Antipollution ultrafiltration membrane of amino acid grafting composite cellulose and preparation method thereof

A technology of composite cellulose and cellulose diacetate, which is applied in the field of membrane separation, can solve problems such as clogged pores and decreased water flux of the membrane, and achieve the effects of good compression resistance, easy cleaning of the membrane, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

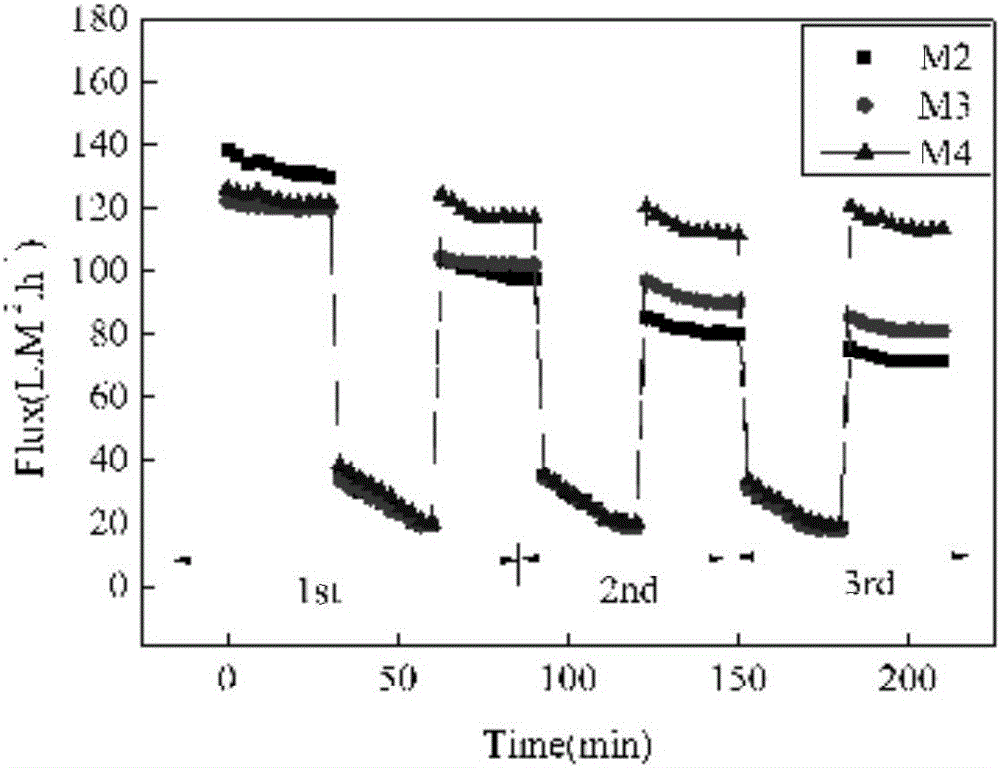

Examples

Embodiment 1

[0029] An anti-pollution ultrafiltration membrane of amino acid grafted composite cellulose, which is prepared by using the ultrafiltration membrane of oxidized nanocellulose composite cellulose acetate as the base membrane, activated in a solution containing EDAC and NHS, and then grafted with lysine become.

[0030] Its preparation method is carried out according to the following steps:

[0031] a. Preparation of composite fiber casting solution: after wood pulp is oxidized by TEMPO method, oxidized nanocellulose is obtained, that is, C on the cellulose 6 The hydroxyl group of the primary alcohol on the position is oxidized to a carboxyl group to form the site of the amidation reaction. The suspension containing 0.015g of acidified oxidized nanocellulose is dispersed in 17g of solvent N,N-dimethylamide After ultrasonic oscillation for 30min, stirring at 200r / min for 4-6h in a water bath at 40°C, then adding 3g of cellulose diacetate and completely dissolving it in the solve...

Embodiment 2

[0039] An anti-pollution ultrafiltration membrane of amino acid grafted composite cellulose, which is prepared by using the ultrafiltration membrane of oxidized nanocellulose composite cellulose acetate as the base membrane, activated in a solution containing EDAC and NHS, and then grafted with lysine become.

[0040] Its preparation method is carried out according to the following steps:

[0041] a. Preparation of composite fiber casting solution: after wood pulp is oxidized by TEMPO method, oxidized nanocellulose is obtained, that is, C on the cellulose 6 The hydroxyl group of the primary alcohol on the position is oxidized to a carboxyl group to form the site of the amidation reaction. The suspension containing 0.015g of acidified oxidized nanocellulose is dispersed in 17g of solvent N,N-dimethylamide After ultrasonic oscillation for 30min, stirring at 250r / min for 5h in a water bath at 45°C, 3g of cellulose diacetate was added and completely dissolved in the solvent N,N-d...

Embodiment 3

[0049] An anti-pollution ultrafiltration membrane of amino acid grafted composite cellulose, which is prepared by using the ultrafiltration membrane of oxidized nanocellulose composite cellulose acetate as the base membrane, activated in a solution containing EDAC and NHS, and then grafted with lysine become.

[0050] Its preparation method is carried out according to the following steps:

[0051] a. Preparation of composite fiber casting solution: after wood pulp is oxidized by TEMPO method, oxidized nanocellulose is obtained, that is, C on the cellulose 6 The hydroxyl group of the primary alcohol on the position is oxidized to a carboxyl group to form the site of the amidation reaction. The suspension containing 0.015g of acidified oxidized nanocellulose is dispersed in 17g of solvent N,N-dimethylamide After ultrasonic oscillation for 30min, stirring at 300r / min in a water bath at 50°C for 6h, then adding 3g of cellulose diacetate and completely dissolving it in the solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com