Apparatus for fabricating a display device

a display device and apparatus technology, applied in the direction of non-linear optics, identification means, instruments, etc., can solve the problems of irradiation of necessary parts, silicon melts and undergoes aggregation, and thermal damage to the substrate, so as to prevent the occurrence of melting or aggregation of silicon film, prevent thermal damage to the glass substrate, and prevent the effect of irradiation high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the invention are described in detail hereinafter with reference to the accompanying drawings.

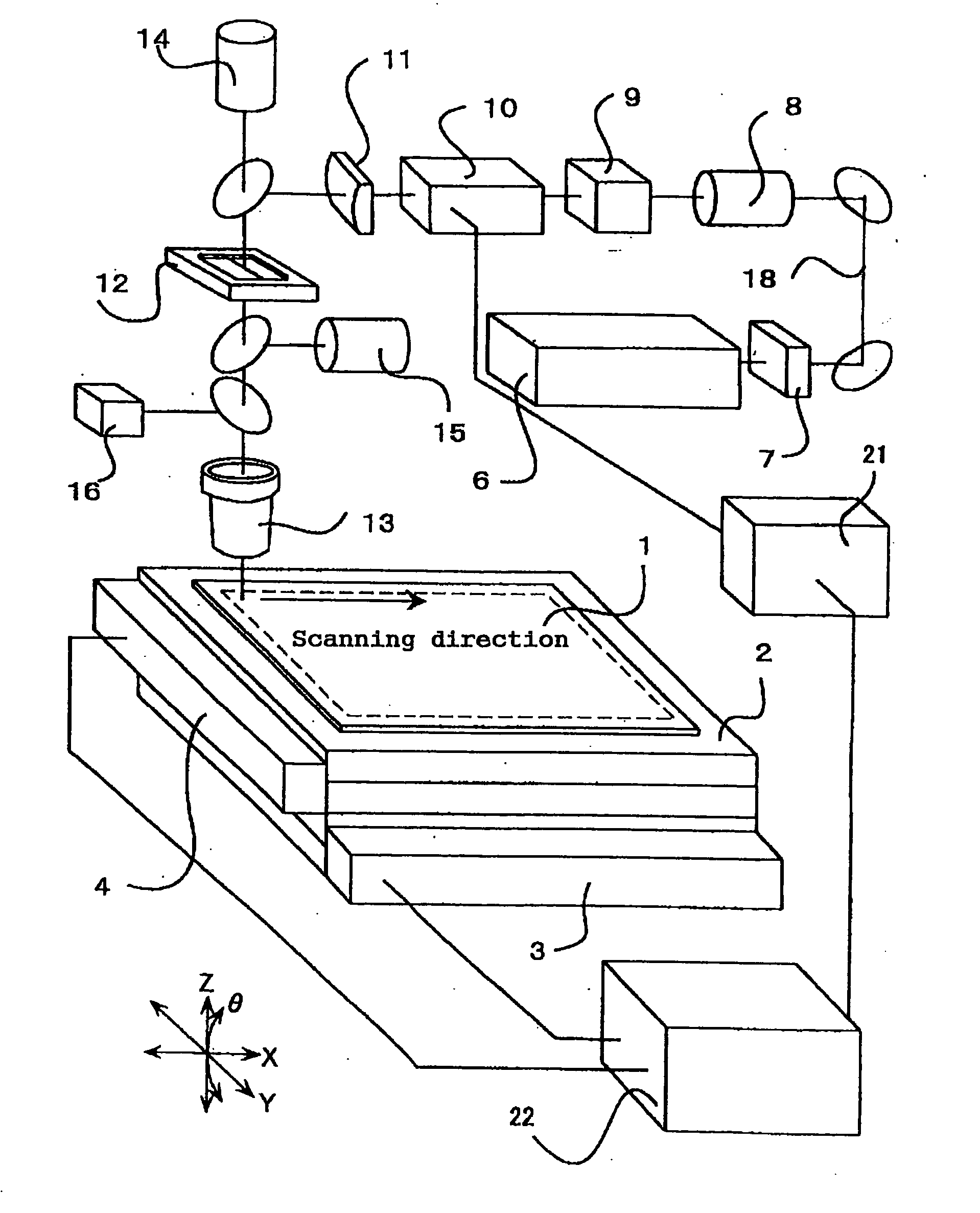

[0062]FIG. 1 is a block diagram for schematically illustrating an embodiment of an apparatus of fabricating a display device according to the invention for carrying out an embodiment of a process of fabricating the display device according to the invention. In this case, for an insulating substrate to serve as a thin-film transistor substrate, a glass substrate is used. A glass substrate 1 is movable in one direction (X) and in another direction (Y) crossing the one direction (X) at right angles, and is placed on a XYθ stage 2 (hereinafter referred to merely as stage) capable of adjusting both the directions (θ). The stage 2 fixedly attached to a platen (not shown) having a vibration isolation mechanism is provided with linear scales (also referred to as linear encoders) 3, 4, for detecting coordinates in the X direction and the Y direction, respectively.

[0063] A las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com