Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

468results about How to "Reduce welding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

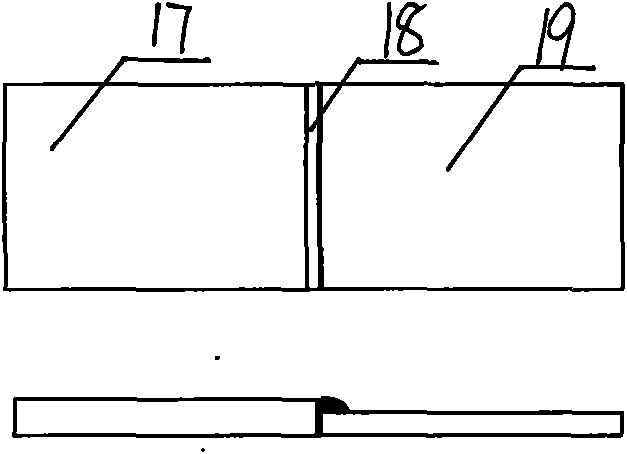

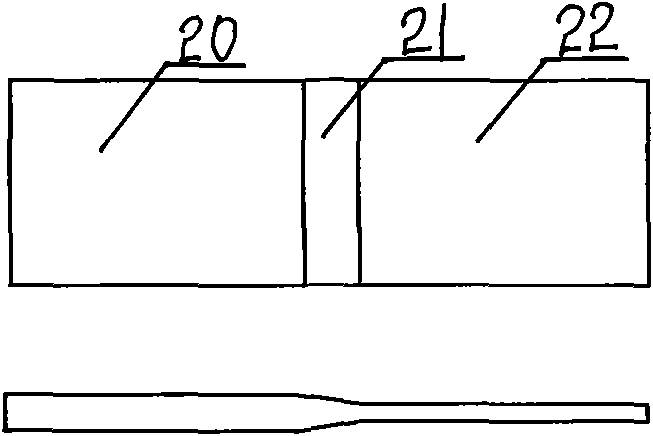

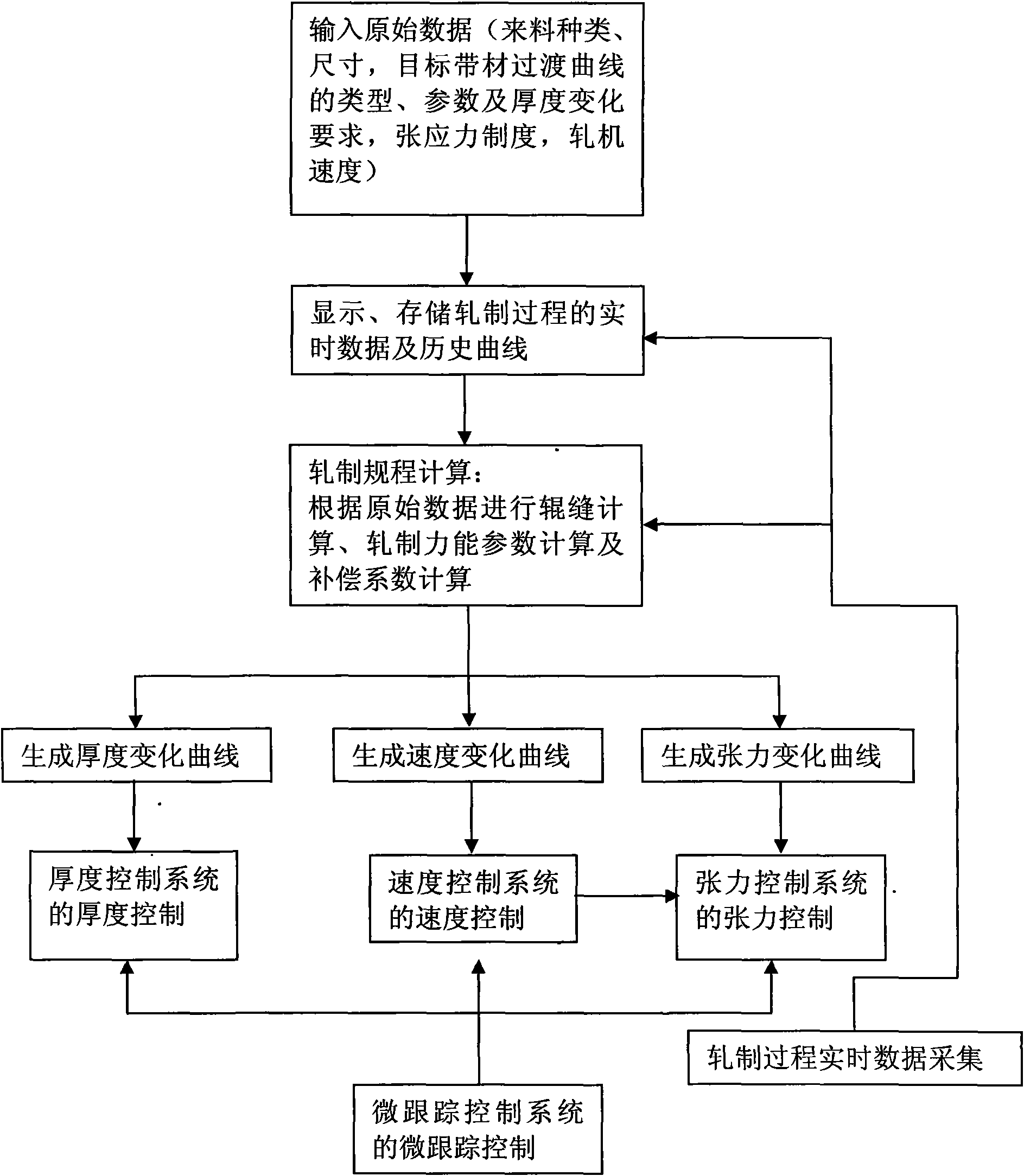

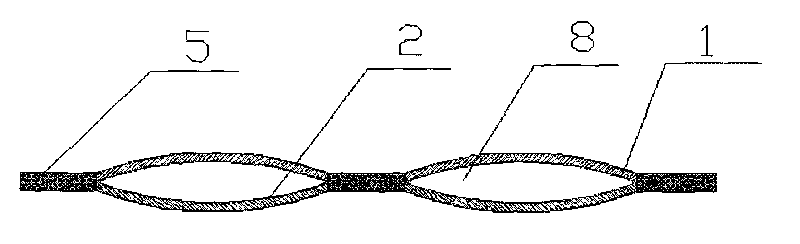

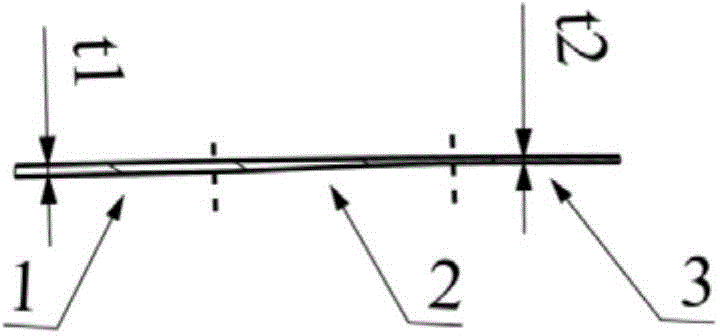

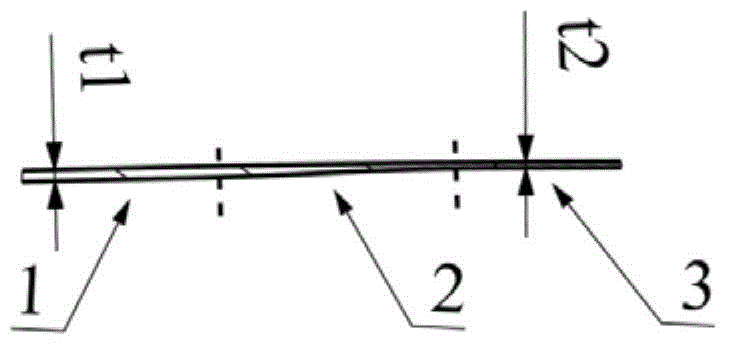

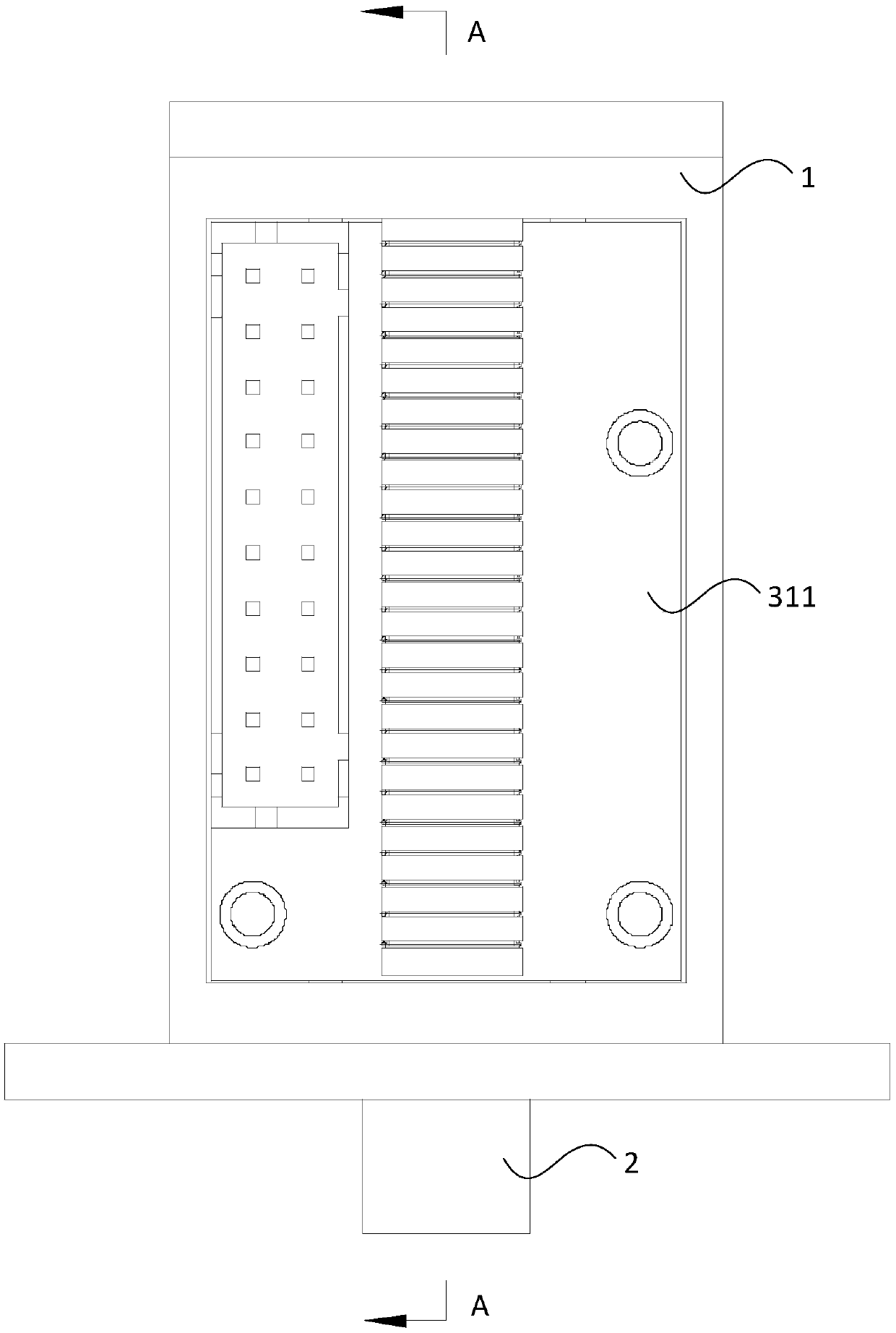

Periodic longitudinal variable-thickness strip and longitudinal variable-thickness plate and preparation method thereof

ActiveCN101607264AReduce welding processReduce manufacturing costProgramme control in sequence/logic controllersMetal rolling arrangementsComputer control systemVariable thickness

The invention belongs to the rolling technical field. The thickness of a periodic longitudinal variable-thickness strip changes periodically, the periodic longitudinal variable-thickness strip has more than two kinds of thicknesses regions and transition regions within a change period, and is formed by rolling. The control procedure of the periodic longitudinal variable-thickness strip comprises the following steps: inputting original data; displaying and storing real-time data and a history curve; computing the rolling procedure; generating a change curve; tracking the position of a rolling piece; and controlling the thickness, the speed and the tension. A device comprises a rolling mill, a reeling machine and a thickness measurer which are arranged at two sides of the rolling mill, and a length measuring roll arranged between the reeling machine and the rolling mill, wherein a reel diameter measurer is arranged on the reeling machine; a rolling force sensor and a hydraulic cylinder are arranged on the rolling machine; a pulse coder and a tension meter are respectively arranged on and below the length measuring roll; and the thickness measurer and the like are connected with a computer control system. A longitudinal variable-thickness plate has two or more kinds of different thickness regions, transition regions are arranged among the thickness regions, and the plate is formed by the strip through the steps of annealing, unreeling by an unreeler, leveling by a leveler, and cutting by a cutting machine.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

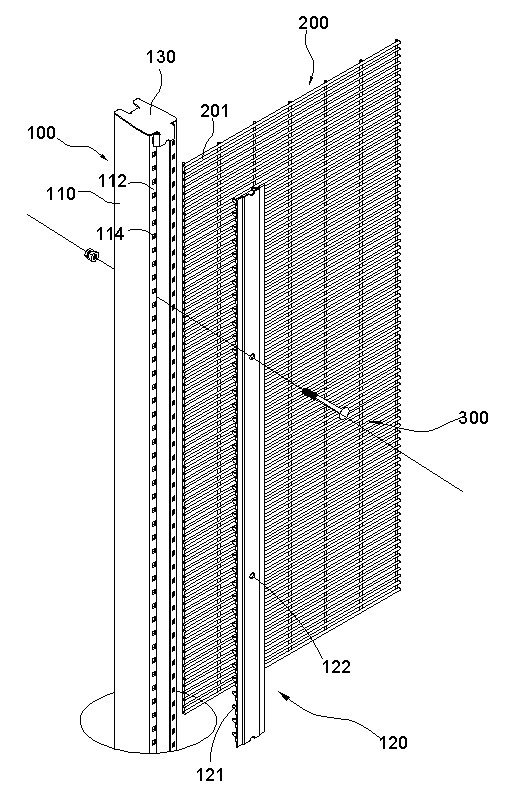

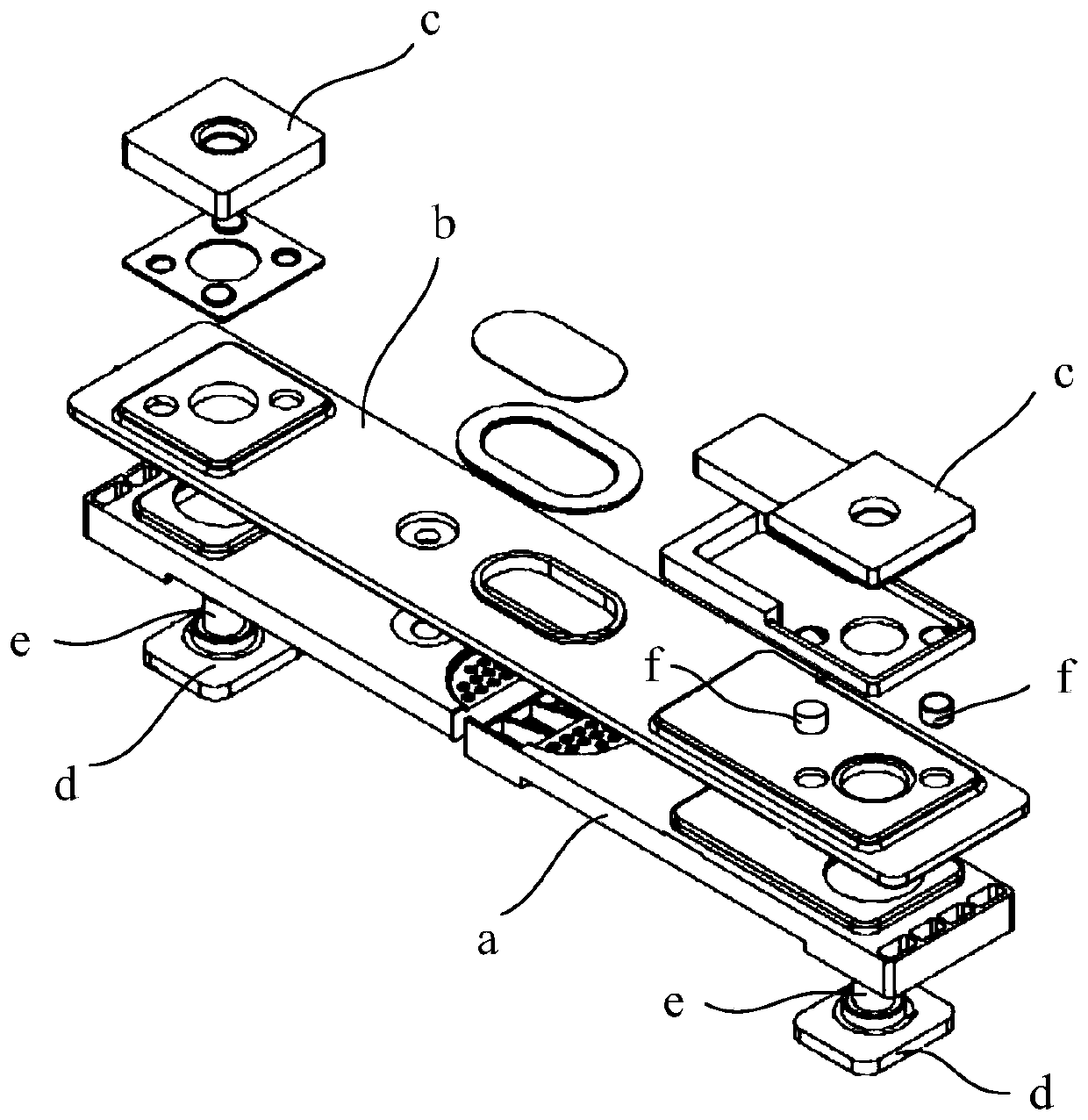

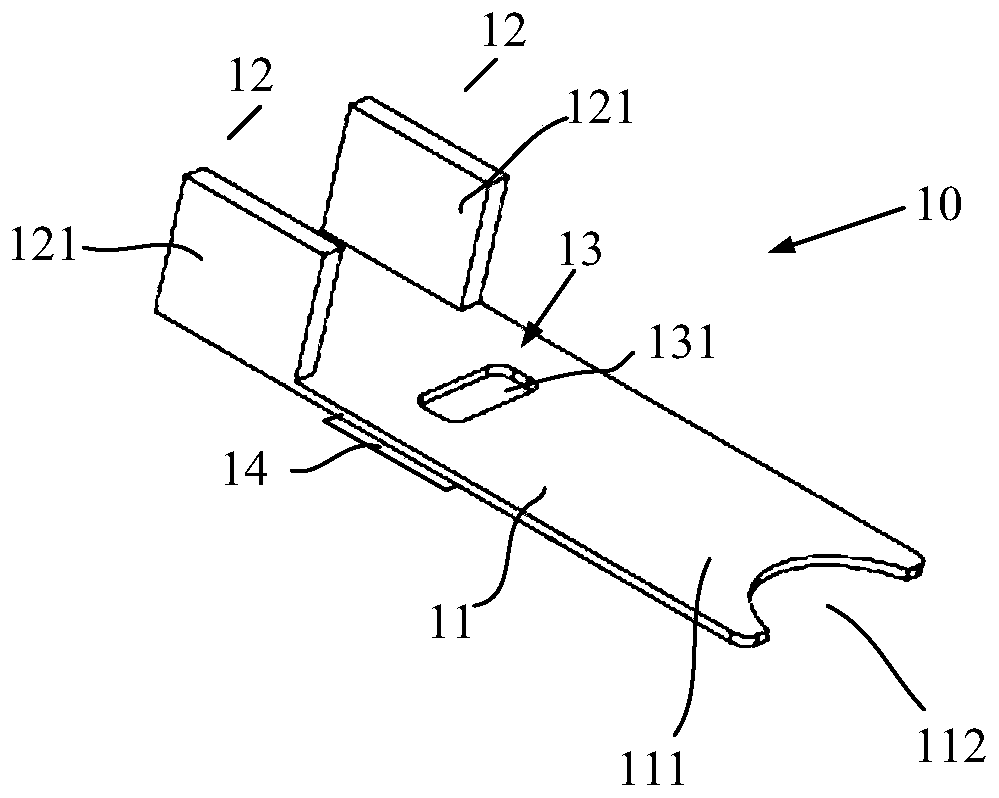

Fencing post and fencing system with same

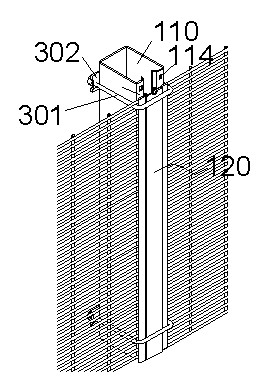

ActiveCN102493710AImprove smoothnessImprove flatnessFencingStructural engineeringMechanical engineering

The invention discloses a fencing post and a fencing system. The fencing post is used for fixedly installing fencing sheet bodies extending along the longitudinal direction and the horizontal direction; the fencing post comprises a first body extending along the longitudinal direction and a second body fixedly connected to the first body; the side of the first body, which is connected with the second body, is provided with a connecting surface on which a plurality of first locating pieces are distributed along the longitudinal direction; a plurality of second locating pieces matched with the first locating pieces are respectively distributed on the second body along the longitudinal direction; one locating piece of the first locating pieces and the second locating pieces is connected with the other locating pieces in a locating way after passing through the sheet bodies; and the sheet bodies are clamped and fixed between the second body and the first body. The fencing post can be used for improving the firmness and the flatness in fixing the fencing sheet bodies and has the advantage of good disassembly and damage preventing effects.

Owner:ZHANGJIAGANG GOLDNET FENCING SYST

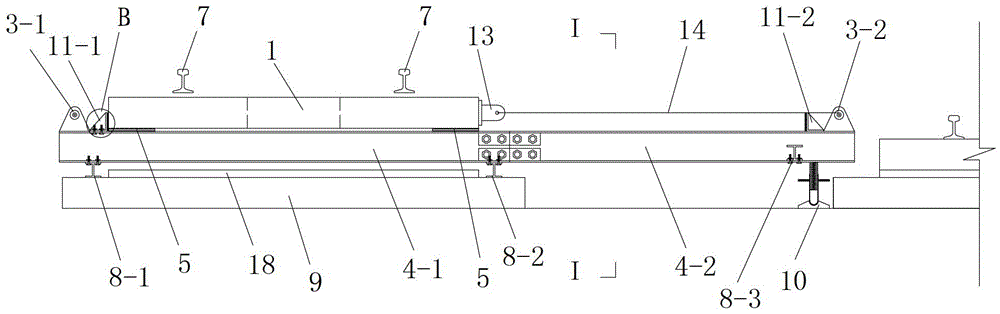

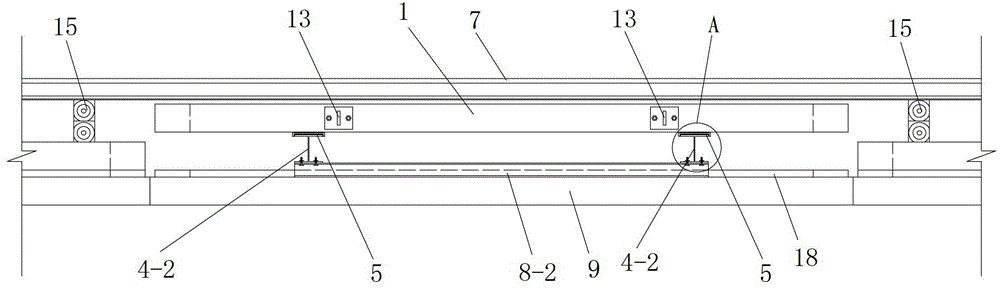

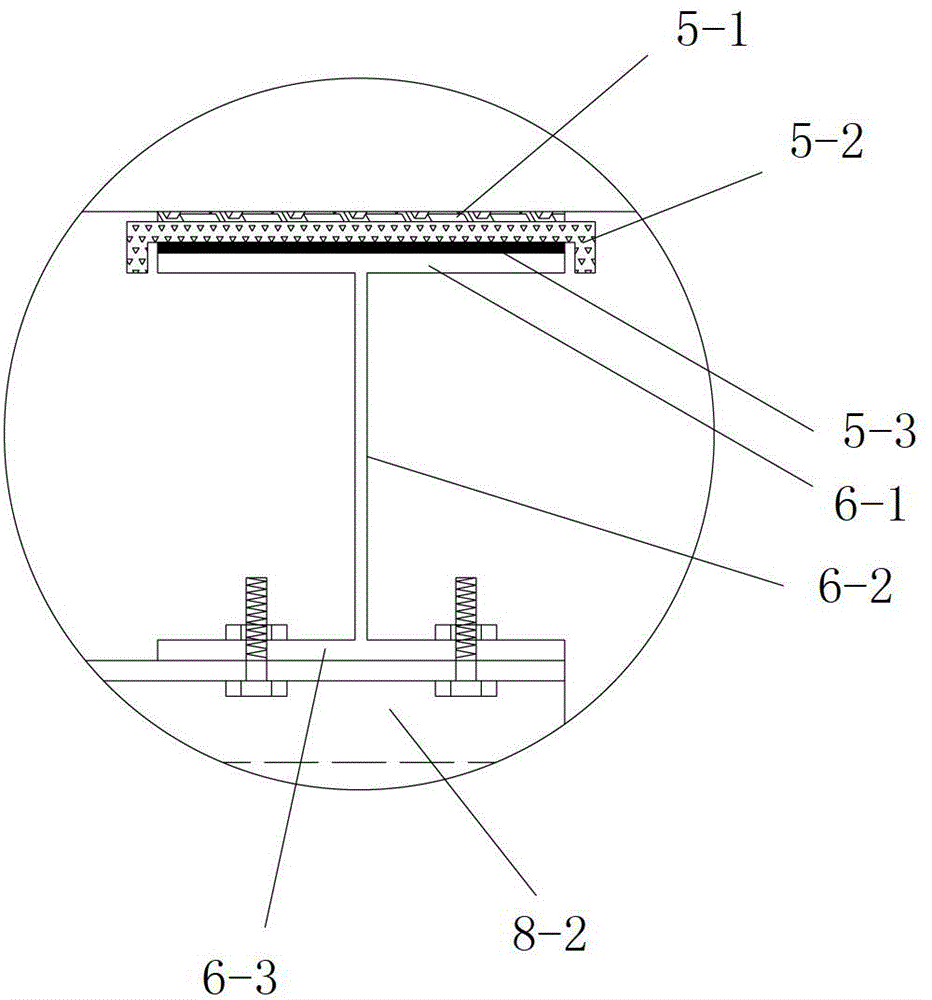

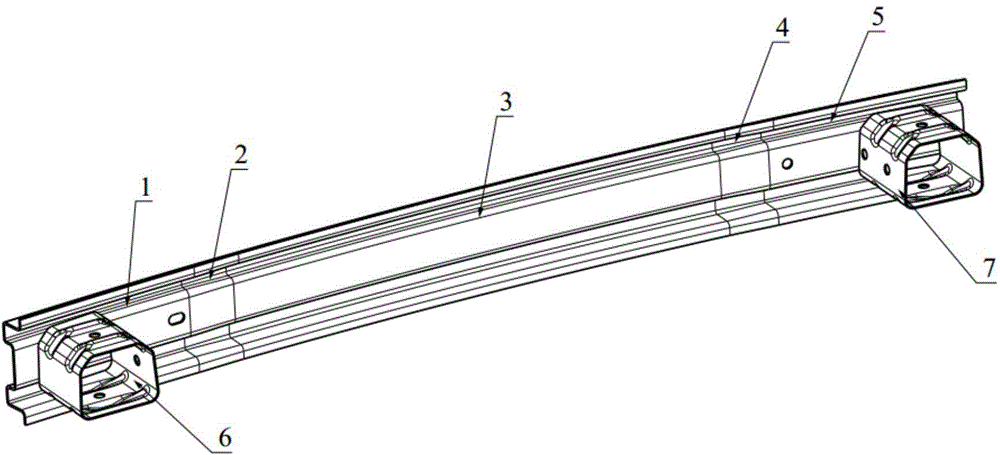

Device and method for replacing track slab of slab ballastless track

ActiveCN103147370ASimple structureReasonable designRailway track constructionStructural engineeringReplacement method

Owner:CHINA RAILWAY FIRST GRP CO LTD

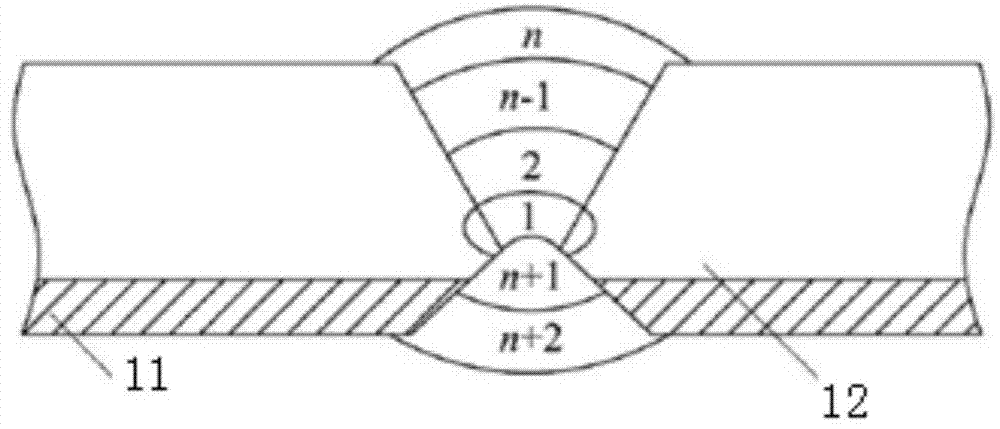

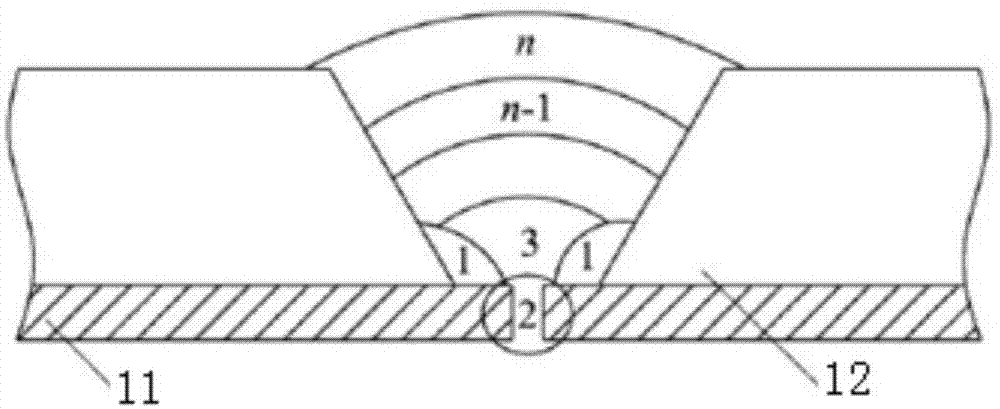

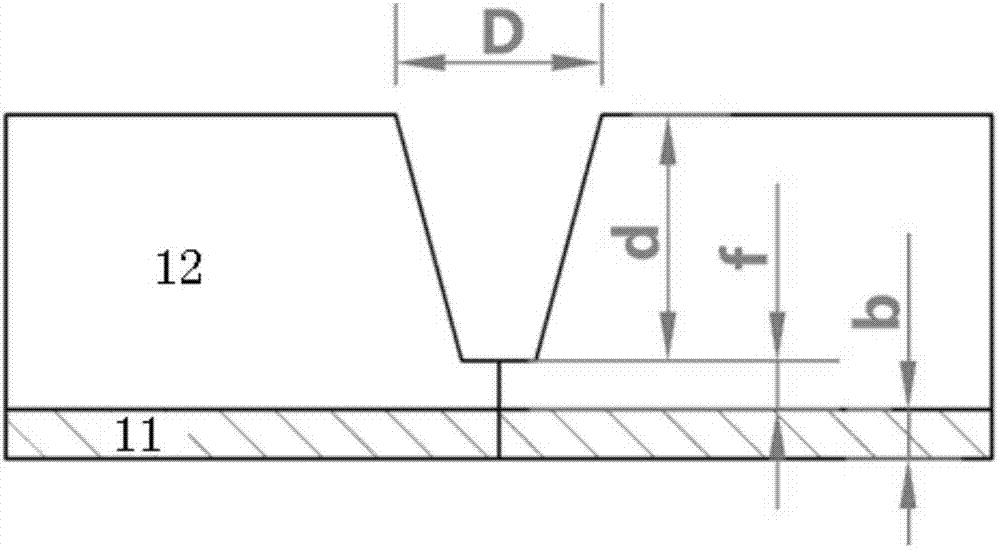

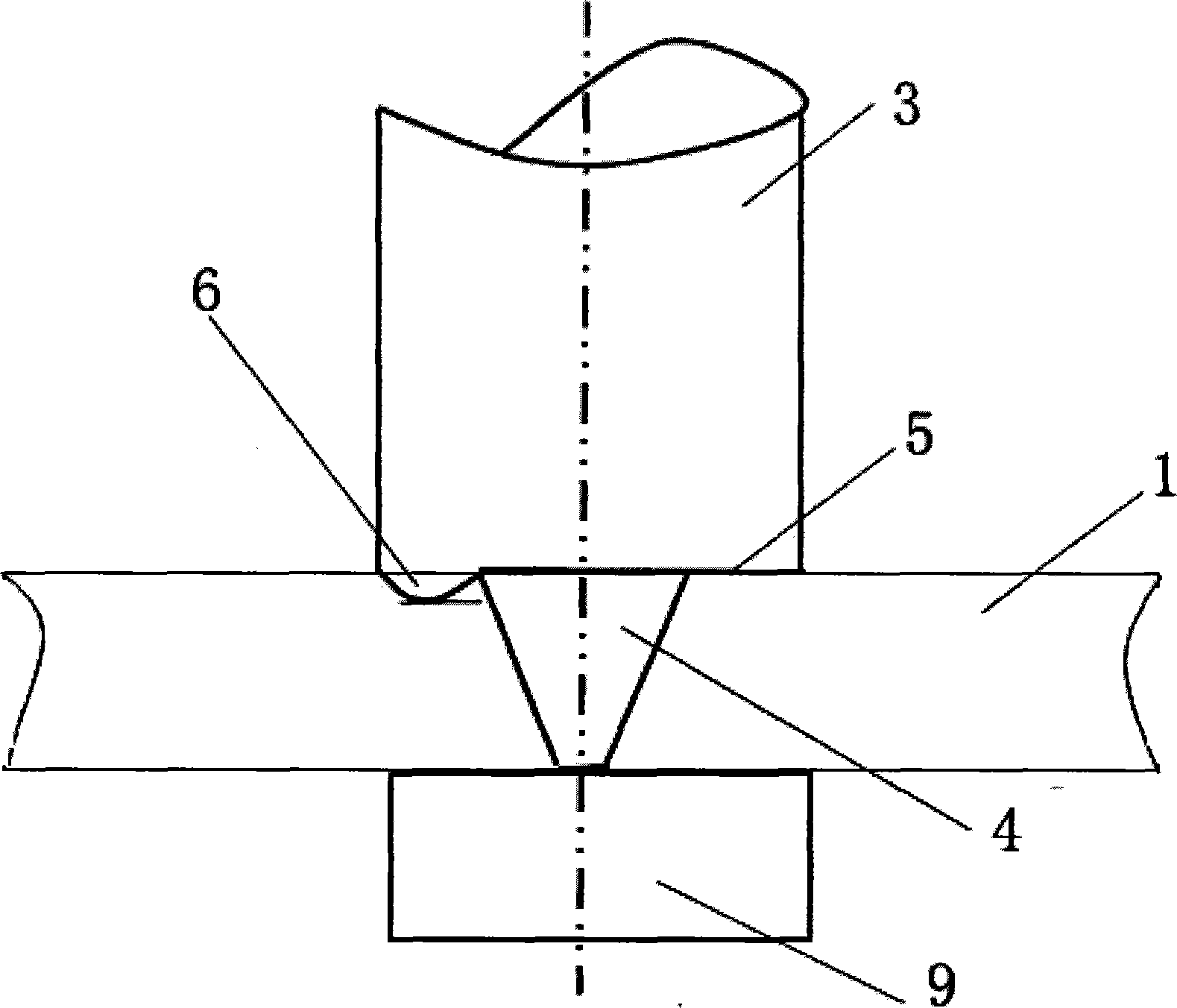

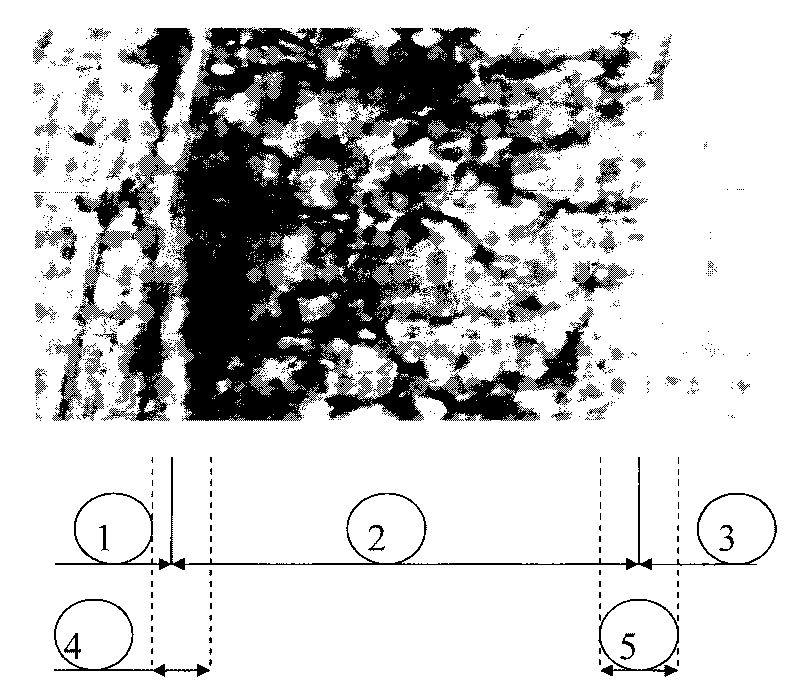

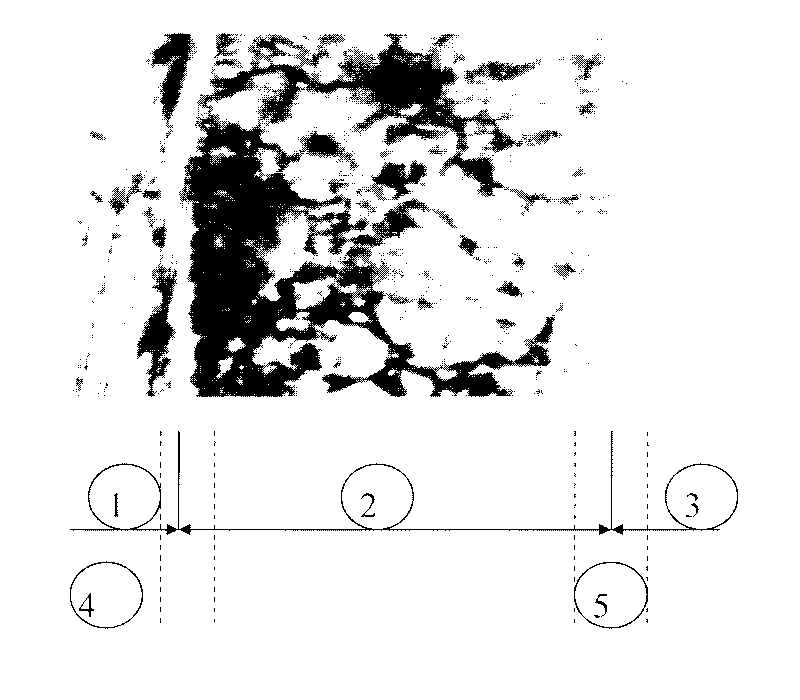

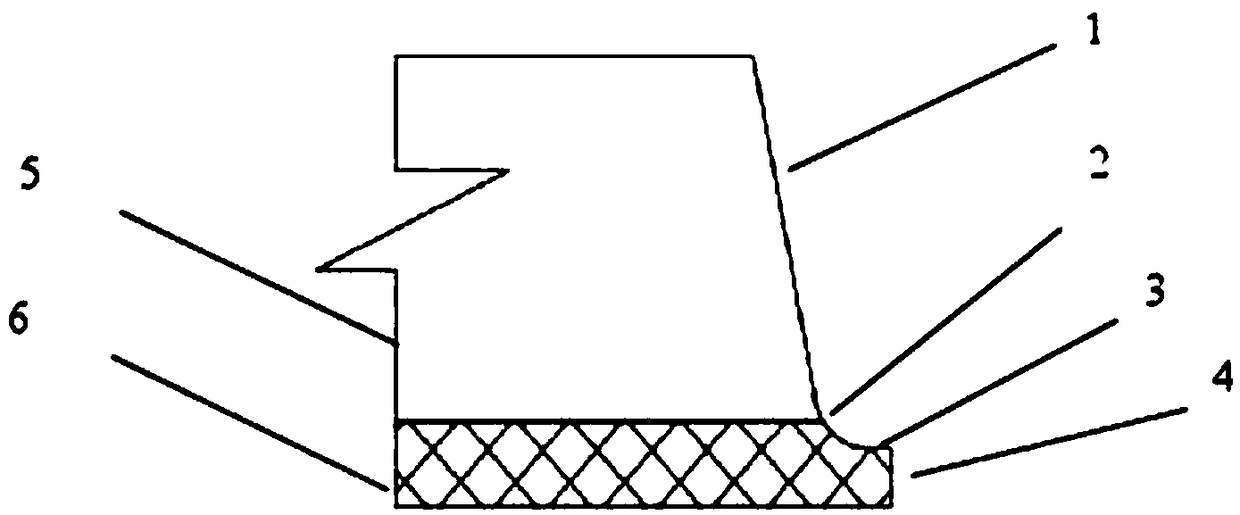

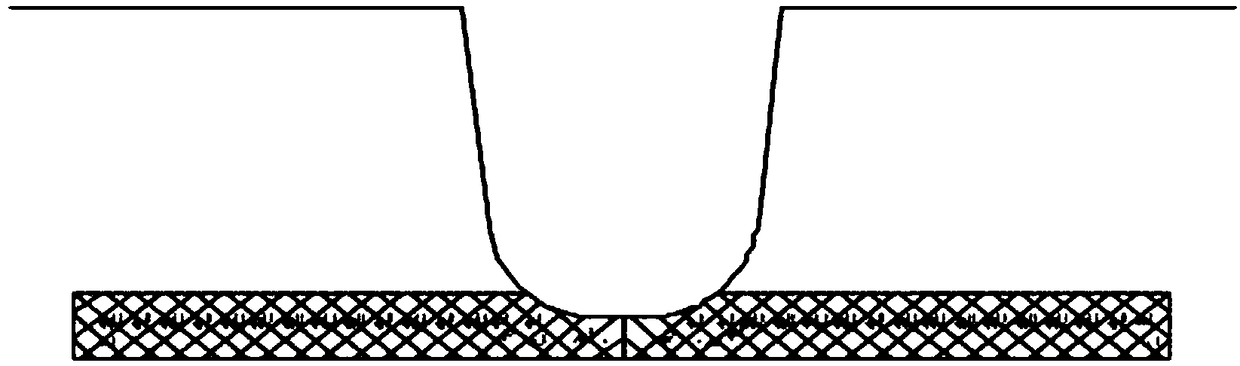

Efficient butt-joint laser welding method for laminated duplex-metal composite material

InactiveCN103878484ARealize one-time welding forming technologyGuaranteed Performance CharacteristicsWelding/soldering/cutting articlesWorkpiece edge portionsMolten bathMetallic materials

The invention discloses an efficient butt-joint laser welding method for a laminated duplex-metal composite material. The efficient butt-joint laser welding method comprises the steps that a base layer retaining layer is arranged at the portion, close to one side of a composite layer, of a base layer to form an I-type groove; the characteristic that in the laser penetration-type welding process, liquid metal at the upper portion and liquid metal at the lower portion inside a molten bath conduct Marangoni convection at the respective positions under the action of metal vapor friction and the temperature gradient, and little convection exchange happens between the liquid metal at the upper portion and liquid metal at the lower portion is used for being matched with the laminated characteristic of the laminated duplex-metal composite material, and the performance characteristics of two metal materials in a weld joint are ensured. The efficient butt-joint laser welding method has the advantages that one-time butt-joint welding forming of metal of the composite layer and some metal of the base layer is achieved, the working procedures of sealing and welding of a transition layer during a traditional composite board or composite pipe butt-joint welding are omitted, and the depth and the width of the remaining groove in the base layer are reduced, in other word, the welding amount of the base layer is reduced.

Owner:XI AN JIAOTONG UNIV

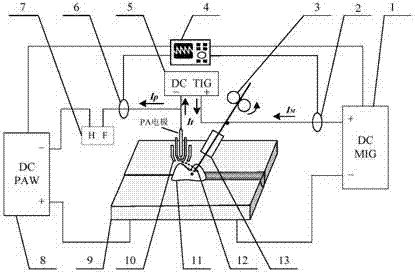

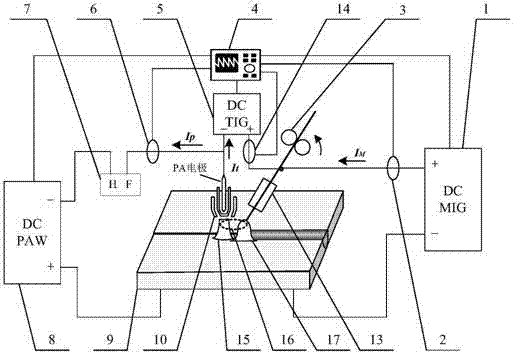

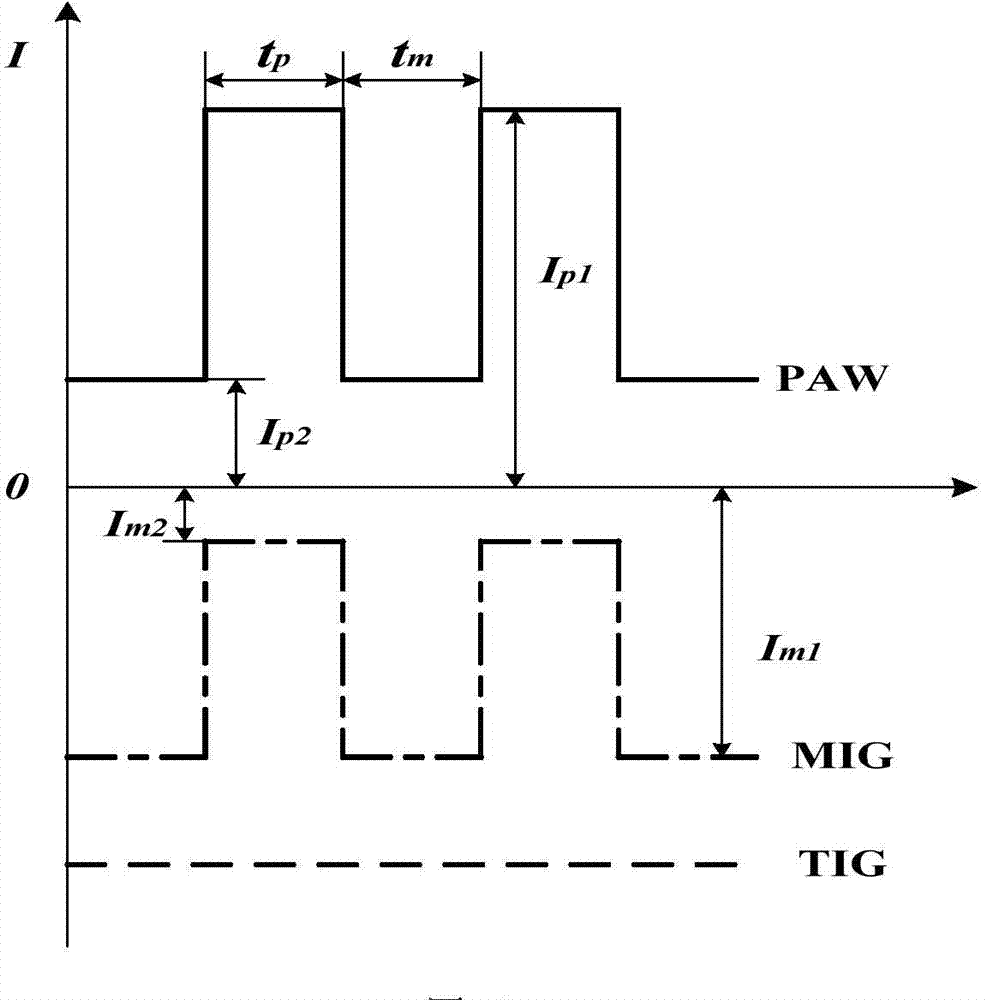

Plasma-melting electrode electric arc dynamic composite welding device and welding method thereof

ActiveCN104493368AHigh tensile strengthHigh elongationWelding apparatusPower flowWelding power supply

The invention provides a plasma-melting electrode electric arc dynamic composite welding device and a welding method thereof. A plasma arc welding gun is combined with a melting electrode electric arc welding gun to obtain a composite welding gun; the two electric arc welding guns are respectively connected with a negative pole of a direct-current pulsed plasma arc welding power supply and a positive pole of a direct-current pulsed melting electrode arc welding power supply and are also connected with a negative pole and a positive pole of an argon arc welding power supply (a TIG power supply); and a negative pole of the plasma arc welding power supply and a positive pole of the melting electrode arc welding power supply are connected with a workpiece. In order to prevent electromagnetic interference between a plasma arc and a melting electrode electric arc during welding, a pulsed coordination control method is used, namely, when melting electrode electric arc current waveform is a pulsed basic value pilot arc, the plasma arc is a pulse peak value, and welding is carried out; and when plasma arc current waveform is a pulse basic value, the melting electrode arc is pulse peak value welding current, and so forth. By the plasma-melting electrode electric arc dynamic composite welding device and the welding method thereof, the problems that electromagnetic interference between electric arcs is large, parameters are adjusted complexly, and electrodes are burnt down severely are solved.

Owner:HARBIN ENG UNIV

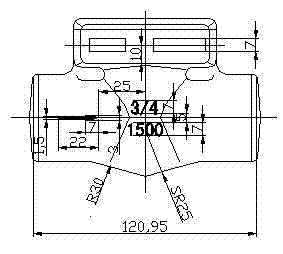

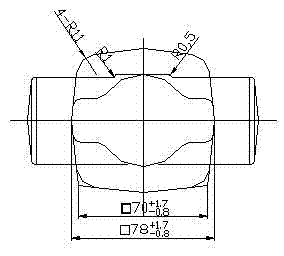

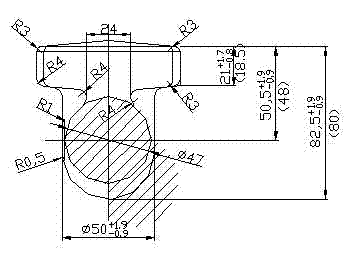

Technology for integrally forging valve with flange

InactiveCN102198481AImprove forging flowImprove performanceValve arrangementsMetal-working apparatusFlangeWelding process

The invention adopts valve and flange integral forged formation, overcomes the defect in the prior art, and provides a technology for integrally forging a valve with a flange. In the technology, a valve and flange integral die forging mode is adopted, wherein a forging die is formed first, and then a forging machine is adopted for forging, so that once forming is achieved, a welding process is saved, the forging stream line of the valve and the whole performance are improved, and the nice appearance is achieved.

Owner:DALIAN DAGAO VALVE

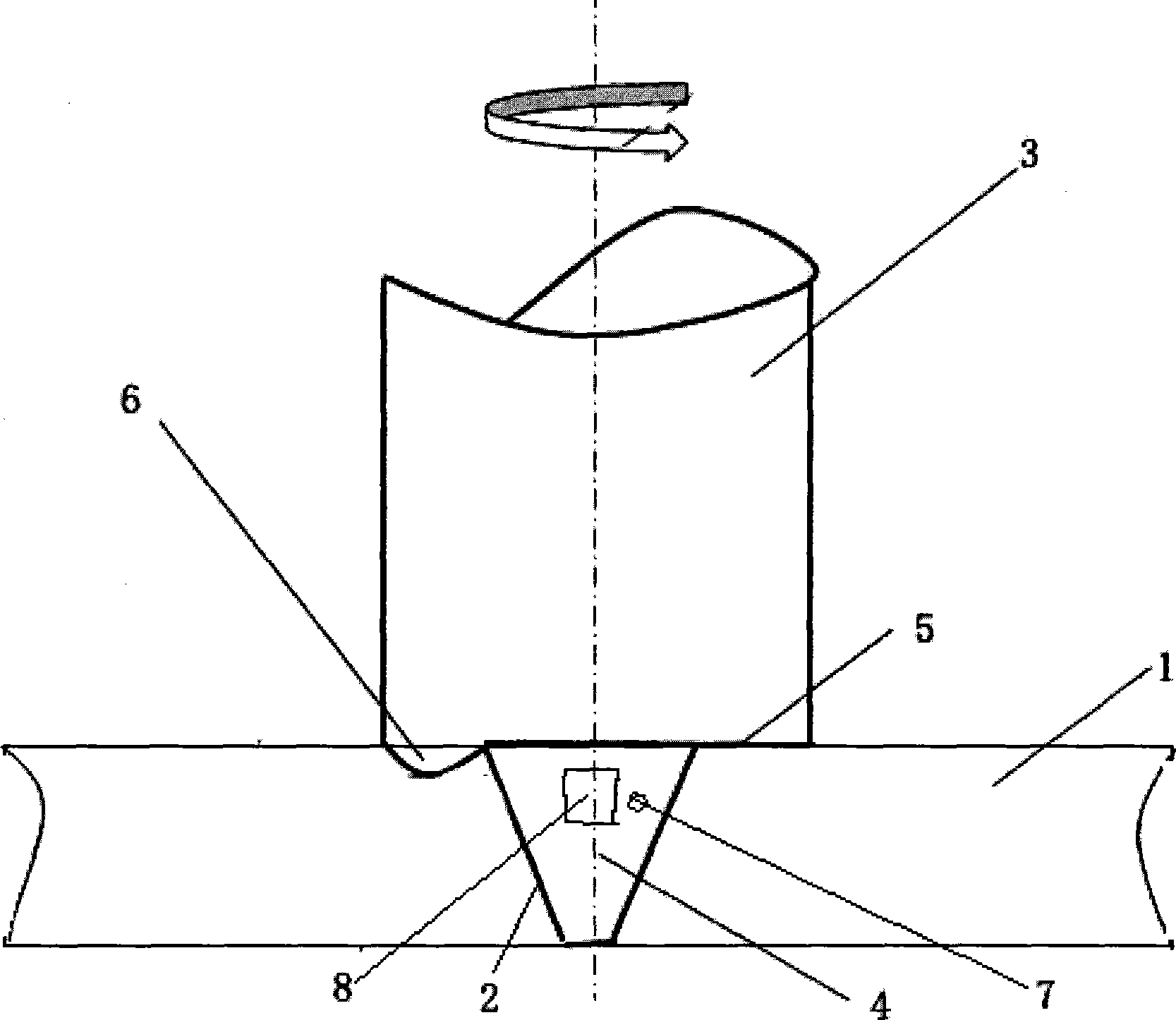

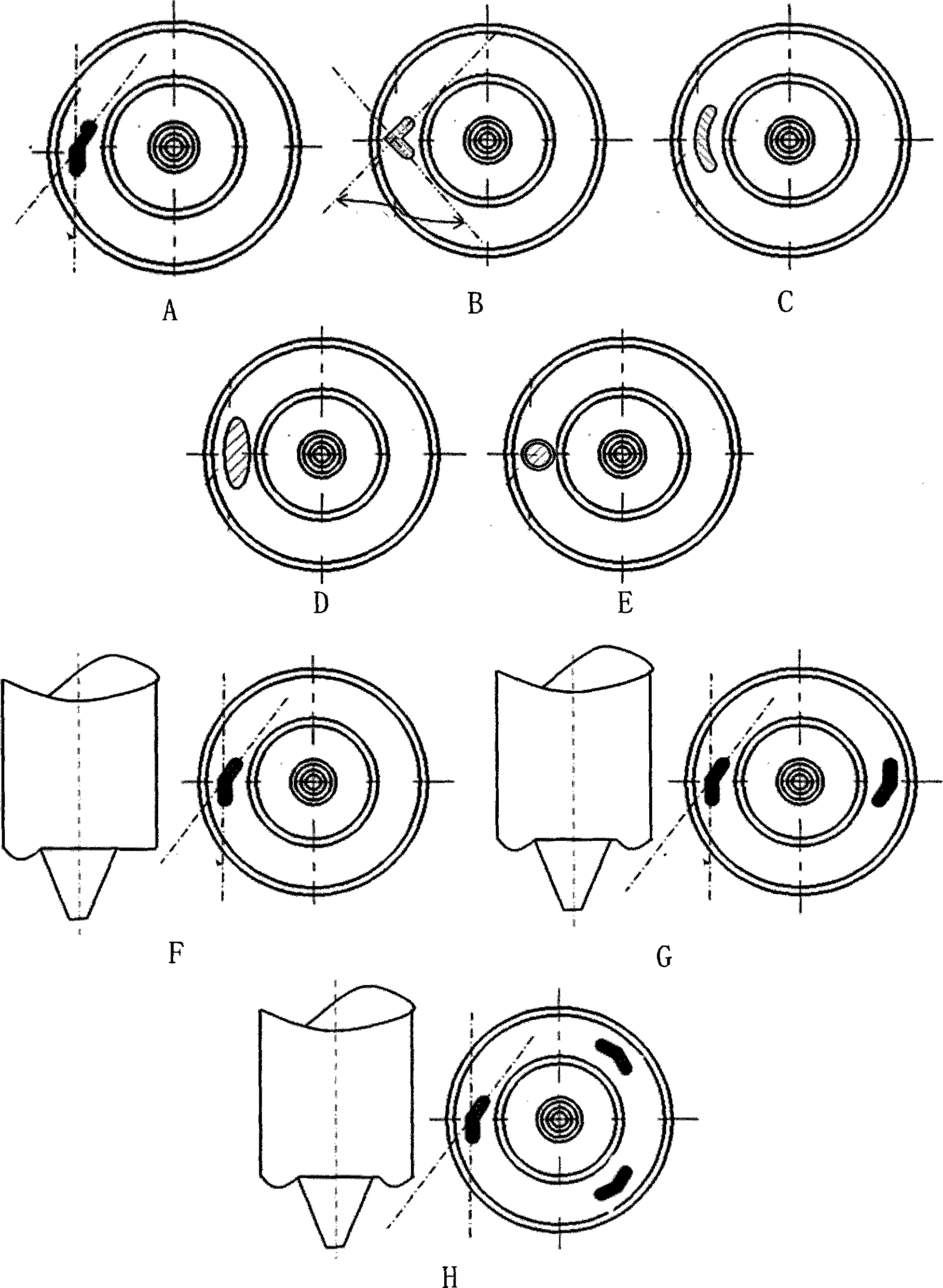

Aclinal self-upsetting, stirring and friction welding method and tool

ActiveCN104014926AReduce complexityDecrease productivityNon-electric welding apparatusFriction weldingWeld seam

The invention relates to the technical field of welding, in particular to an aclinal self-upsetting, stirring and friction welding method and tool. The tool comprises a stirring head and a stirring needle, the stirring head is of a hollow structure, the stirring needle is rotatably arranged in the hollow structure of the stirring head and can stretch and retract in the stirring head, the axis of the stirring head and the axis of the stirring needle are overlapped, a shaft shoulder of the stirring head is provided with a forging boss, and the height of the forging boss is smaller than the height of the stirring portion left after the stirring needle extends out of the stirring head. In the whole welding process, a dip angle adjusting mechanism does not need to be arranged on equipment, complexity of the welding equipment is reduced, the angle between the shaft shoulder of the stirring head and a plane normal of a material to be welded is 0 degree, and accordingly aclinal stirring friction welding is achieved. When an aclinal stirring friction welding technology is adopted in two-dimensional plane welding, the angle of the stirring head does not need to be adjusted at a welding seam corner, welding procedures are reduced, meanwhile, the dip angle adjusting mechanism does not need to be arranged on the equipment, complexity of the welding equipment is reduced, and welding efficiency is improved.

Owner:BEIJING FSW TECH

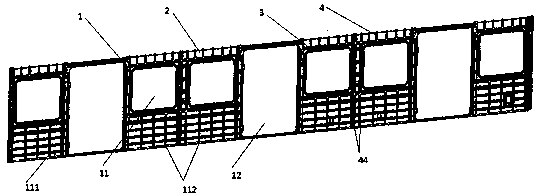

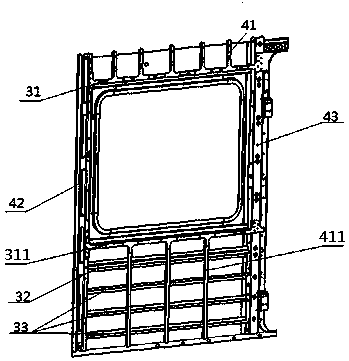

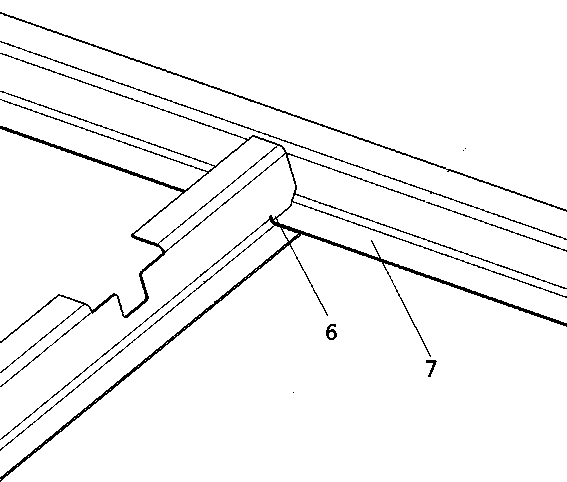

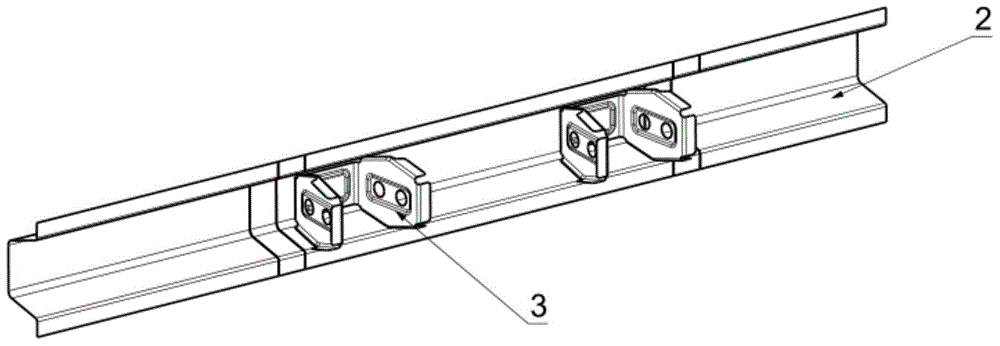

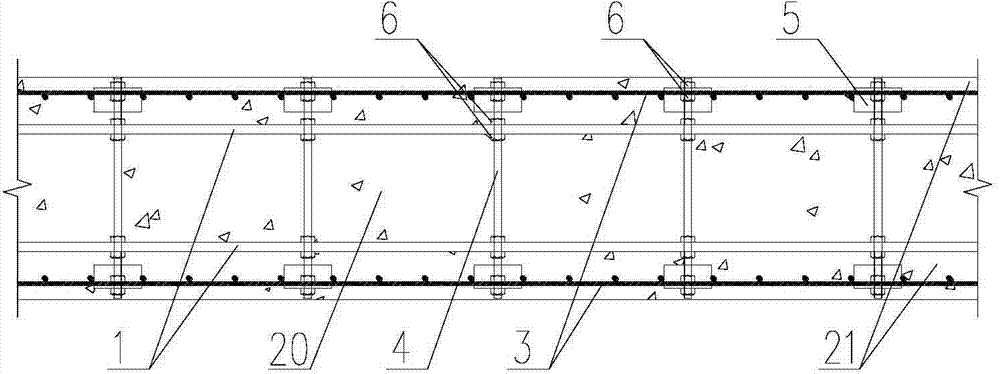

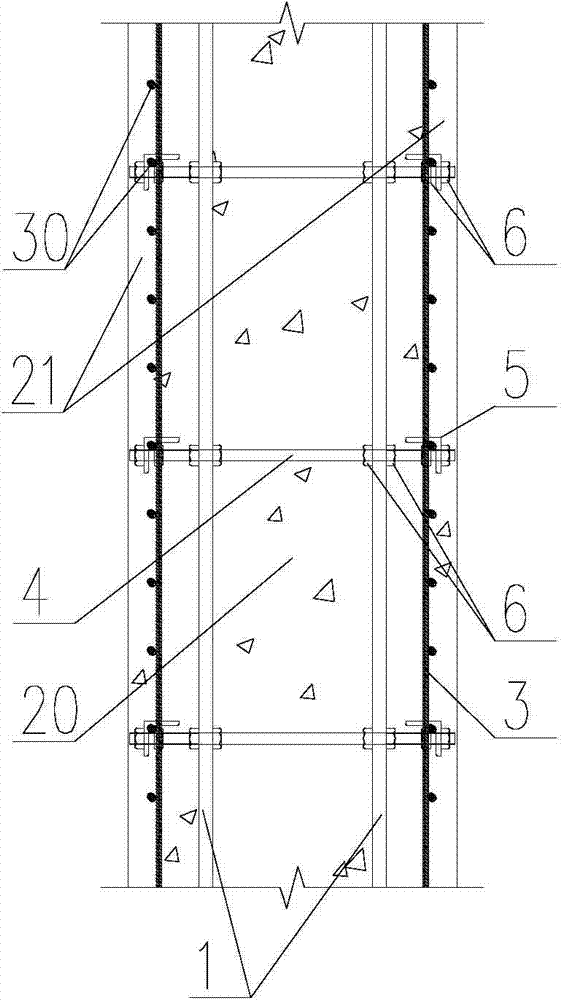

Novel stainless steel side wall structure and mounting method of novel stainless steel side wall

InactiveCN107901932AReduce welding processGuarantee the appearance qualityAxle-box lubricationRailway bodiesStructural engineeringEngineering

The invention provides a novel stainless steel side wall structure and a mounting method of a novel stainless steel side wall. The novel stainless steel side wall structure comprises a side wall skeleton. The side wall skeleton is formed by connecting a plurality of cross beams and a plurality of vertical columns in a mutually-crossing mode, and the cross beams and the vertical columns are fixed through mutual inserting; end vertical columns are arranged on the left and right sides of the side wall skeleton correspondingly; door vertical columns are arranged on the left and right sides of doorframes correspondingly; a window upper cross beam is arranged on the upper portion of each window frame, and a window lower cross beam is arranged on the lower portion of each window frame; a waist cross beam is arranged below each window lower cross beam; three lower cross beams are arranged below each waist cross beam; a window upper vertical column is connected to each window upper cross beam;skeleton connecting plates are welded inside the connecting positions of the window upper cross beams and the window upper vertical columns in the side wall skeleton; window lower vertical columns are connected among each window lower cross beam, the corresponding waist cross beam and the three corresponding lower cross beams; and skeleton connecting plates are welded inside the connecting positions of the window lower cross beams and the window lower vertical columns in the side wall skeleton. The cross beams and the vertical columns of the novel stainless steel side wall structure are fixedthrough mutual inserting connection, the deformation problem caused by welding of a skeleton is solved, the production cost is saved, and the assembly production efficiency is improved.

Owner:CRRC NANJING PUZHEN CO LTD

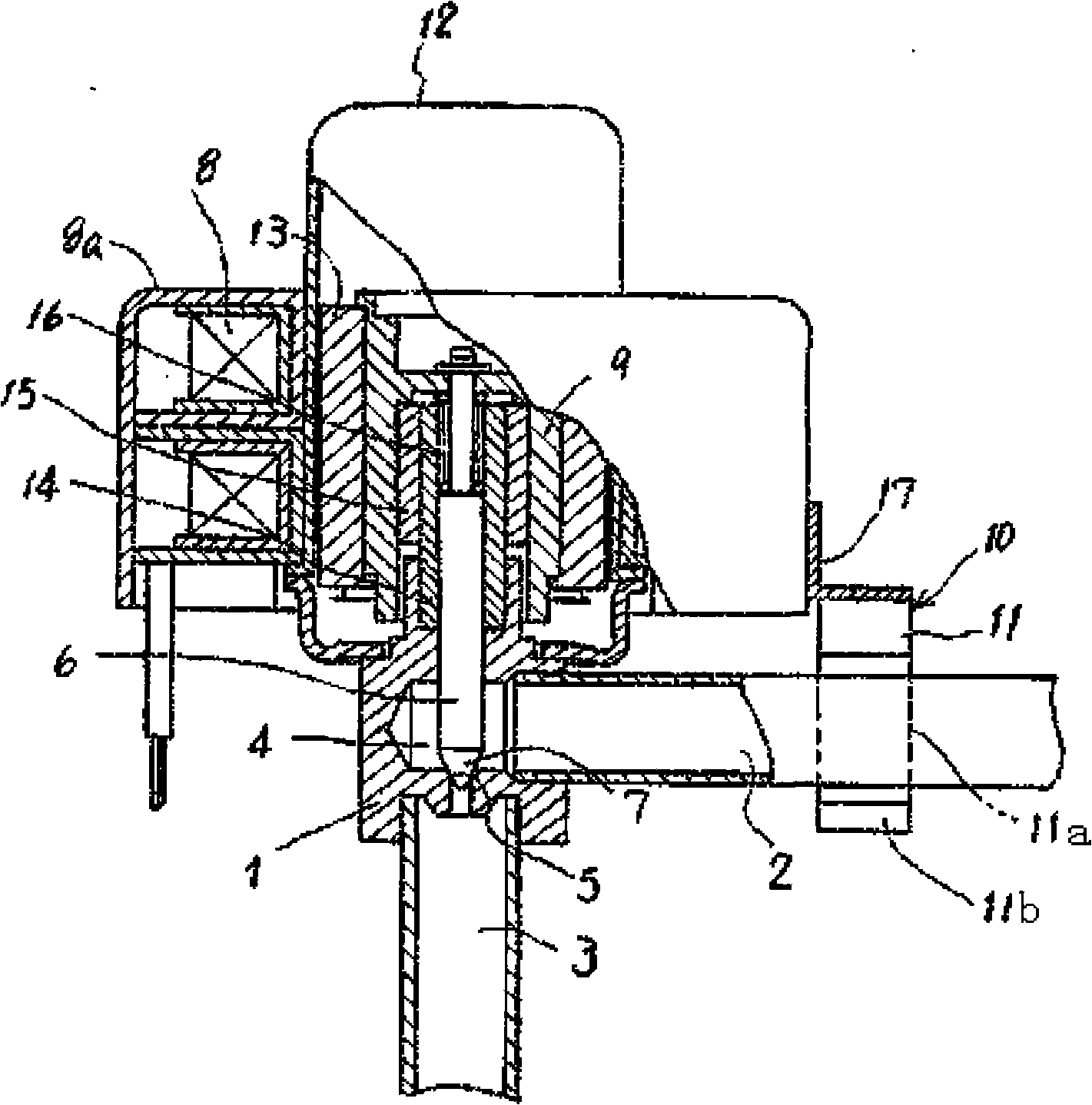

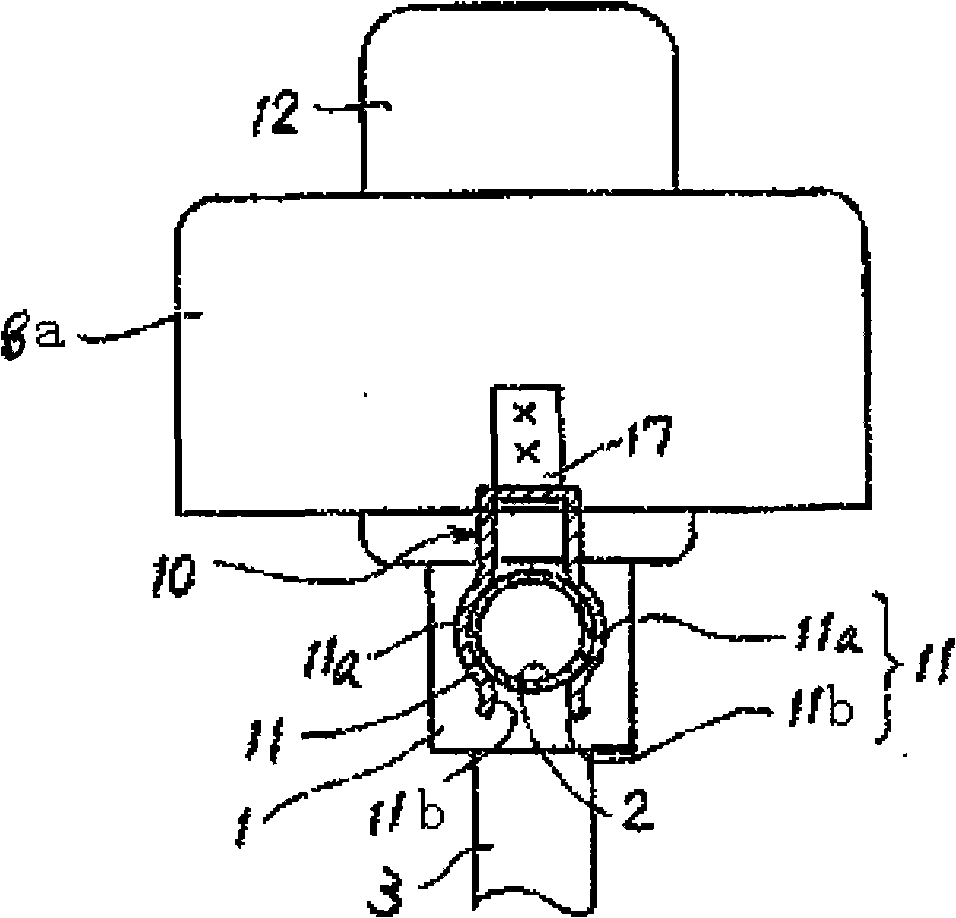

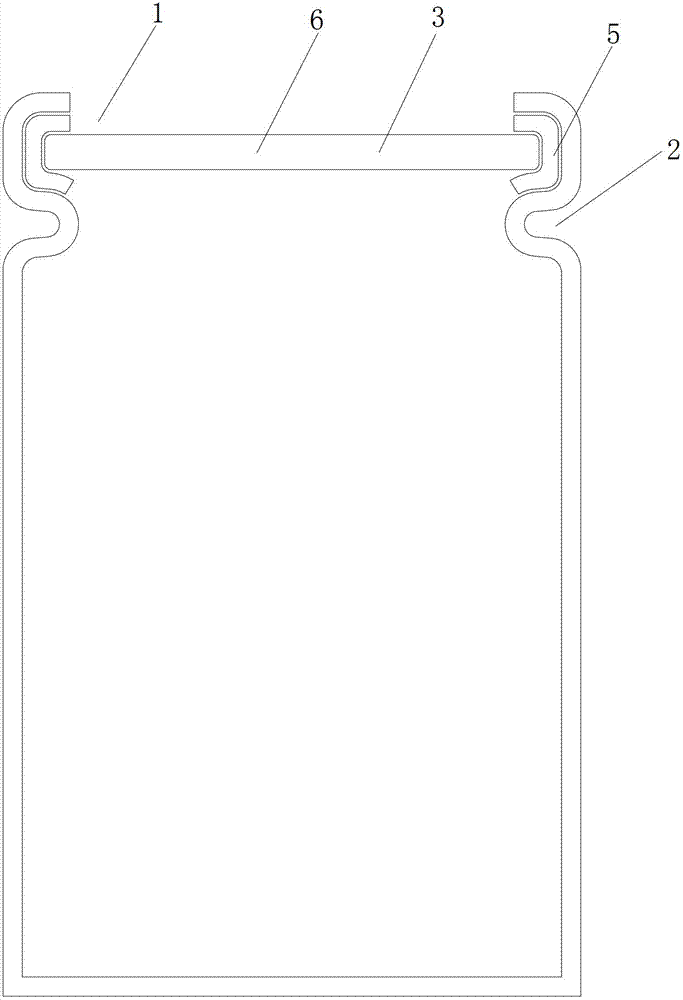

Electric Valve

ActiveCN101493156AEnhance card position abilityIncrease elasticityOperating means/releasing devices for valvesEfficient regulation technologiesStator coilEngineering

The invention discloses an electrically operated valve, aiming at the problems that the elasticity of a stopping part for preventing a coil from being loosened corresponding to a valve body is low in the prior art; the technical proposal of the invention comprises a valve seat, a valve needle, the stopping part and a stepping motor which is composed of a rotor and a stator for driving the valve needle and the valve seat to joint or detach; the stopping part is fixedly connected with a stator coil box, and internally concave bending parts which are opposite are additionally arranged above externally convex bending parts on two arm parts extended downwards thereof respectively. As the two arm parts of the stopping part are respectively provided with two bending parts, higher elasticity is obtained under the condition of same deformation, the fixation is reliable and the working noise is low; the valve has the advantages of compact structure and good assembling operability; moreover, the vibration reduction is greatly improved for obtaining accurate flow control; therefore, the valve is particularly suitable for refrigerators, air conditioning refrigerating units, water heaters and dehumidifiers, thus realizing defrosting, the flow control and on-off control and the like of a heating system.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

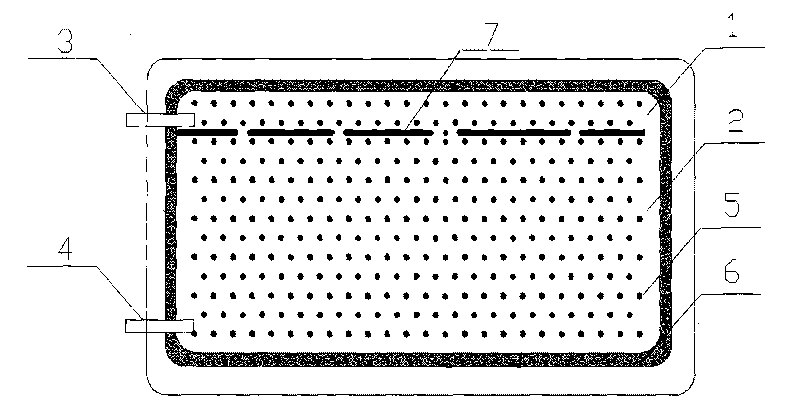

Aluminum honeycomb type evaporation plate and processing molding method thereof

InactiveCN101691978ANot easy to form dead angleLow flow resistanceShaping toolsArc welding apparatusAluminum honeycombEvaporation

The invention discloses an aluminum honeycomb type evaporation plate and a processing molding method thereof. The evaporation plate adopts a high strength aluminum alloy plate and consists of an upper plate, a lower plate, an inlet pipe and an outlet pipe, wherein the two high strength aluminum alloy plates are overlapped and welded together by a solid-phase stir friction connecting method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two high strength aluminum alloy plates and are connected with the high strength aluminum alloy evaporation plate body by using an electric arc welding method; and then the evaporation plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

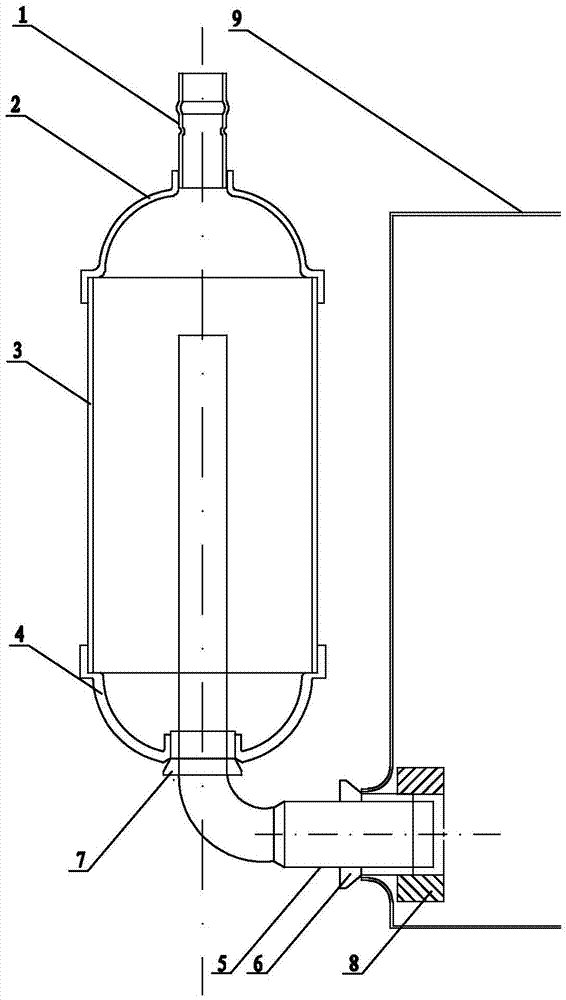

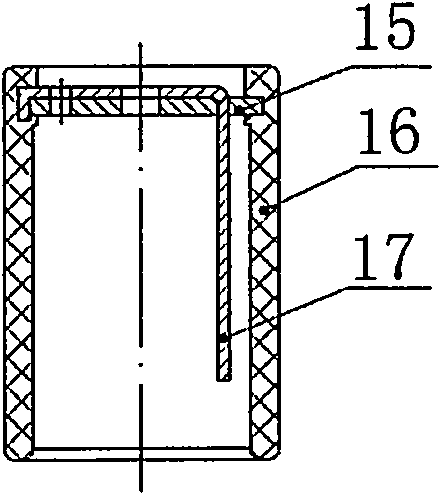

Connection structure of cooling system of refrigerating plant

InactiveCN103542644AHigh surface finishImprove the finishMechanical apparatusFluid circulation arrangementInterference fitEngineering

The invention relates to a connection structure of a cooling system of a refrigerating plant, in particular to the technical field of connection relations among liquid reservoirs and liquid dispensers and among the liquid dispensers and compressors of air-conditioning cooling systems. The connection structure comprises a liquid reservoir, a liquid dispenser and a compressor. The liquid dispenser comprises an air inlet tube, an upper end cover, a middle barrel, a lower end cover and an air outlet tube, the air outlet tube of the liquid dispenser is pressed into a cylinder hole of the compressor in an interference fit manner, and a first flange is sleeved between the air outlet tube and a shell of the compressor and is connected with the shell of the compressor and the air outlet tube by means of welding. According to the technical scheme, the connection structure has the advantages of convenience in machining, simple structure and the like.

Owner:SHENGZHOU XINGAOLUN REFRIGERATION EQUIP

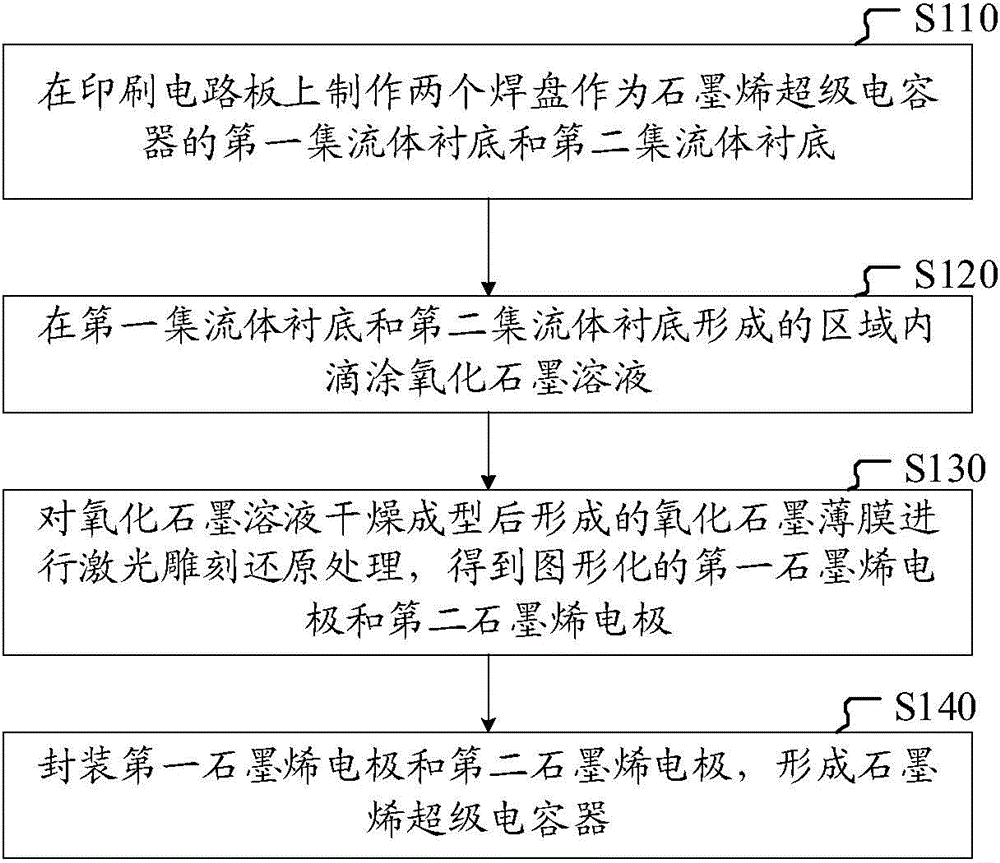

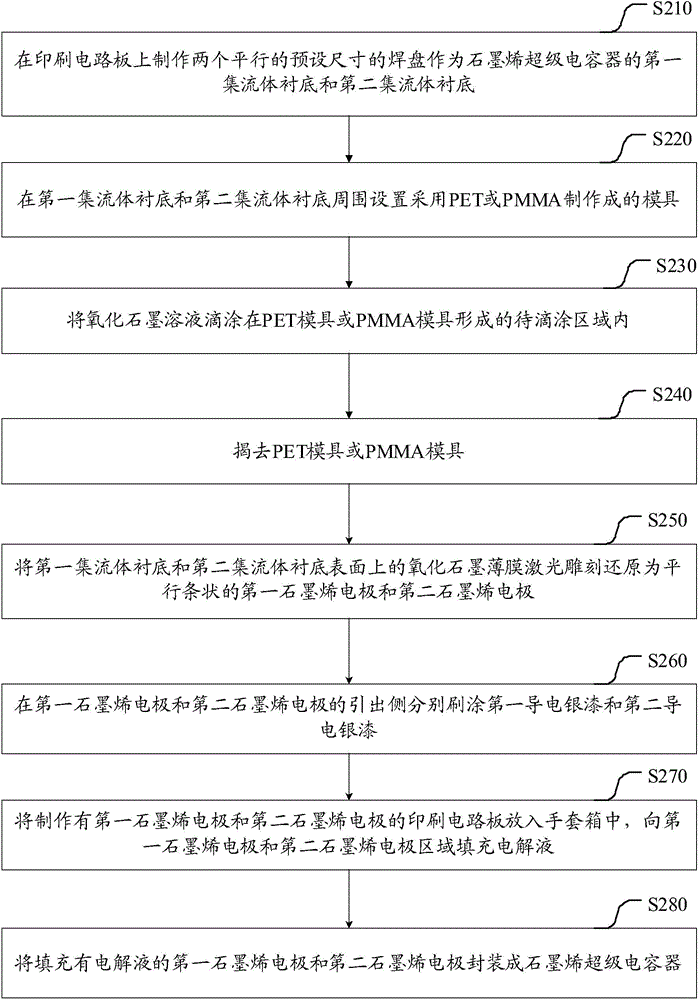

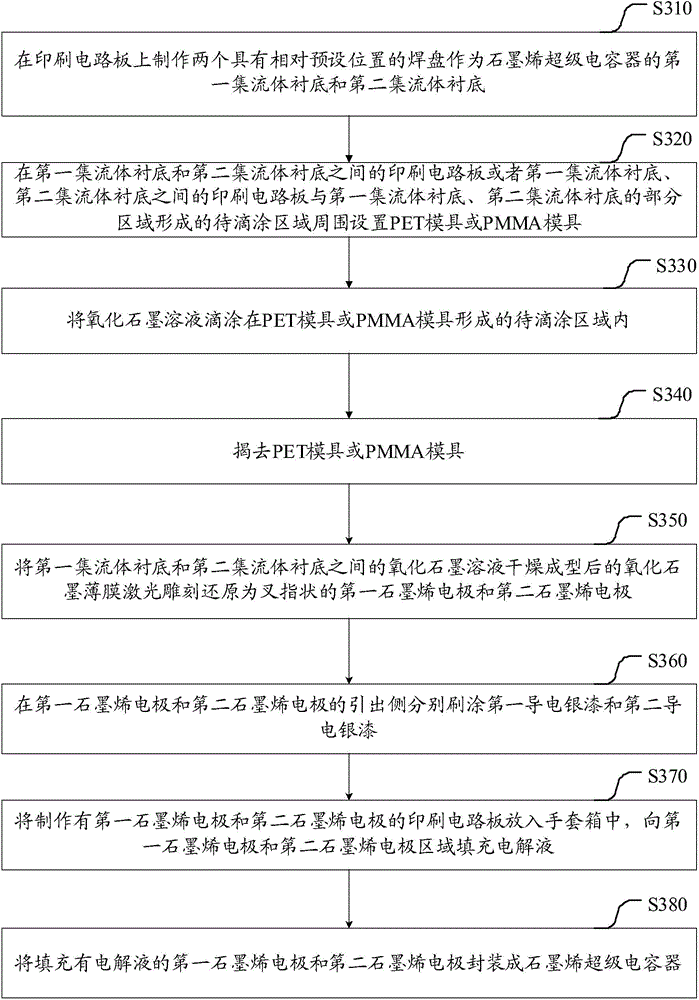

Graphene supercapacitor and preparation method thereof, and energy storage system

ActiveCN104810163ASimple preparation processSmall footprintHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorLaser engraving

The invention discloses a graphene supercapacitor and a preparation method thereof, and an energy storage system. The method comprises two pads are prepared on a PCB and serve as first and second current collector substrates of the graphene supercapacitor; a graphite oxide solution is dropped in a to-be-dropped areas formed on the first and second current collector substrates; laser engraving reduction is carried out on graphite oxide films formed by drying and molding the graphite oxide solution to form first and second patterned graphene electrodes; and the first and second graphene electrodes are packaged by filling an electrolyte to form the graphene supercapacitor. According to the scheme, the pads on the circuit board serve as the current collector substrates, the preparation technology of the graphene supercapacitor is optimized, the procedure of welding is omitted, and the integrated level of the PCB is improved.

Owner:NEWNAGY TANGSHAN

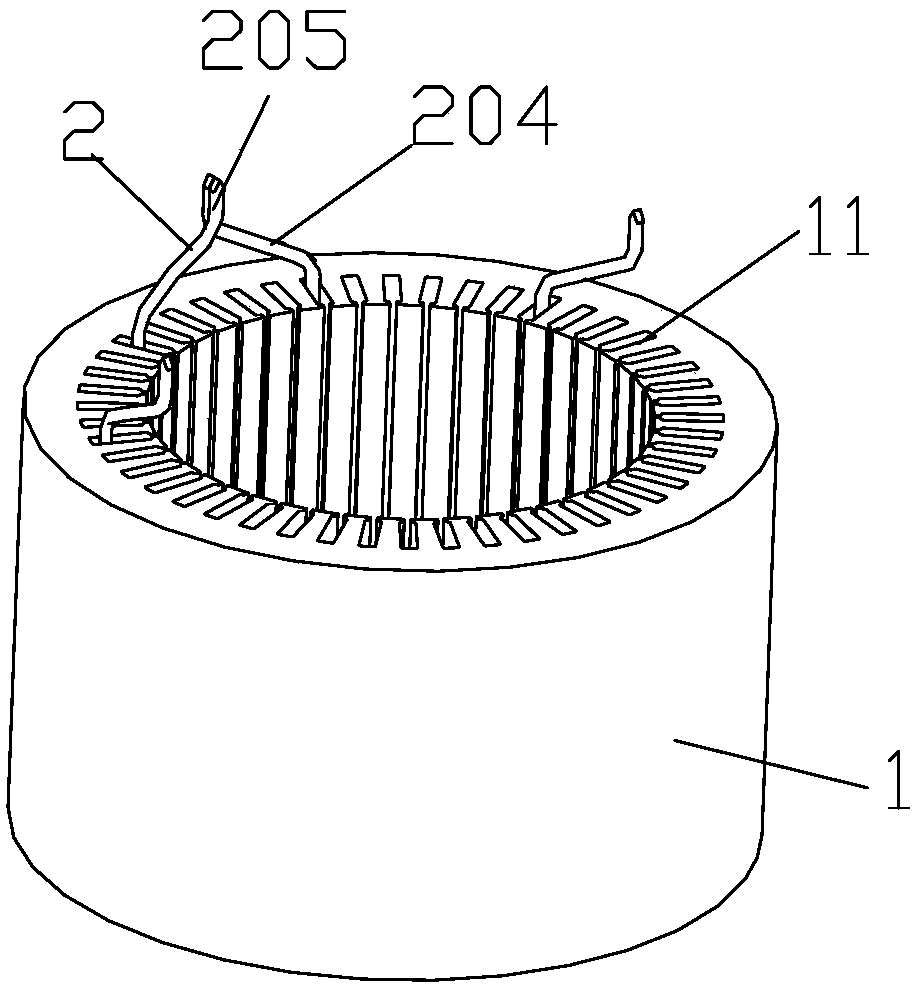

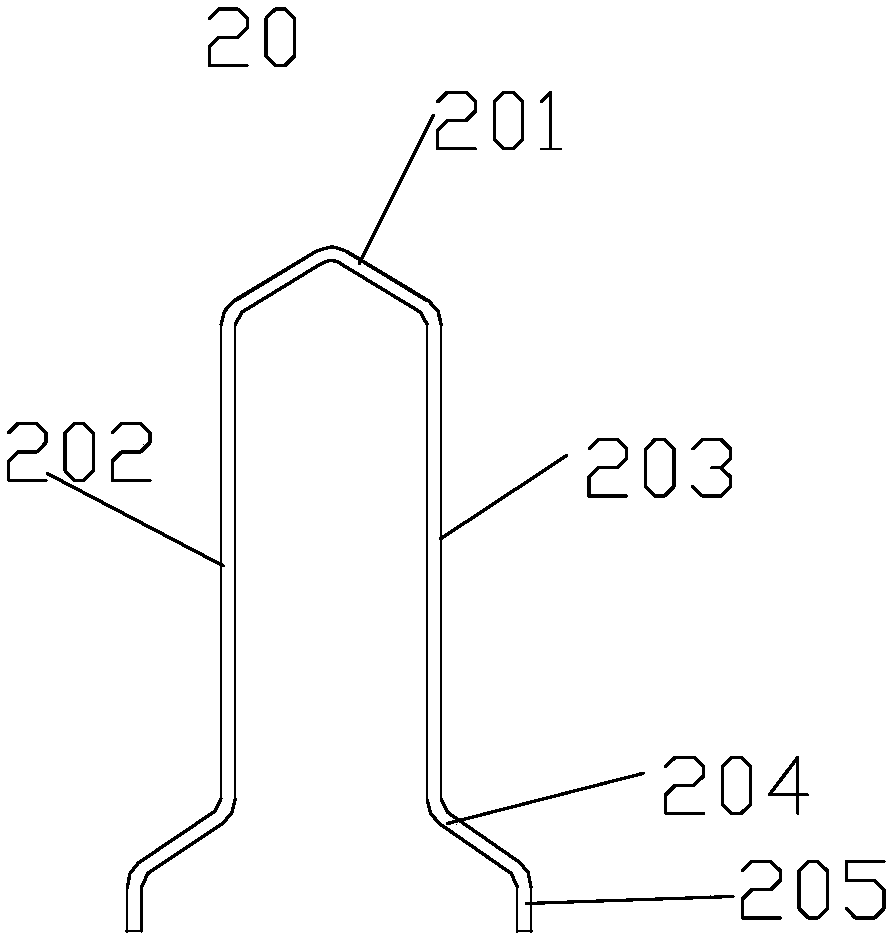

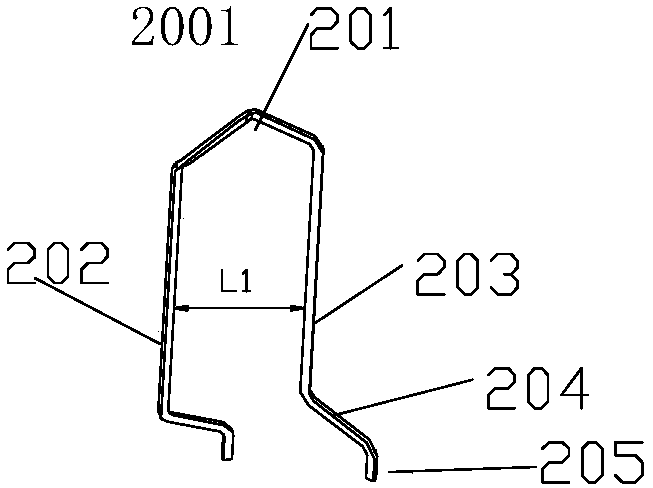

Motor, stator assembly and coil winding method thereof

ActiveCN109586456AReduced risk of insulation breakdownType of reductionManufacturing dynamo-electric machinesWindings conductor shape/form/constructionMechanical engineeringVoltage

The invention discloses a winding method suitable for a stator assembly of a z-slot 2p-grade m-phase motor. The stator assembly comprises a stator iron core and a stator winding, wherein the stator winding is made of flat wires. According to the winding method, a plurality of U-shaped conductor sections are configured and connected, so that a part of a stator groove is wound in the forward direction, then reverse winding is carried out, next, forward winding is carried out on the other part of the stator groove, and then reverse winding is performed circularly. Through the wave winding mode, the flat wire voltage difference between adjacent groove layers in the same groove is smaller than that of an existing scheme, so that the insulation breakdown risk of the motor can be effectively reduced, and the reliability is high.

Owner:BYD CO LTD

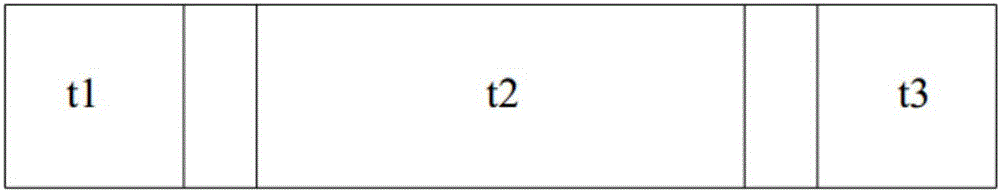

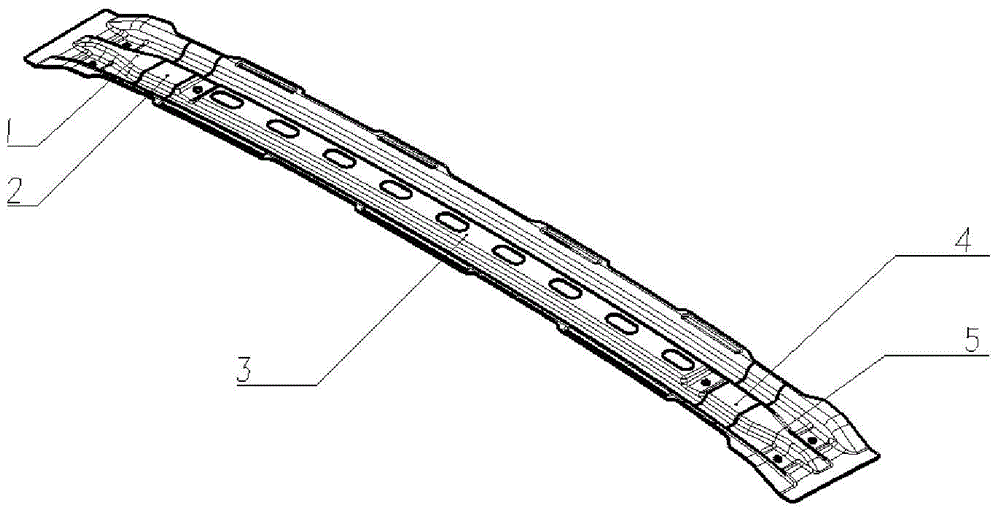

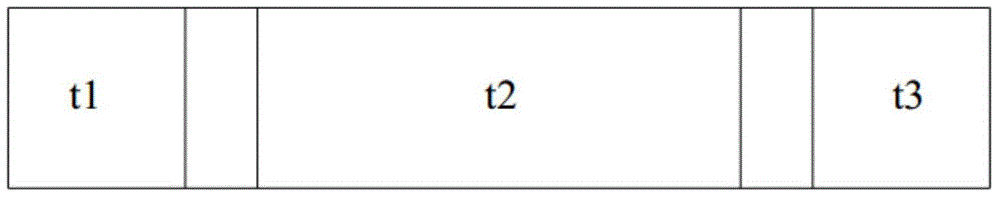

Variable-thickness automobile front bumper and manufacturing method thereof

InactiveCN104925009ASimple structureReduce manufacturing costBumpersVariable thicknessEnergy absorption

The invention provides a variable-thickness automobile front bumper and a manufacturing method thereof. The automobile front bumper comprises a front bumper body which is of a thin-wall structure. The front bumper body sequentially comprises a left body section, a left transition section, a right body section, a right transition section and a right body section. A left energy absorption box and a right energy absorption box are arranged on the inner side faces of the left body section and the right body section of the front bumper body respectively, so that the front bumper body is connected with an automobile front longitudinal beam. The left body section and the right body section are of a uniform-thickness structure. The left transition section and the right transition section are of a continuous variable-thickness structure and become thinner gradually from the two ends to the middle body section. The middle body section is of a uniform-thickness structure and is the thinnest portion of the whole front bumper body. According to the variable-thickness automobile front bumper, by means of the design of parts of different thicknesses, the requirement for collision safety of the automobile front bumper is met, and the design of light parts can be achieved at the same time.

Owner:BAOSHAN IRON & STEEL CO LTD

Vacuum welding method for titanium alloy and stainless steel

InactiveCN101695785APrevent oxidationIncrease penetration depthArc welding apparatusWelding/cutting media/materialsDepth of penetrationTitanium alloy

The invention relates to a vacuum welding method for titanium alloy and stainless steel, wherein a fusion welding material is pure silver or a silver alloy; the welding method finishes operation in an enclosed cavity in an argon arc welding way and comprises the following specific welding steps of: (1) cleaning operation for removing an oxide film on the surface of a work-piece and for improving the wettability of the welding material; (2) combing and fixing the work-piece to be welded, placing the combined and fixed work-piece into the enclosed cavity, vacuumizing the enclosed cavity and opening an argon gas valve when an absolute pressure value in the cavity is lower than 500 Pa so as to fill the cavity with argon gas; and (3) heating and melting the silver alloy in the argon arc welding way, allowing silver alloy melt to flow into a gap between the stainless steel and the titanium alloy and cooling the silver alloy to finish a welding technique for the stainless steel and the titanium alloy. The welding method of the invention can reduce device cost and shorten welding flow. Argon gas protection can prevent a welding interface from being oxidized, increase depth of penetration for a welding bead and effectively improve bonding strength between the titanium alloy and the stainless steel.

Owner:陈亚

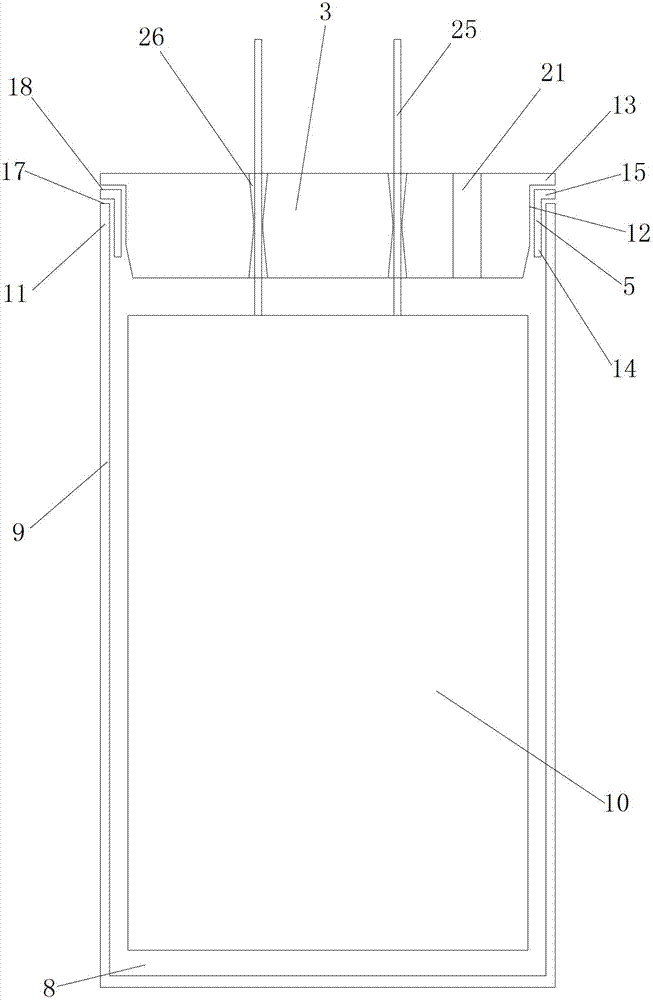

Method for sealing and fixing cylindrical battery cell, battery and shell cover

ActiveCN103208594ASimple manufacturing processSave sealing processCell component detailsEngineeringBattery cell

The invention discloses a method for sealing and fixing a cylindrical battery cell, a battery and a shell cover. The cell comprises a shell, the cover, a wound core and a sealing ring made of elastic materials; the wound core is provided with a positive electrode and a negative electrode, the shell is cylindrical and is provided with an opening positioned on the top of the shell, the cover is fixed to the opening, the cover and the shell form a closed casing, the wound core is sealed in the closed casing, the cover is provided with a first cylindrical matching portion, and the sealing ring is plugged into the opening and is tightly sleeved on the first matching portion; and the sealing ring is squeezed, then deforms and is in close fit with the opening, so that the cover and the shell are sealed and fixed. Compared with the prior art, the method has the advantages that a working procedure for sealing a cylindrical shell and a working procedure for welding a cover with a shell are omitted, and a process for manufacturing the cylindrical battery is simplified.

Owner:沧州市昊泽电池制造有限公司

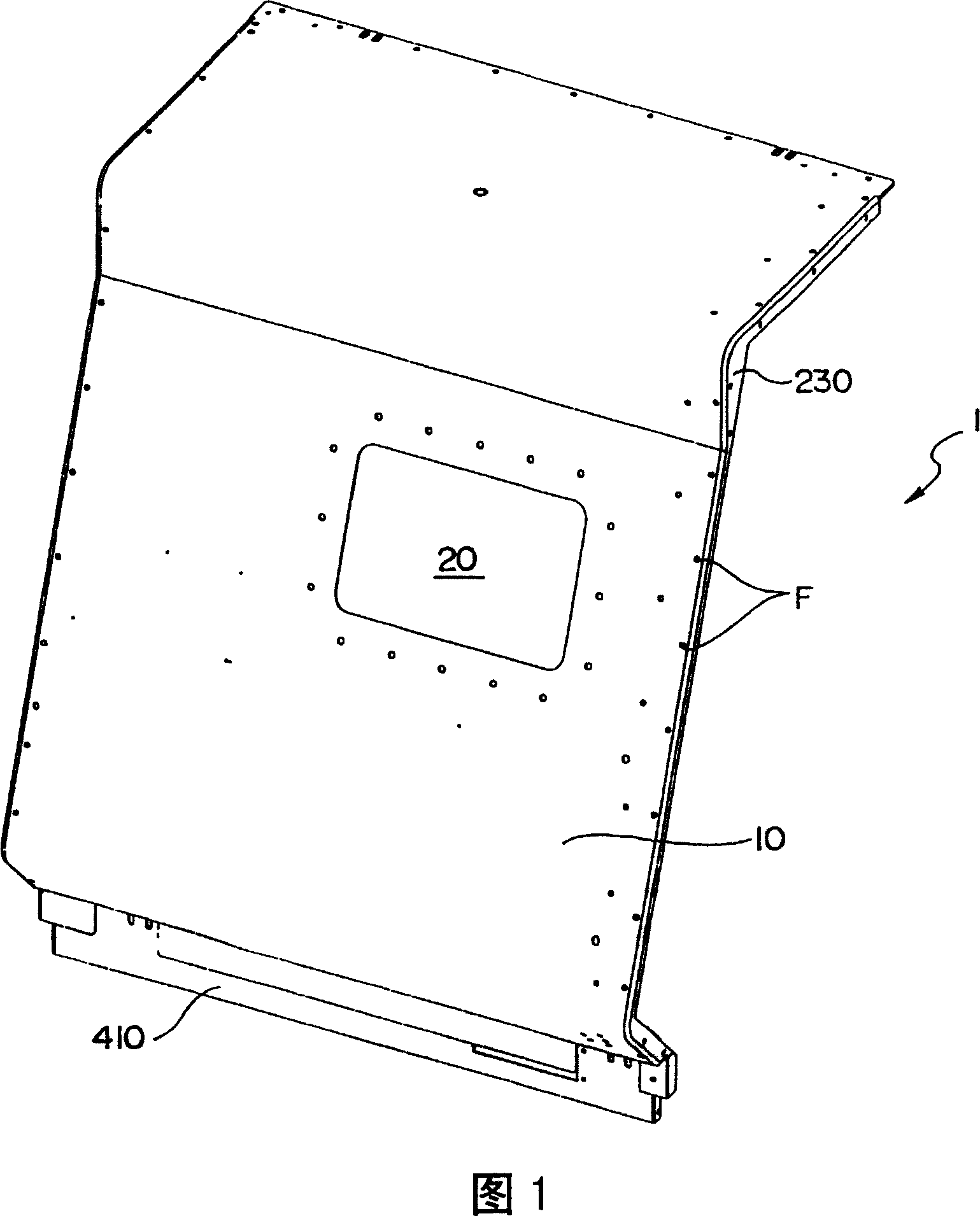

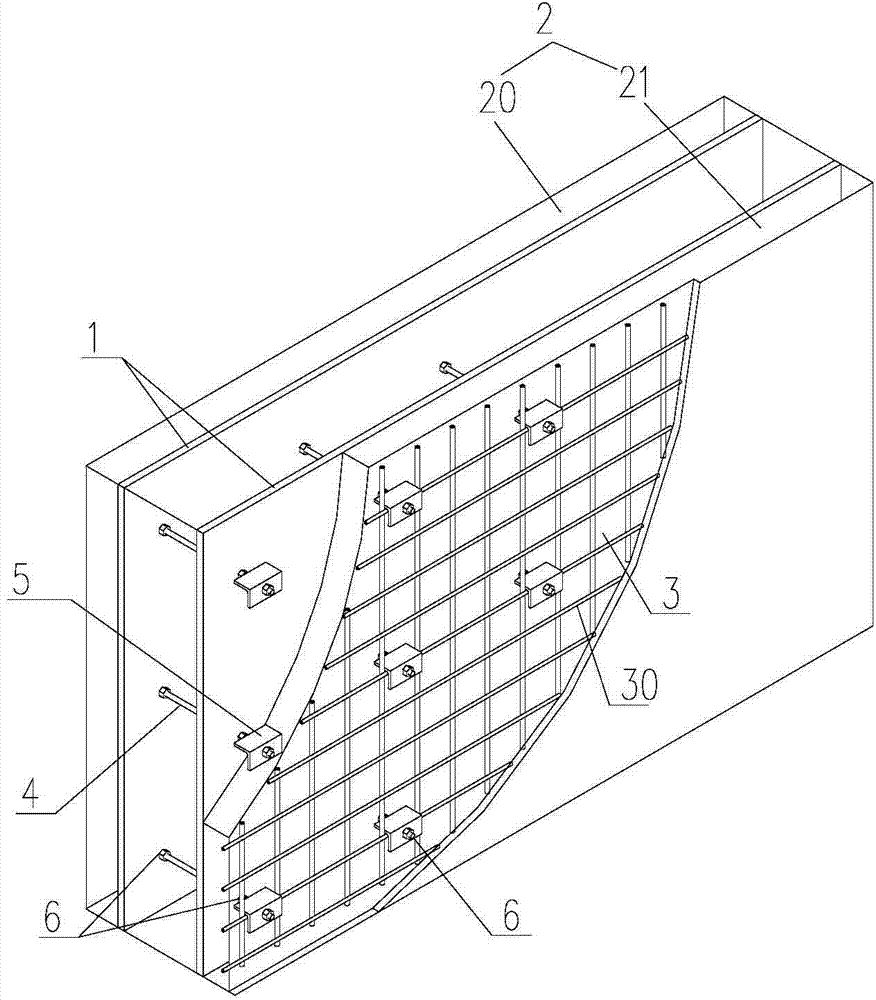

Method for fabricating sheet metal product having three-dimensional shape, and product

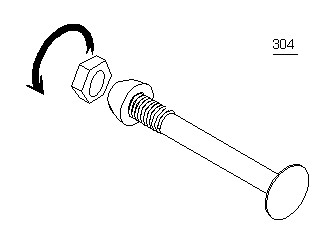

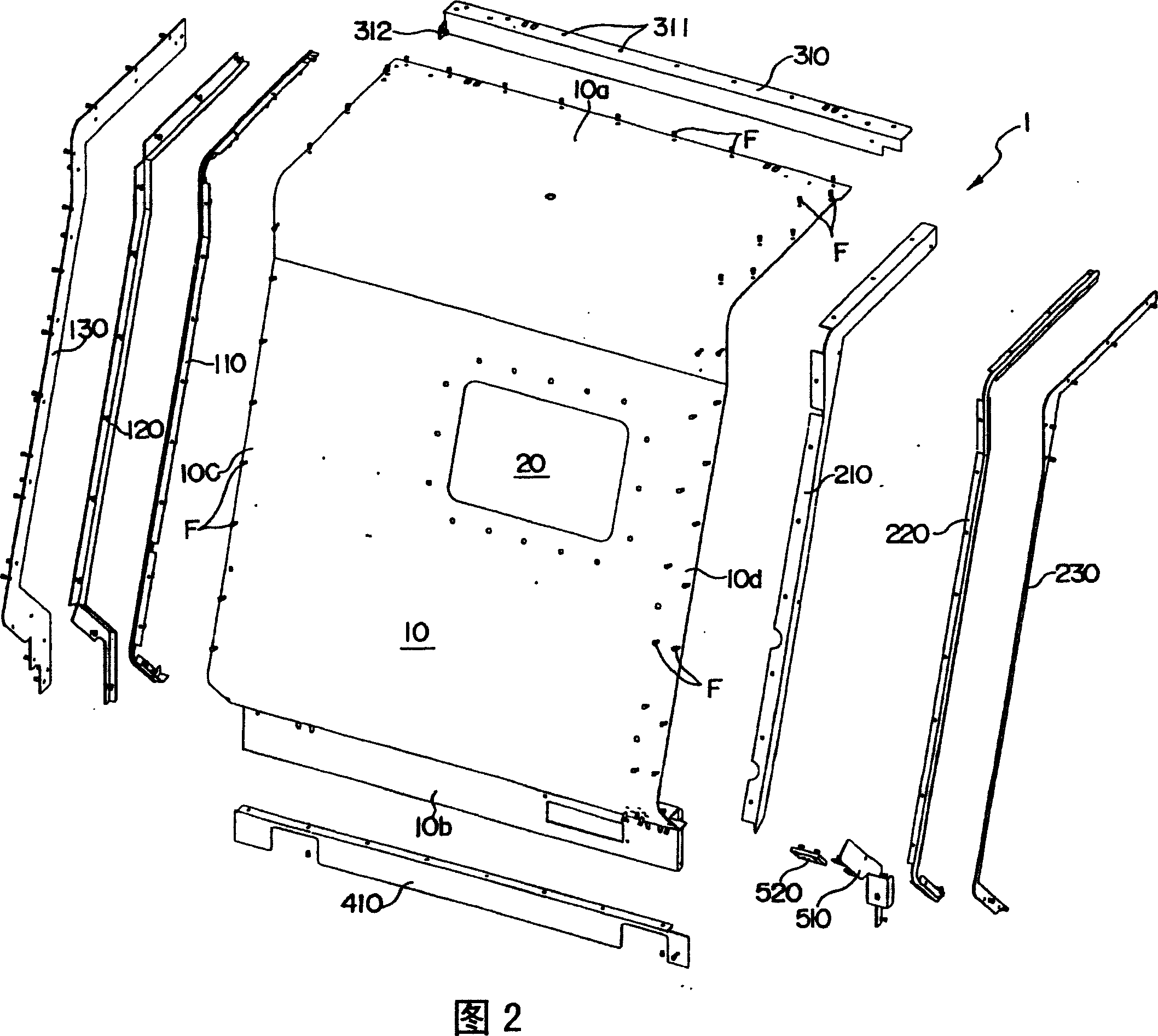

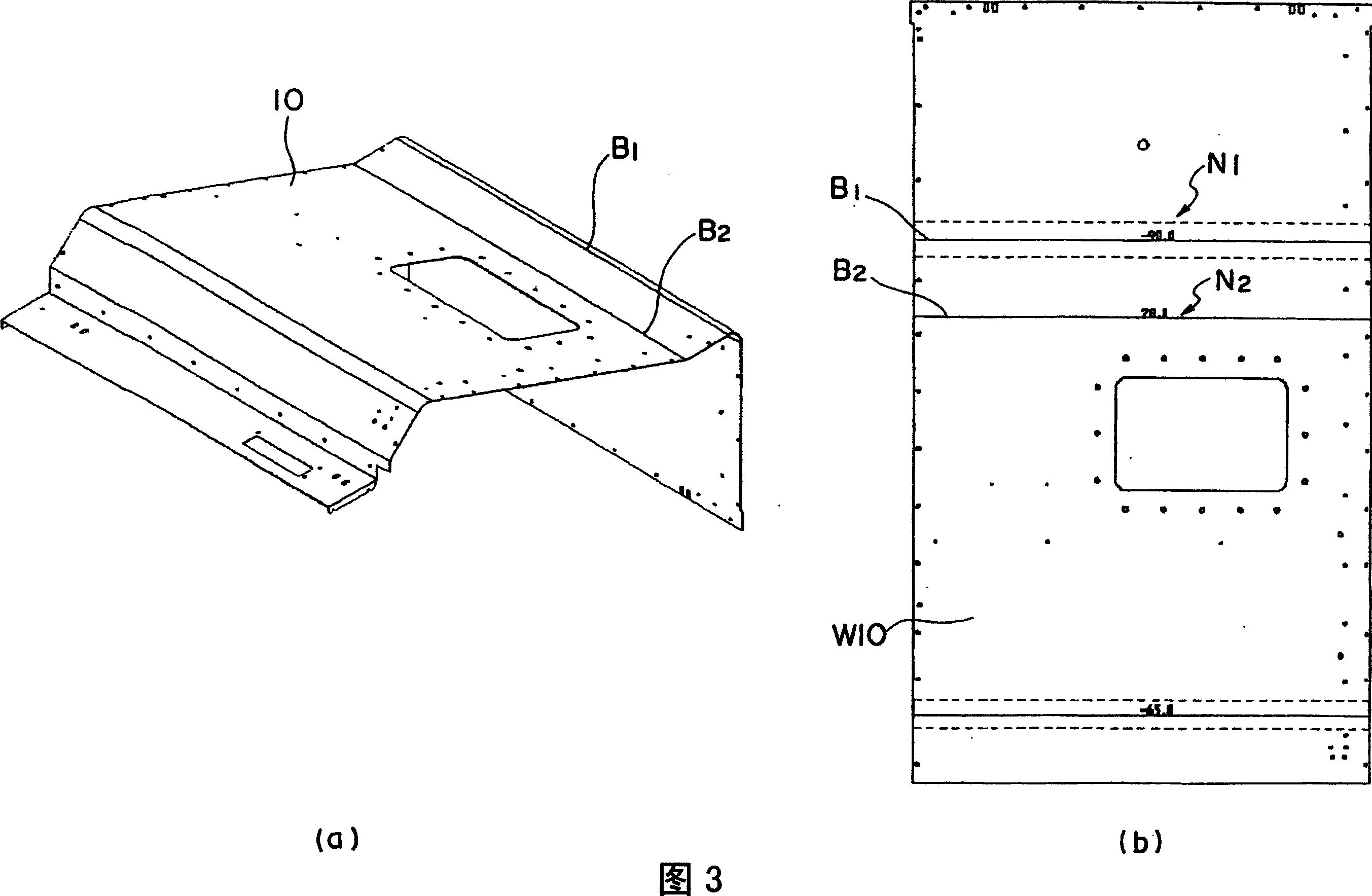

InactiveCN101041219AReduce welding processHigh precisionMachine framesOther manufacturing equipments/toolsLaser processingLaser beam machining

To provide a method of manufacturing a large-size sheet metal product with a three-dimensional shape such as a cover for a machine tool without a welding step, and also to provide its product. A cover unit 1 for a machine tool is manufactured by fixing edge members 110, 120, 130, 210, 220, 230 on the periphery of a cover sheet 10 by a fixing tool such as a bolt or a nut. In the cover sheet 10 or the respective edge members, the flat development based on data of a three-dimensional solid model of the cover unit 1 is nested on the sheet metal material on a laser beam machine, and laser beam machining is carried out. In the laser beam machining, the respective members are marked with information on bending lines, bending angles, or the like necessary for post processes. The members which have been precisely laser beam machined are subjected to necessary bending works, and assembled by the fixing tool, so as to obtain the large-size sheet metal product with the three-dimensional shape without the welding step.

Owner:YAMAZAKI MAZAK KK

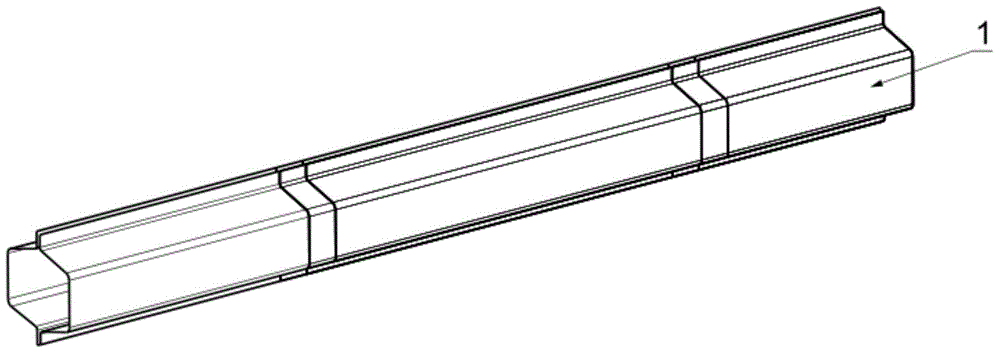

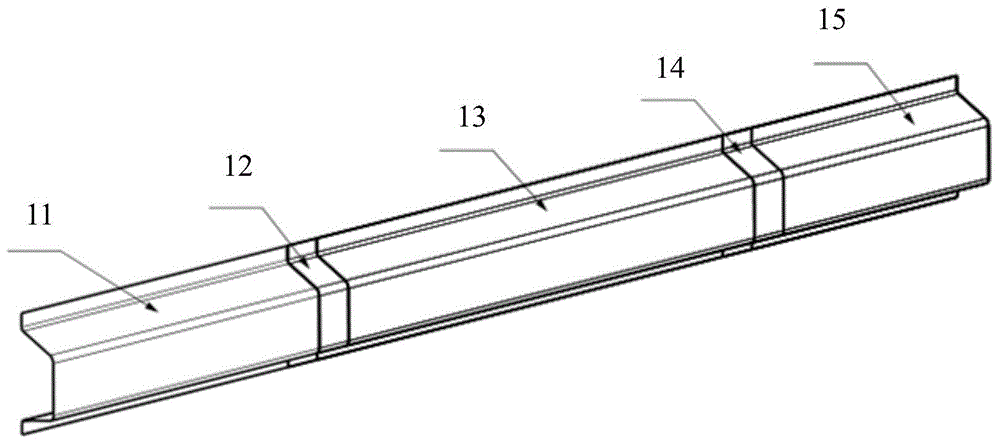

Variable-thickness automobile doorsill beam and manufacturing method thereof

InactiveCN104943753AMeet crash safety requirementsIncreased crash resistance safety performanceSuperstructure subunitsMetal rolling arrangementsVariable thicknessSheet steel

The invention provides a variable-thickness automobile doorsill beam and a manufacturing method thereof. The variable-thickness automobile doorsill beam comprises a doorsill beam outer plate, a doorsill beam inner plate and a connecting plate arranged between the doorsill beam outer plate and the doorsill beam inner plate. The doorsill beam outer plate sequentially comprises an outer plate front section, an outer plate front transition section, an outer plate middle section, an outer plate rear transition section and an outer plate rear section. The doorsill beam inner plate sequentially comprises an inner plate front section, an inner plate front transition section, an inner plate middle section, an inner plate rear transition section and an inner plate rear section. The inner plate front section, the outer plate front section, the inner plate middle section, the outer plate middle section, the inner plate rear section and the outer plate rear section are of equal-thickness structures. The inner plate front transition section, the inner plate rear transition section, the outer plate front transition section and the outer plate rear transition section of the doorsill beam are of variable-thickness structures. The thicknesses of the sections are gradually decreased from thicker zones on two sides to the thinner zone. The variable-thickness automobile doorsill beam can well meet the collision safety requirement of an automobile body, is simple in structure and is manufactured by adopting a continuous variable-thickness steel plate, excessive design on the aspects of material thickness and part number can be avoided, the manufacturing cost of the doorsill beam can be reduced, and the lightweight effect is good.

Owner:BAOSHAN IRON & STEEL CO LTD

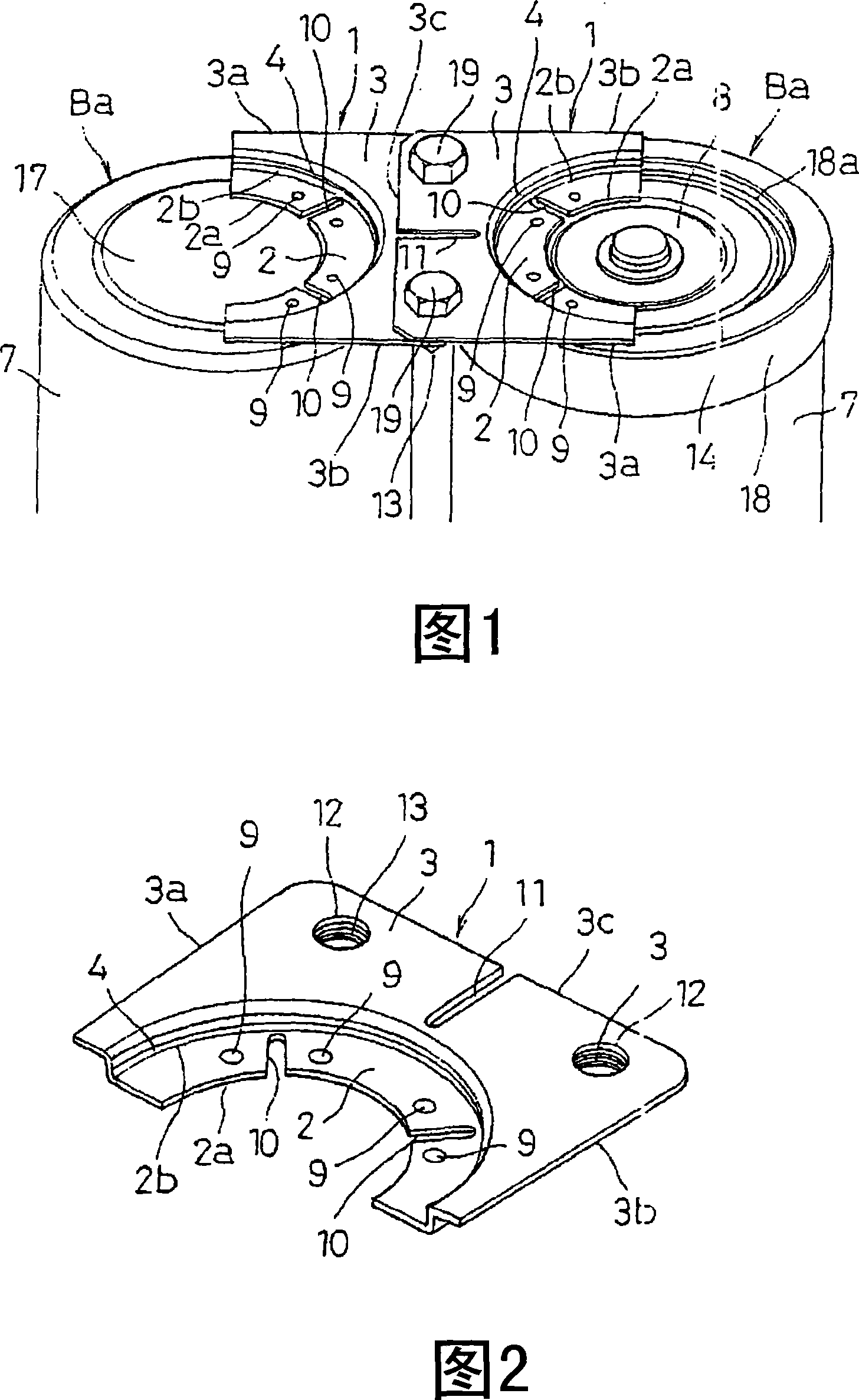

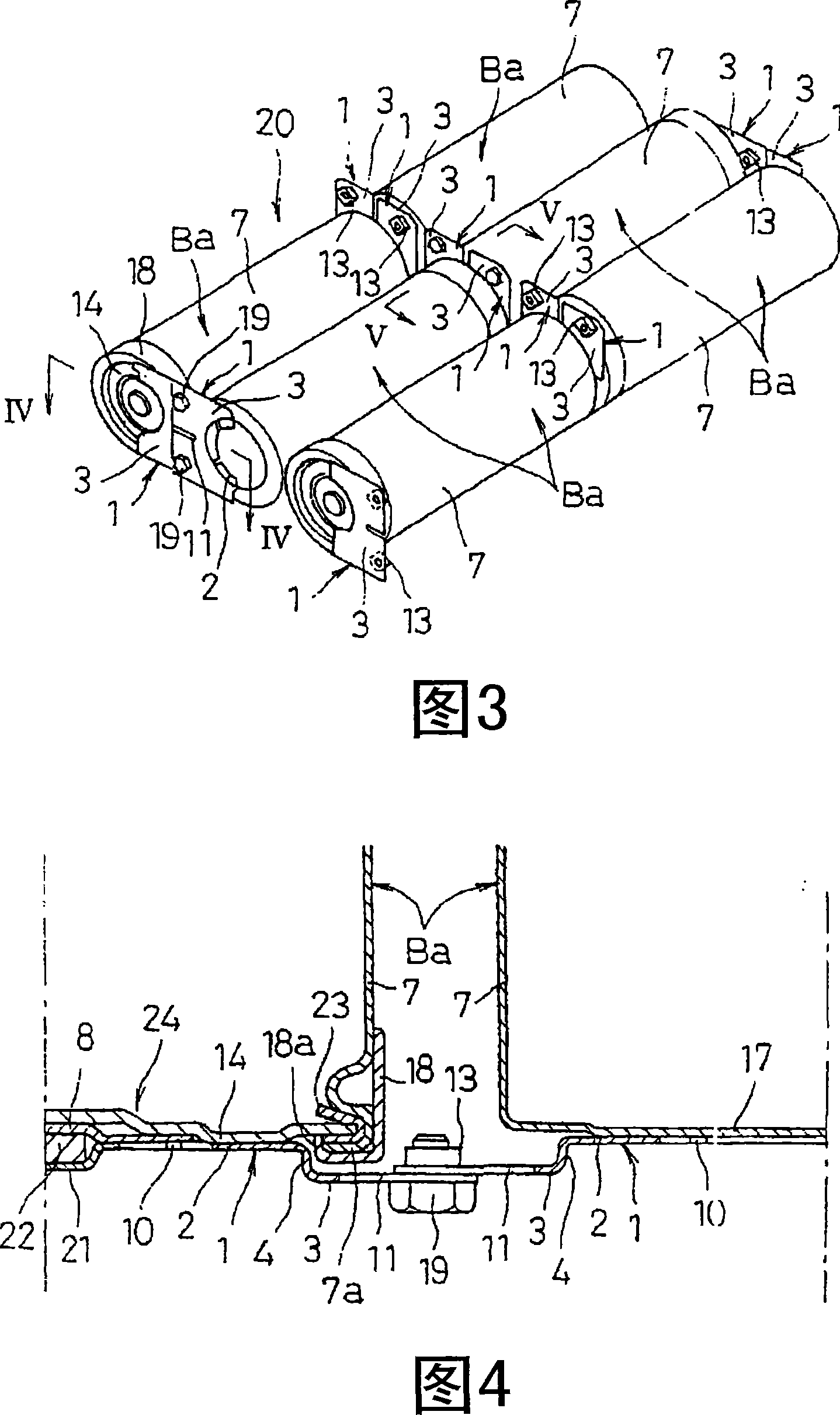

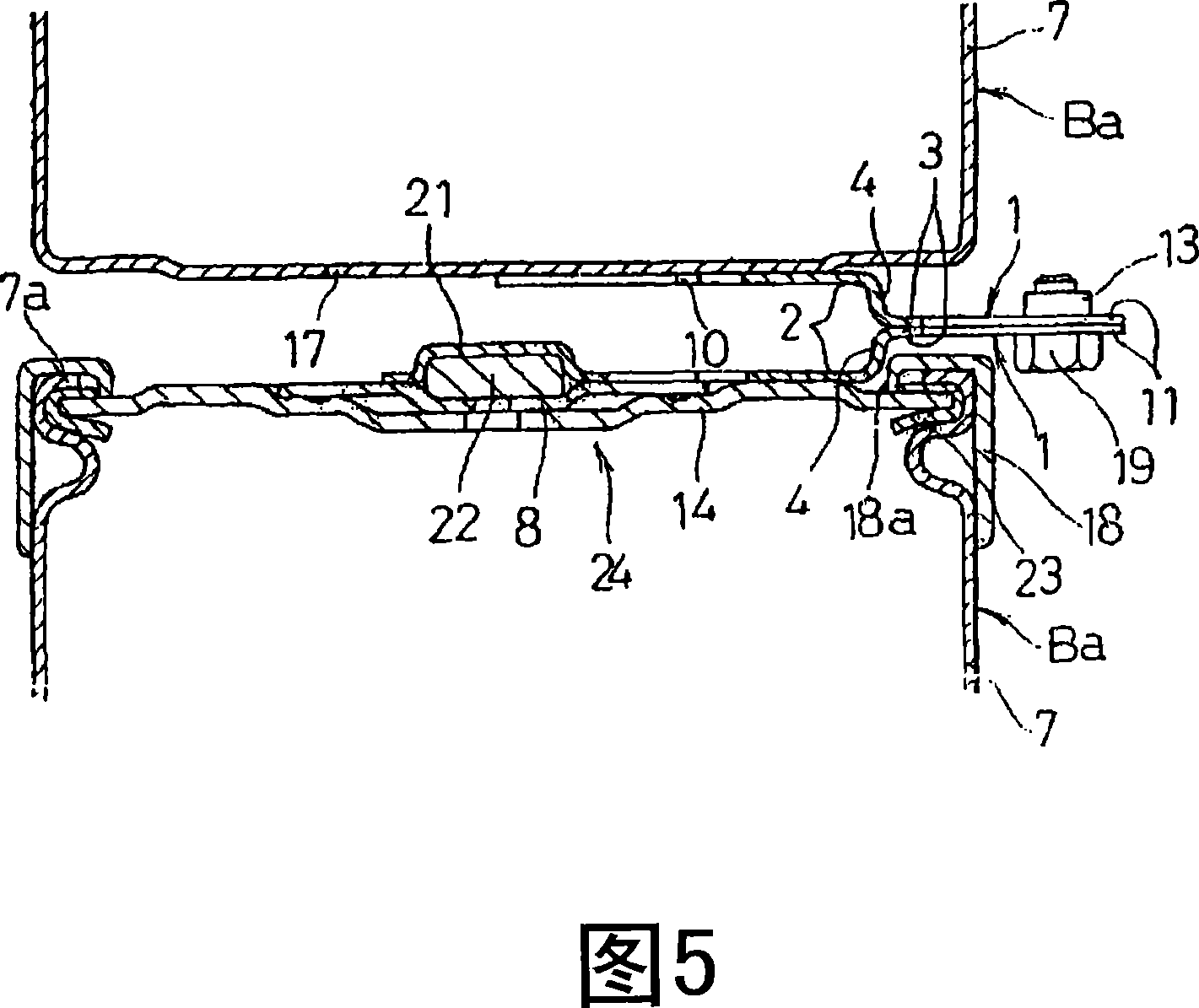

Production method for electric device assembly and electric device assembly

InactiveCN101160676ASimplify the manufacturing processSimple structurePrimary cell to battery groupingCurrent conducting connectionsEngineeringAssembly cells

Cell-to-cell connection plates (1) each integrally having a welding part (2) shaped to fall within a circular end of a battery case (7) and a connecting part (2) extending from this welding part (2) are provided. The cell-to-cell connection plates (1) are attached to one electrode terminal and the other electrode terminal of the battery case (7) by welding the welding parts (2), respectively. The connecting parts (3) of the respective cell-to-cell connection plates (1) attached to each adjoining pair of cylindrical batteries (Ba) are overlapped with each other and coupled into electric connection. Consequently, regardless of whether a plurality of cylindrical batteries (Ba) are axially arranged in series or radially juxtaposed, each adjoining two can be connected to each other by using the identical cell-to-cell connection plates (1) for cost reduction. It is also possible to provide a sufficient heat dissipation effect and achieve sufficient robustness and weight saving even when connecting large-sized cylindrical batteries.

Owner:PANASONIC CORP

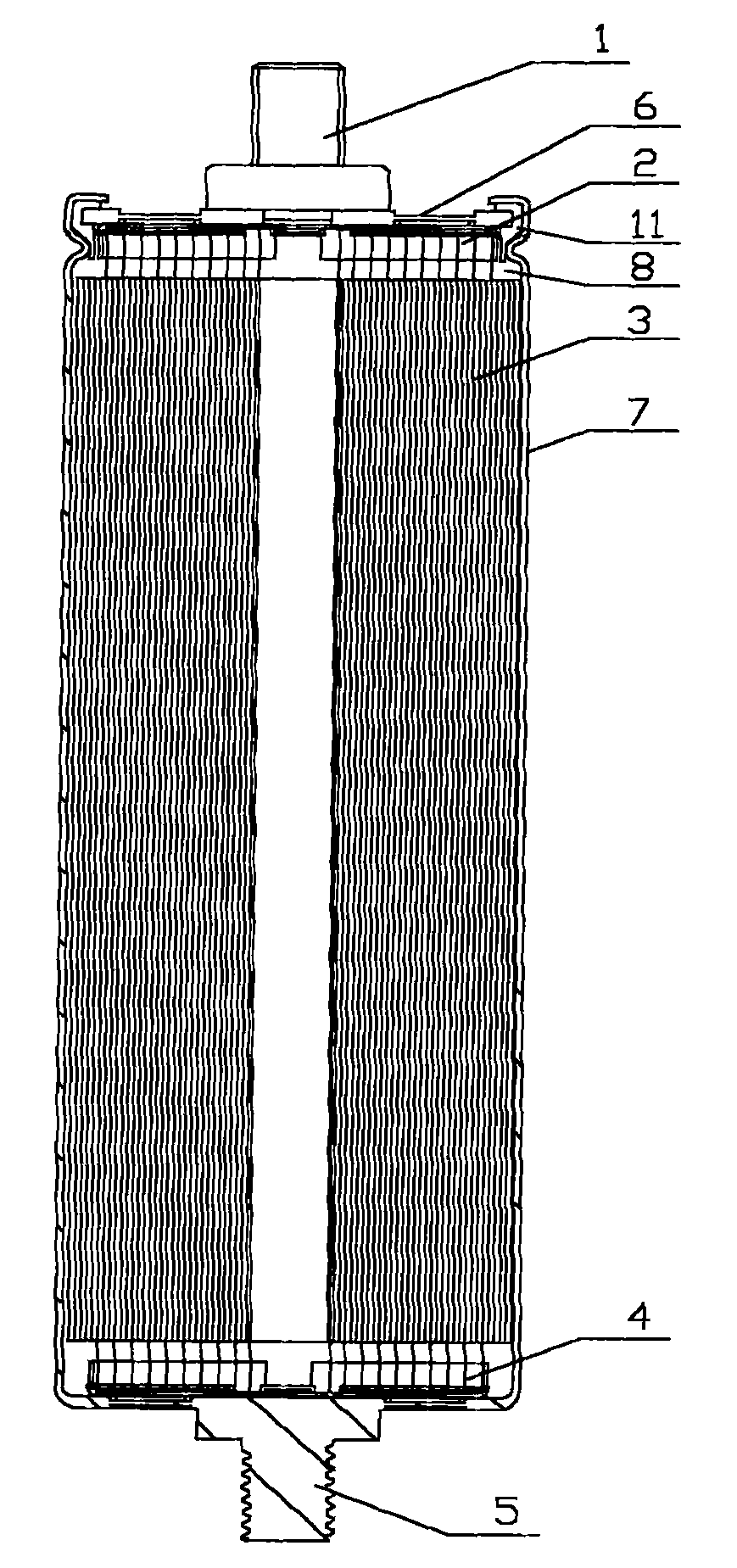

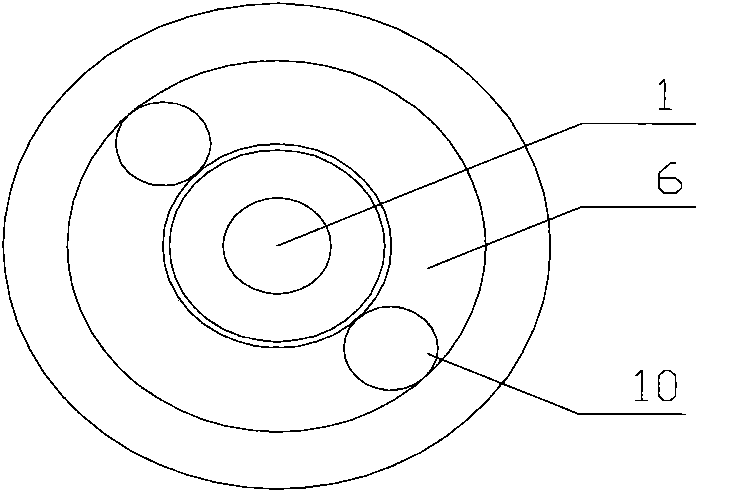

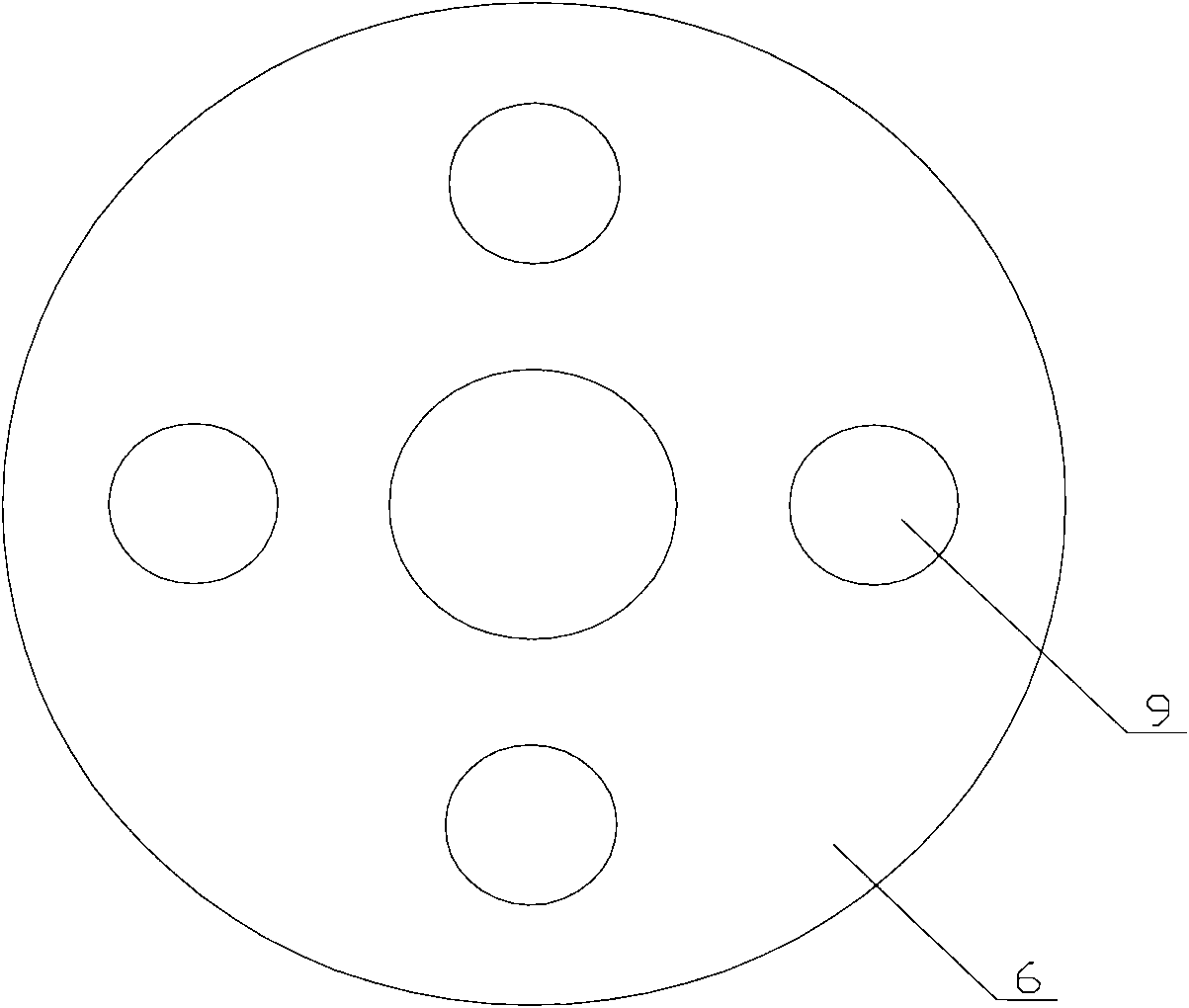

Secondary lithium battery

ActiveCN101944575ALower internal resistanceReduce manufacturing costSmall-sized cells cases/jacketsInternal resistanceElectrical and Electronics engineering

The invention discloses a secondary lithium battery which can effectively solve the problem of the exorbitant internal resistance of the existing secondary lithium battery. The secondary lithium battery comprises a negative terminal, a negative collecting ring, a rolled core, a positive collecting ring, a positive terminal, a cover plate and a casing, wherein the casing is provided with a accommodation cavity; the positive collecting ring, the rolled core and the negative collecting ring are successively connected from top to bottom in the accommodation cavity; the cover plate is arranged in the accommodation cavity on the negative collecting ring; the positive terminal is arranged on the bottom end of the casing; the positive terminal and the casing are manufactured as a whole; the positive terminal is connected with the positive collecting ring; the negative terminal is arranged on the cover plate on the top end of the casing; and the negative terminal is connected with the negativecollecting ring. The invention has the advantages that the whole product has smaller weight, and the positive terminal and the casing are manufactured as a whole, thus omitting the welding technologyand lowering the internal resistance of the battery and the production cost.

Owner:徐敖奎

Wire outlet structure of plastic packaging stator and plastic packaging motor

ActiveCN104505972AReduce axial sizeIncrease productivityWindings insulation shape/form/constructionSupports/enclosures/casingsPlastic packagingElectric machine

The invention is suitable for the field of motors, and discloses a wire outlet structure of a plastic packaging stator and a plastic packaging motor. The wire outlet structure of the plastic packaging stator comprises a power wire, a stator assembly, a wire clamp and a plastic packaging shell, wherein the wire clamp is arranged on the stator assembly, and the plastic packaging shell is arranged outside the stator assembly and the wire clamp in a packaging way; the stator assembly is provided with a winding leading wire; one end of the power wire is connected with the winding leading wire and is fixedly arranged in the plastic packaging shell in a packaging way, and the other end of the power wire penetrates out of the plastic packaging shell from the wire clamp. According to the wire outlet structure of the plastic packaging stator and the plastic packaging motor, disclosed by the invention, the power wire penetrates out of the wire outlet structure after being directly connected with the winding leading wire, and meanwhile, the part, which is positioned between the wire clamp and the winding leading wire, of the power wire, is fixedly packaged through the plastic packaging shell, so the fixing of the power wire is realized, the design of a circuit board is reduced, the cost is reduced, and the axial size of the plastic packaging motor is reduced; meanwhile, the welding technology between the circuit board and the power wire as well as the welding technology between the circuit board and the winding leading wire of a stator are reduced, the wire outlet technology of the power wire is further simplified, and the wire outlet structure is beneficial for increasing the production efficiency of the plastic packaging motor.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

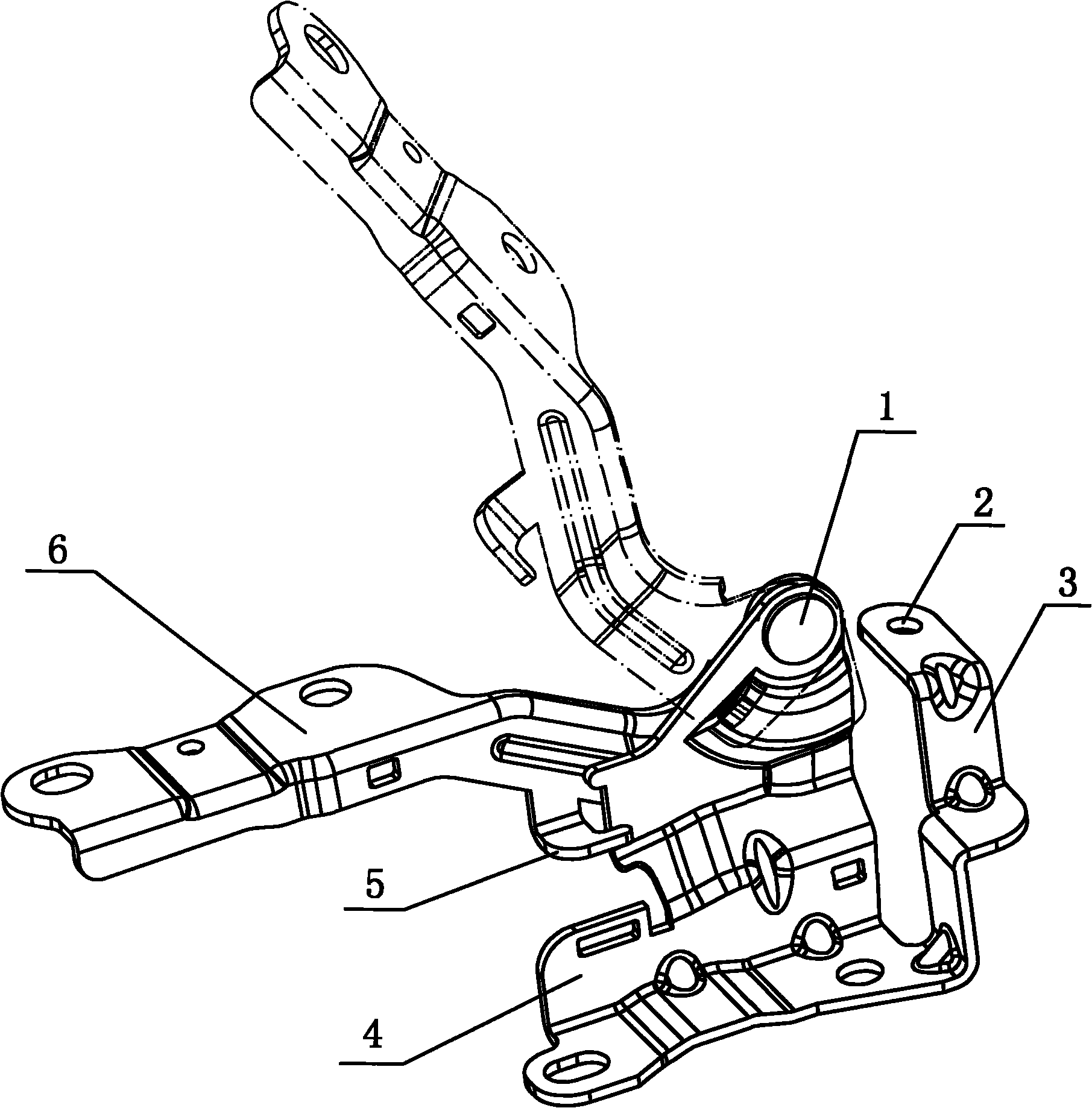

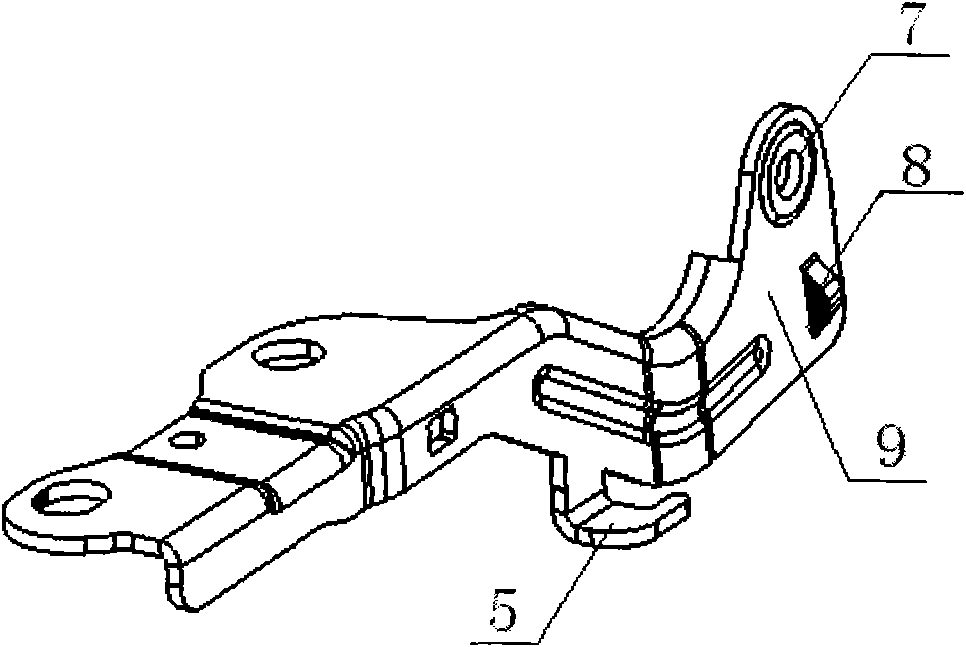

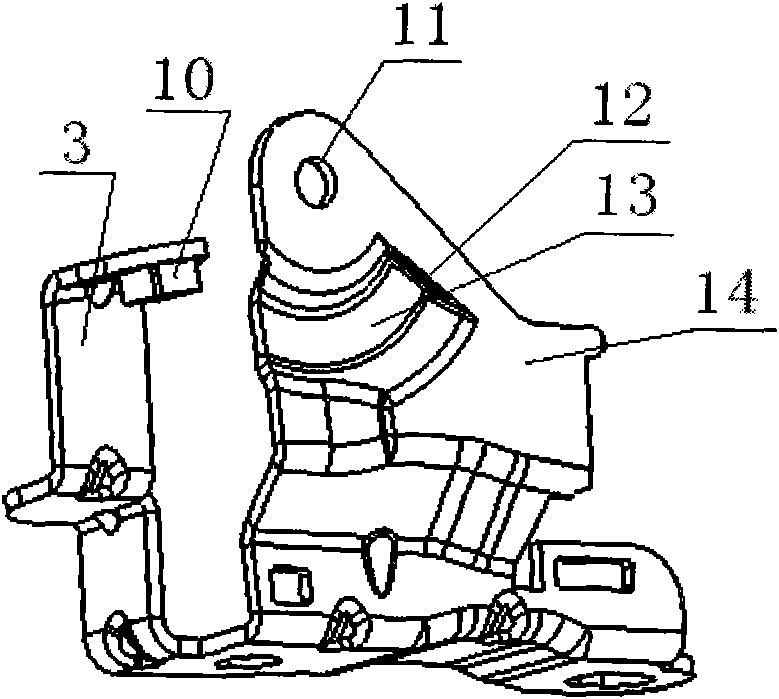

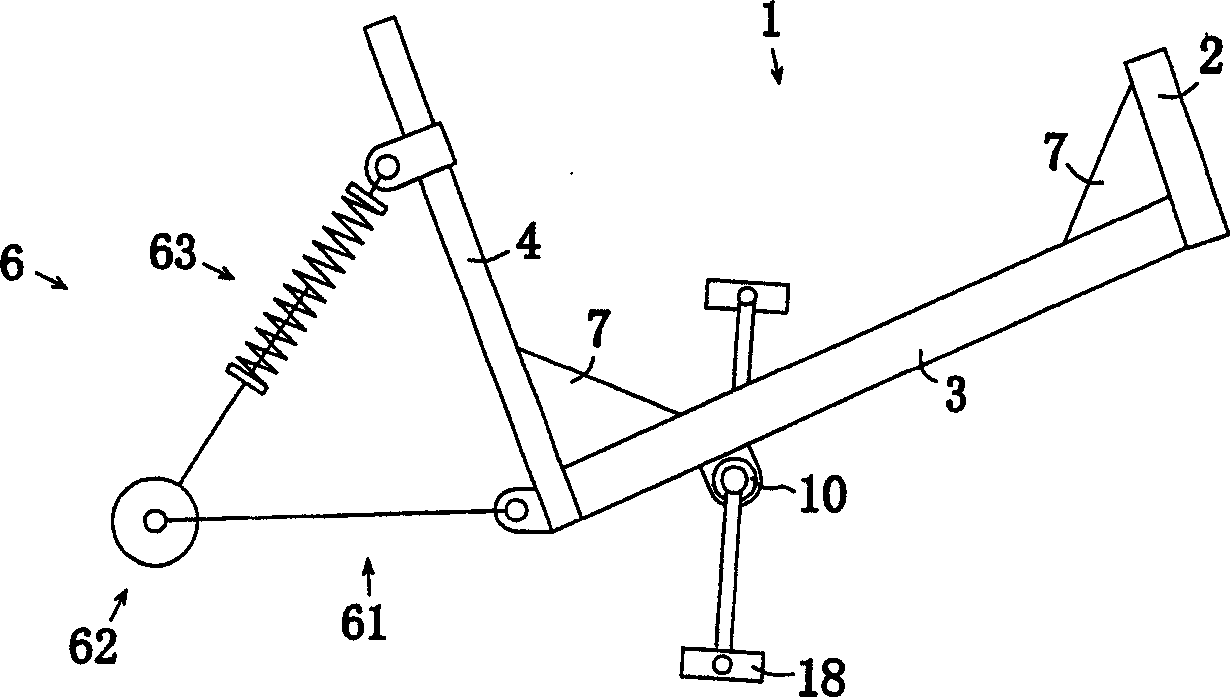

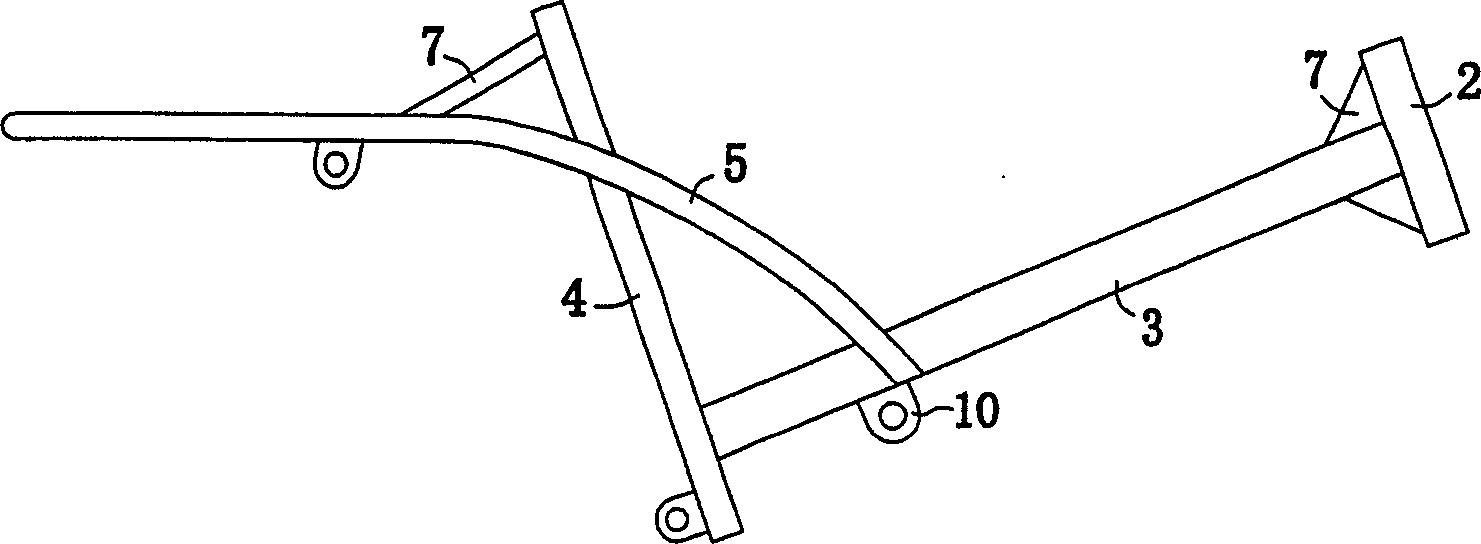

Automobile front hood hinge

The invention relates to an automobile front hood hinge for articulating an automobile front hood with a front cabin bracket. The automobile front hood hinge comprises a fixing seat and a rotating arm, wherein, the fixing seat is hinged with the rotating arm through a hinge pin, and the hinge pin is composed of a pin shaft and a self-lubricating bushing; the rotating arm is equipped with a retaining arm, and the retaining arm is positioned right ahead of the vertical plate of the fixing seat when the hinge is in a closed status; the vertical plate of the fixing seat is equipped with a limit groove, the hinge board of the rotating arm is equipped with a limit boss, and the limit boss is positioned in the limit groove; and the fixing seat is equipped with a mounting bracket, and projection welding nuts are welded on the mounting bracket. The front hood hinge is durable and has better quality and stronger use function.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

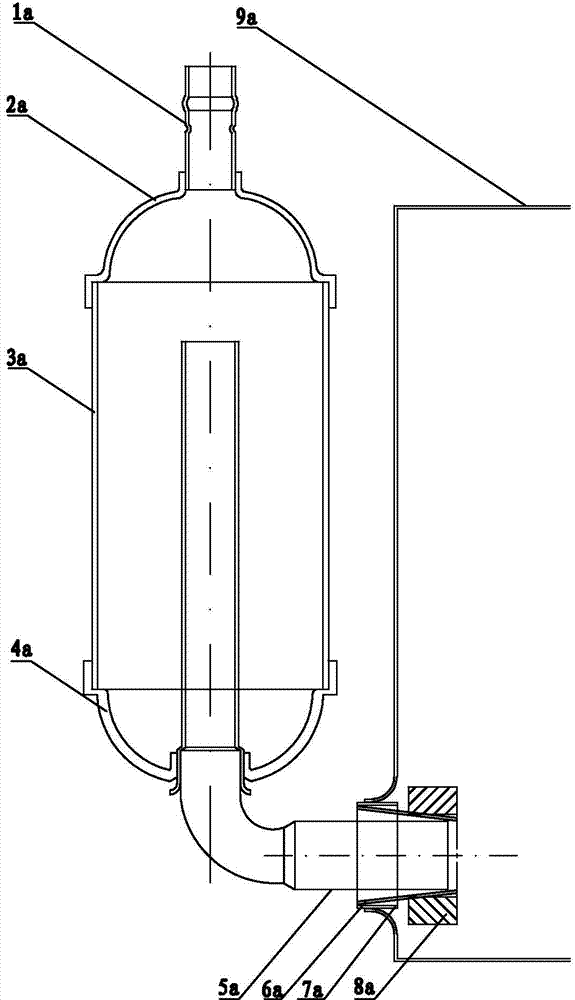

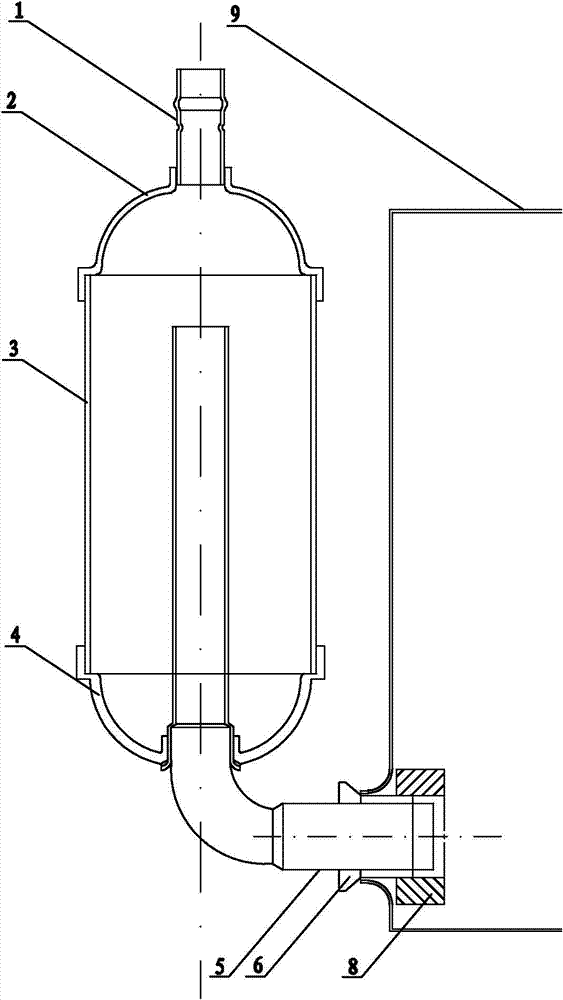

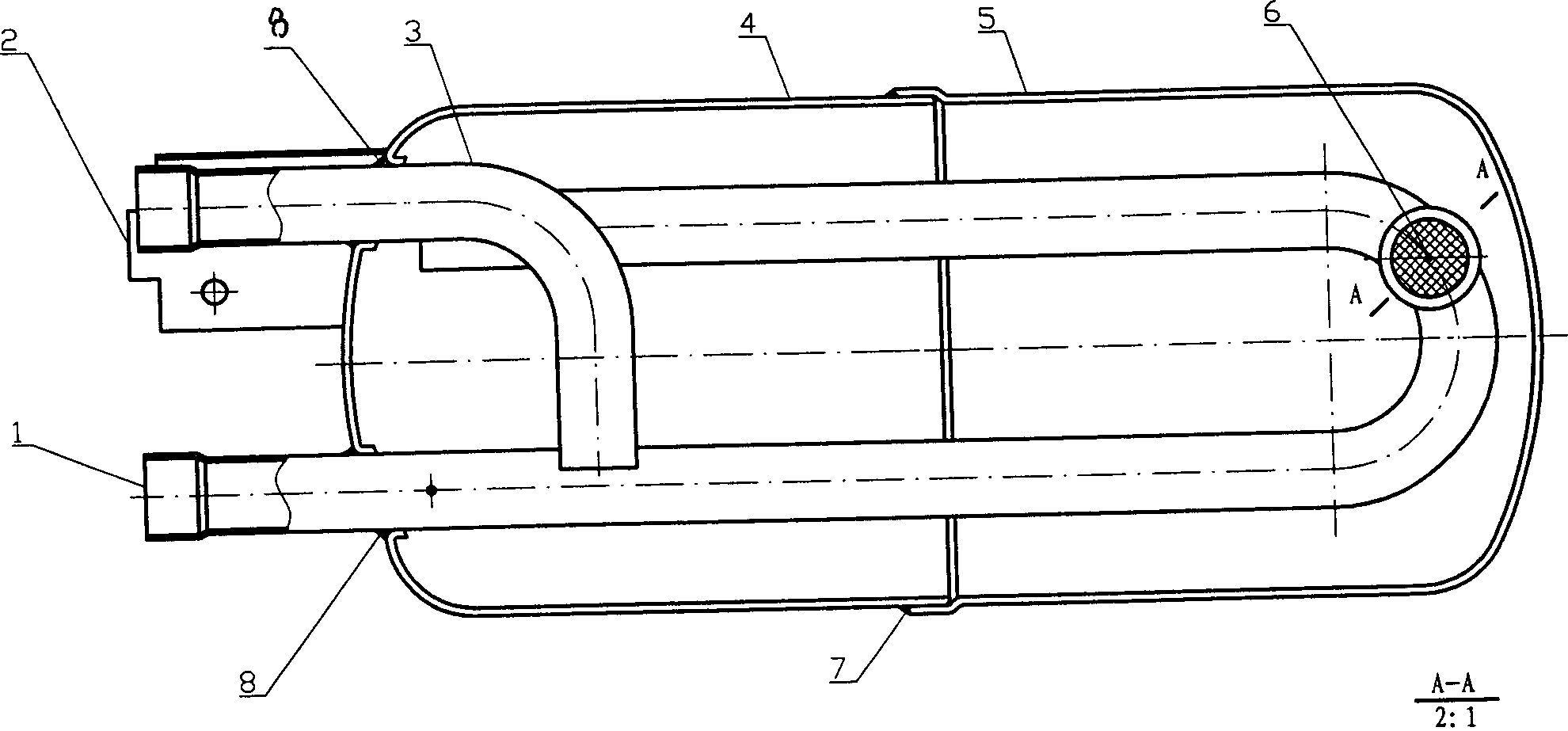

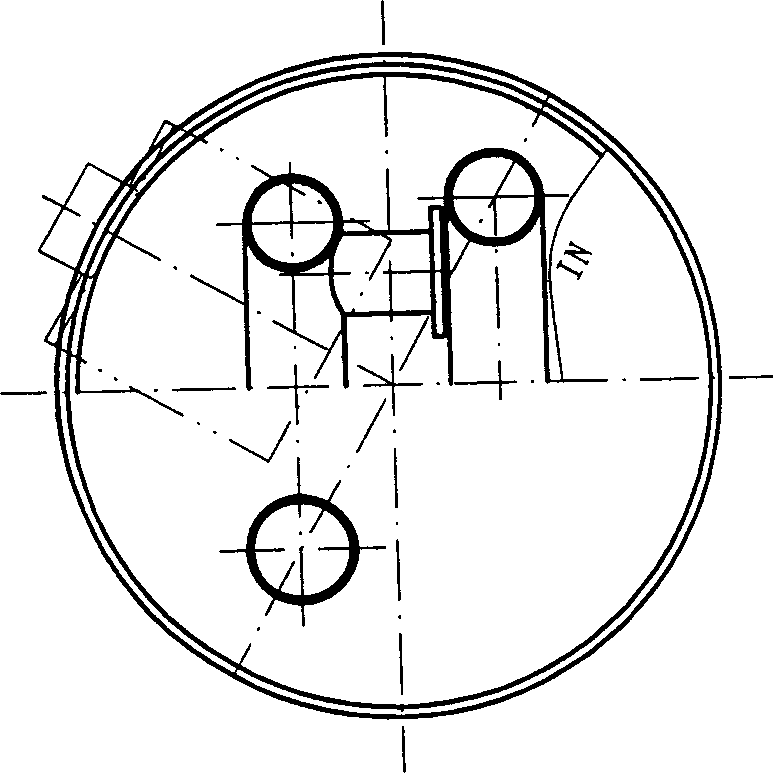

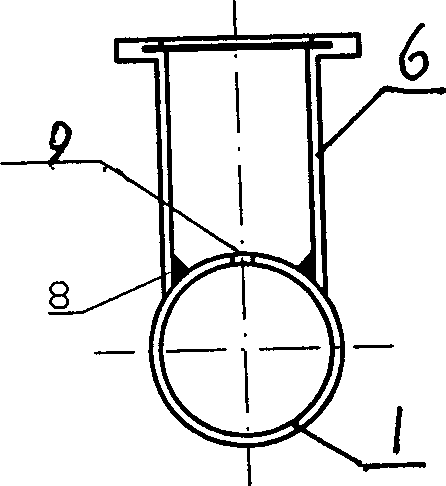

Steam and liquid separator for air conditioner and its producing method

Separator for steam and liquid includes exhaust pipe, mounting plate, air inlet pipe, filter, and barrel characters are that both exhaust pipe and air inlet pipe are prepared from iron pipe. Advantages are: reasonable structure, lowering production cost, no lap joint in one whole iron pipe, no welding line. Procedure for welding exhaust pipe, air inlet pipe and up barrel is changed to about 1130 deg.C furnace brazing under protective atmosphere from flame weld. Advantages of the procedure are: simplified operation technique, fine welding line, high weld strength, good air-tightness, and no pile of solder. Protection weld of CO2 gas is adopted for welding between up barrel and low barrel. Then, tube end expansion is carried out for exhaust pipe, and air inlet pipe so as to guarantee reasonable assembly technique.

Owner:广州大津电器制造有限公司

Variable-thickness automobile roof middle cross beam and manufacturing method thereof

InactiveCN104925141AEnsure safetyReduce weightSuperstructure subunitsVariable thicknessCollision resistance

The invention provides a variable-thickness automobile roof middle cross beam. A roof middle cross beam body is of a thin-wall structure and sequentially comprises a left body section, a left transition section, a middle body section, a right transition section and a right body section. The left body section and the right body section are connected with an automobile side body column B and have a uniform thickness. The left transition section and the right transition section are of a continuous variable-thickness structure and become smaller in thickness from the two ends to the middle body section. The middle body section is the thinnest portion of the roof middle cross beam. According to the variable-thickness automobile roof middle cross beam, by means of the design that parts of different thicknesses are arranged along an automobile body in the Y axis direction, the safety requirements for collision resistance and pressure resistance of the roof middle cross beam are met, and the design of light parts can be achieved at the same time.

Owner:BAOSHAN IRON & STEEL CO LTD

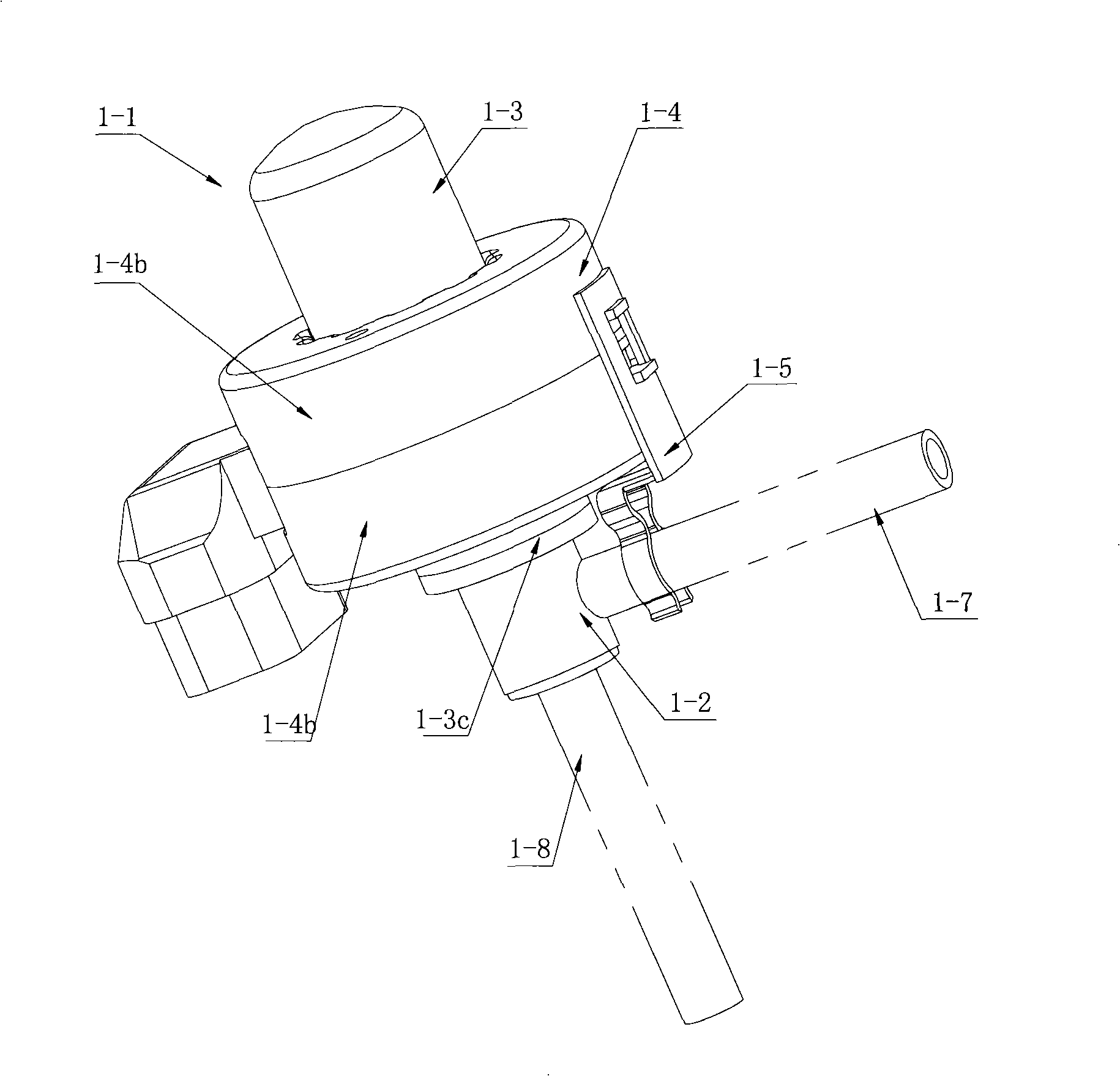

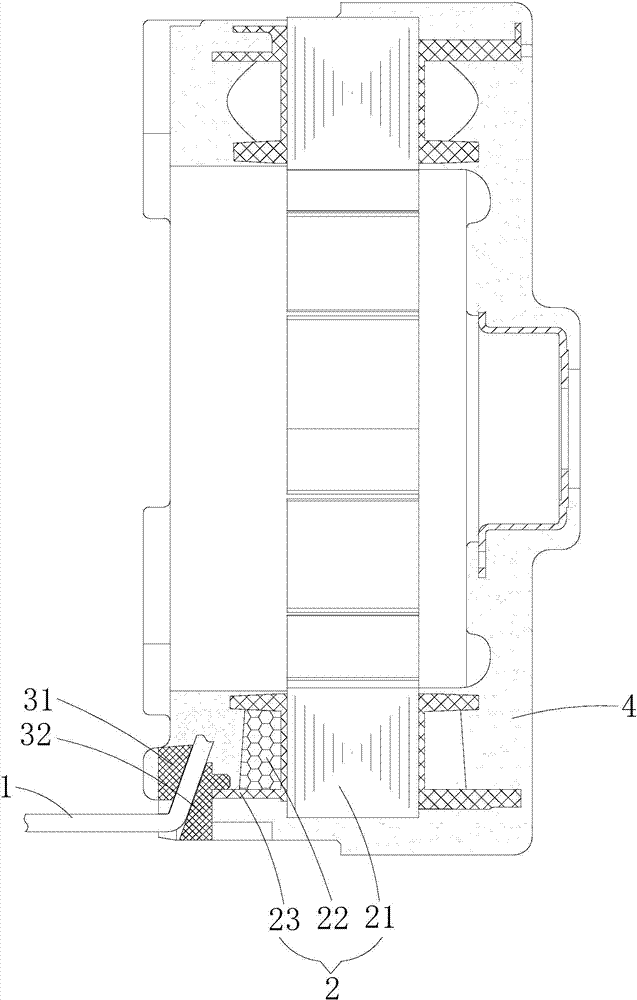

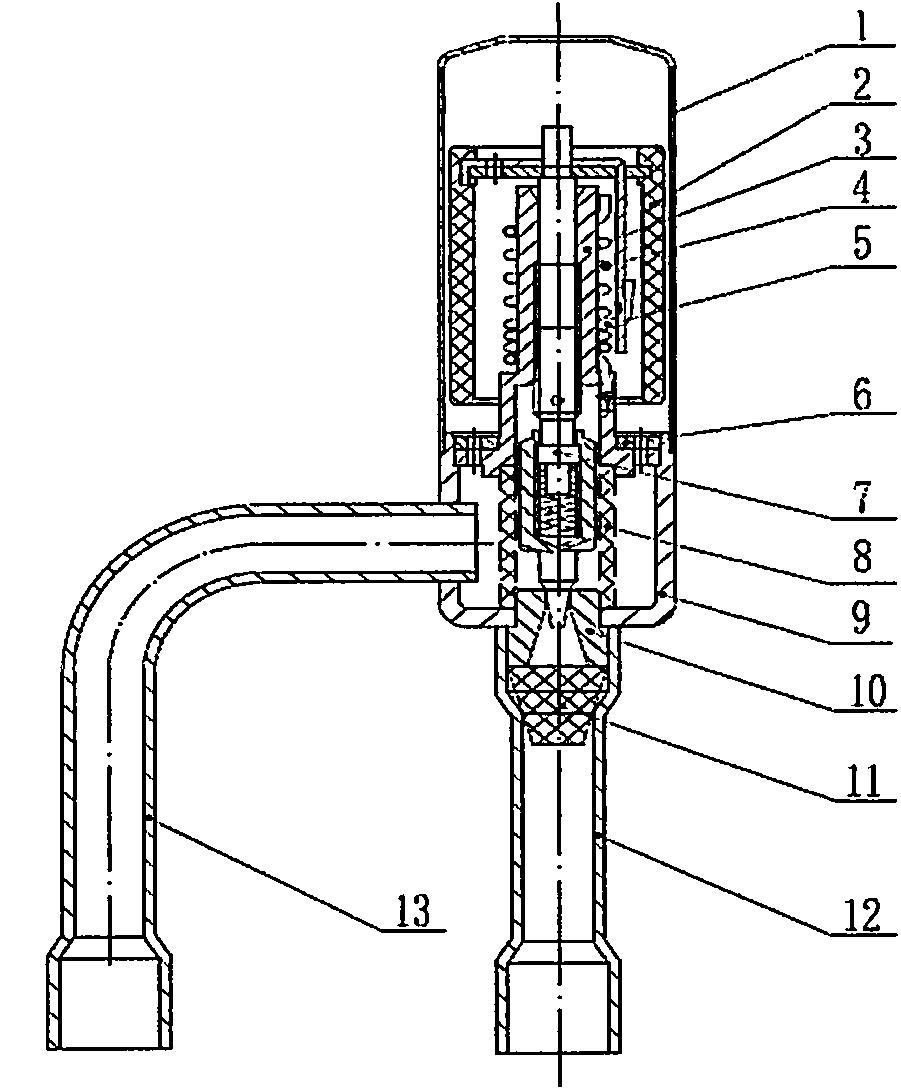

Electronic expansion valve

InactiveCN103994231AEasy injection moldingReduce thicknessOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringEqualization

The invention discloses an electronic expansion valve which comprises a valve cover (1), a magnet rotor assembly (2), a screw sleeve (3), a check ring guide rail (4), a check ring (5), a screw sleeve pressing plate (6), a valve needle assembly (7), a flow equalization device (8), a valve body (9), a valve deck (10), a filter screen (11), a lead-out pipe (12) and a lead-in pipe (13). The magnet rotor assembly (2) is arranged in the expansion valve, the upper end of the valve needle assembly (7) penetrates through and is welded together with a central hole of the magnet rotor assembly (2), the valve needle assembly (7) is sleeved with the screw sleeve (3) and can only do axial movement, and the screw sleeve (3) is embedded in and presses the flow equalization device (8). By means of the electronic expansion valve, the magnet rotor installation and fixation procedures can be reduced, machining cost can be reduced, impact which is exerted on a valve needle by flow can be effectively reduced, noise can be effectively lowered, and a valve opening can be effectively protected. By means of the electronic expansion valve, reliability and stability can be improved, the service life can be prolonged, and noise in the valve can be effectively lowered.

Owner:吴俊云

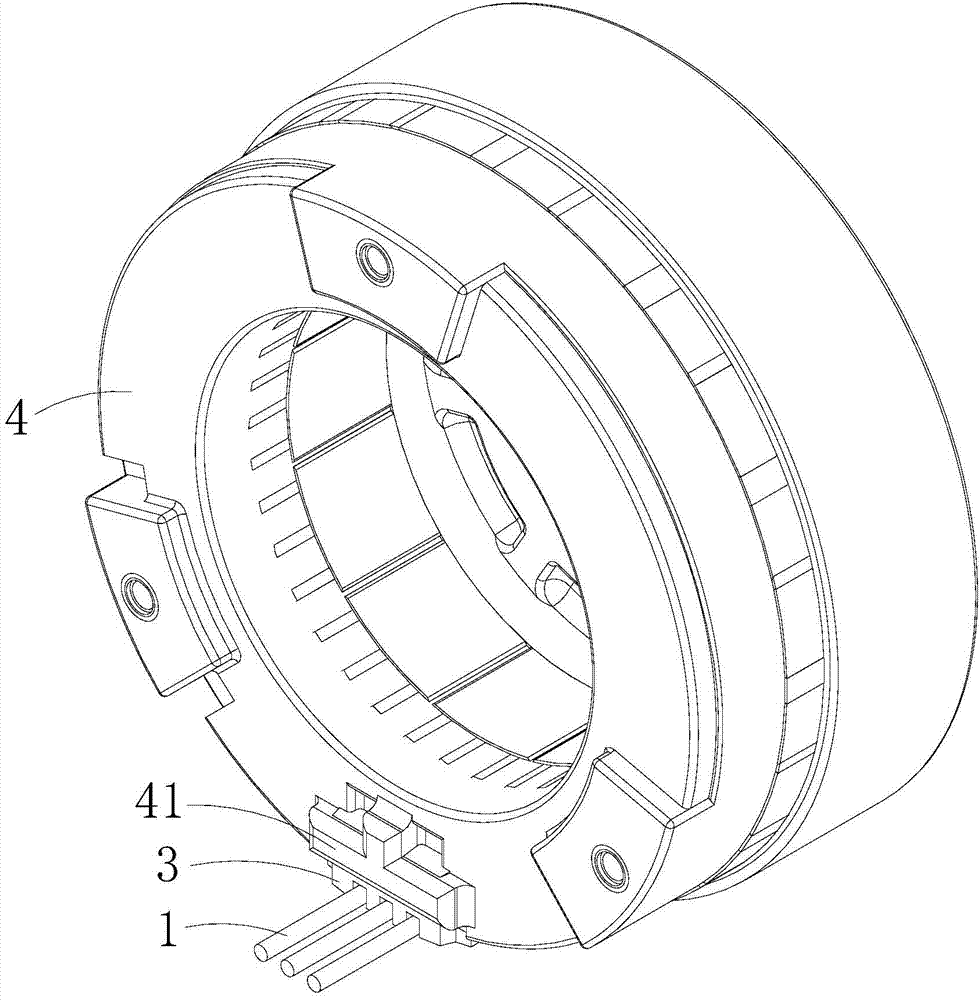

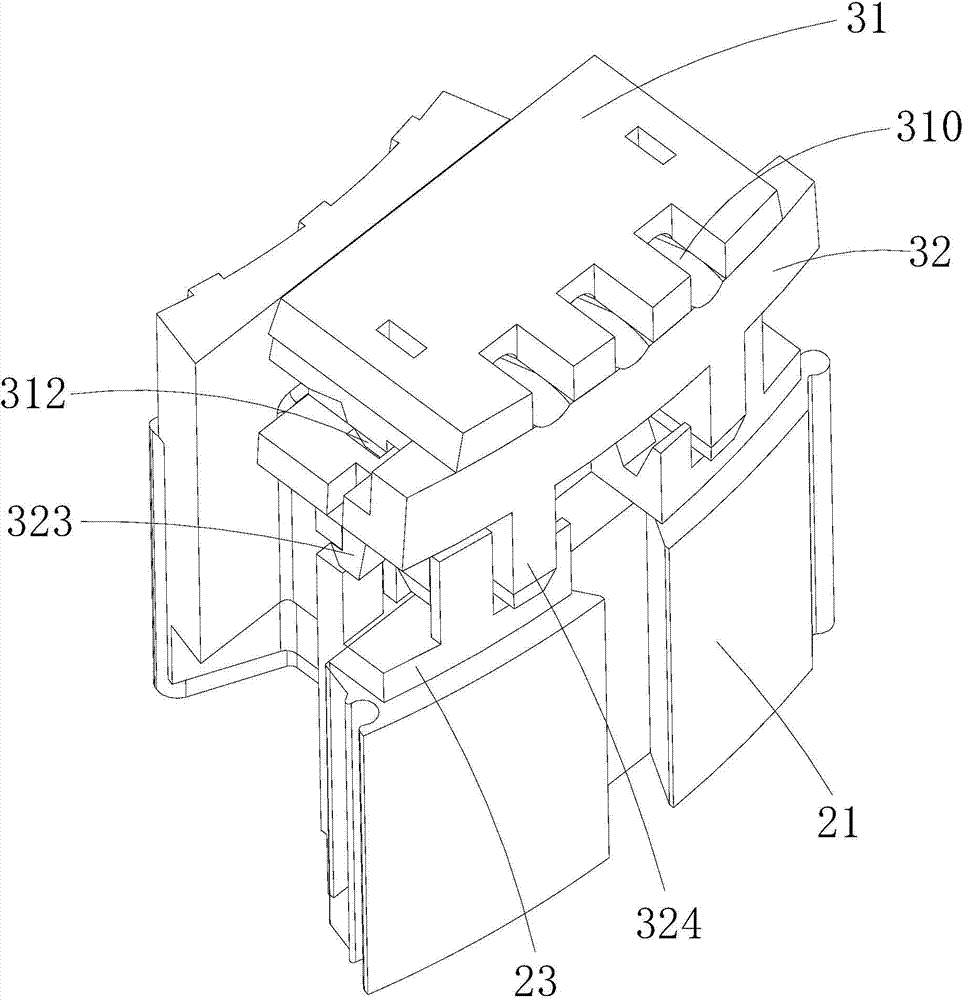

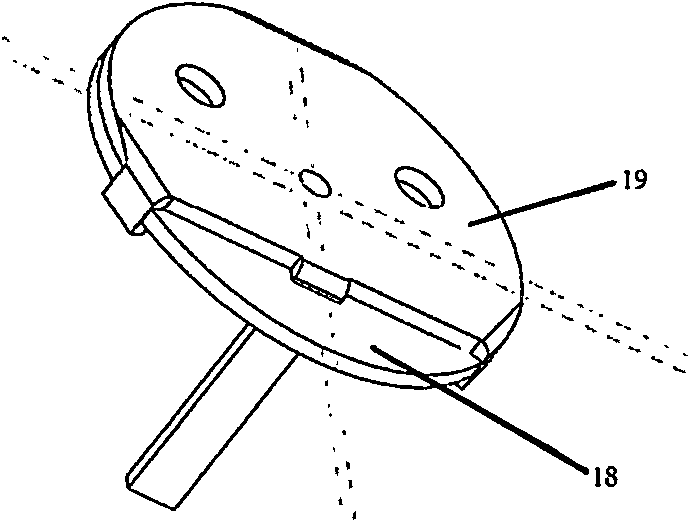

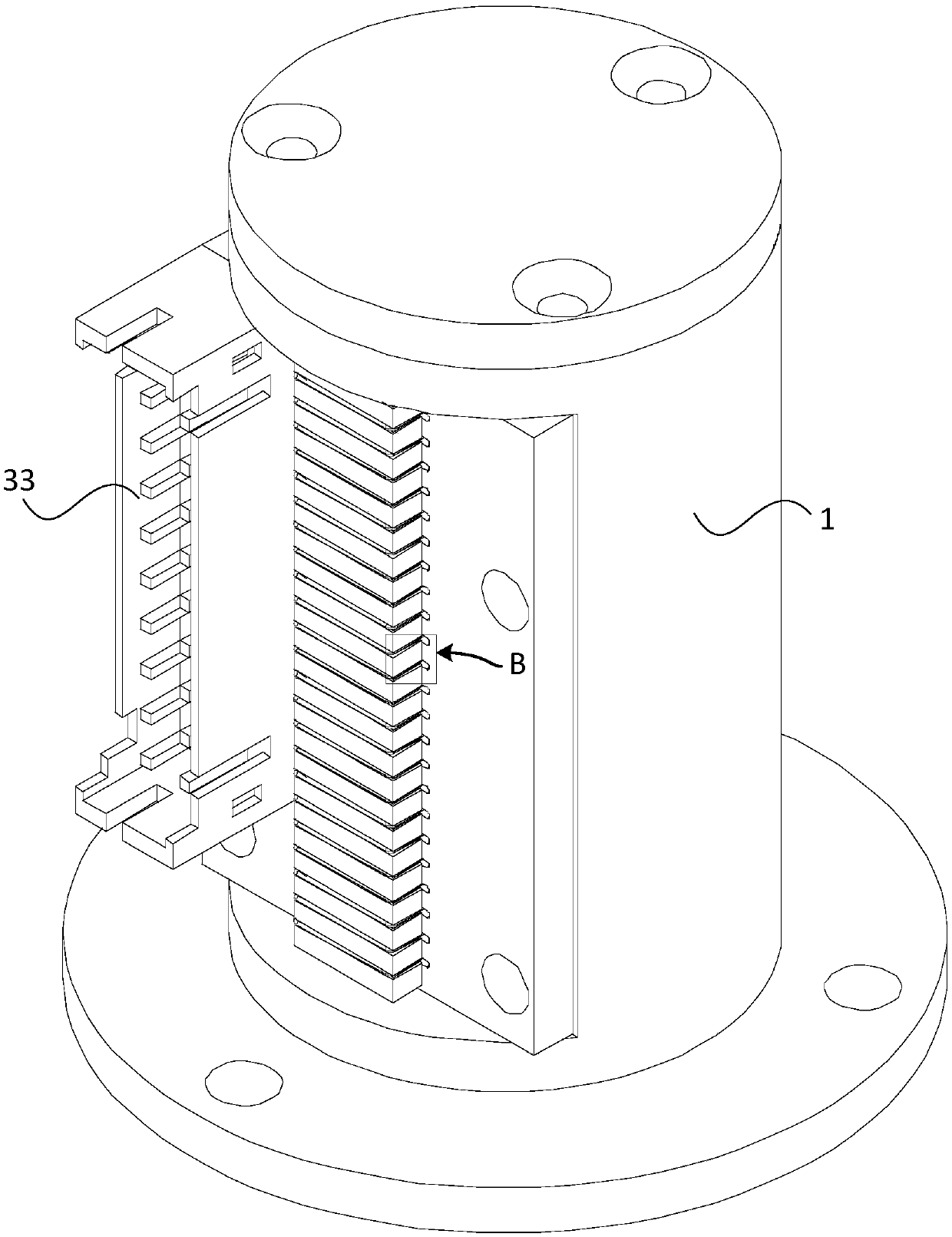

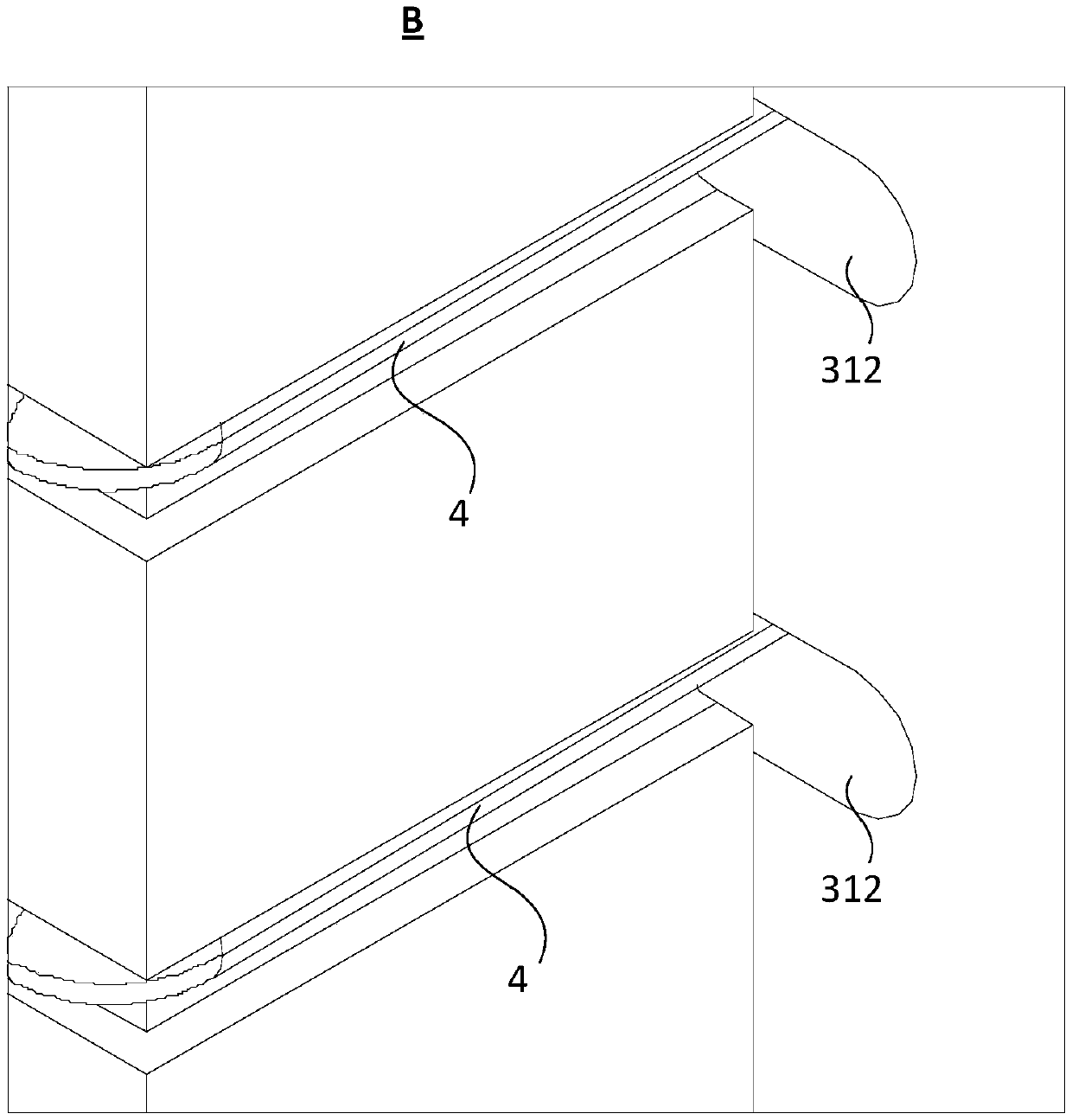

Slip ring mechanism

ActiveCN111200225AEasy to useFirmly connectedRotary current collectorElectrical connectionEngineering

The invention provides a slip ring mechanism, which comprises a stator sleeve, a rotor shaft and a conduction module, wherein the stator sleeve is provided with an opening in the circumferential surface; the rotor shaft is arranged in the stator sleeve in a penetrating mode, and the rotor shaft is provided with a plurality of copper rings distributed in the axial direction; and the conduction module is arranged on the stator sleeve at the opening, the conduction module is provided with a brush wire array which is correspondingly in conductive contact with the plurality of copper rings, and theconduction module is also provided with a cable socket which is in conductive connection with the brush wire array. The slip ring mechanism is provided with the conduction module, the connection of brush wires and cables is realized through the conduction module, and the procedure of welding the brush wires and the cables is omitted, so that on the one hand, welding residues cannot be generated to influence sliding contact between the brush wire and the copper ring, the impedance between the brush wire and the copper ring is kept constant in use, the transmission of electric energy and signals is ensured to be stable; and on the other hand, the conduction module is provided with a cable socket, the cable is connected to the cable socket in use, and the operation is simple.

Owner:HANGZHOU HIKVISION DIGITAL TECH

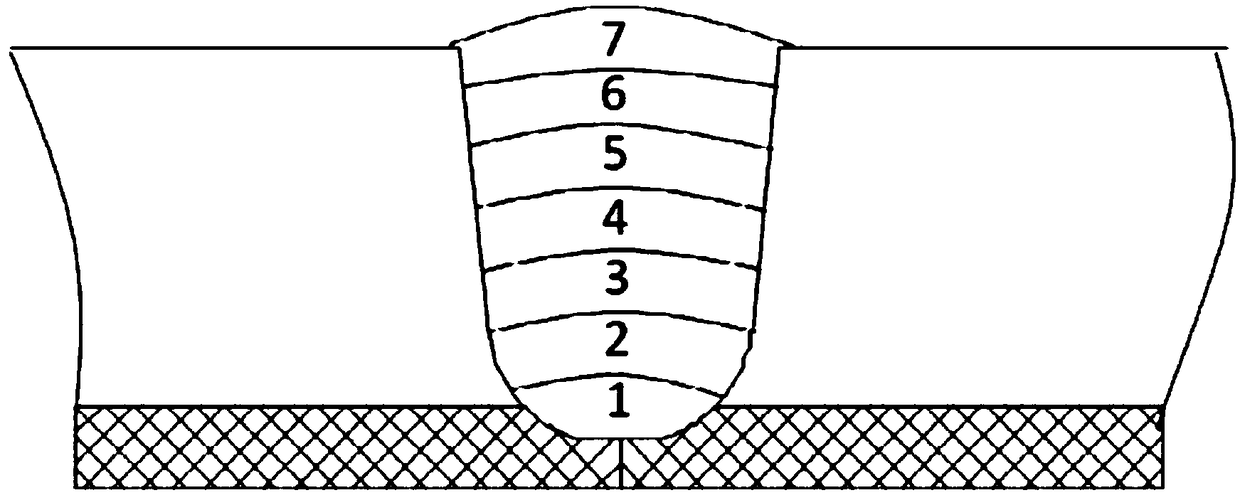

Upright full-automatic argon arc welding process for bimetal composite pipes

InactiveCN108581138AReduce labor intensityImprove welding qualityArc welding apparatusWorkpiece edge portionsUltimate tensile strengthIndustrial engineering

The invention discloses an upright full-automatic argon arc welding process for bimetal composite pipes. The process comprises the following steps: (1) the preparation is performed before welding; (2)the bottoming welding is performed; and the upright welding is performed in bottoming from the position of 6 o'clock to the position of 12 o'clock; (3) the welding process is divided into a hot welding bead and filling; the upright welding is performed in the hot welding bead and the filling from the position of 6 o'clock to the position of 12 o'clock, wherein the peripheral angles of pipe bodiesare divided into four sections; the filling is divided into multiple layers according to different wall thicknesses; and each layer is once welded; (4) a cover surface is adopted in the welding process, and is uprightly welded from the position of 12 o'clock to the position of 6 o'clock; and (5) nondestructive detection is performed after welding. The process solves the full-automatic all-position welding demand problem, reduces welding procedures, saves welding materials, greatly reduces the production cost and the labor intensity of workers, and improves the welding quality and efficiency of bimetal composite seabed pipelines.

Owner:OFFSHORE OIL ENG CO LTD

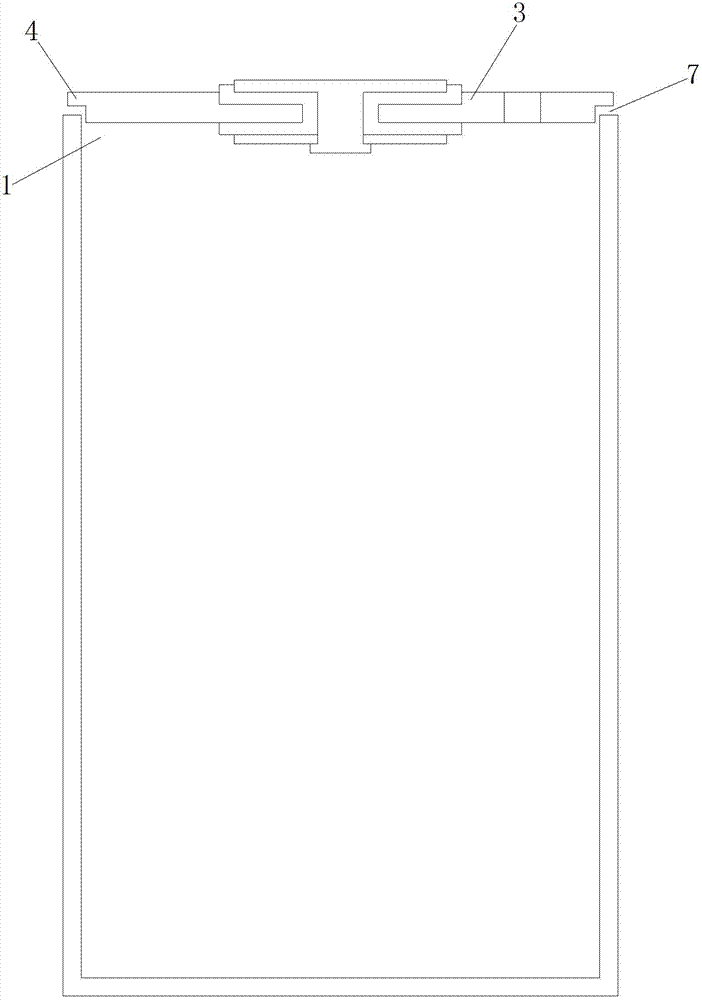

Connecting piece, cover plate assembly, and battery

InactiveCN109786644AReduce in quantityReduce welding processSmall-sized cells cases/jacketsCell lids/coversEngineeringMechanical engineering

The invention discloses a connecting piece, a cover plate assembly, and a battery. The connecting piece comprises a body part, and at least one pole part arranged at one end of the body part, whereinthe other end of the body part serves as a connecting part connected with a tab of the battery, and the pole part is protruded out of the body part to serve as a pole of the battery. The connecting piece, the cover plate assembly and the battery provided by the invention have the advantages that the cover plate assembly can be connected with a battery core through the body part of the connecting piece; and the pole part can be used as the pole, so that additional poles need not be arranged on the cover plate assembly, the number of parts in the cover plate assembly can be decreased, and the corresponding mold cost can be reduced.

Owner:蜂巢能源(武汉)有限公司

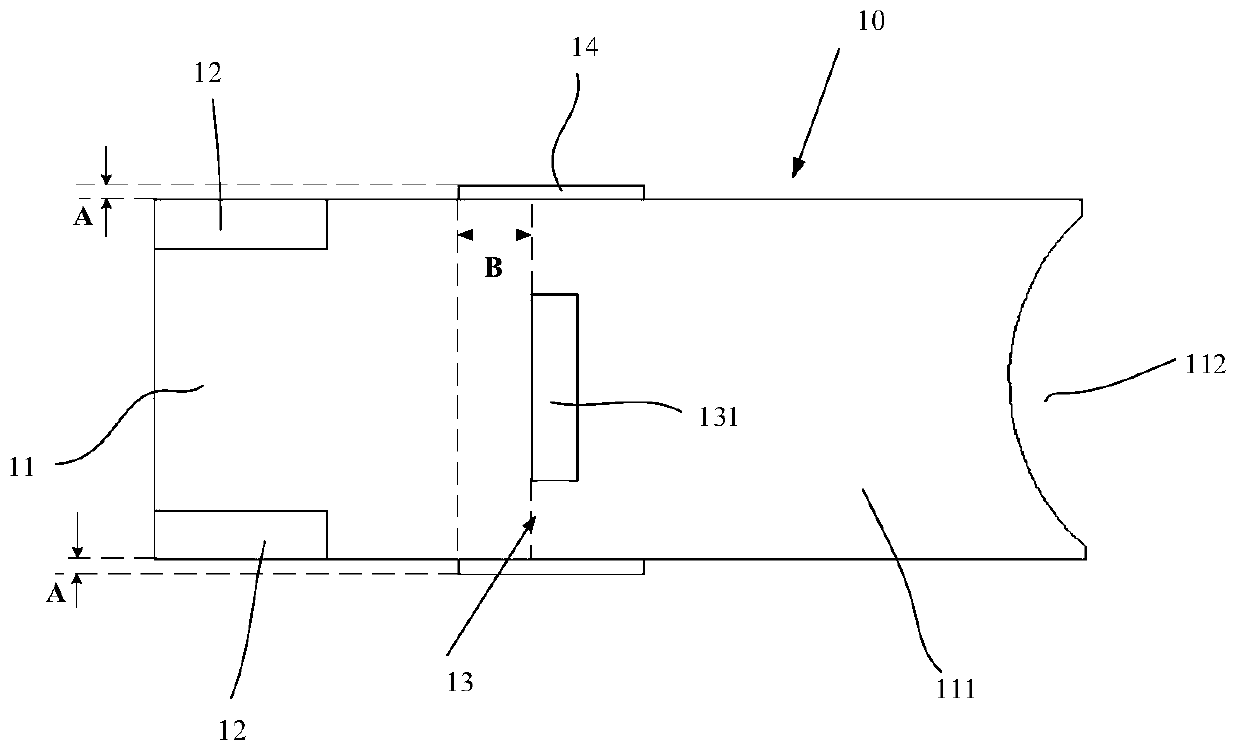

Concrete composite shear wall with embedded steel plates and production method thereof

InactiveCN104775546APrevent destabilizationImprove bearing capacityWallsUltimate tensile strengthMaterials science

The invention provides a concrete composite shear wall with embedded steel plates, which is used for civil engineering. The shear wall comprises at least one group of steel plates and concrete layers, which are mutually mixed, wherein each concrete layer is filled between the steel plates and coats the periphery of the corresponding steel plate; through combination of the steel plates clamped in the concrete layers, support for the overall shear wall is reinforced; through the concrete layers which are staggered with the steel plates, the overall strength of the shear wall is improved. The invention also provides a method for producing the composite shear wall.

Owner:CCCC FHDI ENG +1

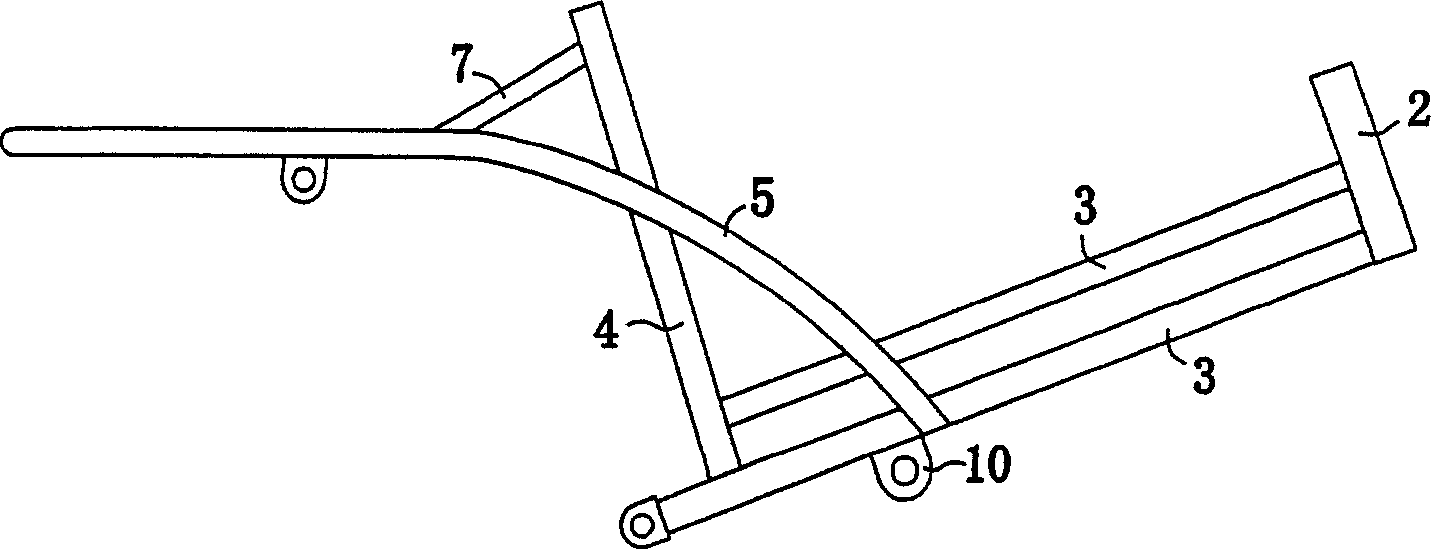

Mini type tricycle and its car frame

A miniature tricycle has a frame consisting of a main frame, a sleeve pipe for central axle and installed in main frame, and connecting mechanism of back axle, which is composed of guide part, connecting plate assemblage and vibration damper. Said main frame is composed of front pipe, lower pipes and vertical back pipe (or L-shaped or U-shaped frame), which are connected to become V-shaped, H-shaped, or U-shaped frame. Its advantages are simple structure and high stability.

Owner:FOSHAN NANHAI SANEAGLE BICYCLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com