Quartz stone and preparation method thereof

A technology of quartz stone and compression molding, which is applied in the field of artificial quartz stone, can solve the problems of not being able to meet the market demand, the complicated preparation process of quartz stone, and the low competitiveness of products, and achieves non-deformation, small internal stress and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Therefore, the present invention provides a method for preparing quartz stone, which can form various types of patterns on the surface of quartz stone, especially linear patterns, without using a mold, so as to improve the competitiveness of the product.

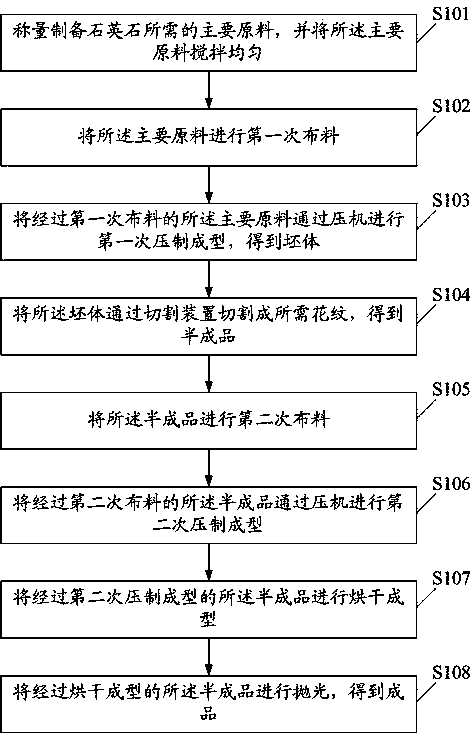

[0049] see figure 1 , the invention provides a method for preparing quartz stone, comprising:

[0050] S101. Weigh the main raw materials required for preparing the quartz stone, and stir the main raw materials evenly.

[0051] The formula of the main raw materials required for the preparation of quartz stone is as follows (in weight percentage):

[0052] Aggregate 85-95%

[0053] Resin 5-15%;

[0054] The aggregate includes quartz sand and quartz powder;

[0055] The resin is an unsaturated polyester resin.

[0056] Preferably, the formulation of the main raw materials required for the preparation of quartz stone is as follows (in weight percentage):

[0057] Aggregate 88-92%

[0058] Resin 8-12%.

[0059] Mo...

Embodiment 1

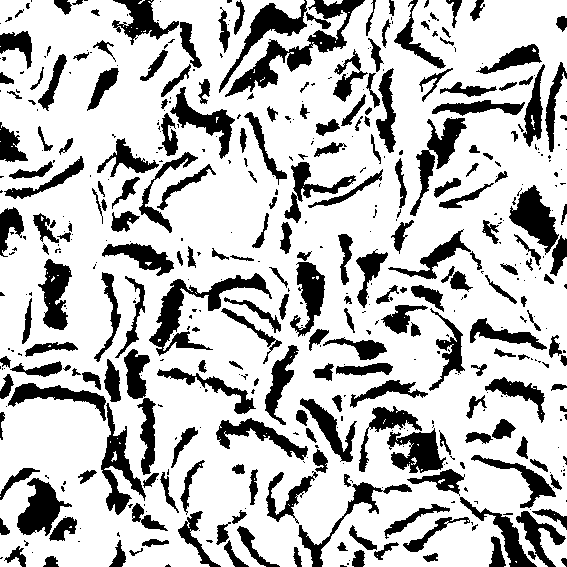

[0099] A. Stirring and mixing: add 90% of quartz sand and quartz powder and stir for 2 minutes, then add 0.05% of silane coupling agent KH-570 and 0.05% of OT curing agent, 0.4% of colorant and 9.5% of unsaturated polyester The resin was stirred for 2 minutes, and then poured into a mixer and stirred with quartz sand and quartz powder for 5 minutes, and the curing temperature was set at 90°C, wherein the color materials included A, B, and C, and A material was yellow (mainly color), B material is white, C material is gray, A, B, C three kinds of color materials are stirred evenly with their respective mixers;

[0100] B. Spread the raw material through the distributing machine to realize the first distributing process. During the first distributing process, three kinds of color materials A, B, and C are added in sequence and distributing, that is, first distributing A material, then distributing B material, and finally cloth C material;

[0101] C. The raw material that has p...

Embodiment 2

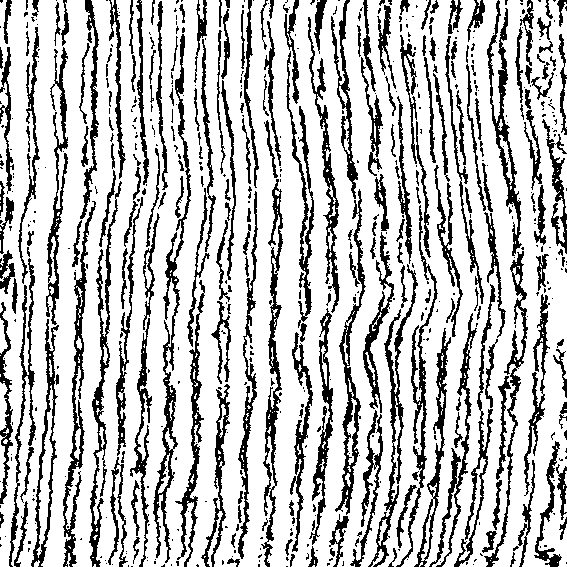

[0108] A. Stirring and mixing: add 90% of quartz sand and quartz powder and stir for 2 minutes, then add 0.05% of silane coupling agent KH-570 and 0.05% of OT curing agent, 0.4% of colorant and 9.5% of unsaturated polyester The resin was stirred for 2 minutes, and then poured into a blender and stirred with quartz sand and quartz powder for 5 minutes, and the curing temperature was set at 90°C. The color materials included A, B, and C, and A material was white (mainly color), material B is yellow, material C is green, material A is stirred evenly with a mixer, material B and C are dry powder materials and do not need a mixer;

[0109] B. Spread the raw materials through the distributing machine to realize the first distributing process. During the first distributing process, first dispose material A, then cloth B, then cloth C, and then cloth A;

[0110] C. The raw material that has passed through the first cloth is pressed and formed for the first time by a press to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com