Small paster type quartz crystal resonator and processing method thereof

A quartz crystal and chip-type technology, applied in the direction of electrical components, impedance networks, etc., can solve problems such as frequency drift, easy cracking of the chip, use, etc., to improve vibration resistance and frequency stability, improve mechanical and electrical performance, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

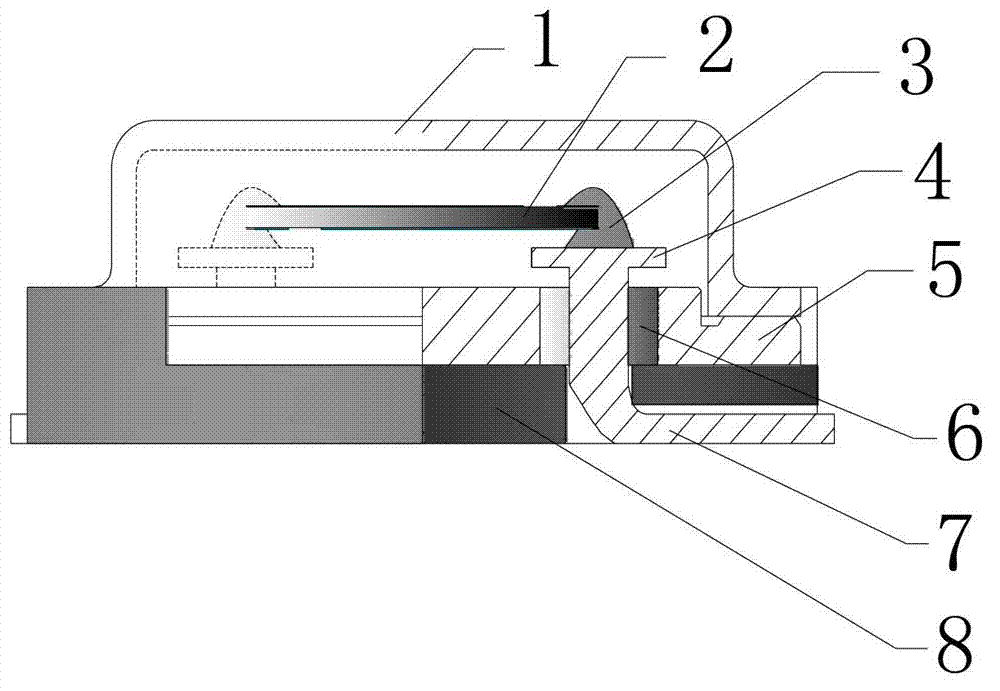

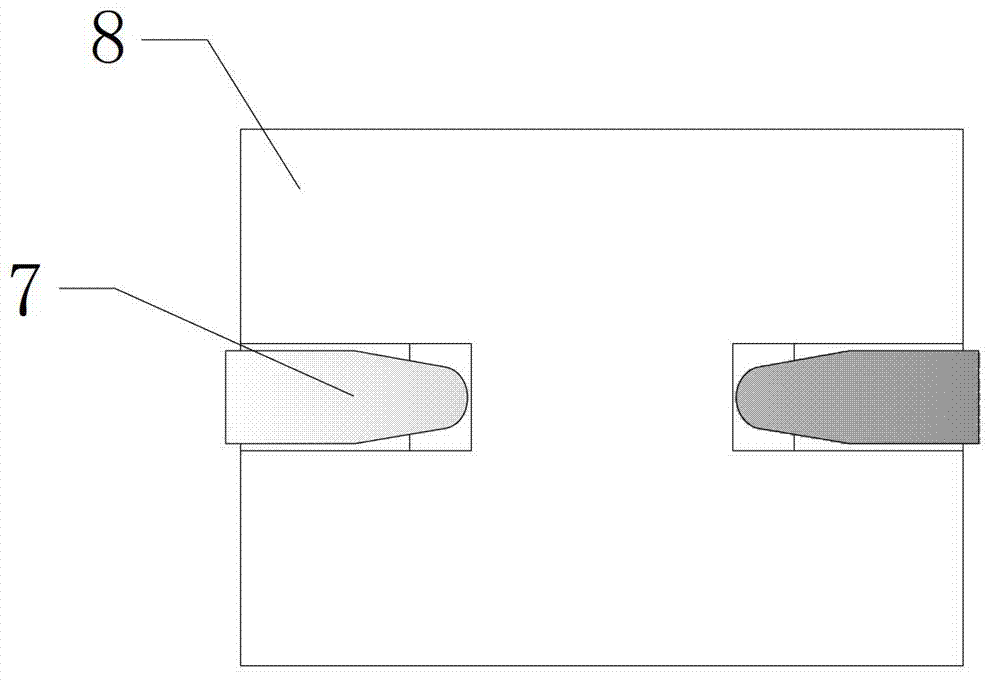

[0030] like Figure 1-2 As shown, the small patch type quartz crystal resonator disclosed by the present invention includes a shell 1, a quartz wafer 2 coated with electrodes, a conductive glue 3, a base 5, a glass bead 6, a lead wire 7, an insulating gasket 8, and a lead wire 7 The top of the top is provided with a plug 4 connected to the quartz wafer 2 through a conductive glue 3, there are two lead wires 7, the wheelbase of the two lead wires 7 is 2.3 mm or less, the thickness of the base 5 is 0.5 mm or less, and the quartz wafer 1 It is bar-shaped, with a size of 2.3×1.6mm or less.

[0031] Preferably, the diameter of the lead wire 7 is 0.35 mm or less, and the diameter of the plug 4 is 0.6 mm or less.

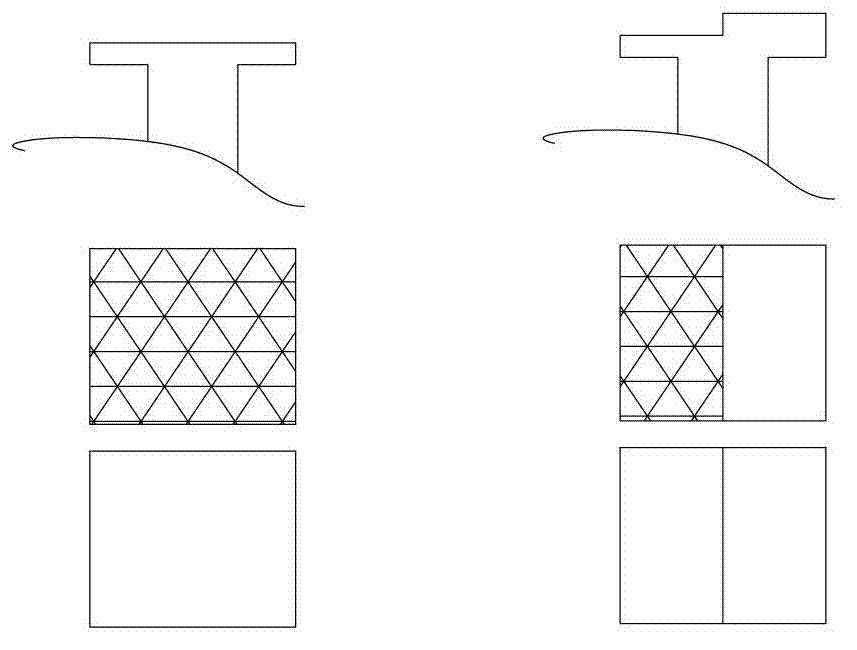

[0032] like Figure 3-5 As shown, further, the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com