Preparation method of wrapped polytetrafluoroethylene ultra-micro filter tube membrane

A technology of polytetrafluoroethylene and tubular membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve uniform and consistent bonding, high filtration accuracy, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a) Slit the unsintered polytetrafluoroethylene microporous membrane with a pore size of 0.03 microns and a film thickness of 50 microns into polytetrafluoroethylene strip-shaped films with a width of 10 mm;

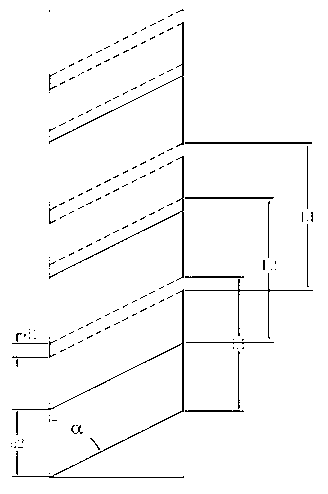

[0027] b) Wrap the polytetrafluoroethylene strip membrane prepared in step a) on a stainless steel wire braided tube (aperture 5000 microns) with an outer diameter of 10 mm and a wall thickness of 0.5 mm at a helix angle of 65 degrees for 3 layers, and the inner tape of the same layer The overlapping distance of the polytetrafluoroethylene film is 0 mm, and the stagger distance between different layers is 25 mm.

[0028] c) Sintering the support tube wrapped with the polytetrafluoroethylene membrane prepared in step b) at 400° C. for 20 seconds to prepare a wrapped polytetrafluoroethylene ultramicrofiltration tubular membrane with a filter layer pore size of 0.01 μm.

Embodiment 2

[0030] a) Divide the biaxially stretched unsintered polytetrafluoroethylene microporous membrane with a pore size of 0.1 microns and a film thickness of 30 microns into polytetrafluoroethylene strip-shaped films with a width of 5 mm;

[0031] b) Wrap the polytetrafluoroethylene tape film prepared in step a) on a porous aluminum alloy tube (pore diameter 1 micron) with an outer diameter of 25 mm and a wall thickness of 5 mm for 12 layers at a helix angle of 50°, and the inner tape of the same layer The overlapping distance of the polytetrafluoroethylene film is 0.5 mm, and the stagger distance between different layers is 2.5 mm.

[0032] c) Sintering the support tube wrapped with the polytetrafluoroethylene membrane prepared in step b) at 380° C. for 80 seconds to prepare a wrapped polytetrafluoroethylene ultramicrofiltration tubular membrane with a filter layer pore size of 0.03 μm.

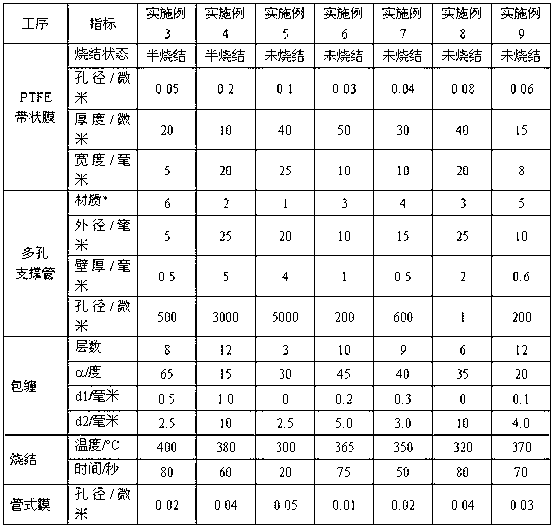

[0033] Examples 3-9 are shown in Table 1.

[0034] Table 1: for Examples 3-9

[0035]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com