Polyvinylidene fluoride resin polymer and preparation method thereof

A polyvinylidene fluoride resin and polymer technology, which is applied in the field of polyvinylidene fluoride resin polymer and its preparation, can solve the problems of reduced qualified rate of molded body, long crystallization time, reduced crystallinity and the like, so as to reduce the defective molding rate , The effect of improving impact strength and accelerating the speed of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

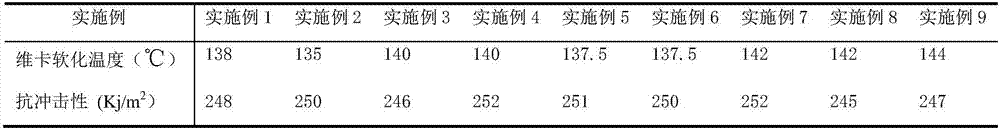

Examples

Embodiment 1

[0054] (1) Mixing: polyvinylidene fluoride resin: 90 parts, sodium silicate material: 0.1 part, mica powder: 2 parts, methyl methacrylate: 0.1 part, perfluoroalkyl polyurethane: 1 part, and the raw materials are as follows Add sequentially, first add mica powder and sodium silicate material in the composite nucleating agent for stirring, then add polyvinylidene fluoride resin for stirring, and finally add methyl methacrylate and perfluoroalkyl polyurethane;

[0055] (2) Stirring: heat the raw materials to 100°C and stir for 20 minutes to mix the raw materials evenly;

[0056] (3) Extrusion molding:

[0057] A. the mixture that step (2) is obtained is placed in the feeding device of screw extruder;

[0058] b. The mixture is extruded by the screw and enters the conveying section for preheating. The screw speed is 30r / min, the screw compression ratio is 1:1, and the preheating temperature is 190°C;

[0059] c. The preheated mixture enters the compression section through screw ...

Embodiment 2

[0064] (1) Mixing: polyvinylidene fluoride resin: 93 parts, sodium silicate material: 0.1 part, mica powder: 0.1 part, methyl methacrylate: 0.1 part, perfluoroalkyl polyurethane: 1 part, magnesium oxysulfide crystal Whiskers: 0.1 part, add raw materials in the following order, first add mica powder, sodium silicate material, magnesium oxysulfate whiskers in the composite nucleating agent and stir, then add polyvinylidene fluoride resin and stir, and finally add methacrylic acid Methyl esters, perfluoroalkyl polyurethanes;

[0065] (2) Stirring: heat the raw materials to 100°C and stir for 20 minutes to mix the raw materials evenly;

[0066] (3) Extrusion molding:

[0067] A. the mixture that step (2) is obtained is placed in the feeding device of screw extruder;

[0068] b. The mixture is extruded by the screw and enters the conveying section for preheating. The screw speed is 30r / min, the screw compression ratio is 1:1, and the preheating temperature is 190°C;

[0069] c. Th...

Embodiment 3

[0074] (1) Mixing: polyvinylidene fluoride resin: 95 parts, mica powder: 8 parts, methyl methacrylate: 0.3 parts, perfluoroalkyl polyurethane: 2 parts, magnesium oxysulfide whiskers: 0.2 parts, and the raw materials were pressed according to Add in the following order, first add mica powder and magnesium oxysulfide whiskers in the composite nucleating agent for stirring, then add polyvinylidene fluoride resin for stirring, and finally add methyl methacrylate and perfluoroalkyl polyurethane;

[0075] (2) Stirring: heat the raw materials to 100°C and stir for 25 minutes to mix the raw materials evenly;

[0076] (3) Extrusion molding:

[0077] A. the mixture that step (2) is obtained is placed in the feeding device of screw extruder;

[0078] b. The mixture is extruded by the screw and enters the conveying section for preheating. The screw speed is 35r / min, the screw compression ratio is 2:1, and the preheating temperature is 200°C;

[0079] c. The preheated mixture enters the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening temperature | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com