Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Improve bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

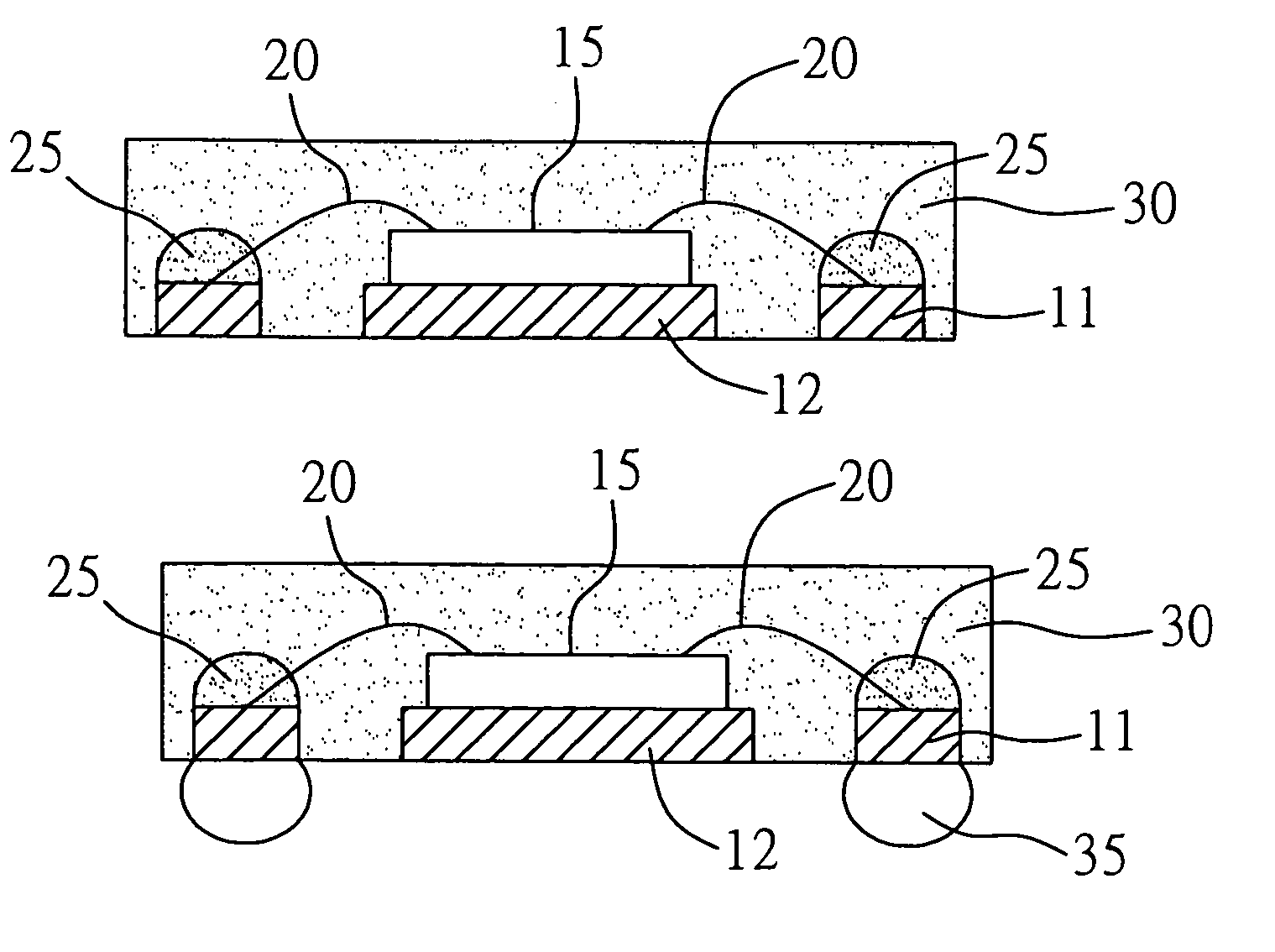

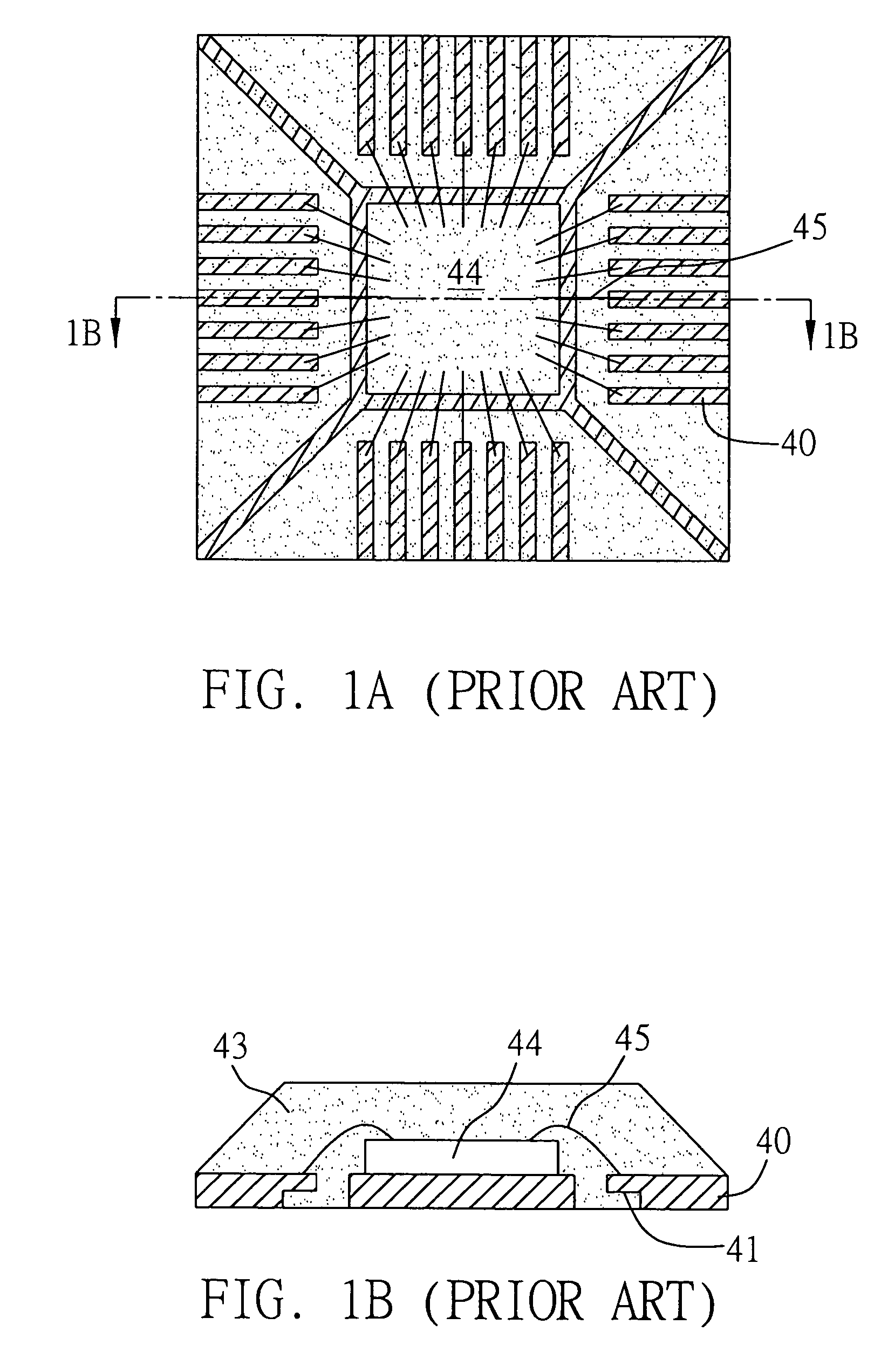

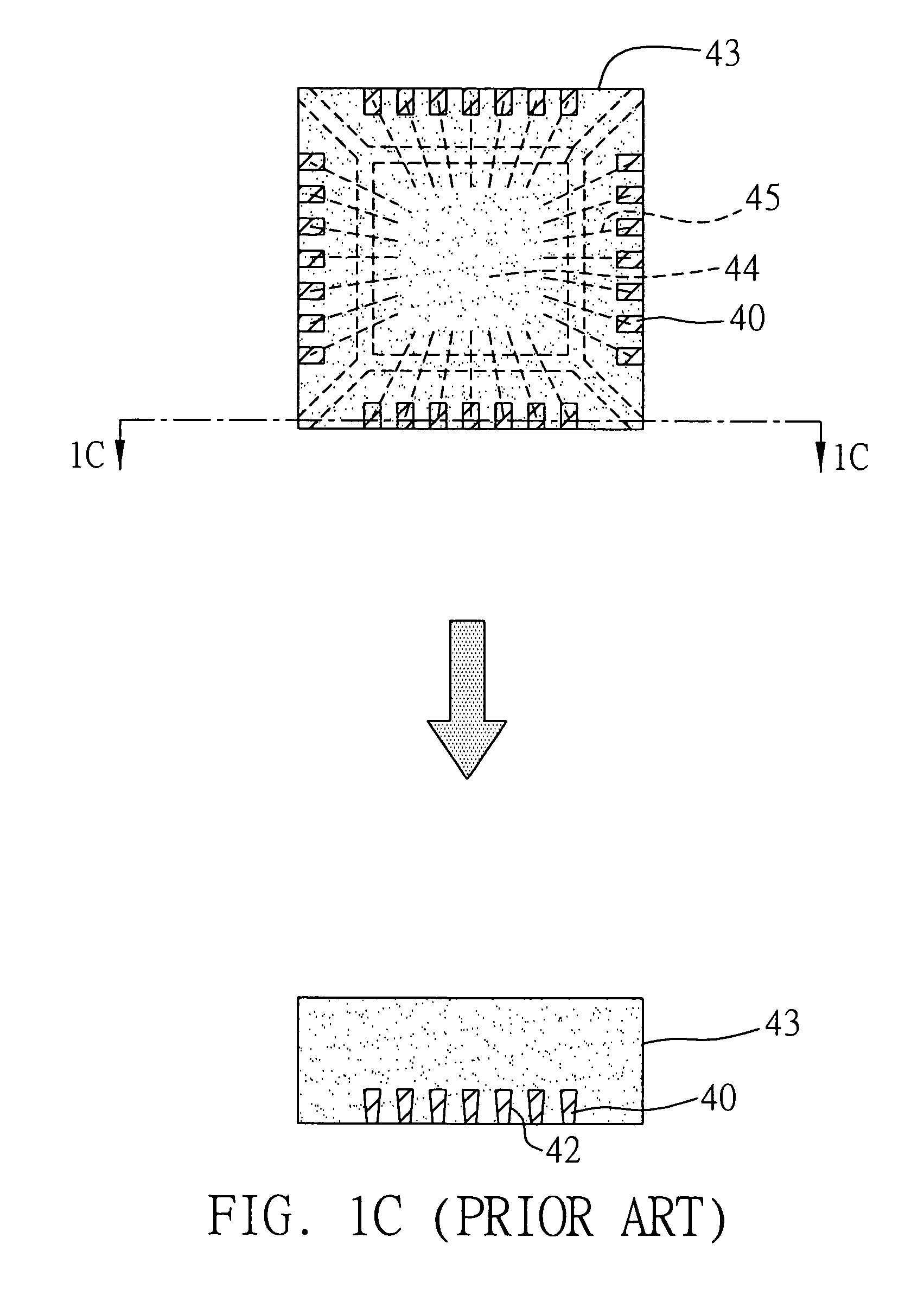

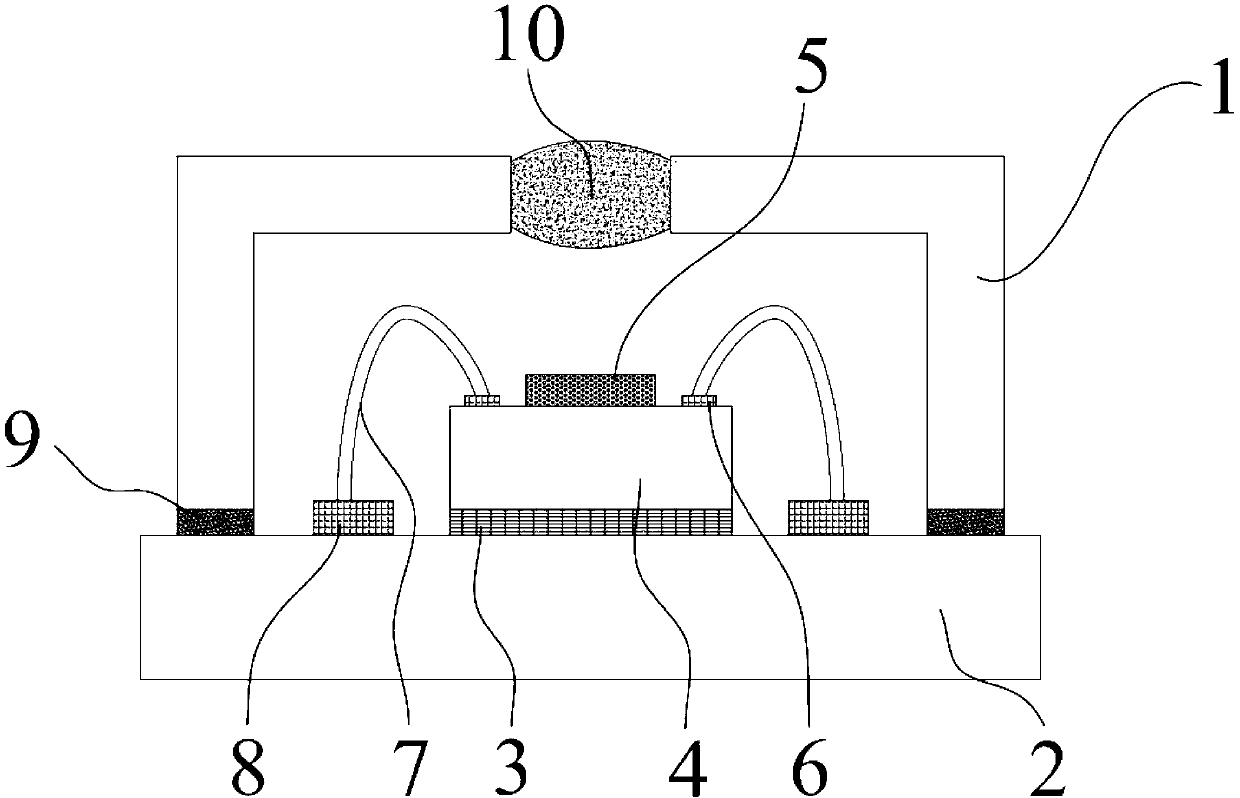

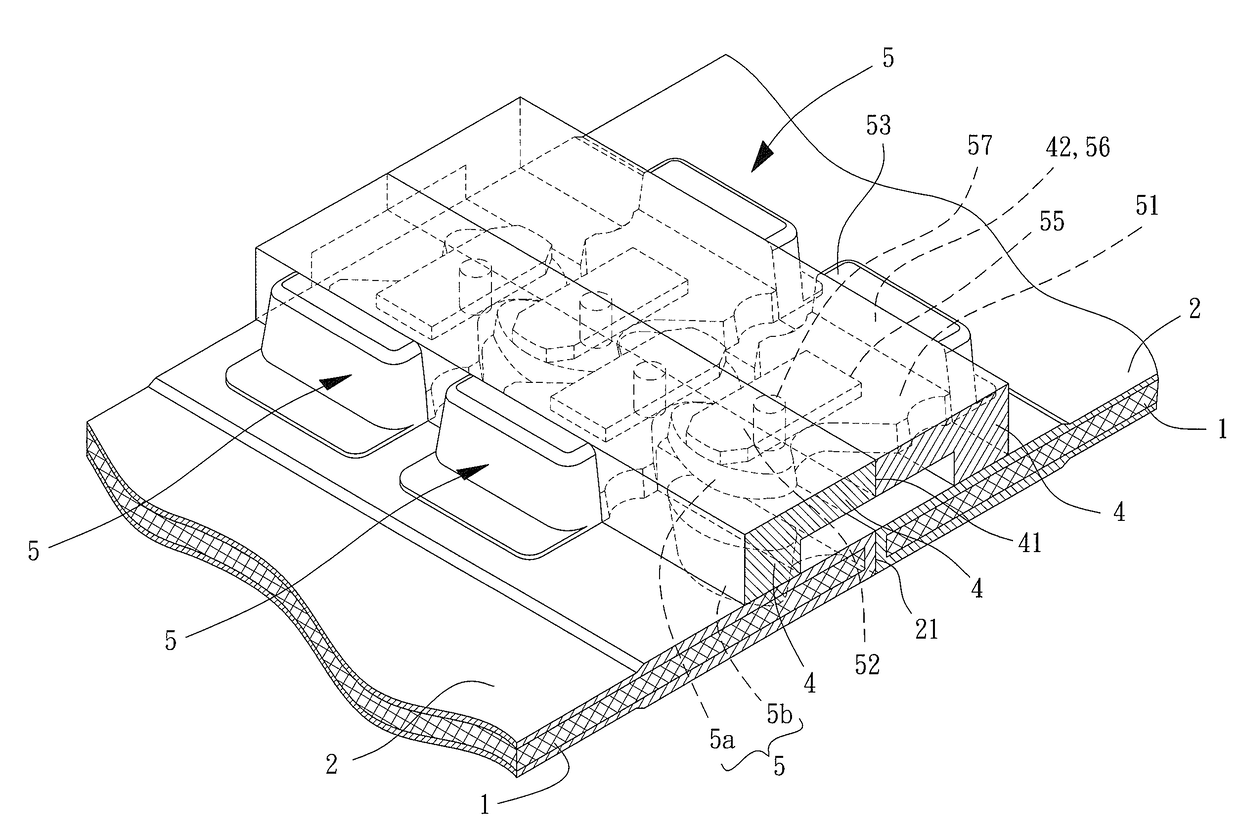

Carrier-free semiconductor package and fabrication method thereof

InactiveUS7314820B2Improve bond strengthAvoid delaminationSemiconductor/solid-state device detailsSolid-state devicesSealantCoating

A carrier-free semiconductor package and a fabrication method thereof are provided. The fabrication method includes the steps of: providing a carrier having a plurality of electrical contacts formed thereon; mounting at least one chip on the carrier; electrically connecting the chip to the electrical contacts via a plurality of bonding wires; forming a coating layer on each of the electrical contacts to encapsulate a bonded end of each of the bonding wires on the electrical contacts; performing a molding process to form an encapsulant for encapsulating the chip, the bonding wires and the electrical contacts; and removing the carrier, such that bottom surfaces of the electrical contacts are exposed from the encapsulant. This obtains a semiconductor package not having a carrier, and the coating layers can enhance adhesion between the electrical contacts and the encapsulant.

Owner:SILICONWARE PRECISION IND CO LTD

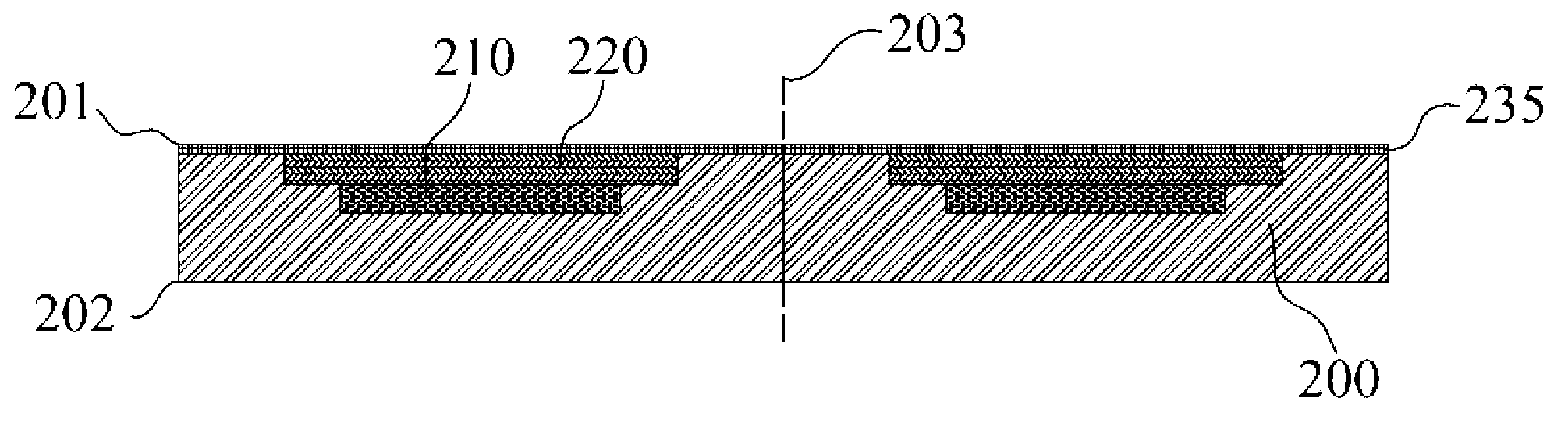

Wafer level chip size package and manufacturing method thereof

InactiveCN103021983AImprove bond strengthImprove layeringSemiconductor/solid-state device detailsSolid-state devicesMetalPolymer

The invention discloses a wafer level chip size package and a manufacturing method of the wafer level chip size package, belonging to the field of sensors. The wafer level chip size package comprises a wafer, wherein the positive surface of the wafer is a first surface which forms an image sensing region, the negative surface of the wafer is a second surface, and the first surface comprises a microlens, a metal interconnection layer and an optical interaction region from top to bottom; a silicon through hole which does not penetrate through a silicon substrate and a redistribution region are manufactured on the first surface, and I / Os at the periphery of the optical interaction region are connected with the silicon through hole; the wall of the silicon through hole is manufactured into a passivation layer and is filled; a polymer material is manufactured into a second protective layer on the redistribution region; the first surface is in bonding with a glass sheet, and a cavity is formed between the glass sheet and the wafer; the second surface is thinned and forms a groove structure through an etching process, and the silicon through hole is exposed; a line layer is manufactured on the second surface, and the silicon through hole is connected to a solder pad cushion; a welding prevention layer is manufactured on the line layer, and the solder pad cushion is exposed; and a solder ball is arranged on the solder pad cushion. With the adoption of the wafer level chip size package and the manufacturing method of the wafer level chip size package, the technological process is reduced, the reliability and the production efficiency of a product are improved, and the production cost is lowered.

Owner:BEIJING UNIV OF TECH

Modified polyethylene film and composite film made of same

ActiveCN102717573AImprove bond strengthGood easy to peel performanceSynthetic resin layered productsEthylene propylene copolymerLow-density polyethylene

The invention provides a modified polyethylene film which is characterized by comprising, by weight, 40-60 parts of linear low density polyethylene and / or low density polyethylene, 15-25 parts of polybutylene or modified polybutylene and 25-35 parts of ethylene-propylene copolymer. The invention further provides a composite film made of the modified polyethylene film. Horizontal and longitudinal tensile strength of the modified polyethylene film are improved, no stratification occurs when the modified polyethylene film is processed and used, composite film packing materials which are made further have good sealing effect, and the modified polyethylene film keeps good easy-to-uncover performance.

Owner:ZHEJIANG GOLDSTONE PACKING

Binding process of insulator

The invention discloses a binding process of an insulator, and the process comprises the following steps: (1) preparing the parts of the insulator, such as a metal cap, a metal seat and a ceramic body; (2) preparing a binding agent; (3) binding the metal cap and the metal seat at the upper part and lower part of the ceramic body through the binding agent; and (4) placing the bound insulator into a maintenance pool to be maintained until the binding agent is completely solidified. The technical scheme of the invention has the beneficial effects that the binding process of the insulator disclosed by the invention is provided; and the special binding agent is matched with the special maintenance steps to produce the insulator which has the advantages of high cementation intensity, long service life and short production cycle.

Owner:SUZHOU AIJIAN ELECTRICAL PORCELAIN

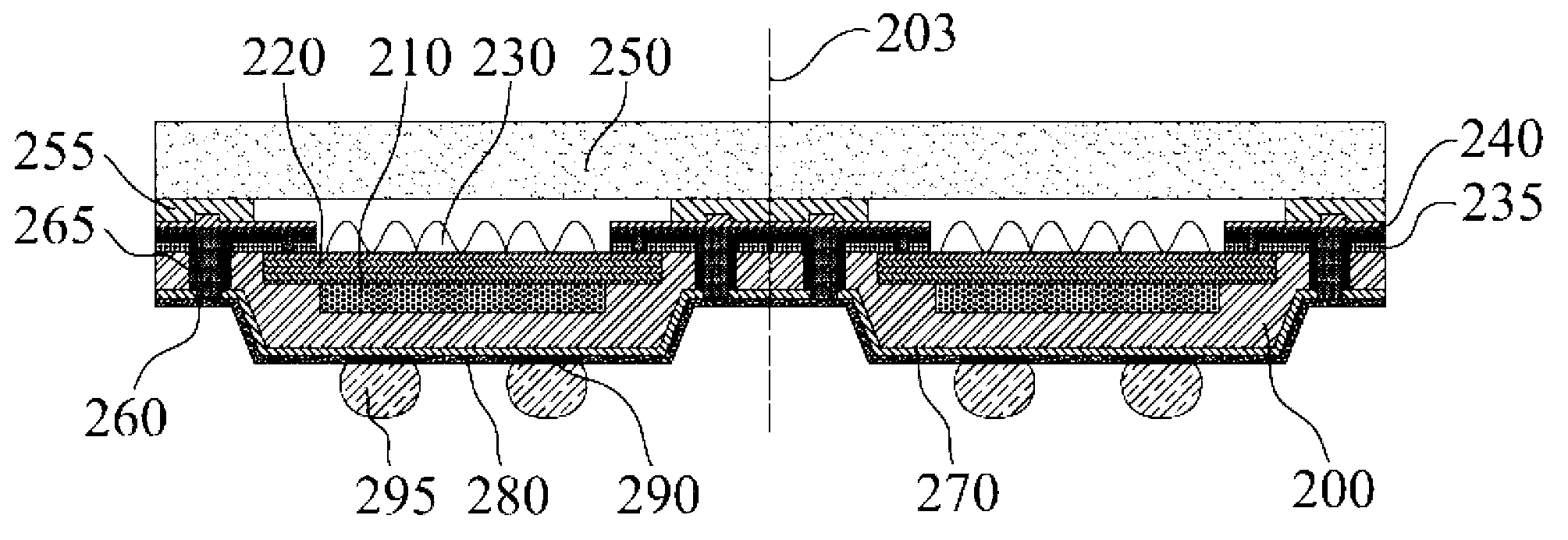

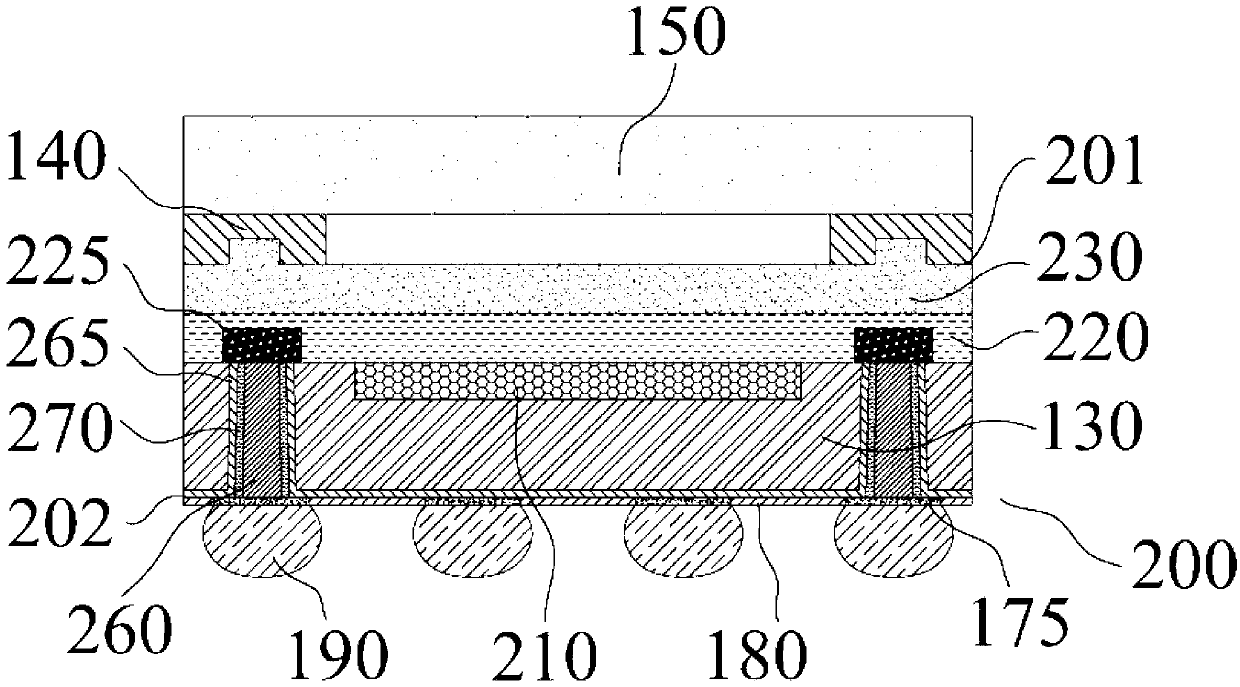

Large chip scale package and manufacturing method thereof

InactiveCN103000648AImprove bond strengthImprove layeringRadiation controlled devicesEngineeringInput/output

The invention provides large chip scale package and a manufacturing method thereof and belongs to the technical field of sensors. An optical interaction region is arranged at the center above a silicon substrate in a first surface of a wafer, one side provided with the optical interaction region is connected with a metal interconnection structure, and an input-output (I / O) around the optical interaction region on the silicon substrate is connected to an electrode pad through the metal interconnection structure. The surface of the metal interconnection structure is provided with a protective layer, and a stepped protrusion or groove structure is formed on the protective layer. The first surface of the wafer is bonded with a glass piece together, and a cavity is formed between the glass piece and the wafer. A second surface of the wafer is provided with a through silicon via (TSV) hole, the electrode pad penetrates through the silicon substrate through the TSV hole to be connected to a bonding pad on the second surface of the wafer, a passivation layer and a metal liner are sequentially manufactured on a hole wall of the TSV hole, and a polymer material is filled into the TSV hole. An anti-welding layer is manufactured on the second surface of the wafer, and a weld ball is manufactured on the bonding pad. By means of the large chip scale package and the manufacturing method, the layering problem of glass and the silicon substrate in an existing package structure is solved, and the packing reliability is improved.

Owner:BEIJING UNIV OF TECH

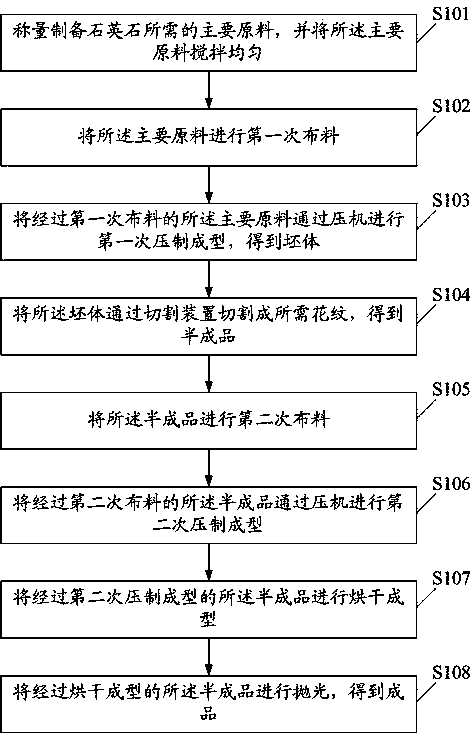

Quartz stone and preparation method thereof

The invention discloses a preparation method of quartz stone. The method comprises the following steps of: A, weighing and uniformly stirring main raw materials required for preparing the quartz stone; B, primarily distributing the main raw materials; C, performing first compression moulding on the primarily distributed main raw materials through a press to obtain a blank; D, cutting the blank to required figures through a cutting device to obtain a semi-product; E, secondarily distributing the semi-product; F, performing second compression moulding on the secondarily distributed semi-product through the press; G, drying and moulding the secondarily pressed semi-product; and H, polishing the dried and moulded semi-product to obtain a finished product. Correspondingly, the invention further discloses the quartz stone prepared by the preparation method. Due to the adoption of the preparation method disclosed by the invention, under the premise of no dies, figures of various types, especially linear figure patterns can be formed on the surface of the quartz stone, so that the competitiveness of the product is improved.

Owner:FOSHAN BLUE SEA QUARTZ STONE

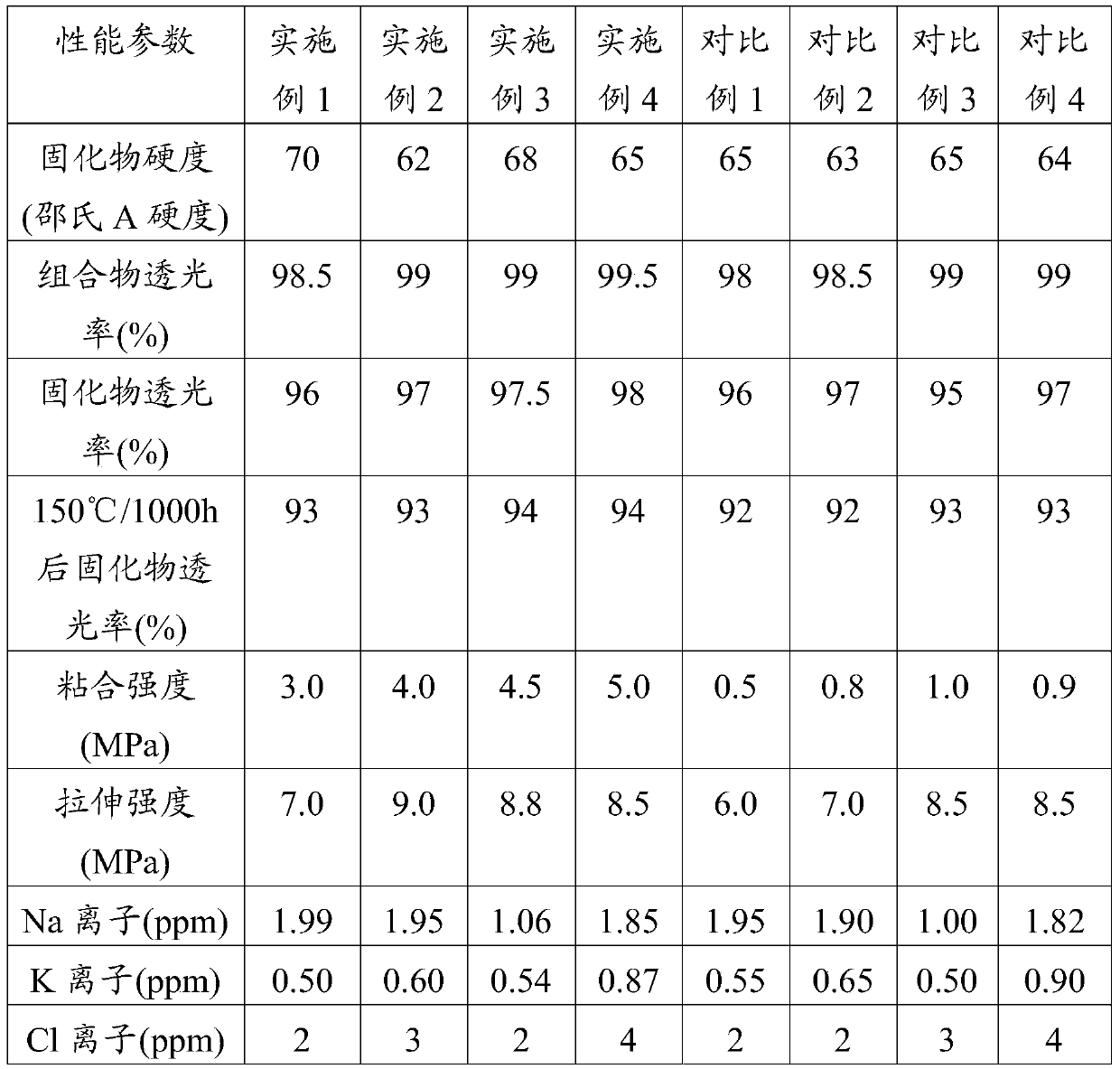

Phenyl vinyl silicon resin for adhering base as well as preparation method and application thereof

InactiveCN104710621AImprove bonding abilityImprove bond strengthAdhesivesComposite materialSilicone resin

The invention discloses phenyl vinyl silicon resin for adhering a base as well as a preparation method and an application thereof. The phenyl vinyl silicon resin consists of solid silicon resin containing Si-H, methyl, phenyl and vinyl as well as an organic compound containing a tackifying radical and vinyl; under the effect of a hydrosilyation catalyst, the phenyl vinyl silicon resin is generated through a hydrosilyation reaction, wherein the tackifying radical is an organic radical capable of enhancing the adhesive capacity of the base. When the phenyl vinyl silicon resin provided by the invention is used as a reinforcing tackifying material in an LED, and can provide high hardness, high tenacity, high refractive index and higher lighting effect of LED packaging glue water; moreover, the phenyl vinyl silicon resin has good adhesive capacity for various bases, the material has excellent reliability in the using process, and the phenyl vinyl silicon resin has extremely high practicability.

Owner:SHENZHEN CAPCHEM TECH

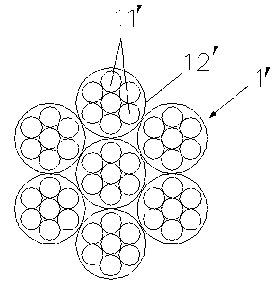

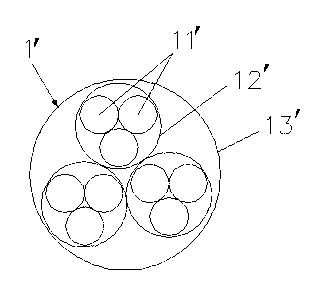

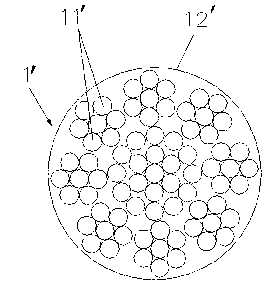

Polyurethane wrapping basalt fiber wire rope and processing method thereof

InactiveCN103132353AImprove bond strengthGood wear resistanceRope making machinesYarnEngineeringWire rope

The invention relates to a polyurethane wrapping basalt fiber wire rope and a processing method thereof. The polyurethane wrapping basalt fiber wire rope is composed of a basalt fiber core wire and a wrapping layer, wherein a thermal plastic type polyurethane elastomer wrapping layer is arranged on the outer portion of the basalt fiber core wire, and the basalt fiber core wire comprises a single strand wire which is made of basalt fiber untwisted roving in a primary twisted mode or a single core wire which is made of basalt fiber untwisted roving in a secondary twisted mode. The processing method of the polyurethane wrapping basalt fiber wire rope comprises the steps of drying, manufacturing a core wire, wrapping and manufacturing a rope. The polyurethane wrapping basalt fiber wire rope and the processing method thereof resolve the problem that the basalt fibers are very easy to broken in the process of industrial belt manufacture, the wrapping core wire contains thermal plastic type polyurethane elastomer, the wrapping core wire as a tensile resistance framework layer is melted with the thermal plastic type polyurethane elastomer material with body glue, and thus the adhesive strength of a framework rope is strong. The polyurethane wrapping basalt fiber wire rope and the processing method thereof resolve the defect of the poor abrasion resistance of a basalt fiber wire rope, and has good abrasion resistance, oil resistance, water-proof, high strength, low elongation rate, light weight and long service life.

Owner:GUANGDONG TAUGHNESS CONVEYOR BELTING

Formula of nylon/aramid fiber composite cord hanging glue for aircraft tire

ActiveCN101200626AImprove bond strengthHigh adhesion retentionNatural rubber adhesivesYarnButadiene-styrene rubberAdhesion strength

The present invention discloses a prescription of nylon and aramid fibre composite cord coating used for an aircraft tire and is characterized in that glue stock considers caoutchouc as the main material and contains the main auxiliary materials of styrene butadiene rubber, adhesion promoter, high abrasion furnace black, high dispersion white carbon black, silane coupling agent, indiscerptible sulfur and sulfenamide accelerant. The main material and the main auxiliary materials are mixed and milled by an internal mixer according to the certain proportion. The glue stock of the prescription has the advantages that the adhesion strength of the nylon and aramid fibre composite cord with the glue stock of rubber can be improved; the adhesion holding rate after thermal aging is high; a tread bracing layer part does not have the quality problems of glue-cord delamination and the delamination between layers when the glue stock is used under the rigorous using condition with high tensile strength, high tear strength and high load.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Reinforced toughened nylon material can be used for 3D printing and preparation method thereof

InactiveCN107652668AImprove bond strengthImprove overall performanceAdditive manufacturing apparatusPolyamideMechanical property

The invention discloses a reinforced toughened nylon material can be used for 3D printing and a preparation method thereof. The reinforced toughened nylon material is consisted of the following components in percentage by mass: 60%-75% of polyamide 6 (PA6), 10%-20% of glass fiber (GF), 10%-20% of a toughening agent, 4%-8% of a compatibilizer, 0.3%-0.6% of an antioxidant, 0.3%-2% of a coupling agent, and 0.2%-1% of a nucleating agent. The material has the advantages that: 1, the addition of the compatibilizer and the coupling agent remarkably improves the compatibility and the bonding strengthbetween each component, so that the overall performance of the material is obviously improved; 2, the use of a certain diameter long glass fiber reinforcement reduces the shrinkage rate of the material, and improves the serious warpage shortcoming of the material when the material is used for printing; and 3, the addition of the toughening agent solves the shortcoming that the nylon material is lack in toughness after the glass fiber is reinforced, so that consumable printing use is facilitated. Compared with the performance of an existing nylon material, the material prepared in the inventionhas better mechanical properties, higher heat-resistant temperature, and lower molding shrinkage rate, and is not liable to warpage, so that the material is very suitable for preparing FDM-3D printing consumables.

Owner:四川鑫达企业集团有限公司

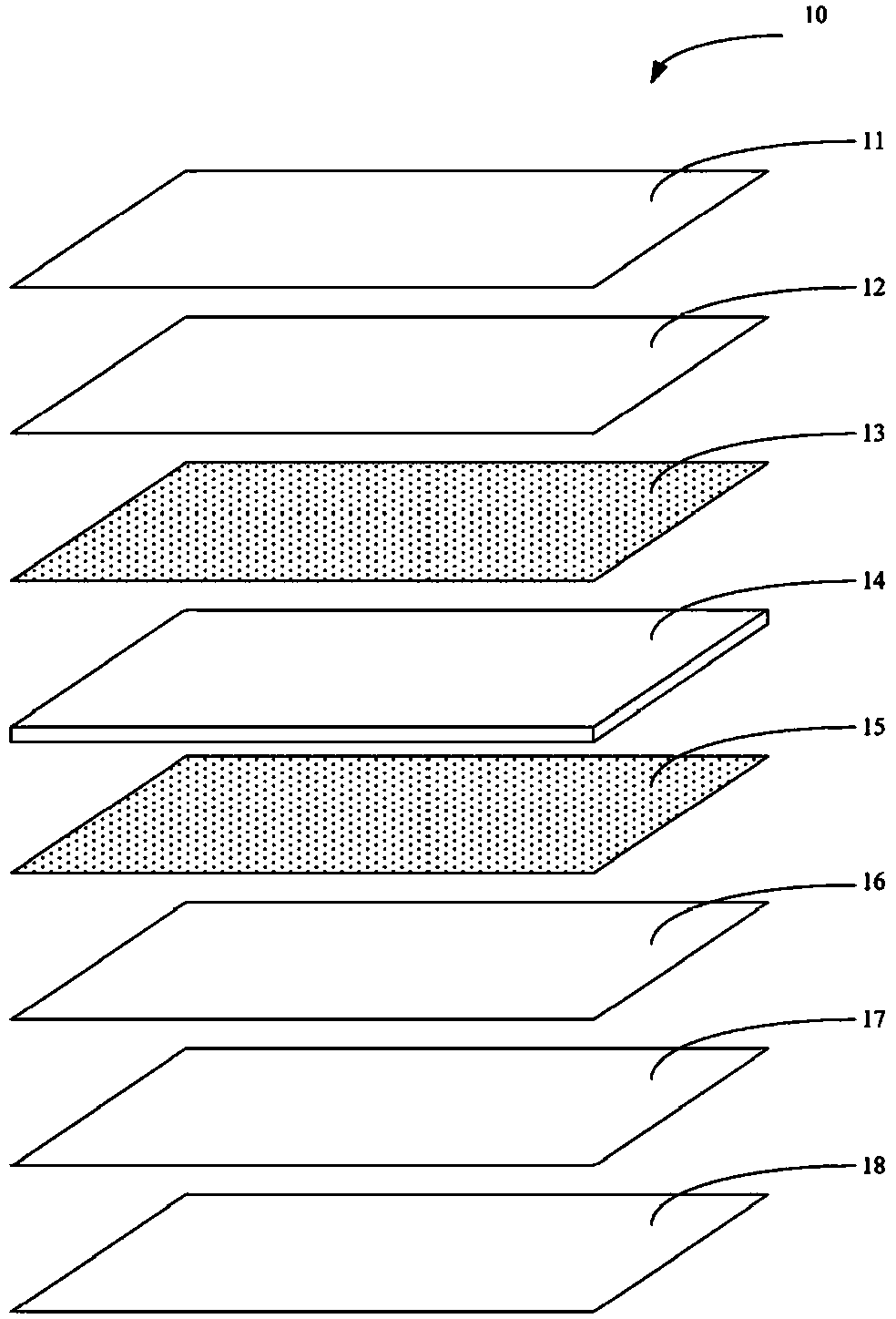

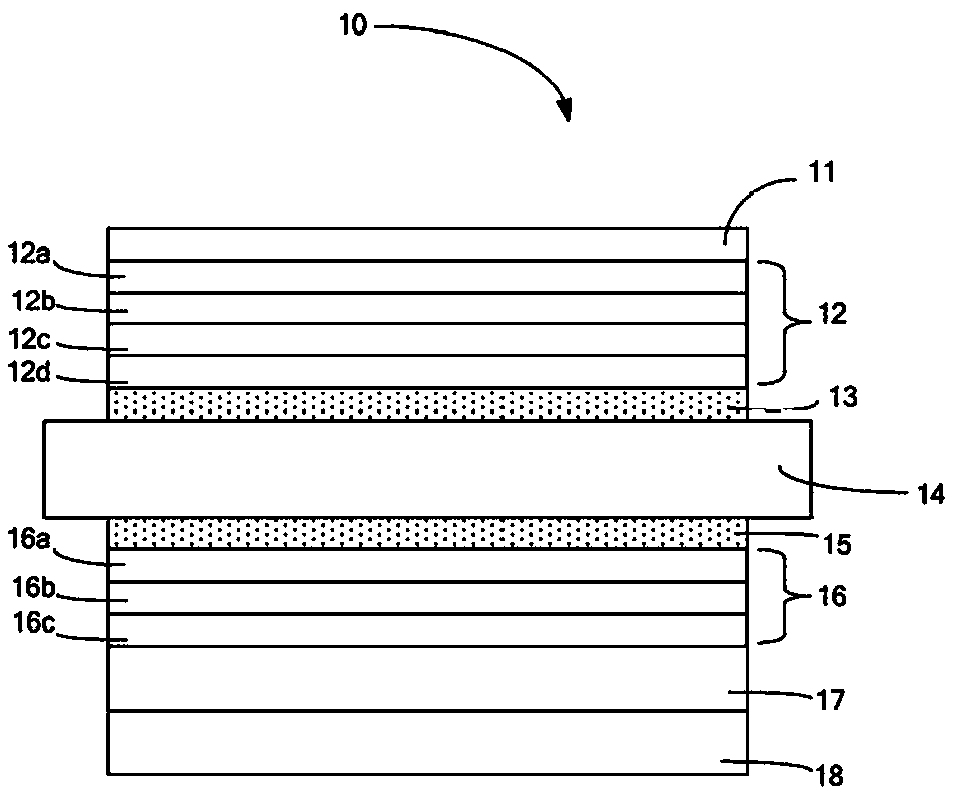

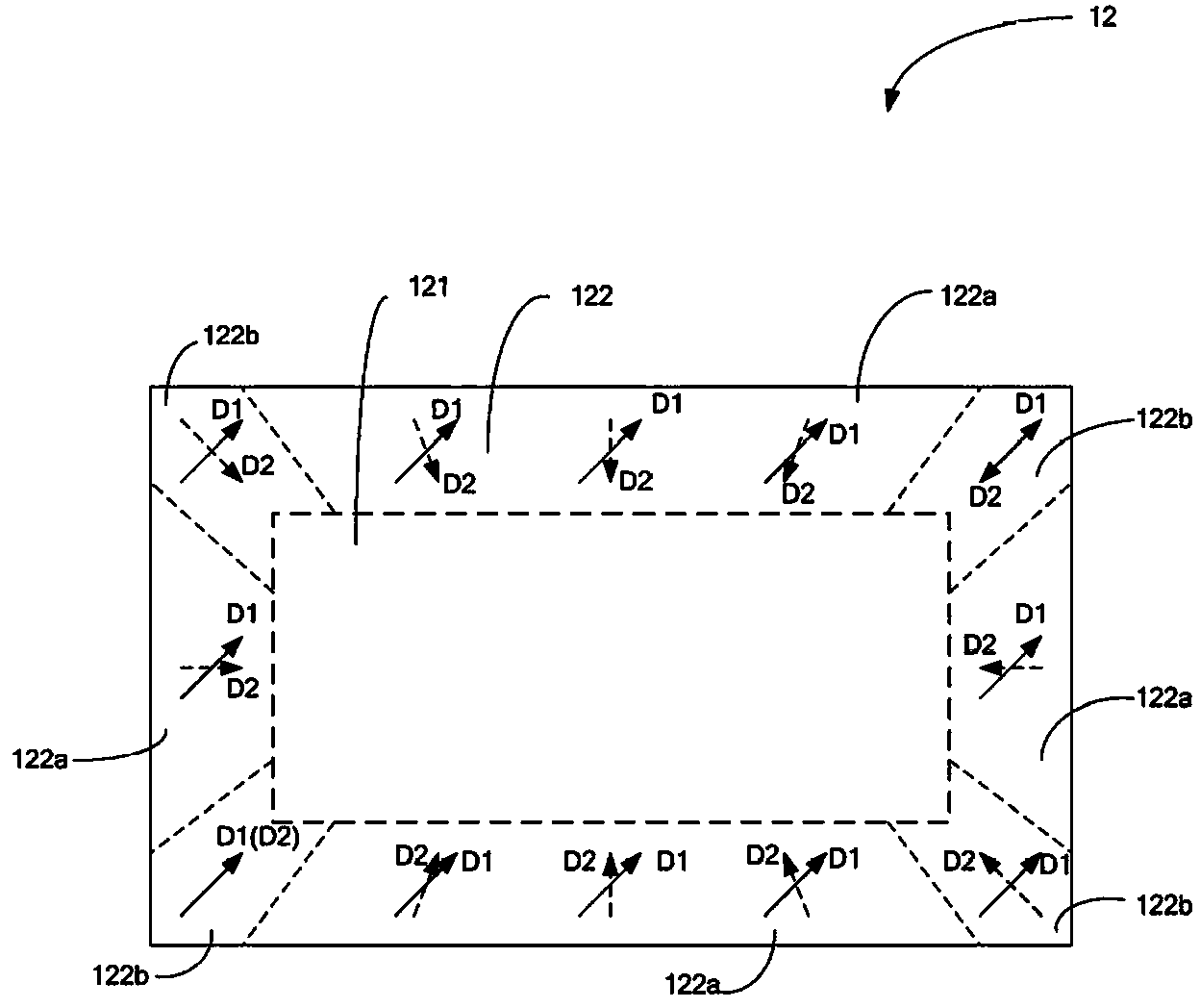

Liquid crystal display device, manufacturing method thereof and electronic device

ActiveCN104122703AImprove bond strengthSuppress dark state light leakageLamination ancillary operationsLayered product treatmentPolarizerLiquid-crystal display

The invention provides a liquid crystal display device. The liquid crystal display device comprises a liquid crystal display panel and polarizers, wherein the polarizers and the liquid crystal display panel are arranged in a stacked mode. The polarizers are provided with central areas and peripheral areas in a defined mode, wherein the central areas are located in the middles of the polarizers, and the peripheral areas are located on the peripheries of the central areas. The polarizers are bonded with the liquid crystal display panel, and the adhesive strength of the polarizers and the liquid crystal display panel meets the requirement that the adhesive strength between the peripheral areas and the liquid crystal display panel is higher than the adhesive strength between the central areas and the liquid crystal display panel. The invention further provides a manufacturing method of the liquid crystal display device. According to the liquid crystal display device and the manufacturing method of the liquid crystal display device, the dark state light leakage phenomenon of the liquid crystal display device can be effectively restrained, and the display effect of the liquid crystal display device is improved.

Owner:INNER MONGOLIA ZHONGSEN SMART TERMINAL R & D CO LTD

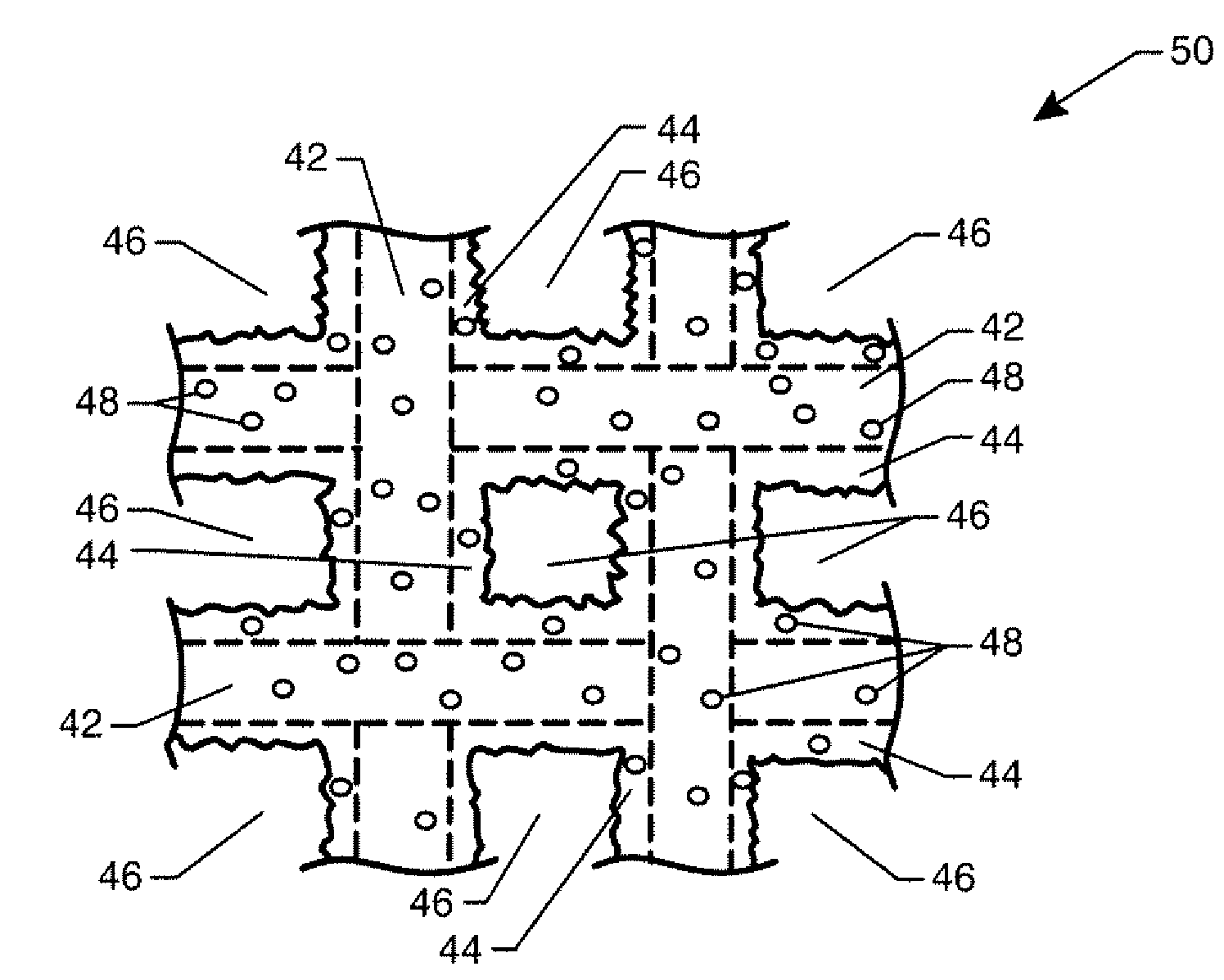

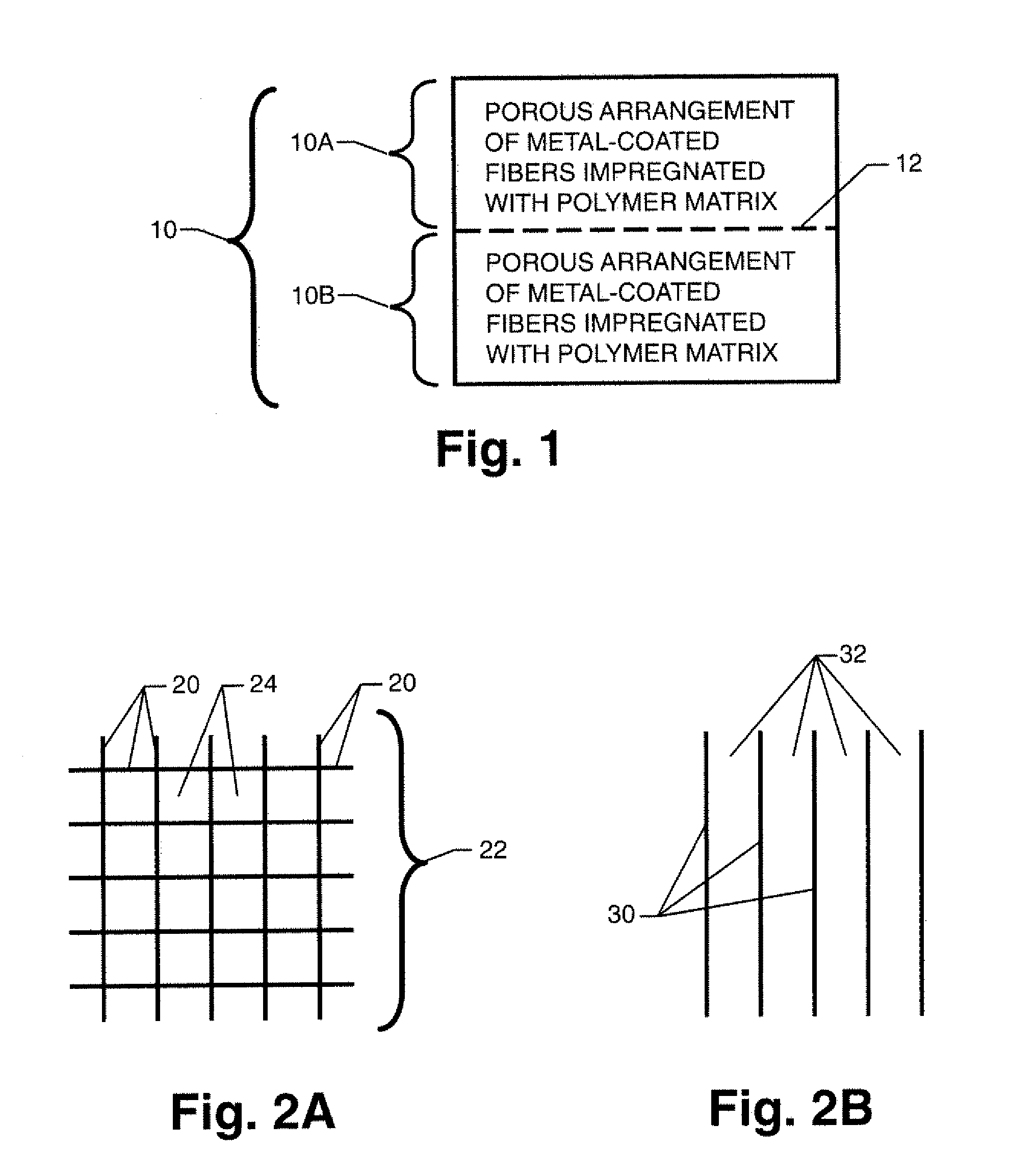

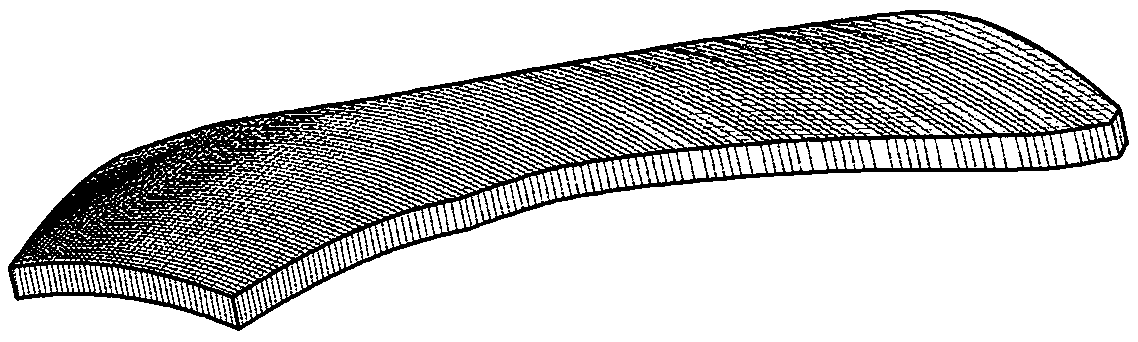

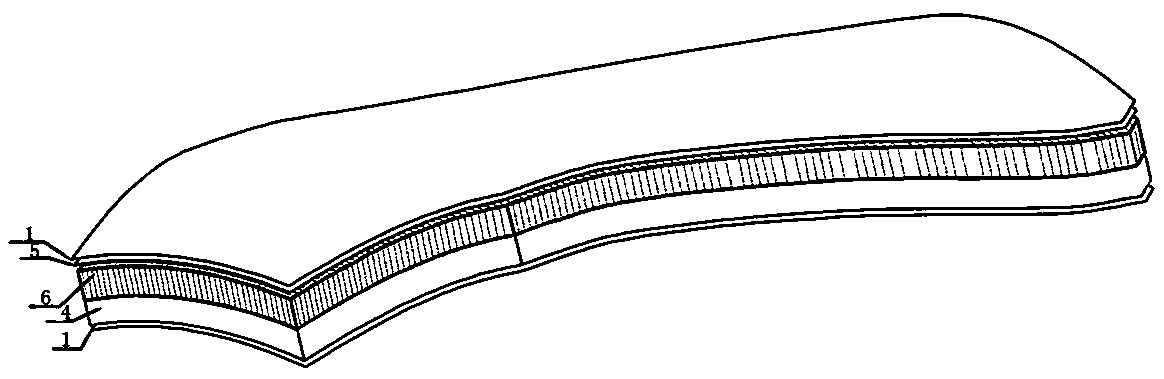

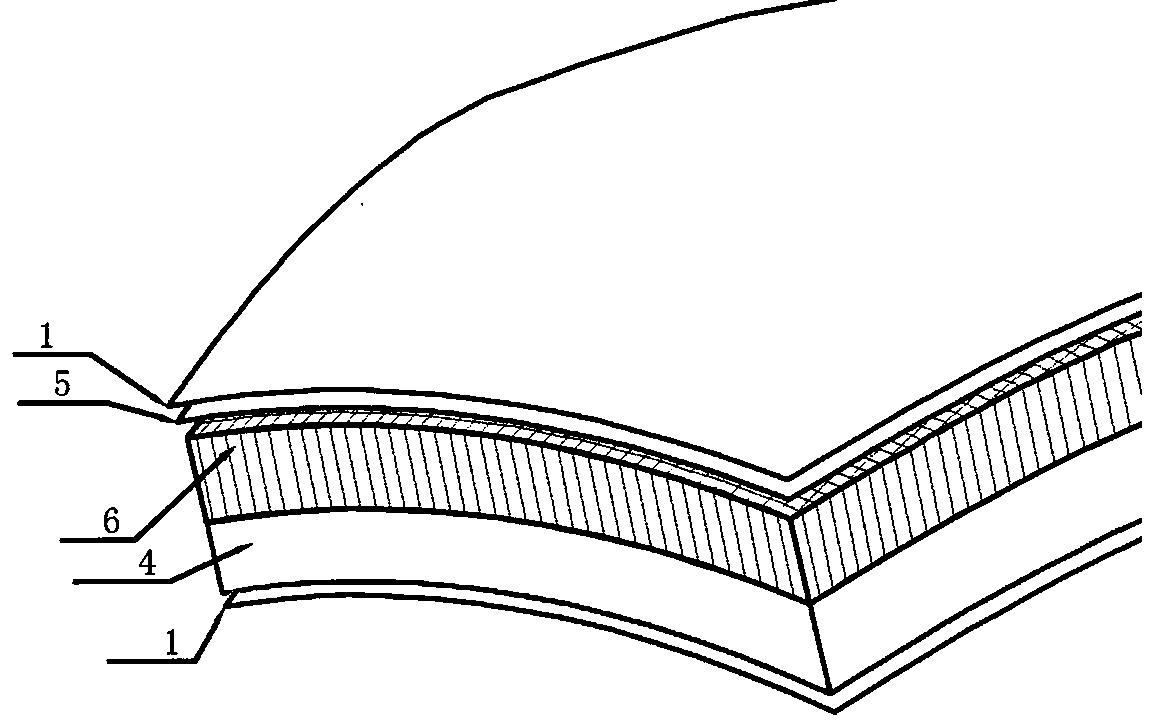

Metal/Fiber Laminate and Fabrication Using A Porous Metal/Fiber Preform

ActiveUS20090022975A1Improve bond strengthHigh bonding strengthNatural cellulose pulp/paperSynthetic resin layered productsFiberPorous metal

Owner:NASA

Electroluminescent material of dendritic functional Ir (III) metal organic complex

InactiveCN1772838AImprove luminous efficiencyImprove stabilityLuminescent compositionsSolubilityIridium

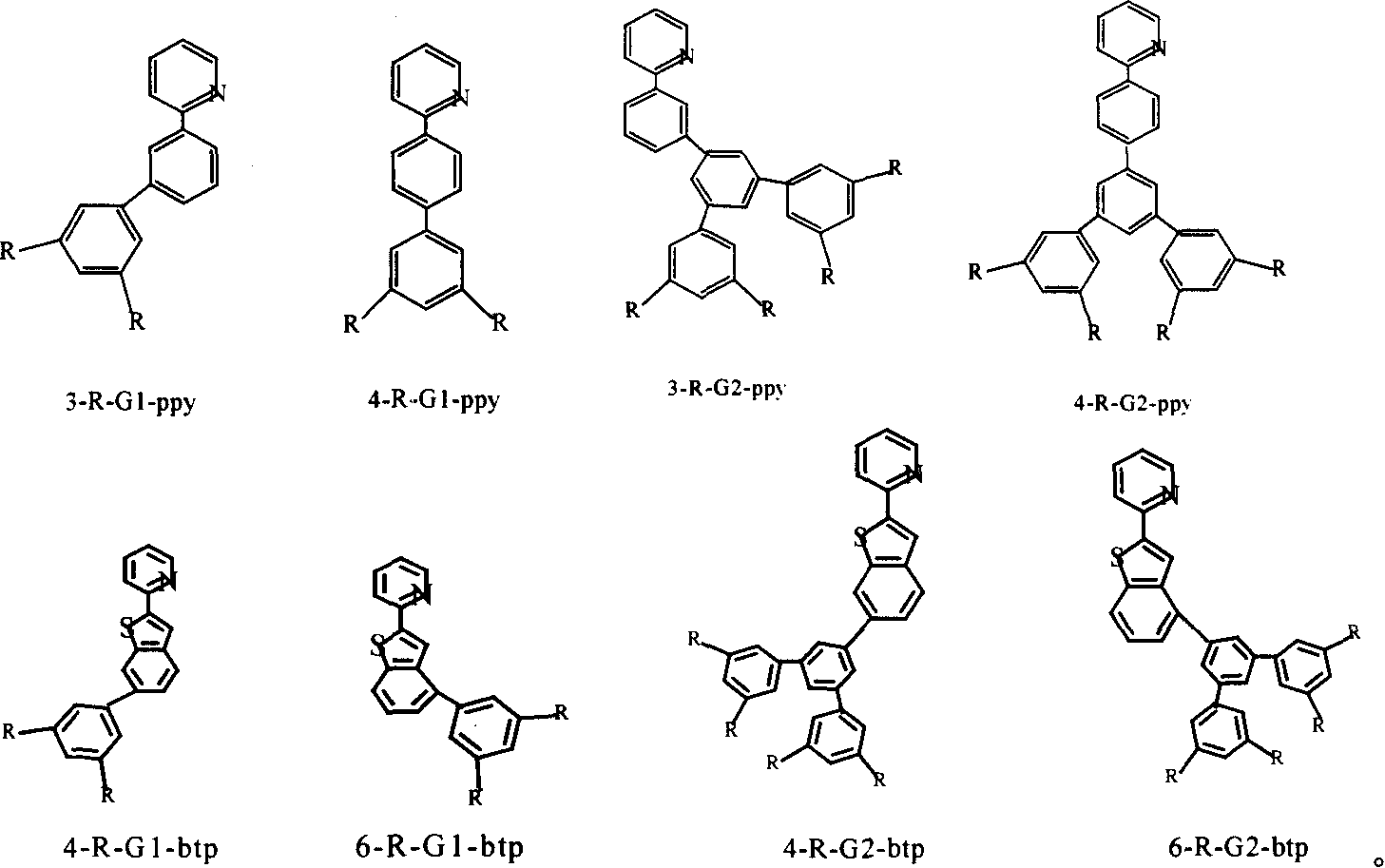

The present invention relates to one kind of electroluminescent material of dendritic functional Ir(III) metal organic complex. The electroluminescent material has surface functional radical of triarylamino, 1, 3, 4-furodiazole or alkyl carbazole, with the radical of triarylamino, furodiazole or carbazole carrying also long chain alkyl, alkoxl or fluoro radical, so that it has raised carrier implantation function and greatly improved dissolubility and filming performance. The electroluminescent material may be used in preparing single layer electroluminescent device through direct rotary spraying process, and this provides new way for making large size OLED device. The electroluminescent material contains two kinds of ligands, including the first ligand to regulate the luminescent color and the second ligand to raise the stability of the material.

Owner:XI AN JIAOTONG UNIV +1

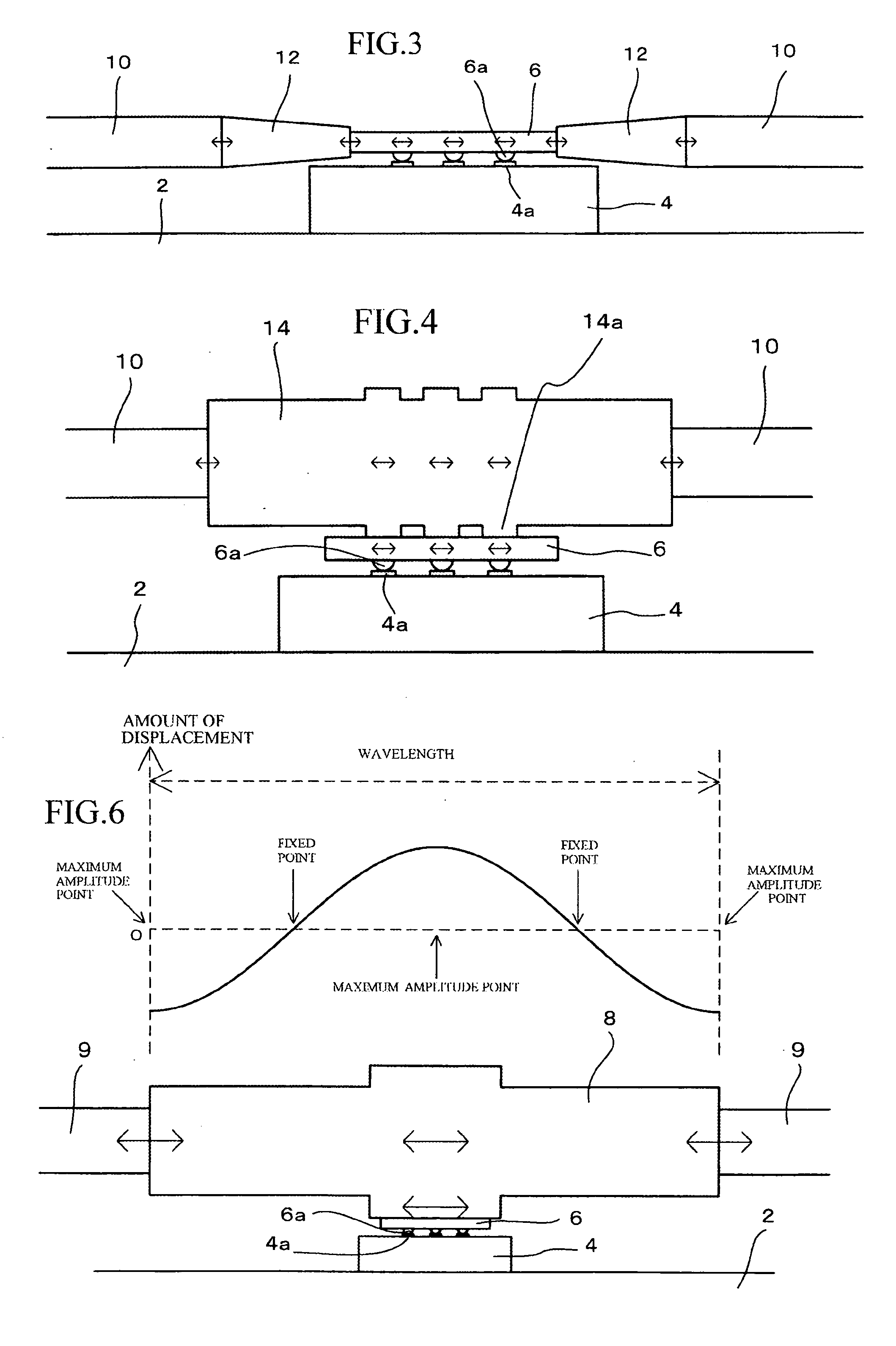

Method of bonding and bonding apparatus for a semiconductor chip

InactiveUS20060043149A1Bonding strengthImprove bond strengthSolid-state devicesWelding/cutting auxillary devicesPhysicsUltrasonic vibration

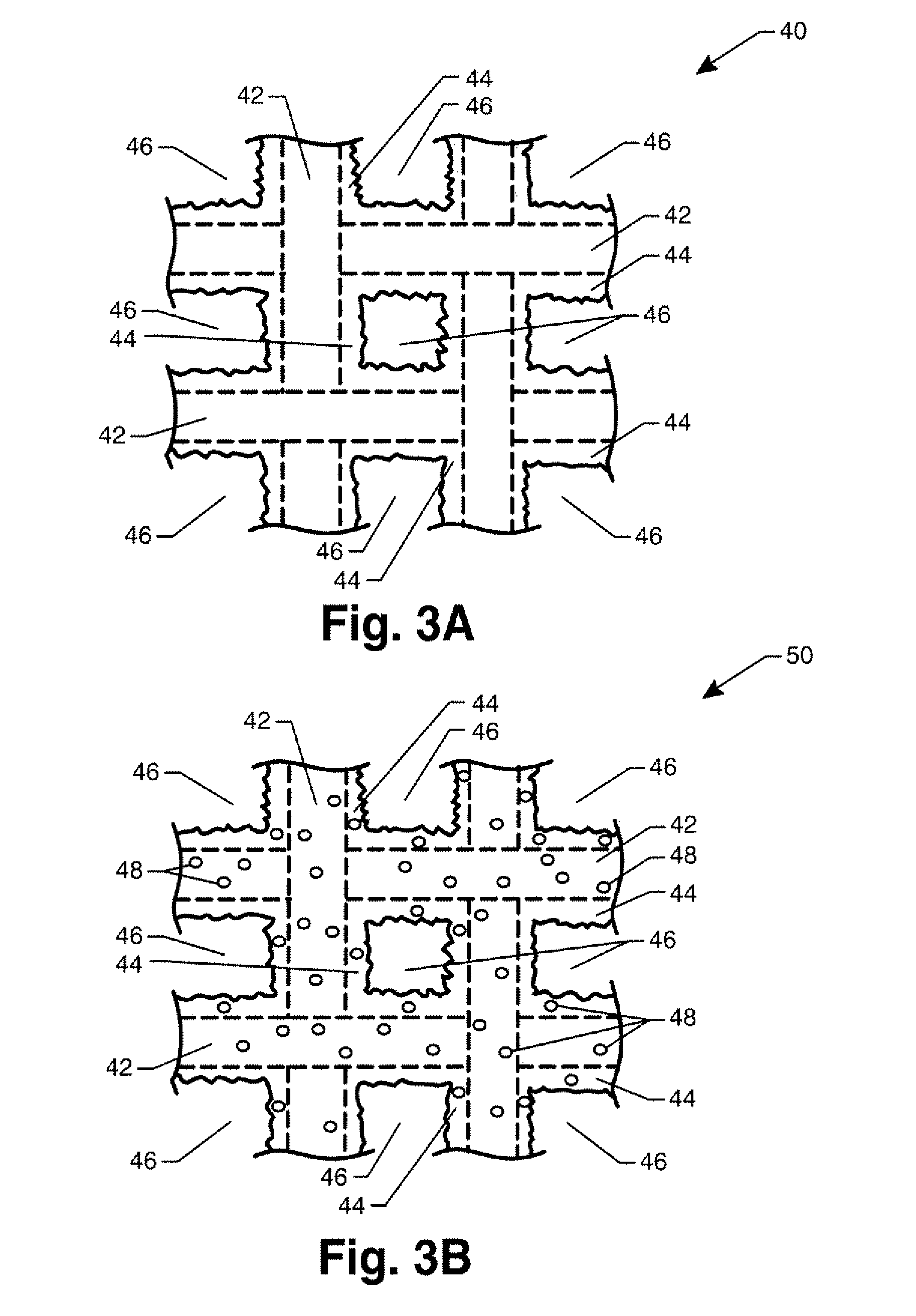

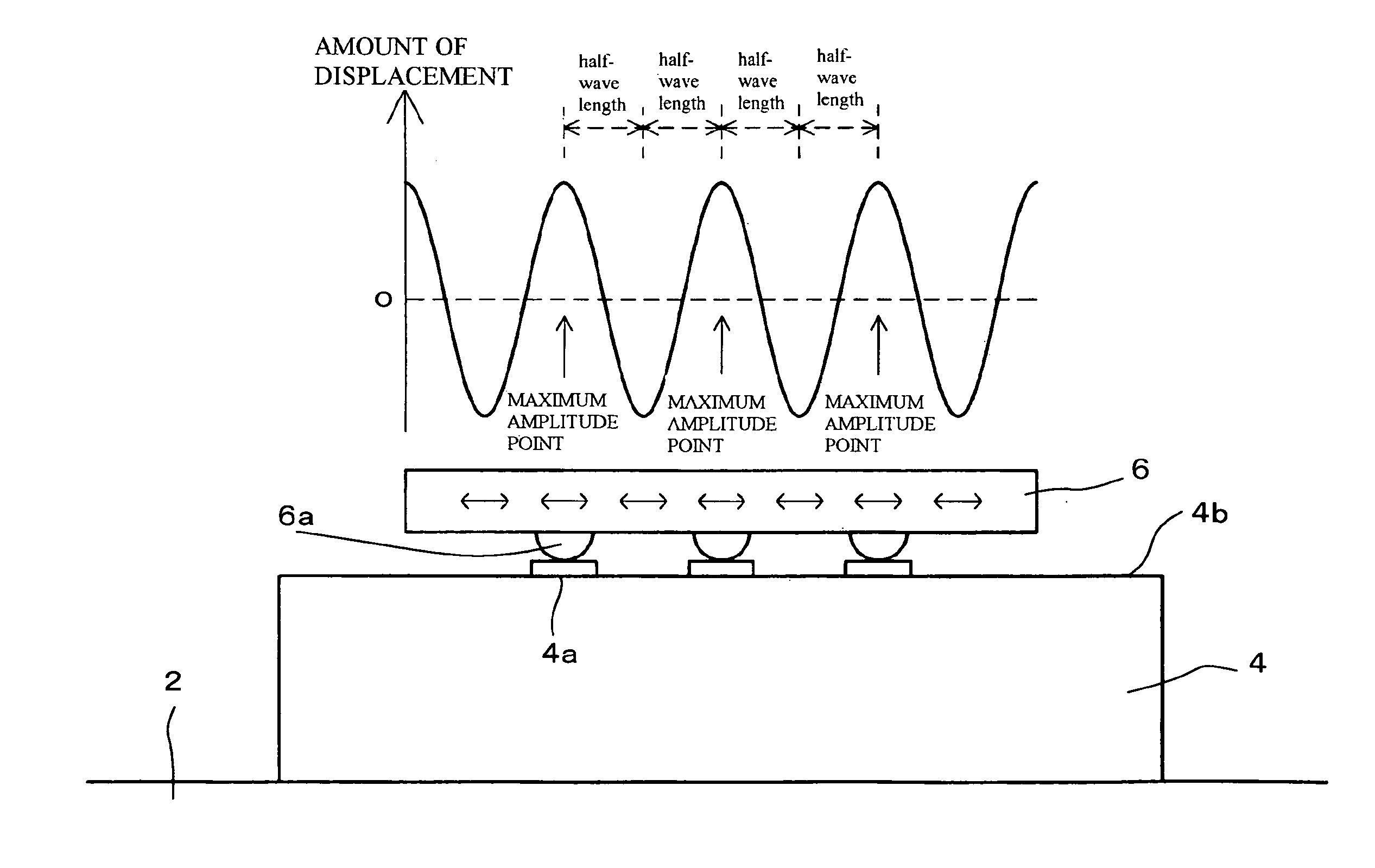

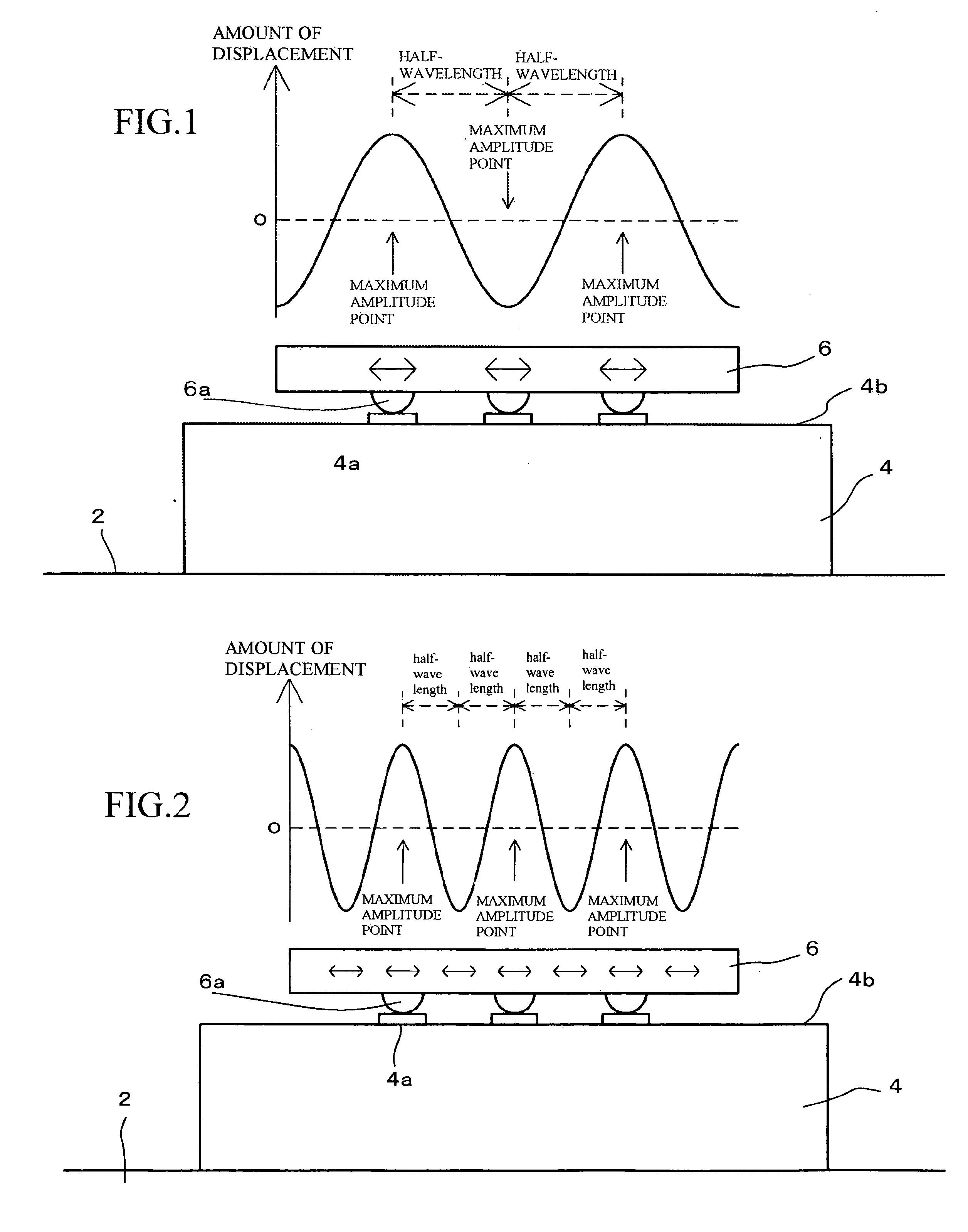

A method of bonding and a bonding apparatus for a semiconductor chip uses ultrasonic vibration but can improve the bonds between electrode terminals of a semiconductor chip and a substrate. In a method of bonding a semiconductor chip that places electrode terminals of the semiconductor chip and electrode terminals of a substrate in contact and applies ultrasonic vibration to the semiconductor chip to bond the electrode terminals of the semiconductor chip and the substrate together, the ultrasonic vibration is compressional waves that are transmitted to the semiconductor chip and is set so that a half-wavelength of the ultrasonic vibration is a length given by multiplying a gap between adjacent electrode terminals in a direction of the compressional waves by a reciprocal of a natural number, and maximum amplitude points are located at positions of the respective electrode terminals of the semiconductor chip and the substrate.

Owner:FUJITSU LTD

Structure of integral boron carbide bulletproof plugboard and ceramic pretreatment process

The invention relates to a structure of an integral boron carbide bulletproof plugboard and a ceramic pretreatment process, and belongs to the field of individual soldier human body protection products. The integral boron carbide bulletproof plugboard structure comprises a face packaging layer, a super-strong damping layer, a bulletproof ceramic super-strong constraint body and a bulletproof fiberlaminated board. On the surface of the bulletproof ceramic, a bulletproof fiber filament is adopted for carrying out full-circumference constraint winding, and a bulletproof ceramic super-strong constraint body is formed. The bulletproof ceramic super-strong constraint body and the bulletproof fiber laminated board are bonded by adopting an adhesive, so that the bonding strength of the compositeinterface of the bulletproof ceramic super-strong constraint body and the bulletproof fiber laminated board is ensured. The integral boron carbide bulletproof plugboard obtained by adopting the structure and the ceramic pretreatment process is excellent in anti-foaming bullet attack performance, the integral boron carbide can still keep a whole under the protection of an ultra-strong constraint when being hit by a first gun, a second gun and a third gun are protected with a relatively complete ceramic large block, and finally the problem that the anti-multiple elastic capability of the bulletproof ceramic whole plate is insufficient is solved.

Owner:中硼科技(大连)有限公司

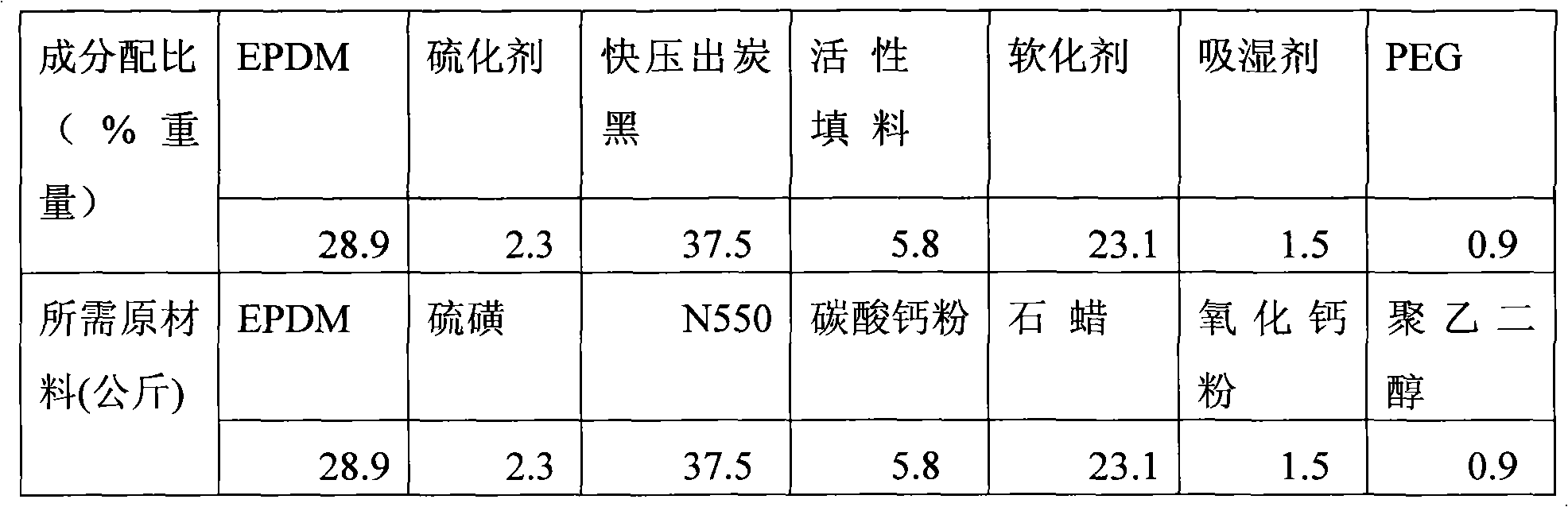

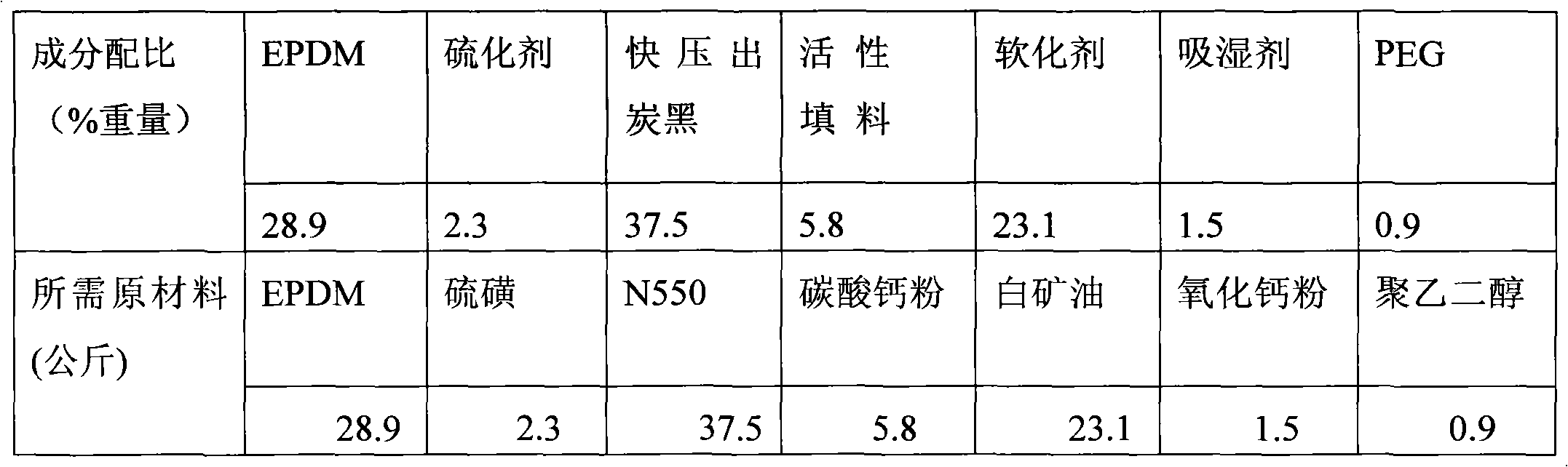

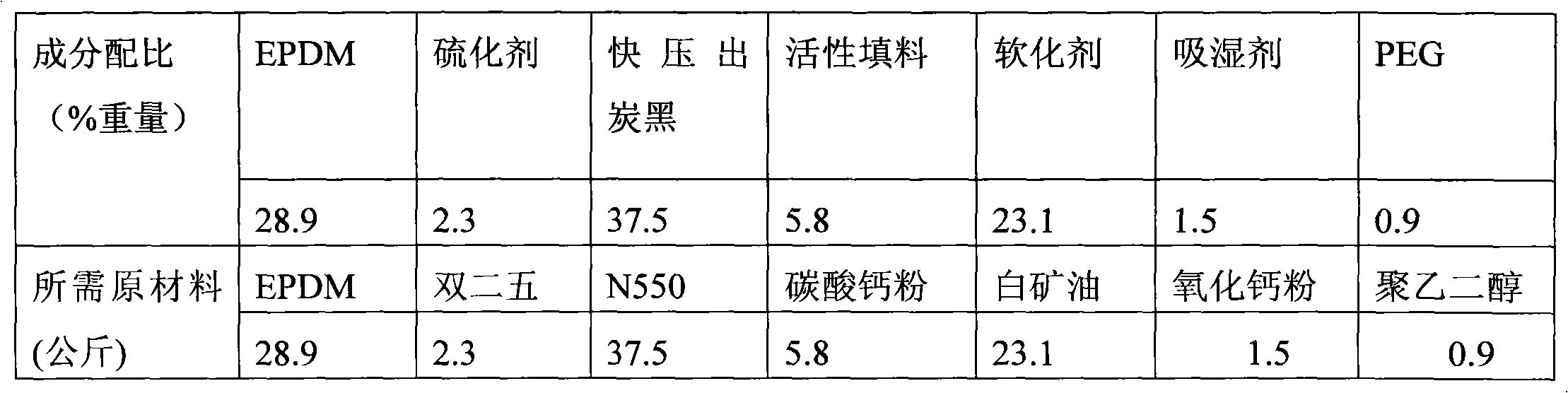

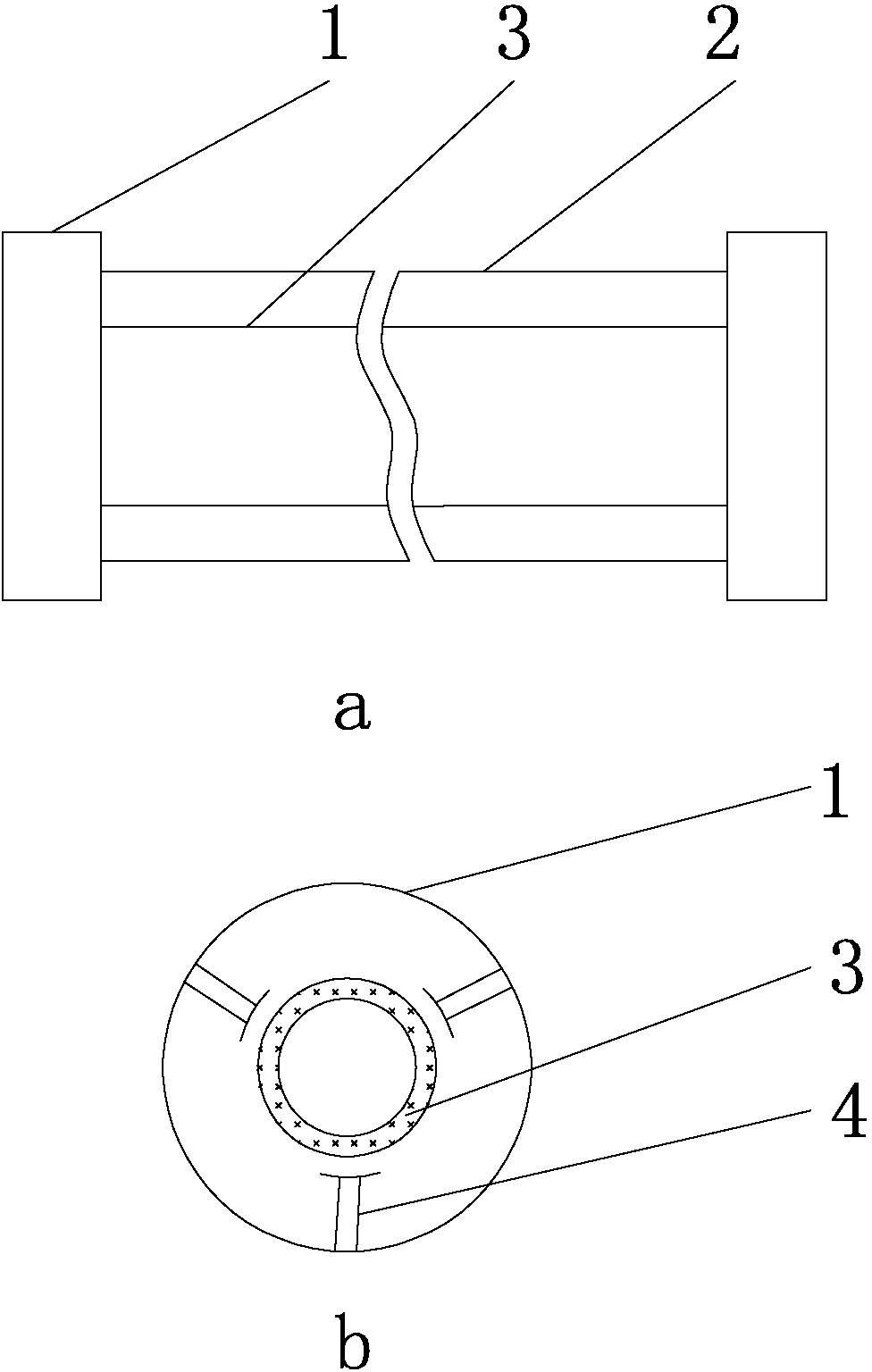

EPDM (ethylene propylene diene monomer) rubber sealing strip compatible with silicone rubber and productive technology thereof

The invention relates to an EPDM (ethylene propylene diene monomer) rubber sealing strip compatible with silicone rubber, which comprises the following components in percentage by weight: 25 to 30 percent of EPDM virgin rubber, 2 to 4 percent of vulcanizing agent, 3 to 5.8 percent of active filler, 35 to 40 percent of carbon black, 2 to 25 percent of softener, 1 to 2 percent of hygroscopic agent and 0.5 to 1 percent of polyethylene glycol, wherein the vulcanizing agent comprises sulphur or DBPMH; and the softener comprises paraffin or paraffin oil. A corresponding performance test carried out according to ASTMC1087 shows that under the condition of the same weighing and using amount of the raw materials, when the DBPMH is used as the vulcanizing agent and the paraffin oil is used as the softener, the compatibility and the ageing resistance are optimal and reach the grade of zero, and the color is not changed. Due to the adoption of the composition proportion and a productive technology of adopting the vulcanizing agent, the softener and peroxide to continuously vulcanize, the compatibility of the EPDM sealing rubber strip with the silicone rubber is good; the bonding strength of a silicone rubber strip and a curtain wall rubber strip to glass is improved and the service life of the EPDM sealing rubber strip is prolonged. Compared with the imported EPDM-S material rubber strip, the cost of the sealing strip of the product is reduced to half of the original cost.

Owner:宁波新安东橡塑制品有限公司

Seam allowance abrasion resisting glue containing short fiber and preparation method thereof

The invention relates to seam allowance abrasion resisting glue containing short fiber and a preparation method thereof. The seam allowance abrasion resisting glue containing the short fiber is characterized by comprising the first step of primary mother mixing, wherein natural rubber, butadiene rubber, carbon black N375 nylon short fiber, an anti-aging agent 4020, zinc oxide, stearic acid and aromatic hydrocarbon oil are sequentially added into an internal mixer to be subjected to banburying, and primary mother glue is obtained; the second step of secondary mother mixing, wherein the primary mother glue is added into the internal mixer to be subjected to banburying, and secondary mother glue is obtained; the third step of final mixing, wherein the secondary mother glue, insoluble sulfur and accelerant DZ are added into the internal mixer to be subjected to final mixing, and the seam allowance abrasion resisting glue is obtained. The seam allowance abrasion resisting glue containing the short fiber and the preparation method are suitable for full-steel radial tire seam allowance glue protection parts, a traditional mixing technology is adopted to a formula for mixing, the nylon short fiber is subjected to phenolic resin latex immersion treatment, and the adhesive strength of the nylon short fiber with rubber is improved.

Owner:JIANGSU GENERAL SCI TECH

Elastomer composite mud absorption rubber tube and manufacturing technique thereof

ActiveCN103267179AShorten vulcanization timeImprove bond strengthFlexible pipesCoatingsDeformation ProblemPolyurea

The invention provides an elastomer composite mud absorption rubber tube and the manufacturing technique thereof. The elastomer composite mud absorption rubber tube mainly comprises a mud absorption rubber tube body, cord fabric, a tightening steel wire, a rubber tube outer layer, a steel ring and a flange steel short sleeve, wherein a middle layer is arranged on the inner surface of the cord fabric, the middle layer is made of canvas, a composite layer is arranged on the inner surface of the middle layer, and the composite layer is made of polyurethane materials or polyurea materials. After a rubber tube blank is manufactured, the cast-molding technique or the centrifugal molding technique or the spray-molding technique is adopted to manufacture the elastomer composite mud absorption rubber tube. According to the elastomer composite mud absorption rubber tube and the manufacturing method thereof, due to the elimination of inner glue existing in a current mud absorption rubber tube, the vulcanizing time of the tube blank is shortened; the middle canvas layer single-face rubber lining technique improves the bonding strength between an elastomer and the cord fabric; due to the fact that specialized supports are designed and used in the centrifugal technique and in the spraying technique, the deformation problem of the tube body in a manufacturing process is solved, and the uniformity of the thickness of the composite layer is guaranteed.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

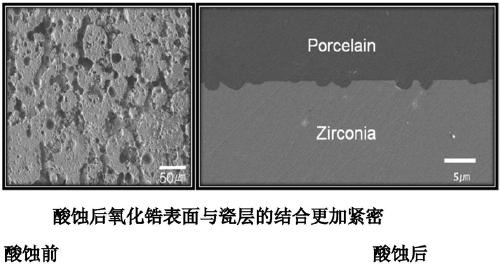

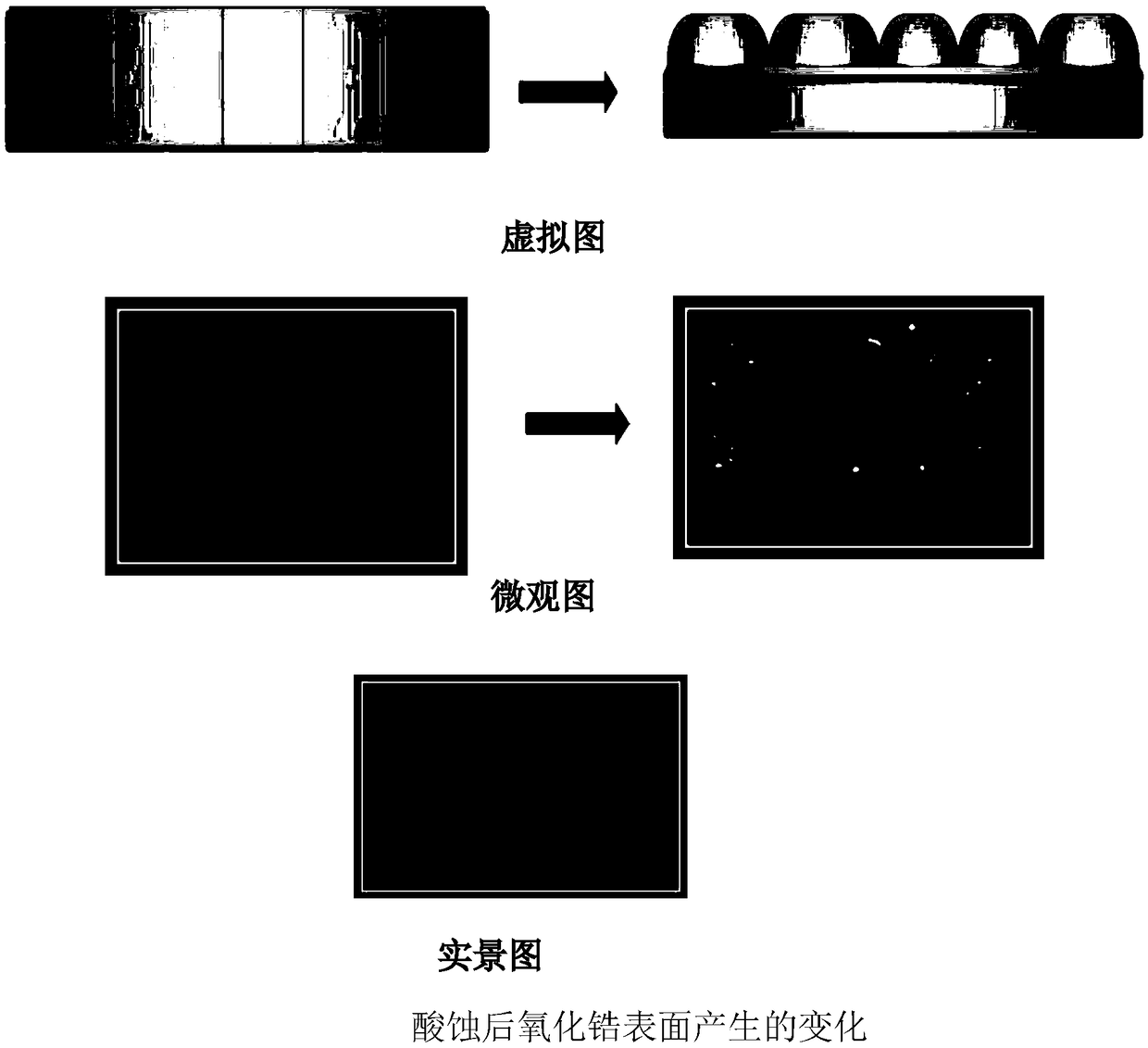

Zirconia surface processing method

InactiveCN109125801AImprove bond strengthImprove long-lasting durabilityPharmaceutical delivery mechanismTissue regenerationSurface bondingCeramic glaze

The invention discloses a zirconia surface processing method, and belongs to the field of dental repairing technologies. The method comprises the steps that processing treatment is conducted on a dental zirconia block, the dental zirconia block is ground into a zirconia dental crown; the dental crown is dyed by using zirconia dyeing liquid, the dyeing liquid is dried, and sintering processing is conducted on zirconia by using a zirconia crystallizing furnace; the zirconia dental crown is soaked in a surface treatment solution to ensure that the inner and outer surfaces of the dental crown arein contact with the solution, the inner surface of the dental crown is used for bonding to an abutment tooth, and the outer surface is used for porcelain coating or glaze coating; the zirconia dentalcrown on which surface processing is conducted is taken out and washed, and porcelain coating or glaze coating are conducted. By bonding the inner surface of the zirconia dental crown to the abutmenttooth, porcelain coating or glaze coating are conducted on the outer surface after surface acid etching processing is conducted, the bonding intensity between the abutment tooth and between the dentalcrown and the porcelain layer and the glaze layer can be improved, and the appearance and durability of a dental repairing body are improved.

Owner:广州壹凌医疗器械科技有限公司 +1

Wafer bonding structure and preparation method thereof

PendingCN107742606AImprove bond strengthGood heat dissipationSemiconductor/solid-state device manufacturingEtchingBonding strength

The invention discloses a wafer bonding structure and a preparation method thereof. The wafer bonding structure and the preparation method thereof mainly aim at solving the technical problems that inthe prior art, the bonding strength is low, and the voidage of bonding is high. According to the wafer bonding structure and the preparation method thereof, two wafers which need to be bonded are subjected to cleaning and metal Al evaporation deposition, the surface of an arbitrary wafer is subjected to photoresist spin-rotating, soft baking, UV exposure and photoresist development, equally-spacedchannels are formed through etching, and low-temperature bonding and low-temperature annealing bonding are conducted in the presence of oxygen to obtain the wafer bonding structure. According to thetechnical scheme, the wafer bonding structure comprises an upper wafer layer and a lower wafer layer, and oxidation and bonding are simultaneously conducted between the two wafer layers, so that the surface after bonding has the air channels of mixed aluminium oxide and air; by means of the wafer bonding structure and the preparation method thereof, it is achieved that the voids between the wafersare small, the bonding strength is high, and a device produced based on an SOI structure has high heat dissipating performance; the wafer bonding structure and the preparation method thereof can be used for low-temperature bonding of wafers.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Waterborne tackifying resin exclusively used for PVC electrical adhesive tape and preparation method thereof

ActiveCN103849328AImproved water resistance and adhesion adaptabilityImprove bond strengthNon-macromolecular adhesive additivesFilm/foil adhesivesRosinChemistry

The invention discloses a waterborne tackifying resin exclusively used for a PVC electrical adhesive tape, and relates to the technical field of chemical engineering. The tackifying resin comprises following components by weight: 30-53% of rosin, 1-1.5% of auxiliary agents, 5-18% of polyol, 5-20% of an emulsifier, 30-53% of water, 3-20% of styrene-isoprene-styrene segmented copolymer and 3-20% of styrene-butadiene-styrene segmented copolymer. Compared with the prior art, the initial adhesion and the holding power of the tackifying resin adopting a water miscible tackifying agent using the elastomer styrene-isoprene-styrene segmented copolymer and the elastomer styrene-butadiene-styrene segmented copolymer as tackifying substrates in the fields of tackifying and coating using are several times of those of common rosin type emulsion and polyacrylate emulsion tackifying agents. The waterproofness and the adhesion adaptability of the tackifying agent are significantly improved. The tackifying agent can significantly enhance the adhesive strength of emulsion adhesives.

Owner:广西藤县通轩立信化学有限公司

Silicon rubber composition and its preparation process and use

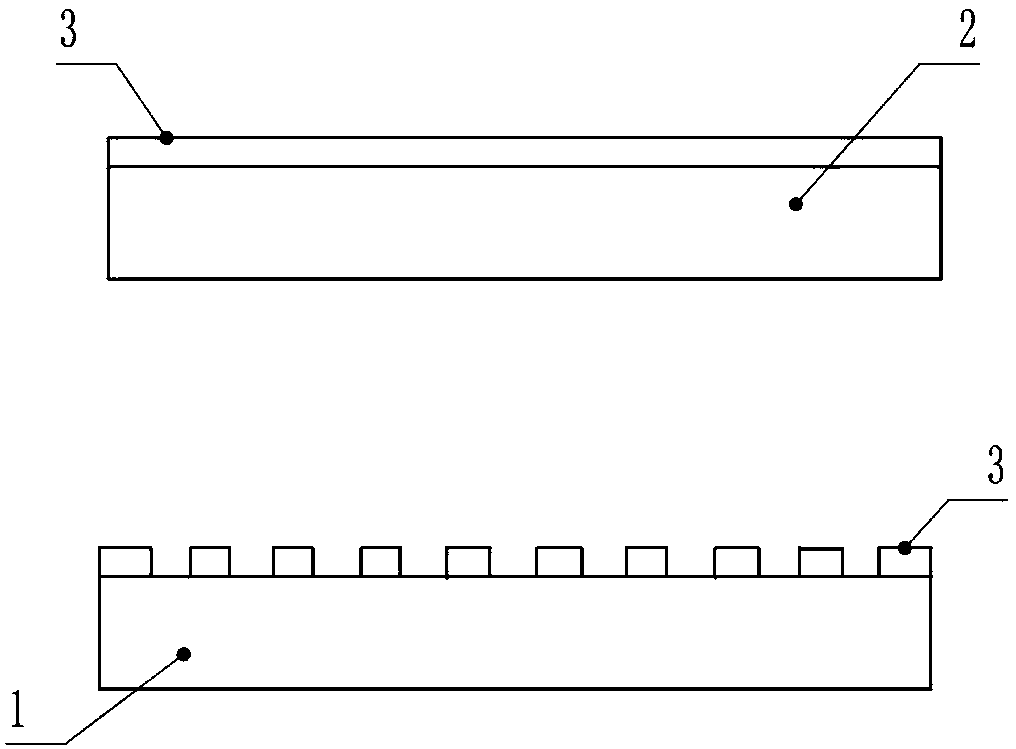

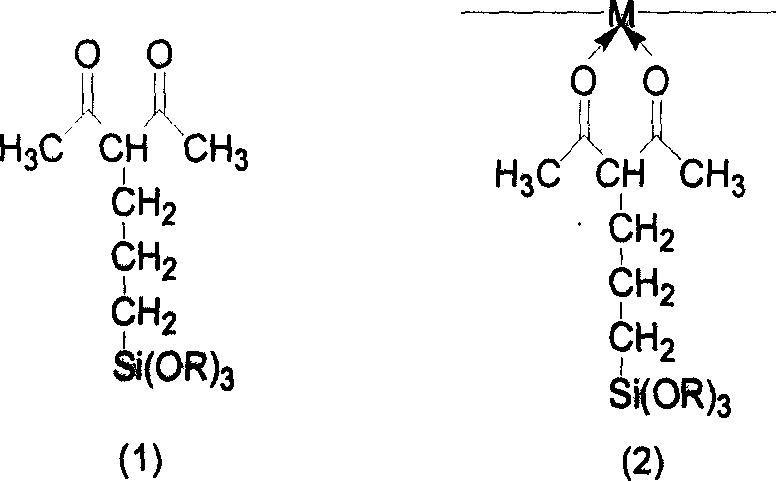

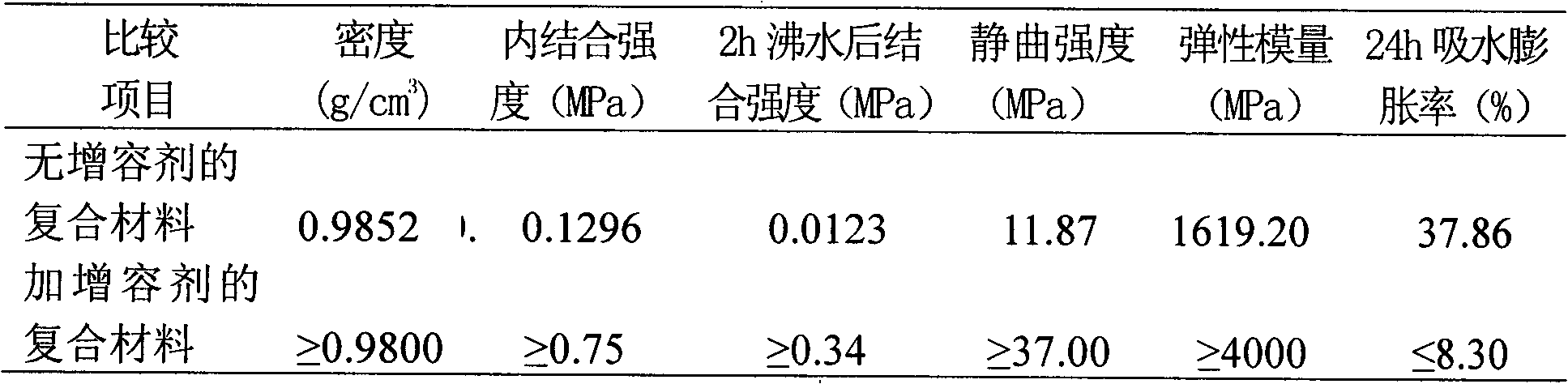

A silicon- rubber composition comprises crude silica gel, cross linking agent, catalyst, filling material and gamma-(3-acetylacetone) propyl trialkoxy silicane, these components are blended at room temperature (25-40 deg. C.). The composition can be used for the adhesion with metals.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Hot melt polyester-polyamide, preparation method and application thereof

The invention relates to hot melt polyester-polyamide, a preparation method and application thereof, which belong to the technical field of composite material melt-assist agents. The hot melt polyester-polyamide is prepared from recovered recovering polyethylene terephthalate (PET), diglycolamine, nylon acid, polycondensation catalyst and heat stabilizer by microwave radiation and reduced pressuredistillation. The hot melt polyester-polyamide is used for improving the physical and mechanical properties of agricultural wastes / thermoplastic plastic composite material. The invention blends the recovered PET and the nylon acid to use, reduces the cost of the raw materials of products and improves the additional value of the products; anhydride impurities in the nylon acid can be effectively utilized; the microwave radiation method is adopted, so the production efficiency is high; and industrial economy and social benefits are obvious.

Owner:UNIV OF JINAN

Nanometer composite heat-insulating material and preparation method thereof

ActiveCN108673977AStrong interactionImprove bond strengthLaminationLamination apparatusResin compositeFormamide

The invention provides a nanometer composite heat-insulating material. The nanometer composite heat-insulating material comprises a flame-resistant bubble layer and is characterized in that a flame-resistant glue layer, an aluminum foil layer and an aerogel layer are arranged on one side of the flame-resistant bubble layer sequentially; the aerogel layer is prepared from the following components in parts by weight: 5 to 20 parts of silicon dioxide-phenolic resin composite aerogel, 20 to 30 parts of epoxypropane, 80 to 130 parts of acetic acid, 50 to 70 parts of polyethylene glycol 600, 10 to 30 parts of formamide, 20 to 30 parts of toluene diisocynate tripolymer and 10 to 15 parts of isophorone diisocyanate tripolymer. Through the silicon dioxide-phenolic resin composite double-network structure aerogel, the adhesiveness of the aerogel and the aluminum foil can be improved and the heat-insulating property of the material is improved.

Owner:ZHEJIANG PENGYUAN NEW MATERIAL TECH GRP CO LTD

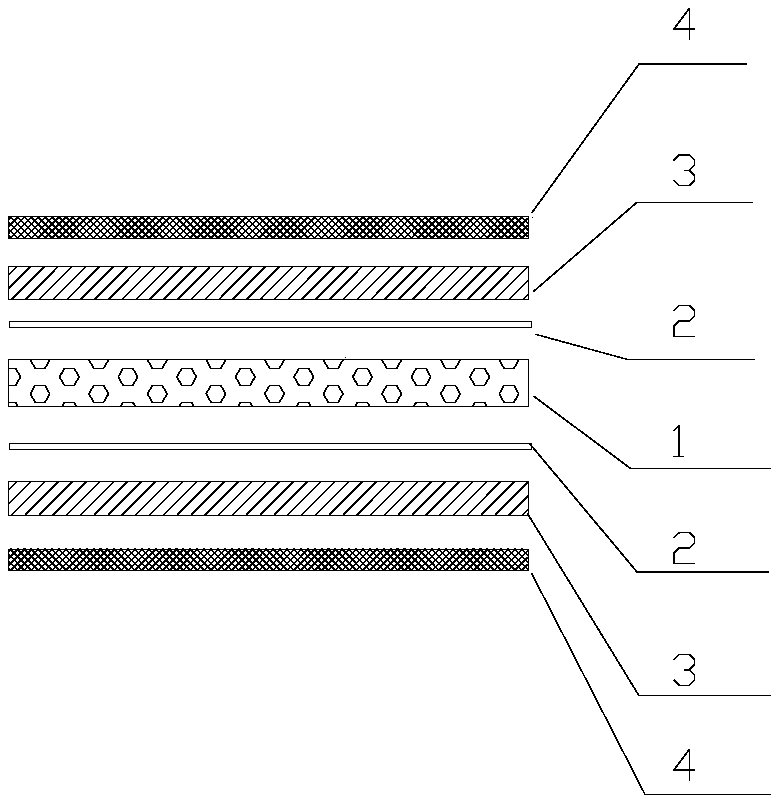

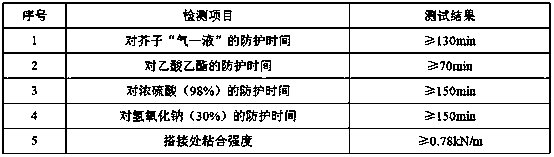

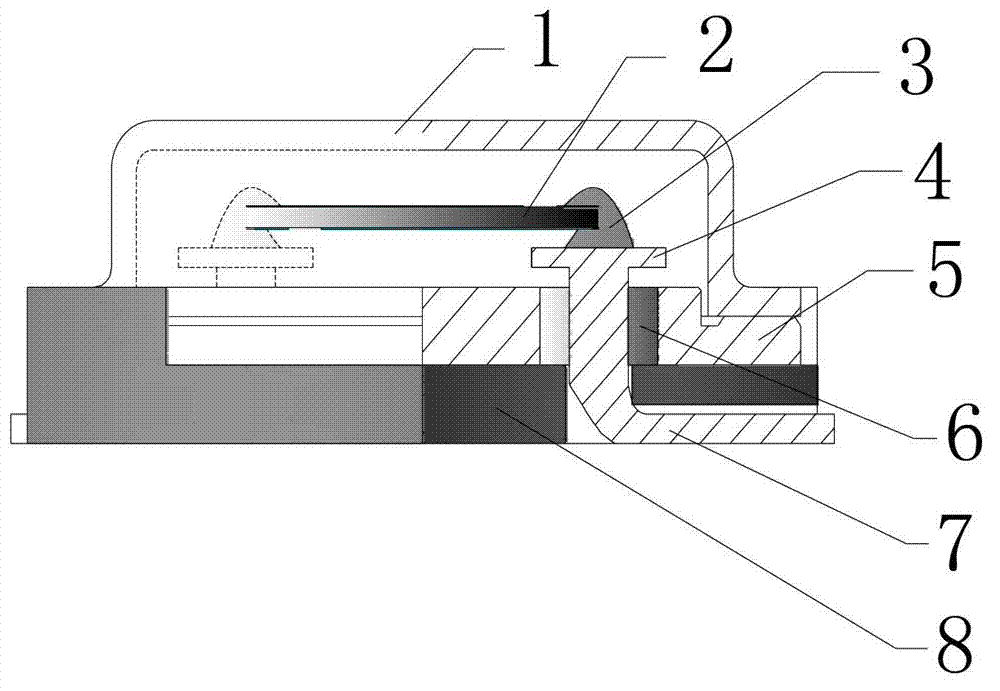

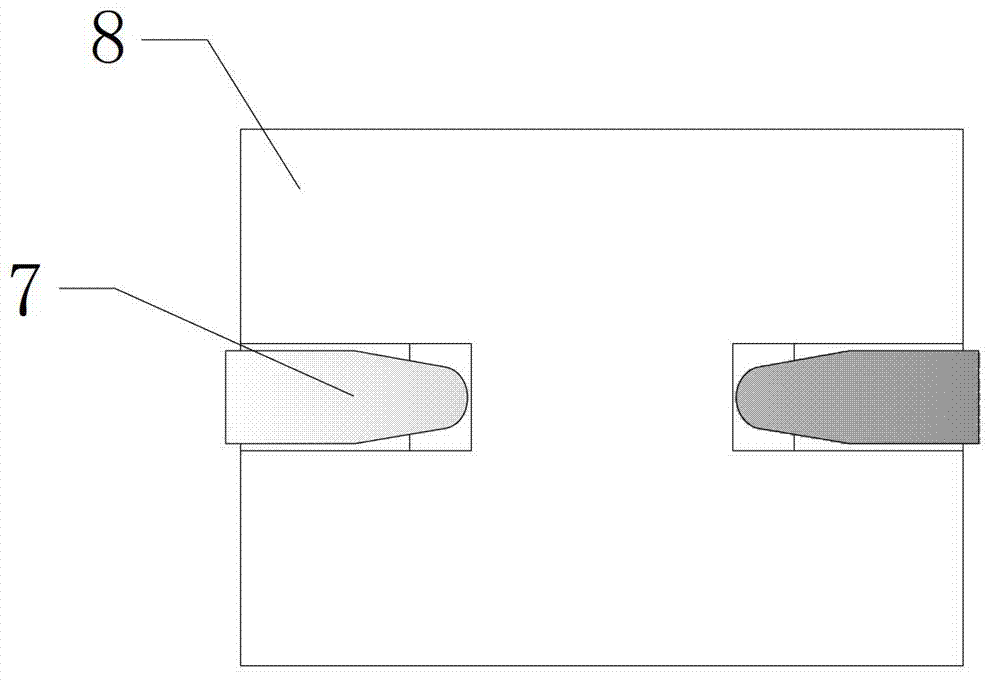

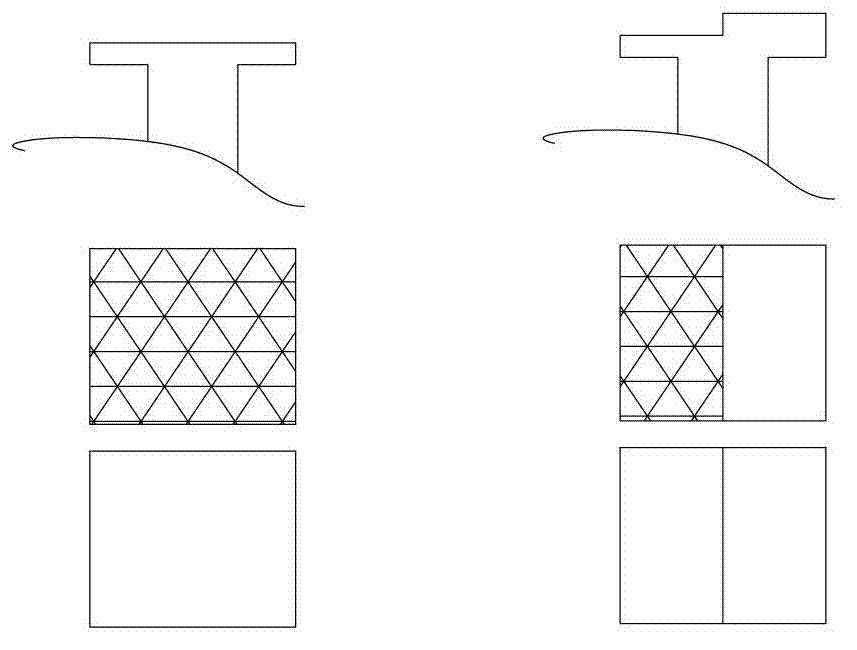

Rubberized fabric material with polyester cotton lining and capable of preventing chemical penetration

ActiveCN109501415AImprove bond strengthHigh bonding strengthSynthetic resin layered productsClothingsCotton clothPolyester

The invention discloses a rubberized fabric material with a polyester cotton lining and capable of preventing chemical penetration. The rubberized fabric comprises base cloth, wherein two side surfaces of the base cloth are respectively coated with a fluororubber layer and a chlorobutyl rubber layer; polyester cotton cloth is compounded outside the fluororubber layer. According to the rubberized fabric material, the polyester cotton cloth is laminated to the fluororubber layer, so that the bonding strength of the rubberized fabric is improved; the two surfaces of the base cloth are respectively coated with fluororubber and chlorobutyl rubber; the one layer of polyester cotton cloth is laminated to the fluororubber layer; after drum type primary vulcanization, secondary vulcanization is performed in a vulcanizing tank, and thereby a finished product is obtained. Compared with the prior art in China, the rubberized fabric material has the advantages that the bonding strength of the rubberized fabric is improved while physical and mechanical properties, medium resistance and protecting performance are prevented from being reduced.

Owner:SHANXI XINHUA CHEM

Environment-friendly (methyl) acrylate modified rubber type adhesive and preparation process thereof

ActiveCN103289597AImprove bond strengthWide range of bondingNatural rubber adhesivesNon-macromolecular adhesive additivesNatural rubberSaturated carboxylic acid

The invention relates to a preparation process and material composition of an environment-friendly (methyl) acrylate modified rubber type adhesive. A novel rubber-metal adhesive is prepared by carrying out reaction modification on high-molecule materials, such as natural rubber and the like, under the action of initiating agents, such as a hyperoxide and the like, by unsaturated carboxylic acid, such as acrylic acid and the like, or other polymerized monomers with second functional groups and substances, such as a metal oxide and the like which can be reacted with the polymerization monomers. The acrylate modified rubber type adhesive prepared through the process disclosed by the invention has the advantages of high adhesive strength, wide adhesive range, easiness and convenience for an adhesive process, no pollution of preparation and usage, and the like.

Owner:江苏矽时代材料科技有限公司

Small paster type quartz crystal resonator and processing method thereof

InactiveCN102970002AIncrease bonding areaImprove bond strengthImpedence networksQuartz crystal resonatorGlass ball

The invention discloses a small paster type quartz crystal resonator which comprises a casing, a quartz crystal wafer plated with an electrode, conductive glue, a base, glass balls, leads and an insulation gasket. A top head connected with the quartz crystal wafer through the conductive glue is arranged at the top of each lead, the axial distance of the two leads is 2.3mm or below 2.3mm, the thickness of the base is equal to or smaller than 0.5mm, the quartz wafer adopts a strip wafer, and the size of the quartz wafer is equal to 2.3*1.6mm or smaller than 2.3*1.6mm. A processing method of the small paster type quartz crystal resonator is further disclosed. The small paster type quartz crystal resonator is capable of meeting the requirement for miniature, improves mechanical performance and improves frequency stability.

Owner:CHENGDU KINGBRI FREQUENCY TECH

Double-Layered Watertight Zipper

InactiveUS20180020784A1High melting pointImprove bond strengthSlide fastenersEngineeringElectrical and Electronics engineering

A double-layered watertight zipper is provided to improve the watertight effect of the conventional zipper. The watertight zipper includes first and second stringer tapes. Each stringer tape includes a tape, a first leakproof layer, a plurality of scoops and a second leakproof layer. The first leakproof layer and the tape construct a waterproof tape. The first leakproof layer includes an inner face forming a first abutting face. The scoops are arranged on the waterproof tape. The second leakproof layer is arranged on the scoops and connected to the first leakproof layer. The second leakproof layer includes an inner face forming a second abutting face. When the scoops of the first and second stringer tapes are engaged with each other, the first abutting faces of the first and second stringer tapes abut with each other, and the second abutting faces of the first and second stringer tapes abut with each other.

Owner:UNITECH ZIPPER & MACHINERY

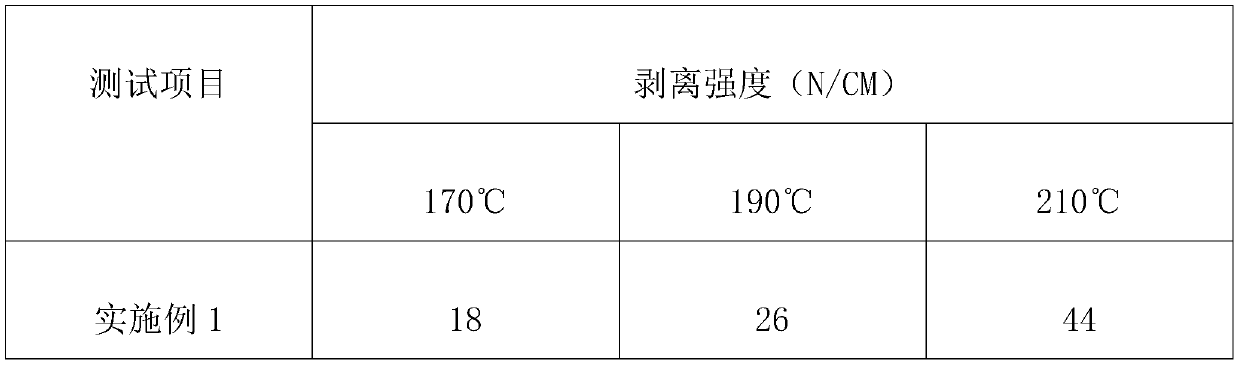

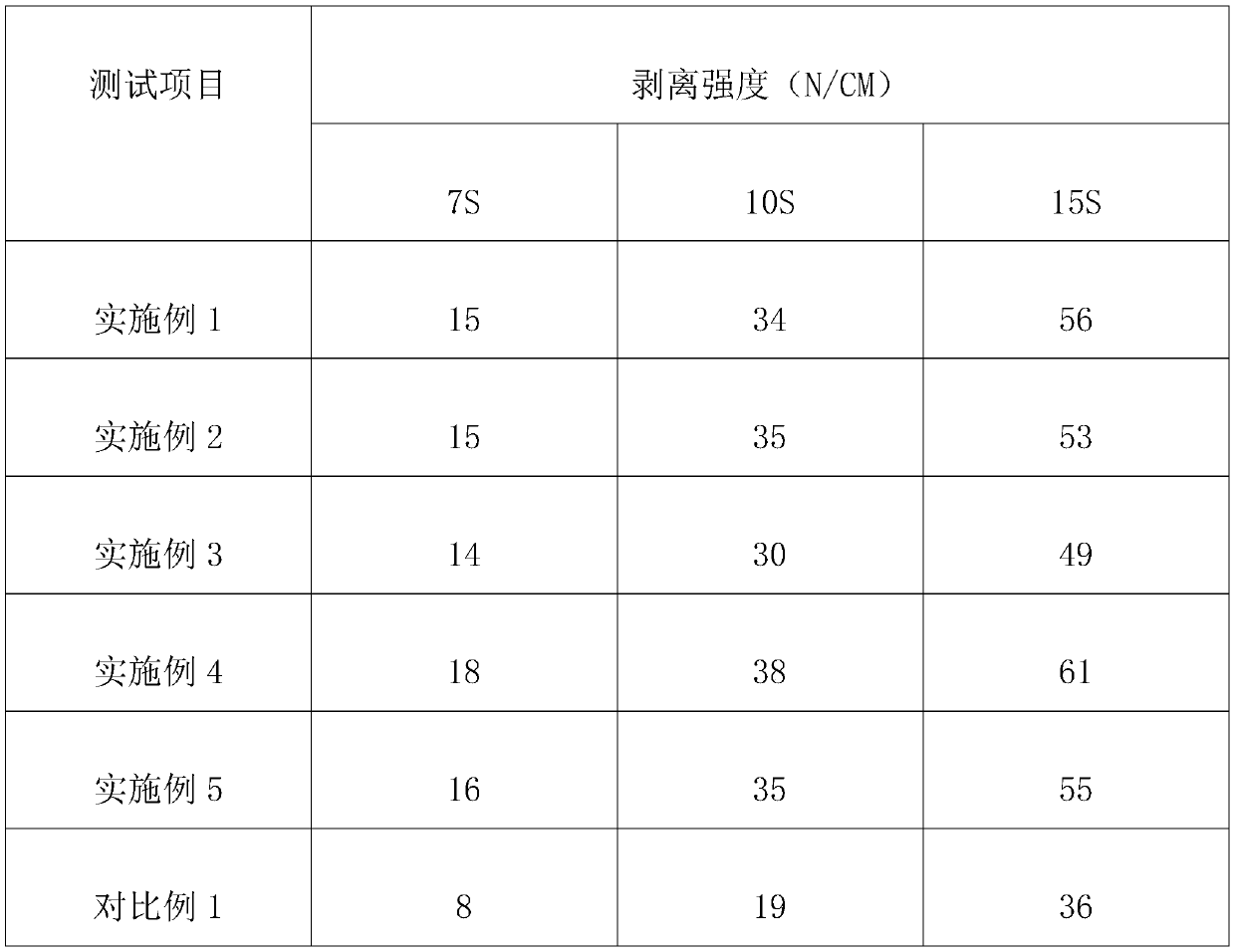

Modified polypropylene hot melt adhesive and preparation method thereof

The invention discloses a modified polypropylene hot melt adhesive. The adhesive is prepared from, by weight, 5-30 parts of functionalized modified polypropylene, 50-90 parts of first random copolymerpolypropylene, 5-20 parts of ethylene-alpha-olefin copolymer and 0.05-0.5 part of an antioxidant. The invention also discloses a preparation method of the above modified polypropylene hot melt adhesive. The modified polypropylene hot melt adhesive has high adhesive strength, can quickly conduct bonding and has strong adhesive force especially under low temperature conditions, and can also help toreduce the production cost and improve the production efficiency.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

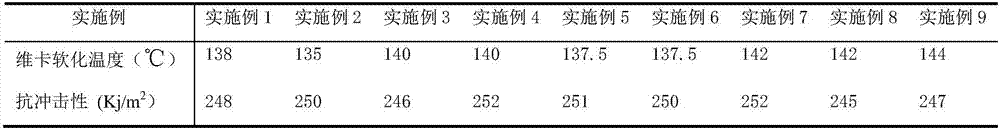

Polyvinylidene fluoride resin polymer and preparation method thereof

The invention discloses a polyvinylidene fluoride resin polymer which comprises the following components in parts by weight: 90-100 parts of polyvinylidene fluoride resin, 0.1-1 part of methyl methacrylate, 1-5 parts of perfluoroalkyl polyurethane and 0.3-10.8 parts of compound nucleating agent, wherein the compound nucleating agent is prepared from mica powder and at least one of sodium silicate, magnesium oxysulfate whisker and potassium titanate whisker. The invention can enhance the heat resistance of the polyvinylidene fluoride resin polymer, can increase the crystallizing speed thereof in extruding process, can reduce the shrinking percentage, can greatly improve the degree of crystallinity and can increase the forming rate. Besides, the reject ratio of the end product is reduced and the production efficiency is increased when the resin polymer is injected and processed into an end product. The vicat softening temperature of the resin particle according to the invention at least reaches up to 135 DEG C and the impact resistance at least reaches up to 240Kj / m<2>.

Owner:LICHANG TECH GANZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com