Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Good compactness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image Generation Unit and Method to Use an Image Generation Unit

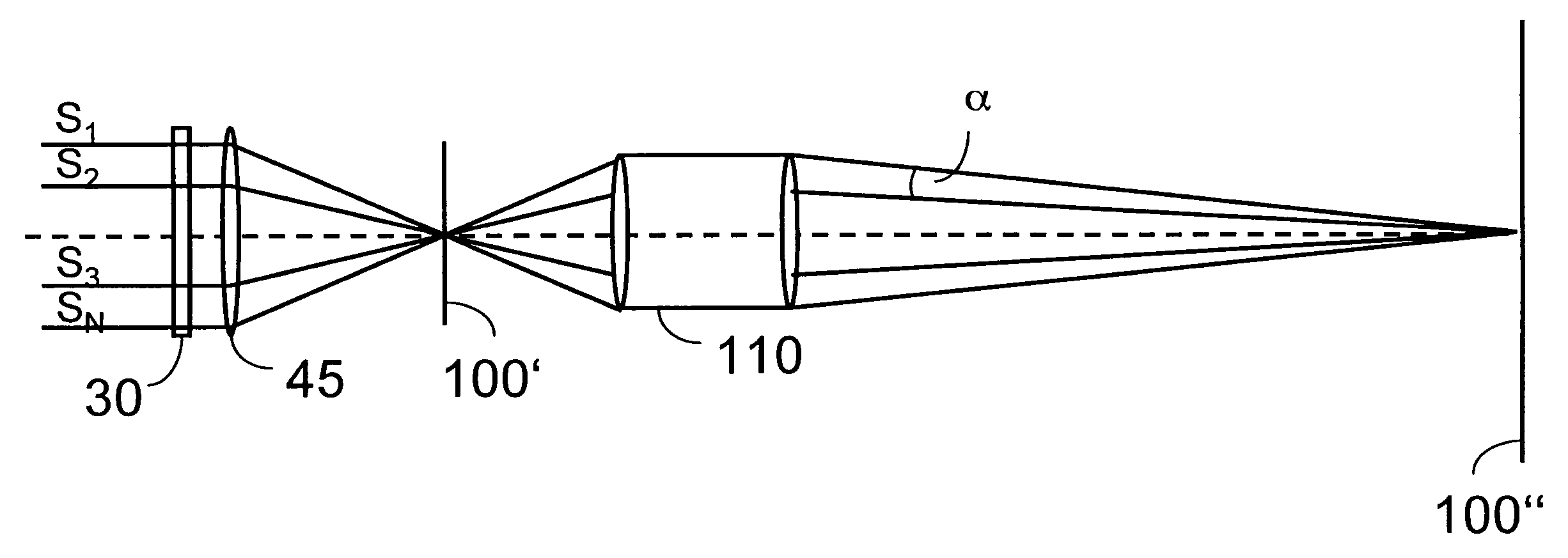

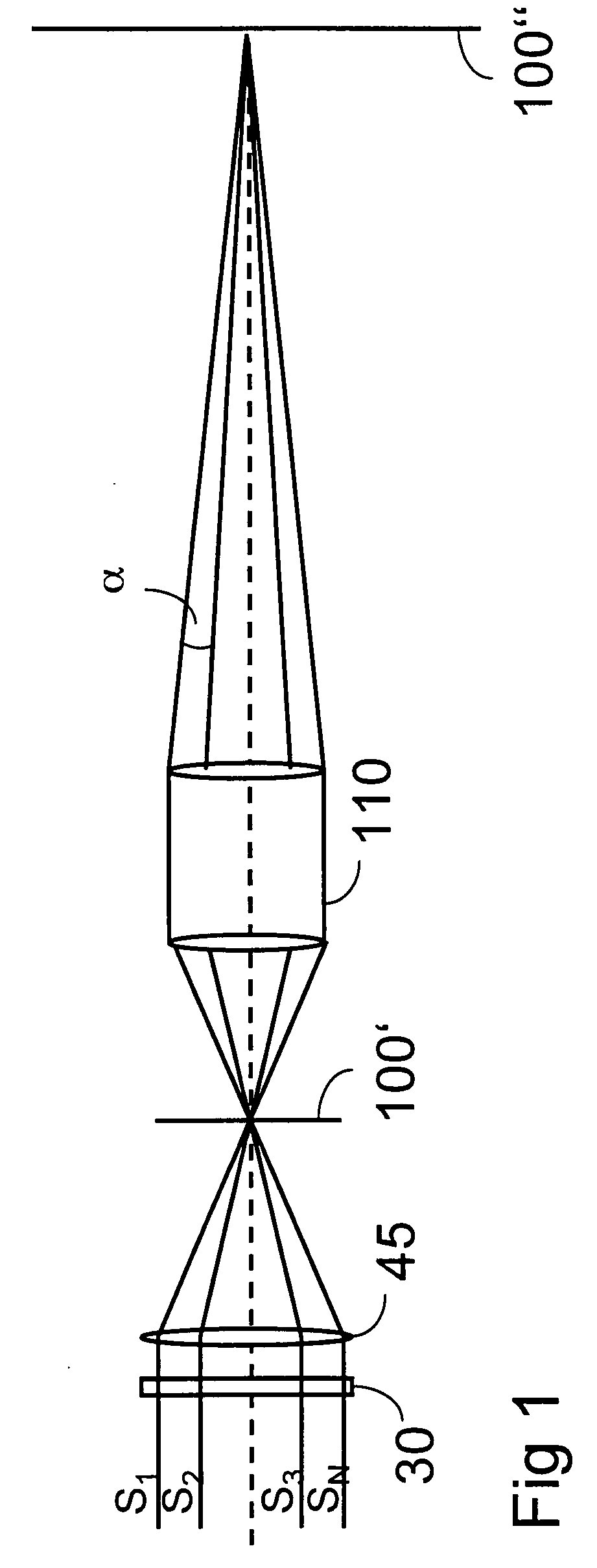

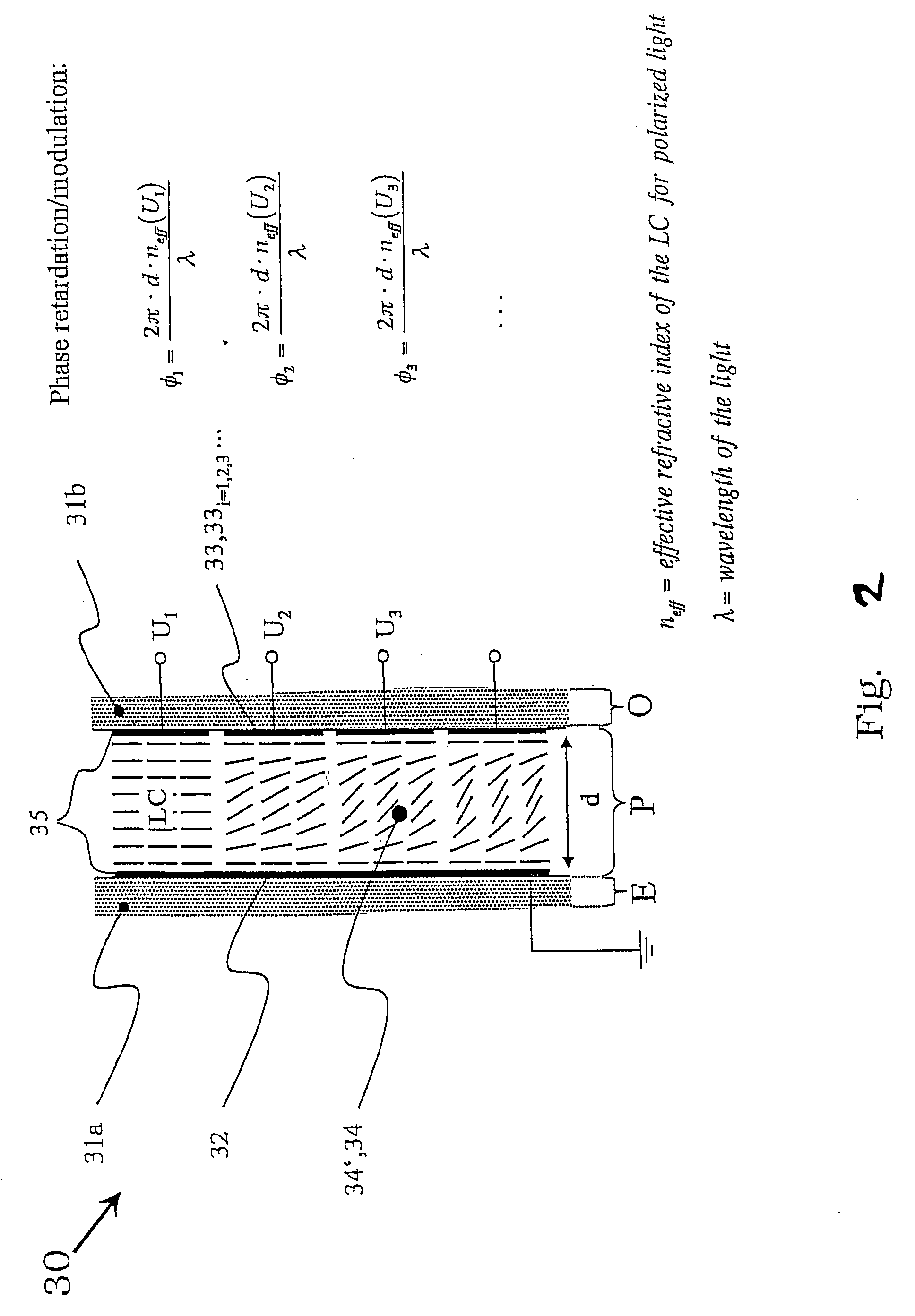

InactiveUS20080204847A1Simpler production feasibilityGood compactnessColor television detailsNon-linear opticsPhase modulationLight beam

An image generation unit with an illumination unit for generating a plurality of coherent sub-beams and for illuminating an image modulator, including a light source, and a projection lens for superimposing each of the coherent sub-beams onto a projection screen plane. An optical set-up introduces angles between each two of the sub-beams, which are chosen to produce uncorrelated speckle patterns in the projection screen plane, resulting in an interference speckle pattern. A phase modulator including a liquid crystal cell changes its directory profile in a lateral manner, thereby being able to change the phase of light of each sub-beam individually.

Owner:SONY DEUT GMBH

Special thin anti-crack plastering mortar for autoclaved aerated concrete

The invention discloses a special thin anti-crack plastering mortar for autoclaved aerated concrete and belongs to the technical field of building materials. According to the special thin anti-crack plastering mortar disclosed by the invention, a dry material is added with water by a mass ratio that water to dry material ratio is equal to 1:4, and then stirred for 3-5 minutes to prepare mortar, wherein the dry material consists of the following components in mass by percentage: 20%-35% of cement, 10%-30% of 40-70-mesh quartz sand, 30%-50% of 80-100-mesh quartz sand, 2%-7% of 200-mesh coarse whiting powder, 1.5%-4% of redispersible emulsion powder; 0.15%-0.5% of water-retaining agent; 0.2%-0.7% of wood fiber and 0.11%-0.45% of short fiber. Being prepared by adopting quartz sand of 40-70 meshes or 80-100 meshes, the special thin anti-crack plastering mortar for the autoclaved aerated concrete disclosed by the invention has an excellent anti-crack performance, realizes effective control on contraction percentage of the mortar, causes no cracks during large-area construction, achieves good caking property, and realizes organic combination between the mortar and the surface layer of the autoclaved aerated concrete.

Owner:山东高阳建材有限公司

Method for preparing high-bonding strength catbon steel based Al2O3 ceramic coating with colloidal sol-gel rubber

InactiveCN101270476ASimple processGood compactnessLiquid/solution decomposition chemical coatingSuperimposed coating processIonSolvent

The invention discloses a method for preparing high bonding intensity carbon steel-based Al2O3 ceramic coat by sol-gel. The method adopts the carbon steel as a compound coating basic body, adopts nickel vitriol as main salt, adopts NaH2PO2 as a reducer to chemically plate a Ni-P alloy in an acid medium, takes aluminium isopropoxide as a precursor, takes secondary de-ionized water as a solvent and takes nitric acid as a glue solvent to prepare boehmite sol acordign to a mol ratio of 1:80 to 120: 0.1 to 03; adopts a dip-coating method to coat and then bake the gel. The invention takes a chemically plated Ni-P alloy as a middle transition layer and adopts the sol-gel method to prepare the Al2O3 ceramic coat on the surface of the carbon steel, thus solving the technical difficulty of the lower bonding force of the carbon steel-based ceramic coat. The compound processing method provided by the invention has a simple and convenient technique and needs no expensive and complex devices; besides, the prepared compound coat has excellent compactness and uniform components. The technique can be used for carbon steel anti-high temperature oxidation coat; the technique of the method is easy to realize industrialization and is not restrained by the shape of a workpiece.

Owner:ZHEJIANG UNIV

Method for preparing sweet apricot kernel

InactiveCN101273788AGood film formingGood compactnessFruit and vegetables preservationConfectioneryChemistryPrunus amygdalus

The invention provides a preparing method for sweet almond, the method solves the problems that the surface of the existing sweet almond obtained by frying technique is easy to fall off, and the grease is easy to be oxidized and rancid so as to cause short storage period, etc. The preparing method of the invention comprises the following steps that: firstly, polysaccharides solution of pullulan with a certain concentration is prepared, and then is divided into two parts, wherein, one part is used for soaking the almond until the solution is blotted by the almond, and the other part is used for frying and spraying the almond in a stir pan at the same time in the process of frying, thus leading the fried almond to have a layer of dense protective membrane wall; the preparing method of the invention has simple formula and easy control of technique, the prepared product has good taste and complete surface, and the dense protective membrane wall lead the product to have longer protection period and better appearance than the product obtained by the prior manufacturing technique.

Owner:广东富味健康科技有限公司

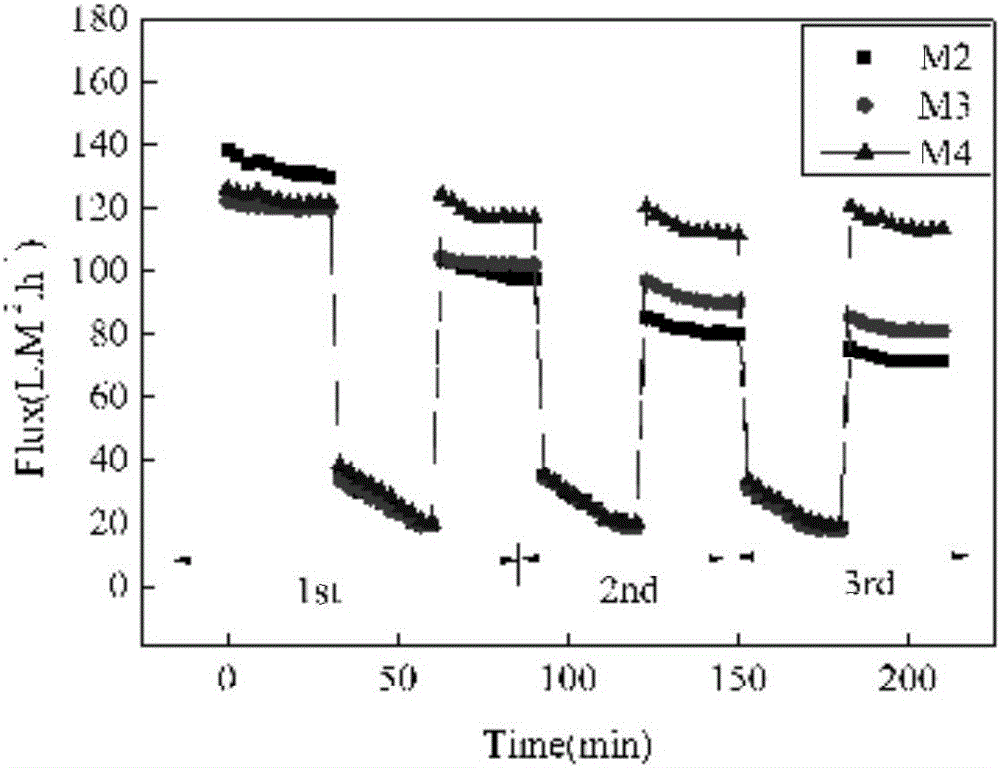

Antipollution ultrafiltration membrane of amino acid grafting composite cellulose and preparation method thereof

ActiveCN105727760AImprove anti-pollution performanceGood compactnessSemi-permeable membranesMembranesUltrafiltrationCellulose acetate

The invention discloses an antipollution ultrafiltration membrane of amino acid grafting composite cellulose. An ultrafiltration membrane of sodium oxide nanocellulose composite cellulose acetate is adopted as a basic membrane and activated in a solution containing a carbonyl activating agent formed by a condensating agent and amide and is then grafted with amino acid to obtain the antipollution ultrafiltration membrane, the chemical general formula of the amino acid is NH2-R-CH(NH2)-COOH, wherein R is an alkyl chain. The preparation method comprises the steps: preparing a primary membrane casting solution; preparing a composite cellulose membrane casting solution; preparing a composite cellulose ultrafiltration membrane; activating: activating carbonyl functional groups in the sodium oxide nanocellulose; and grafting: washing the activated composite cellulose ultrafiltration membrane, and soaking in an amino acid solution to obtain the composite cellulose ultrafiltration membrane. The ultrafiltration membrane prepared by adopting the preparation method of the invention has the advantages of good compressive compactness, good antipollution effect, easiness for washing the membrane and the like; and the cellulose is wide in source, low in price, low in cost, wide in application field, easy to degrade and harmless to the environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

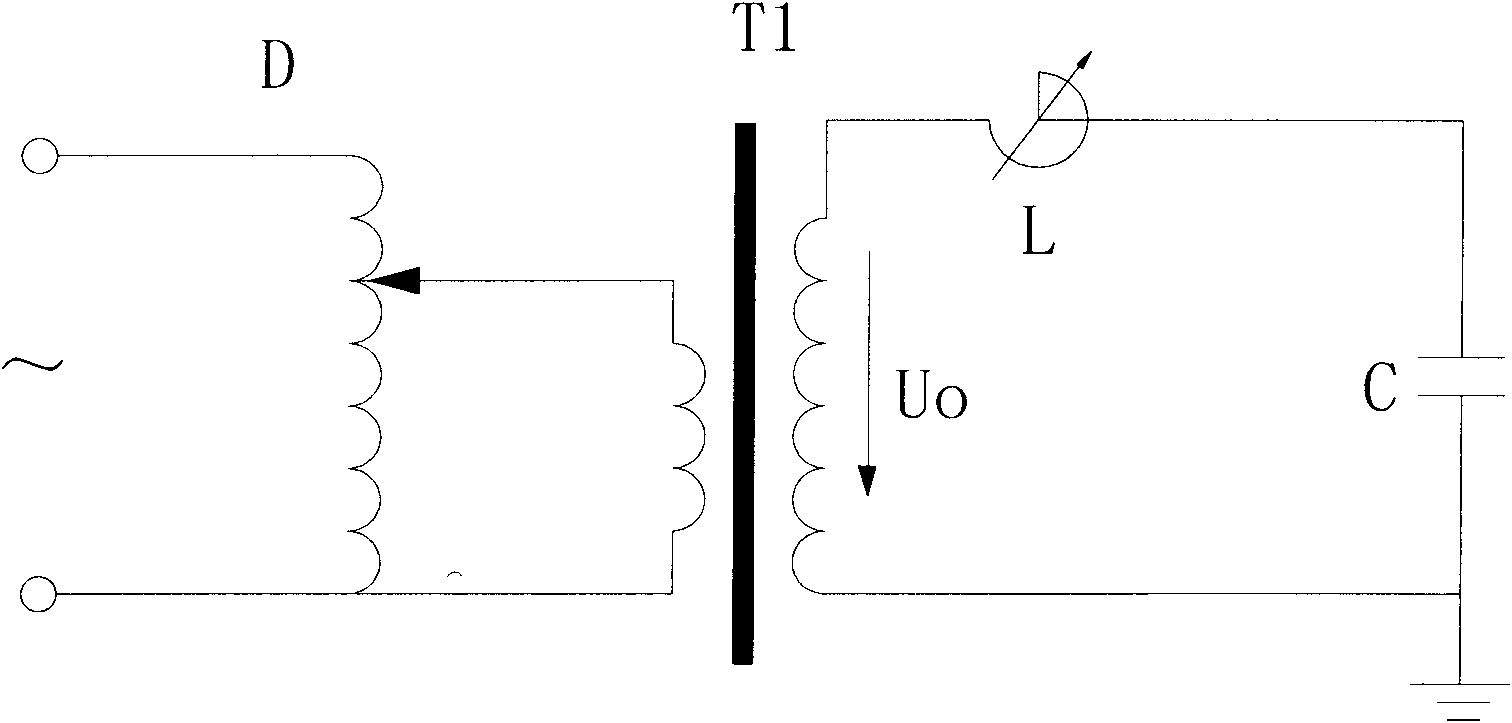

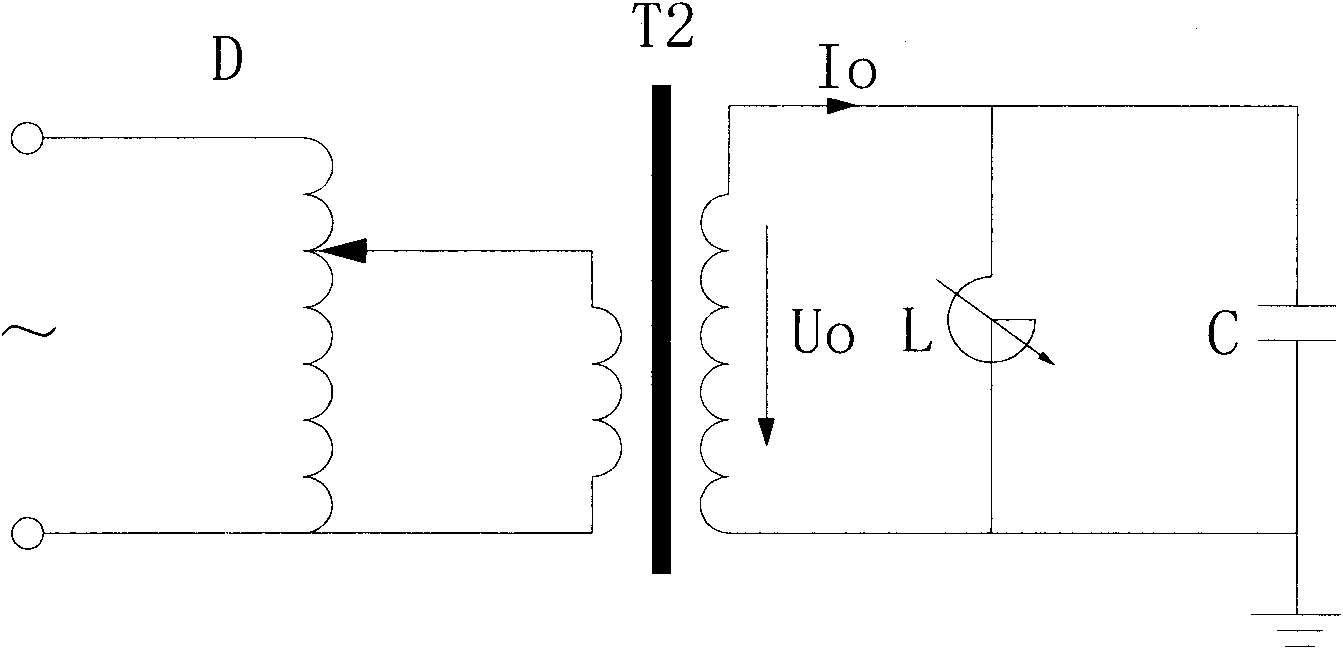

Industrial frequency resonance transformer

ActiveCN101833059ACheck for insulation defectsReduce noiseTesting dielectric strengthTransformersLow noiseFailure rate

The invention relates to a transformer capable of realizing resonance in industrial frequency under the condition of no mechanical governor mechanism. The technical scheme adopted by the invention is as follows: the transformer comprises an excitation transformer, a rectifier connected with the excitation transformer, an isolation transformer and a controller, wherein the isolation transformer is used to ensure that the excitation transformer and the controller realize high potential isolation; after detecting the collected currents on primary side and secondary side of the isolation transformer and the output current of the rectifier, the controller adjusts the AC excitation impedance of the excitation transformer through DC magnetic bias to form resonance with the impedance of a test. On one side, the industrial frequency resonance transformer can form resonance in industrial frequency, output industrial frequency test voltage, have the same working frequency with the device to be tested and effectively detect the insulation defect of the device to be tested; on the other side, the transformer has the advantages of no moving part, low noise and non-maintaining; and furthermore, the variable-frequency power source with large capacity is not needed, the cost is reduced and the failure rate is low.

Owner:青岛菲特测控节能科技有限公司

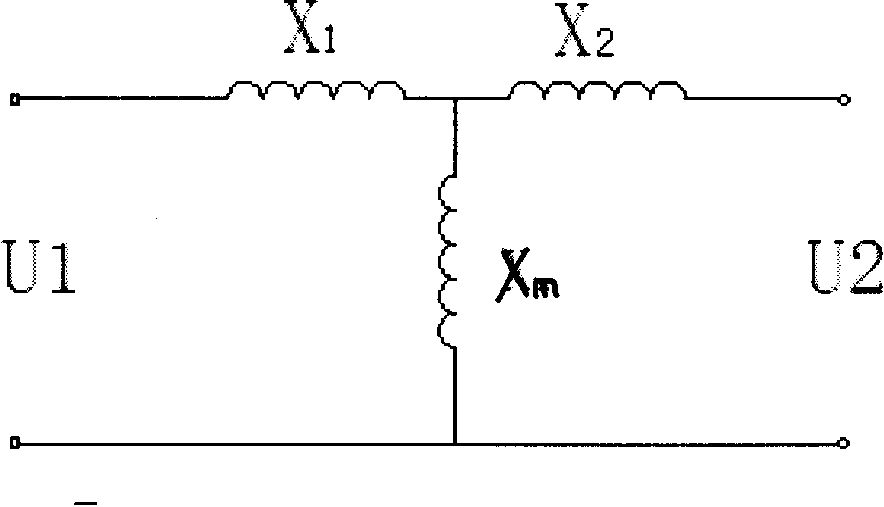

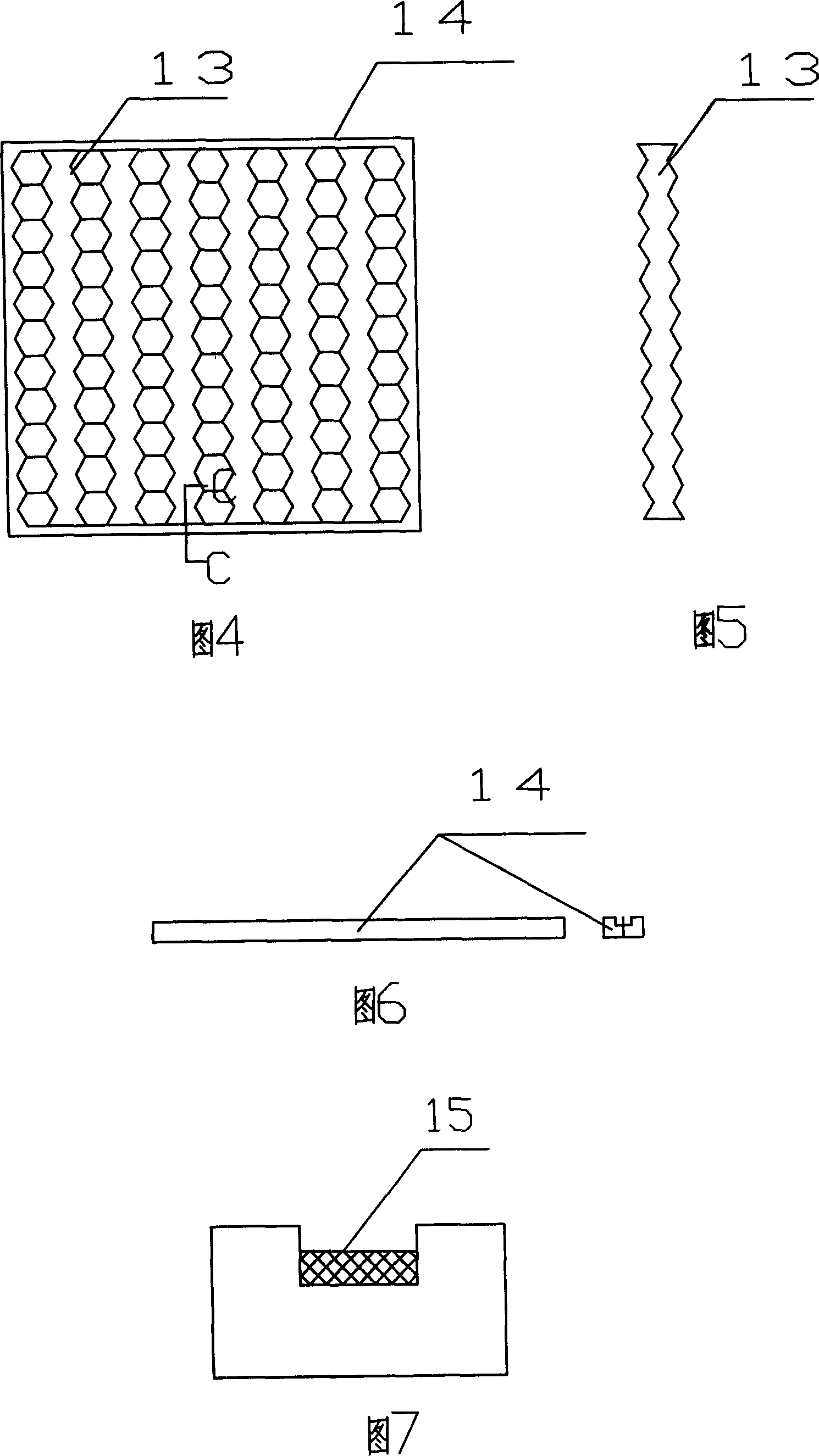

Exchanger with honeycomb structure

InactiveCN101008557AIncrease the heat exchange areaGood compactnessStationary conduit assembliesTubular elementsHoneycomb structureEngineering

The invention discloses an exchanger with honeycomb structure, wherein, its frame (10) is in regular hexagon shape; the tube beam has several short honeycomb tubes (3) and long honeycomb tubes (4) to form honeycomb tube element (1), while the long honeycomb tubes (4) are adjacent with the short ones (3) with shared walls; the thickness of the wall of long and short tubes (4, 3) is 0.2-2mm; two ends of long honeycomb tube (4) are through to the inlet (7) and the outlet (1) of tube box (8). The invention has large unit heat exchange area, compact structure, high factor K, and high flexibility.

Owner:SOUTH CHINA UNIV OF TECH

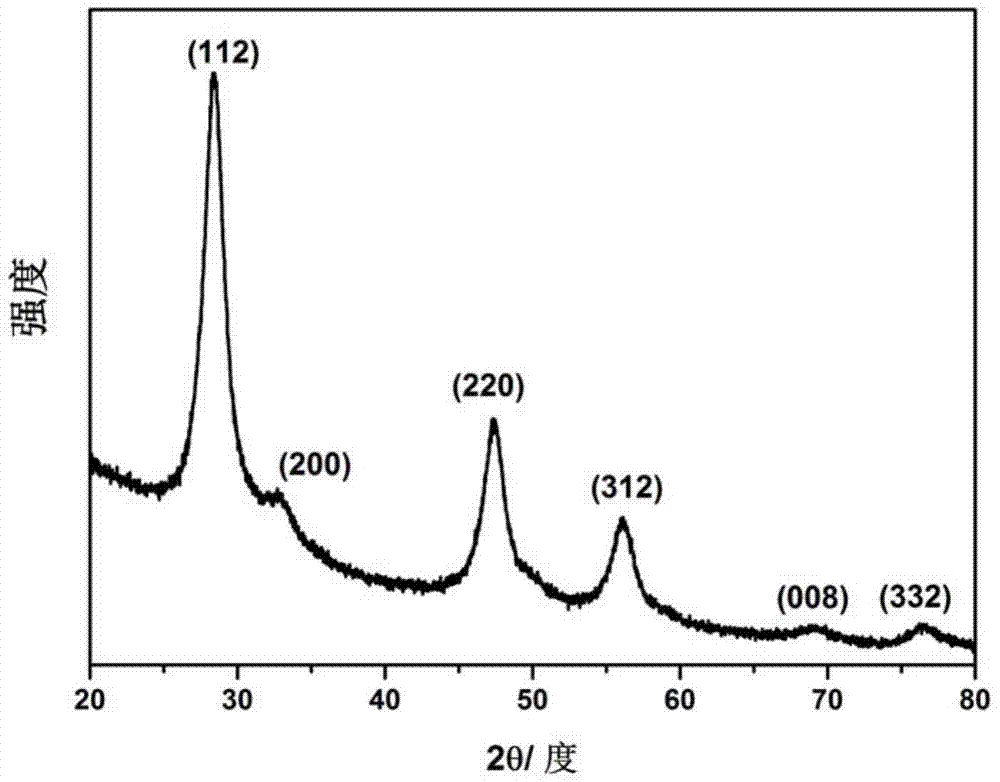

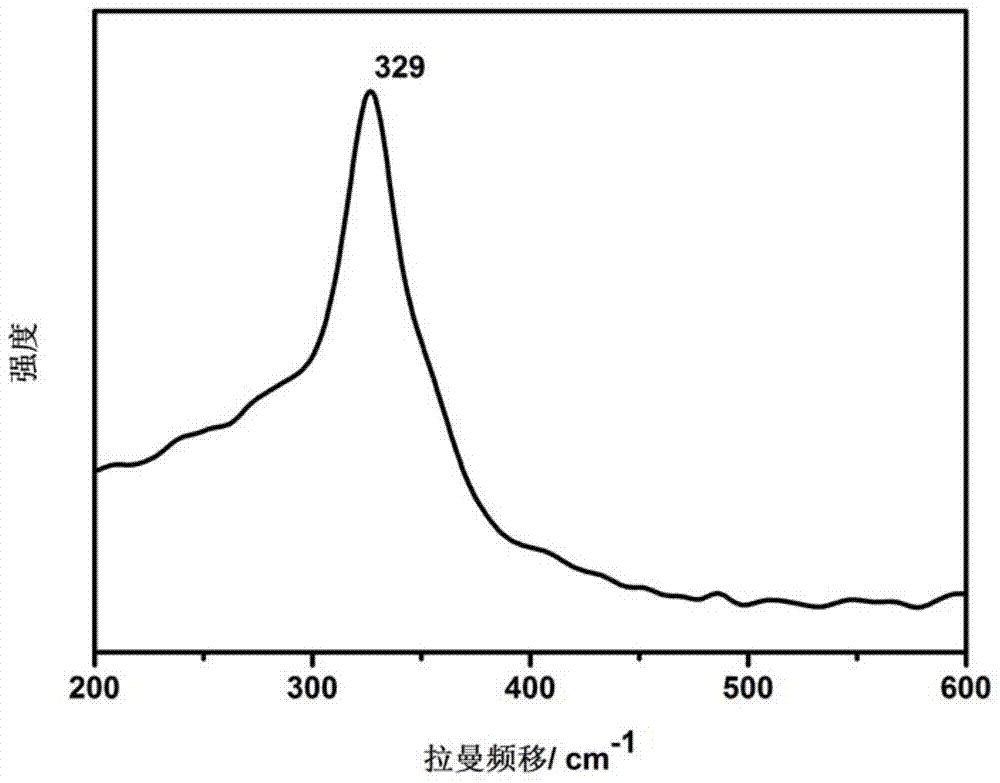

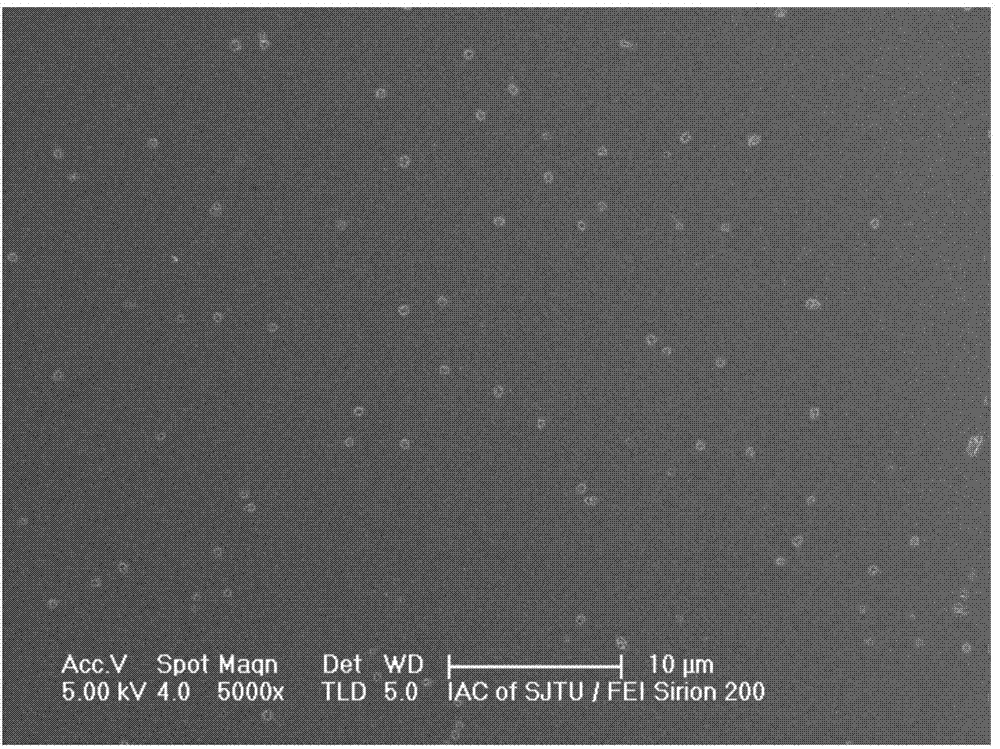

Copper-zinc-tin-sulfur (CZTS) thin film and preparation method and purposes thereof

InactiveCN103943721AEasy to prepareGood compactnessFinal product manufactureSemiconductor/solid-state device manufacturingIonChemistry

The invention discloses a preparation method of a copper-zinc-tin-sulfur (CZTS) thin film. The preparation method includes the first step of preparing a precursor solution, dissolving copper chloride, zinc chloride, stannous chloride and thiourea jointly into methyl alcohol or ethyl alcohol and stirring the solution to be clear and transparent, the second step of carrying out ultrasonic cleaning on a substrate FTO in acetone, ethanol and deionized water respectively and sequentially, the third step of coating the precursor solution on the surface of the substrate FTO and then drying the substrate FTO, and the fourth step of placing a sample obtained in the third step into nitrogen or argon for calcining to obtain the CZTS thin film. The preparation method of the CZTS thin film is simple, easy to implement and suitable for mass production; the prepared CZTS thin film is smooth in surface, free of cracks, excellent in performance, good in photoelectrochemical performance, high in chemical stability and capable of being widely applied to the field of production of semiconductor nano-films and photoelectrocatalysis.

Owner:SHANGHAI JIAO TONG UNIV

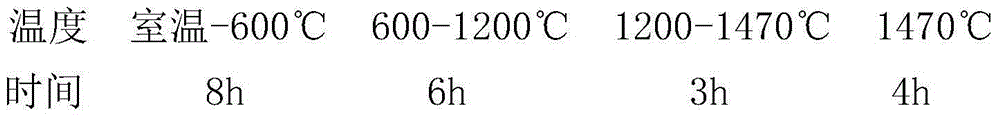

Preparation method of pink zirconia ceramic

The invention relates to a preparation method of pink zirconia ceramic. The preparation method comprises the following steps: with zirconia powder as a raw material of a ceramic matrix, adding erbium oxide powder to the zirconia powder to be used as a colorant and adding a binder to form a mixed material; preparing a ceramic body by using the mixed material; and carrying out multi-stage sintering treatment on the ceramic body to obtain a pink zirconia ceramic product, wherein the multi-stage sintering treatment at least comprises the following stages: firstly sintering for 7-9h at the temperature of room temperature to 600 DEG C, then sintering for 4-8h at the temperature of 600 DEG C-1200 DEG C, and then sintering for 6-8h at the temperature of 1200 DEG C-1500 DEG C. By utilizing the preparation method of the pink zirconia ceramic, zirconia can be stably colored to pink by pigment on premise of ensuring complete compactness of sintering of zirconia, and low manufacturing cost is maintained simultaneously.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

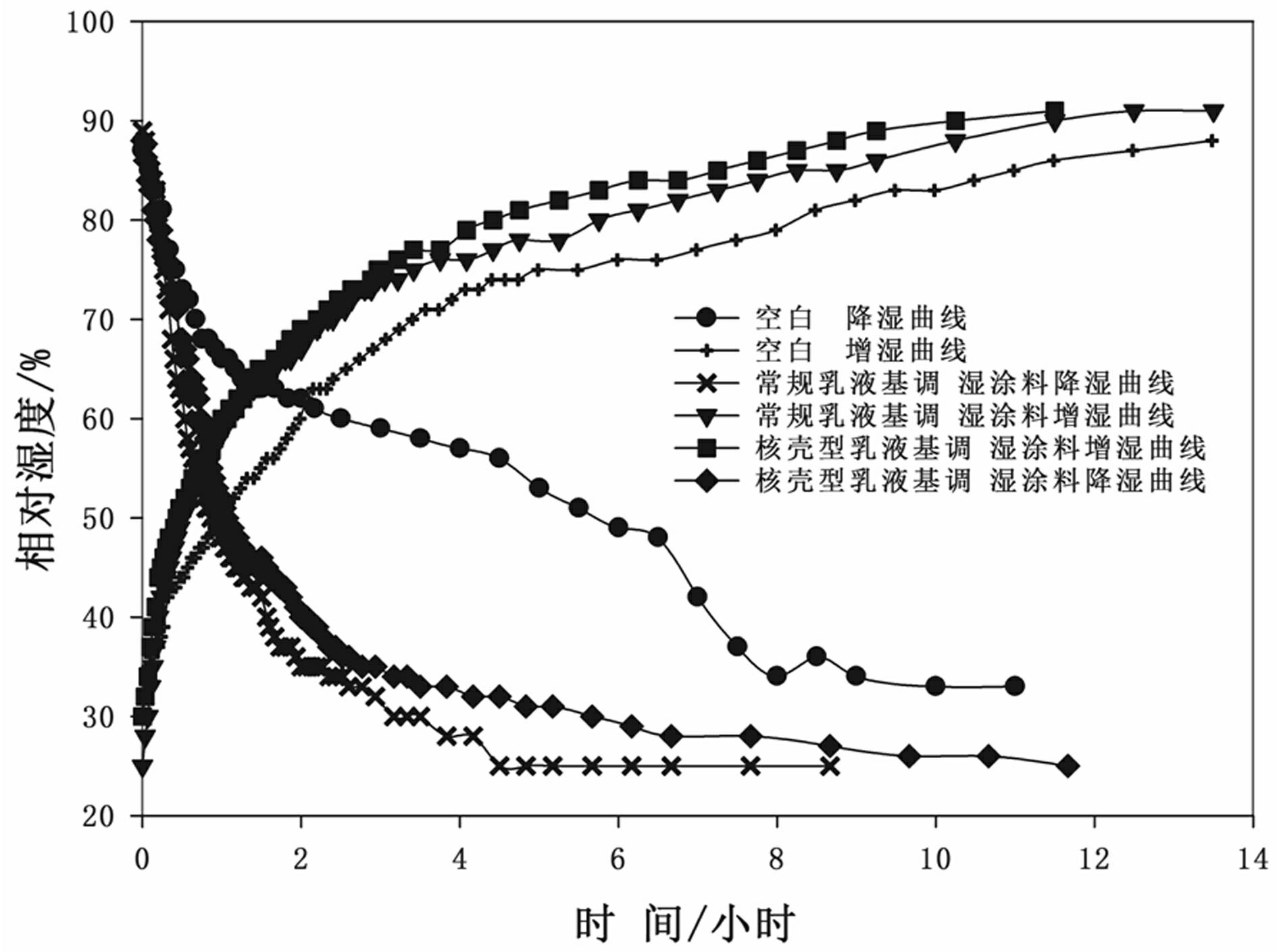

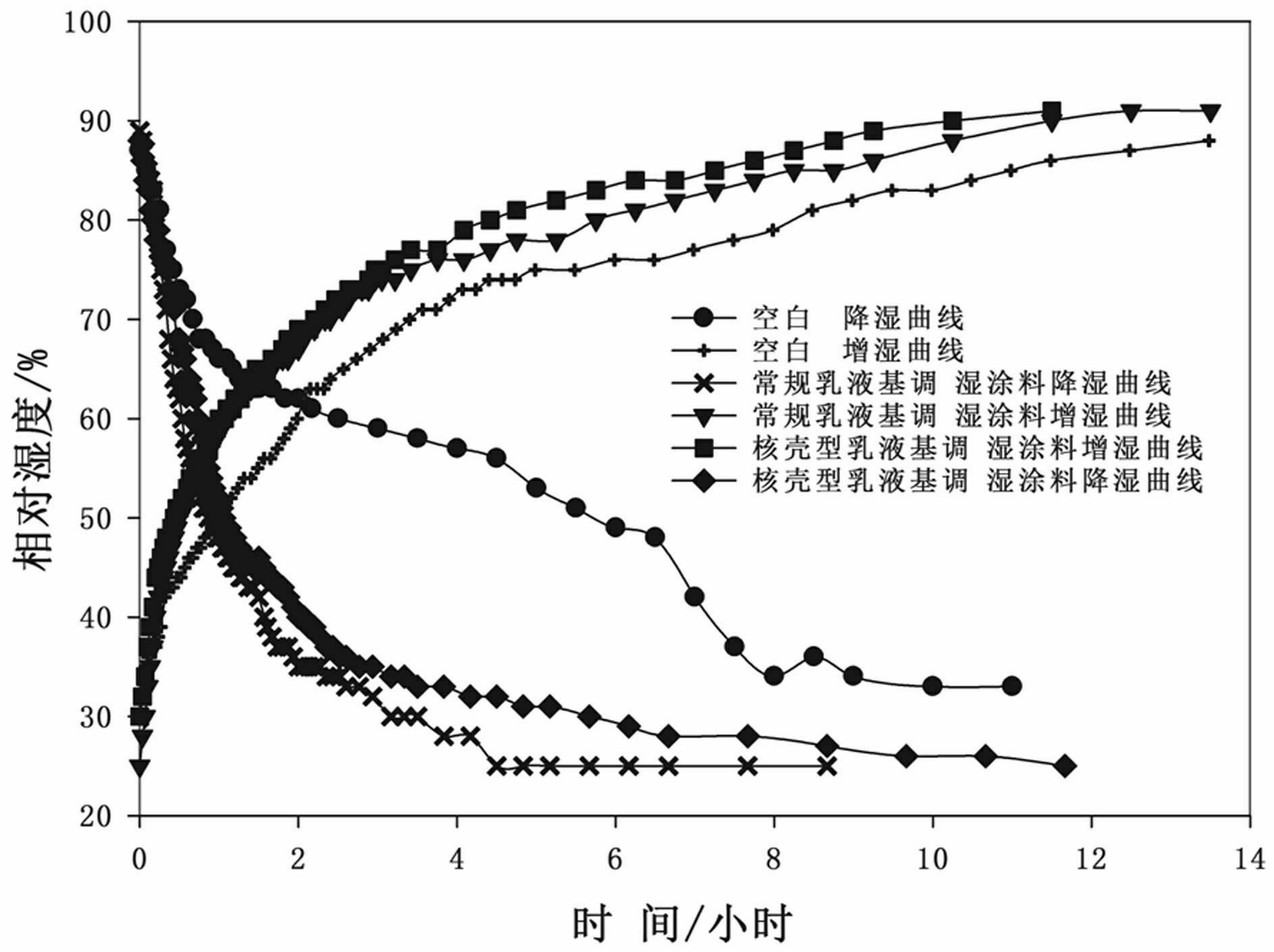

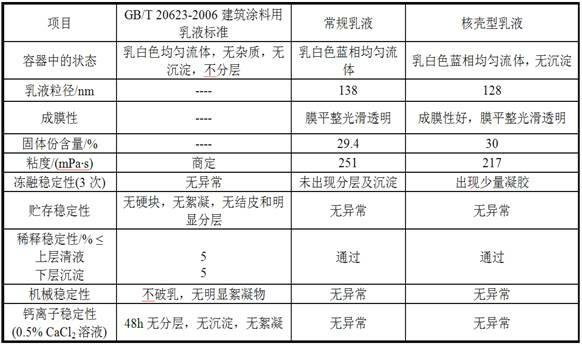

Organic silicon-acrylic ester copolymer emulsion and preparation and application thereof

The invention provides organic silicon-acrylic ester copolymer emulsion, which utilizes organic silicon, methyl methacrylate, butyl acrylate, unsaturated alkyl acid and methacrylic acid-beta-hydroxypropyl ester as comonomers, utilizes deionized water as solvent, utilizes potassium peroxydisulfate or ammonium persulfate as an initiator and utilizes sodium bicarbonate as a neutralizer, and is prepared by polymerization in the presence of an emulsifying agent. The emulsion introduces the organic silicon into polyacrylate, the rigidness of a copolymer is improved to a certain extent, and cohesion of the copolymer emulsion is improved due to the introduction of a polar group. Interior wall humidity-conditioning paint prepared by the copolymer emulsion serving as a film former integrates multiple functions of decoration, humidity conditioning performance, permeability, insulation and anti-condensation performance, water resistance, alkali resistance, alkali-resistant performance and antibiosis, the paint film is durable and long in service life, and the organic silicon-acrylic ester copolymer emulsion serving as the interior wall humidity-conditioning paint has application prospects.

Owner:NORTHWEST NORMAL UNIVERSITY

Process for pasting construction of floor tiles

InactiveCN101713250AScientific and reasonable processGood compactnessFlooringEngineeringBuilding construction

Owner:孙清海

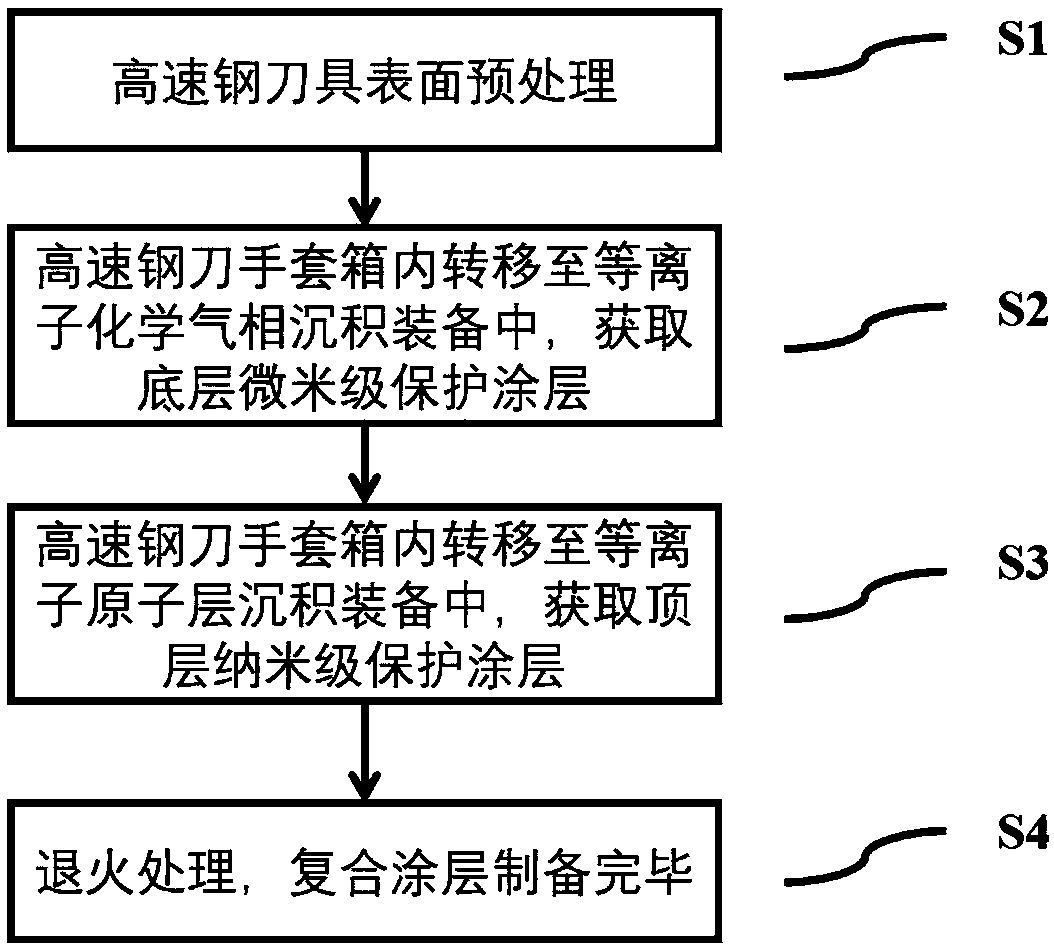

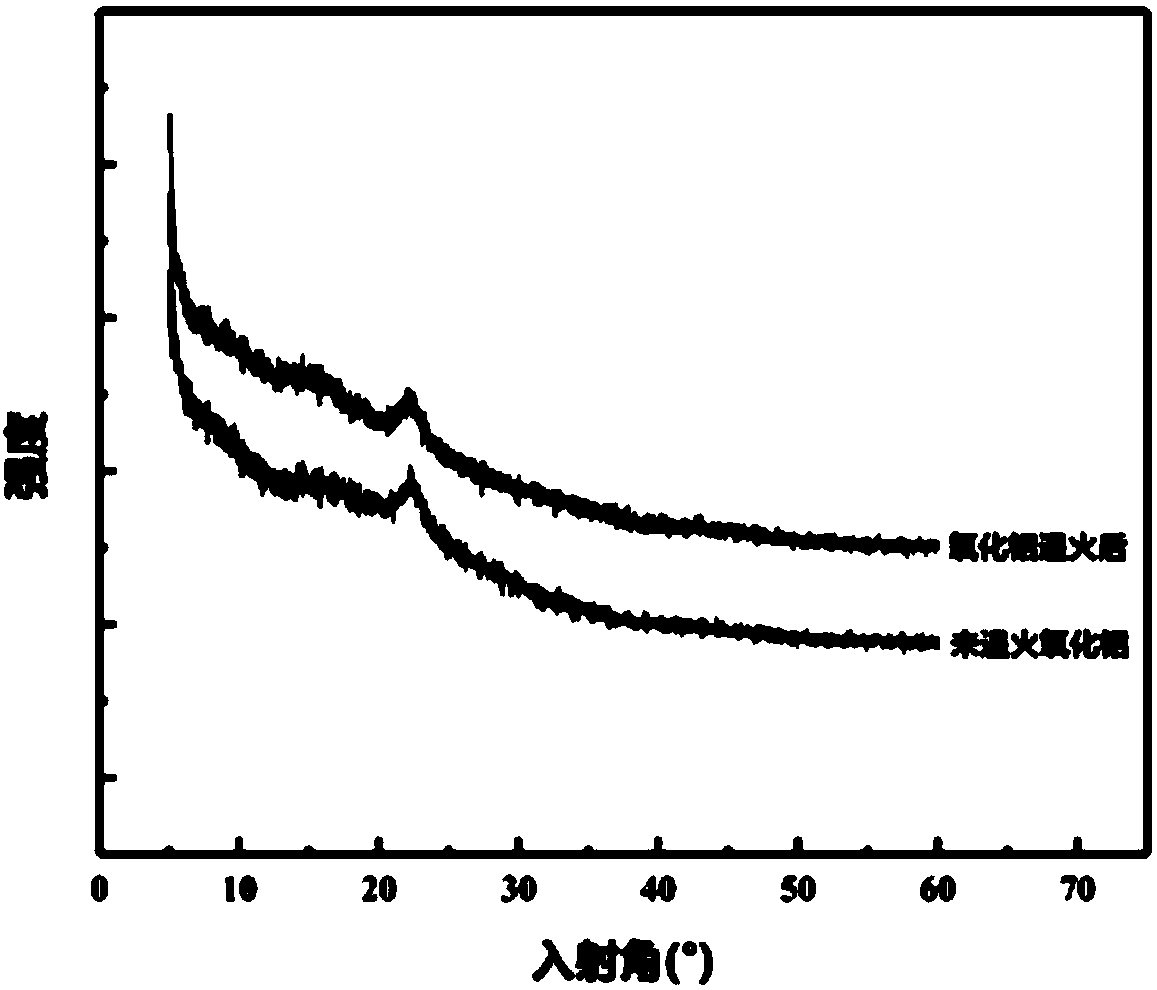

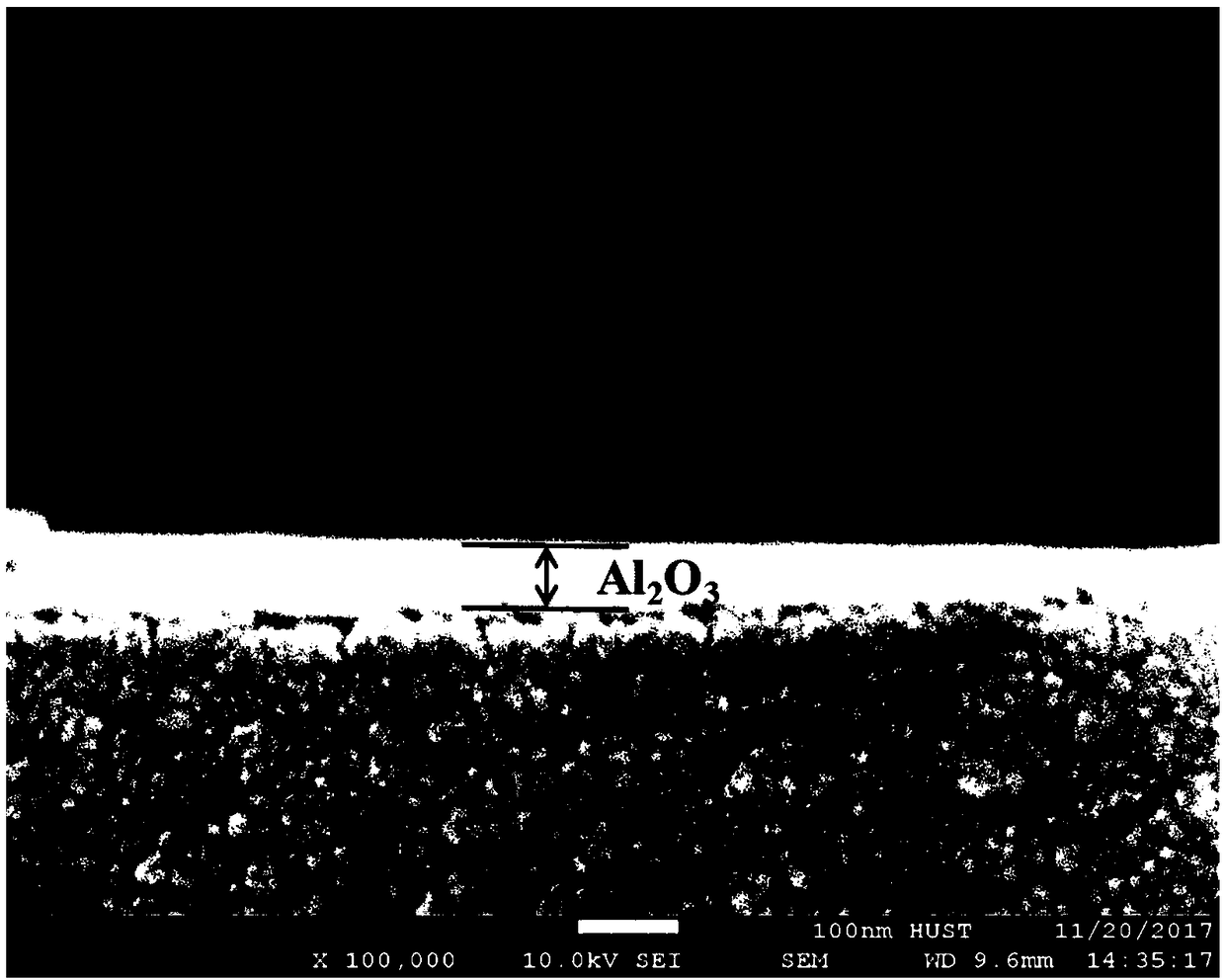

Preparation method of high-speed steel tool protective coating

ActiveCN108411279AReduces oil and particle contaminationGood compactnessChemical vapor deposition coatingPre treatmentNanoscopic scale

The invention belongs to the field of film preparation, and particularly discloses a preparation method of a high-speed steel tool protective coating. The preparation method comprises the steps that the surface of a tool is pretreated, and the tool is placed in plasma enhanced chemical vapor deposition equipment and is deposited with a micron-sized inorganic film; the tool is placed in plasma enhanced atomic layer deposition equipment, and on the conditions of a proper temperature, pressure and proper plasma power, different precursors are alternately supplied, so that saturation adsorption issequentially formed on the surface of the tool and chemical reaction is completed; and finally a composite coating is subjected to annealing treatment. Through a nano-scale film formed by plasma atomic layer deposition, the surface defects of a chemical vapor deposition film can be reduced effectively, and then effective protection on the tool in machining and storage states is realized. Preparation of the tool surface protective coating can be realized by utilizing a chemical vapor deposition means on a cold condition, and then the effective protection on the tool is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

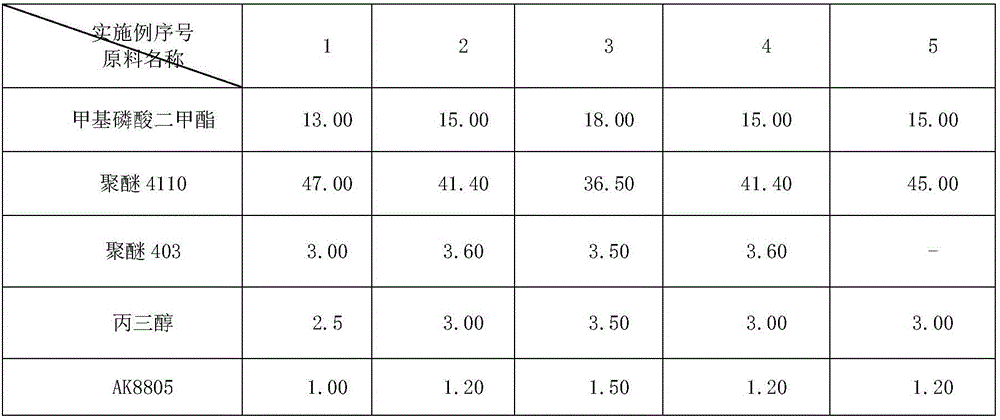

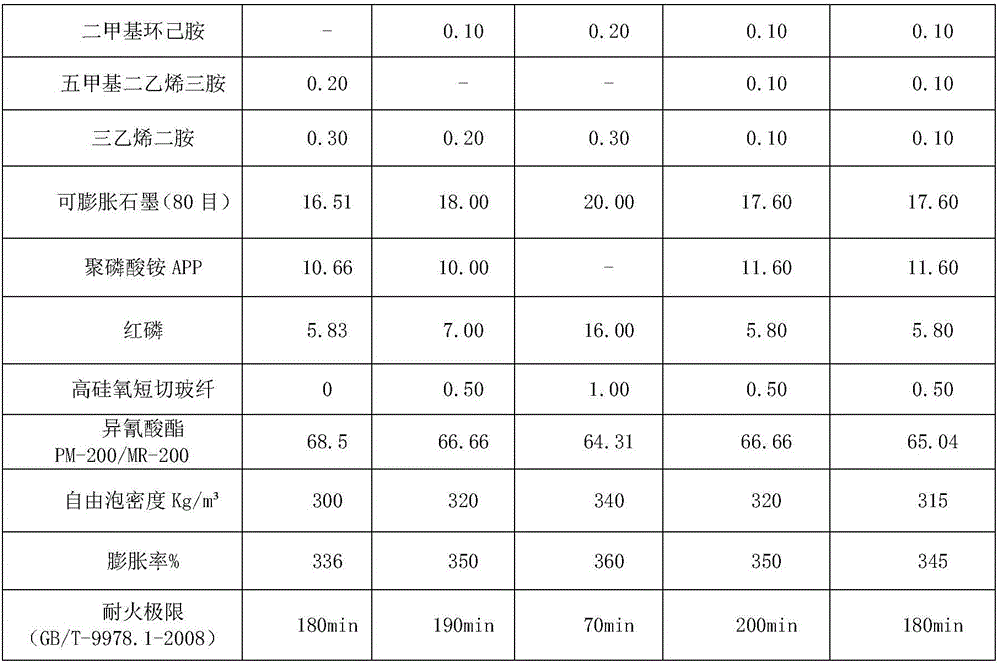

Efficient fireproof environment-friendly foam plugging material

The invention relates to the technical field of fire-proof sealing materials, and discloses an efficient fireproof environment-friendly foam plugging material. The foam plugging material comprises a component A and a component B; the component A comprises polyether polyol, phosphate flame retardant, cross-linking agent, foam stabilizer, catalyst, powder flame-retardant masterbatch and carbon-layer anti-crack fiber; the component B comprises isocyanate. The efficient fireproof environment-friendly foam plugging material is high in fireproof limit, free of halogen, green and environment friendly and has advantages of high foam strength, good dimensional stability, good plug sealing effect, oil proofness, water proofness, corrosion protection, rat proofness and the like, routine maintenance is not required after construction, and service life is as long as 20-30 years.

Owner:BEIJING MUCHEN FIREPROOF INSULATION SPECIAL MATERIALS CO LTD

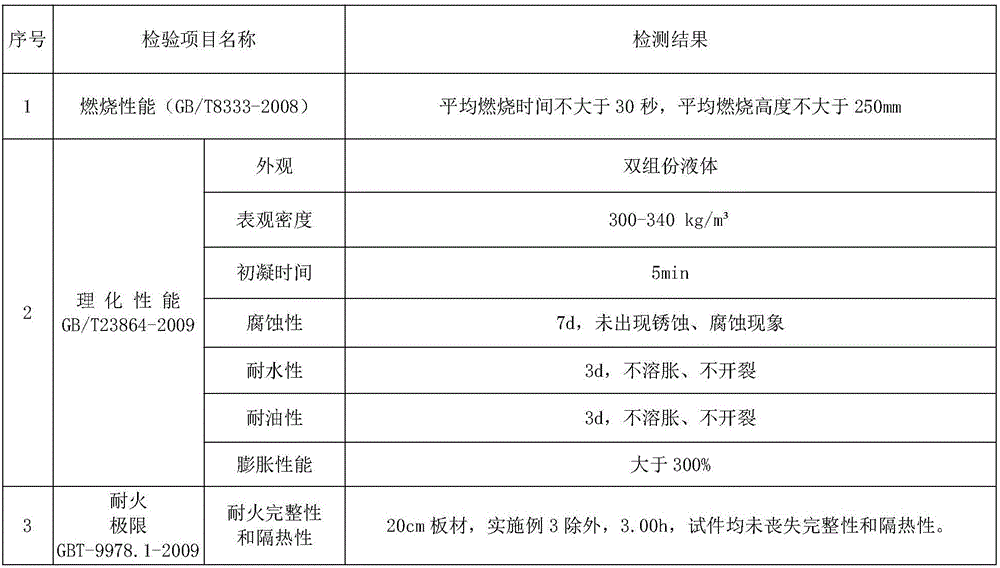

Protective paint for retarding or preventing migration of conductive silver ions, preparation method and application thereof

The invention provides a protective paint for retarding or preventing migration of conductive silver ions. The protective paint is prepared from the following raw materials by weight part: 7-12 parts of sericite powder, 0-5 parts of graphite powder, 80-85 powder of polyester resin solution and 2-8 parts of dimethyl solvent. The invention also provides a preparation method and application of the protective paint. The protective paint has a variety of synergetic effects, can retard or prevent migration of conductive silver ions, prevents product performance from being reduced or lost due to resistance variation caused by the migration of silver ions, and is particularly suitable for occasions such as conductive silver paste or silver wires, silver electrodes, silver contacts and the like. In addition, metal or alloy materials for a conductive purpose besides metallic silver can also be used as suitable objects to be protected to achieve the same purpose.

Owner:张跃进 +1

Degradable and extratracheal outer suspending support and indirect 3D printing method thereof

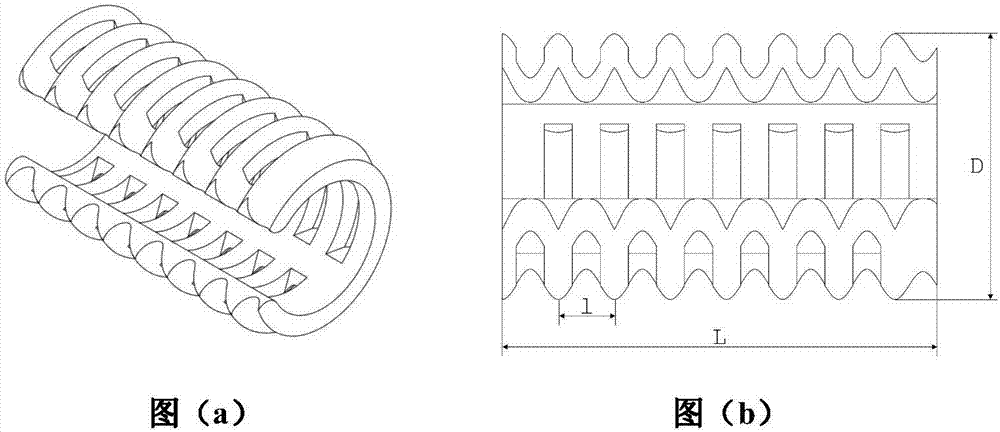

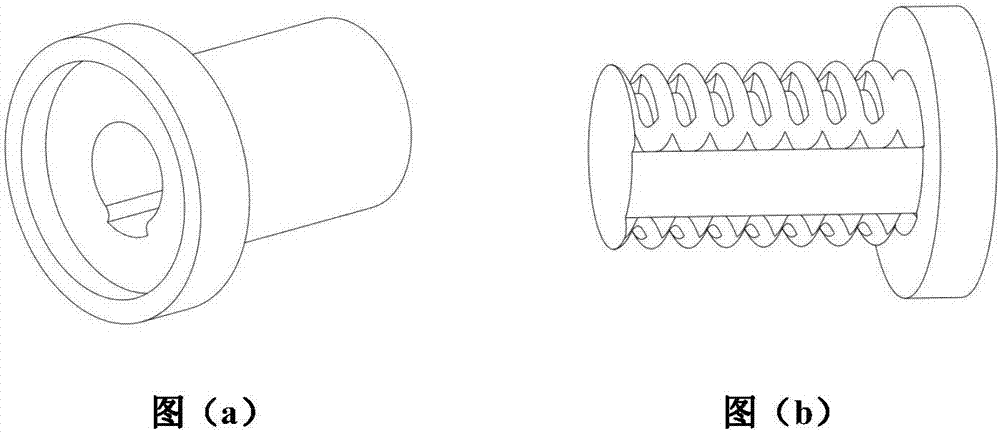

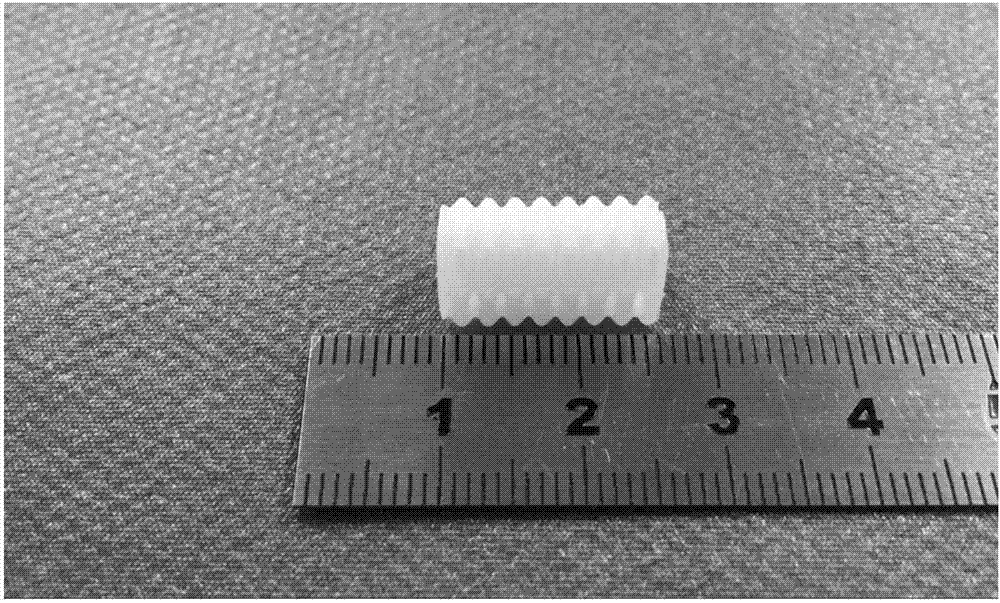

ActiveCN107296669AGood compactnessImprove mechanical strengthStentsAdditive manufacturing apparatusMechanical properties of carbon nanotubesBiomedical engineering

The invention discloses a degradable and extratracheal suspending support and an indirect 3D printing method thereof. The support is provided with several C-shaped cylindrical ring structures, the C-shaped cylindrical ring structures are arranged in an array mode, the opening angle of the cylindrical rings is 90 degrees, and the surface of each C-shaped cylindrical ring structure is in an arc shape, so that the extratracheal support shows fluctuating heave-and-sunken structures as a whole; on the C-shaped cylindrical ring structures, penetrating holes are punched at every 90 degrees on the protrusion structures. The indirect 3D printing method of the support comprises the steps of using a 3D printing technology to manufacture resin parts formed by internal dies and external dies, cleaning clearly the resin parts, using biological silica gel to conduct rollover on the resin parts, preheating the obtained silica gel die, afterwards adding a medical biological degradable material in a silica gel external die, conducting vacuum pumping treatment after the material is totally fused, afterwards putting the fused material into a silica internal die to fix the material, naturally cooling, demolding the material after the material cools down to obtain the degradable and extratracheal suspending support. The manufactured degradable and extratracheal suspending support has high mechanical performance and surface roughness, and has an in-vivo degradable property.

Owner:XI AN JIAOTONG UNIV

Cement waterproofing coating, and preparation method and application thereof

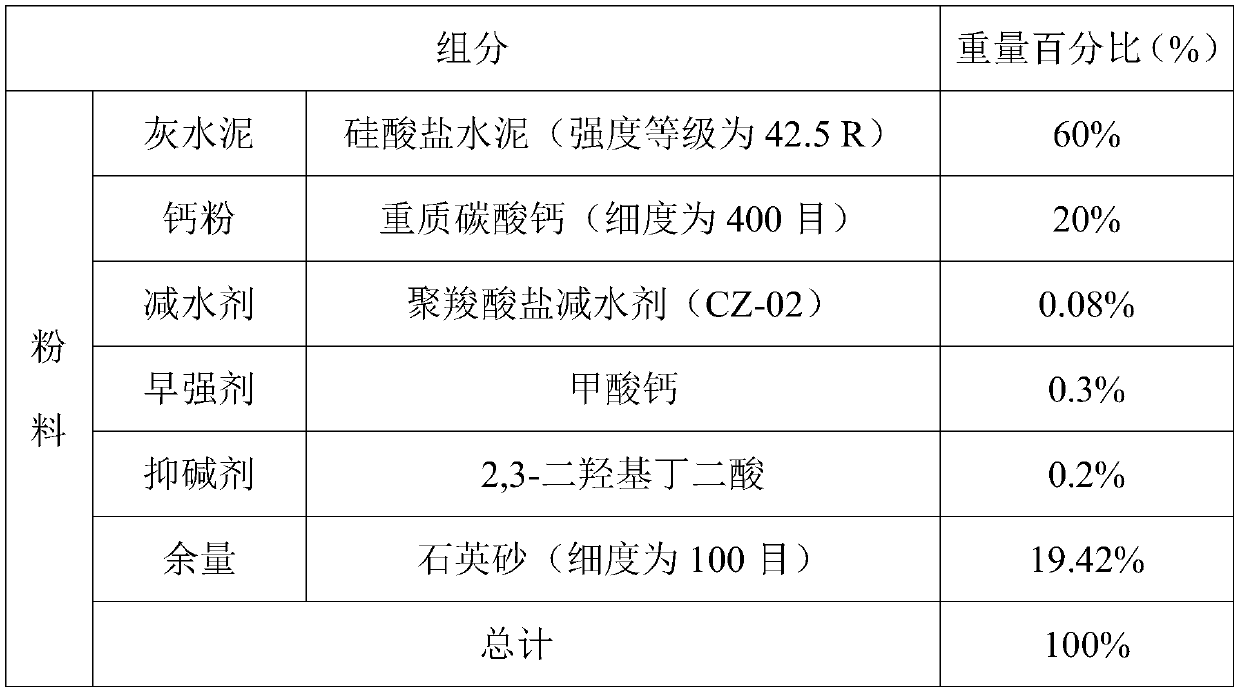

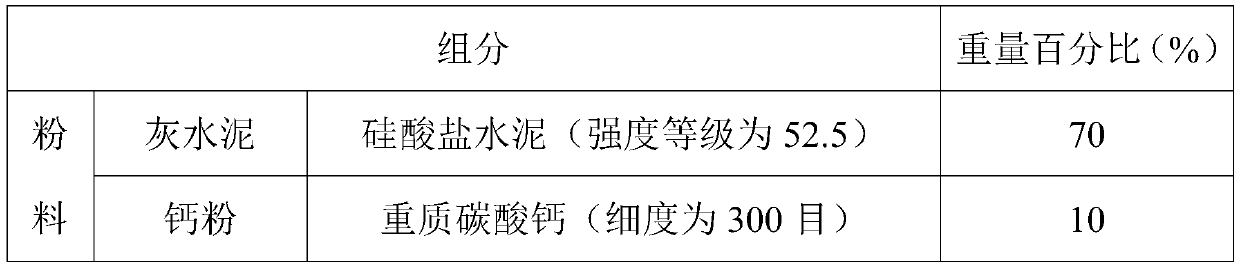

ActiveCN111117314AGood compactnessReduce free precipitationCement coatingsDefoaming AgentsPolymer chemistry

The invention provides a cement waterproofing coating, and a preparation method and an application thereof. The cement waterproofing coating is composed of a powder material and a liquid material, 100wt% of the powder material comprises 50-70 wt% of ash cement, 10-30 wt% of calcium powder, 0.02-0.1 wt% of a water reducing agent, 0.1-0.4 wt% of an early strength agent, 0.1-0.3 wt% of an alkali inhibitor, and the balance of quartz sands; and 100 wt% of the liquid material comprises 75-80 wt% of an emulsion, 0.2-0.4 wt% of a defoaming agent, 0.5-3.0 wt% of a coalescing agent, 0.3-0.6 wt% of a thickening agent, and the balance of water. The cement waterproofing coating enables a coating film to form a compact and non-whitening coating film under low-temperature and high-humidity conditions, and meanwhile, the film formed by the coating is excellent in tensile strength, elongation at break and waterproof performance.

Owner:SHENZHEN ZHUOBAO TECH +1

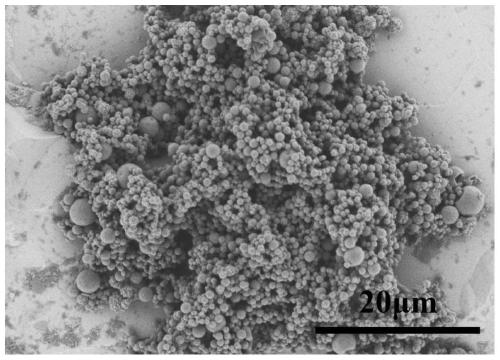

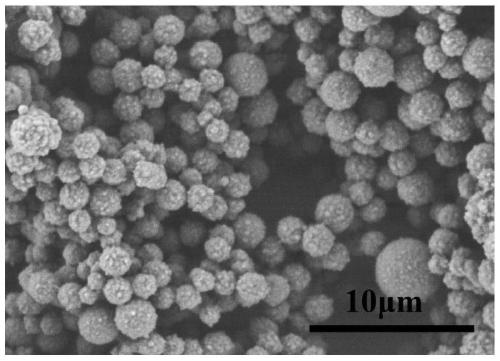

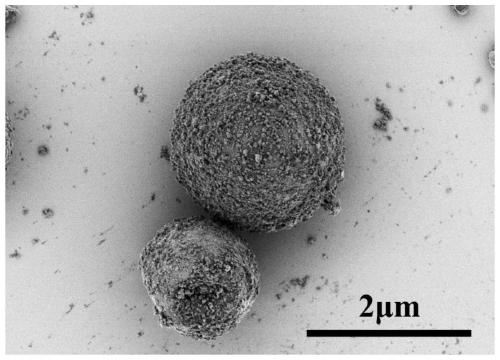

Organic-inorganic hybrid shell bifunctional phase change capsule and preparation method thereof

ActiveCN111205830ANot easy to fall offGood compactnessGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsMicro nanoPolymer chemistry

The invention relates to an organic-inorganic hybrid shell bifunctional phase change capsule and a preparation method thereof. The material comprises a main body material, a monomer, an initiator andan emulsifier, wherein the mass percentage content of each component is as follows: 25%-75% of the main body material, 30%-50% of the monomer, 0.5%-3% of the initiator and 2%-20% of the emulsifier; the main body material is industrial organic paraffin with a melting point of 5-58 DEG C; and in the preparation process, the polydivinylbenzene / TiO2 hybrid shell bifunctional phase change capsule withadjustable micron-scale to nano-scale particle sizes is prepared through Pickering emulsion polymerization. According to the preparation method, the organic-inorganic mixed phase is pretreated throughhigh-speed dispersion under the condition that a co-emulsifier is not added, so that the organic-inorganic hybrid shell bifunctional phase change capsule has a smaller micro-nano size, and the prepared capsule has better heat-conducting property and mechanical property; the heat transfer rate is improved; and moreover, the excellent formaldehyde light degradation performance is also realized.

Owner:HEBEI UNIV OF TECH

Cultural relic protection wax and preparation method thereof

The invention relates to the technical field of cultural relic protection materials, in particular to protection wax which is exclusively used in cultural relic protection. The cultural relic protection wax comprises, by weight, 3-13 parts of hexadecyltrimethylammonium chloride, 3-13 parts of glyceryl monostearate, 3-13 parts of ethylene glycol, 10-15 parts of liquid paraffin, 3-8 parts of borax,2-13 parts of dimethyl polysiloxane, 10-15 parts of carnauba wax, 3-13 parts of sorbitan monooleate, 10-20 parts of deionized water, and 10-20 parts of nano-SiOx, wherein x in the SiOx is range from 1.3-1.55. According to the cultural relic protection wax, after the protection wax is coated on surfaces of cultural relics, compactness is excellent, and the protection effect is excellent; the invention further provides a preparation method of the cultural relic protection wax to simplify preparation process.

Owner:海麟文博(厦门)文物预防性保护技术有限公司

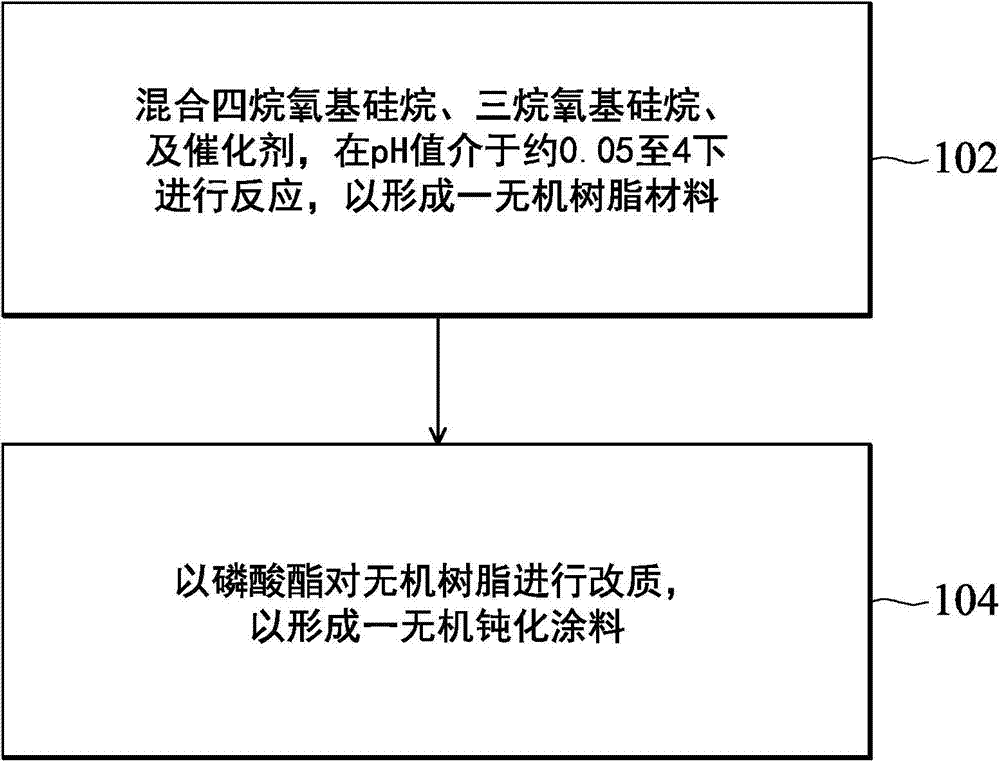

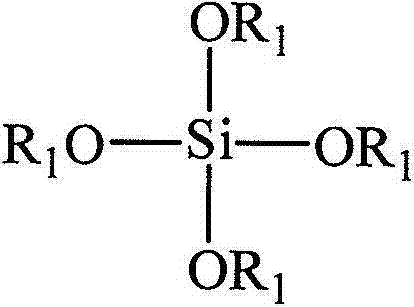

Inorganic passivation material, method for forming the same, and inorganic passivation protective film produced therefrom

ActiveCN104745075AHigh hardnessImprove corrosion resistanceAnti-corrosive paintsMetallic material coating processesPhosphoric Acid EstersPtru catalyst

A method for forming an inorganic passivation material is provided. The method includes mixing about 5 to 80 parts by weight of trialkoxysilane, about 10 to 80 parts by weight of tetraalkoxysilane, and about 1 to 30 parts by weight of catalyst to perform a reaction at pH of about 0.05 to 4 to form an inorganic resin material. The inorganic resin material is modified by phosphate ester to form an inorganic passivation material, wherein phosphate ester is about 0.1-10 parts by weight based on 100 parts by weight of the inorganic resin material. An inorganic passivation material and a passivation protective film produced therefrom are also provided.

Owner:IND TECH RES INST

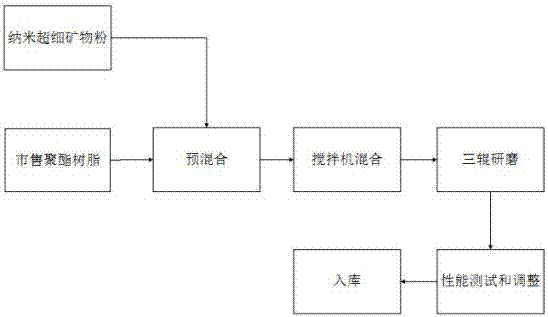

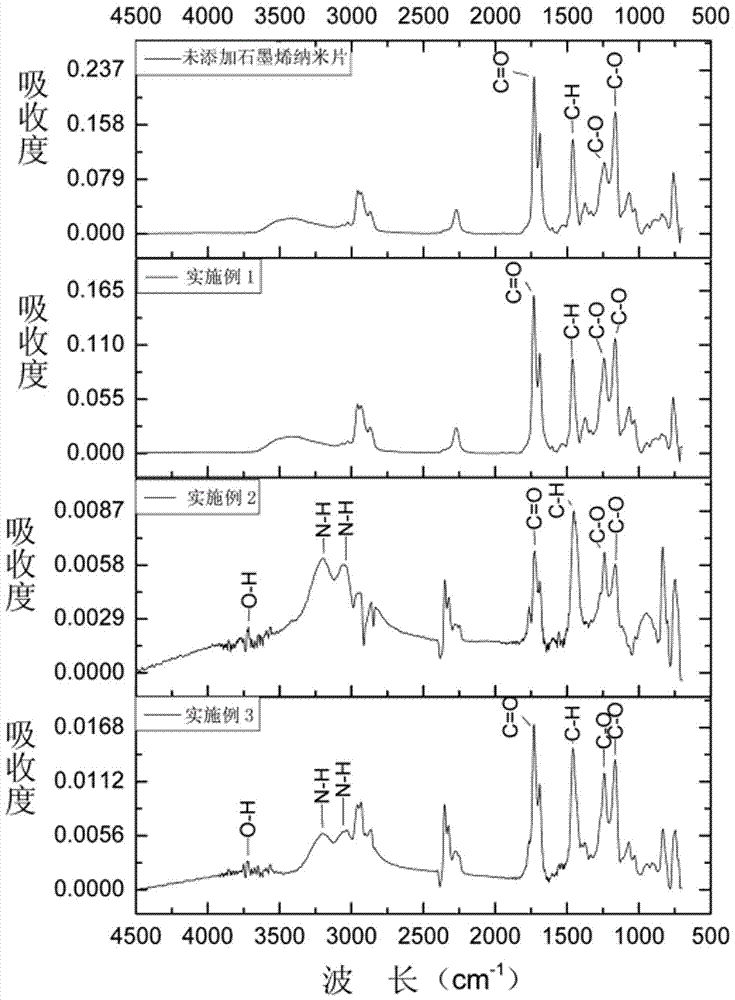

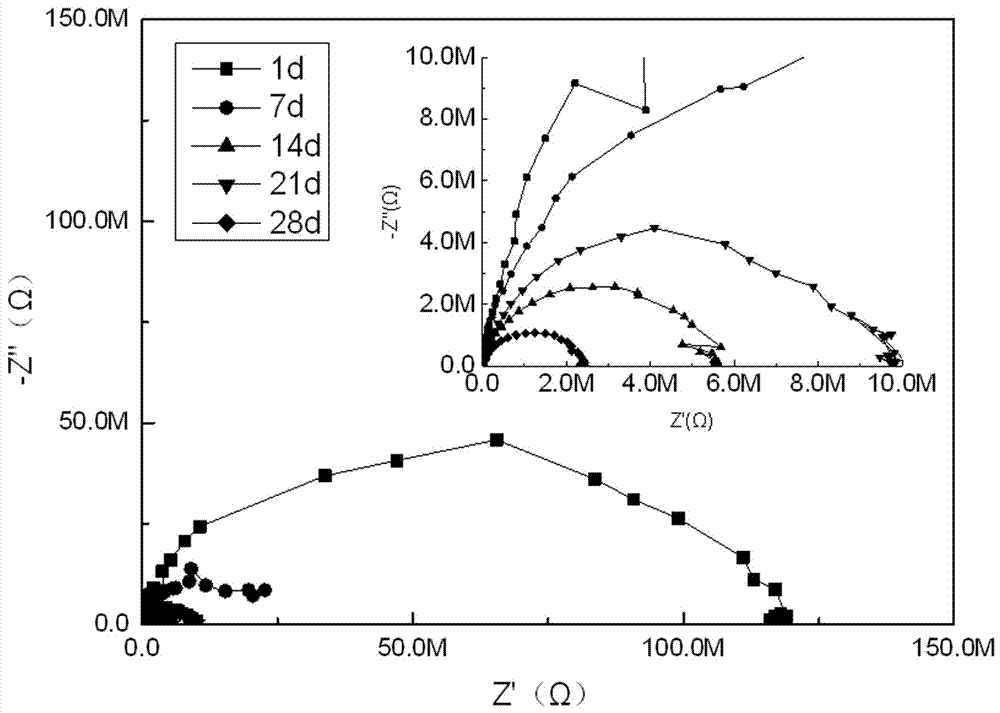

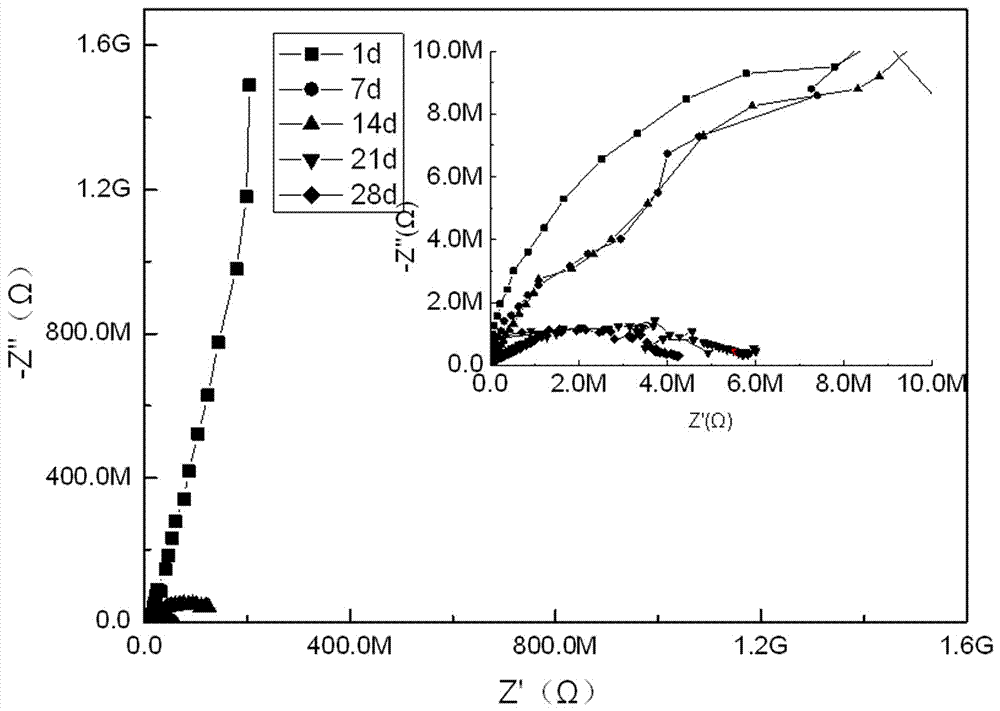

Modified graphite nanoflake heavy anti-corrosion coating and preparation method thereof

ActiveCN107384184AIncrease the degree of cross-linkingGood compactnessAnti-corrosive paintsPolyurea/polyurethane coatingsOhmAcrylate

The invention discloses a modified graphite nanoflake heavy anti-corrosion coating and a preparation method thereof. The coating is prepared from the following components of acrylate polyurethane resin, a graphene nanoflake, a modifier, benzofuran and a drier at the mass ratio of 100:(1-5):(2-10):(30-50):(0.1-0.3). According to the heavy anti-corrosion coating, hydroxyl in the acrylate polyurethane resin is combined with the modified graphene nanoflake, so that oxygen-containing functional groups in the system are increased, and thus the cross-linking degree of the coating is improved, the impedance value of the coating can reach 10<7>-10<9>ohm and the coating has good electrochemical corrosion resistance.

Owner:SHANGHAI MARITIME UNIVERSITY

Mildew corrosion resisting polymer modified asphalt waterproof coiled material

InactiveCN108437321AFlat surfaceGood compactnessRoof covering using flexible materialsProtective foundationCorrosionPolymer modified

The invention relates to the technical field of building water prevention, in particular to a mildew corrosion resisting polymer modified asphalt waterproof coiled material. By means of the mildew corrosion resisting polymer modified asphalt waterproof coiled material, mildew growth can be reduced, and influences on the living quality of people are weakened. The production process of the mildew corrosion resisting polymer modified asphalt waterproof coiled material comprises the first step of pretreatment, the second step of high polymer modified asphalt coverage material manufacturing, the third step of high polymer modified asphalt coverage material checking, the fourth step of forming and the fifth step of tidying.

Owner:盘锦禹王防水建材集团有限公司

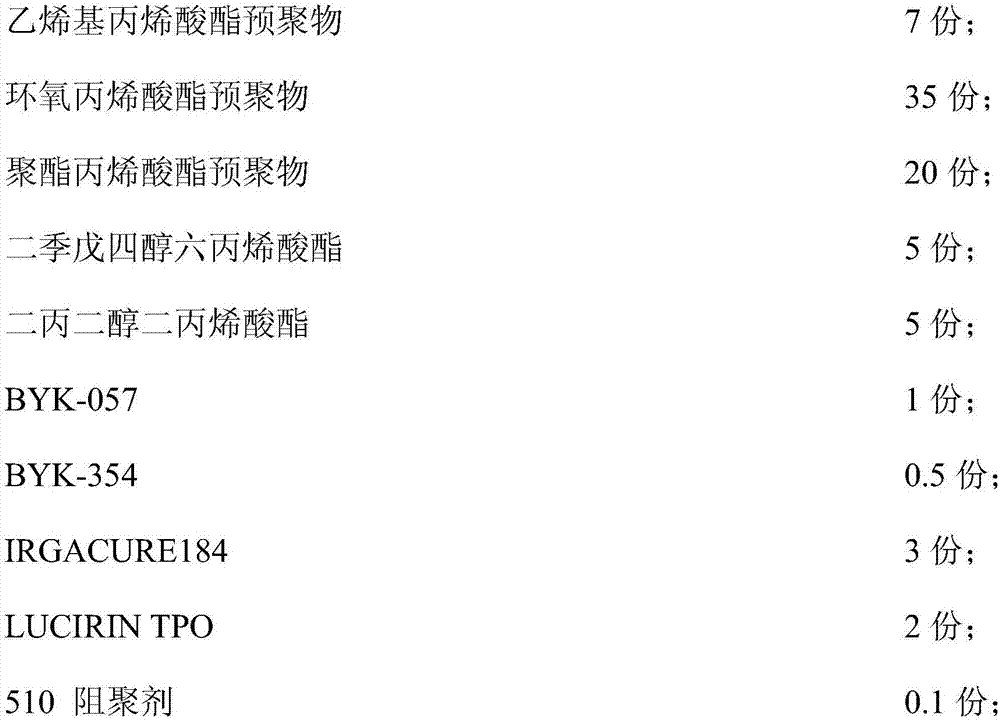

UV-curing glass protecting ink with fragment stripping and preparation method thereof

The invention relates to UV-curing glass protecting ink with fragment stripping. The UV-curing glass protecting ink comprises the following components in parts by weight: 45-65 parts of acrylate prepolymer, 10-15 parts of a diluting agent, 5-8 parts of a photopolymerization initiator, 20-30 parts of filler and 2.1-4 parts of an additive. The UV-curing glass protecting ink has the advantages that the resistance to long-time water and cutting-liquid soaking is achieved, the resistance to a CNC (Computerized-Numerical-Control) process is good, the resistance to scratching is achieved, and the protectiveness is good; the stripping time is short and the stripping is complete without residues; and small-fragment stripping is adopted and no hanging is caused, so that the production efficiency is improved.

Owner:广州亦盛环保科技有限公司

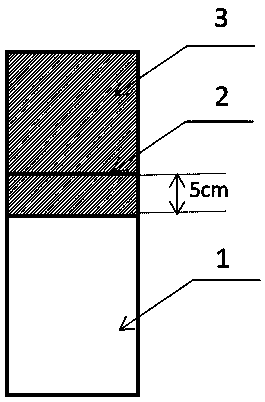

Preparation method of anticorrosive coating on surface of electrolytic zinc anode plate

The invention discloses an anticorrosive coating on surface of an electrolytic (deposited) zinc anode plate and a preparation method thereof. The method comprises the step that a spraying material resistant to sulfuric acid solution, fluoride ion and chloride ion corrosion is sprayed in a range from the upper end of the anode plate to 5 cm below a liquid level line so as to obtain the anticorrosive anode plate with a coating. The spraying material selected in the anticorrosive coating on the surface of an electrolytic (deposited) zinc anode plate and the preparation method thereof is sprayed on the anode plate, the electrolytic efficiency of zinc is not affected, the corrosion of the polar plate is effectively slowed down, so that the service life of the anode plate is prolonged by 2-3 months. The preparation method has small investment, simple process flow, no special requirements on equipment, low energy consumption, no pollution and wide application prospect.

Owner:FUZHOU UNIVERSITY

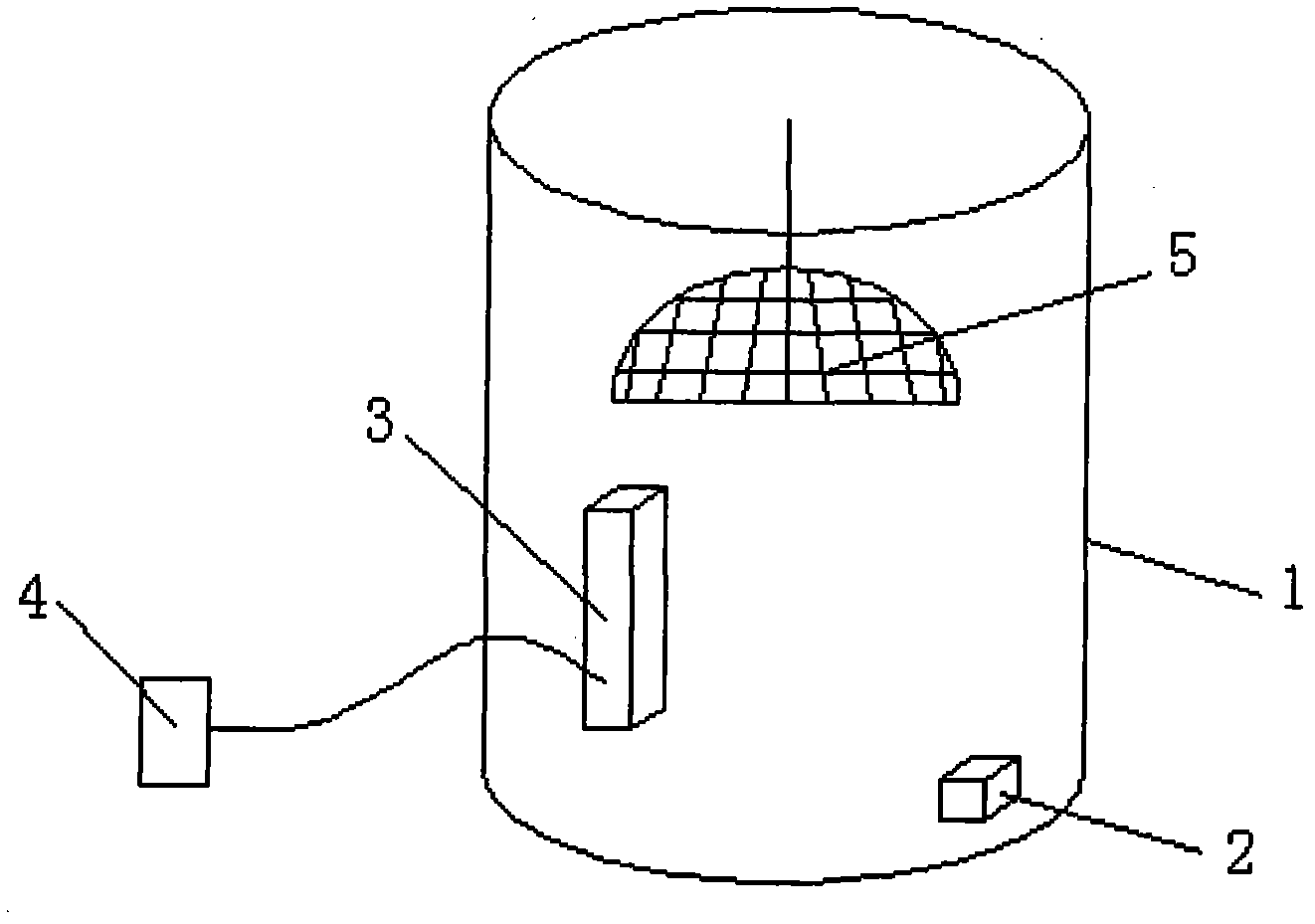

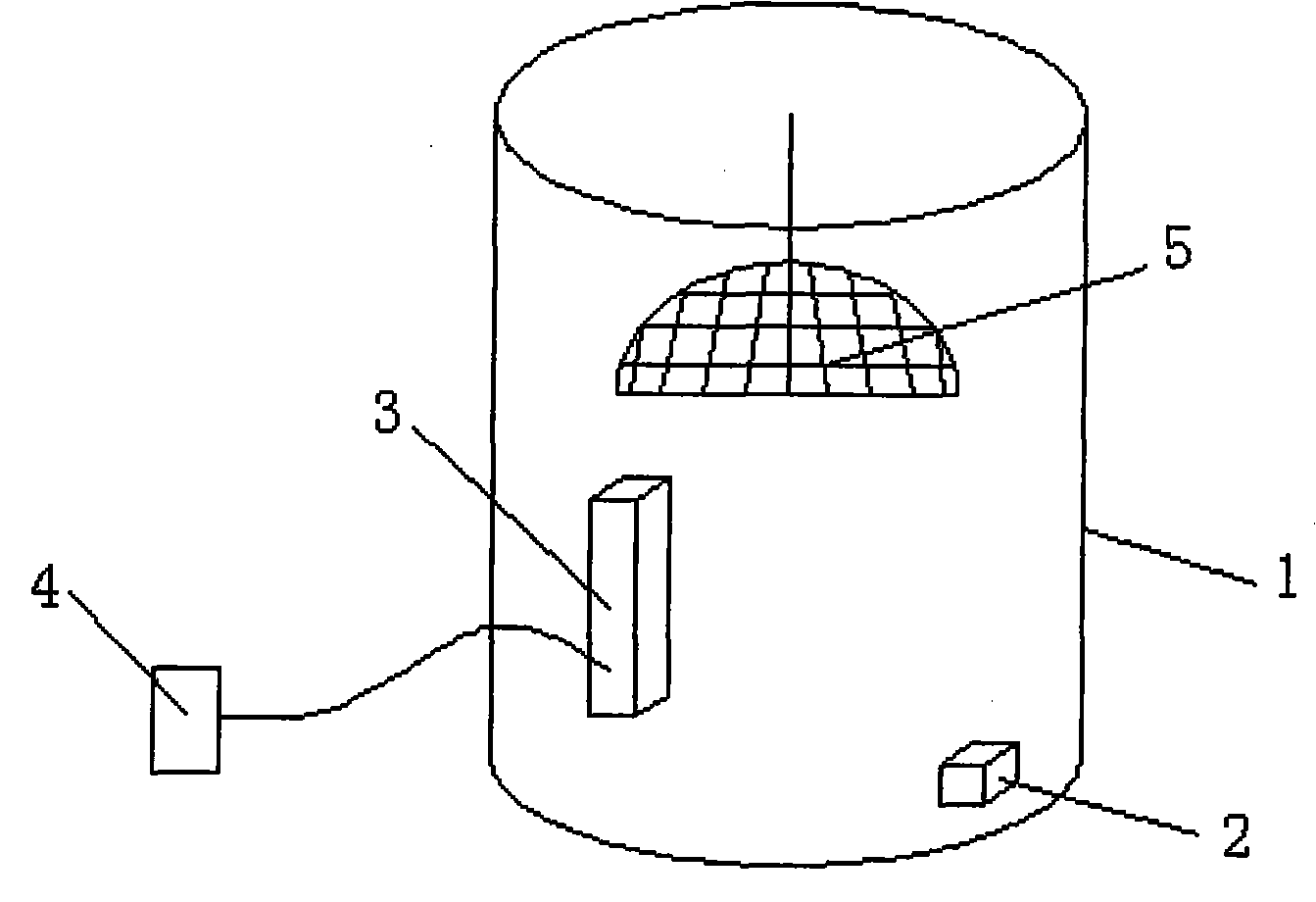

Ion plating device

InactiveCN101956161AHigh film strengthGood compactnessVacuum evaporation coatingSputtering coatingFilm materialIon source

The invention discloses an ion plating device and relates to a device for plating through the vacuum evaporation, sputtering or ion injection of a coating forming material, in particular to an ion plating device. The device comprises a plating furnace and a film material arranged in the plating furnace. The device is characterized in that the plating furnace is internally provided with an ion source for emitting plasma, and the ion source is used for emitting plasma to heat the film material to ensure that the film material becomes steam and is uniformly plated on a glass sheet to effectively enhance the film layer strength, thus the plating compactness is better, the reject ratios due to scraping, spot stains, and the like in the production process of lenses are reduced, and the yield of the process is effectively improved; the ion source is arranged on the middle rear part of the plating furnace so as to be beneficial to the uniformity of the ion emitting angle of the ion source to realize uniformly plating; and argon is added to mixed gas, which can increase the ion density and prolong the service life of lamp filaments of the ion source.

Owner:苏州五方光电科技有限公司

Method for preparing monocrystalline silicon surface-passivated cell

ActiveCN105374900AGood compactnessGood passivationFinal product manufacturePhotovoltaic energy generationSilicon chipSilicon nitride

The invention discloses a method for preparing a monocrystalline silicon surface-passivated cell. The method specifically comprises the steps of: (1) by adopting an improved diffusion technology, diffusion is carried out on a monocrystalline silicon sheet after cleaning and texturing in a tube-type diffusion furnace; (2) after the monocrystalline silicon sheet is subjected to texturing and diffusion, PSG after the diffusion is removed by HF in a secondary cleaning tank; (3) in the diffusion furnace, a dry-oxygen oxidation method is firstly adopted so as to enable a layer of thin silicon dioxide film to grow on the surface of the silicon sheet, then wet-oxygen oxidation is carried out in a wet-oxygen atmosphere, suitable source introduction deposition is simultaneously carried out, and finally the dry-oxygen oxidation is carried out again; (4) etching is carried out on the passivated monocrystalline silicon sheet in a wet method etching tank for removing PN junctions on the back side; and (5) a PECVD method is utilized for depositing silicon nitride on the front surface of the monocrystalline silicon sheet, and electrode printing and sintering are carried out. The method has the advantages that the compactness is good, the good passivation effect is reflected, and the photoelectric conversion efficiency of the monocrystalline silicon cell is obviously improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

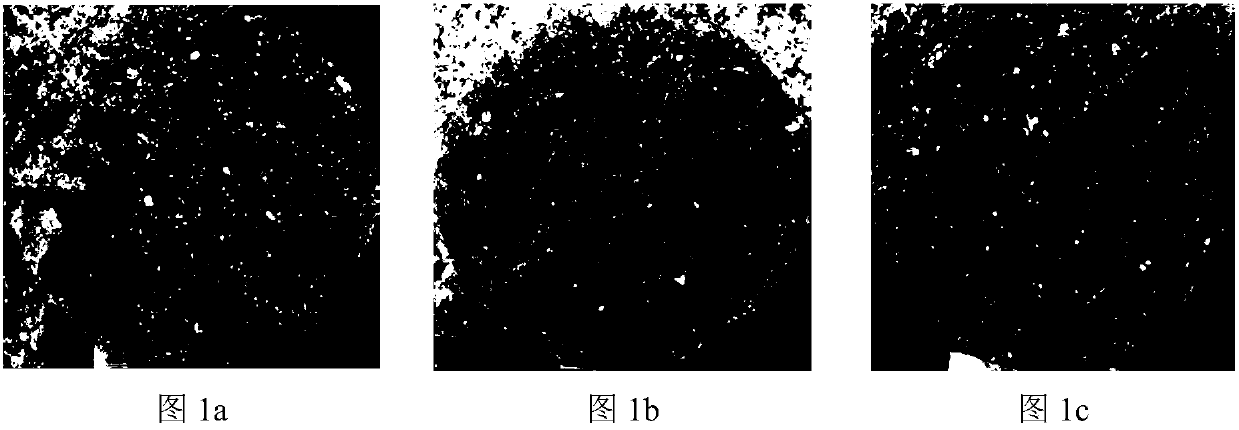

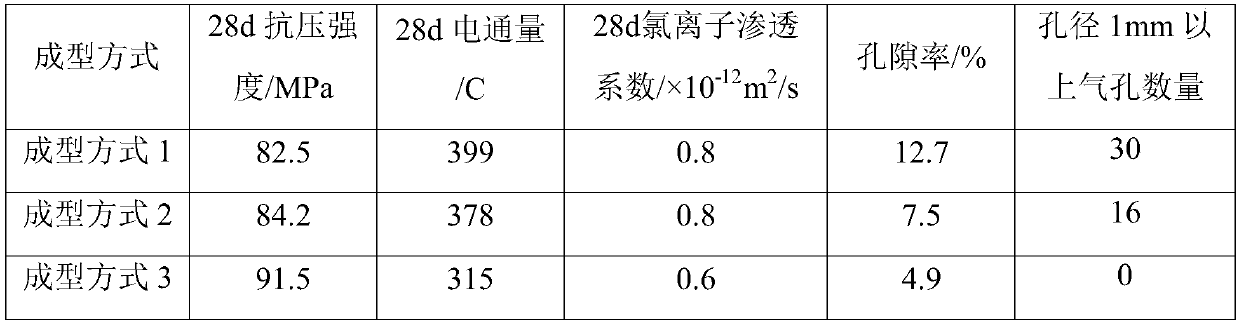

Molding method of high-density and low-porosity concrete

ActiveCN107814528AGood compactnessImprove mechanical properties and durabilityCeramic shaping apparatusDefoaming AgentsAir bubble

The invention discloses a molding method of high-density and low-porosity concrete. The molding method comprises the following steps : (1) adopting the total mass of the concrete as a reference, adding 0.05%-0.1% of a powder defoaming agent into the concrete, adjusting the use amount of a water reducing agent to control the slump of the concrete to 30-120mm, and controlling stirring time; (2) placing a test mold on a vibrating platform, pouring newly-stirred concrete into the test mold by two or more layers; (3) at every completion of pouring of one layer, starting the vibrating platform for vibration till defects in the concrete are filled, and discharging macroscopic bubbles; (4) stopping the vibrating platform, carrying out inserting and tamping on the concrete, wherein inserting and tamping are performed once at every 100-150mm in the form of a rectangular lattice; starting the vibrating platform after all parts of the concrete layer are inserted and tamped, vibrating till the concrete is dense and a surface is smooth; (5) repeating the steps (3) and (4) till the concrete is poured completely, and when the concrete above a second layer is inserted and tamped, inserting an inserting and tamping head to a position 0.1m below the surface of the former layer of concrete.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

High strength corrosion-resistant coating material for brake disc

InactiveCN108315594AStrong combinationGood compactnessBraking discsMetallic material coating processesCorrosion resistantSurface strength

The invention discloses a high strength corrosion-resistant coating material for a brake disc. The raw materials of the high strength corrosion-resistant coating material for the brake disc are prepared from Al, Mg, B, Zr, Sr, Mn, Ti, Si, Ni, Cu, Ce, La, Y and Er, and the balance of Zn and inevitable impurities. The high strength corrosion-resistant coating material for the brake disc disclosed bythe invention can be firmly combined with a brake disc base body, is good in compactness and improves the performances, for example, surface strength, corrosion resistance and the like, of the brakedisc, so that the service life of the brake disc is prolonged, and the reliability of the brake disc is improved.

Owner:广德亚太汽车智能制动系统有限公司

Alloy manufacturing method for aircraft shell

The invention provides an alloy manufacturing method for an aircraft shell. The specific manufacturing method comprises the steps of: pretreatment, alloy liquid smelting, alloy ingot casting, alloy ingot remelting, purity improvement and casting formation; and the composition proportions of alloy raw materials are provided. The unique manufacturing method and component proportions are adopted, so that the aircraft shell manufactured by an alloy obtained through the method is excellent in compactness and higher in mechanical performance, meanwhile, is light in mass, can adapt to cold-hot alternation of high / low temperatures, and is higher in adaptability.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

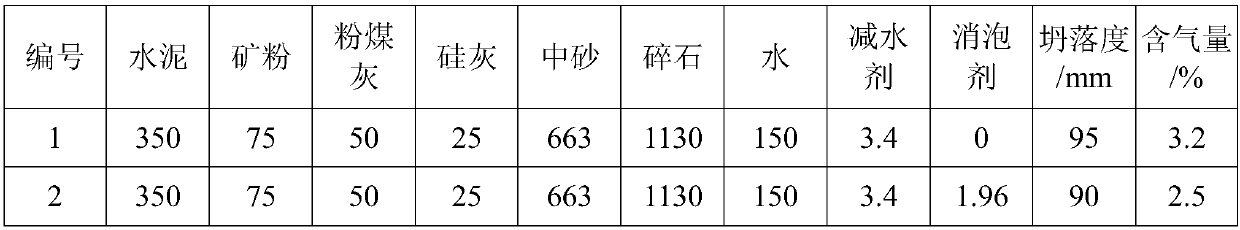

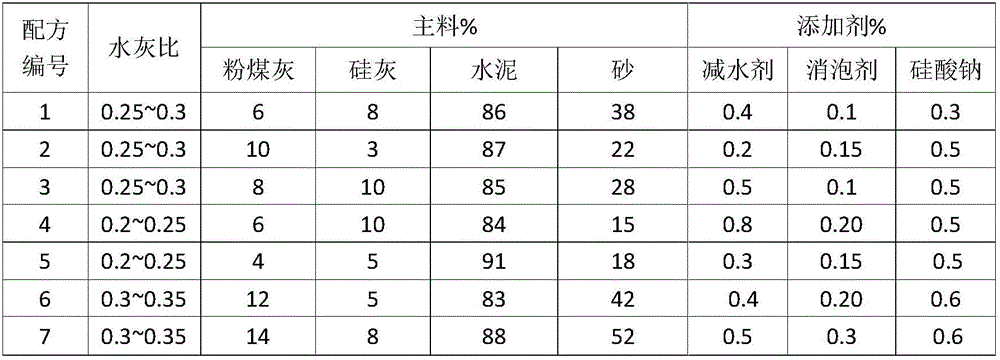

Cement mortar for fixing low-medium level radioactive sundries and preparation method thereof

The invention discloses cement mortar for fixing low-medium level radioactive sundries and a preparation method thereof, solving the problem that in the prior art, performance of the cement mortar is very difficult to meet a current standard EJ1186-2005. The cement mortar for fixing provided by the invention comprises water, ash, sand and additive, wherein the ash comprises the following materials in percentage by weight: 6%-12% of coal ash, 3%-10% of silica fume and the balance of cement; the weight ratio of the water to the ash is 0.25-0.3, the weight ratio of the sand to the ash is 0.2-0.4, and the weight of the additive is 0.4%-1.25% of that of the ash. The cement mortar prepared according to the preparation method provided by the invention has average compressive strength of more than 70MPa, fluidity of more than 400mm and anti-permeability of far below 2500C, and meets requirements of the current standard EJ1186-2005; and test raw materials are cheap and prone to acquire, so that the cement mortar is strong in economy, and very applicable to popularization for use.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Non-ferrous metal particle semi-solid forming equipment and process

ActiveCN111390139AHigh surface finishGood compactnessMolten metal supplying equipmentsMaterial storageNonferrous metal

The invention discloses non-ferrous metal particle semi-solid forming equipment. The non-ferrous metal particle semi-solid forming equipment comprises a first-section horizontal feeding mechanism anda second-section vertical forming mechanism, wherein the first-section horizontal feeding mechanism is used for conveying, melting, mixing and storing metal particles and feeding the metal particles into a forming die cavity; the first-section horizontal feeding mechanism is provided with a horizontal feeding tube device, a segmented gradient heating system sleeving the feeding tube device, a material storage device in butt joint with the feeding tube device in a shear opening structure and a drying system arranged outside the material storage device; the second-section vertical forming mechanism is used for realizing die forging casting forming; and the working direction of the first-section horizontal feeding mechanism is arranged perpendicular to the working direction of the second-section vertical forming mechanism, the first-section horizontal feeding mechanism communicates with the interior of the second-section vertical forming mechanism, and the first-section horizontal feedingmechanism and the second-section vertical forming mechanism are in butt joint in a sealed mode through a smooth type material outlet to realize the horizontal feeding and vertical forming. The invention further discloses a non-ferrous metal particle semi-solid forming process.

Owner:刘兴军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com