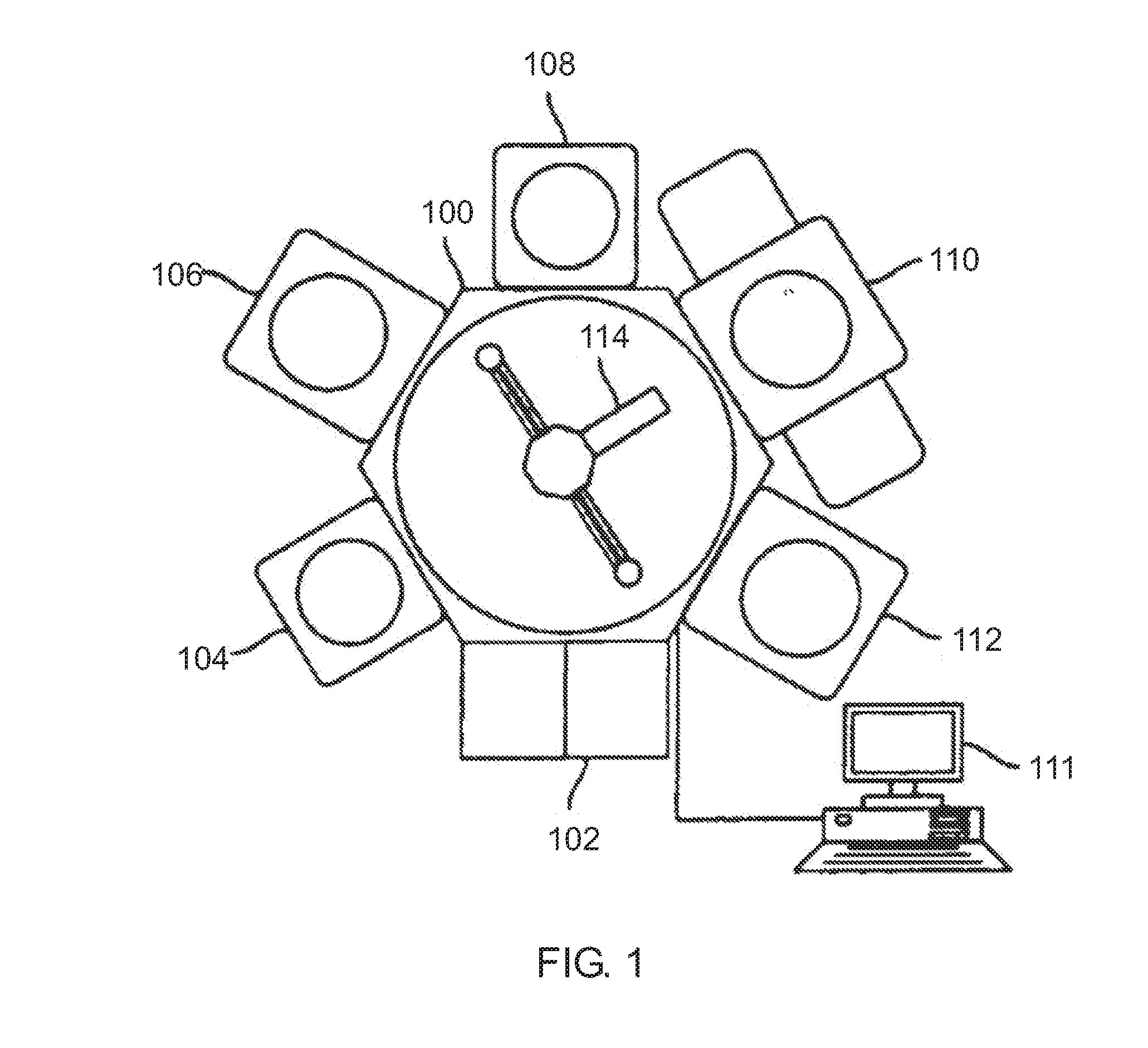

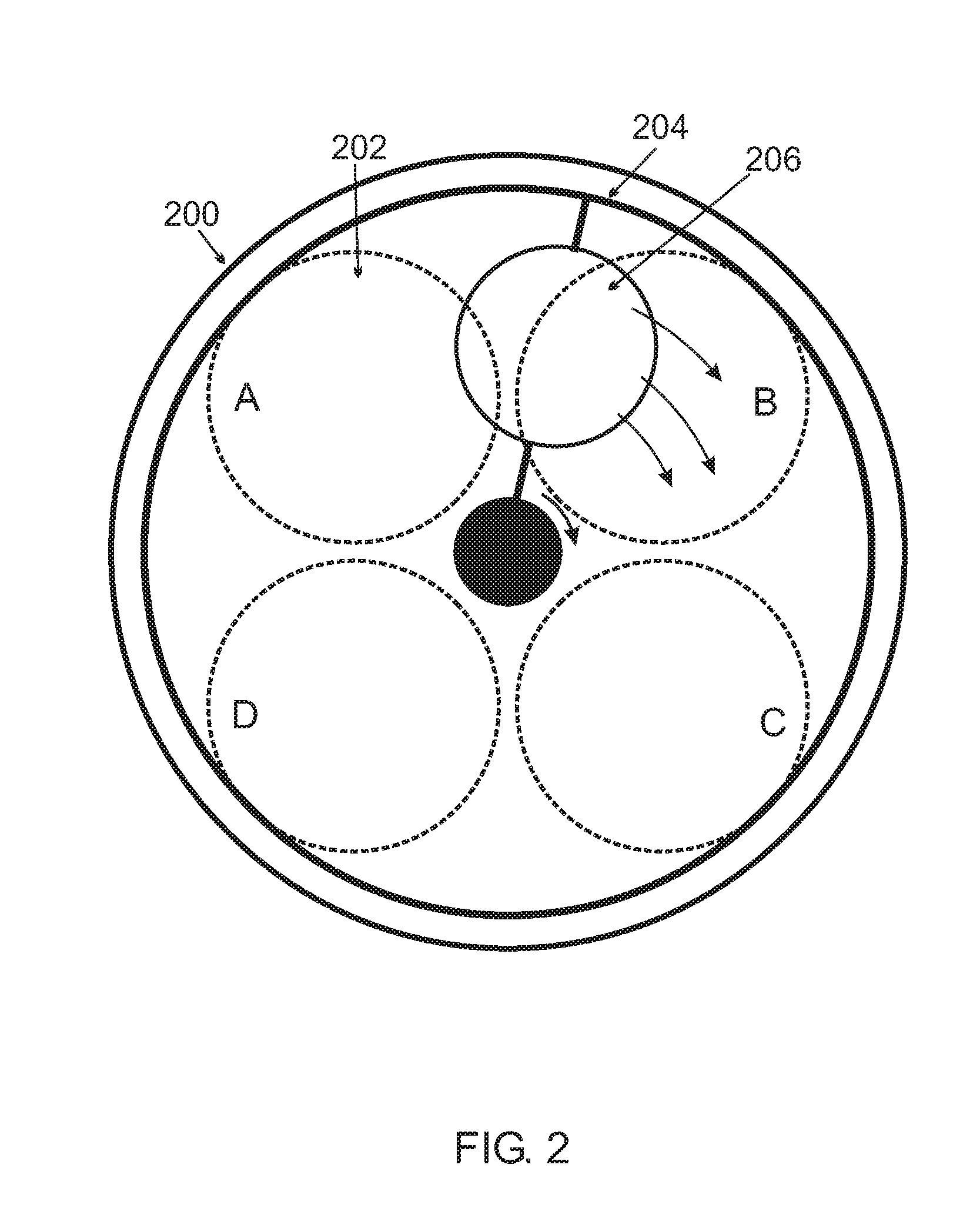

Chemical Vapor Deposition System

InactiveUS20140127887A1Eliminate the problemReduced dust formationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTransport systemControl system

Chemical vapor deposition (CVD) systems for forming layers on a substrate are disclosed. Embodiments of the system comprise at least two processing chambers that may be linked in a cluster tool. A first processing chamber provides a chamber having a controlled environmental temperature and pressure and containing a first environment for performing CVD on a substrate, and a second environment for contacting the substrate with a plasma; a substrate transport system capable of positioning a substrate for sequential processing in each environment, and a gas control system capable of maintaining isolation. A second processing chamber provides a CVD system. Methods of forming layers on a substrate comprise forming one or more layers in each processing chamber. The systems and methods are suitable for preparing Group III-V, Group II-VI or Group IV thin film devices.

Owner:INTERMOLECULAR

Heat-resistant synthetic resin microporous film, separator for non-aqueous liquid electrolyte secondary battery, non-aqueous liquid electrolyte secondary battery, and method for producing heat-resistant synthetic resin microporous film

InactiveUS20170012265A1Improve stabilityUniformly formedFinal product manufactureSynthetic resin layered productsHeat resistanceSynthetic resin

Provided are a heat-resistant synthetic resin microporous film having enhanced heat resistance while having reduced deterioration of mechanical strength, and a method for producing the same. Disclosed is a heat-resistant synthetic resin microporous film which includes a synthetic resin microporous film containing a synthetic resin; and a coating layer formed on at least a portion of the surface of the synthetic resin microporous film and containing a polymer of a polymerizable compound having a bifunctional or higher-functional radical polymerizable functional group, the heat-resistant synthetic resin microporous film having a surface aperture ratio of 30% to 55%, gas permeability of 50 sec / 100 mL to 600 sec / 100 mL, a maximum thermal shrinkage obtainable when the film is heated from 25° C. to 180° C. at a rate of temperature increase of 5° C. / min, of 20% or less, and a piercing strength of 0.7 N or more.

Owner:SEKISUI CHEM CO LTD

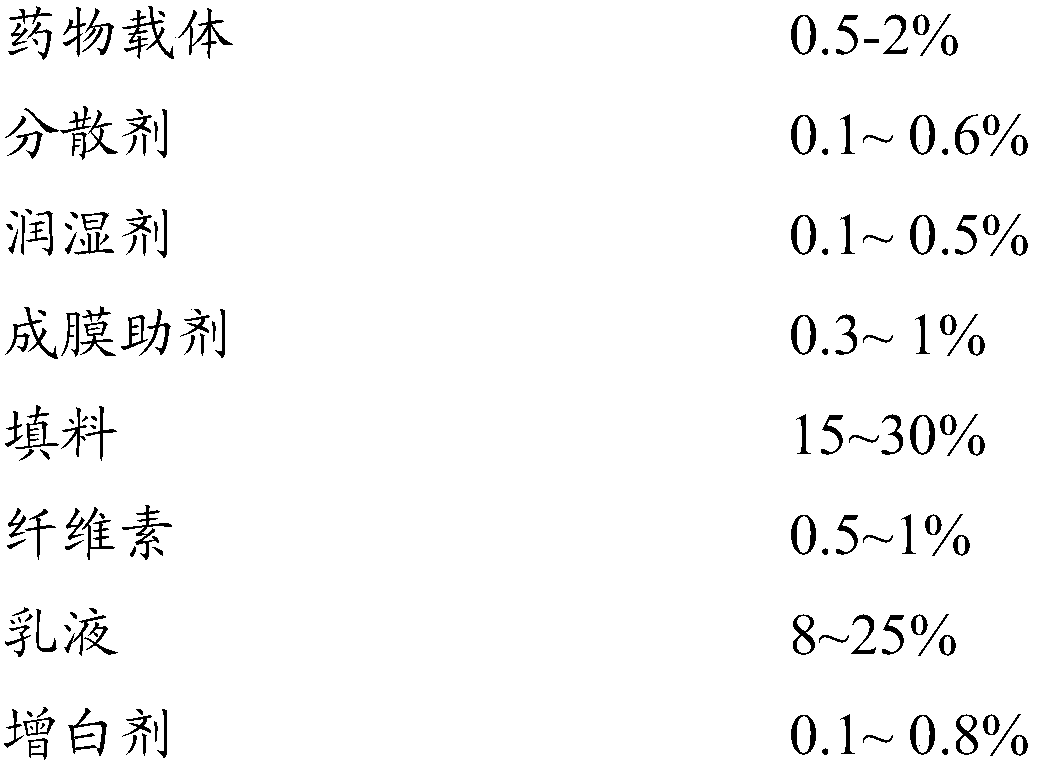

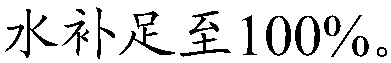

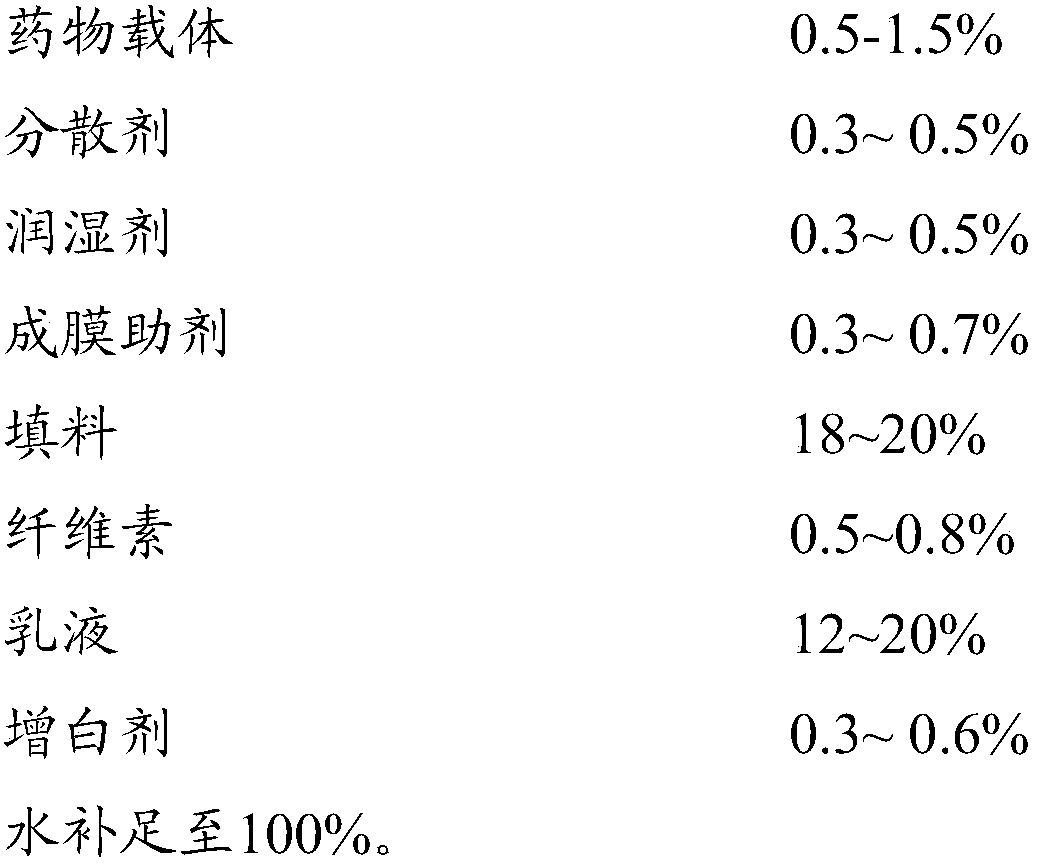

Neutral whitening agent containing drug carrier and preparation method thereof

ActiveCN108467631ATo achieve the effect of sustained releaseWon't breakAntifouling/underwater paintsPaints with biocidesCelluloseFrost

The invention discloses a neutral whitening agent containing a drug carrier and a preparation method thereof, and belongs to the technical field of tree protection. The neutral whitening agent containing the drug carrier includes the following components by the weight percentage: 0.5 to 2% of the drug carrier, 0.1 to 0.6% of a dispersant, 0.1 to 0.5% of a wetting agent, 0.3 to 1% of a film formingauxiliary agent, 15 to 30% of a filler, 0.5 to 1% of cellulose, 8 to 25% of an emulsion, 0.1 to 0.8% of a whitening agent, and water added to make the total amount of 100%. The prepared neutral whitening agent containing the drug carrier has the advantages of strong bonding strength, long protection time and good frost damage prevention effect.

Owner:山东润涵新材料科技有限公司

Degradable non-poisonous seed-coating agent and preparation method thereof

InactiveCN101416650AHigh adhesionSeed coat capacity is goodBiocideAnimal repellantsChemistryApparent viscosity

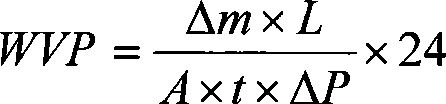

A degradable nontoxic seed coating agent comprises basic materials of water-soluble chitosan of 1.0-1.5wt%, gelatine of 0.05-0.1wt%, glycerol of 0.05-0.1wt%, PVA of 1.0-1.5wt% and plant extract of remainder, with the tensile strength of 18.7MPa, elongation of 10.1%, vapor transmission rate of 12.69g.mm / mm2.hr.mmHg, air permeability of (CO2)0.358*10-10ml.cm / cm2s.cmHg, air permeability of (O2)0.215*10-10ml.cm / cm2s.cmHg, hygroscopic rate of 47% and apparent viscosity of 290cp; uses water-soluble chitosan, PVA and plant extract to form seed coating film to not only meet performance requirement of conventional seed coating agents, but remarkably improve performance of film.

Owner:DALIAN POLYTECHNIC UNIVERSITY

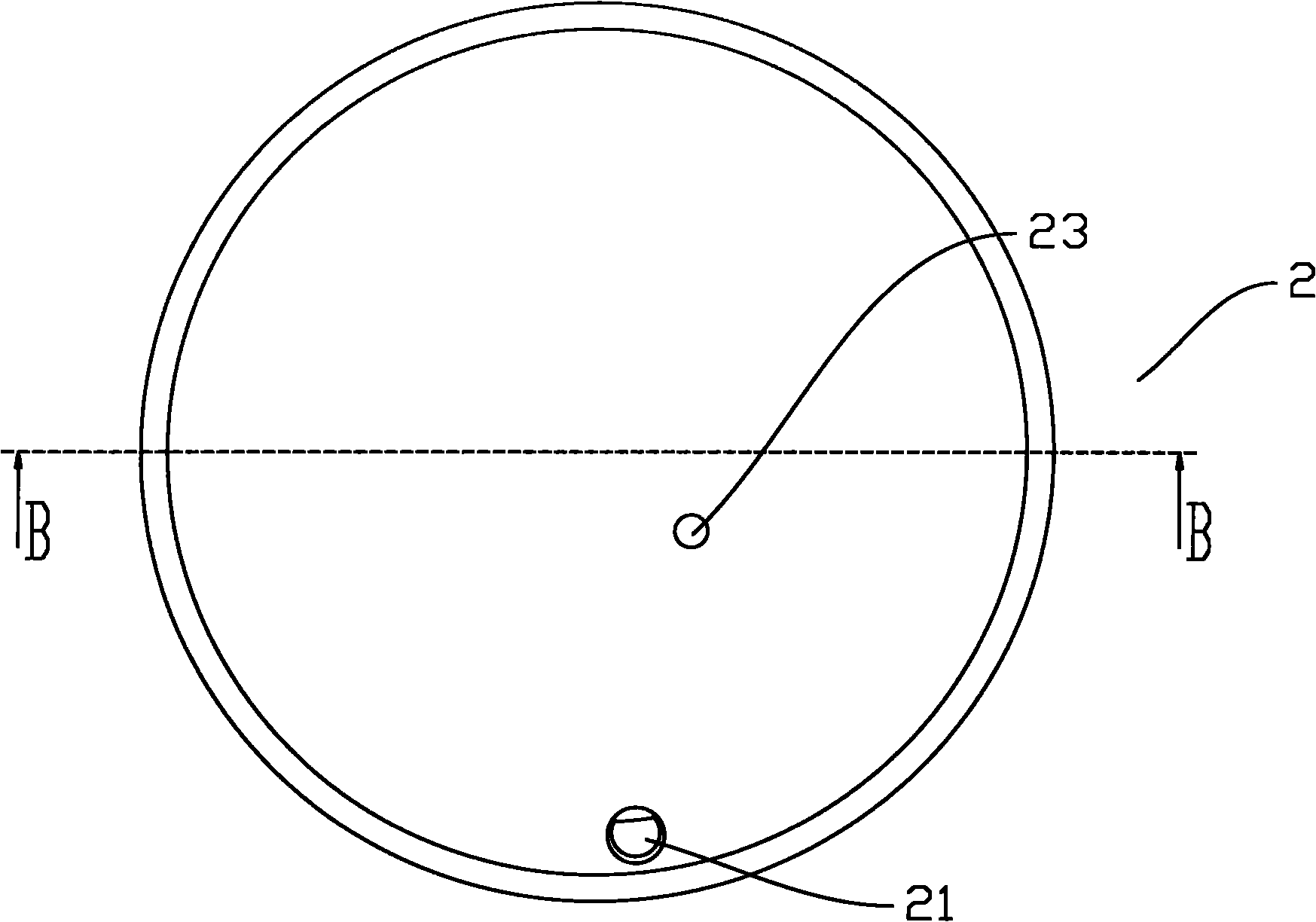

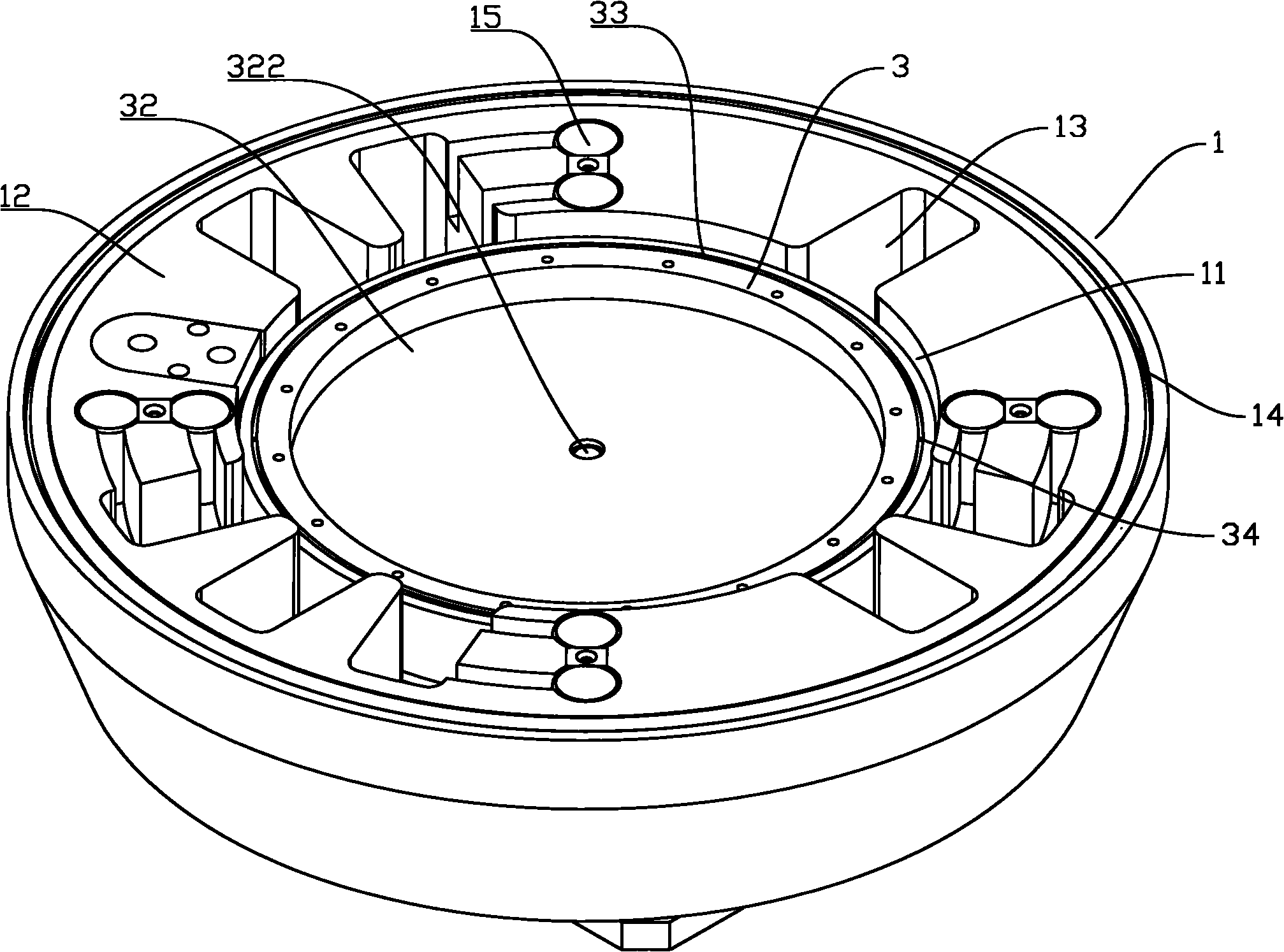

Method and device suitable for laminating film for ultrathin wafer

ActiveCN102082078AReduce minimum thicknessImprove abilitiesSemiconductor/solid-state device manufacturingElectrical and Electronics engineering

The invention discloses a method suitable for laminating a film for an ultrathin wafer, which is characterized in that when film lamination is carried out, a certain pressure is supplied to push a wafer to a thin film so as to adhere the thin film and the wafer together. In the method and the device suitable for laminating the film for the ultrathin wafer, provided by the invention, pressure is applied to the wafer so as to enable the wafer to be adhered to the thin film. The wafer and the thin film can be firmly adhered together through the pressure applied to the wafer. When film lamination is carried out, the thin film can supply supporting force to the wafer so as to prevent the wafer from cracking due to excessive deformation. Therefore, by using the method and the device provided by the invention for laminating the film, the problem that the ultrathin wafer cracks can be effectively avoided.

Owner:上海技美科技股份有限公司

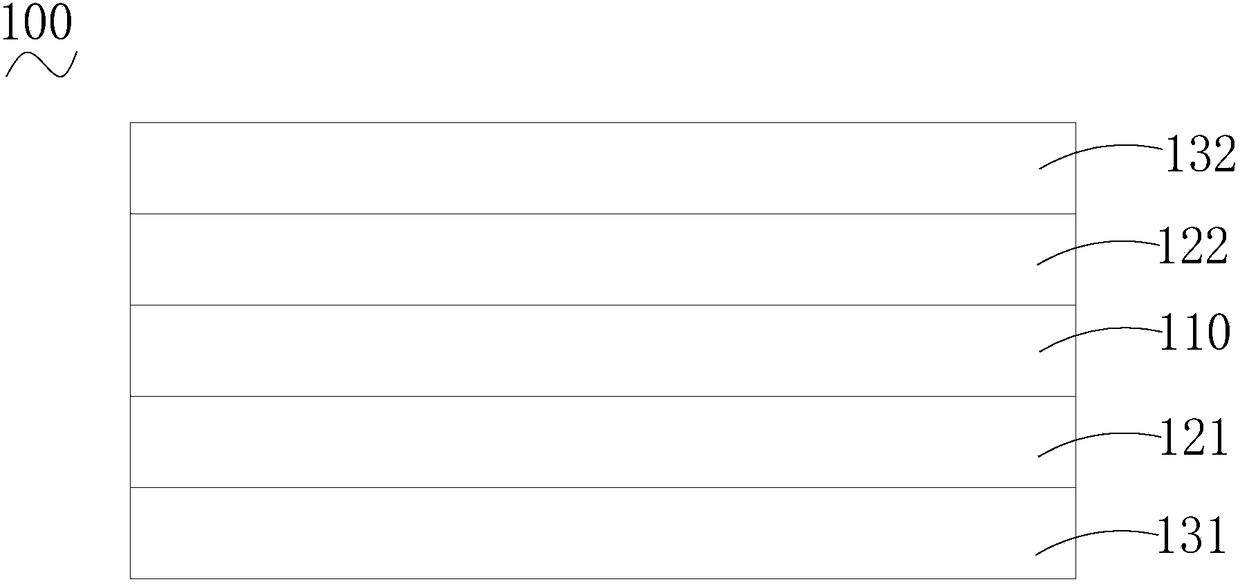

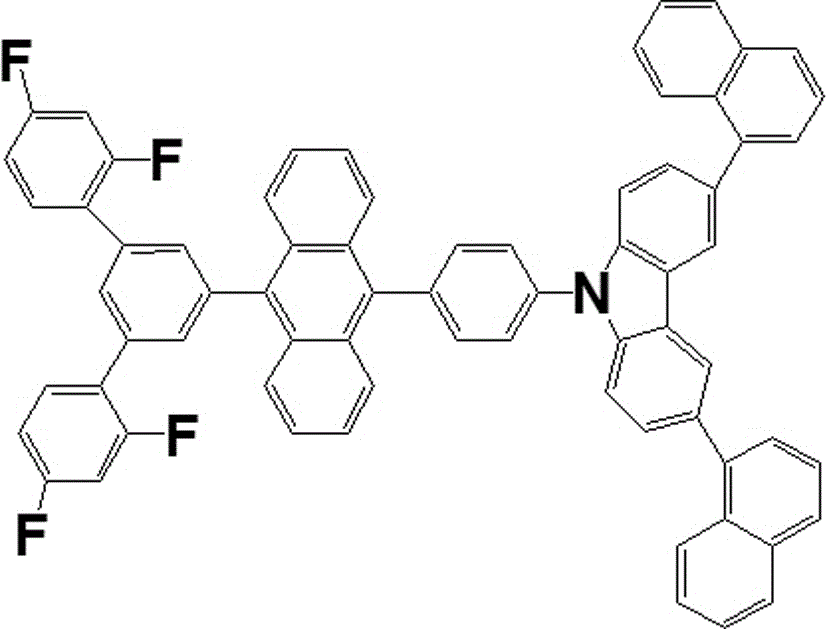

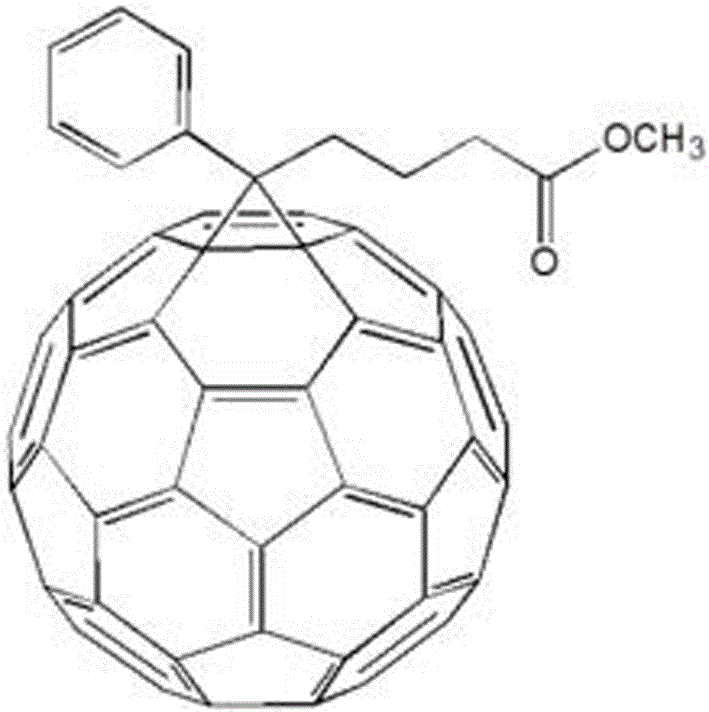

Preparation method of doped anthracene organic compound thin film and application thereof

ActiveCN106449882AConvenience filmImprove conductivityFinal product manufacturePhotovoltaic energy generationAnthraceneSimple Organic Compounds

The invention relates to a preparation method of a doped anthracene organic compound thin film and application thereof. The novel conducting anthracene compound doping suitable for PCBM ([6,6]-phenyl-C61-butyric acid methyl ester) is introduced; ABMG has high conductivity, so that the mixed concentration of the ABMG in the PCBM can reach 10 percent to 15 percent, and the electron transmission performance of the PCBM is reduced; a formed PCBM film after the mixing with the ABMG is smoother; the coverage is more complete. The ABMG with high film forming performance and high conductivity is mixed in a conventional electron transmission layer material of PCBM; the electron transmission layer thin film with high flatness and complete coverage is obtained. Meanwhile, the thin film technology is applied onto perovskite solar batteries, so that the voltage of the solar battery, the filling factor and the conversion efficiency are all improved; the repeatability and the efficiency uniformity of multiple batches of solar batteries are also improved.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

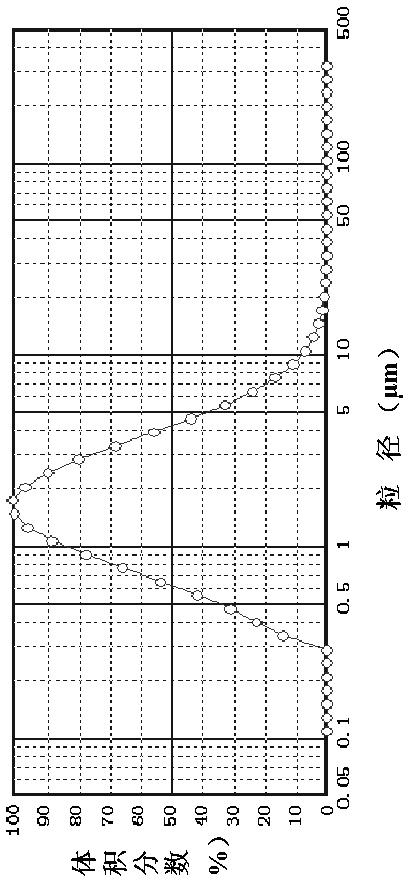

Evening primrose oil microcapsule and pulverization method

InactiveCN102204940ASimple processReduce equipment costsAntipyreticMetabolism disorderChemistryFunctional health

The invention relates to an evening primrose oil microcapsule and a pulverization method. Evening primrose oil is difficult to dissolve in water and ethanol, is easy to be oxidized by oxygen and has a special grease taste; currently, crude evening primrose oil and evening primrose oil soft microcapsule are mainly products in a market, thereby greatly limiting the application range of the evening primrose oil as a functional health care product and a food additive. The evening primrose oil microcapsule is characterized by comprising the following components in parts by weight: 1 part of evening primrose oil core material, 0.6-8.5 parts of acrylic resin II or acrylic resin III or acrylic resin II and acrylic resin III and 0.05-0.5 part of polyoxyethylene hydrogenated castor oil RH40. The evening primrose oil microcapsule is applied to the field of medicaments.

Owner:HEILONGJIANG UNIV

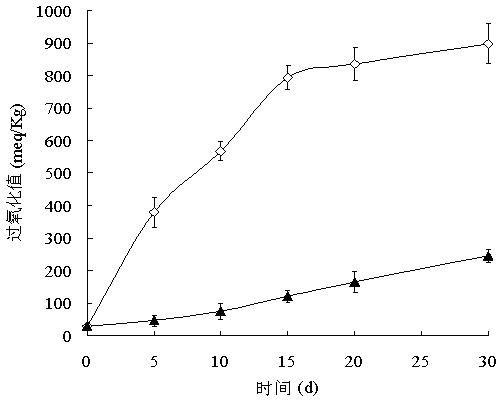

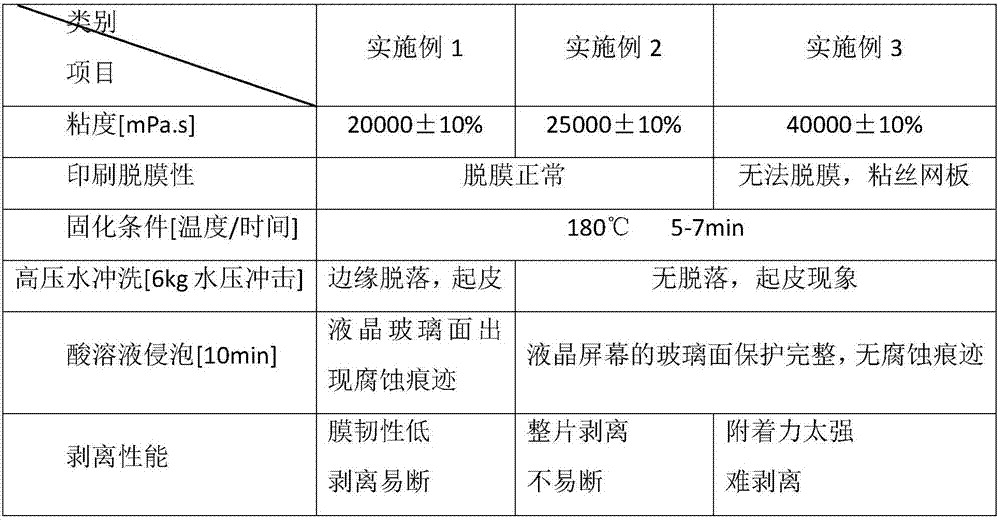

Thermosetting peelable blue gum

InactiveCN107057481AGood film formingGood flexibility and toughnessAnti-corrosive paintsChemistryDefoaming Agents

Thermosetting peelable blue gum comprises, by weight, 30-60 parts of paste resin, 10-30 parts of a filling material, 10-30 parts of a plasticizer, 0.1-1 part of silane coupling agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a thixotropic agent, 0.03-1 part of a leveling agent, and 0.1-1 part of a pigment. The thermosetting peelable blue gum has good toughness and flexibility, is highly adhesive to a liquid crystal screen, and is tolerant to high-pressure water flushing with zero delamination; a film of the thermosetting peelable blue gum can tolerate acidic and alkaline solutions and can protect a liquid crystal screen from being corroded by an acid during production.

Owner:雅拓莱焊接科技(惠州)有限公司

Production technology of contrast-effect automobile seat cushion leather

ActiveCN103667542AFlexibleImprove viewabilityTanning treatmentPre-tanning chemical treatmentFolding enduranceRoom temperature

The invention relates to a production technology of contrast-effect automobile seat cushion leather. The protection technology comprises the steps of liming: dissolving Na2S, NaHS and lime into water in a mass ratio of 1:1:2 to form a liming alkali liquor, reacting fur with the liming alkali liquor in a liquor ratio of 100:100 for 6 h, adding the liming alkali liquor step by step to enable the liquor ratio to increase to 100:200, and continuously reacting for 12 h; retanning: for every 100 parts of fur, adding 100 parts of water, 1 part of a pre-fatting agent and 3 parts of a chrome tanning agent or a chrome-free tanning agent, reacting at the normal temperature for 1 h, adding 2 parts of sodium formate, reacting at the temperature of 40 DEG C for 1 h, and controlling the pH in a range of 3.6-4.0; and finishing: the finishing comprises the steps of roller coating of a bottom layer, embossing, spraying of a color layer, roller coating of an effect layer and spraying of a top layer. The leather produced through the technology is soft, fine in grain side, full in hand feeling, elastic, safe and environment-friendly and has characteristics of wear resistance, folding endurance, light resistance, color migration resistance and the like; and ornamental and pleasant characteristics of the leather are added due to roller coating of the effect layer, and the rigid and non-flexible appearance of ordinary automobile seat cushion leather is changed.

Owner:HAINING SENDE LEATHER

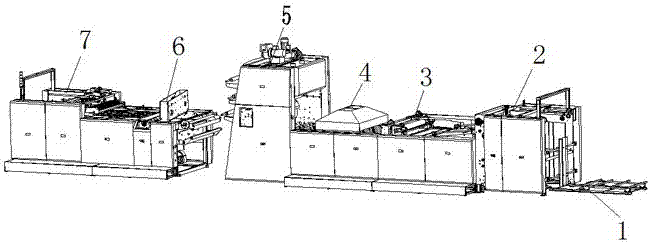

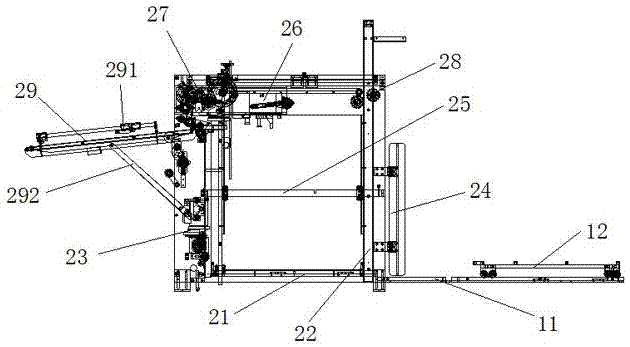

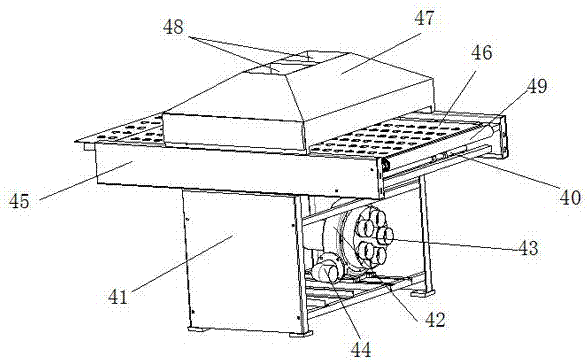

Windowing film laminating machine

InactiveCN107097520ALeveling and adjusting balanceImprove flatnessPrinting press partsFully automaticAutomation

The invention discloses a windowing film laminating machine comprising a pre-folded paper feeding frame, a paper conveying mechanism, a glazing oil head mechanism, a drying mechanism, a film laminating main machine, a chain cutter paper cutting mechanism and a paper collecting mechanism. Fully-automatic feeding, conveying, glue smearing, drying, film sticking and pressurizing, cutting and collecting of paper can be integrated together; the film laminating machine conducts operation automatically in the whole process, and the automation operation degree is high; a servo motor is adopted to drive the glazing oil head mechanism to smear glue on the paper, so that the whole machine conducts a series operation of feeding, conveying, glue smearing, drying, film sticking and pressurizing, cutting and collecting and the like on the paper with the consistent speed, and accordingly the high precision and good effect of glue smearing, film sticking and cutting of the paper, using is convenient and rapid, the cost is low, and the windowing film laminating machine is especially suitable for paper with a window; and the problems that labor strength is large, and the labor cost is high due to the fact that the paper is subjected to traditional manual operation of glue smearing, film sticking, cutting and the like are solved.

Owner:广东鑫佳机械科技有限公司

High-film-forming-property aqueous polyurethane resin as well as preparation method and use method of high-film-forming-property aqueous polyurethane resin

InactiveCN105440244AExcellent peelabilityExcellent film-forming propertiesPolyurea/polyurethane coatingsCross-linkPolyester

The invention discloses high-film-forming-property aqueous polyurethane resin, which is prepared from the following ingredients in percentage by weight: 10 to 35 percent of isocyanate, 5 to 20 percent of polyester polyol, 1 to 5 percent of polyester polyol cross-linking agents, 0.5 to 10 percent of micromolecule chain extenders, 1 to 5 percent of hydrophilic chain-extending agents, 1 to 5 percent of neutralizers, 0 to 5 percent of amine chain extenders, 0.02 to 0.1 percent of organic catalysts, 5 to 15 percent of cosolvent and 50 to 70 percent of deionized water. The invention also discloses a preparation method of the high-film-forming-property aqueous polyurethane resin. The invention also discloses a use method of the high-film-forming-property aqueous polyurethane resin. The high-film-forming-property aqueous polyurethane resin, the preparation method and the use method have the advantages that the film forming property is excellent; the viscosity is low; the coating can be thicker; the transfer printing paint process can be improved; the cost is favorably reduced; the benefits are improved; in addition, green and environment-friendly effects are achieved; the production cost is low.

Owner:GUANGDONG BANGGU CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com