Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Occurrence can be prevented" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

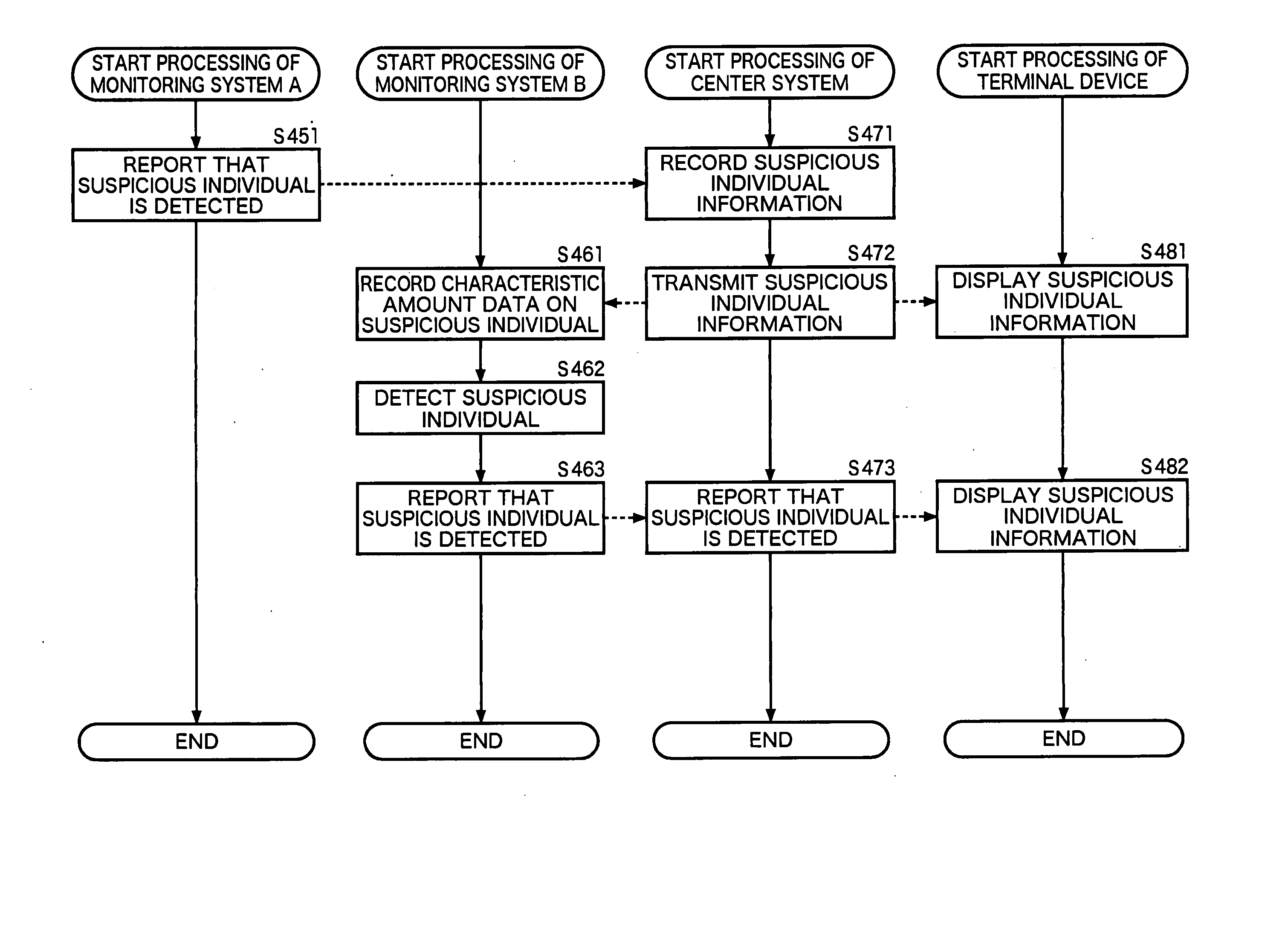

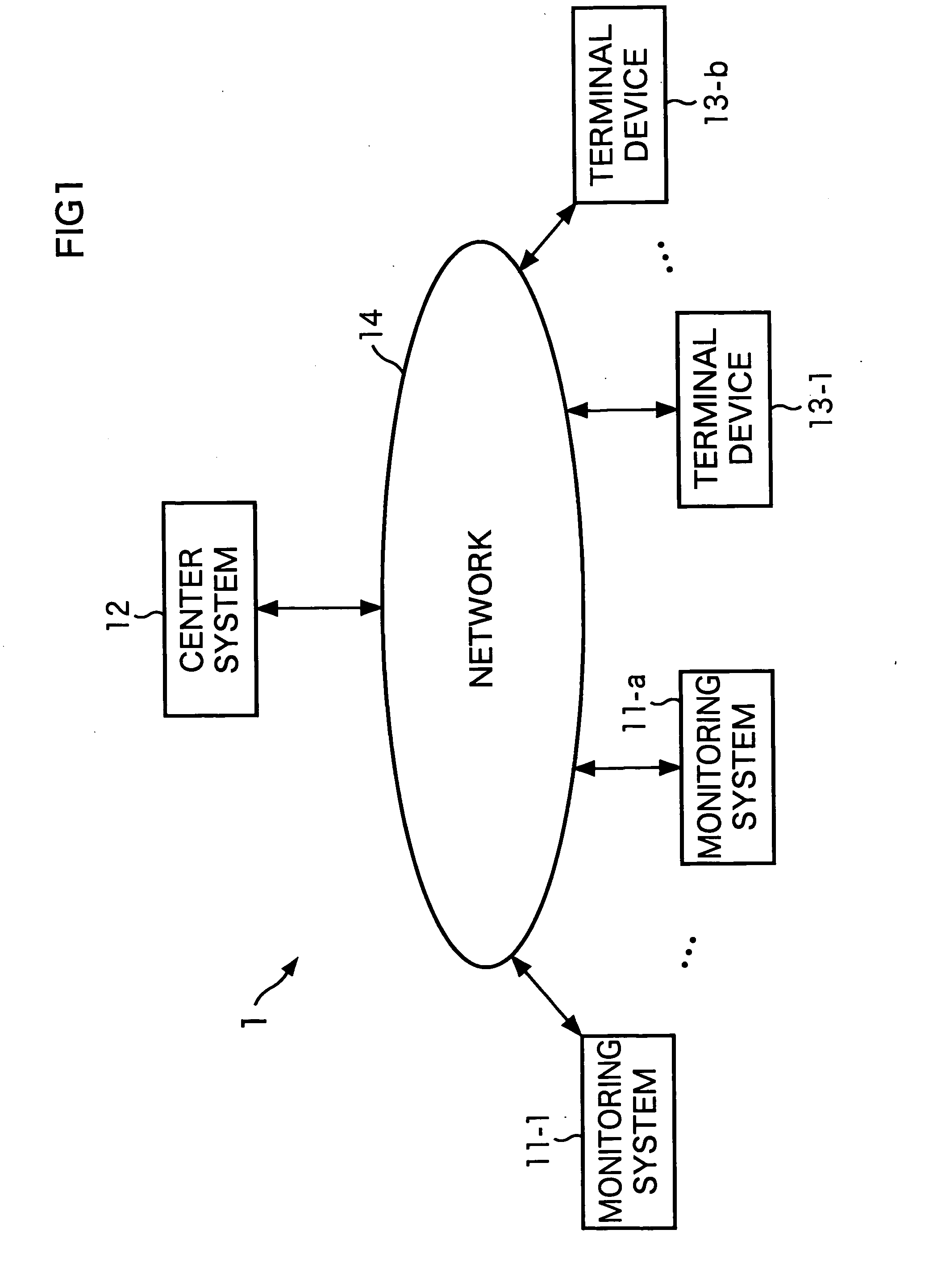

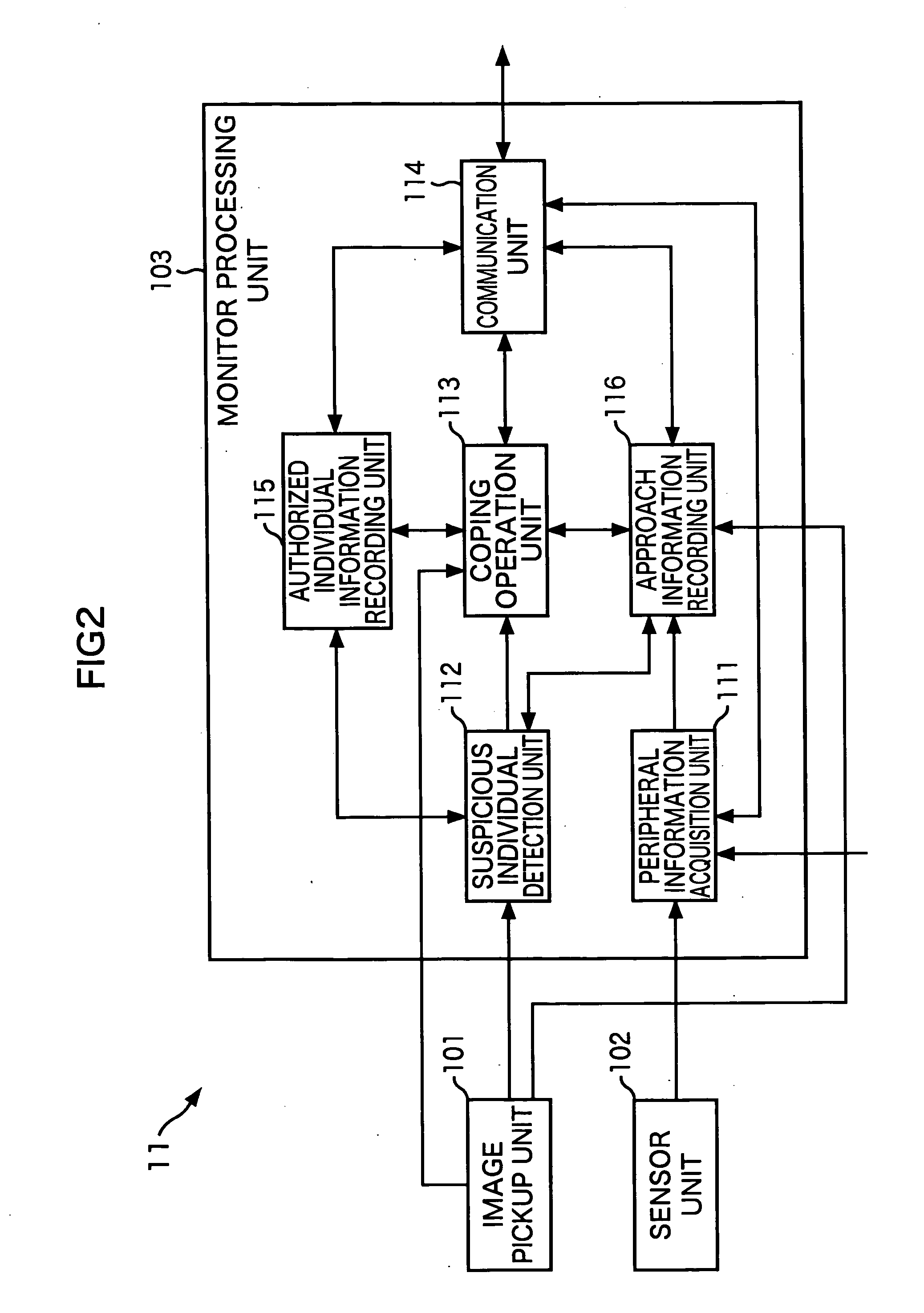

Monitoring system, monitoring device and method, recording medium, and program

InactiveUS20070014439A1Accurate detectionAvoid expansionCharacter and pattern recognitionBurglar alarmPersonal recordMonitoring system

A suspicious individual can be detected more accurately. A face detecting unit detects a face image of an approaching individual from a monitor image, and a characteristic amount detecting unit detects the characteristic amount of the approaching individual from the face image. A collating unit identifies an approaching individual by collating the characteristic amount of the approaching individual with the characteristic amount of an authorized individual which is recorded in an authorized individual information recording unit and the characteristic amount of a previously detected individual which is recorded in an approach information recording unit. An approaching activity detecting unit and an abnormal activity detecting unit compute the degree of suspiciousness of the approaching individual on the basis of the frequency with which the approaching individual approaches a target of monitoring, time at which the approaching individual approaches a target of monitoring, distance by which the approaching individual approaches a target of monitoring, and the like. A suspiciousness degree judgment unit judges whether the approaching individual is a suspicious individual or not, on the basis the degree of suspiciousness. The present invention can be applied to an on-vehicle monitoring system.

Owner:ORMON CORP

Functional device and method of manufacturing the same

InactiveUS6953754B2Avoid layeringOccurrence can be preventedTransistorLayered productsEpoxyAcrylic resin

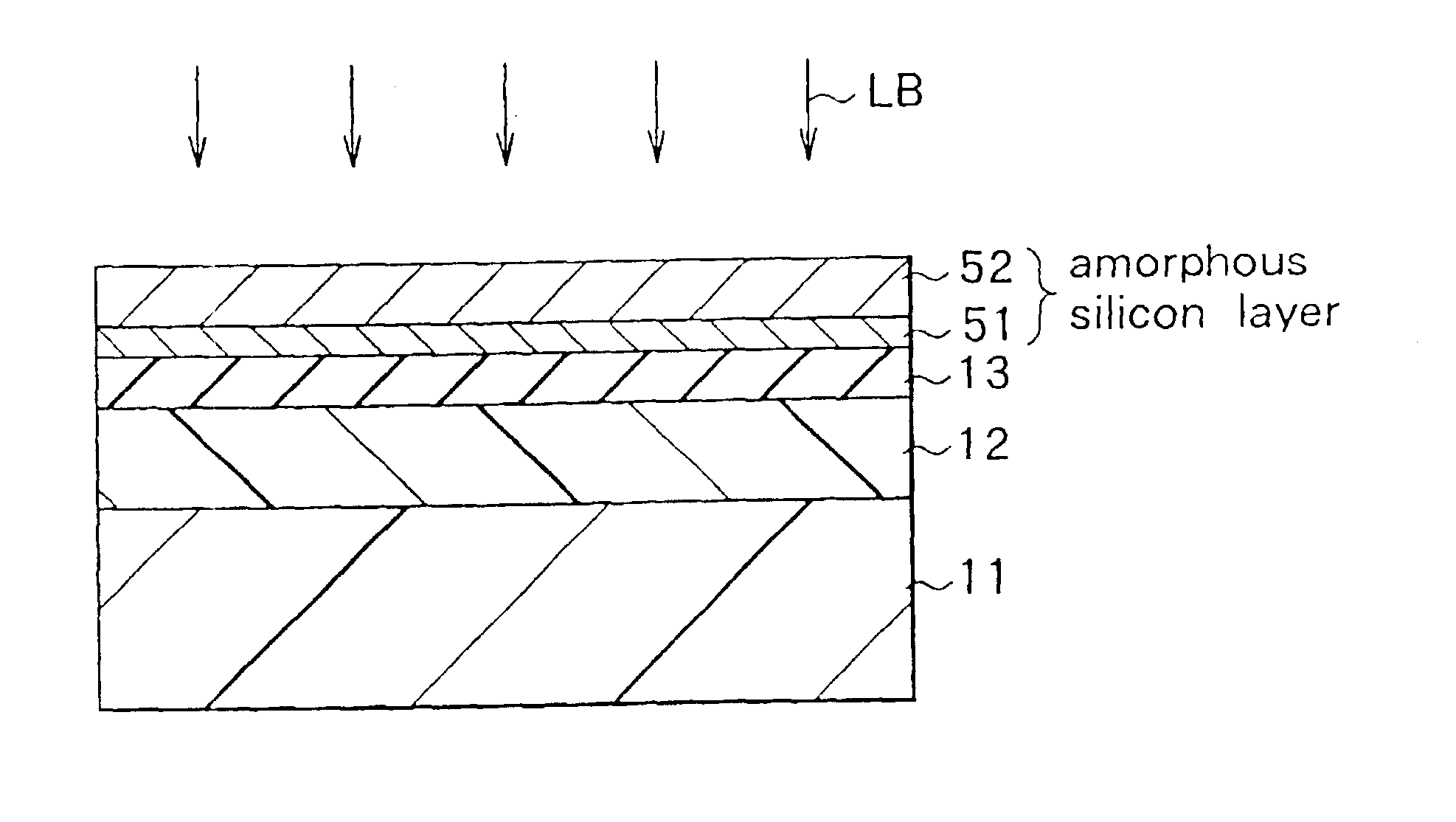

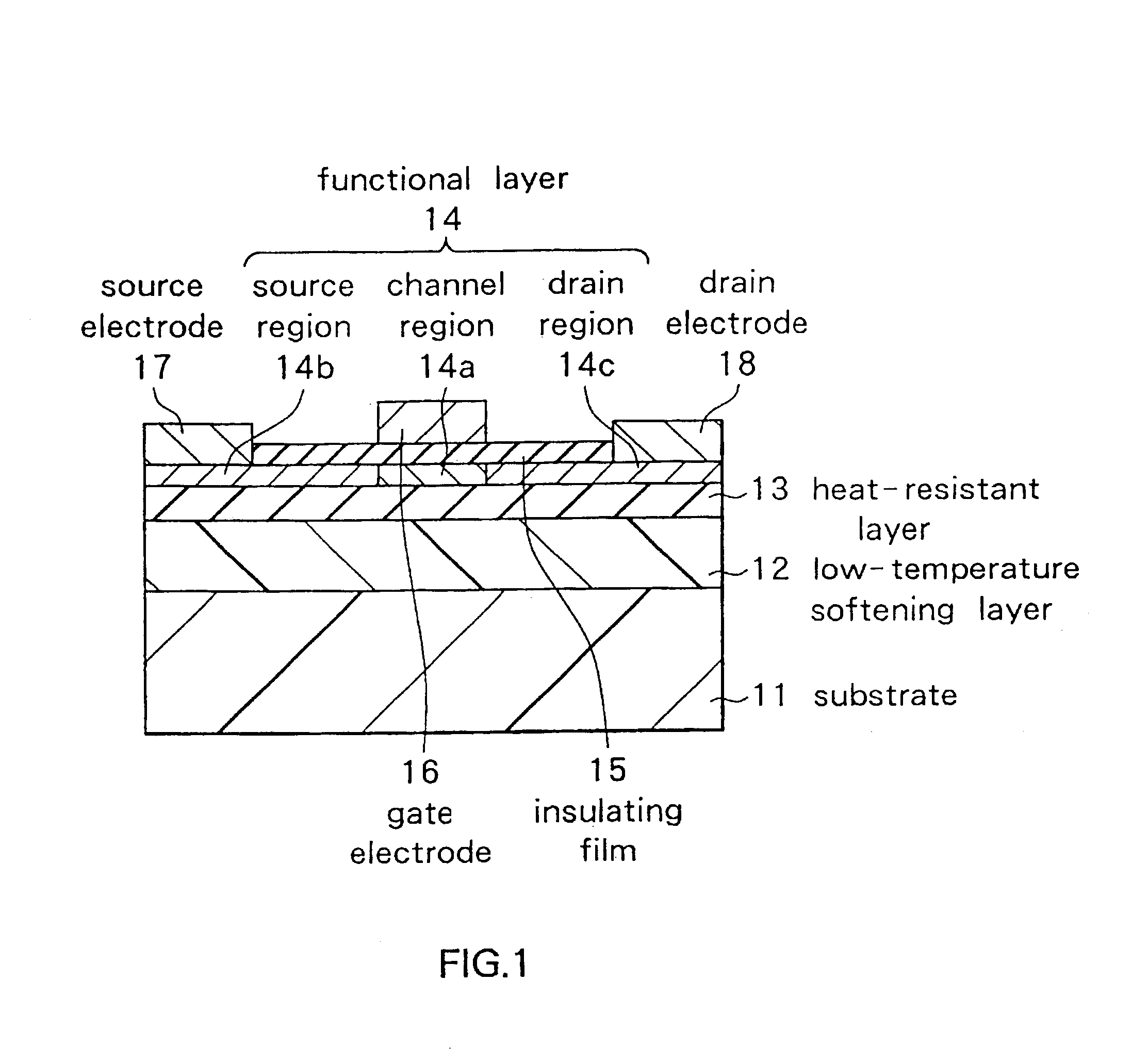

The invention provides a functional device having no cracks and capable of delivering good functional characteristics and a method of manufacturing the same. A functional layer (14) is formed by crystallizing an amorphous silicon layer as a precursor layer by laser beam irradiation. A laser beam irradiation conducts heat up to a substrate (11) to cause it to try to expand; a stress to be produced by the difference in thermal expansion coefficient between the substrate (11) and the functional layer (14) is shut off by an organic polymer layer (12) lower in thermal expansion coefficient than the substrate (11), thereby causing no cracks nor separations in the functional layer (14). The organic polymer layer (12) is preferably made of an acrylic resin, an epoxy resin, or a polymer material containing these that is deformed by an optical or thermal process to undergo a three-dimensional condensation polymerization, for higher compactness and hardness. Inserting a metal layer and an inorganic heat resistant layer between the substrate (11) and the functional layer (14) will permit a more powerful laser irradiation.

Owner:SONY CORP

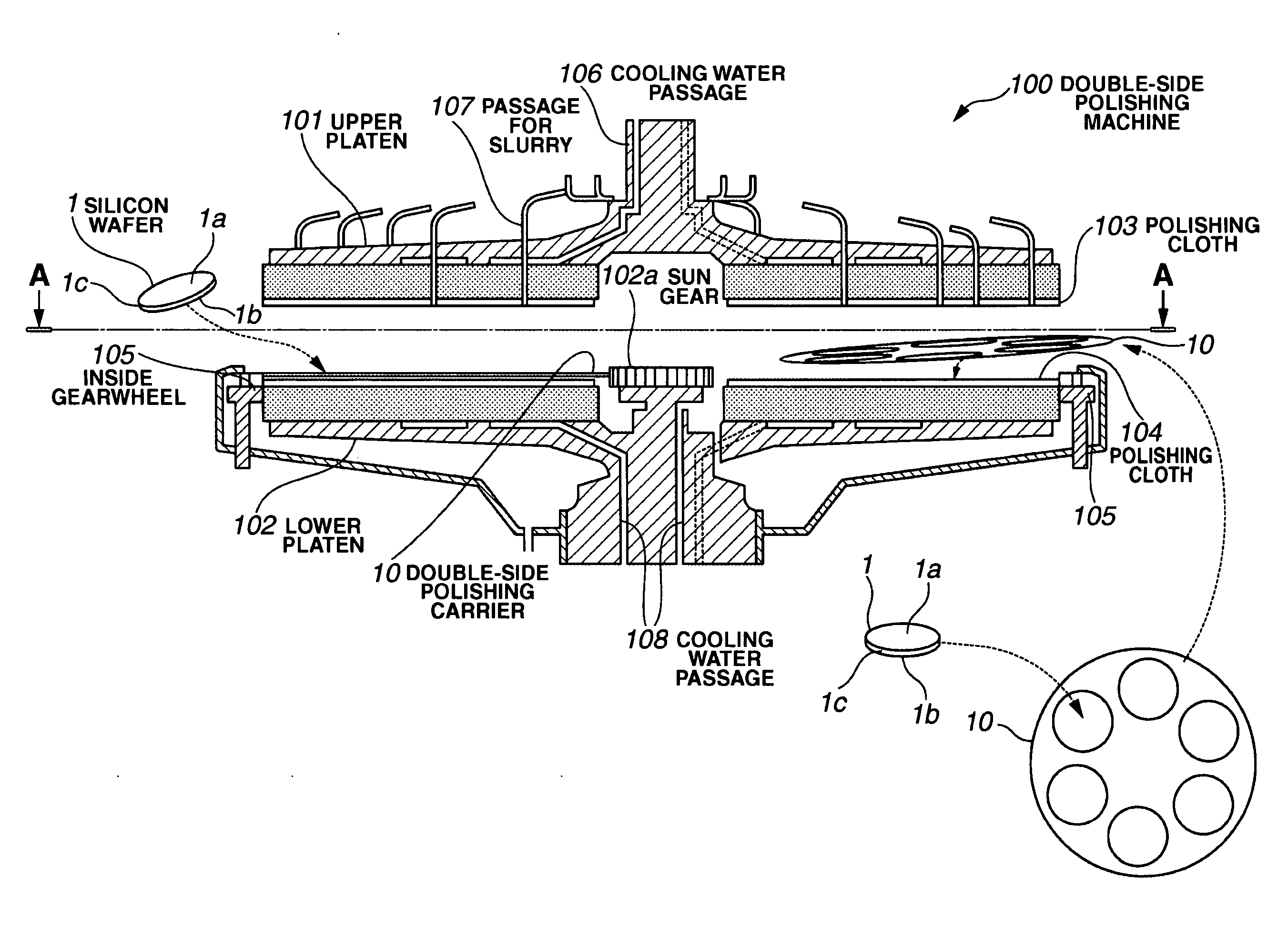

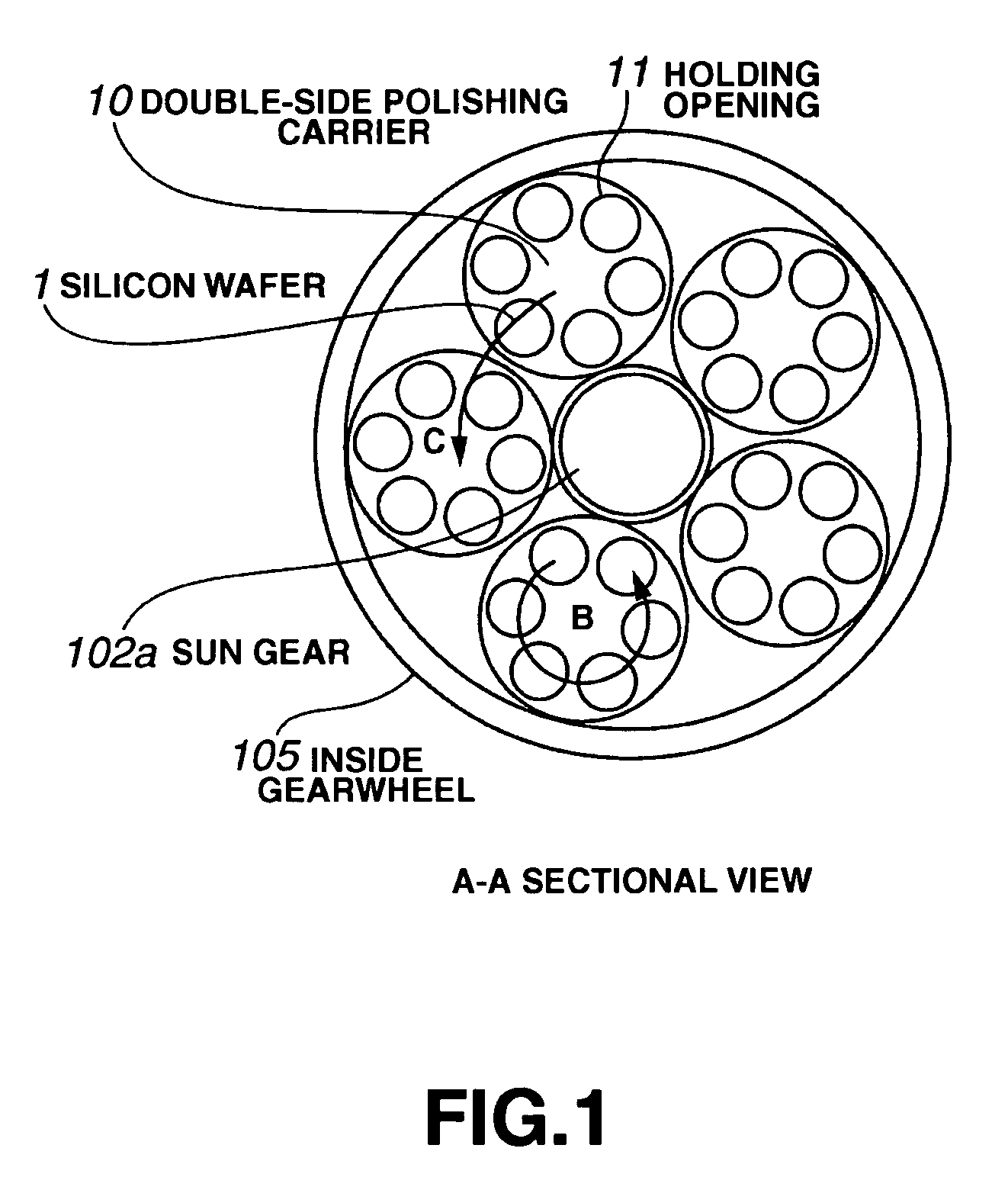

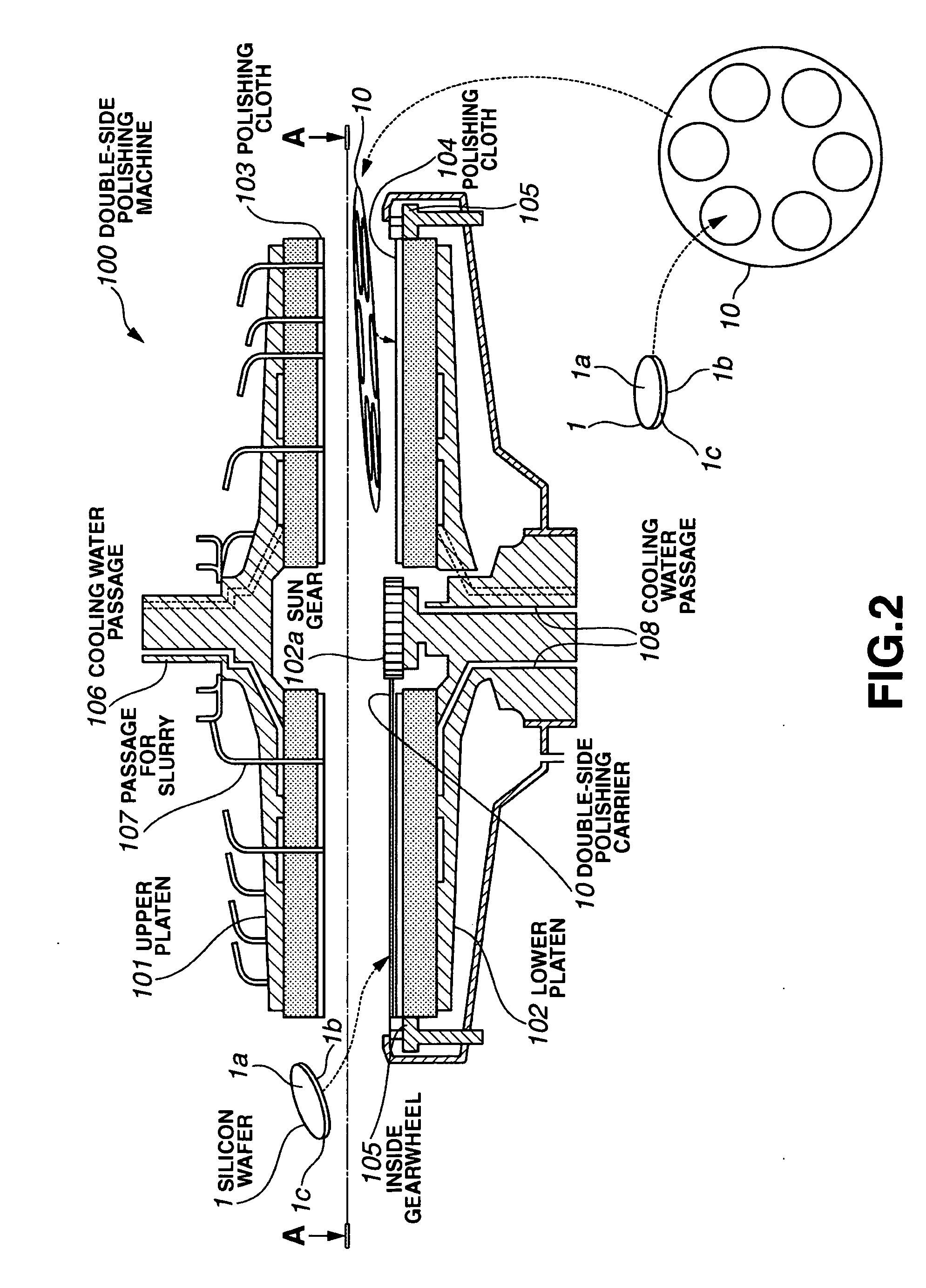

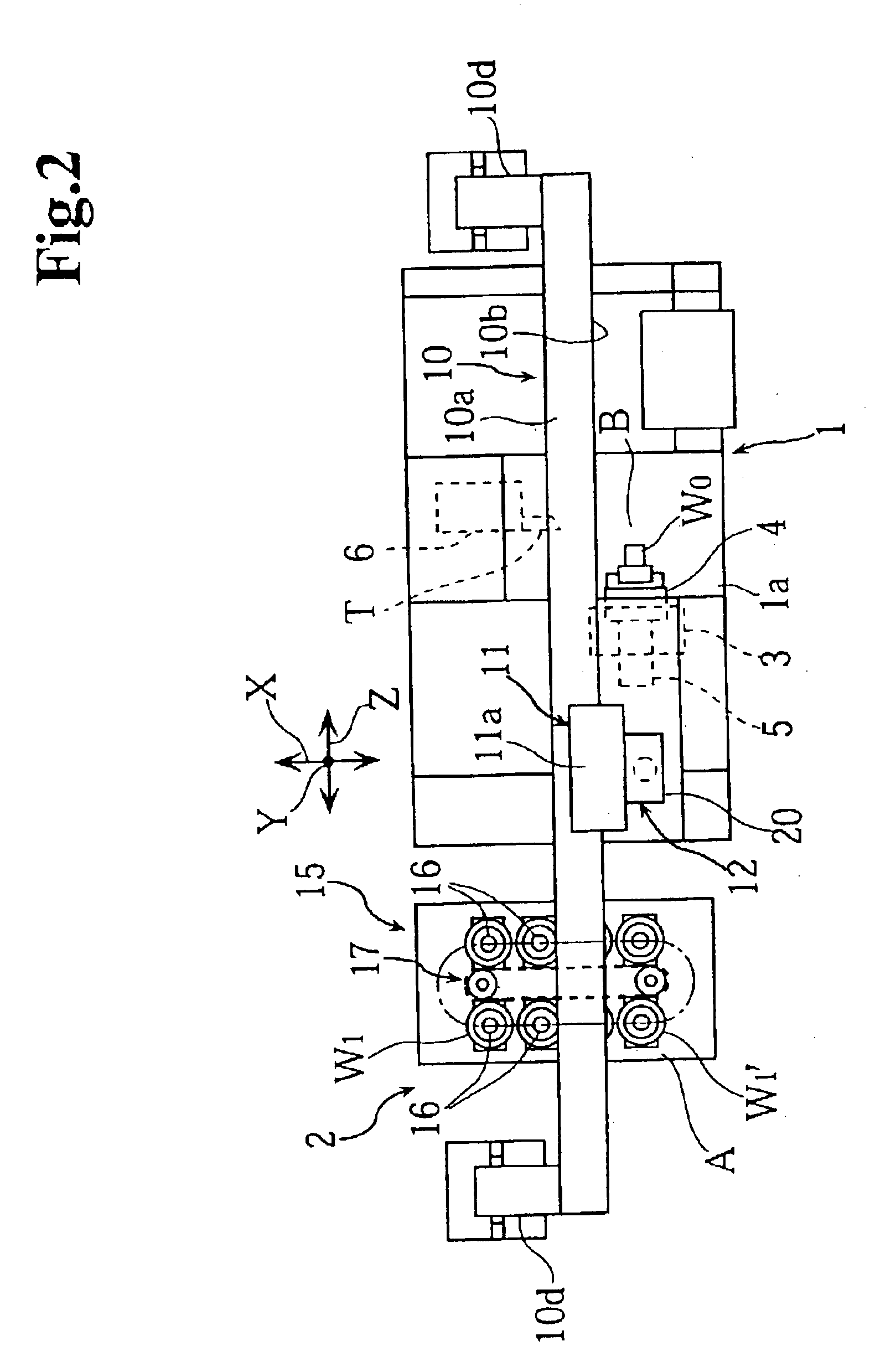

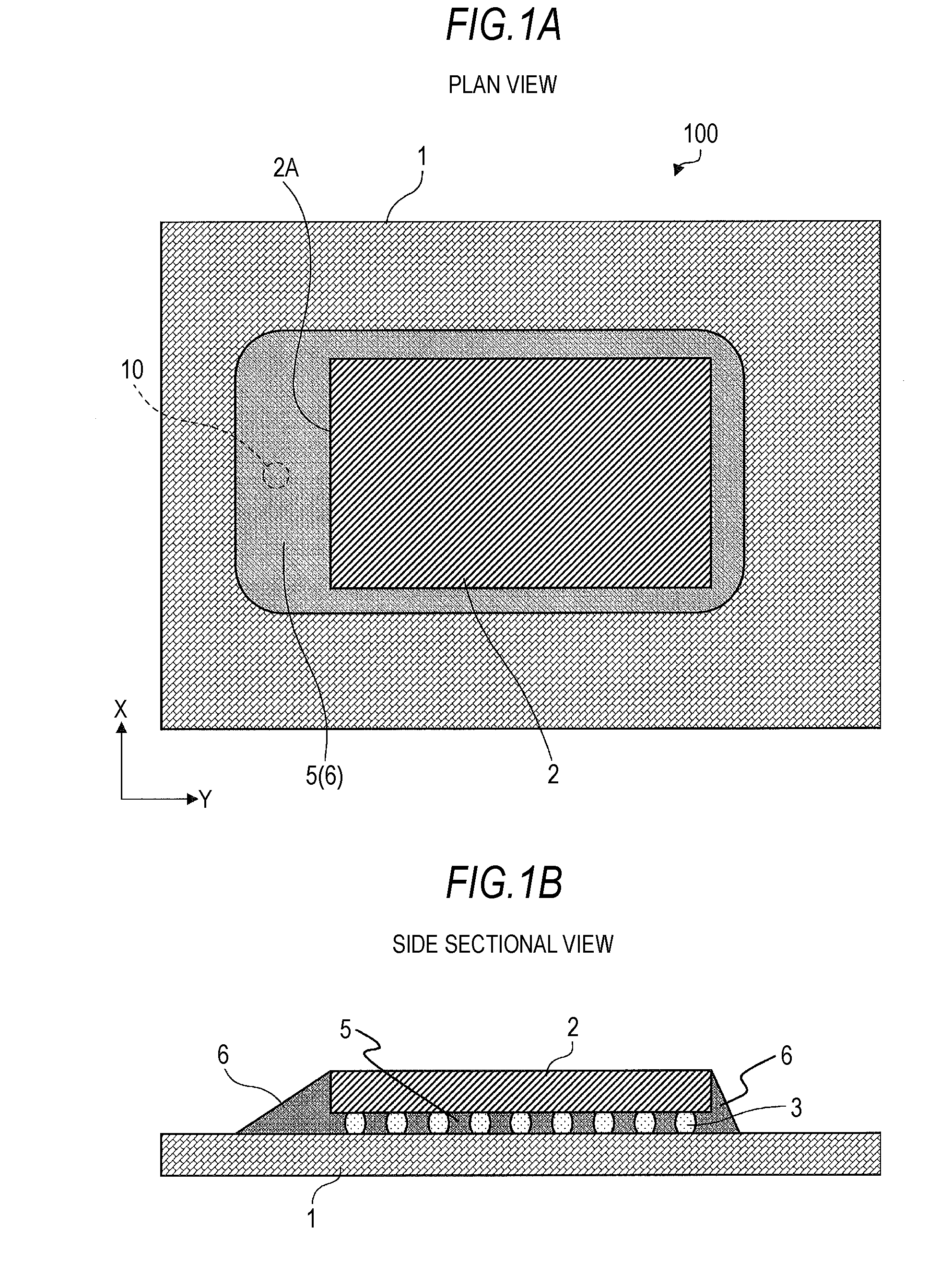

Double-side polishing carrier and fabrication method thereof

InactiveUS20070184662A1Efficient preparationIncrease production costDecorative surface effectsSemiconductor/solid-state device manufacturingDiamond-like carbonSurface roughness

The carrier (10) for double-side polishing has a base material 10a the material of which is stainless steel (SUS) , for example, as is before, and the base material 10a is coated with a coating layer 10b of a material having a hardness higher than that of the base material 10a. The coating layer 10b is desirably coated uniformly without variations in thickness and not warped easily, and the material for the coating layer 10b of the double-side polishing carrier 10 is desirably any one selected from diamond-like carbon, a nitride film, a sapphire film and a titanium nitride film. For production of the double-side polishing carrier 10, a double-side polishing carrier 10′ having been used for polishing is prepared first. The used carrier 10′ is coated with the coating layer 10b. The invention can suppress the progress of abrasion of the double-side polishing carrier, and can provide satisfactory thickness accuracy, film thickness distribution accuracy, and surface roughness.

Owner:SUMCO TECHXIV

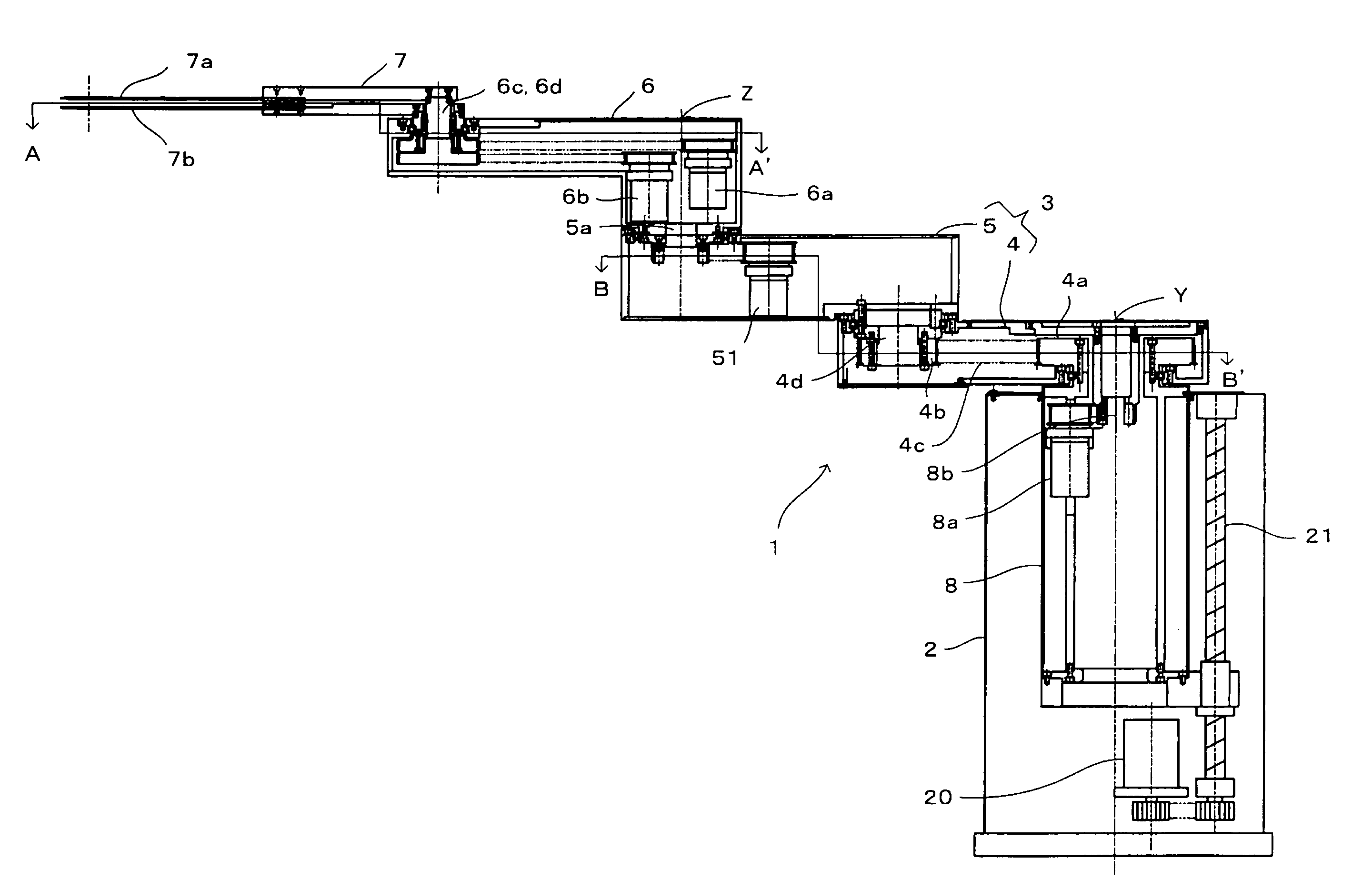

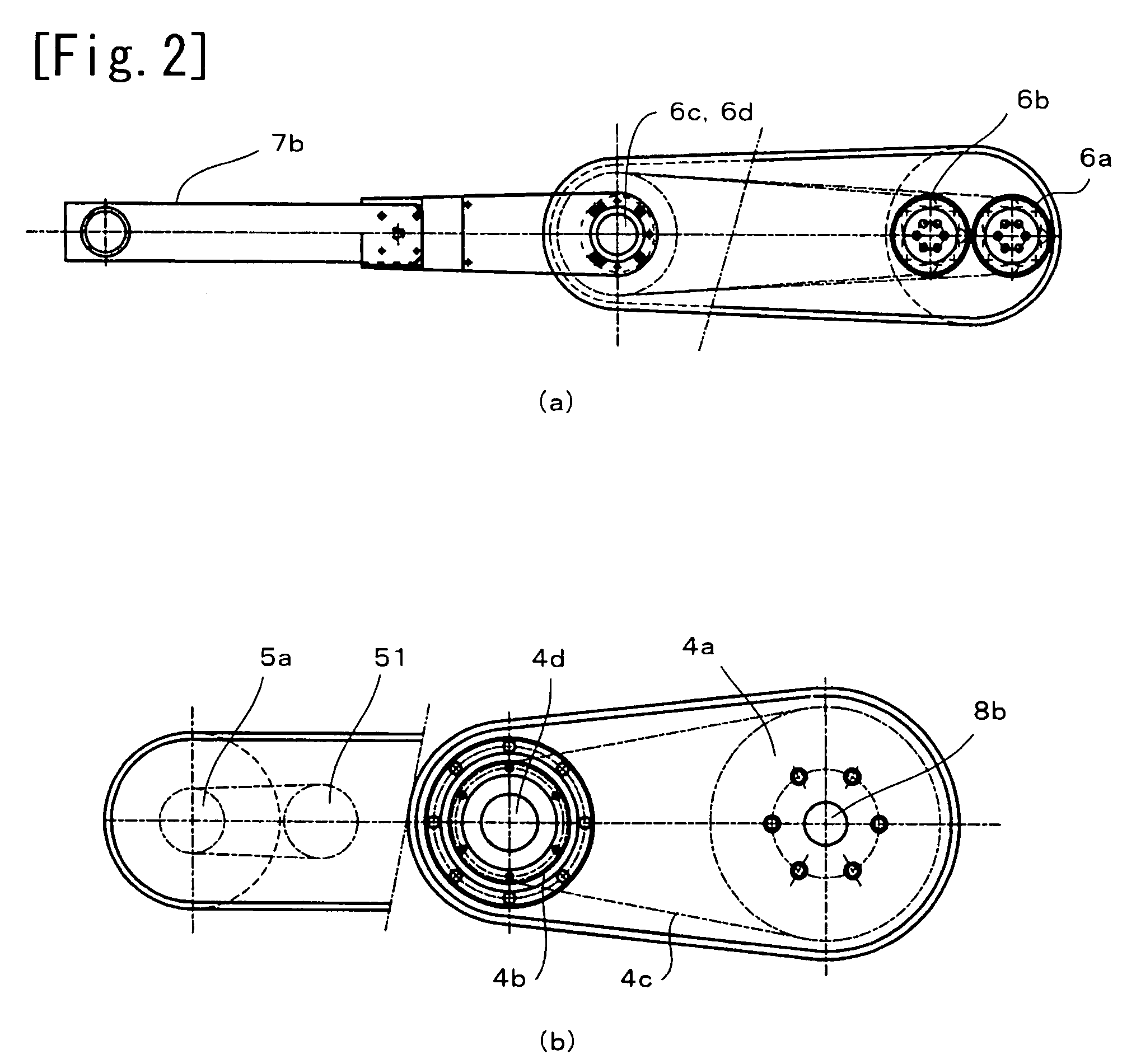

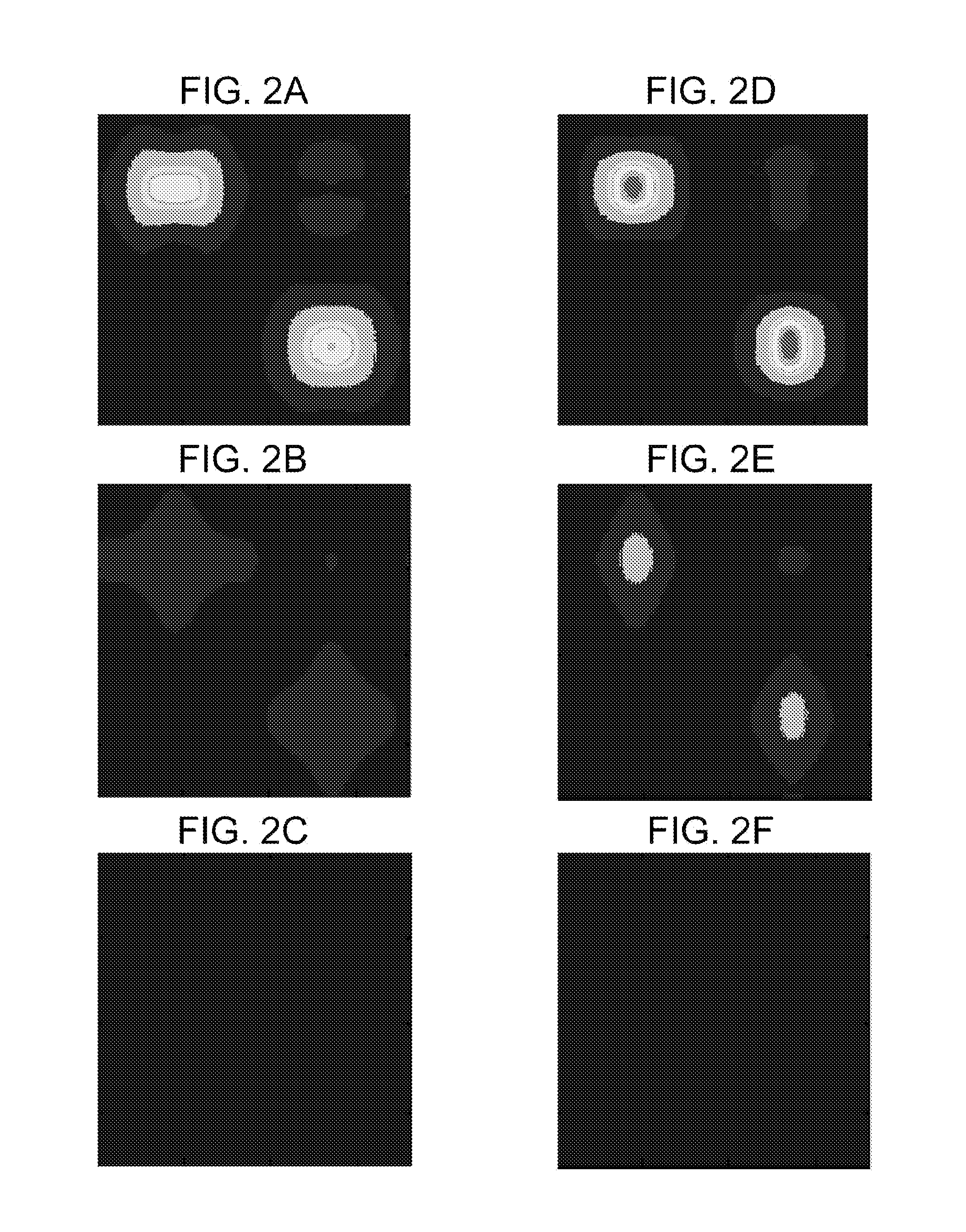

Articulated robot

ActiveUS8136422B2Stable to carryReduce distanceProgramme-controlled manipulatorMechanical apparatusEngineeringMechanical engineering

A multi-joint robot for loading / unloading a work into / from a cassette, which includes a hand part holding the work, an arm part rotatably holding the hand part, a link mechanism rotatably holding the base end side of the arm part and moving so that the moving route of the base end side of the arm part becomes linear in a direction roughly orthogonal to a direction for loading / unloading the work, and a driving device for moving the tip side of the arm part so as to linearly interpolate it in a direction for loading / unloading the work according to the movement of the link mechanism.

Owner:SANKYO SEIKI MFG CO LTD

Nickel powder, conductive paste, and multilayer electronic component using same

ActiveUS20070125195A1Reduced activitySmall sizeStacked capacitorsMetal-working apparatusConductive pasteResidual carbon

A nickel powder with a mean particle size of 0.05 to 1.0 μm, the nickel powder comprising a thin oxidized layer of nickel on a surface thereof and having an oxygen content of 0.3 to 3.0 wt. % and a carbon content of 100 ppm or less per specific surface area of 1 m2 / g of the powder, in a weight proportion of carbon to the nickel powder of unit weight. When the powder is used for a conductive paste for forming inner electrode layers of a multilayer electronic component, it enables the decrease in the residual carbon amount after a binder removal process, thereby making it possible to obtain a multilayer ceramic electronic component with excellent electric characteristics and high reliability in which electrode layers excelling in continuity are formed without decreasing the strength and electric characteristics of the electronic component or creating structural defects.

Owner:SHOEI CHEM IND CO LTD

Fabrication method of nitride-based semiconductor device

ActiveUS20080182384A1Avoid crackingImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesNitrideSemiconductor

A fabrication method of a nitride-based semiconductor device includes the steps of forming a stacked structure constituted of a nitride-based semiconductor on a support substrate, depositing a first bonding metal on the stacked structure, depositing a second bonding metal on a retention substrate, bonding the first bonding metal and the second bonding metal in a state where the first bonding metal and the second bonding metal face each other to unite the retention substrate and the stacked structure, wherein the first bonding metal and the second bonding metal constitute the bonding metal, and separating the support substrate from the stacked structure for removal. The area of the surface of the retention substrate is set smaller than the area of the surface of the support substrate. Accordingly, cracking, fracture, chipping, and the like at the retention substrate can be prevented.

Owner:SHARP FUKUYAMA LASER CO LTD

Process for producing acrolein and acrylic acid

InactiveUS6781013B2High selectivityAvoid accumulationOrganic compound preparationOrganic chemistry methodsAlkaline earth metalGas phase

A process is provided which can effectively inhibit occurrence of hot spots in reaction zones or heat accumulation at the hot spots, in the occasion of producing acrolein and acrylic acid through vapor phase oxidation of propylene in the presence of a catalyst using a fixed bed shell-and-tube reactor, said catalyst having a composition represented by a general formula (1):(wherein A is at least an element selected from Co and Ni; B is at least an element selected from P, Te, As, B, Sb, Sn, Ce, Nb, Pb, Cr, Mn and Zn; C is alkali metal element; D is alkaline earth metal element; E is at least an element selected from Si, Al, Ti and Zr; and O is oxygen; a, b, c, d, e, f, g, h, i and x denote the atomic numbers of Mo, W, Bi, Fe, A, B, C, D, E and O, respectively, and where a is 12, b is 0-5, c is 0.1-10, d is 0.1-10, e is 1-20, fis 0-5, g is 0.001-3, h is 0-3, i is 0-30, and x is a numerical value which is determined depending on the extent of oxidation of each of the elements).Said process is characterized by preparing plural kinds of catalysts having the above composition but differing from each other in (alpha) occupying volume, (beta) calcining temperature and / or (gamma) kind and / or amount of alkali metal element, and filling the reaction zones provided by dividing the catalyst layer in each of the reaction tubes in the reactor into at least two layers in the axial direction of the tube, sequentially with said plural kinds of catalysts in such a manner that the catalytic activity increases from the starting gas inlet side toward the outlet side.

Owner:NIPPON SHOKUBAI CO LTD

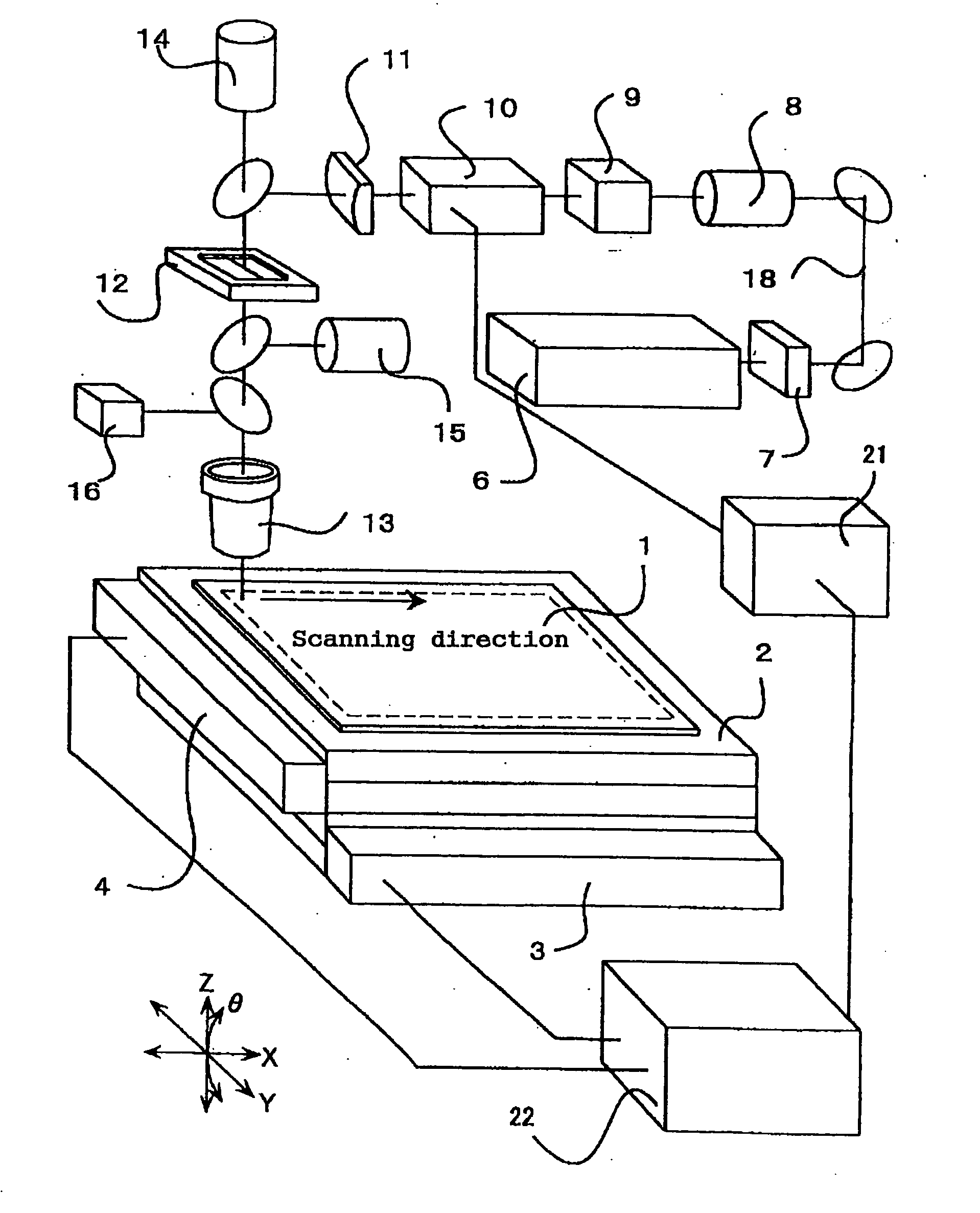

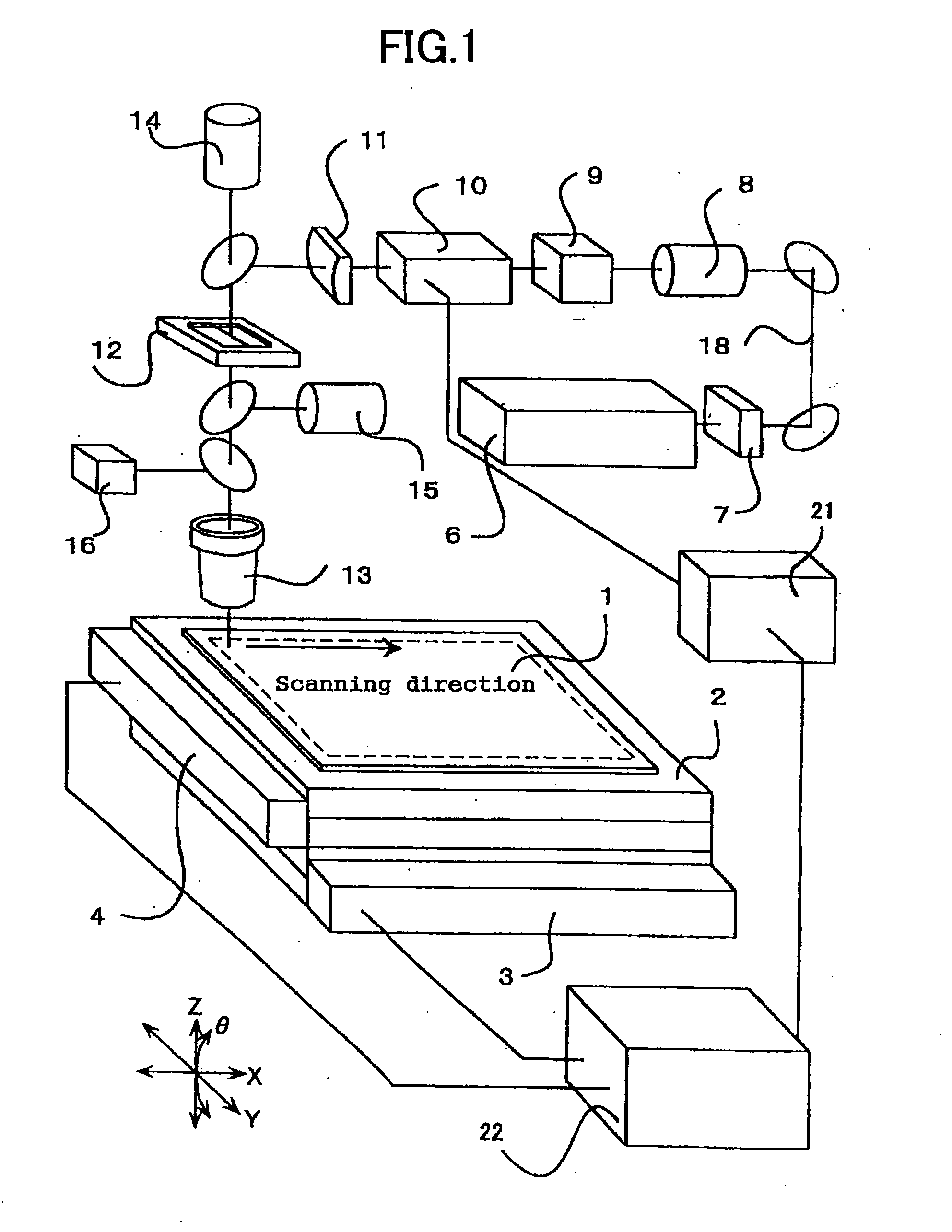

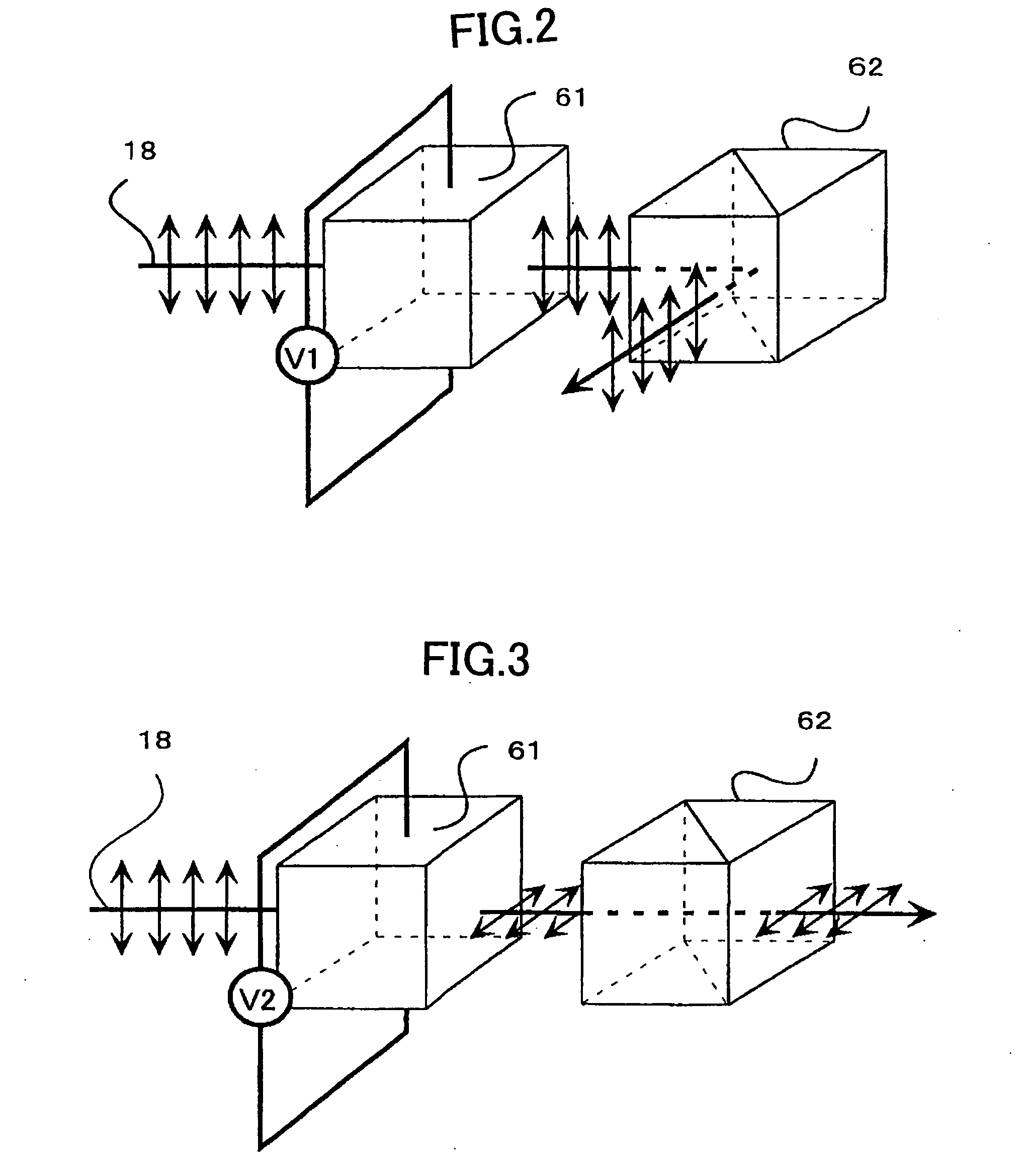

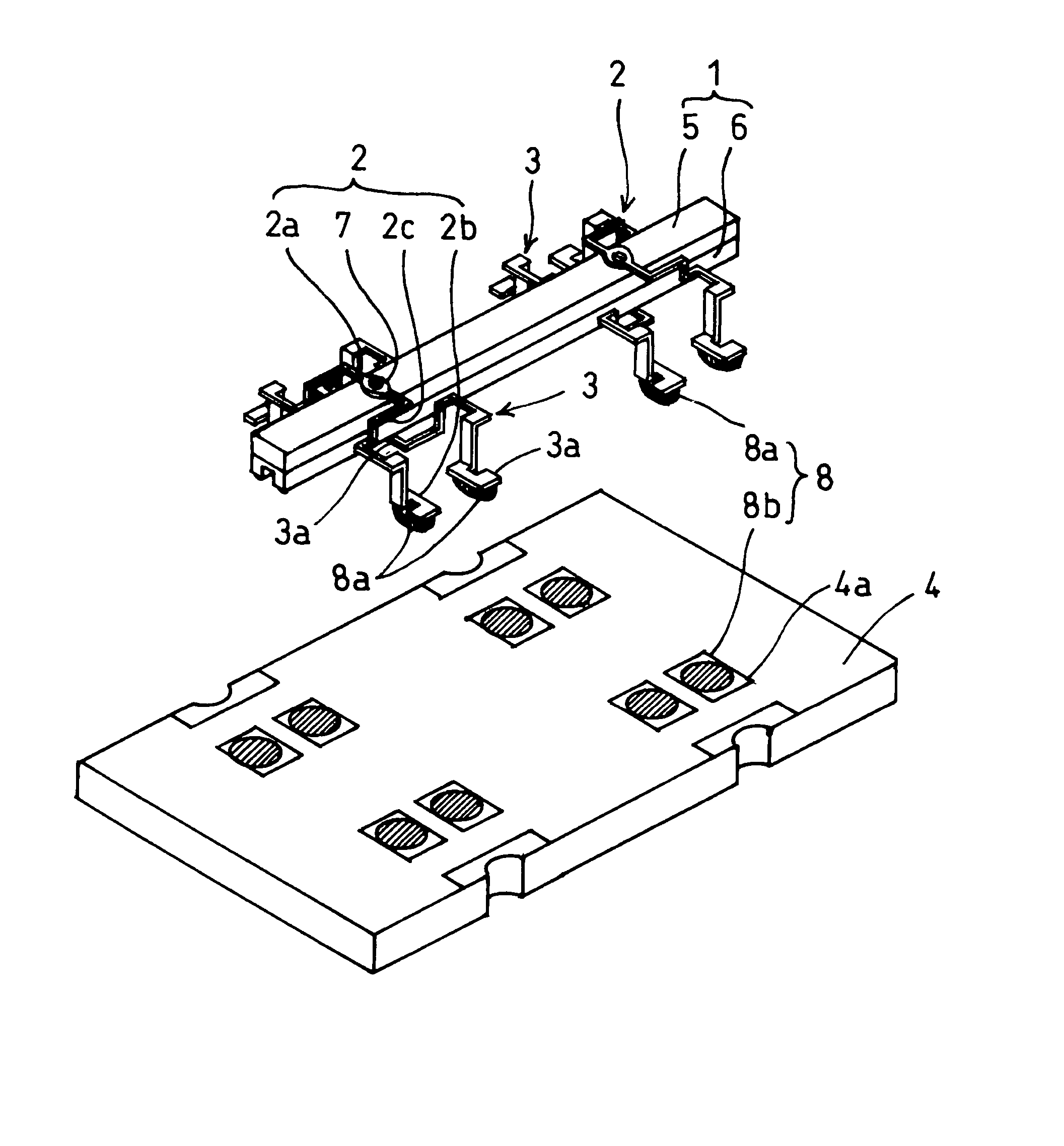

Apparatus for fabricating a display device

InactiveUS20070041410A1Avoid heat damageInhibit aggregationTransistorLaser detailsDisplay deviceLight beam

Apparatus for fabricating a display device includes a stage capable of mounting an insulating substrate of the display device and moving the insulating substrate, linear scales which detect a position or moving distance of the substrate, a laser oscillator which generates continuous-waves laser light, a modulator which turns ON / OFF the continuous-wave laser light, a beam forming optic which shapes the continuous-wave laser light passing through the modulator into a linear or rectangular form, an objective lens which projects the at least one of the laser light on the insulating substrate so as to irradiate the insulating substrate with the laser light. The controller counts signals generated by the linear scales for every movement of the stage for a given distance, causes the modulator to turn the generated continuous-wave laser light in an ON state at time when a position of the insulating substrate on which the laser light irradiation is to be started reaches an area on which the laser light is projected, and causes the modulator to turn the generated continuous-wave laser light in an OFF state at another time.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

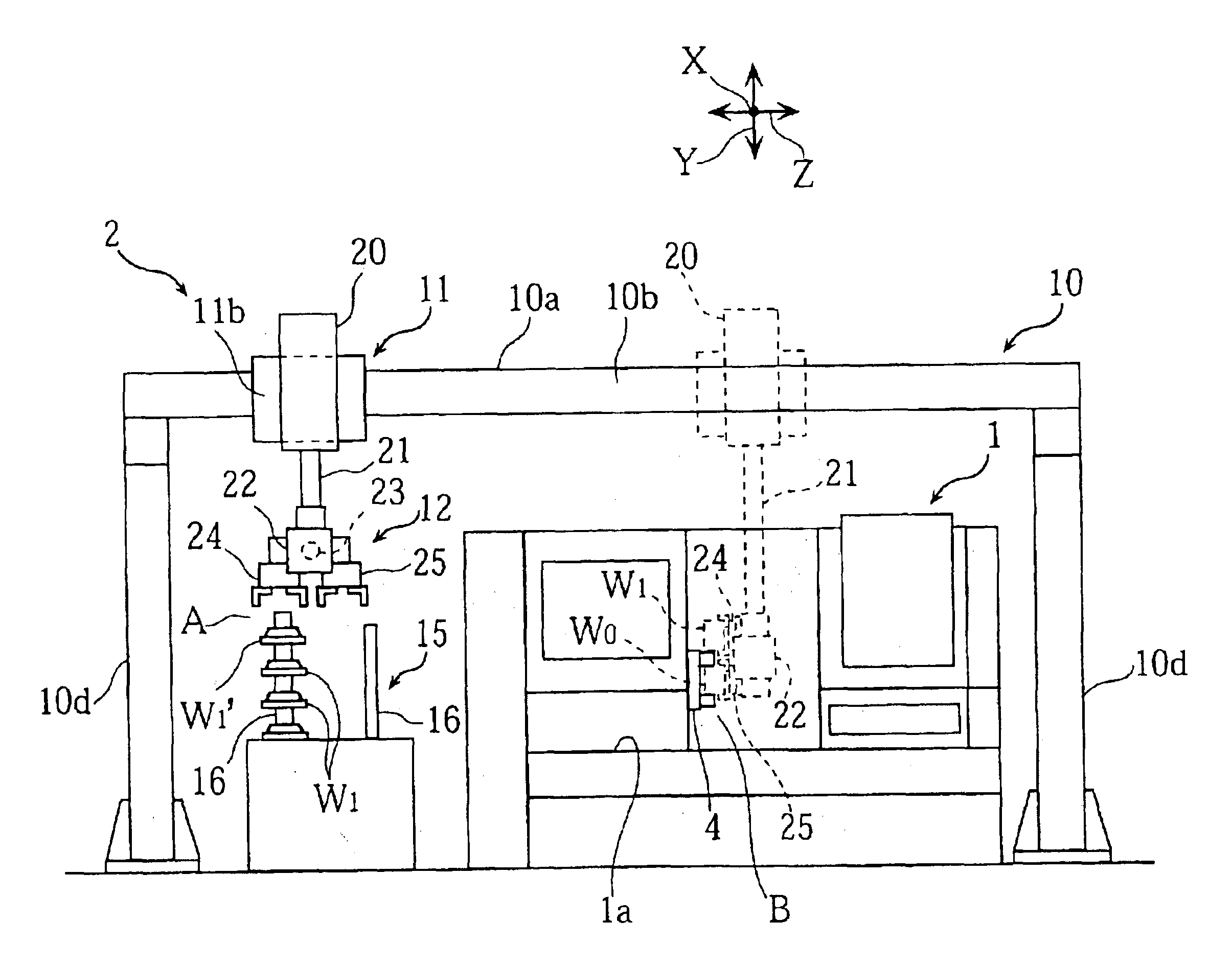

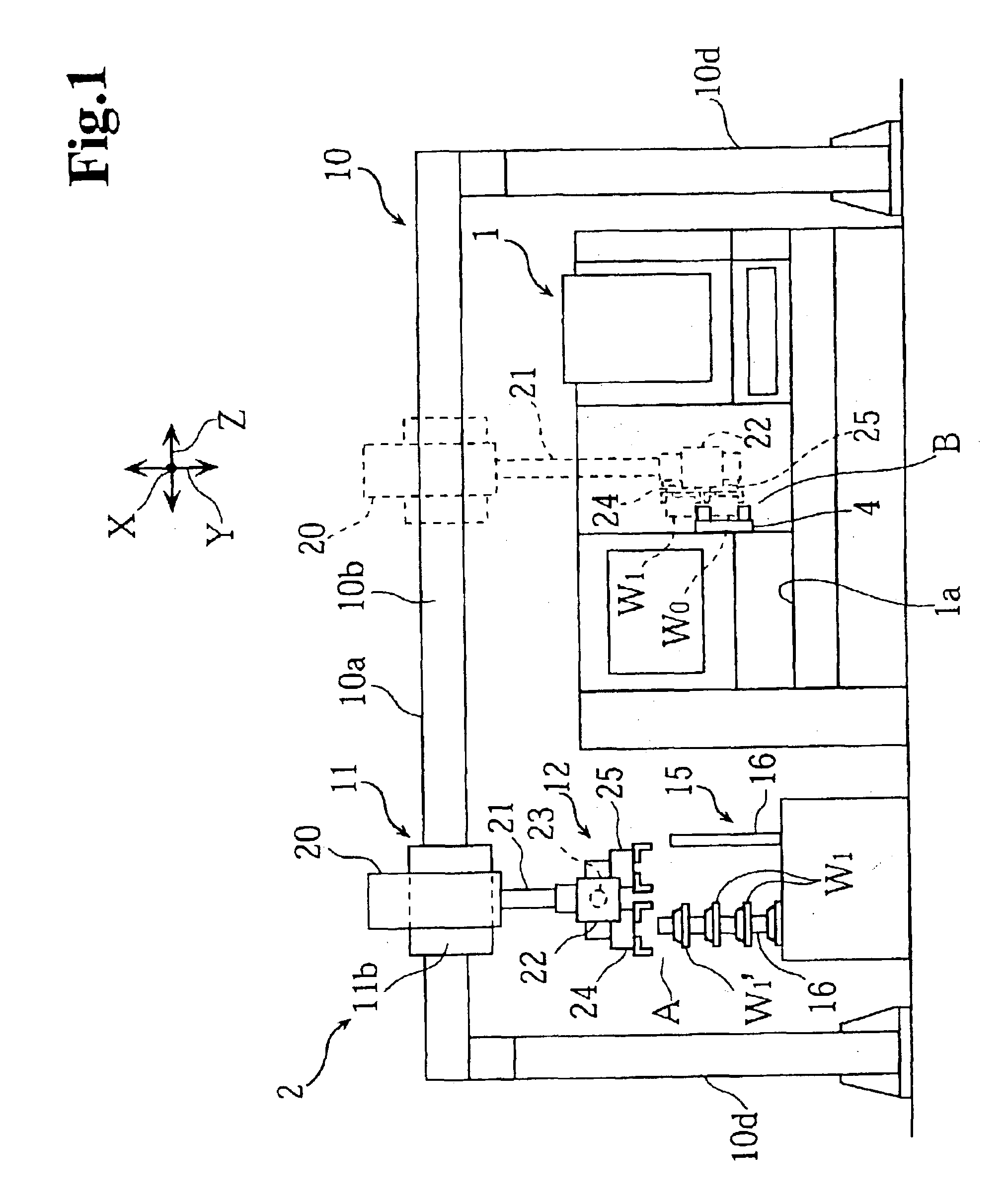

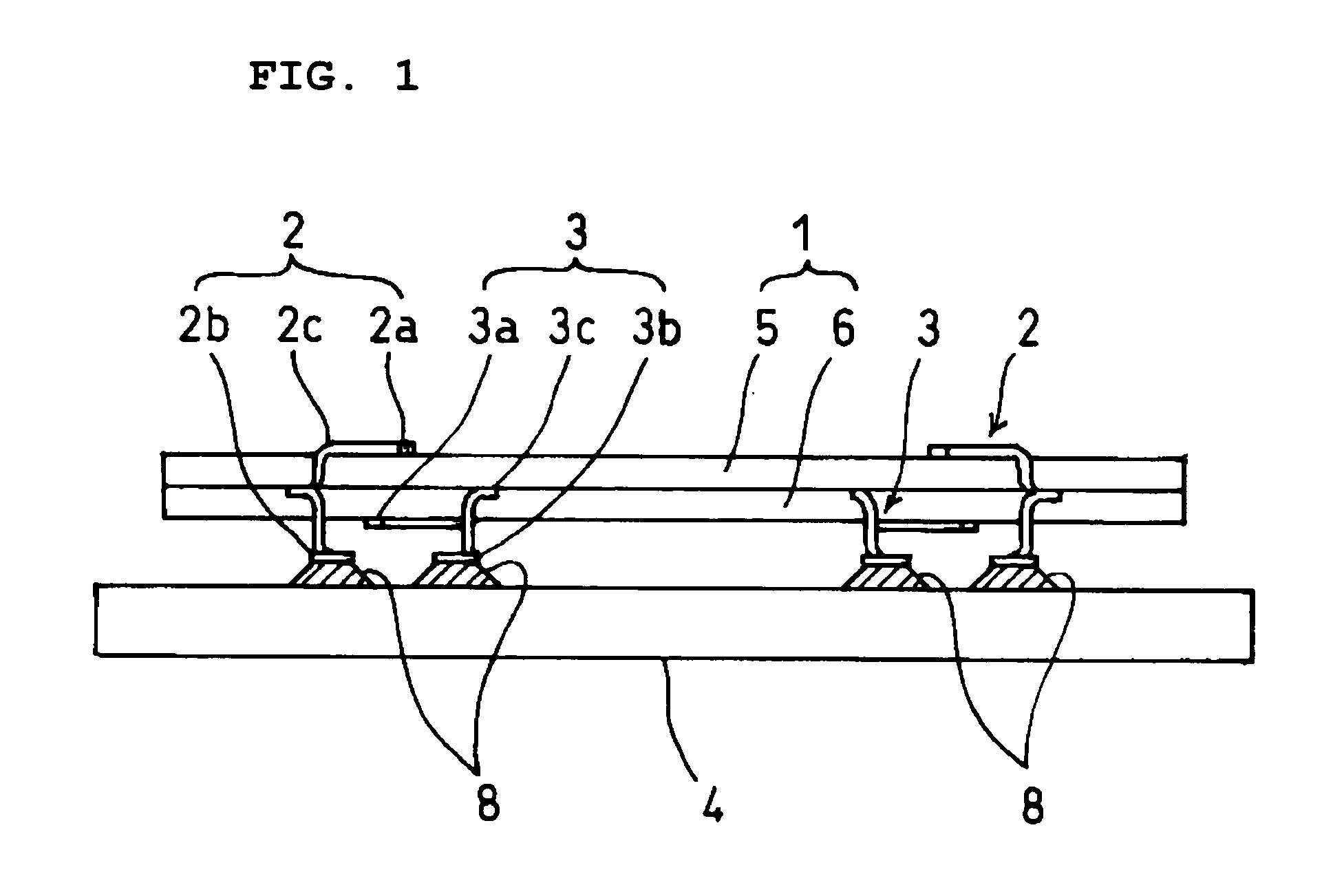

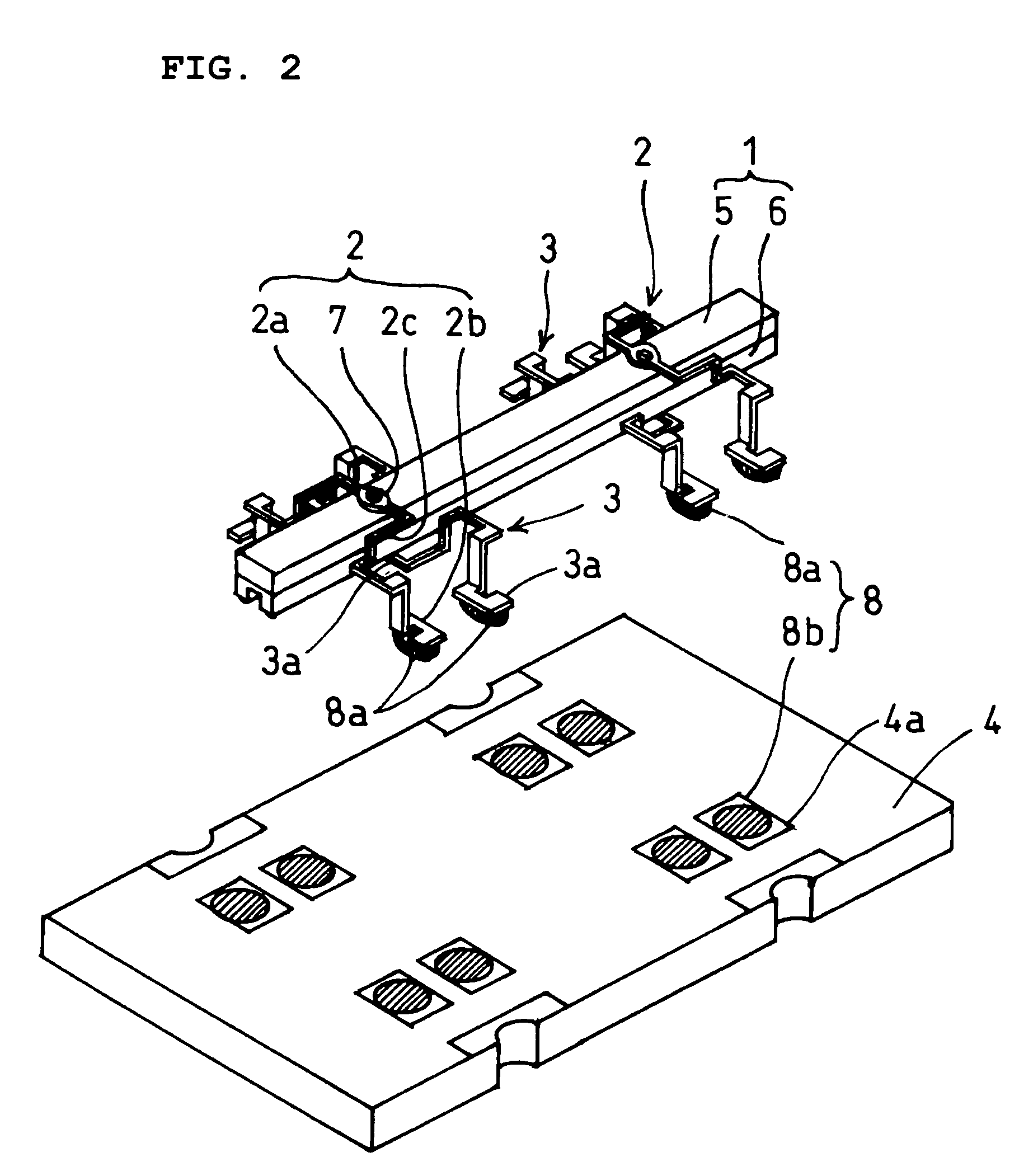

Workpiece transfer device for machine tools

A workpiece transfer device for machine tools that easily achieves positional adjustment of the rack while suppressing increases in cost and therefore preventing occurrences of vibrations and noise is disclosed. The workpiece transfer device includes a frame member having a rectangular cross-section. The device extends from a workpiece machining position to a workpiece loading / unloading position. A support member is hung on the frame member so as to be movable via a linear guide and which has a workpiece holding mechanism mounted thereon. A drive mechanism for rotationally driving a pinion gear engaged with a rack is provided on the frame member so as to be parallel to the linear guide so that the support member is moved between the two positions. The linear guide is disposed on one wall of the frame member and the rack is disposed on another wall surface so as to have its position adjustable.

Owner:DMG MORI CO LTD

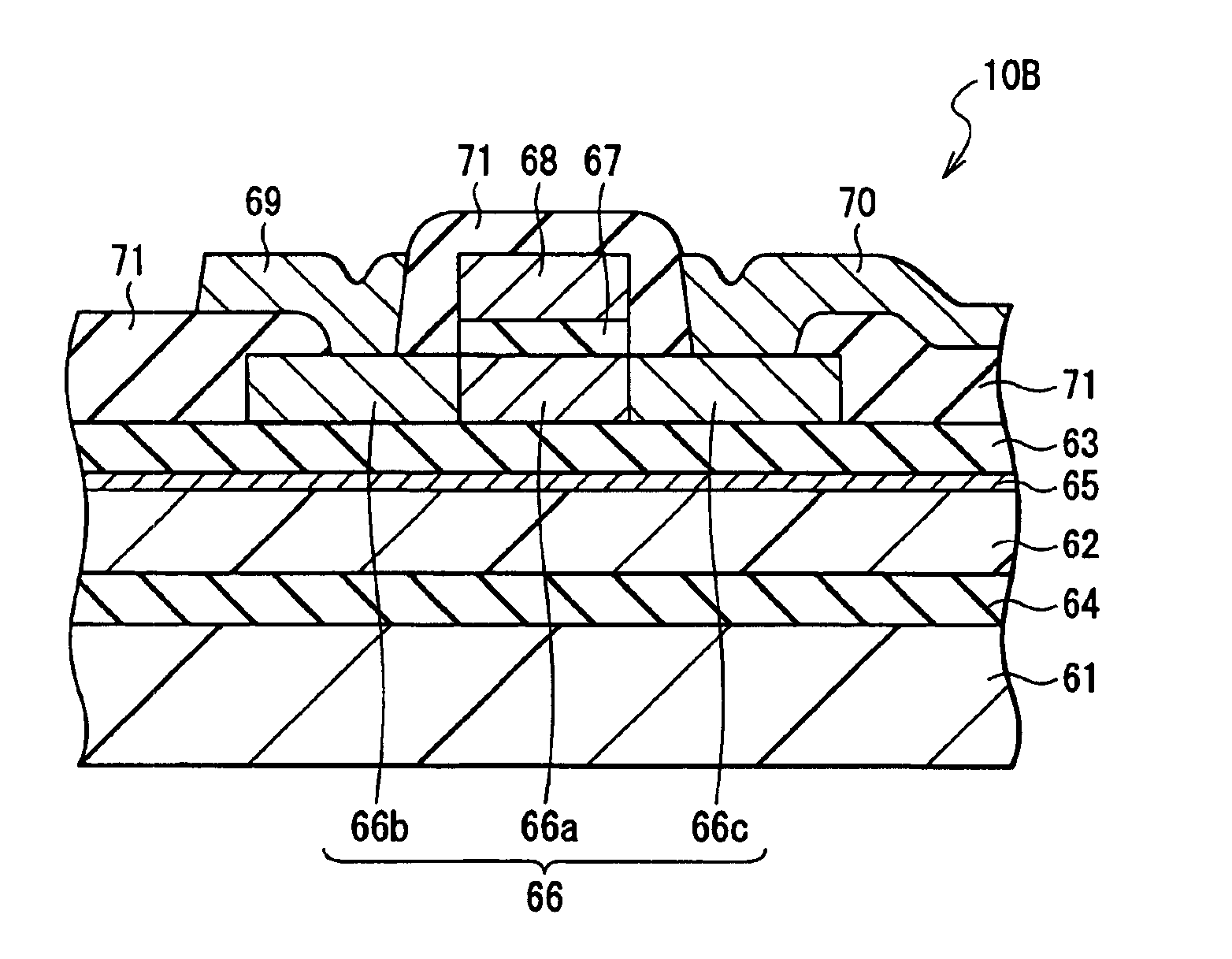

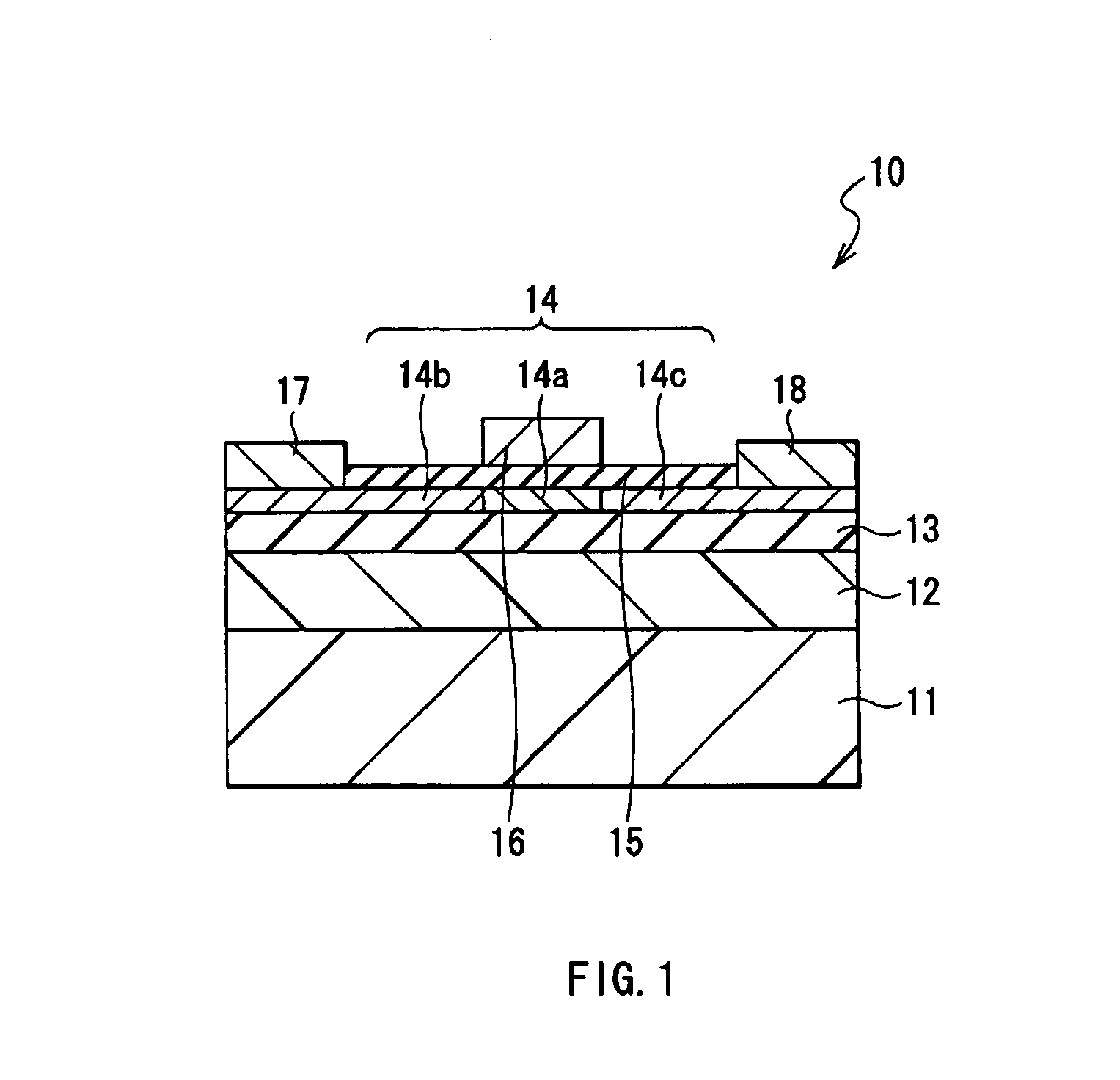

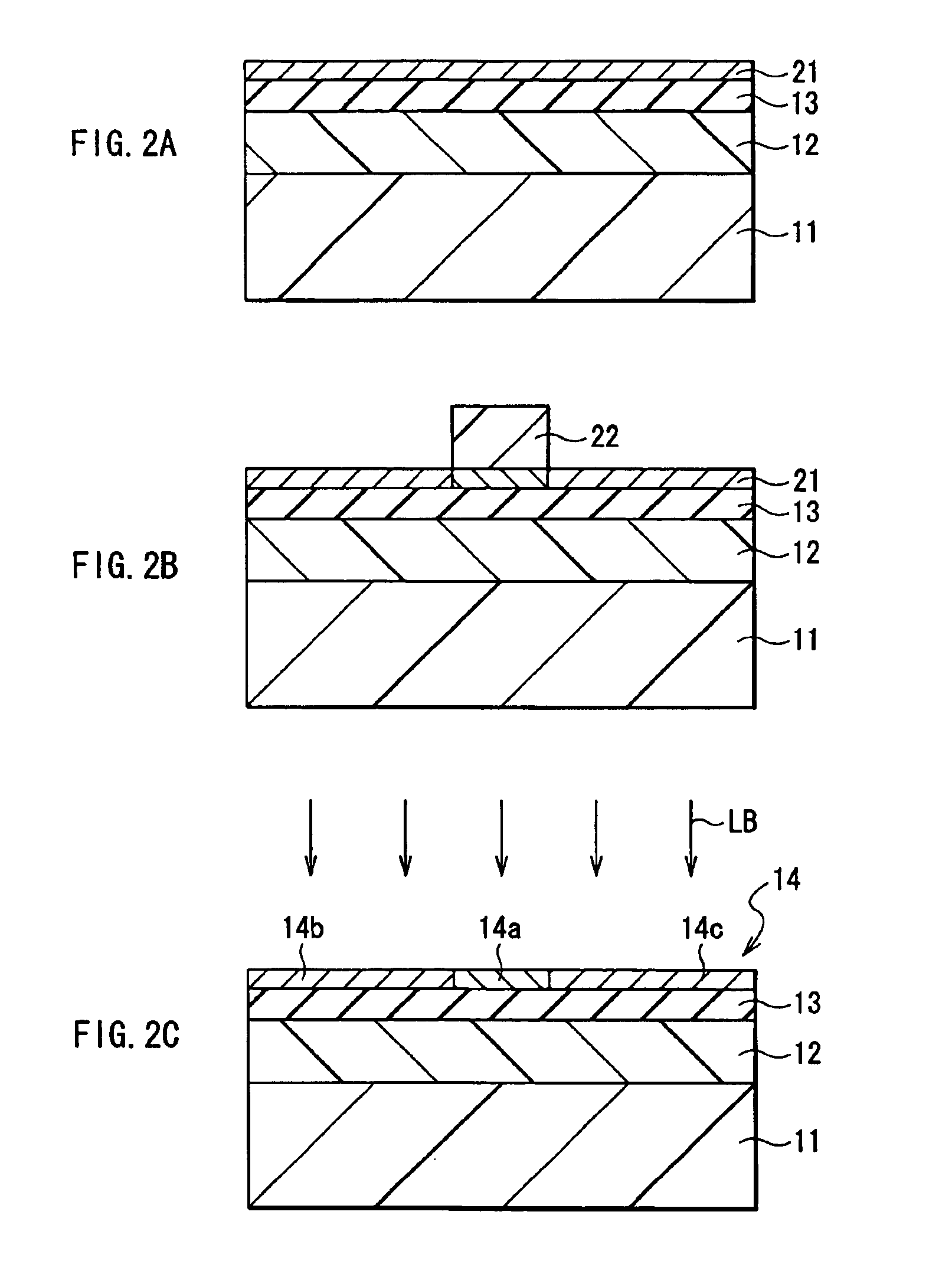

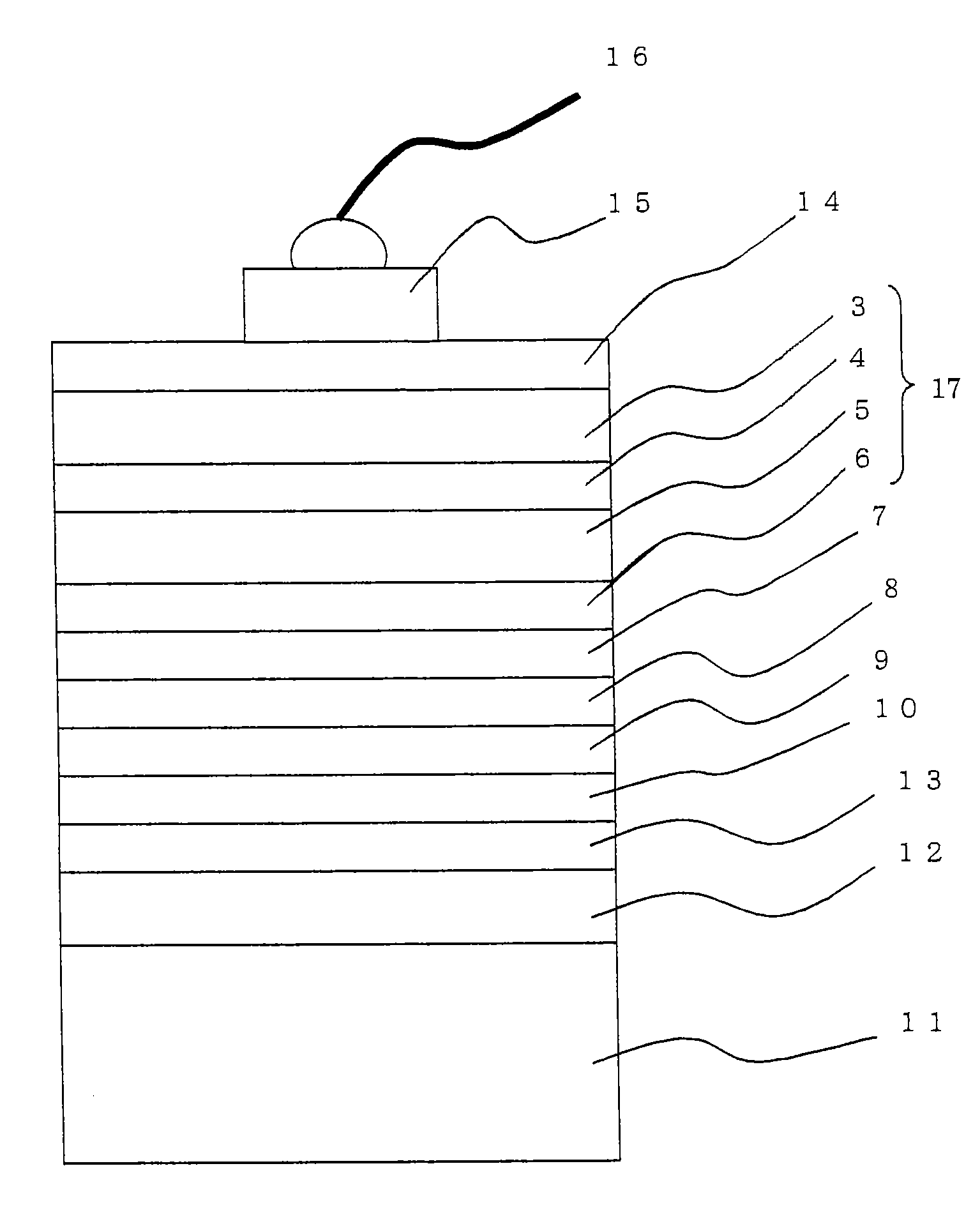

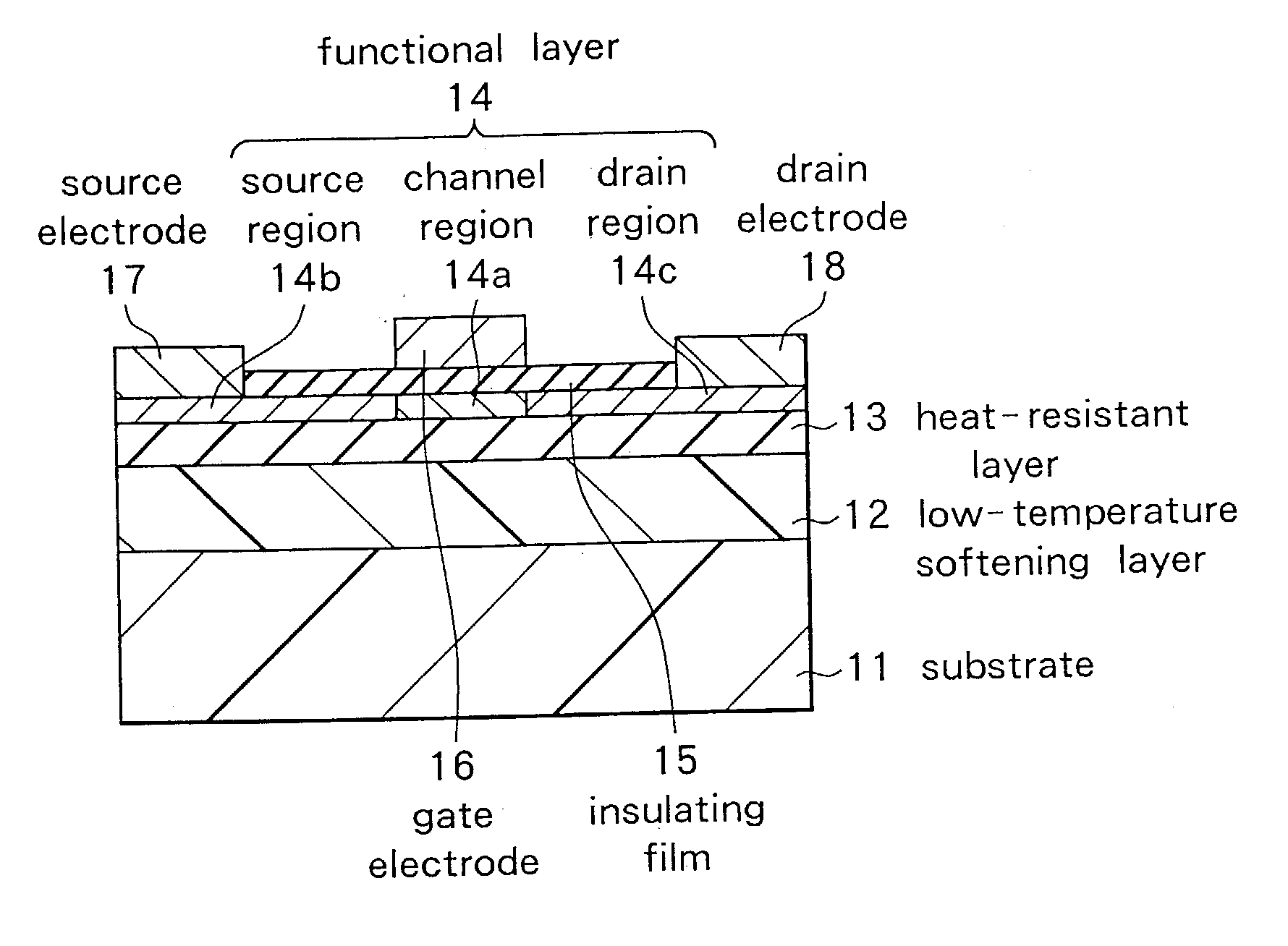

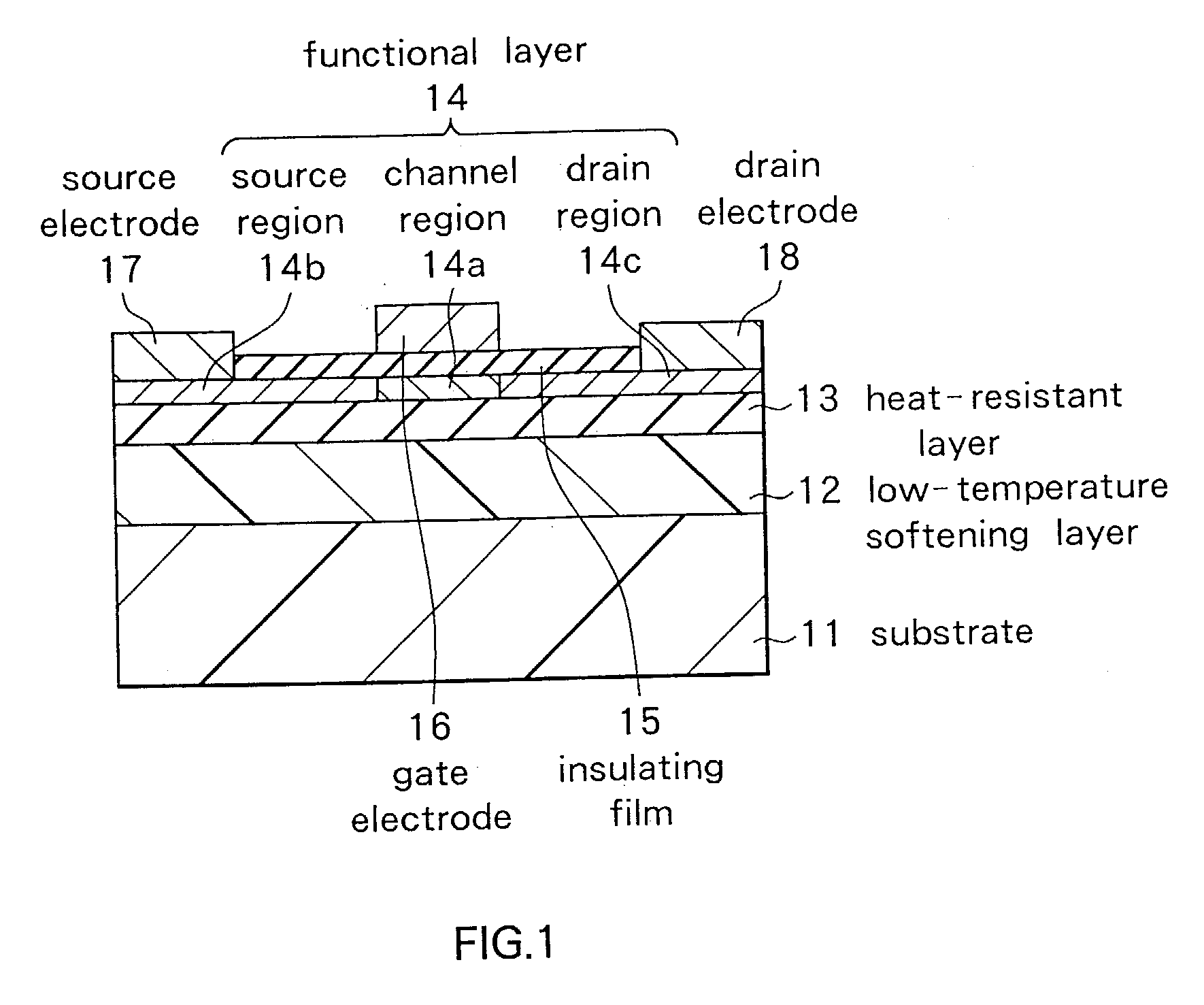

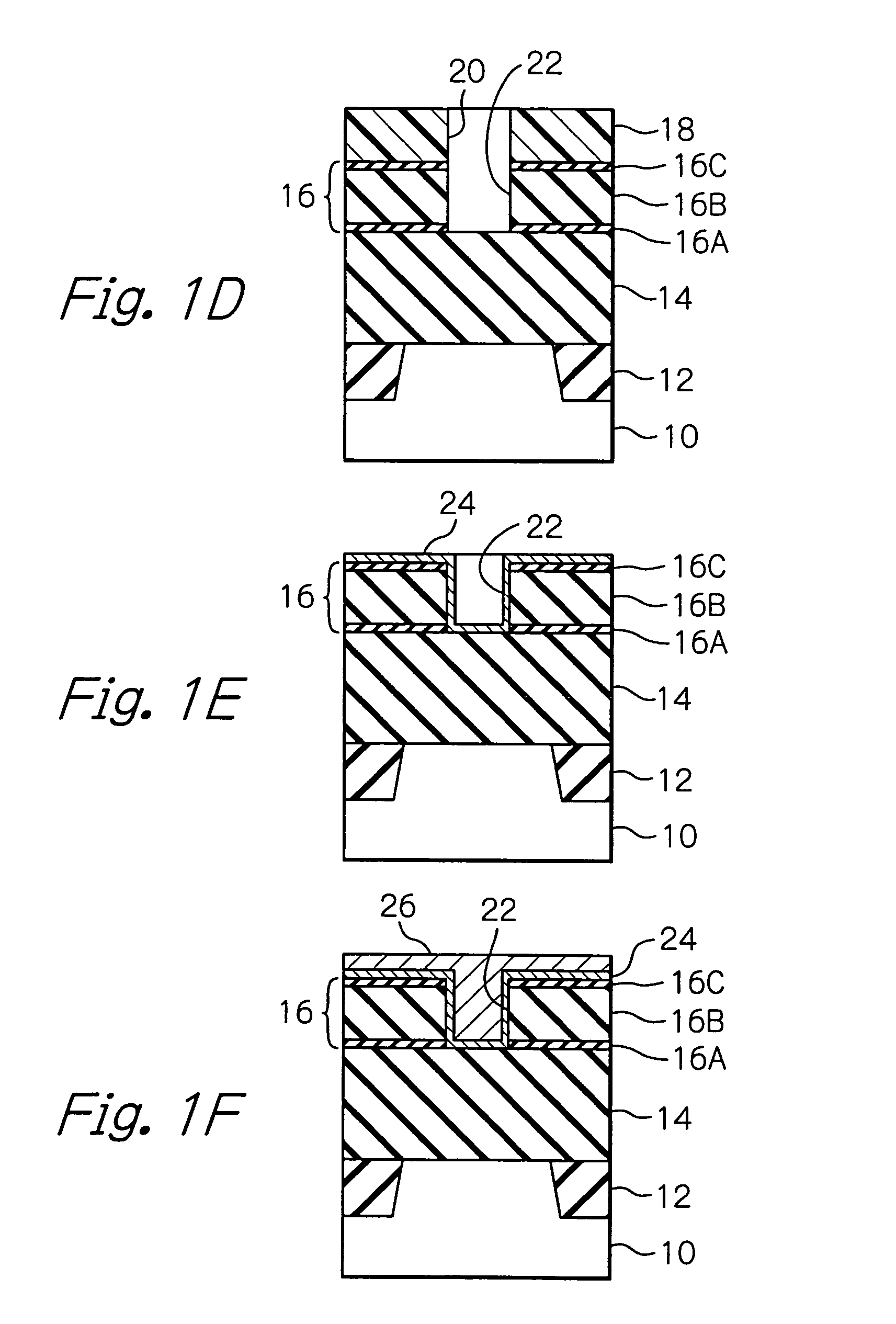

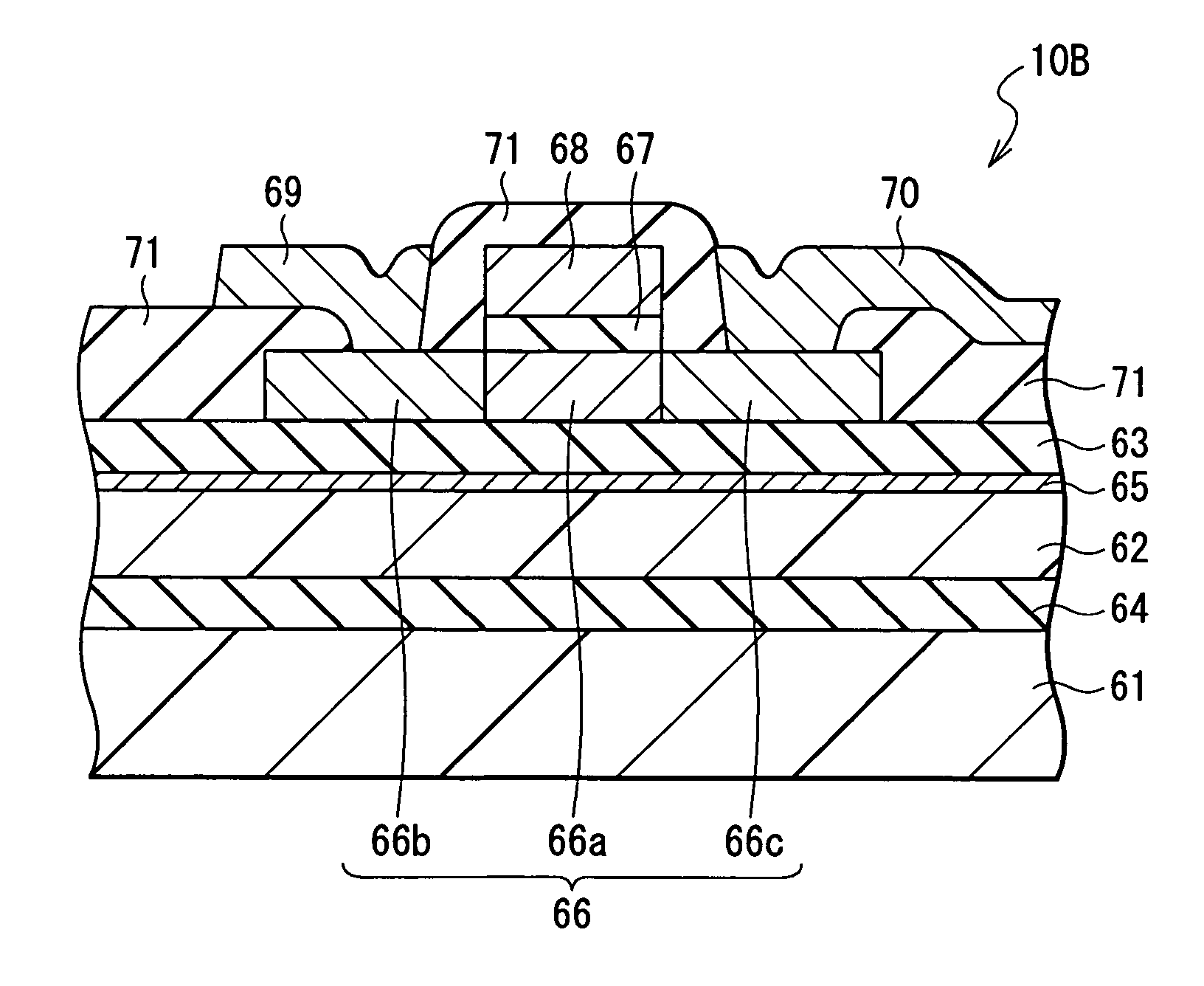

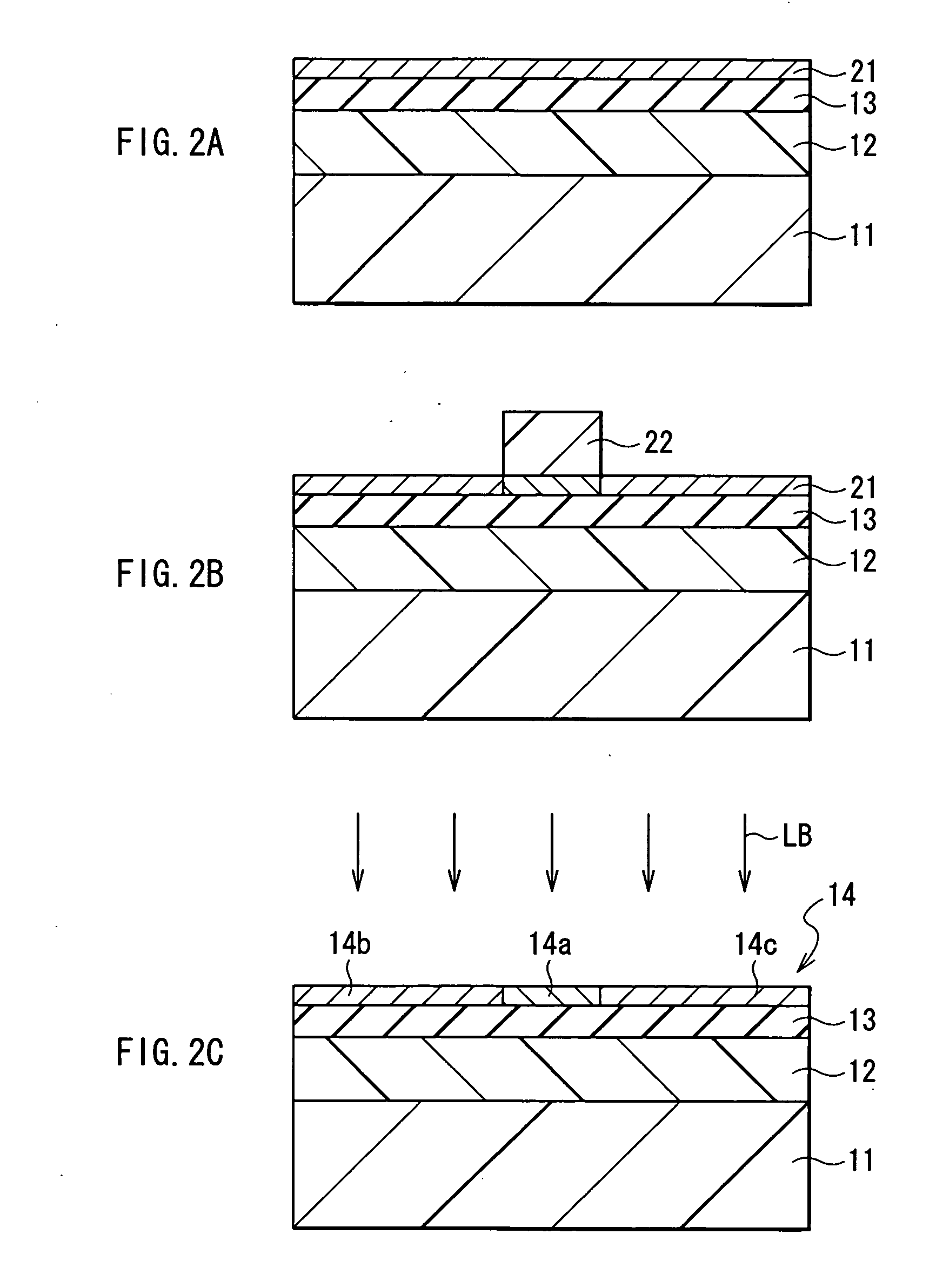

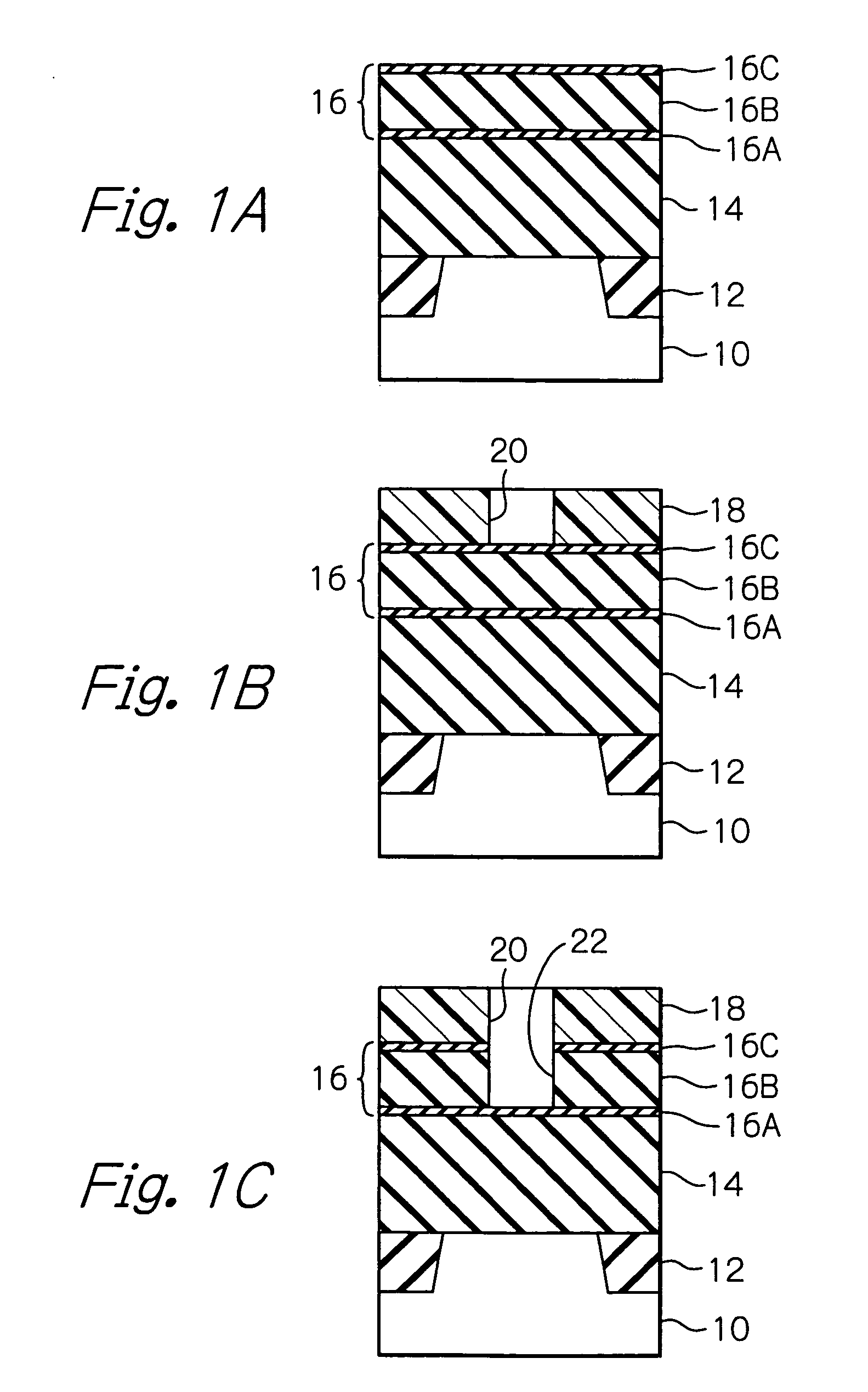

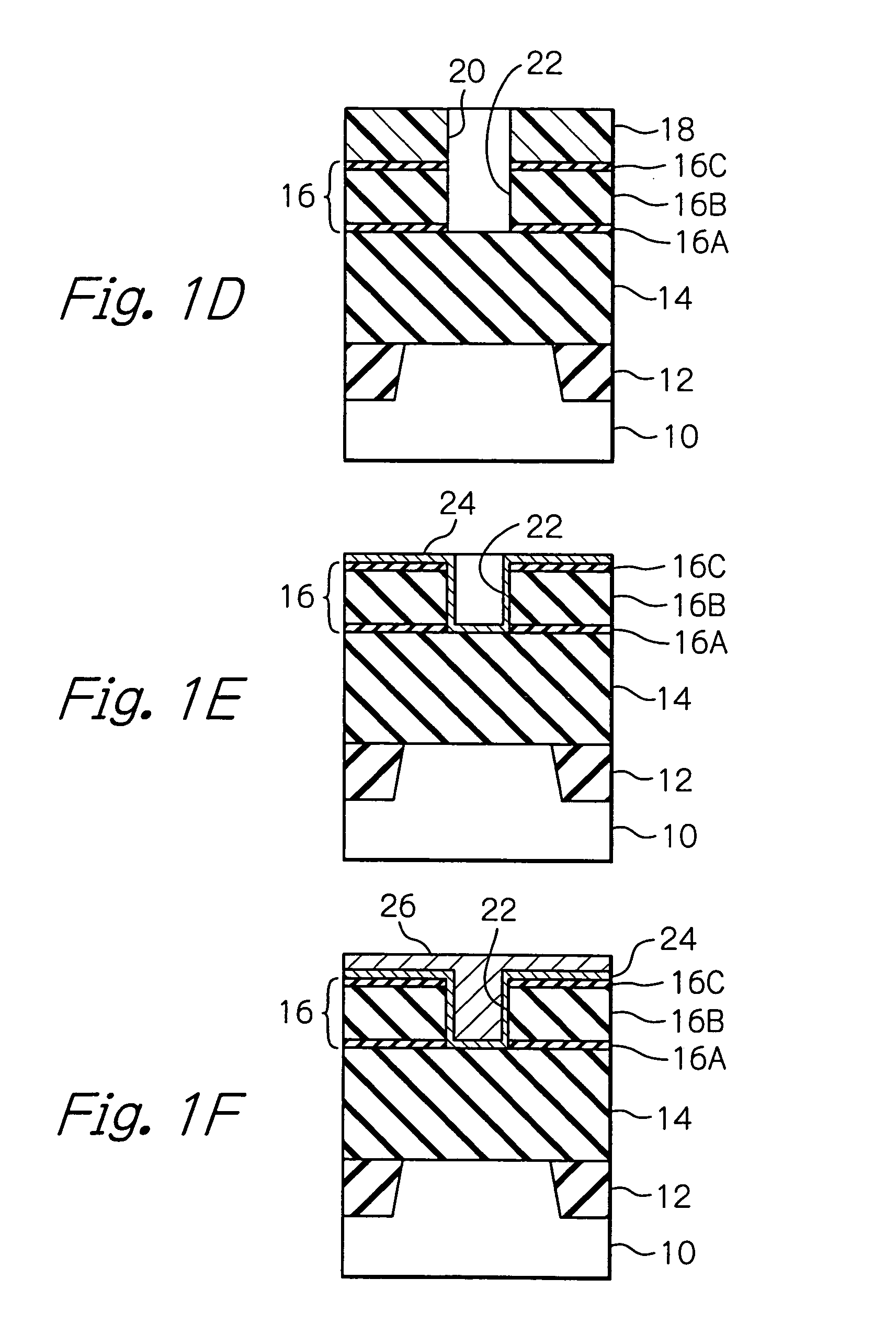

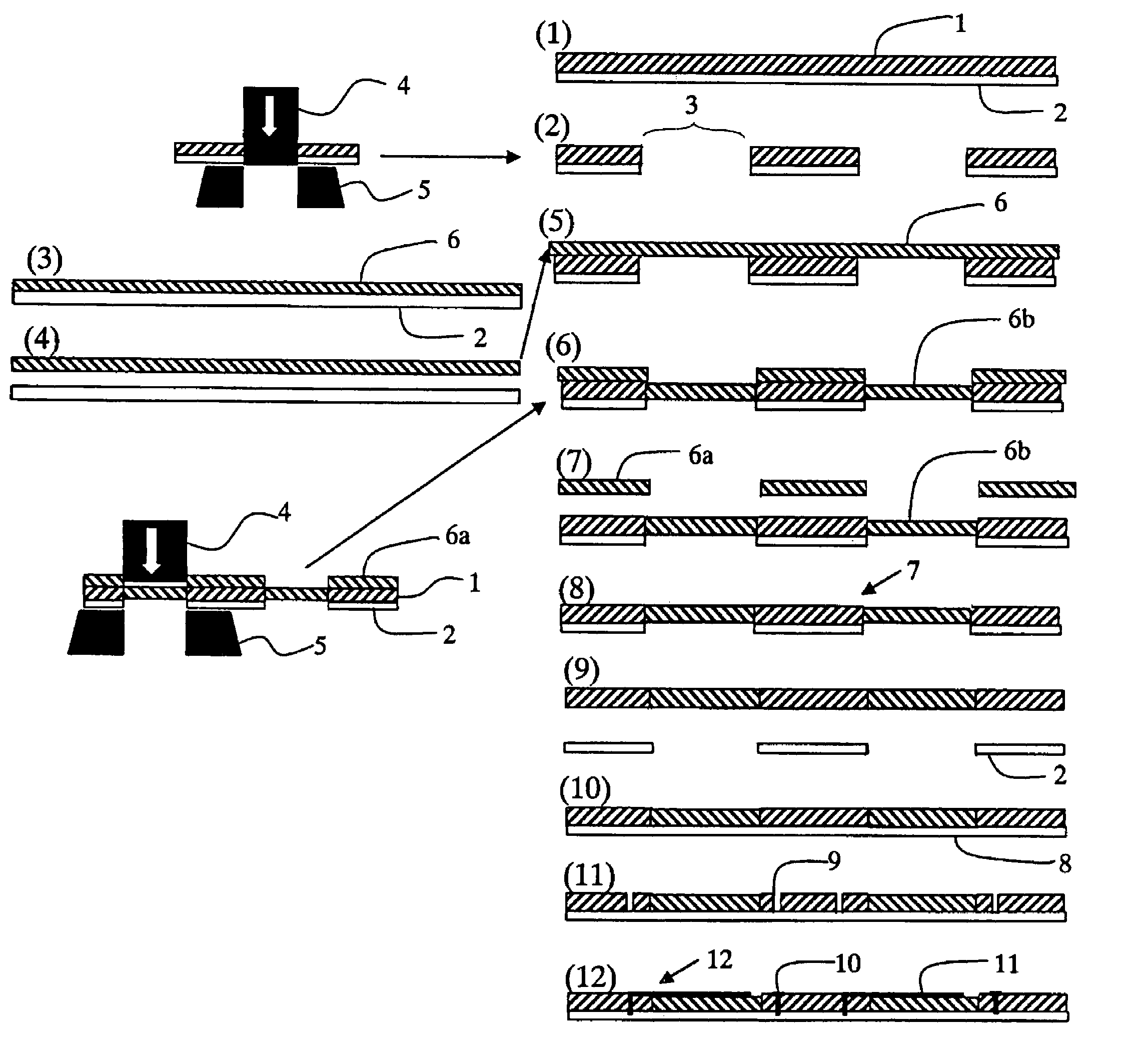

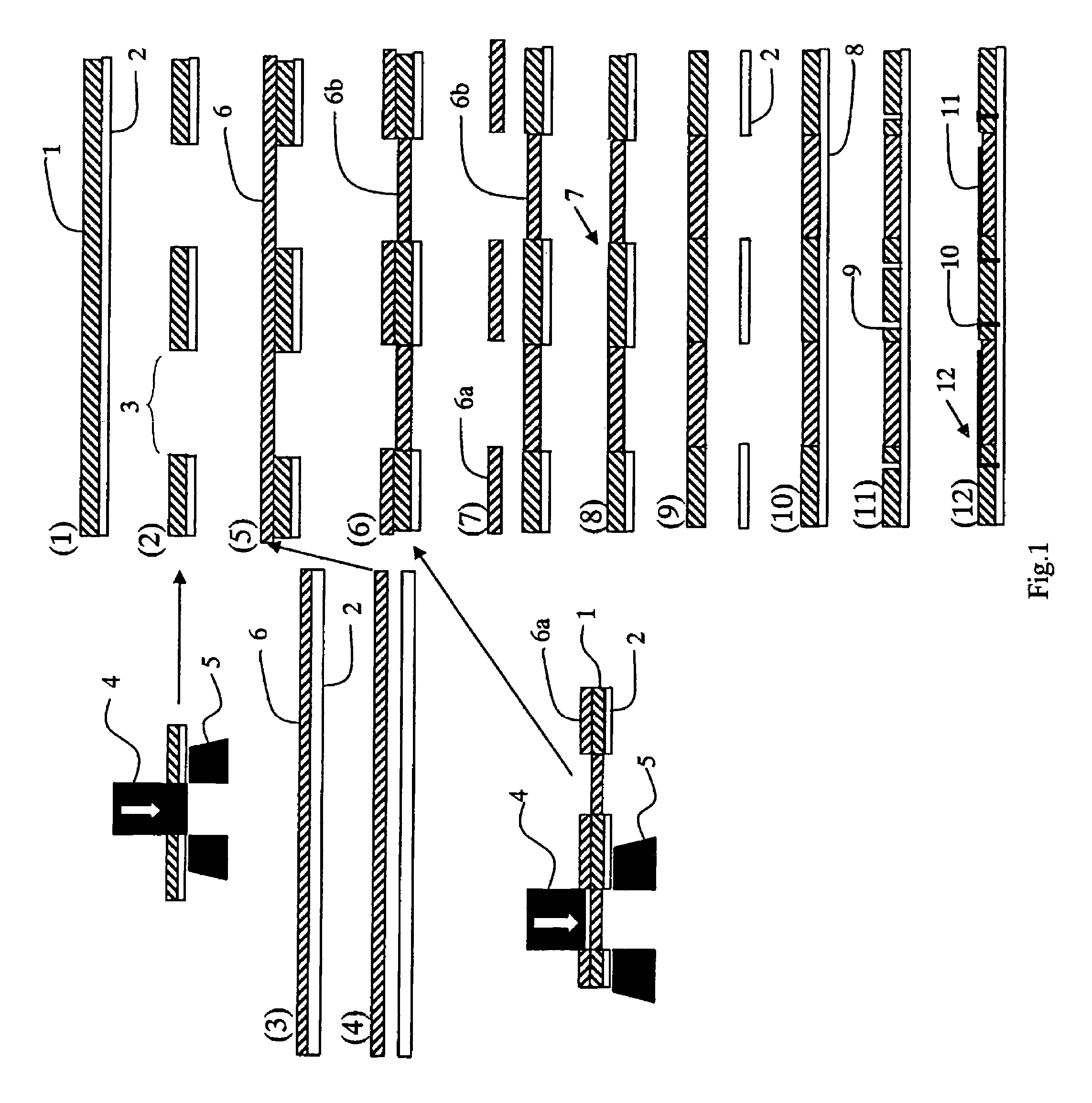

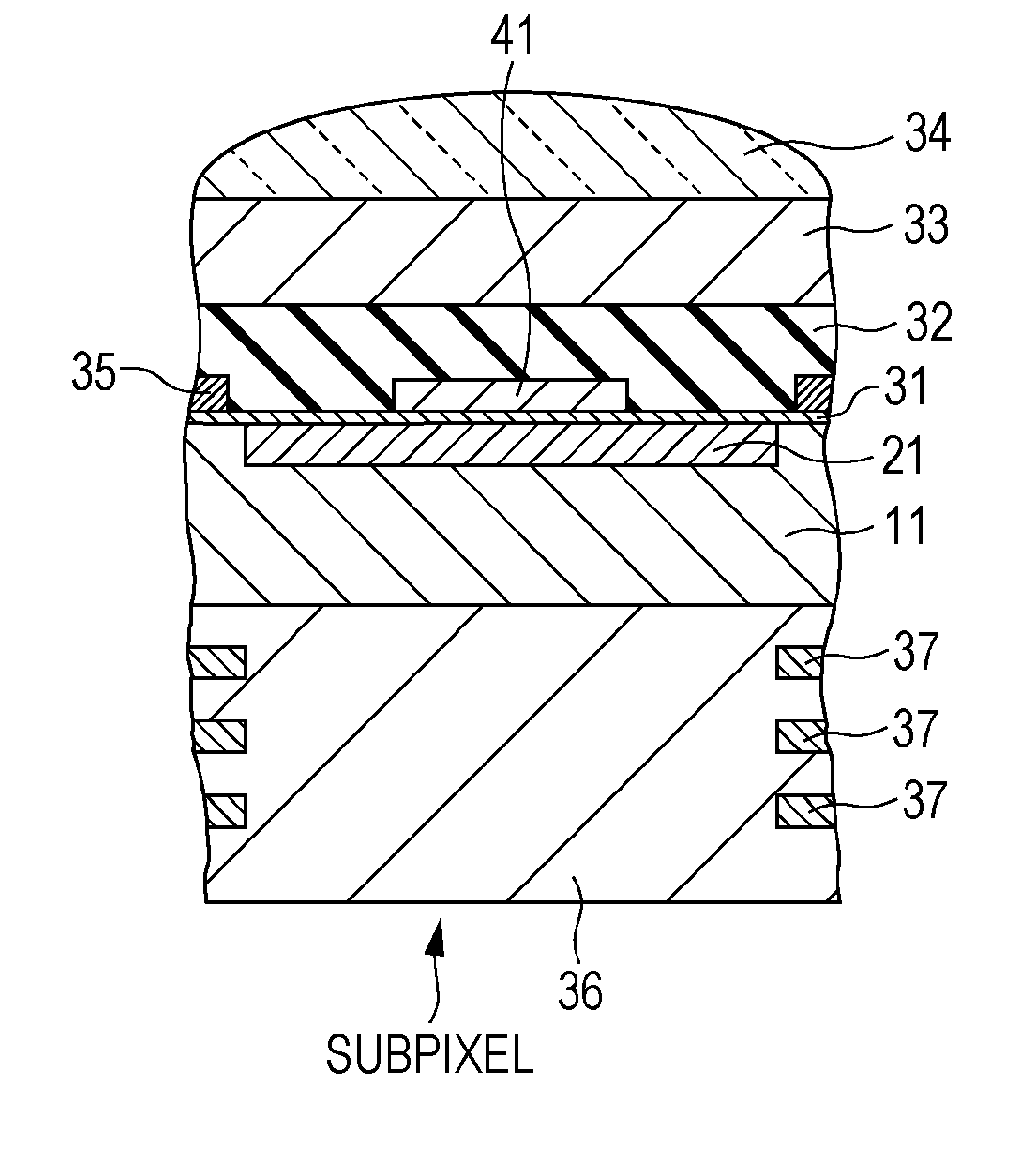

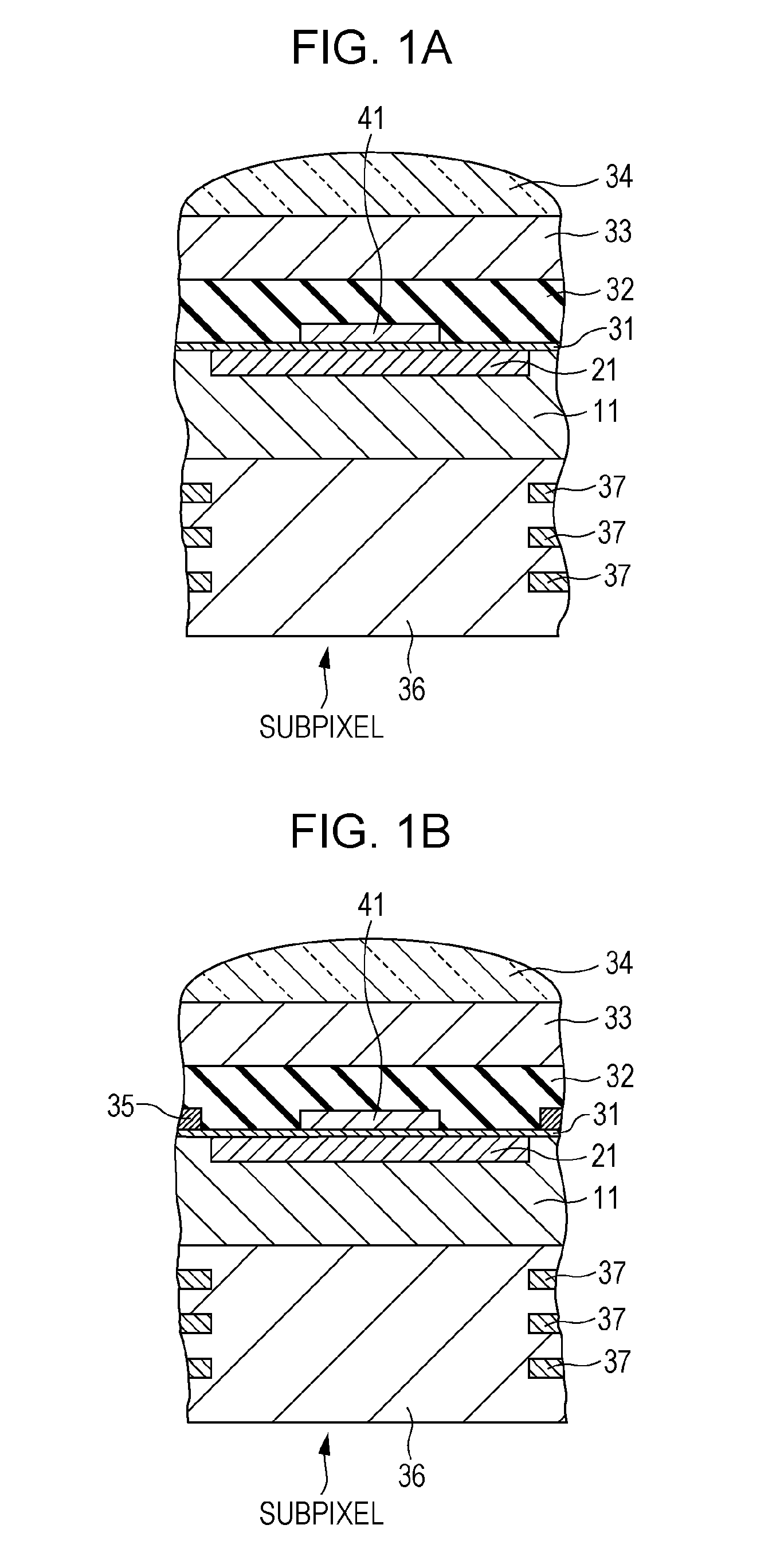

Functional device and method of manufacturing the same

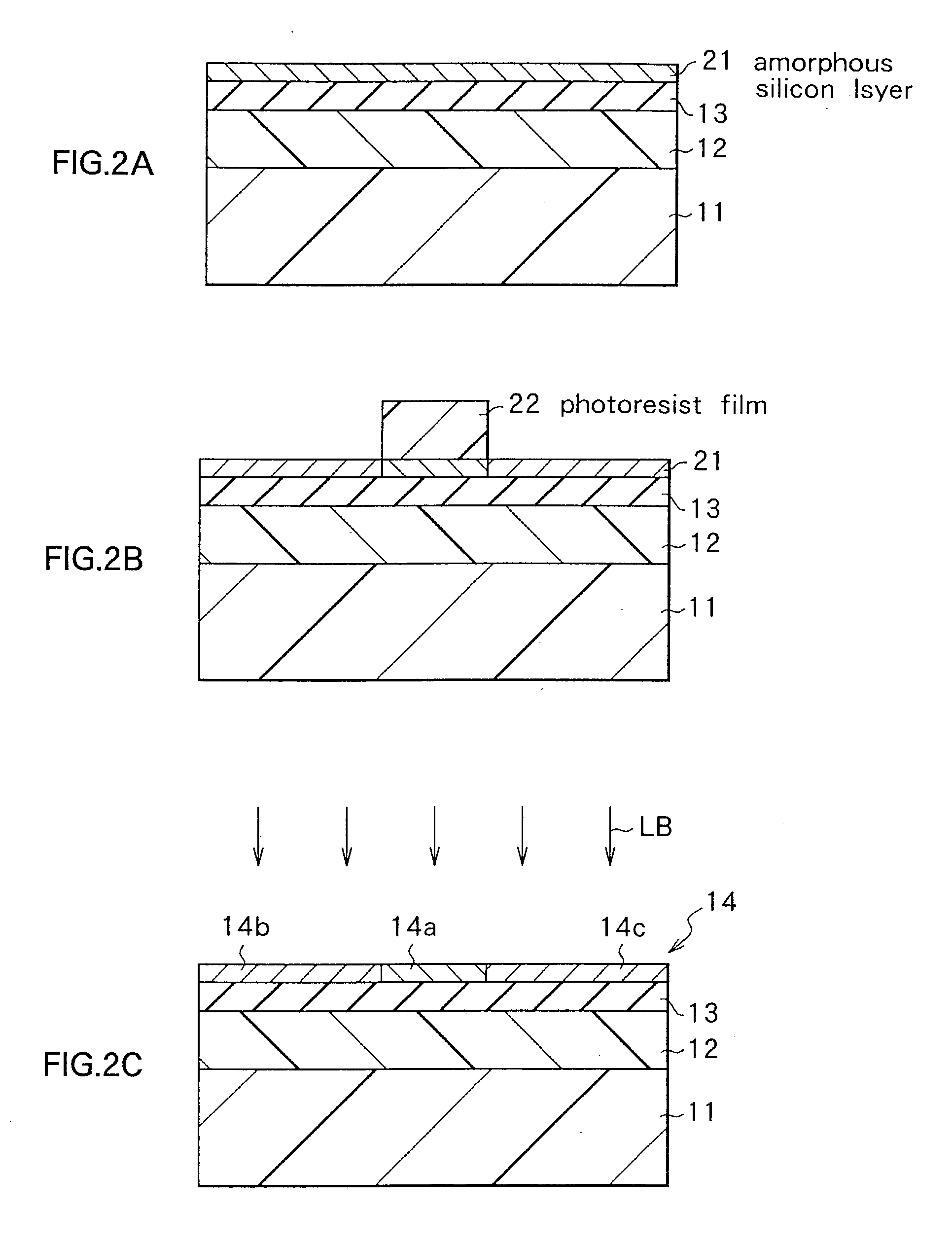

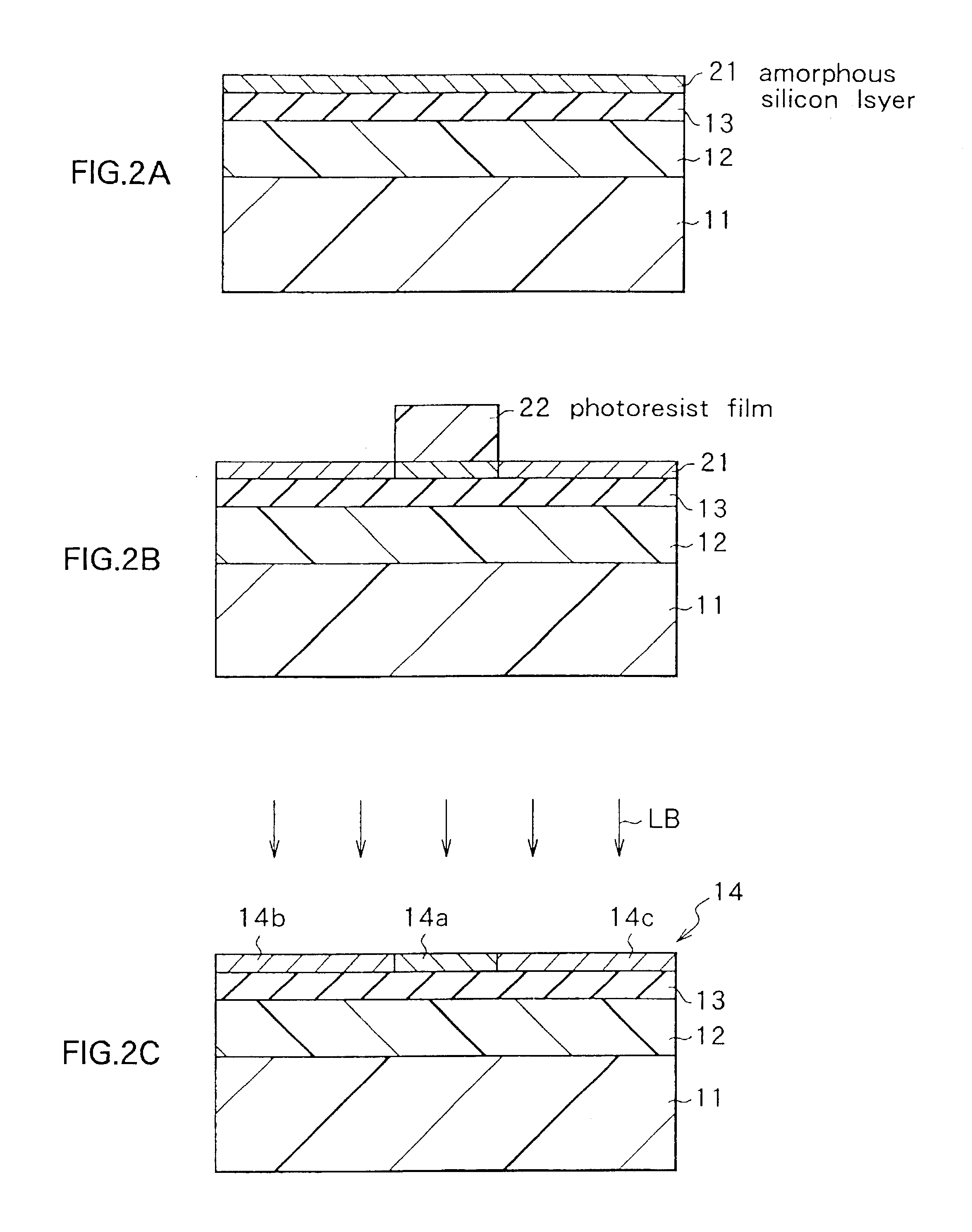

InactiveUS20030173601A1Inhibit the occurrence of cracksAvoid layeringTransistorSolid-state devicesAcrylic resinThermal expansion

A functional device free from cracking and having excellent functional characteristics, and a method of manufacturing the same are disclosed. A low-temperature softening layer (12) and a heat-resistant layer (13) are formed in this order on a substrate (11) made of an organic material such as polyethylene terephthalate, and a functional layer (14) made of polysilicon is formed thereon. The functional layer (14) is formed by crystallizing an amorphous silicon layer, which is a precursor layer, with laser beam irradiation. When a laser beam is applied, heat is transmitted to the substrate (11) and the substrate (11) tends to expand. However, a stress caused by a difference in a thermal expansion coefficient between the substrate (11) and the functional layer (14) is absorbed by the low-temperature softening layer (12), so that no cracks and peeling occurs in the functional layer (14). The low-temperature softening layer (12) is preferably made of a polymeric material containing an acrylic resin. By properly interposing a metal layer and a heat-resistant layer between the substrate (11) and the functional layer (14), a laser beam of higher intensity can be irradiated.

Owner:SONY CORP

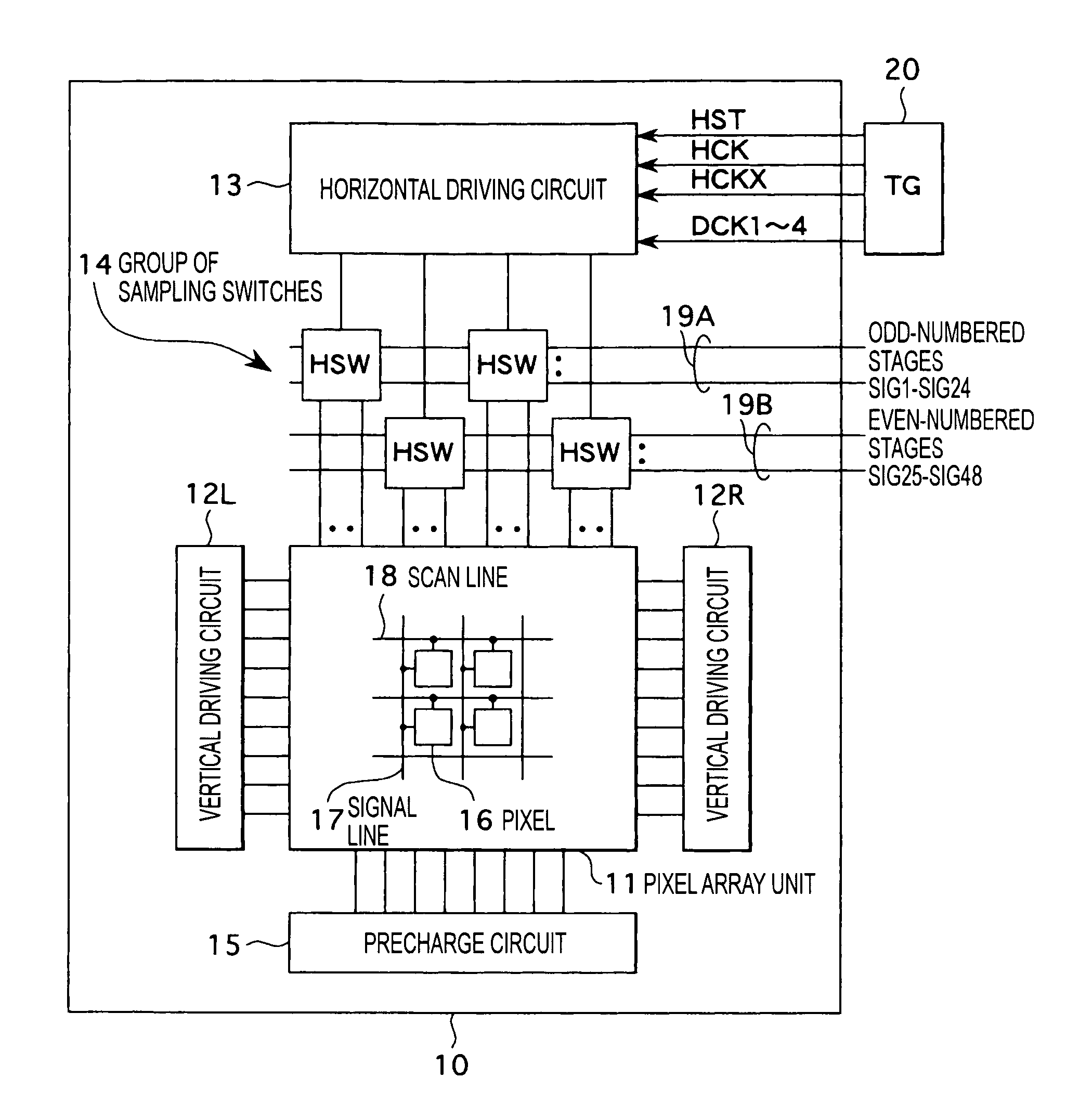

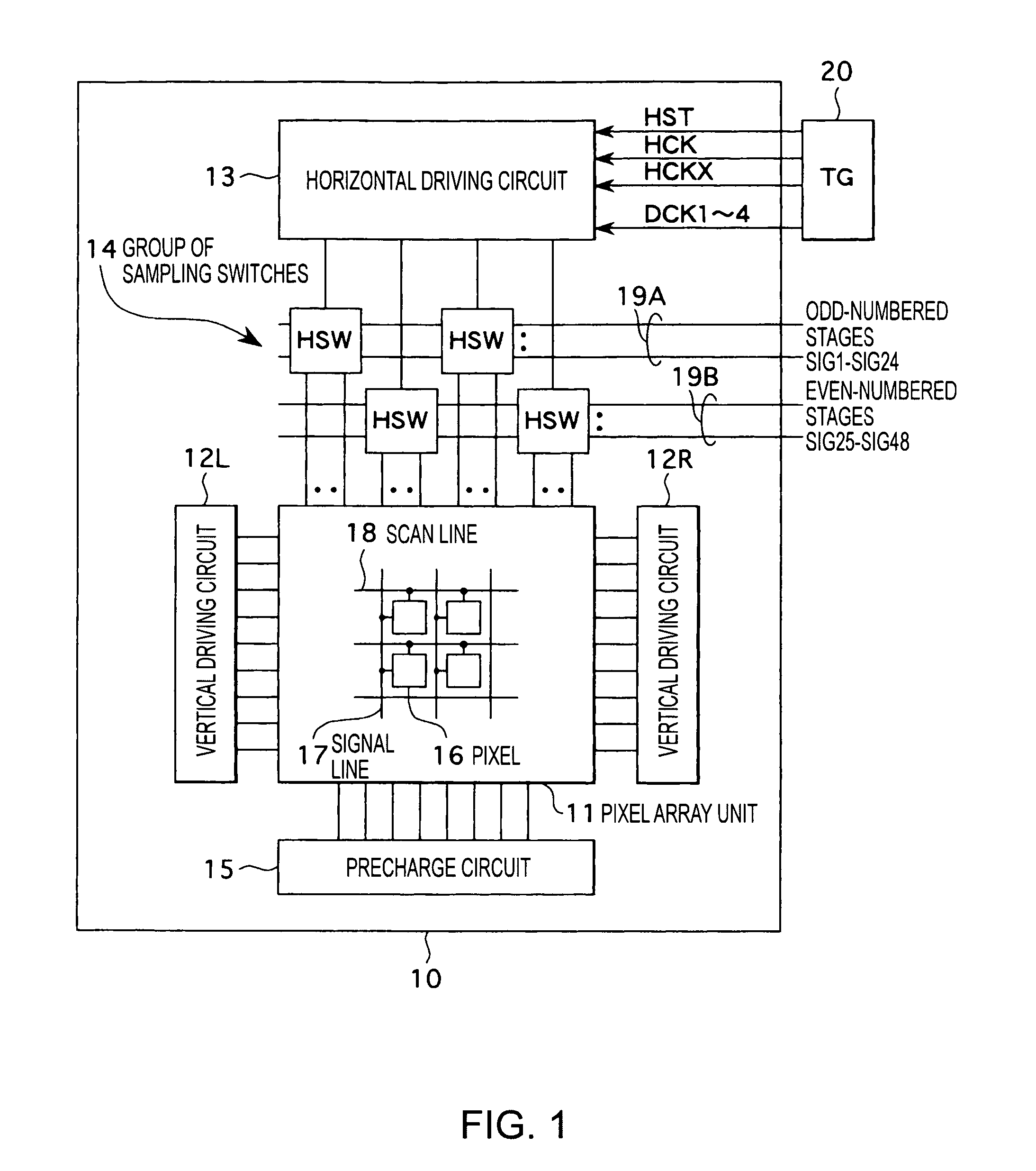

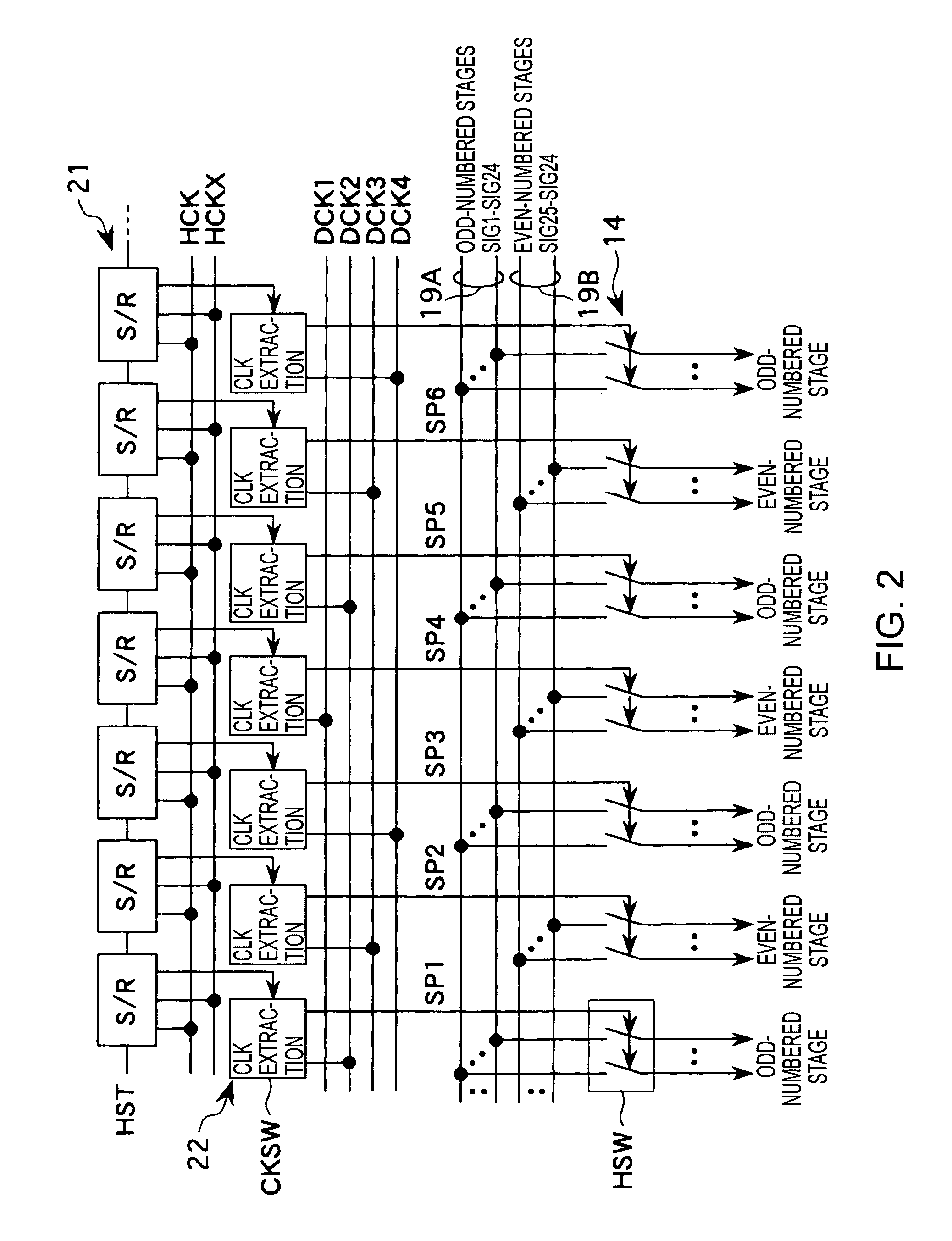

Display device and drive method thereof

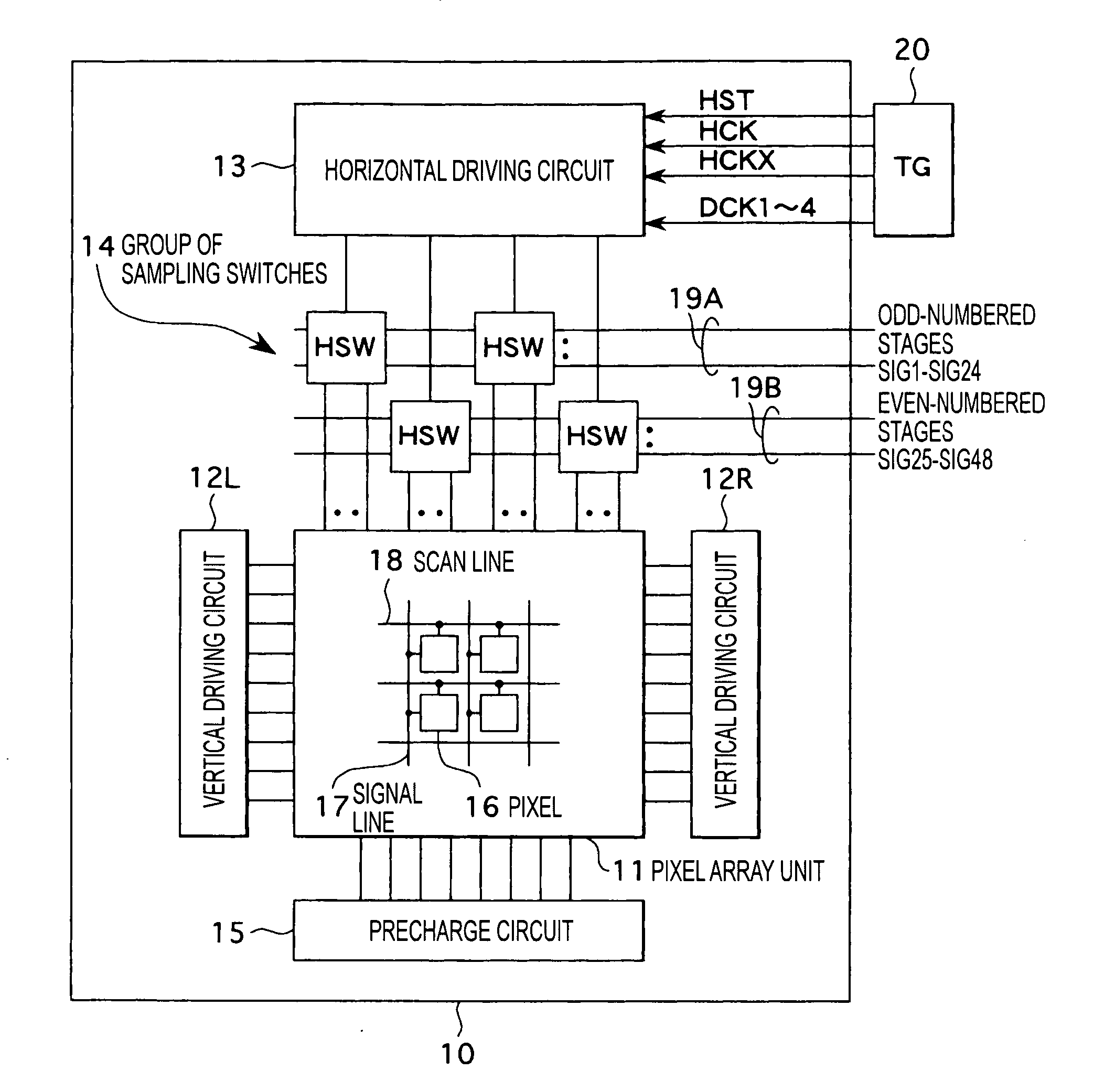

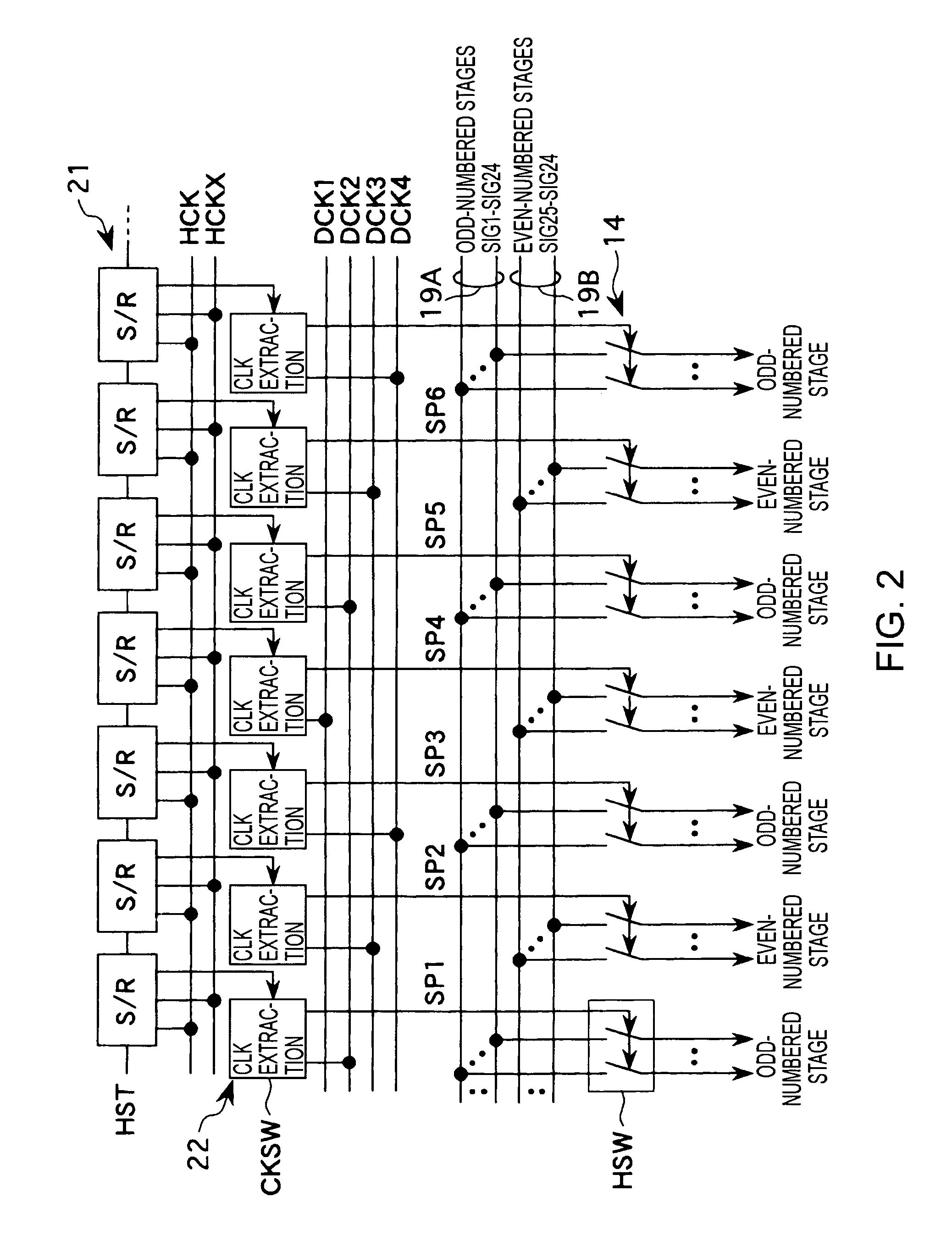

InactiveUS20060232543A1Improve image qualityLarge marginStatic indicating devicesNon-linear opticsRoundingScan line

A display apparatus and a method for driving the display apparatus that are capable of suppressing image quality degradation resulting from delay in sampling pulses or from waveform rounding thereof and image quality degradation caused by coupling between the signal line and the common line and that between the signal line and the scan line even when the simultaneous sampling number is increased. The start pulse HST has a pulse width that includes a plurality of pulse widths of the clock pulses HCK and HCKX, for example, two pulse widths. The clock pulses DCK have four phases. Large margins α1 and α2 in the phase relationship between each of the clock pulses DCK1 to DCK4 and each of transfer pulses used for extracting the clock pulses DCK1 to DCK4 are assured. As a result, even if delay or waveform rounding occurs in the clock pulses DCK1 to DCK4, sampling pulses SP1 to SP6 with a constant pulse width equal to that of each of the clock pulses DCK1 to DCK4 can be generated without being affected by the delay or waveform rounding.

Owner:SONY CORP

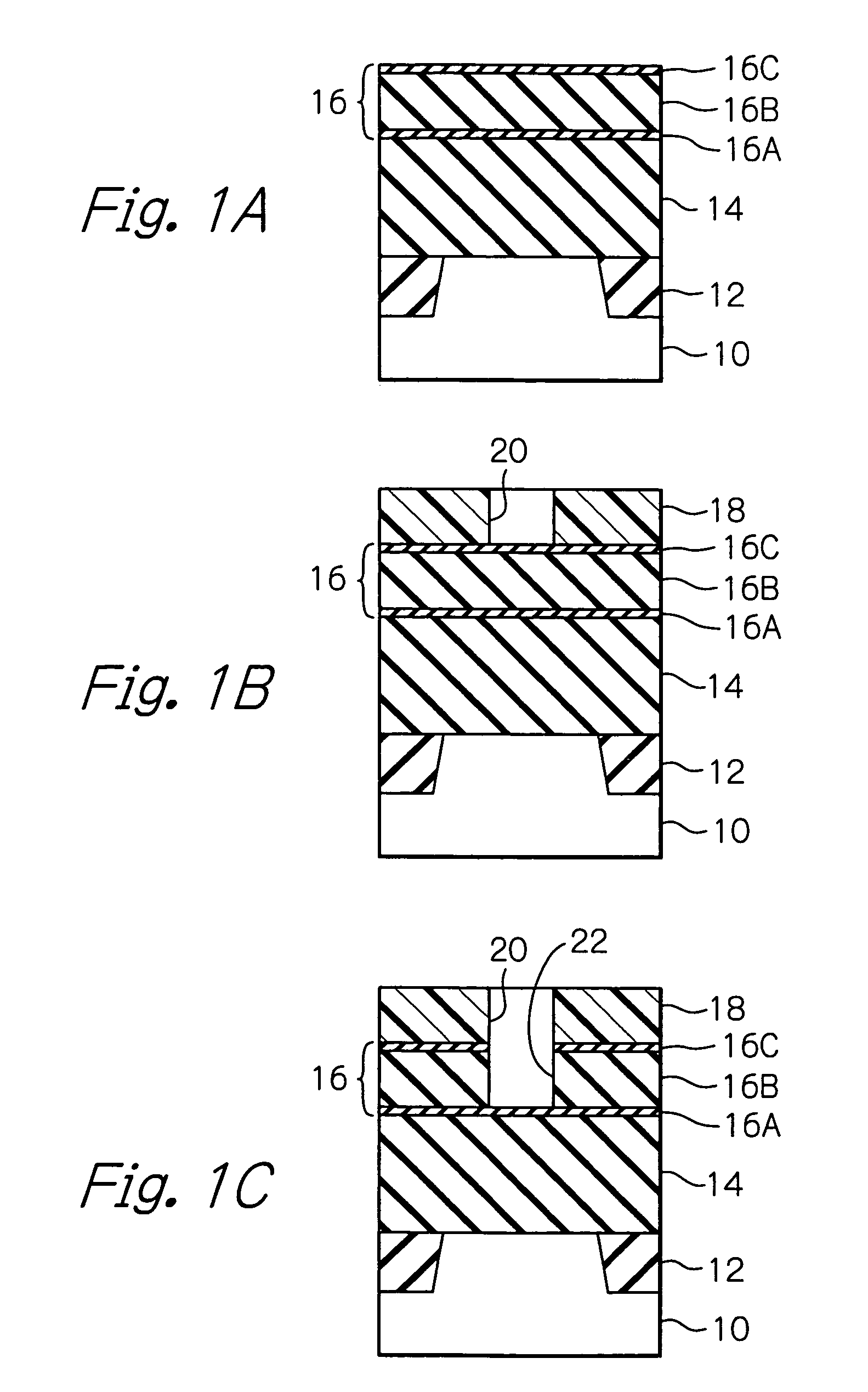

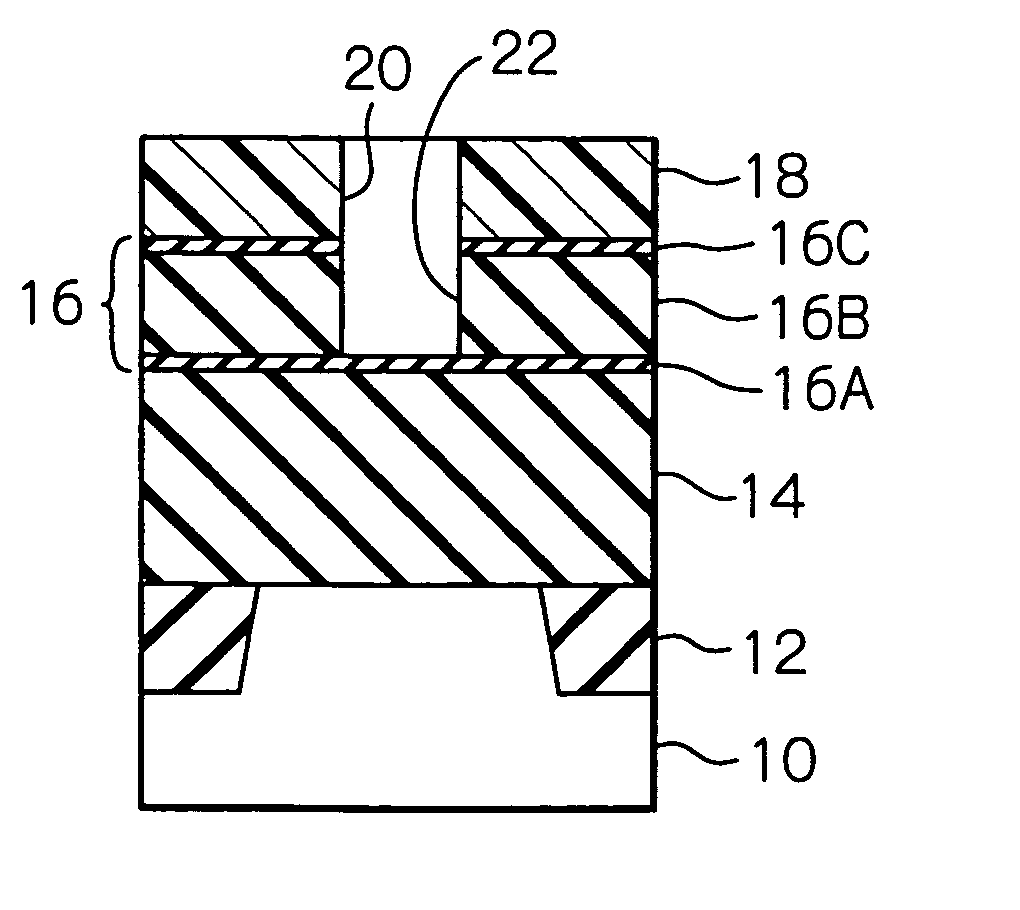

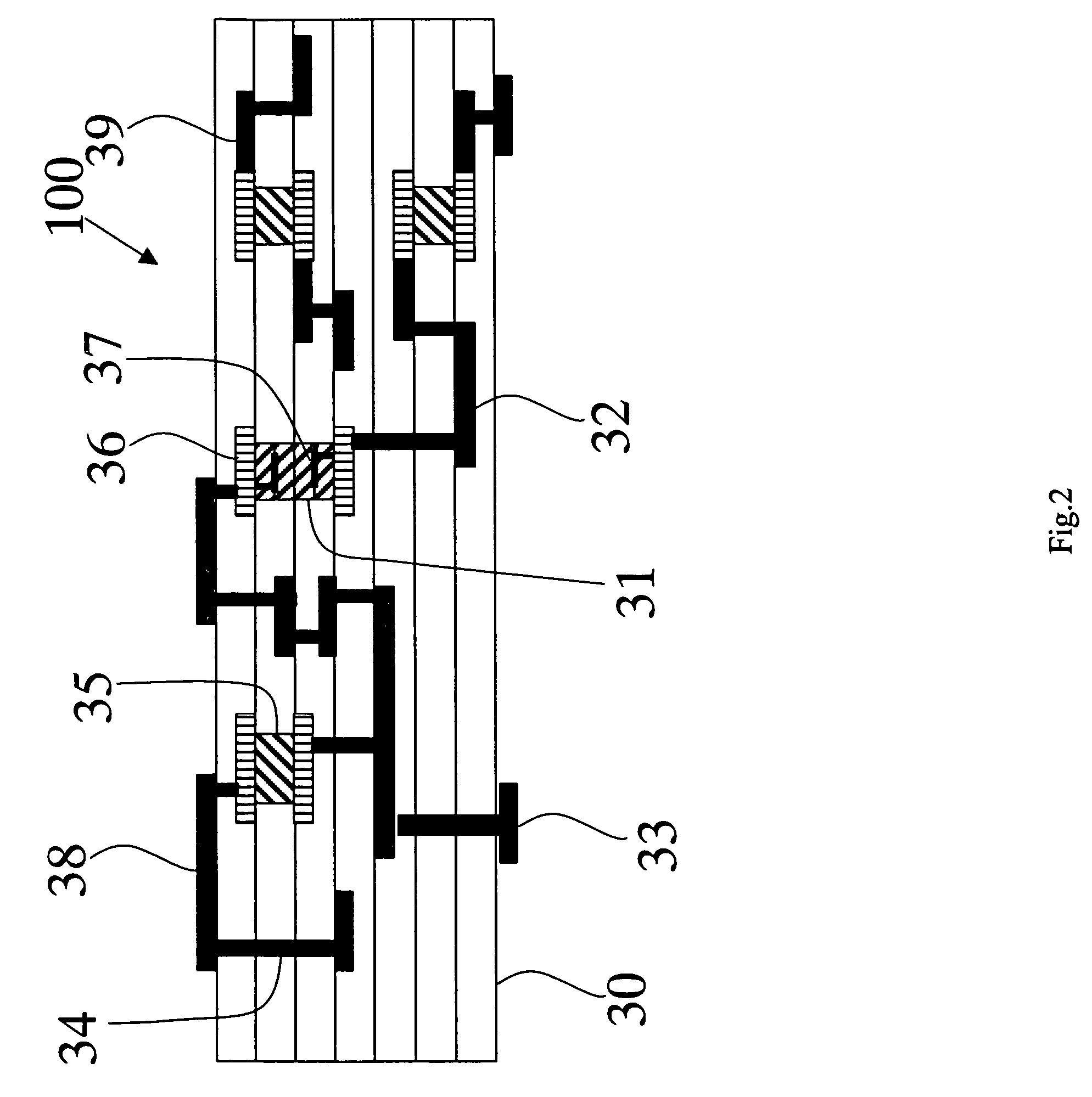

Semiconductor device with multi-layered wiring arrangement including reinforcing patterns, and production method for manufacturing such semiconductor device

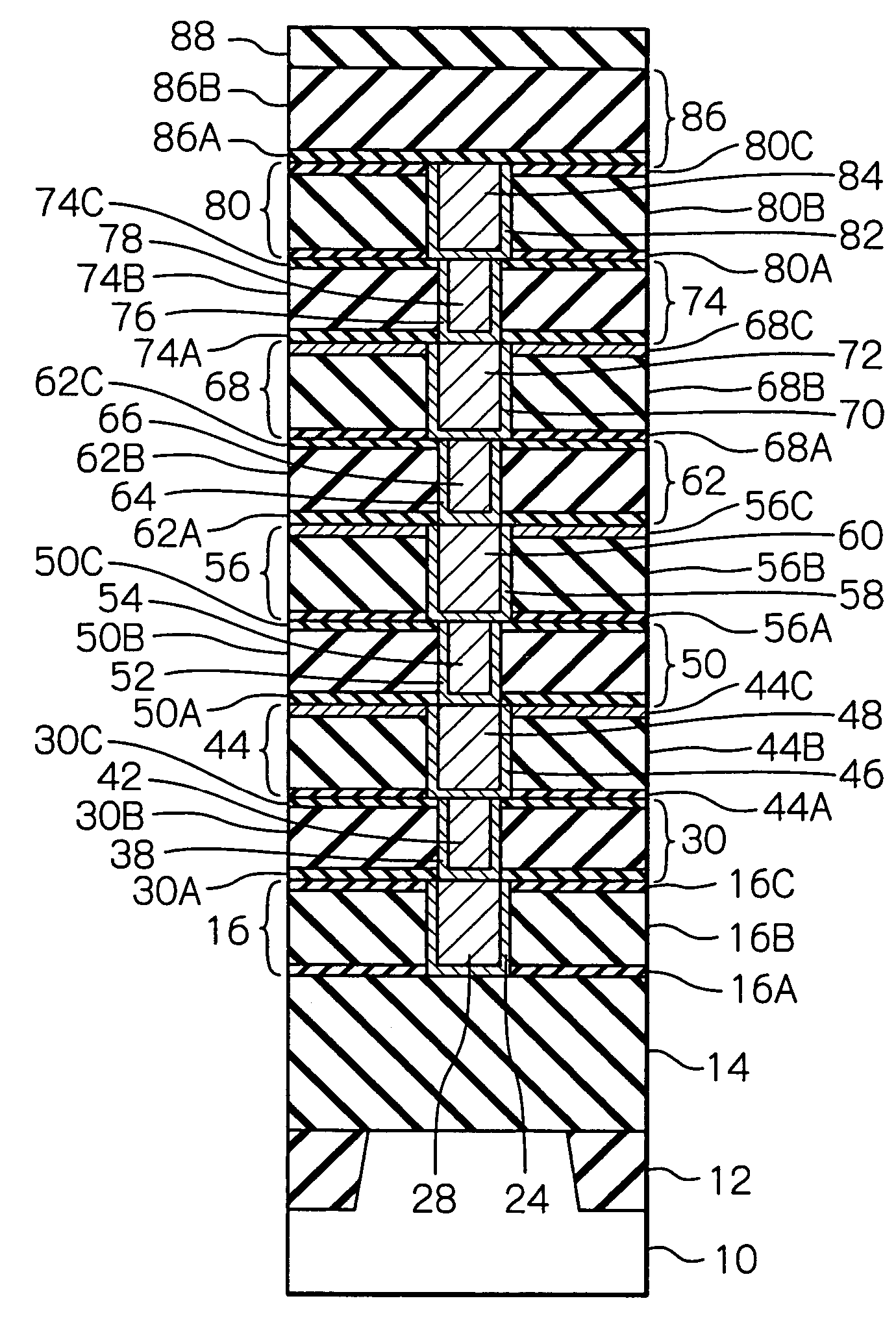

InactiveUS7199042B2Occurrence can be preventedInhibition productionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectronic componentSemiconductor

A semiconductor device includes a semiconductor substrate having electronic elements produced therein, and an insulating underlayer formed thereon, and a multi-layered wiring arrangement constructed on the insulating underlayer semiconductor substrate. The multi-layered wiring arrangement includes a first insulating interlayer structure formed on the insulating underlayer, a second insulating interlayer structure, and a third insulating interlayer structure formed on the first insulating interlayer structure. Each of the first, second and third insulating interlayer structures includes a low-k insulating layer, and has a reinforcing element formed therein. The second insulating interlayer structure has a joint plug formed therein. The reinforcing elements of the first and third insulating interlayer structures are connected to each other through the joint plug.

Owner:RENESAS ELECTRONICS CORP

Functional device and production method therefor

InactiveUS20040157470A1Inhibit the occurrence of cracksAvoid layeringTransistorLayered productsEpoxyAcrylic resin

The invention provides a functional device having no cracks and capable of delivering good functional characteristics and a method of manufacturing the same. A functional layer (14) is formed by crystallizing an amorphous silicon layer as a precursor layer by laser beam irradiation. A laser beam irradiation conducts heat up to a substrate (11) to cause it to try to expand; a stress to be produced by the difference in thermal expansion coefficient between the substrate (11) and the functional layer (14) is shut off by an organic polymer layer (12) lower in thermal expansion coefficient than the substrate (ii), thereby causing no cracks nor separations in the functional layer (14). The organic polymer layer (12) is preferably made of an acrylic resin, an epoxy resin, or a polymer material containing these that is deformed by an optical or thermal process to undergo a three-dimensional condensation polymerization, for higher compactness and hardness. Inserting a metal layer and an inorganic heat resistant layer between the substrate (11) and the functional layer (14) will permit a more powerful laser irradiation.

Owner:SONY CORP

Nickel powder, conductive paste, and multilayer electronic component using same

ActiveUS7618474B2Reduced activitySmall sizeStacked capacitorsSynthetic resin layered productsElectricityConductive paste

Owner:SHOEI CHEM IND CO LTD

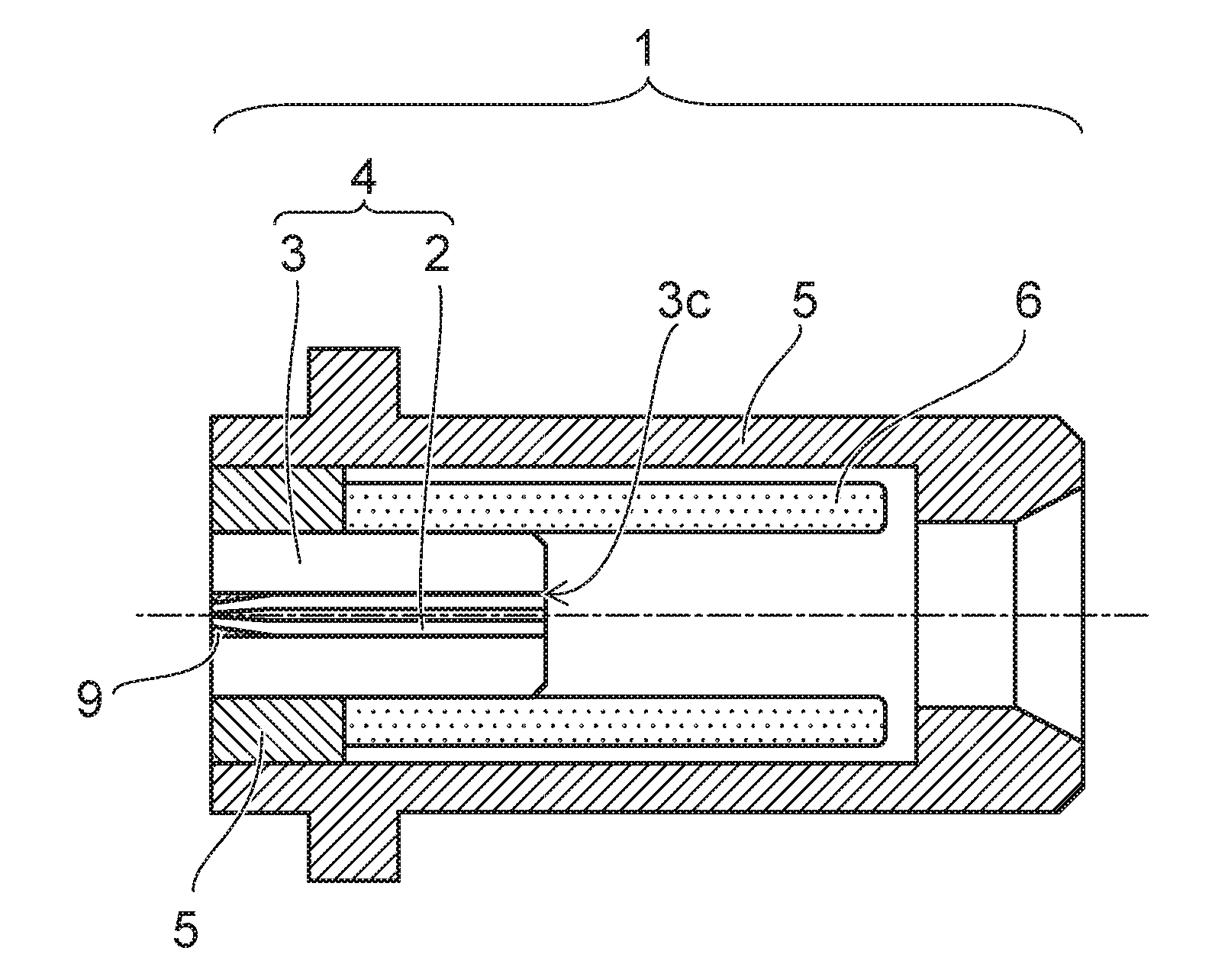

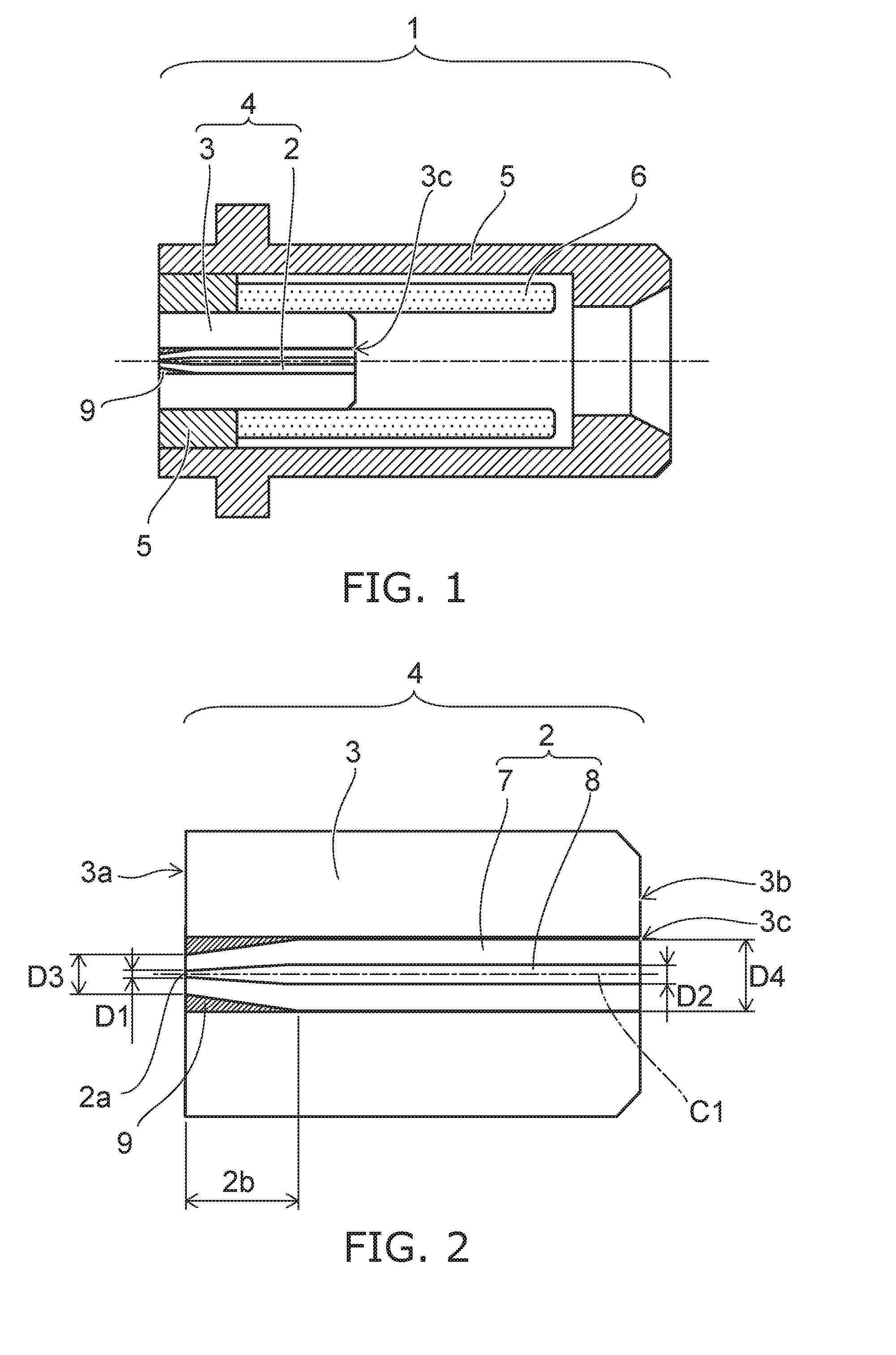

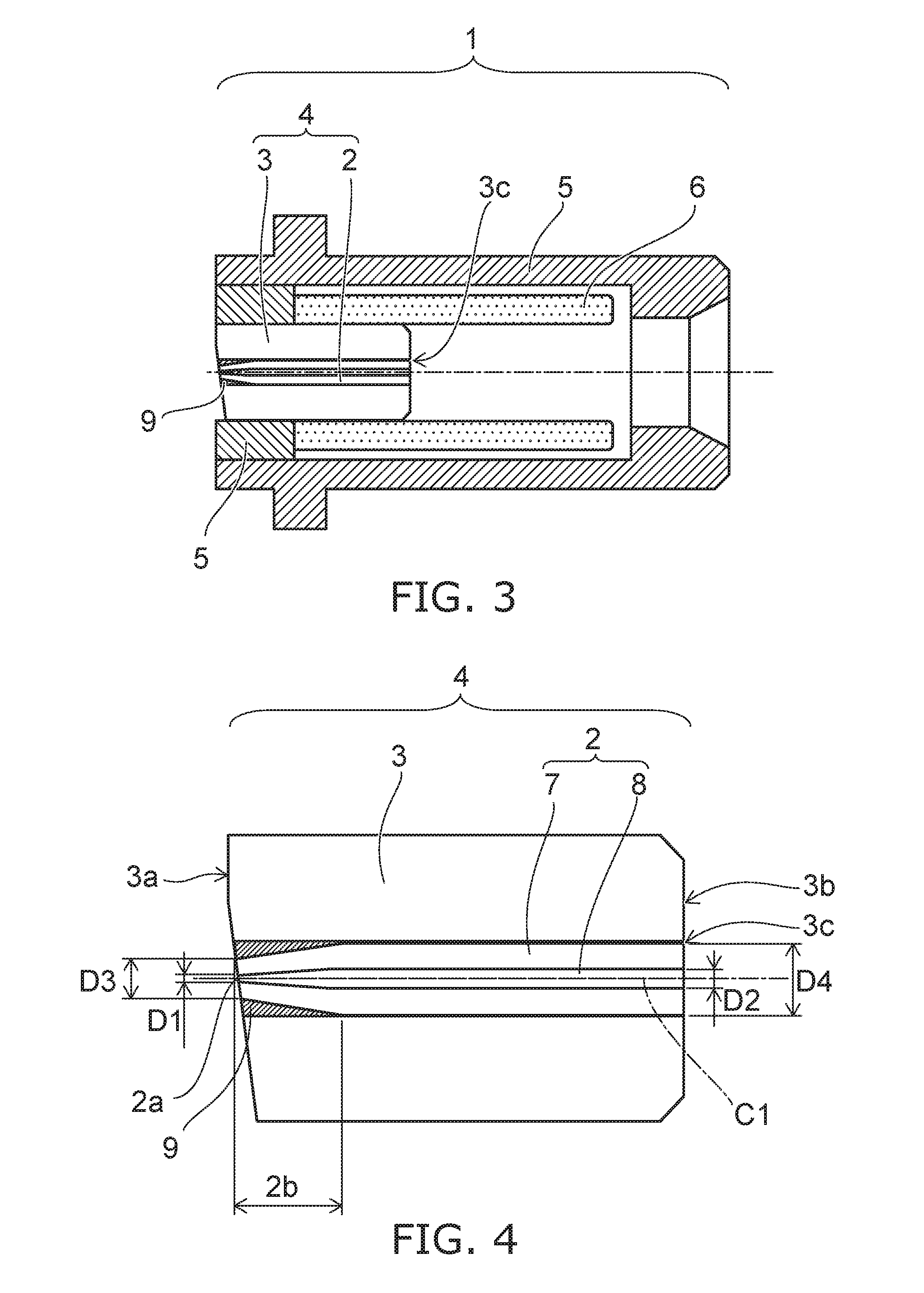

Optical receptacle

ActiveUS20160131850A1Decrease of coupling efficiency can be preventedShorten the lengthCoupling light guidesFiberOptical Module

According to an aspect of the invention, an optical receptacle, comprising: a fiber stub including an optical fiber, a ferrule, and an elastic member, the optical fiber including cladding and a core conducting light, the ferrule having a through-hole fixing the optical fiber, the elastic member fixing the optical fiber in the ferrule; and a holder holding the fiber stub, the optical fiber being disposed inside the through-hole over an entire region of the optical fiber, the optical fiber including a portion, a core diameter and a fiber outer diameter in the portion decreasing gradually toward an end surface of the ferrule on a side opposite to a side to be optically connected to a plug ferrule, the elastic member being filled into a space between the optical fiber and an inner wall of the through-hole. By making the core small at the optical element side end surface of the optical fiber while contributing to shortening the optical module total length, the strength of the deformable portion of the optical fiber can be ensured; the occurrence of breaking and cracks can be prevented; and the decrease of the coupling efficiency can be prevented by suppressing the movement of the optical fiber when using the optical module.

Owner:TOTO LTD

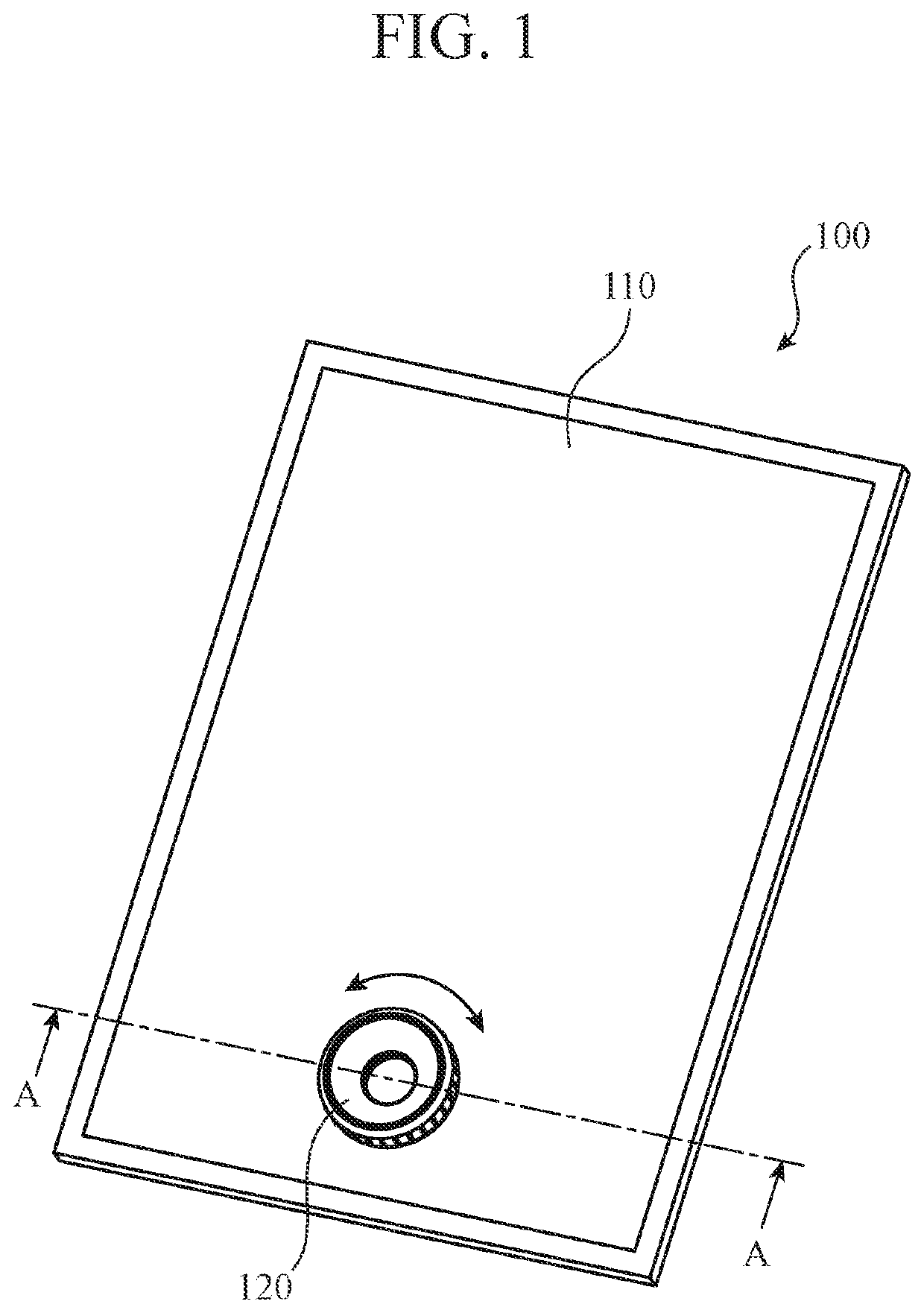

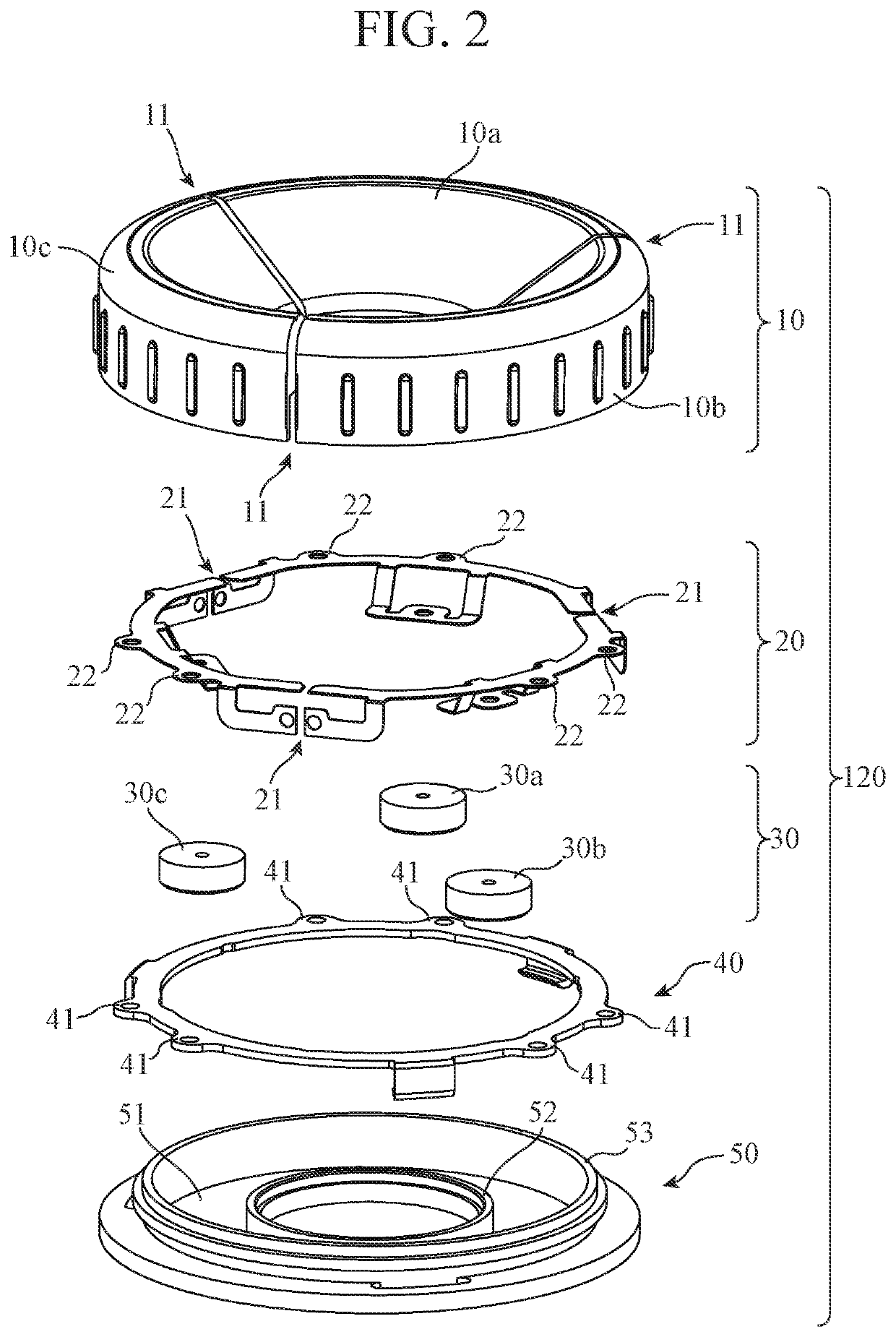

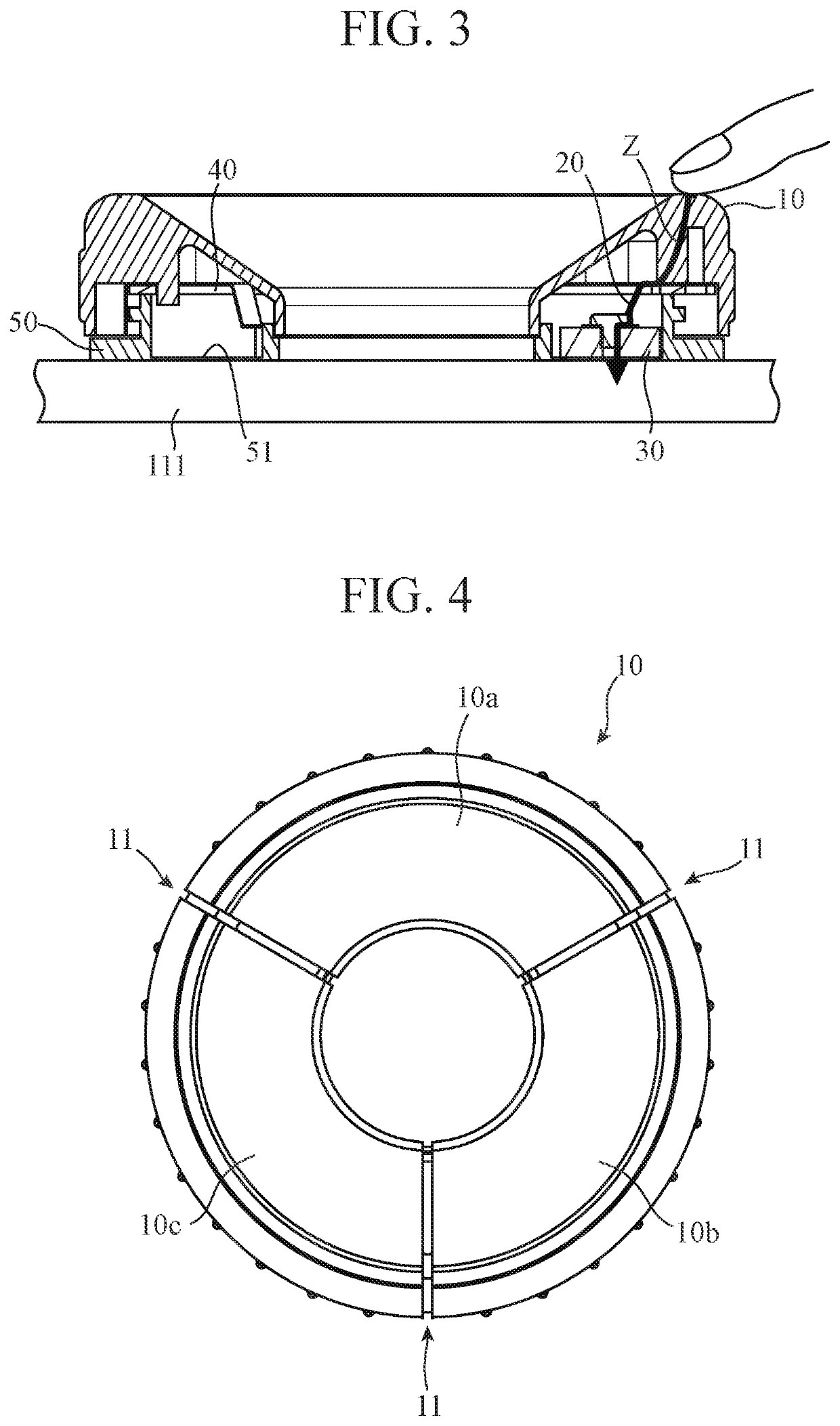

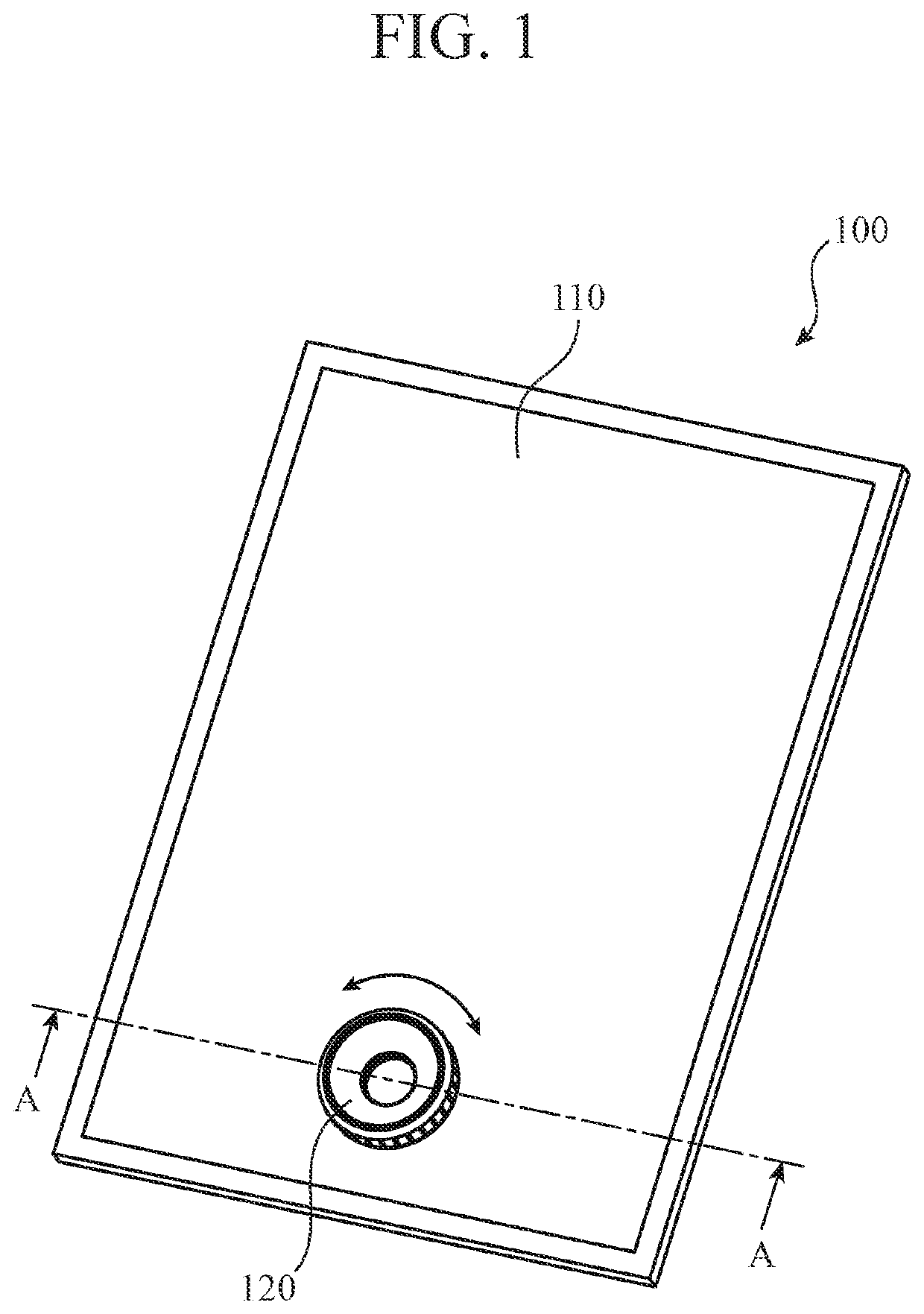

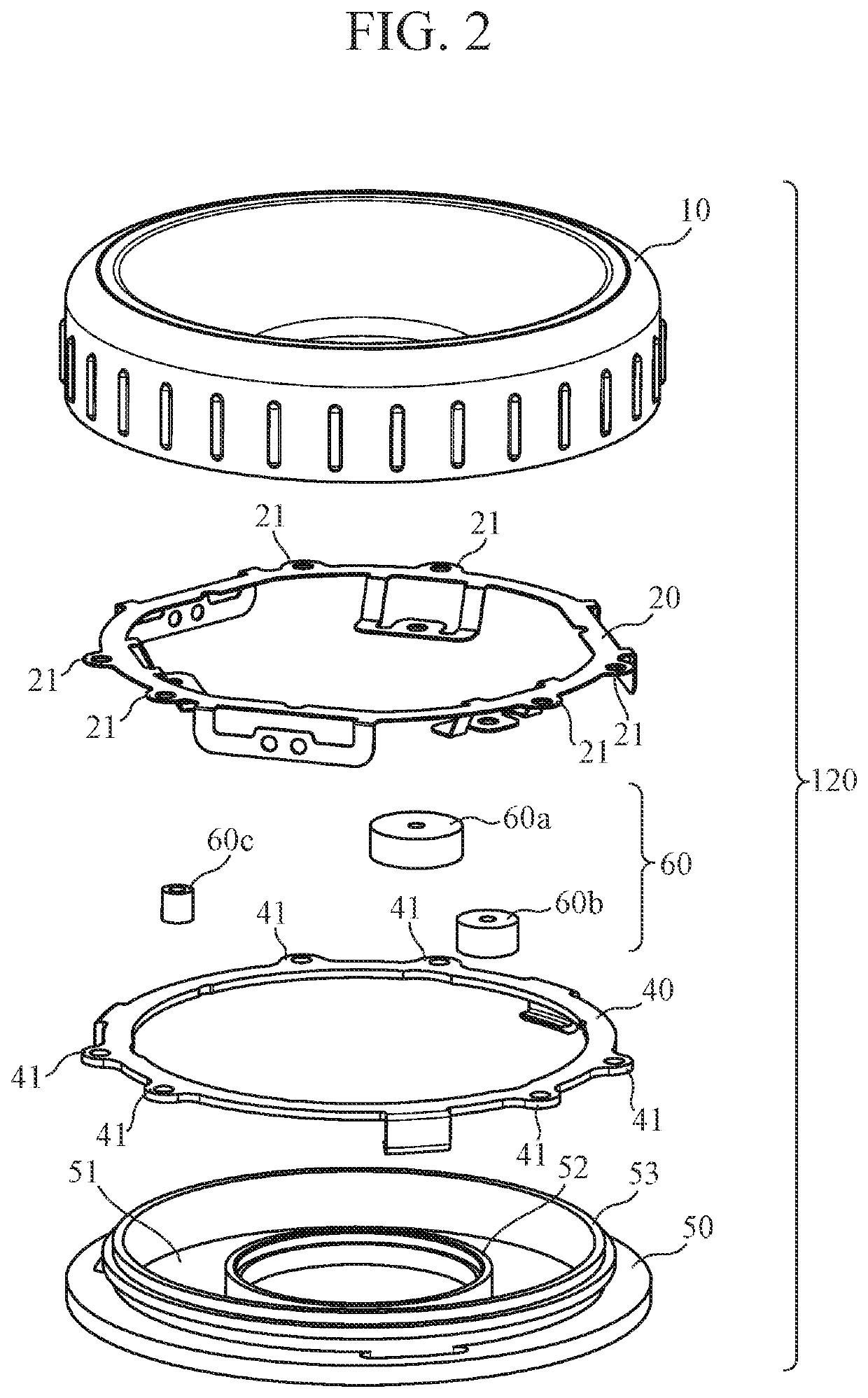

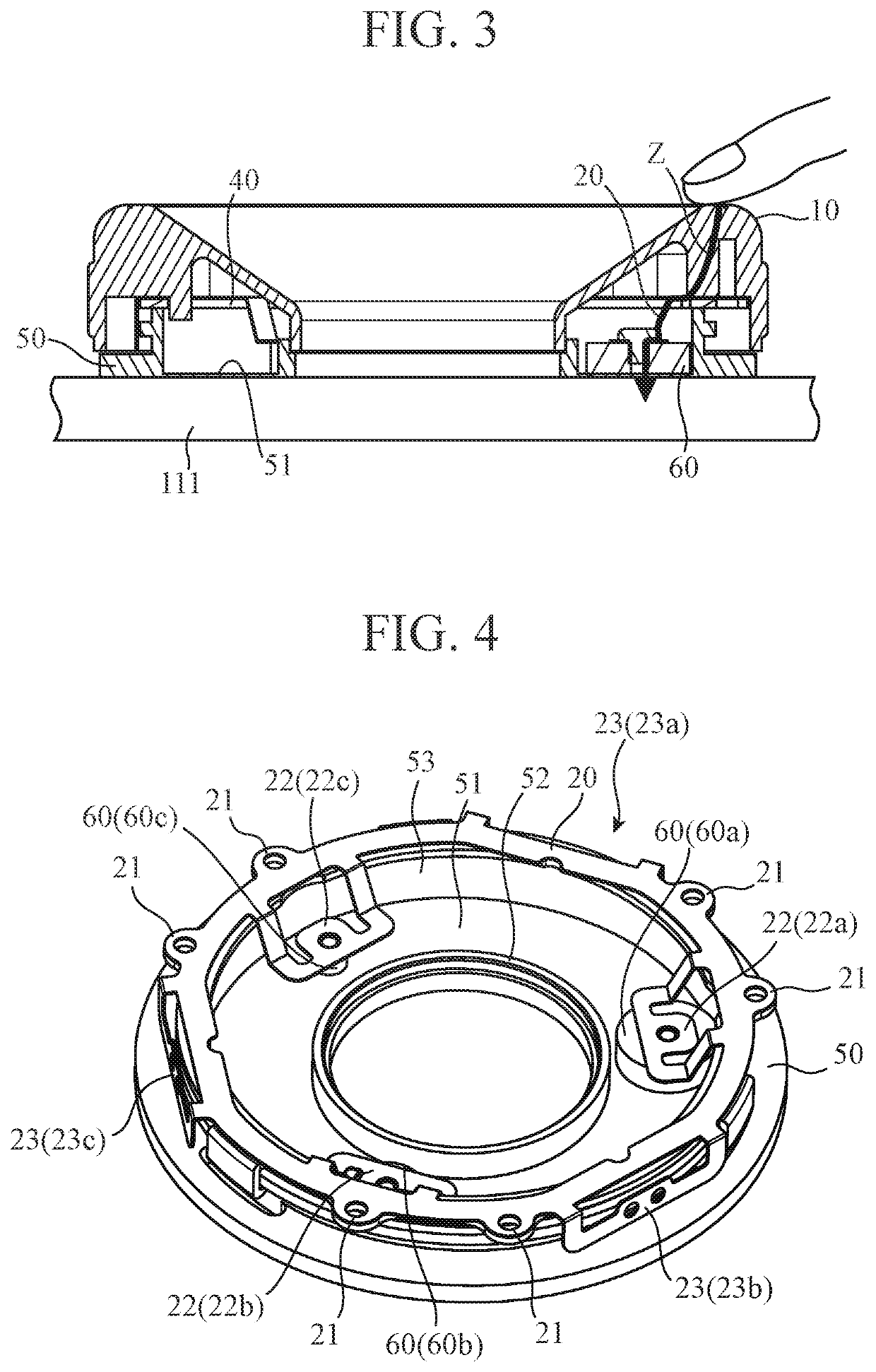

Knob and input device

ActiveUS20200278761A1Avoid detectionOccurrence can be preventedInput/output processes for data processingElectrical connectionControl theory

It includes: an operation portion comprised of a ring-shaped conductive member, a rotational operation being performed on the operation portion; a rotary supporting member comprised of a ring-shaped non-conductive member and fixed onto a capacitive type touch panel, the rotary supporting member rotatably supporting the operation portion; a ring-shaped concave groove disposed in the rotary supporting member; and conductive conducting terminal portions electrically connected to the operation portion, the conductive conducting terminal portions being rotated inside the concave groove integrally with the operation portion, positions of the conducting terminal portions being detected by the touch panel, wherein the operation portion is divided into a plurality of areas electrically insulated from each other in a circumferential direction, and at least two of the conducting terminal portions are mounted to different areas of the plurality of areas.

Owner:MITSUBISHI ELECTRIC CORP

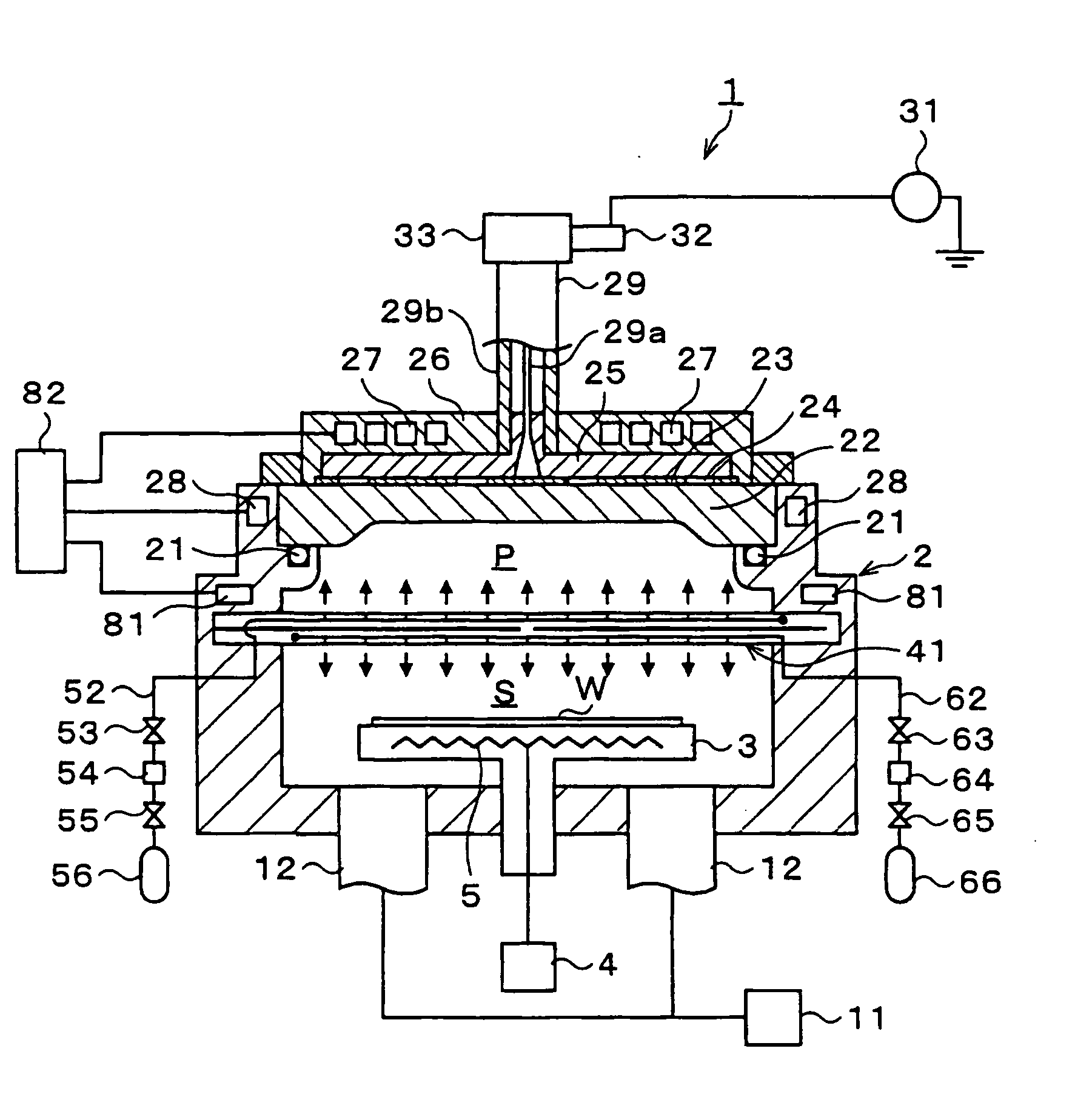

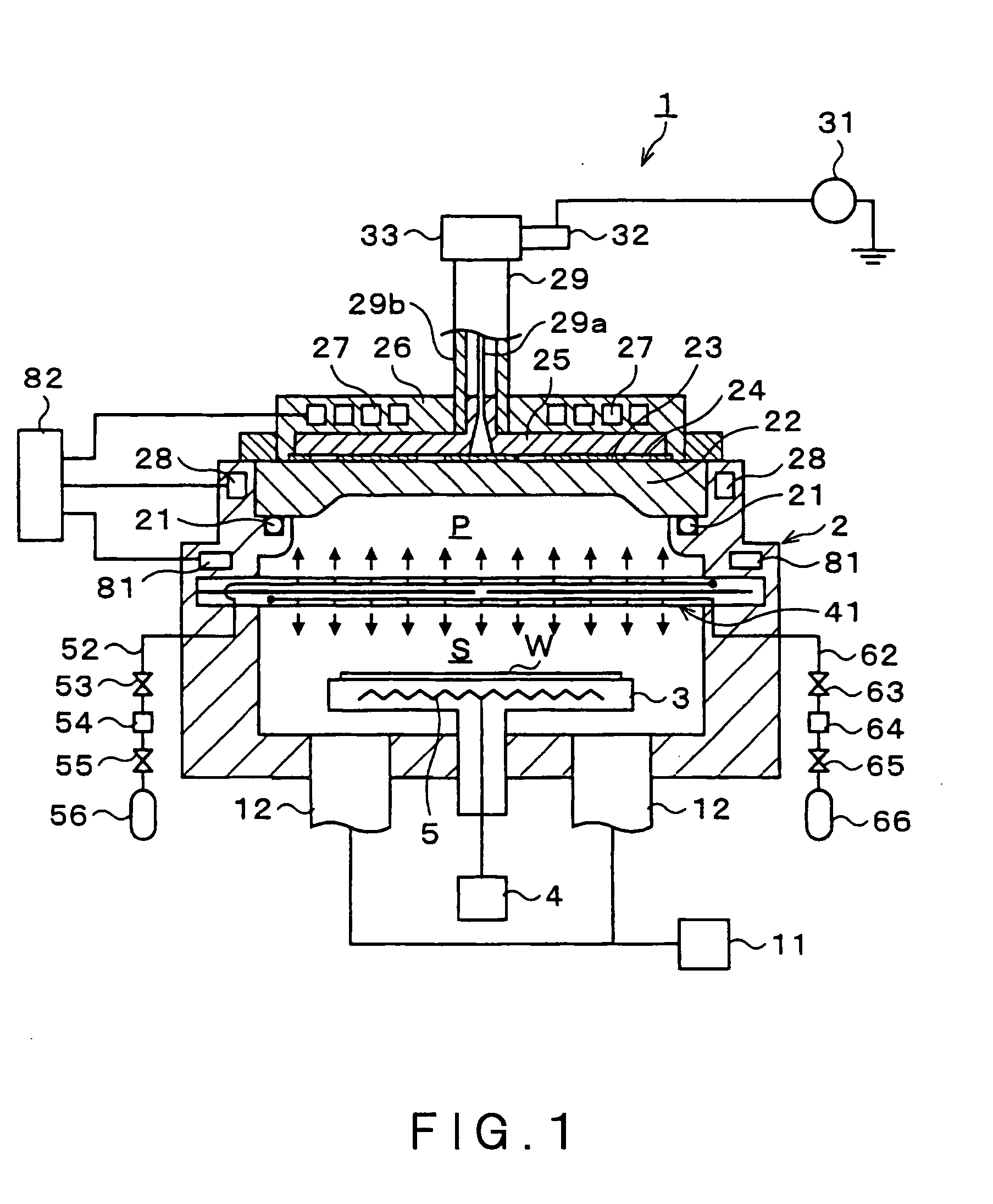

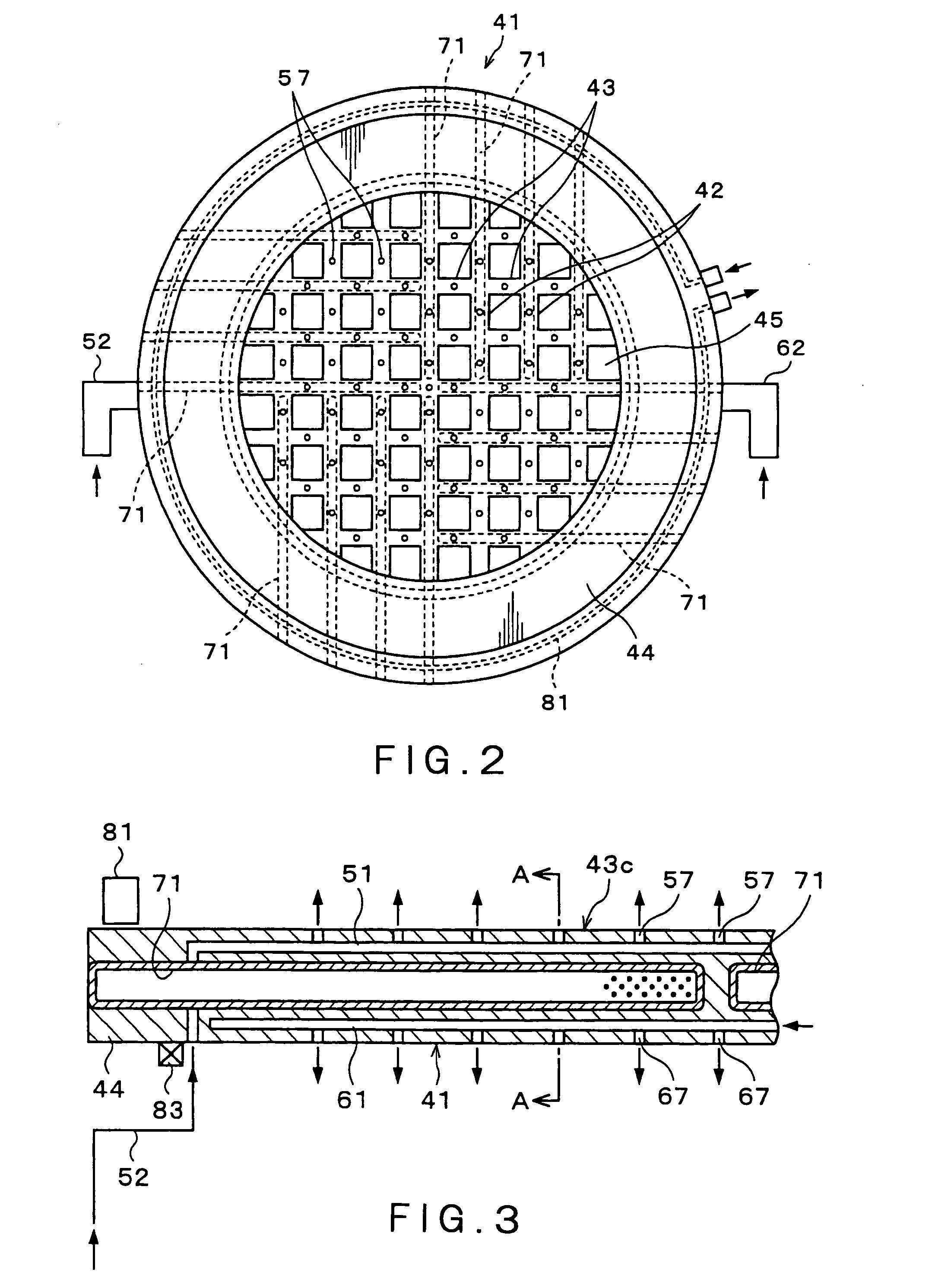

Plasma processing apparatus

InactiveUS20090065147A1Improve in-plane uniformitySuppression of distortionElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasEngineering

This invention is a plasma processing apparatus including: a processing vessel having: a plasma generating space in which a plasma is generated, and a processing space in which a substrate is placed and is subjected to a plasma process; a gas supplying plate arranged in the processing vessel so as to separate the plasma generating space and the processing space in the processing vessel; a process-gas supplying hole provided in the gas supplying plate for supplying a process gas into the processing vessel; a plurality of openings provided in the gas supplying plate for communicating the plasma generating space with the processing space; and a heat transfer member extending from a central region of the gas supplying plate to a peripheral region of the gas supplying plate, the heat transfer member having heat transfer rate higher than that of a material forming the gas supplying plate.

Owner:TOKYO ELECTRON LTD

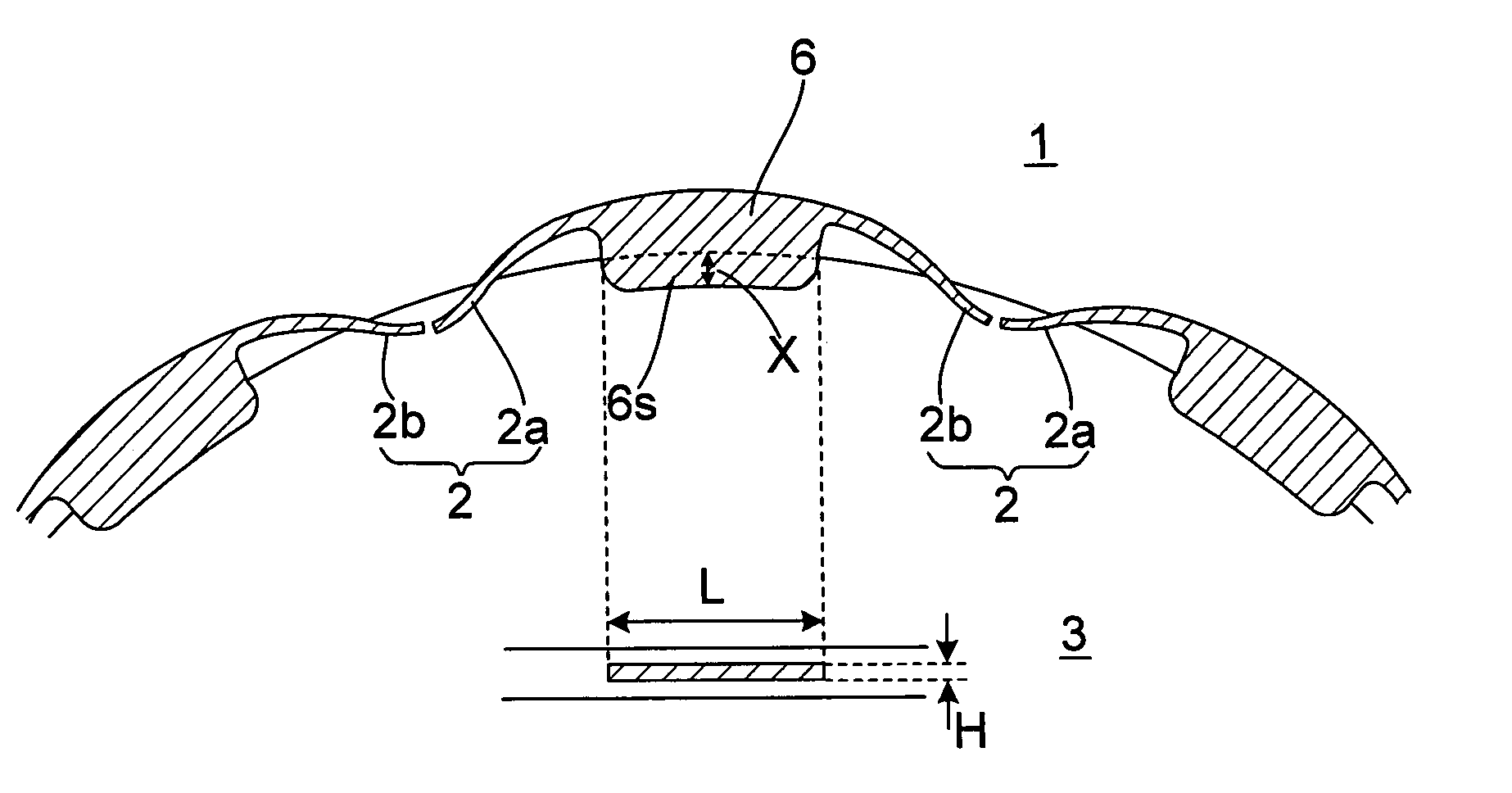

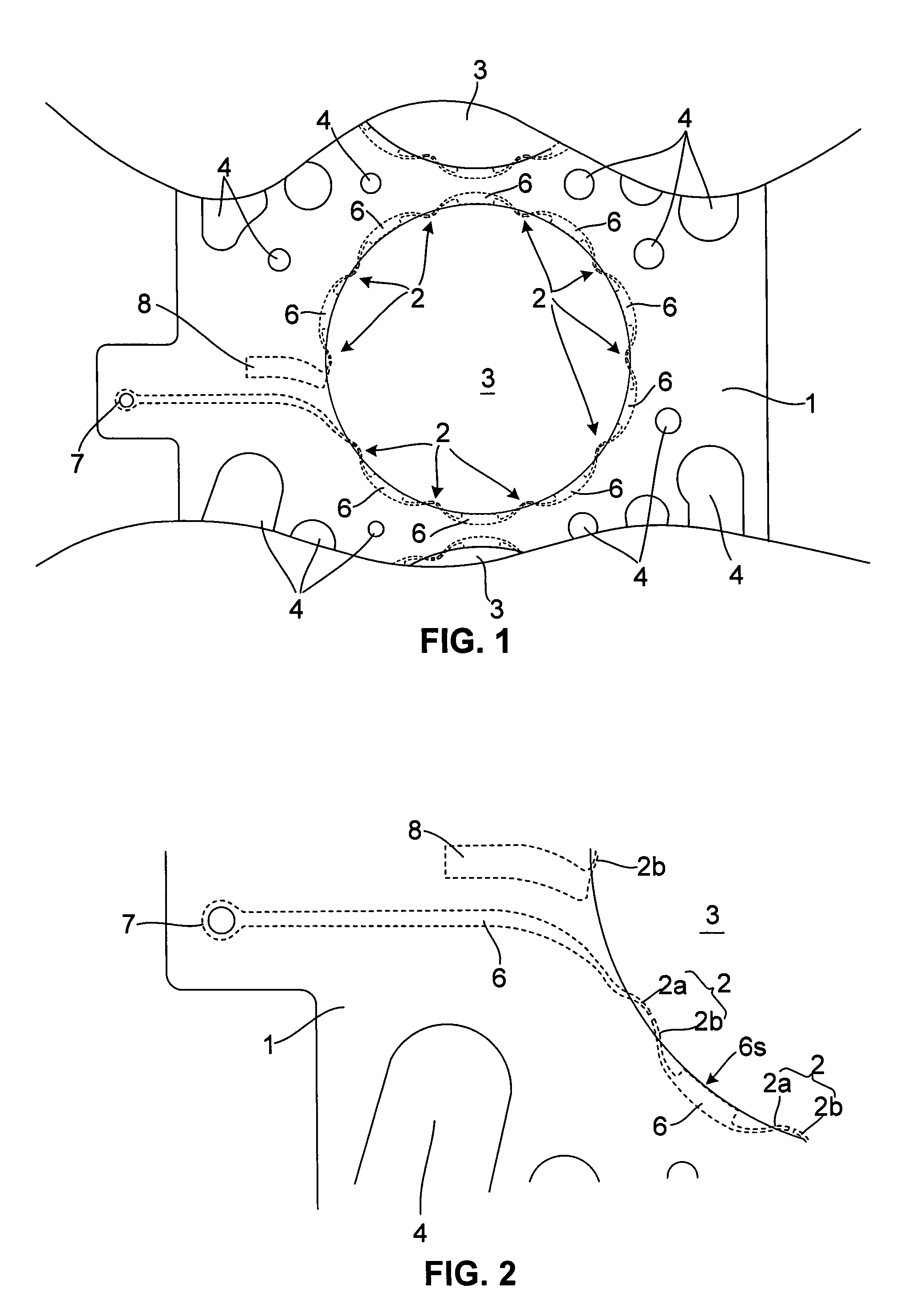

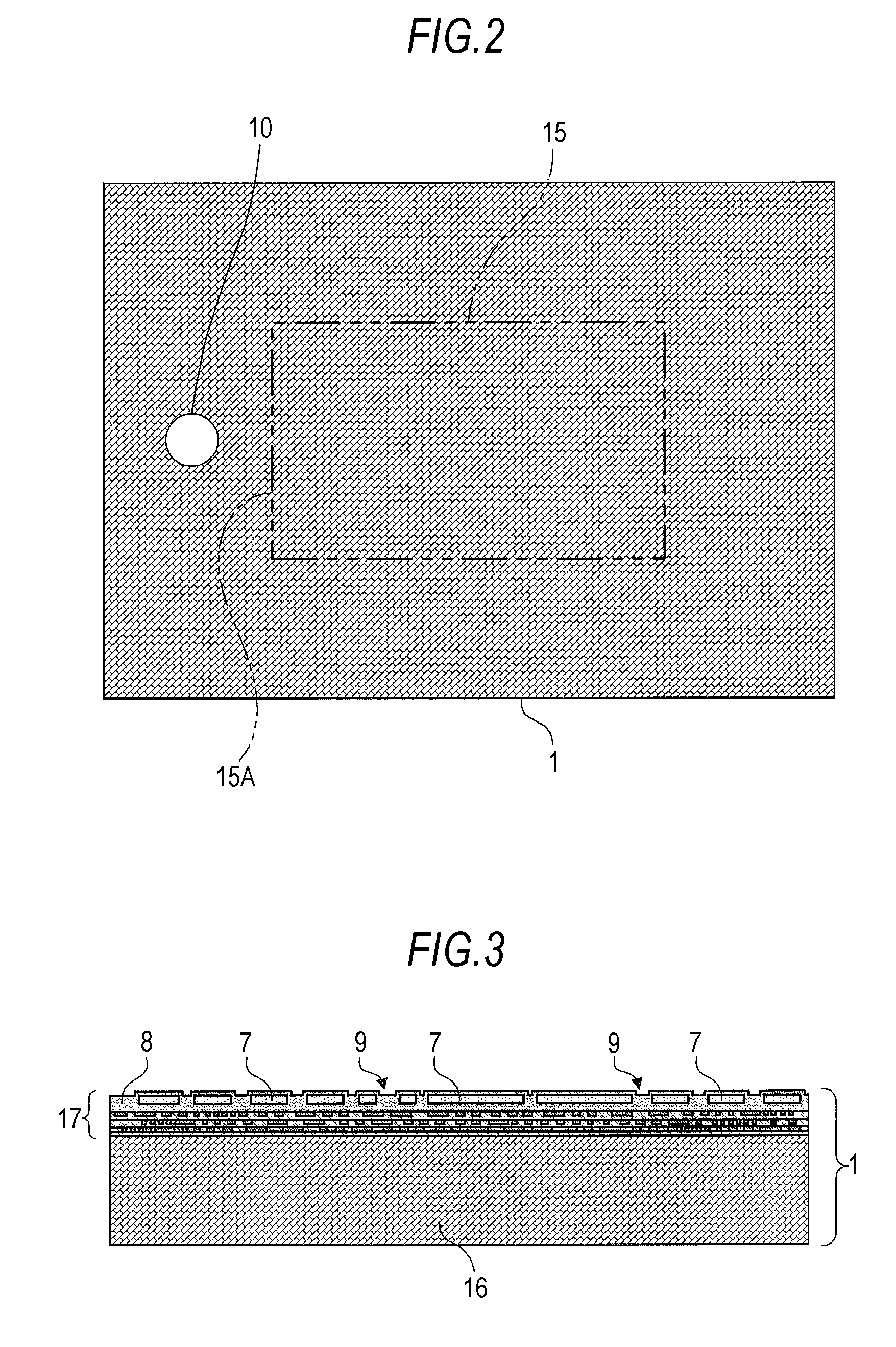

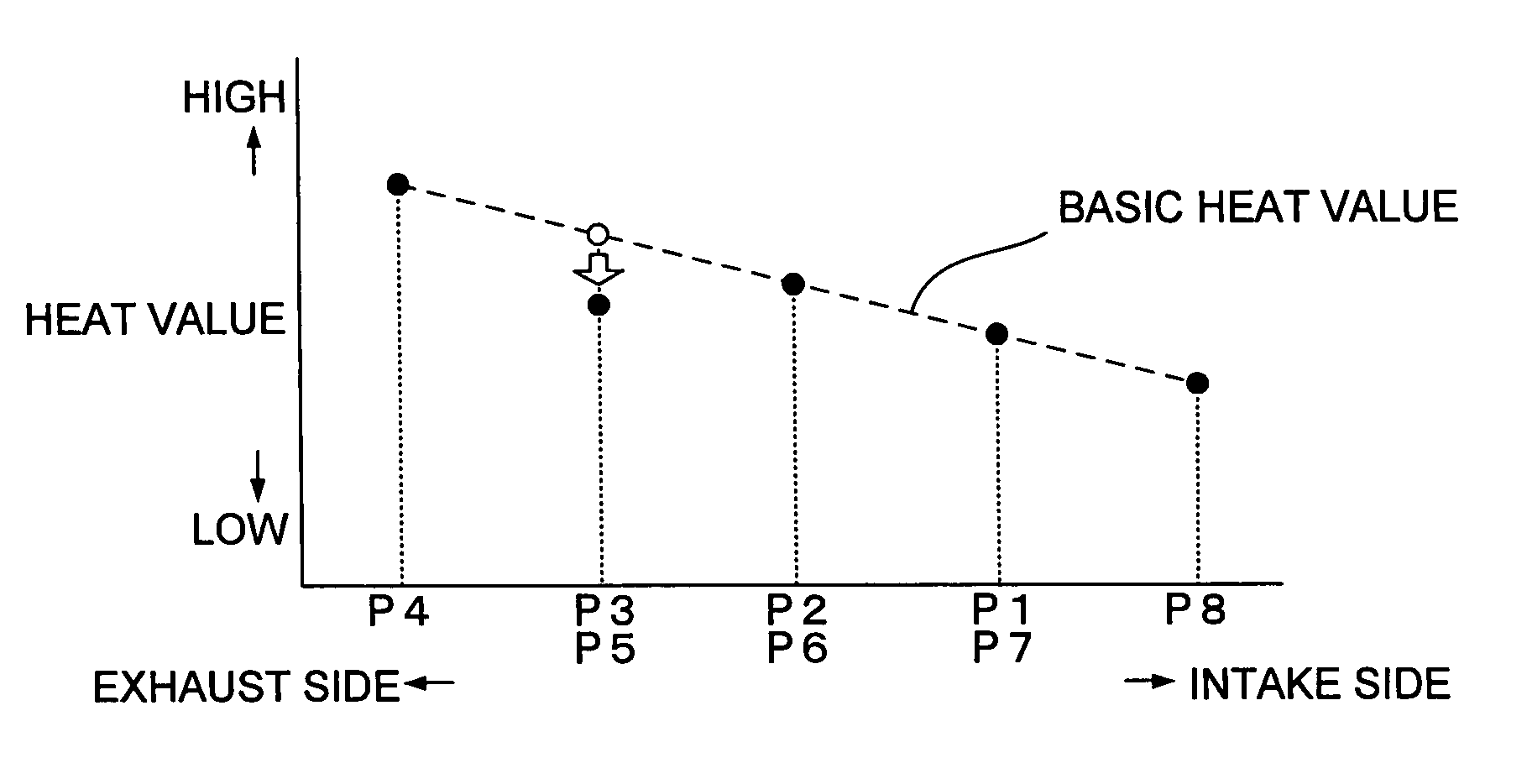

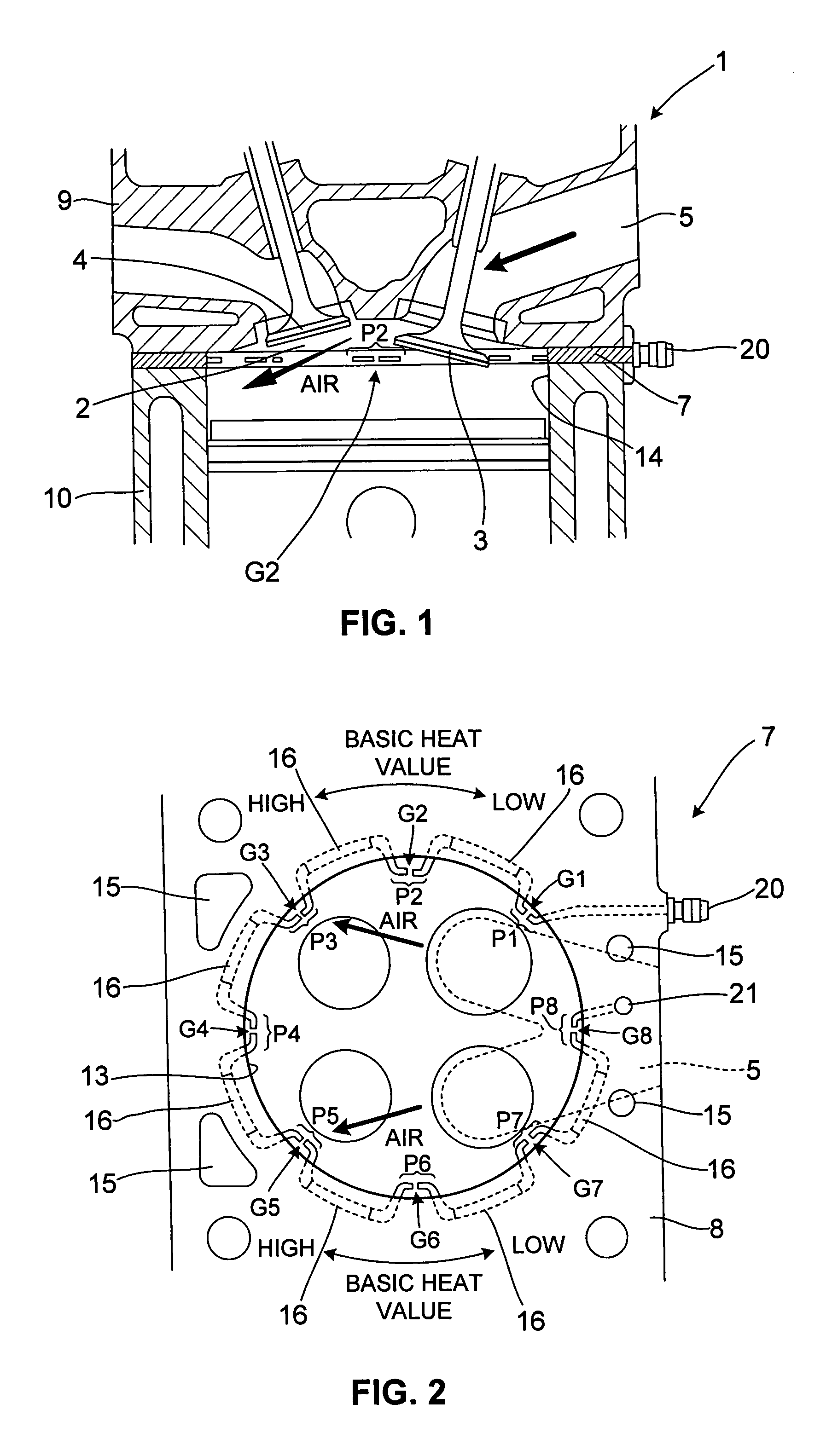

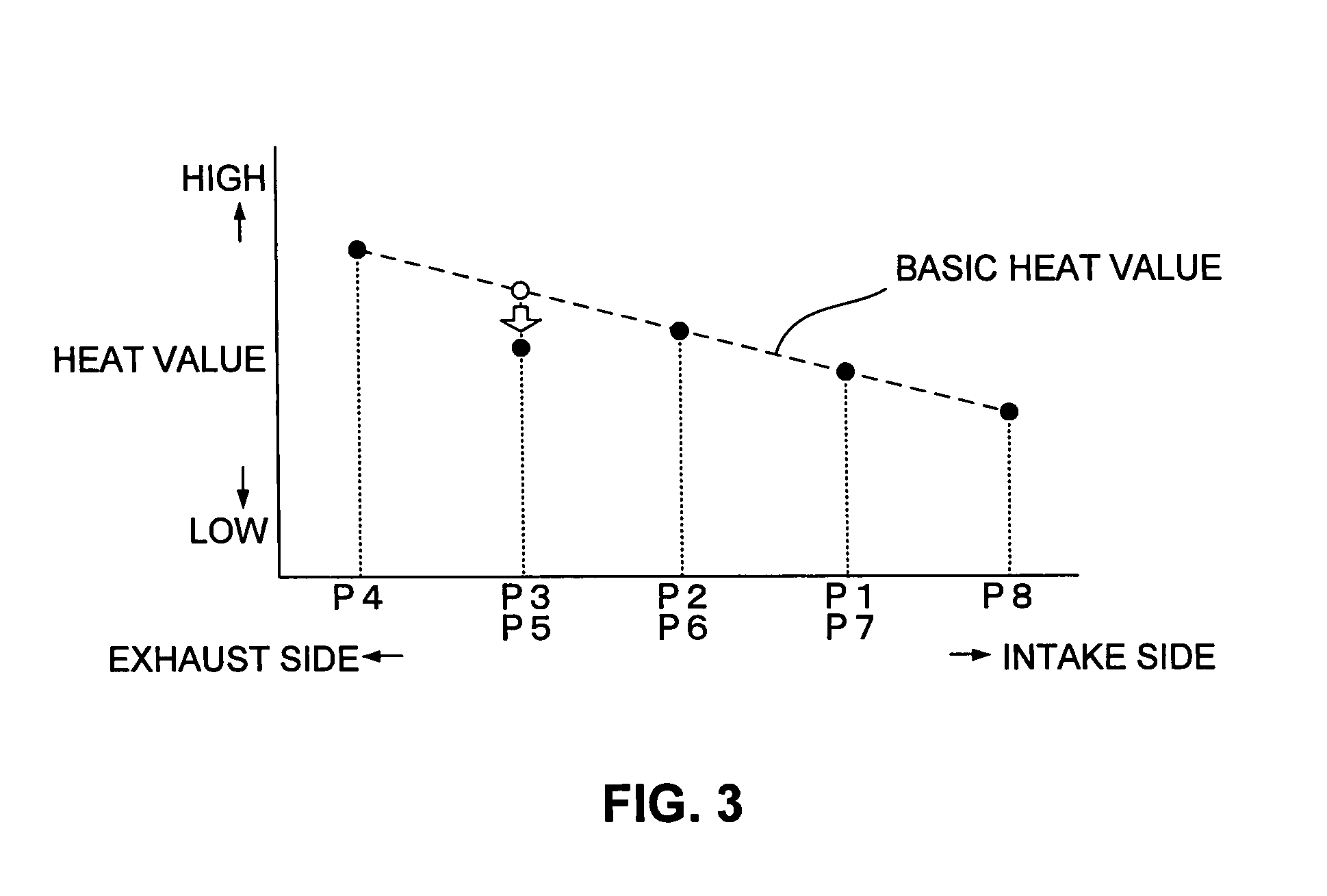

Multipoint ignition device

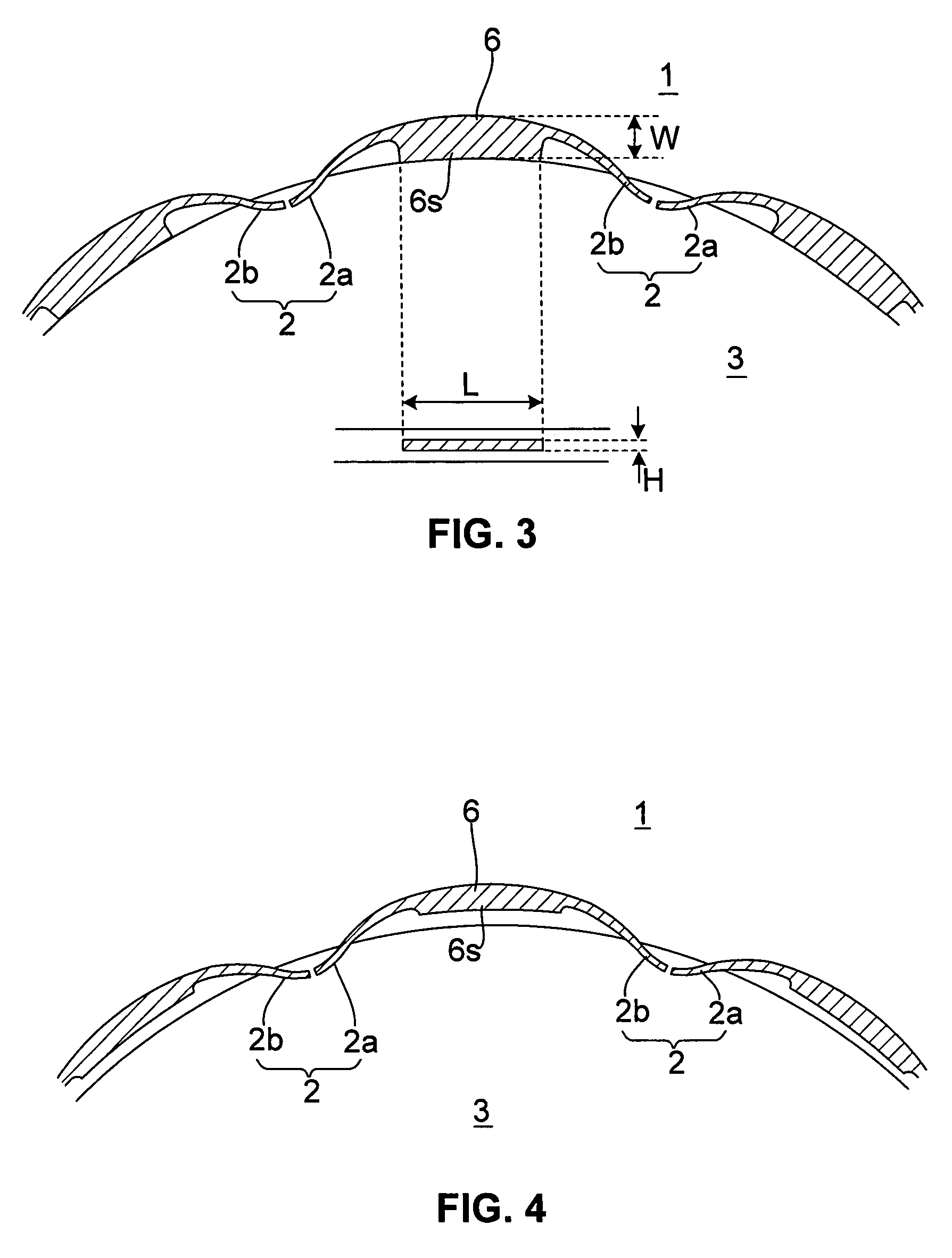

ActiveUS7441526B1Avoid pollutionOccurrence can be preventedSparking plugsElectric ignition installationEngineeringCylinder block

A multipoint ignition device comprises: a head gasket (1) interposed between a cylinder head and a cylinder block of an engine, having an opening (3) in a position corresponding to a cylinder opening portion; and a plurality of intermediate members (6) connected respectively to a plurality of electrode pairs (2) and held in the head gasket (1). Respective heat values of the plurality of electrode pairs (2) are set individually by varying the contact area between the plurality of intermediate members (6) and the head gasket (1) according to the respective disposal positions of the plurality of intermediate members (6).

Owner:MIYAMA

Semiconductor device with multi-layered wiring arrangement including reinforcing patterns, and production method for manufacturing such semiconductor device

InactiveUS20050101117A1Occurrence can be preventedInhibition productionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialElectronic component

A semiconductor device includes a semiconductor substrate having electronic elements produced therein, and an insulating underlayer formed thereon, and a multi-layered wiring arrangement constructed on the insulating underlayer semiconductor substrate. The multi-layered wiring arrangement includes a first insulating interlayer structure formed on the insulating underlayer, a second insulating interlayer structure, and a third insulating interlayer structure formed on the first insulating interlayer structure. Each of the first, second and third insulating interlayer structures includes a low-k insulating layer, and has a reinforcing element formed therein. The second insulating interlayer structure has a joint plug formed therein. The reinforcing elements of the first and third insulating interlayer structures are connected to each other through the joint plug.

Owner:RENESAS ELECTRONICS CORP

Functional device and method of manufacturing the same

InactiveUS6716664B2Avoid layeringOccurrence can be preventedTransistorSolid-state devicesAcrylic resinThermal expansion

A functional device free from cracking and having excellent functional characteristics, and a method of manufacturing the same are disclosed. A low-temperature softening layer (12) and a heat-resistant layer (13) are formed in this order on a substrate (11) made of an organic material such as polyethylene terephthalate, and a functional layer (14) made of polysilicon is formed thereon. The functional layer (14) is formed by crystallizing an amorphous silicon layer, which is a precursor layer, with laser beam irradiation. When a laser beam is applied, heat is transmitted to the substrate (11) and the substrate (11) tends to expand. However, a stress caused by a difference in a thermal expansion coefficient between the substrate (11) and the functional layer (14) is absorbed by the low-temperature softening layer (12), so that no cracks and peeling occurs in the functional layer (14). The low-temperature softening layer (12) is preferably made of a polymeric material containing an acrylic resin. By properly interposing a metal layer and a heat-resistant layer between the substrate (11) and the functional layer (14), a laser beam of higher intensity can be irradiated.

Owner:SONY CORP

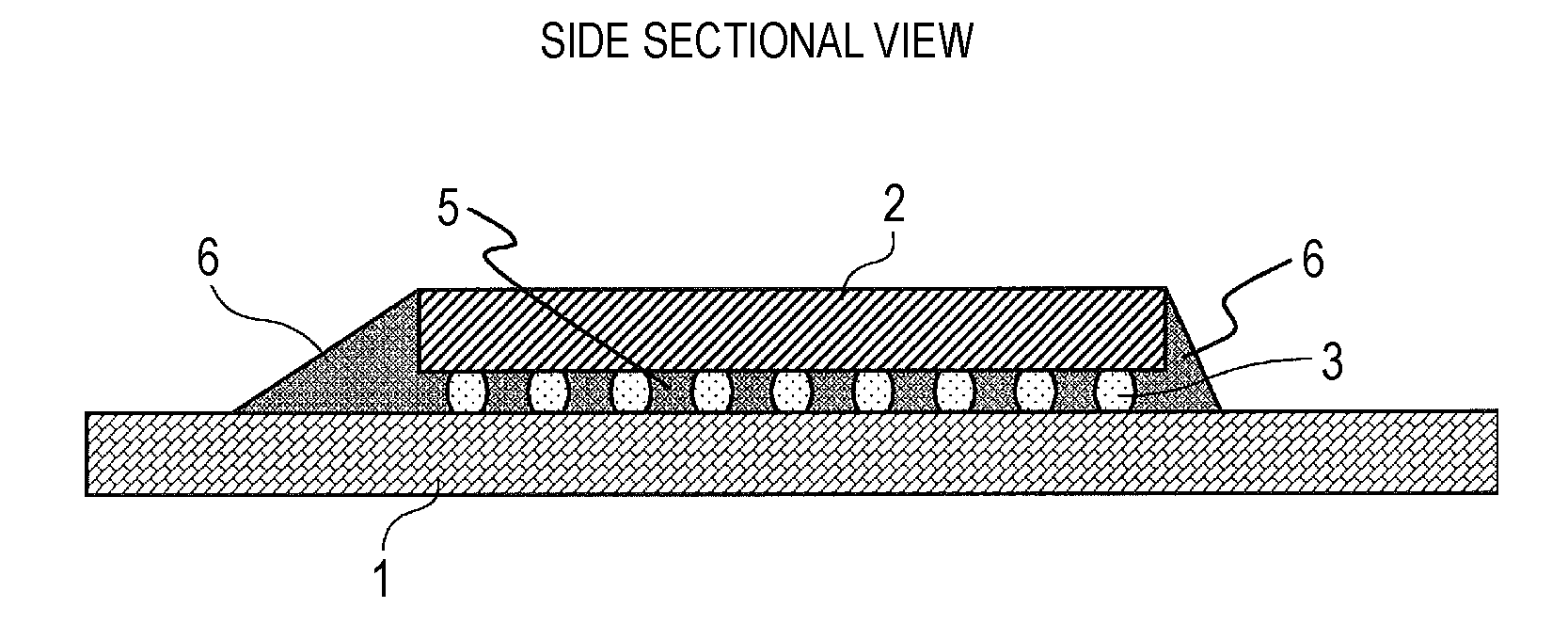

Semiconductor device and manufacturing method of the semiconductor device

ActiveUS20100181680A1Occurrence can be preventedImprove connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesFilling materialsSemiconductor chip

A semiconductor device includes: a mounted body in which a wiring pattern is formed on a first main surface; a semiconductor chip mounted on the surface of the mounted body on which the wiring pattern is formed; an underfill material which is filled between the mounted body and the semiconductor chip and forms a fillet on an outer peripheral part of the semiconductor chip; and an injection section which is disposed on the mounted body and on an outside of a side section, on which the fillet is formed to be longest, of four side sections defining a chip mount area on which the semiconductor chip is mounted, and guides the underfill material to between the mounted body and the semiconductor chip.

Owner:SONY CORP

Production method for a multilayer ceramic substrate

InactiveUS7243424B2Small sizeIncrease flexibilitySemiconductor/solid-state device detailsSolid-state devicesDielectricMetallurgy

An object of the invention is to connect different dielectrics electrically to each other in the direction of main surface of a sheet in a multilayer ceramic substrate and to increase the degree of flexibility in design and make the multilayer ceramic substrate compact in size. A multilayer ceramic substrate in accordance with the invention is formed of a plurality of laminated ceramic substrates including such a composite ceramic substrate of different materials that is made by inserting the second ceramic substrate in a pounched-out portion made in the first ceramic substrate and by planarizing its top and bottom surfaces, wherein a conductive layer is formed in a portion across a boundary between the first ceramic substrate and the second ceramic substrate of the interface of the composite ceramic substrate of different materials.

Owner:TDK CORPARATION

Display device and drive method thereof

InactiveUS7304630B2Image be preventedOccurrence can be preventedStatic indicating devicesNon-linear opticsRoundingScan line

A display apparatus and a method for driving the display apparatus that are capable of suppressing image quality degradation resulting from delay in sampling pulses or from waveform rounding thereof and image quality degradation caused by coupling between the signal line and the common line and that between the signal line and the scan line even when the simultaneous sampling number is increased. The start pulse HST has a pulse width that includes a plurality of pulse widths of the clock pulses HCK and HCKX, for example, two pulse widths. The clock pulses DCK have four phases. Large margins α1 and α2 in the phase relationship between each of the clock pulses DCK1 to DCK4 and each of transfer pulses used for extracting the clock pulses DCK1 to DCK4 are assured. As a result, even if delay or waveform rounding occurs in the clock pulses DCK1 to DCK4, sampling pulses SP1 to SP6 with a constant pulse width equal to that of each of the clock pulses DCK1 to DCK4 can be generated without being affected by the delay or waveform rounding.

Owner:SONY CORP

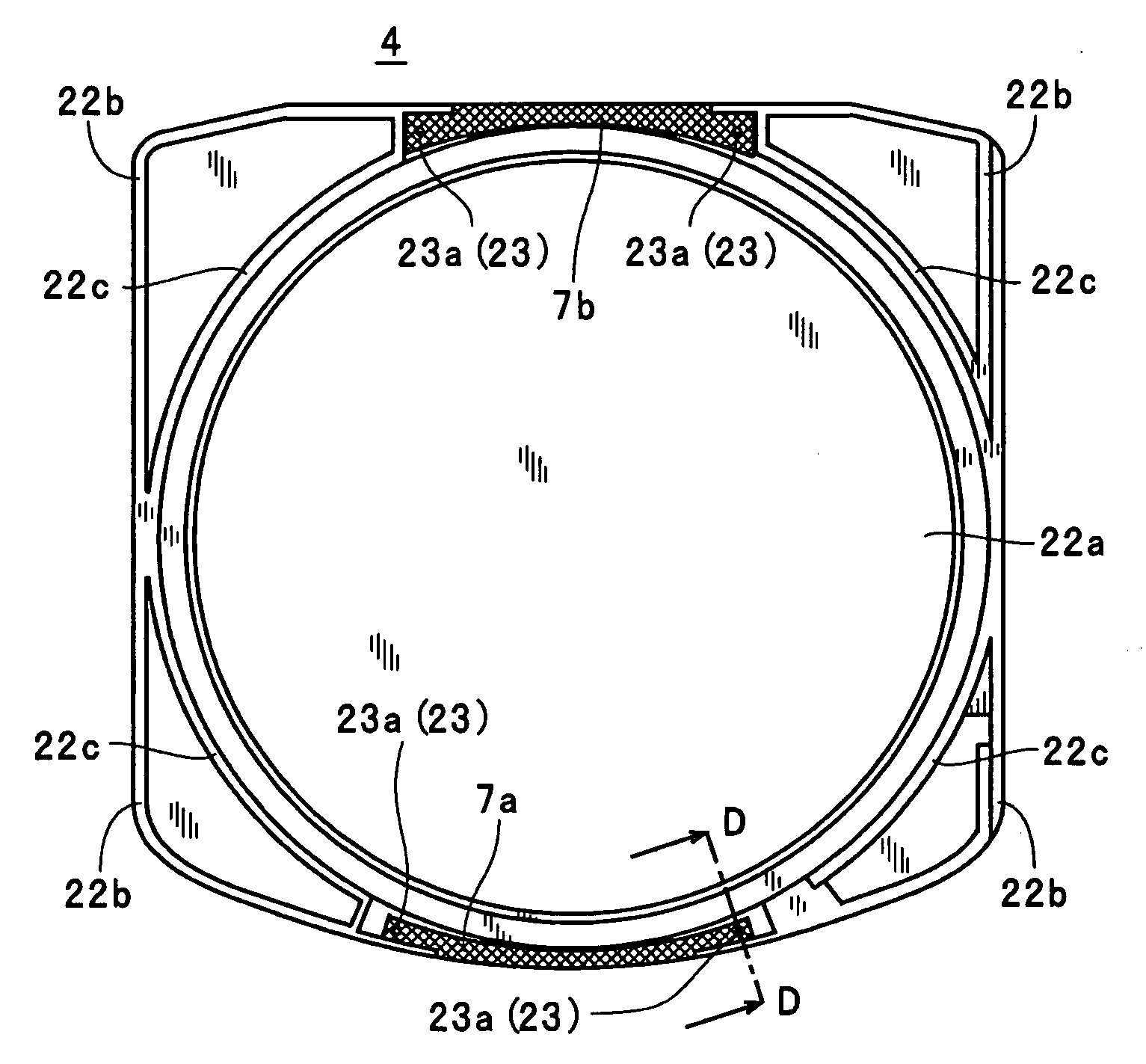

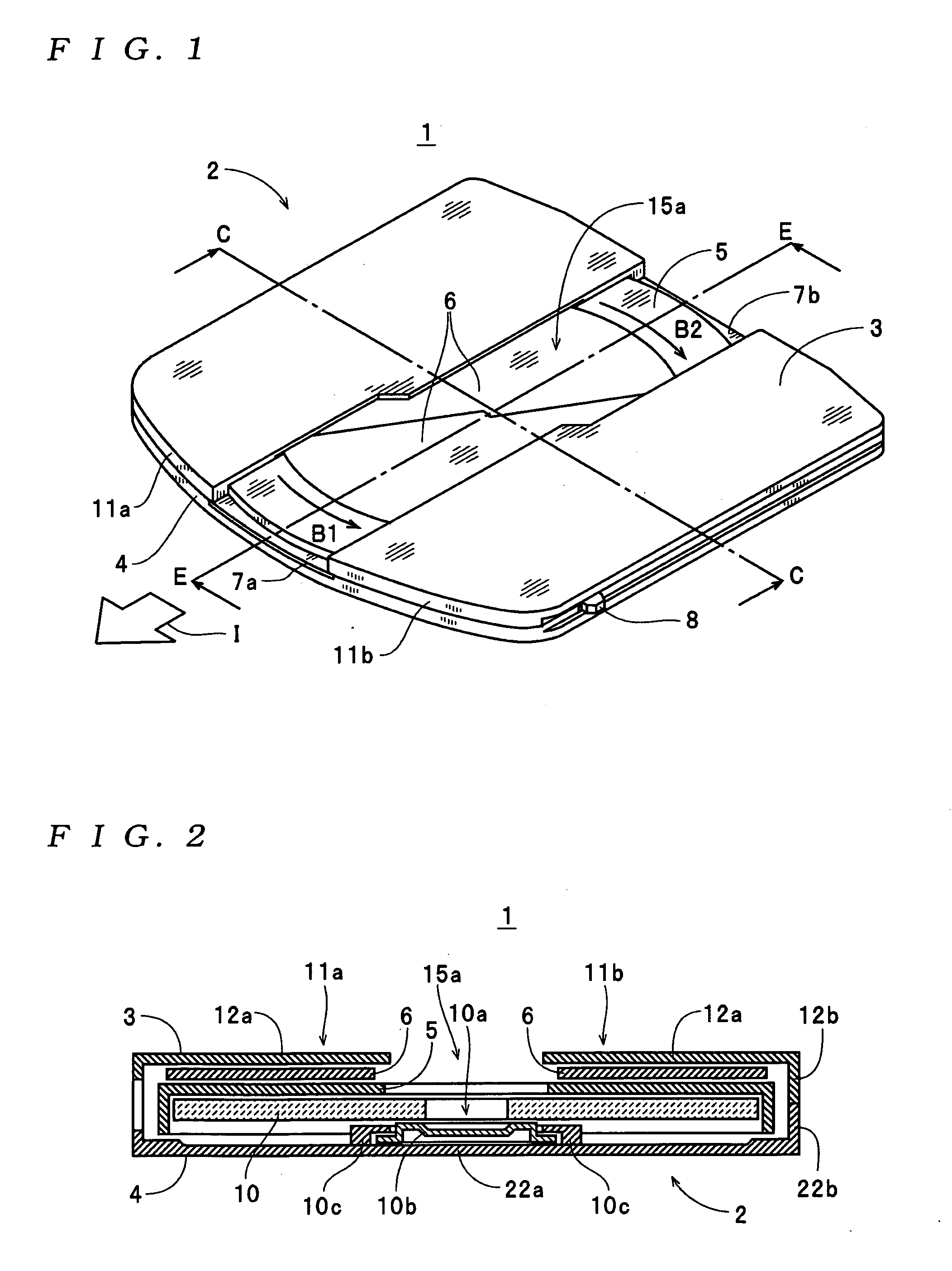

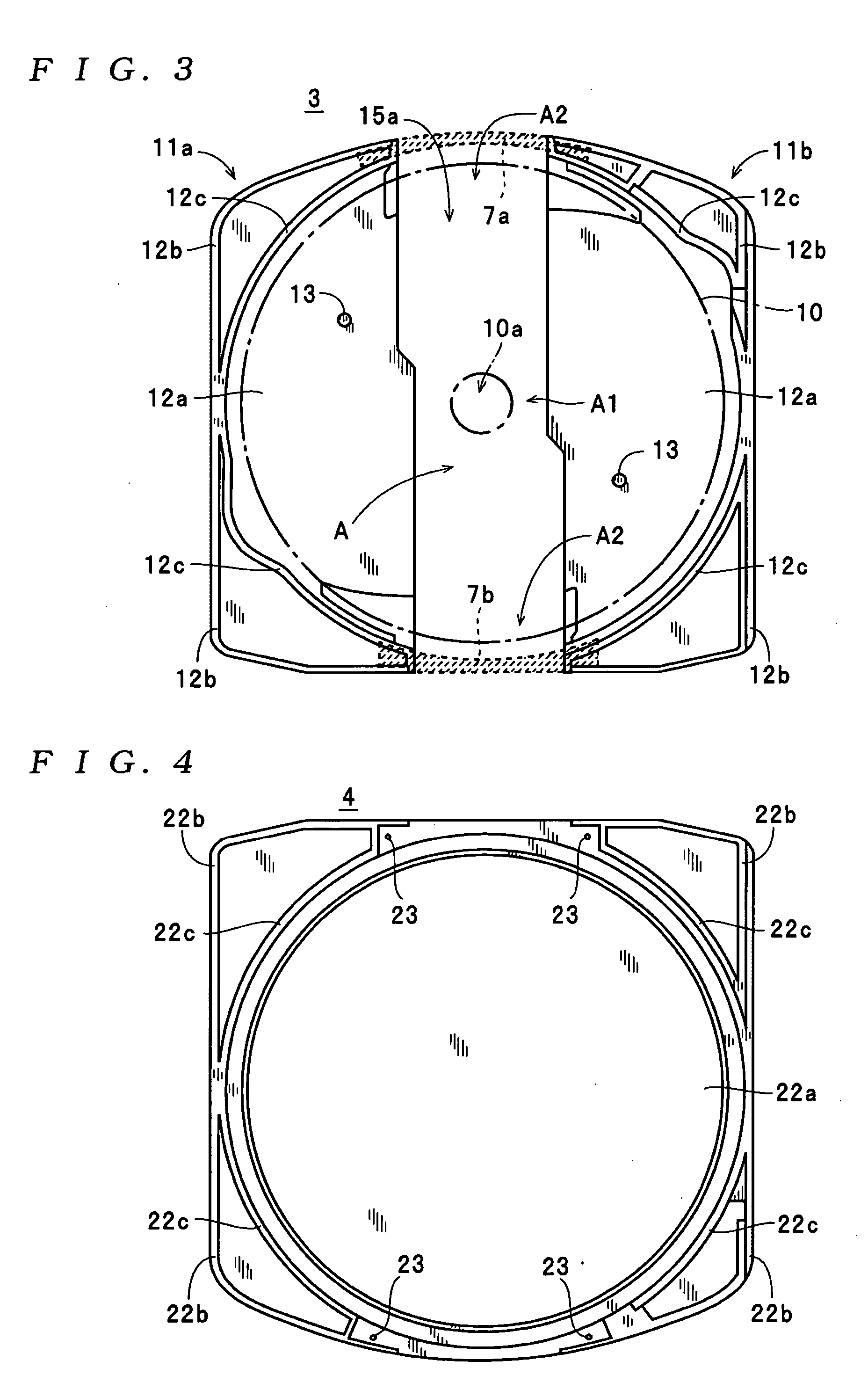

Disc cartridge

InactiveUS20050216929A1Avoid dataOccurrence can be preventedRecord information storageFlat record carrier containersBand shapeEngineering

A disc cartridge includes a disc-shaped recording medium accommodated in a cartridge main body having a lower shell and an upper shell overlapping each other, a disc access opening formed from one outside edge part of the lower shell to a central portion thereof to expose a belt-shaped region of the disc-shaped recording medium accommodated in the cartridge main body from the central region thereof to at least the outside edge part region thereof, and a reinforcing member formed independently of the upper shell and fixed to the inner surface of the upper shell so as to cross a portion located at the outside edge part of the lower shell in the disc access opening at the position where the reinforcing member does not overlap the disc-shaped recording medium accommodated in the cartridge main body in the thickness direction thereof.

Owner:TDK CORPARATION

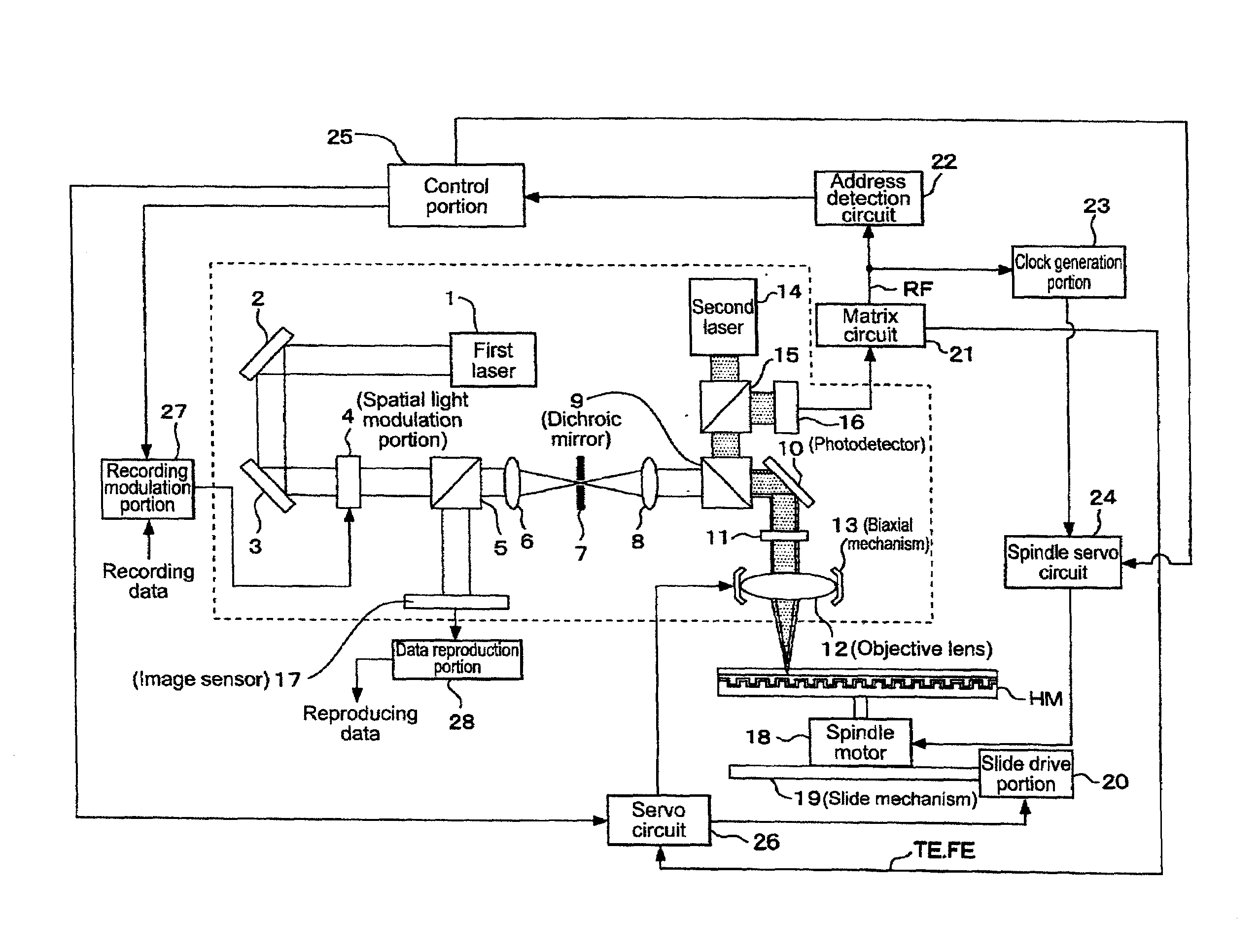

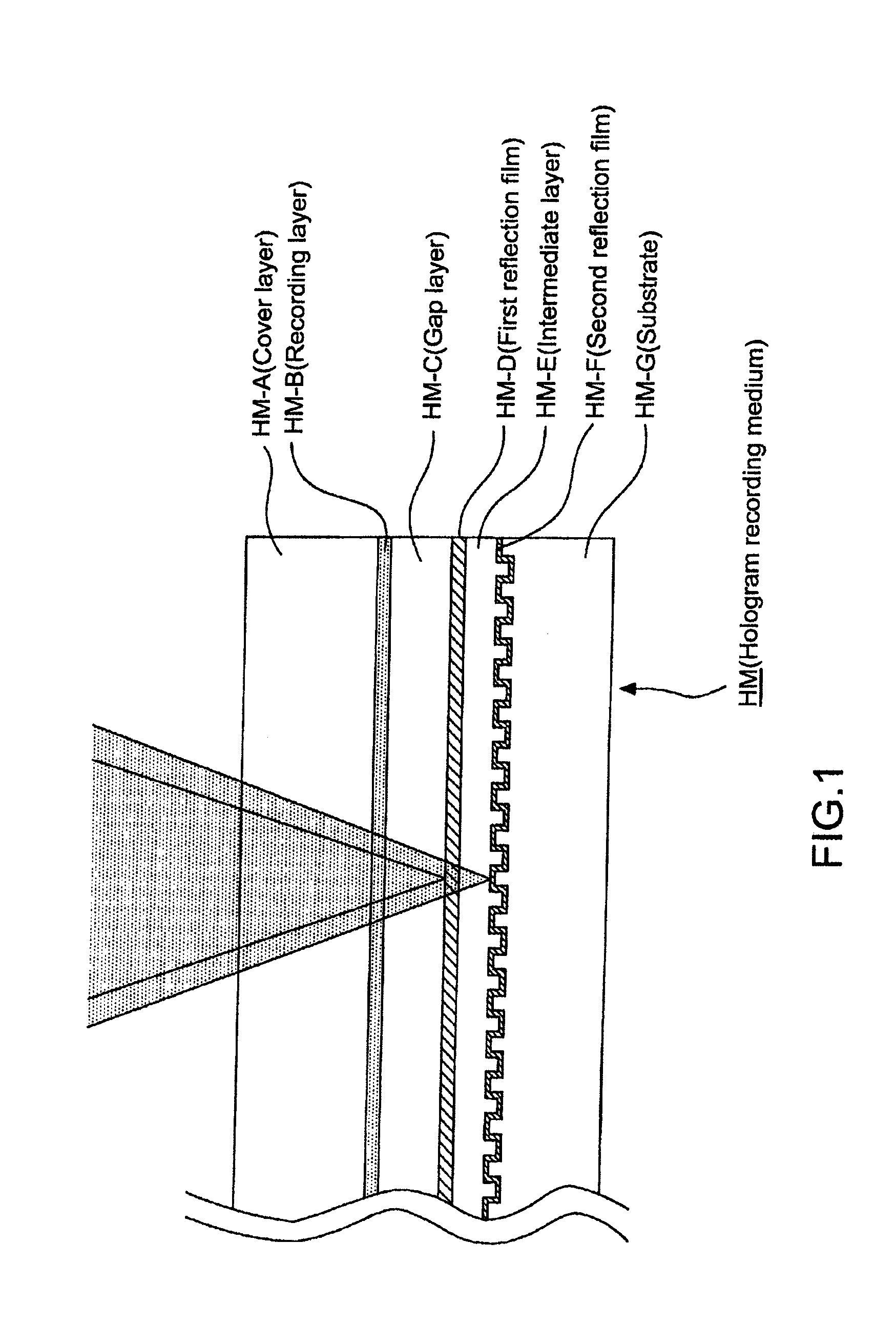

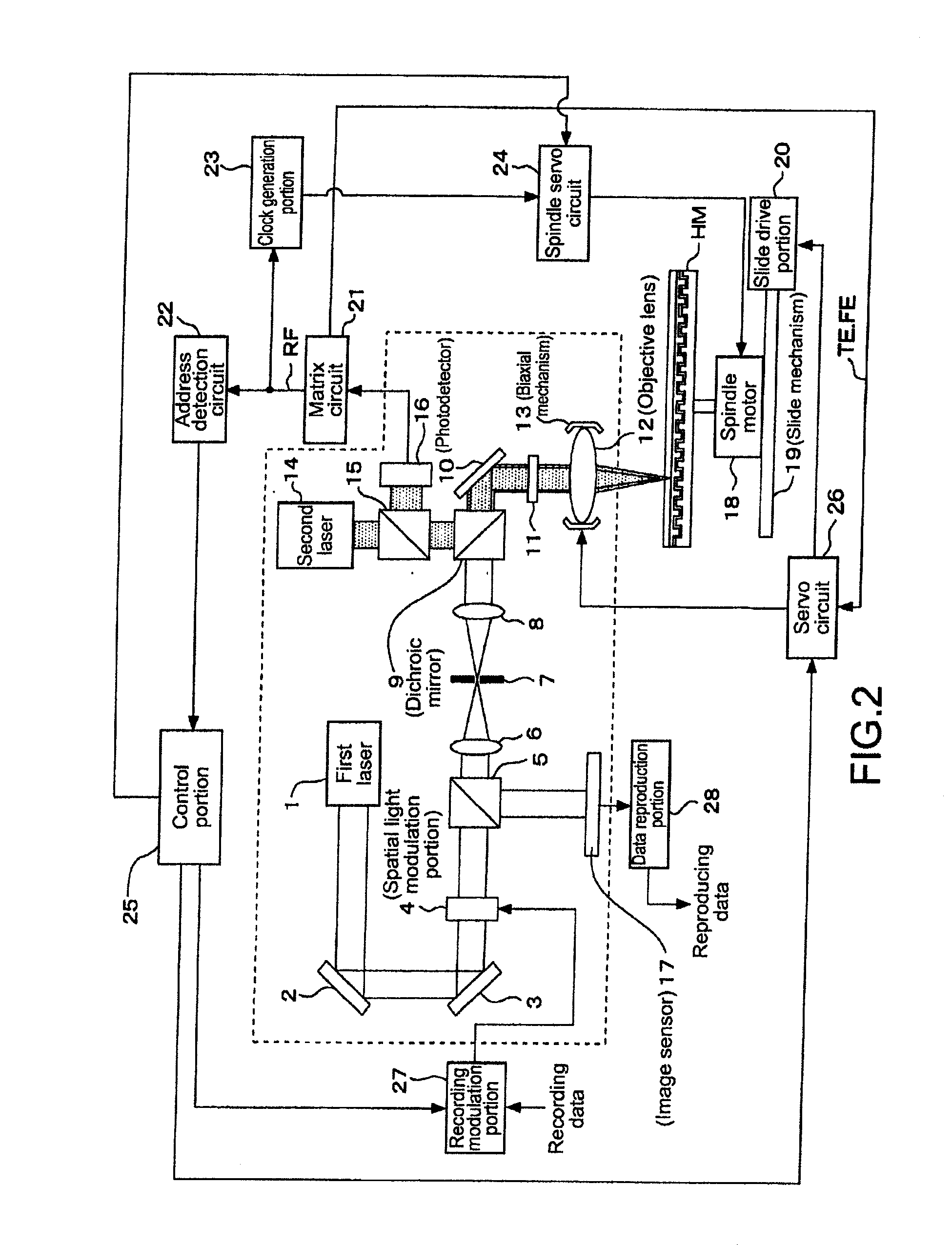

Reproduction method and hologram recording medium

InactiveUS20090219798A1Avoid damageAvoid dataOptical beam sourcesHolographic optical componentsLight irradiationSignal light

Disclosed is a reproduction method for a hologram recording medium on which information is recorded with interference fringes of signal light and reference light, including: generating, based on light from a first light source, the reference light and coherent light caused to have uniform amplitude and phase, and irradiating the hologram recording medium with the reference light and the coherent light, the hologram recording medium including a recording layer on which the information is recorded with the interference fringes of the signal light and the reference light, a first reflection film formed on a lower surface side of the recording layer, and a gap layer formed between the recording layer and the first reflection film; and receiving the coherent light and a reproduction image that corresponds to recording information and is obtained as reflection light from the hologram recording medium through light irradiation in the light irradiation step, and reproducing the information based on a result of the light received.

Owner:SONY CORP

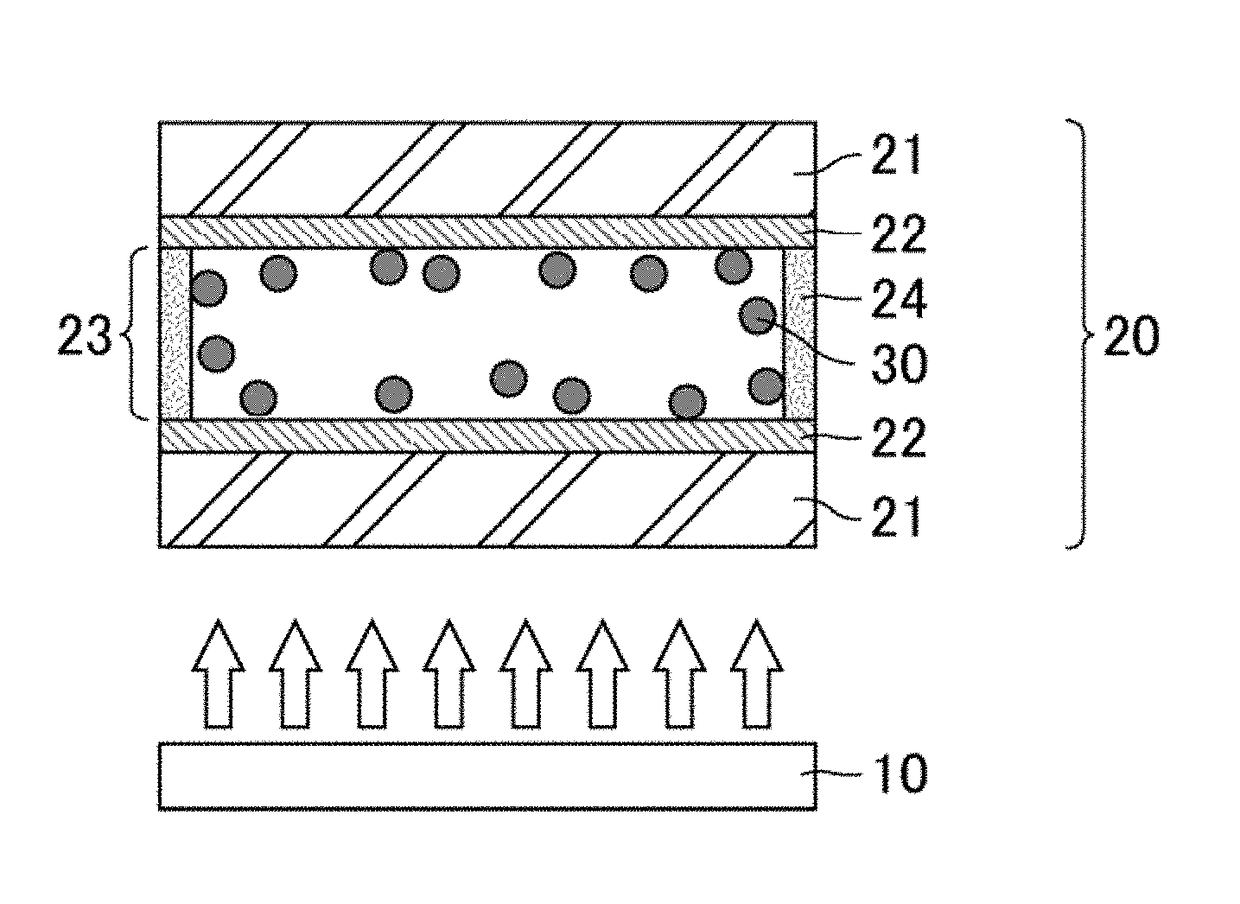

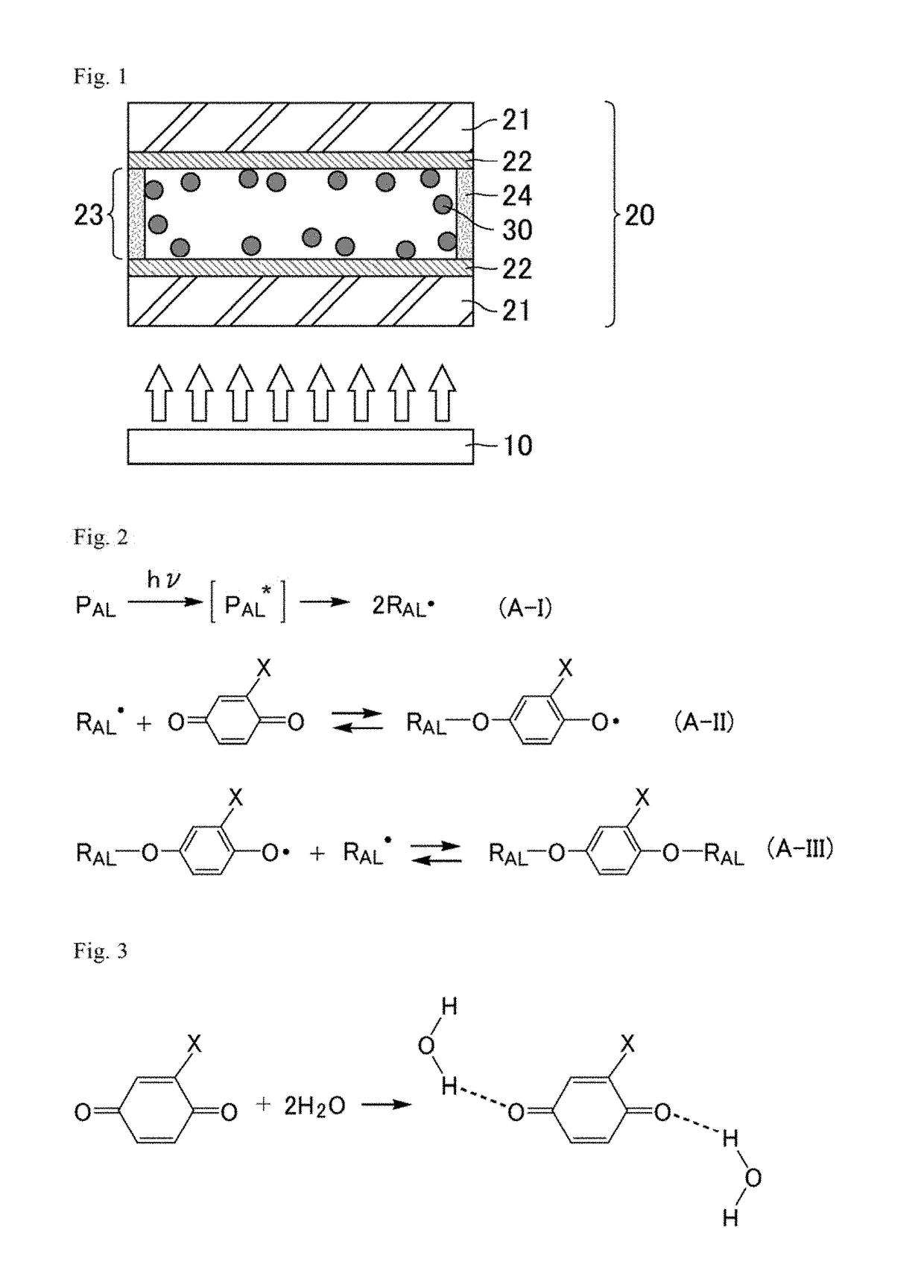

Liquid crystal display device

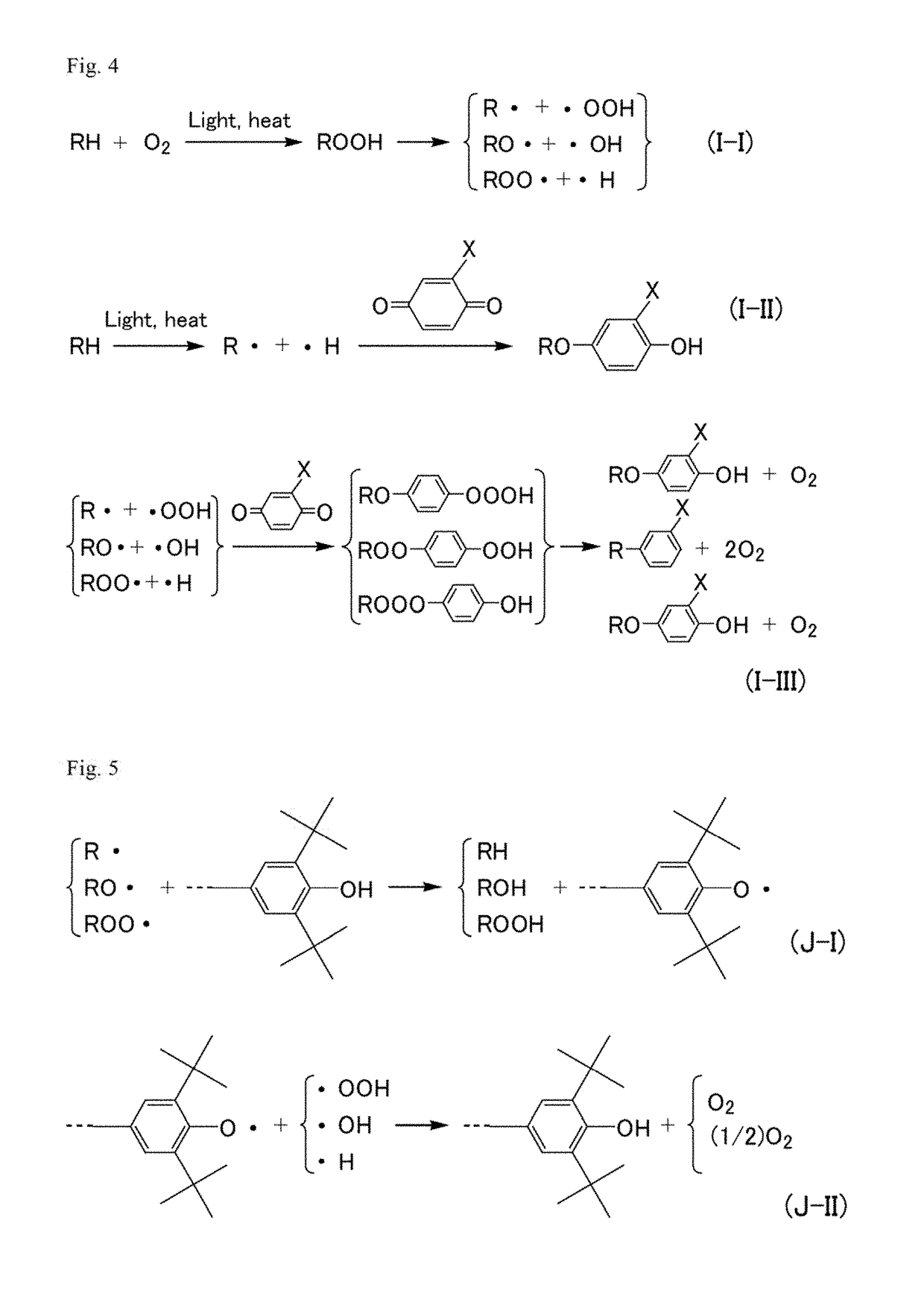

ActiveUS20180113337A1Decrease of voltage holding ratio can be preventedFavorable voltage holding ratioLiquid crystal compositionsNon-linear opticsQuinoneLiquid-crystal display

The present invention provides, by using a photo-alignment film, a liquid crystal display device in which a good voltage holding ratio is retained for a long period of time and occurrence of image sticking and stain in a display screen is prevented. The liquid crystal display device of the present invention includes an active matrix liquid crystal panel and a backlight. The liquid crystal panel includes a liquid crystal layer, a pair of substrates that sandwich the liquid crystal layer in between, and an alignment film disposed on a liquid crystal layer side surface of each of the substrates. The alignment films are photo-alignment films formed from a material that exhibits a photo-alignment characteristic, and contain carboxyl groups on the liquid crystal layer side. The liquid crystal layer contains a liquid crystal material and at least one kind of quinone derivative selected from the group consisting of benzoquinone derivatives and anthraquinone derivatives.

Owner:SHARP KK

Knob and input device

ActiveUS11221692B2Avoid detectionOccurrence can be preventedInput/output processes for data processingElectrical connectionConductive materials

It includes a knob including: an operation portion comprised of a ring-shaped conductive material, a rotational operation being performed on the operation portion; a rotary supporting member comprised of a ring-shaped non-conductive material and fixed onto a capacitive type touch panel, for rotatably supporting the operation portion; a ring-shaped concave groove disposed in the rotary supporting member; and a conductive conducting terminal portion electrically connected to the operation portion and rotating inside the concave groove integrally with the operation portion, the position of the conducting terminal portion being detected by the touch panel, wherein the conducting terminal portion is comprised of a plurality of conducting terminal portions, surfaces of the conducting terminal portions being in contact with the concave groove, at least two of the surfaces of the conducting terminal portions being different in contact area from each other.

Owner:MITSUBISHI ELECTRIC CORP

Solid-state imaging element and method for manufacturing the same

InactiveUS20110139966A1Reduction of sensitivity and color mixing is preventedImprove efficiencySolid-state devicesMaterial analysis by optical meansRefractive indexEngineering

A solid-state imaging element includes a light-receiving element portion disposed in a semiconductor layer, an insulating layer made of a material having a refractive index n0, disposed over the semiconductor layer, and an antenna structure disposed over the light-receiving element portion and surrounded by an insulating layer. The antenna structure is made of a material having a refractive index higher than the refractive index of the insulating layer. The energy of light having entered the antenna structure and the insulating layer is concentrated in the light-receiving element portion.

Owner:SONY CORP

Vibrator support structure and manufacturing method for the support structure

ActiveUS7161282B2Avoid damageOccurrence can be preventedPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyAdhesiveHardness

In a vibrator support structure, a vibrator is supported on a substrate through support pins, substrate connection portions of the support pins and pin connection portions of the substrate are joined through conductive adhesive which is made of a resin including conductive filler and has a pencil hardness of about 4H or less, and the conductive adhesive has a thickness which can buffer vibrations and impacts propagated through the support pins.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com